Full Length Article

Biomass modelling: Estimating thermodynamic properties from the

elemental composition

Emanuela Peduzzi

,

, Guillaume Boissonnet

, François Maréchal

École Polytechnique Fédérale de Lausanne, Industrial Process and Energy Systems Engineering, Rue de l’Industrie 17, Case Postale 440, CH-1951 Sion, Switzerland

CEA – Grenoble DRT/LITEN/DTBH/Laboratoire des Technologies Biomasse, 17 rue des Martyrs, 38054 GRENOBLE cedex 9, France

h i g h l i g h t s

Accuracy of heating value correlations on a consistent database of biomass samples.

Complete and coherent lignocellulosic biomass model for numerical simulations.

Enthalpy and Gibbs free energy as linear correlations of the elemental composition.

Exergy in terms of thermodynamic properties and composition of the environment.

a r t i c l e

i n f o

Article history:

Received 14 September 2015

Received in revised form 14 April 2016

Accepted 21 April 2016

Available online 3 May 2016

Keywords:

Biomass

Heating value

Modelling

Exergy

Gibbs free energy

a b s t r a c t

In the context of modelling biomass conversion processes, the accurate representation of biomass, which

is a complex and highly variable material, is of crucial importance. This study provides a rather simple

and flexible way to represent biomass, especially suited in the context of thermochemical conversion

processes. The procedure to represent the enthalpy of formation, the Gibbs free energy and the exergy of

biomass in terms of its elemental composition (C, H, O, N, S) and moisture content is outlined.

The correlations relating the heating value to the elemental composition of biomass are evaluated

through a database of over one hundred raw and pretreated biomass samples. Results show that such

correlations can predict the higher heating value (HHV) within an accuracy of 1.93% and 2.38%. One of

the correlations is then applied to represent the enthalpy of formation of biomass as a linear function

of the elemental composition.

The procedure is extended to estimate the Gibbs free energy of formation and subsequently the exergy of

biomass, which are expressed as linear functions of the elemental composition. The method proposed for

the estimate of exergy allows taking directly into account the composition of the reference environment.

Results show that the method proposed in this study agrees within 1% accuracy with the widely used cor-

relation proposed by Szargut et al. (1988). The values obtained for Exergy, over the range of compositions

of the samples considered, vary in general between 105% and 115% of the lower heating value (LHV) and

103% and 107% of the higher heating value obtained using the literature correlation by Boie (1953).

On the basis of these correlations, this study provides the thermodynamic properties of C, H, O, N, S and

bound water ‘pseudo-compounds’ that can be used in the thermodynamic properties evaluation packages

used in flowsheeting software and in numerical simulations for a coherent description of biomass as a

function of its composition.

Ó 2016 Elsevier Ltd. All rights reserved.

1. Introduction

The first challenge in the thermochemical modelling of biomass

conversion systems is to model biomass itself, the raw material.

Biomass is not a standard compound and its chemical, elemental

composition, as well as its thermal properties vary significantly.

Different solutions are adopted or suggested, for example, to

model biomass in flowsheeting software. In an example bioethanol

production unit, modelled in ProSim Plus

Ò

, biomass is repre-

sented as a mixture of its chemical constituents by adapting the

properties of glucose, such as the chemical formula, the heat of

formation and the molecular weight, to represent cellulose, hemi-

cellulose and lignin. Aspen Plus

Ò

allows the implementation of

organic substances as non-conventional solid compounds through

the definition of attributes in terms of ultimate (i.e. elemental

http://dx.doi.org/10.1016/j.fuel.2016.04.111

0016-2361/

Ó 2016 Elsevier Ltd. All rights reserved.

⇑

Corresponding author.

E-mail address:

(E. Peduzzi).

Contents lists available at

Fuel

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / f u e l

composition) and proximate (i.e. fixed carbon, volatile matter and

ash content) analysis. The heating value, the heat of formation and

the heat capacity are then calculated by selecting the relevant liter-

ature correlations, generally developed for coal, in the General Coal

Enthalpy Model (HCOALGEN property model

). The attributes can

be changed through the use of subroutines to represent changes in

composition during conversion, for example during coal devolatili-

sation. Rönsch and Wagner

analysed the application of the

empiric correlations used in AspenPlus

Ò

to model wood and straw.

They showed that the heating value correlations, developed for coal,

generally underestimate the values for biomass and they indicated

which correlations can predict the heating values of average wood

and wheat straw samples within their standard deviation.

The objective of this study is to propose an accurate and consis-

tent definition of biomass, especially relevant for the simulation of

thermochemical conversion processes. The goal is to develop a gen-

eric representation of the thermodynamic properties of biomass

that allows to easily update process performances as a function of

the type of biomass, which is considered on the basis of its elemen-

tal composition. The model developed is general and may be used in

any numerical simulation but in this study it is applied to represent

biomass in the flowsheeting software Vali

Ò

by Belsim

. Therefore

the methodology presented refers rigorously to thermodynamics

but the formalism refers sometimes to this software. Thermody-

namic properties packages offered in flowsheeting software, such

as Vali

Ò

, allow in fact the definition of new pseudo-compounds,

that is, user-defined compounds used to model substances that

are not present in the internal database for which thermodynamic

properties need to be defined. In this study, special attention is

given to the coherence of the heating value calculated from the

thermochemical properties of the pseudo-compounds. The heating

value represents the energy content of biomass and is one of the

most important properties for the design and simulation of biomass

thermochemical conversion systems

.

The steps leading to the representation of biomass are presented

in detail. First of all a ‘biomass database’, obtained in the context of

previous work, is used to extract information regarding the

elemental composition and heating value of many representative

lignocellulosic biomass samples. This information is used as a basis

for comparing several correlations available in the literature relat-

ing the elemental composition to the heating value in the range

of compositions of biomass types considered in this study. The sys-

tematic comparison of the correlations and corresponding errors

allows one to identify the correlation best fitting the experimental

data. Finally, given a correlation, the approach and the fundamental

assumptions used to model biomass are presented. The properties

considered are the heating value with the corresponding enthalpy

of formation, the heat capacity, the heat of adsorption of the mois-

ture content. Furthermore the modelling approach is extended to

the entropy, the Gibbs free energy and the exergy of biomass. In par-

ticular, the exergy model presented allows the explicit definition of

the exergy of biomass based on its thermodynamic properties and

the properties of the reference environment.

2. The definition of biomass

From a legal standpoint biomass is ‘‘the biodegradable fraction of

products, waste and residues from biological origin from agriculture

(including vegetal and animal substances), forestry and related indus-

tries including fisheries and aquaculture, as well as the biodegradable

fraction of industrial and municipal waste”

. Biomass therefore

includes a large variety of materials. In this study biomass refers

only to lignocellulosic materials from forestry and agricultural

products, namely wood and straw of different types. Biomass is gen-

erally defined by considering its chemical/structural (i.e. cellulose,

hemicellulose, lignin and extractives), proximate and ultimate anal-

ysis. The ultimate analysis and the heating value are especially

important for the definition of biomass in a thermochemical model,

as they provide the basis for the atomic and energy balance of a con-

version process.

In terms of ultimate analysis, biomass is mainly composed of

C, H, and O, which define, for the most part, its heating value. It also

contains small quantities of N, S, Cl. These six elements make up

the organic phase of biomass. The inorganic phase contains Si, Al,

Ti, Fe, Ca, Mg, Na, K, S, P, and other minor elements which are

Nomenclature

Acronyms

ar

as received basis

daf

dry ash free basis

db

dry basis

EMC

equilibrium moisture content

fsp

fiber saturation point

HHV

higher heating value

hw

hard wood

LHV

lower heating value

MAE

mean absolute error

MBE

mean bias error

MC

moisture content

RMSE

root mean square error

SI

supplementary information

SRC

short rotation coppice

SRF

short rotation forestry

sw

soft wood

Roman letters

B00

biomass on a dry basis, 0% moisture (–)

B

ch

standard chemical exergy (kJ mol

1

)

BX

biomass on a wet basis, X% moisture (–)

p

;dry

heat capacity, dry basis (kJ kg

1

B00

K

1

)

p

;wet

heat capacity, wet basis (kJ kg

1

tot

K

1

)

standard Gibbs free energy (kJ mol

1

)

standard enthalpy (kJ mol

1

)

higher heating value (kJ kg

1

B00

or kJ mol

1

)

B

constant by Battley (–)

lower heating value (kJ kg

1

B00

or kJ mol

1

)

m

molar mass (g mol

1

)

b

moisture content referring to bound water (kg

H

2

O

kg

1

B00

)

fsp

moisture content after evaporation of free water

(kg

H

2

O

kg

1

B00

)

moisture content (kg

H

2

O

kg

1

B00

)

ideal gas constant (J mol

1

K

1

standard entropy (kJ mol

1

K

1

)

temperature (K or

°C)

T00

Torrefied biomass, 0% moisture (–)

Greek letters

humidity (kg

H

2

O

kg

1

tot

)

standard deviation (–)

208

E. Peduzzi et al. / Fuel 181 (2016) 207–217

important for ash characterisation. Biomass usually also contains

traces of heavy metals

The heating value of a fuel, such as biomass, represents its

energy content. It is defined as the heat released by the complete

combustion of a unit of volume of the fuel at 1 bar (101325 Pa),

considering reactants and products at the same reference temper-

ature

. The reference temperature, by convention, is considered

here at 25

°C (T

is 298.15 K). It is possible to distinguish between

two types of heating values: the higher heating value (HHV) if the

heat of condensation of water generated in the combustion (from

the hydrogen originally present in the biomass) is recovered and

the lower heating value (LHV) if this water is considered in its

vapour state (and therefore its heat of condensation is not

recovered). Due to the presence of water and ash in biomass, the

HHV and LHV may be referred to on a weight basis: dry basis

(db), dry ash free basis (daf ), or as received basis (ar).

The relationship between HHV and LHV on a dry basis and the

relationship between LHV on a dry basis and LHV on an as received

basis are reported in Eqs.

respectively.

~

HHV

¼

~

LHV

db

þ

M

m

;H

2

O

M

m

;H

H

100

D

~H

v

ap

ðkJ kg

1

Þ

ð1Þ

~

LHV

wb

¼

~

LHV

db

ð1

U

Þ

D

~H

v

ap

U

ðkJ kg

1

Þ

ð2Þ

M

m

;H

2

O

and M

m

;H

are the molar masses of water and hydrogen, H

is the hydrogen mass percentage in the fuel,

D

~H

v

ap

is the enthalpy

of vaporisation of water at the reference temperature (in kJ kg

1

),

U

is the humidity (in kg

H

2

O

kg

1

tot

) and

is used to refer to properties

on a mass basis. In this study, unless otherwise specified, all values

refer to dry or dry ash free basis. The evaluation of the ultimate

analysis and the heating value of different biomass types is sum-

marised hereafter with the introduction of the biomass database

used in this study.

3. Biomass database

The ‘biomass database’ used in this study is a collection of

experimental elemental compositions and corresponding HHV

and LHV. These values are obtained, in the context of previous

studies, from the analysis of over one hundred samples, which

include both raw and torrefied biomass. The raw biomass database

relies on the characterisation, carried out by Dupont et al.

, of 92

representative samples. The standards used to obtain the ultimate

analysis and the heating values are summarised in

supplementary information (SI)

Hereafter, as in the previous study by Dupont et al.

, the data

is classified in biomass families. Hardwoods (angiosperms) are rep-

resented by broad-leafed trees such as oaks, beech trees, hornbeam

and lime (basswoods) trees. Softwoods (gymnosperms) are

represented by conifers such as pine trees, fir trees, and spruce.

The database includes also short rotation coppice (SRC) and short

rotation forestry (SRF) represented by willow and poplar, and

agricultural biomass represented by straw from barley, corn, rape,

and wheat, and energy crops from alfalfa, miscanthus, fiber and

sweet sorghum, switchgrass, tall fescue, and triticale. The data rel-

ative to torrefied biomass was obtained by Marty

, by Nocquet

et al.

and other previous studies. The database was further

enriched including biomass chars and, as a reference, coal, from

Parikh et al.

. The average values of the ultimate analysis and

heating values obtained for the different raw biomass species are

summarised in

.

Results presented in

show that biomass composition is

similar across biomass types. However, agricultural residues and

energy crops, display a sensibly smaller heating value and carbon

content and higher ash content than other raw biomass types.

4. Correlations estimating the heating value

The direct measure of the heating value of biomass, through

bomb calorimetry, is a complicated and time-consuming proce-

dure. It can therefore be interesting to use a correlation to calculate

the heating value from other conventional properties of biomass,

i.e. proximate and ultimate analysis, which can be obtained rela-

tively easily and cheaply

. An extensive review of correlations

relating the heating value of biomass to its ultimate, proximate,

and chemical/structural analysis, with attention to biomass type,

is presented by Vergas-Moreno et al.

. This review also high-

lights the lack of information which is sometimes encountered in

the literature in terms of the data used to develop and validate

the correlations and their basis (dry basis or dry ash free), but also

in terms of the transcription errors when correlations are referred

to by other authors.

The first model developed to calculate the heating value from

an elemental composition was proposed by Dulong in 1880 and

concerned coal samples. During the 20th century many models

were developed to estimate the heating value of coal and, over

the last 30 years, also of biomass

. A survey of published corre-

lations is also reported by Channiwala and Parikh

, who

reviewed several correlation types and relative basic assumptions.

Sheng and Azevedo

tested the performance of correlations

relating the heating value to the elemental, proximate and chemi-

cal analysis on a large database of biomass samples collected from

the literature. They show that the correlations relating the proxi-

mate composition and the heating value display low accuracy,

but they have recently gained importance among engineers and

researchers due to the ease and speed of proximate analysis

The correlations based on chemical/structural analysis also present

low accuracy because of the variation of biomass components

properties and chemical composition. On the contrary, the correla-

tions relying on the ultimate analysis are the ones that provide the

most accurate results

.

In thermochemical process modelling the use of correlations

relating the heating value to the elemental composition is a good

compromise between accuracy and ease of computation. Given

the database presented in Section

it is possible to either develop

a new correlation or use the ‘biomass database’ to validate the cor-

relations proposed in other studies. The interest in using this data-

base lies in the use of samples which cover a wide range of biomass

fuels, from agricultural to woody and torrefied biomass, and in the

consistency of the measurement procedures. However, given the

relatively small composition variations of the biomass samples,

the unequal distribution across the heating values and in the

interest of a most general approach, correlations from the litera-

ture are validated using the database.

4.1. Evaluation of literature correlations

A survey of correlations from the literature estimating the

heating value from the elemental composition is reported in

. These correlations have been developed considering bio-

mass samples or, even if they were developed for coals or other

hydrocarbon fuels, are sometimes used in the context of biomass.

The oldest correlations reported, for reference, were developed

for coal and are the ones by Dulong, Eq.

, and by Mott, Eq.

. The correlation by Boie

, Eq.

, was derived using

hydrocarbon fuels with an expected error within 1.8%

. This

correlation is sometimes used to model biomass in flowsheeting

software

. The relationship proposed by the Institute of

Gas Technology (IGT)

, Eq.

, is very general and was

developed on the basis of over 700 coal samples, with an error that

lies within 1.2%

E. Peduzzi et al. / Fuel 181 (2016) 207–217

209

In the context of biomass, Tillman

developed a correlation,

Eq.

, to calculate the heating value of wood and wood barks from

their carbon content and later modified it to extend its validity to

the whole range of biomass materials. Predictions for this equation

are reported to be within 5% error. Eq.

represents the

correlation developed by Grabosky and Bain offering predictions

claimed to be within 1.5%

. Channiwala and Parikh

developed a generalised and unified correlation, Eq.

, aiming

at simultaneously describing the heating value of solid, gaseous

and

liquid

fuels

within

the

range

0

% 6 C 6 92:25%,

0

:43% 6 H 6 25:15%, 0:00% 6 O 6 50:00%, 0:00% 6 N 6 5:60%,

0

:00% 6 S 6 94:08%, 0:00% 6 A 6 71:4%, 4.745 MJ kg

1

6 HHV

6 55.345 MJ kg

1

, where C, H, O, N, S and A represent carbon,

hydrogen, oxygen, nitrogen, sulphur and ash contents of a fuel,

respectively, in wt% (dry basis).

These fuels include terrestrial

and aquatic biomass material, industrial waste and municipal solid

waste, refuse and sludge, as well as chars, coals and coke

According to the authors this correlation yields a mean absolute per-

centage error of 1.45% and mean bias error (MBE) error of 0.00%.

Sheng and Azevedo

proposed a new correlation, Eq.

based on a database of biomass samples collected from the open

literature. According to the authors this relationship provides

90% of predictions within ±5% error.

More recently, Friedl et al.

used 122 plant biomass samples

and obtained a correlation, Eq.

, by ordinary least squares

regression (OLS) and by partial least squares regression (PLS)

which allows HHV prediction with a standard error of 2%.

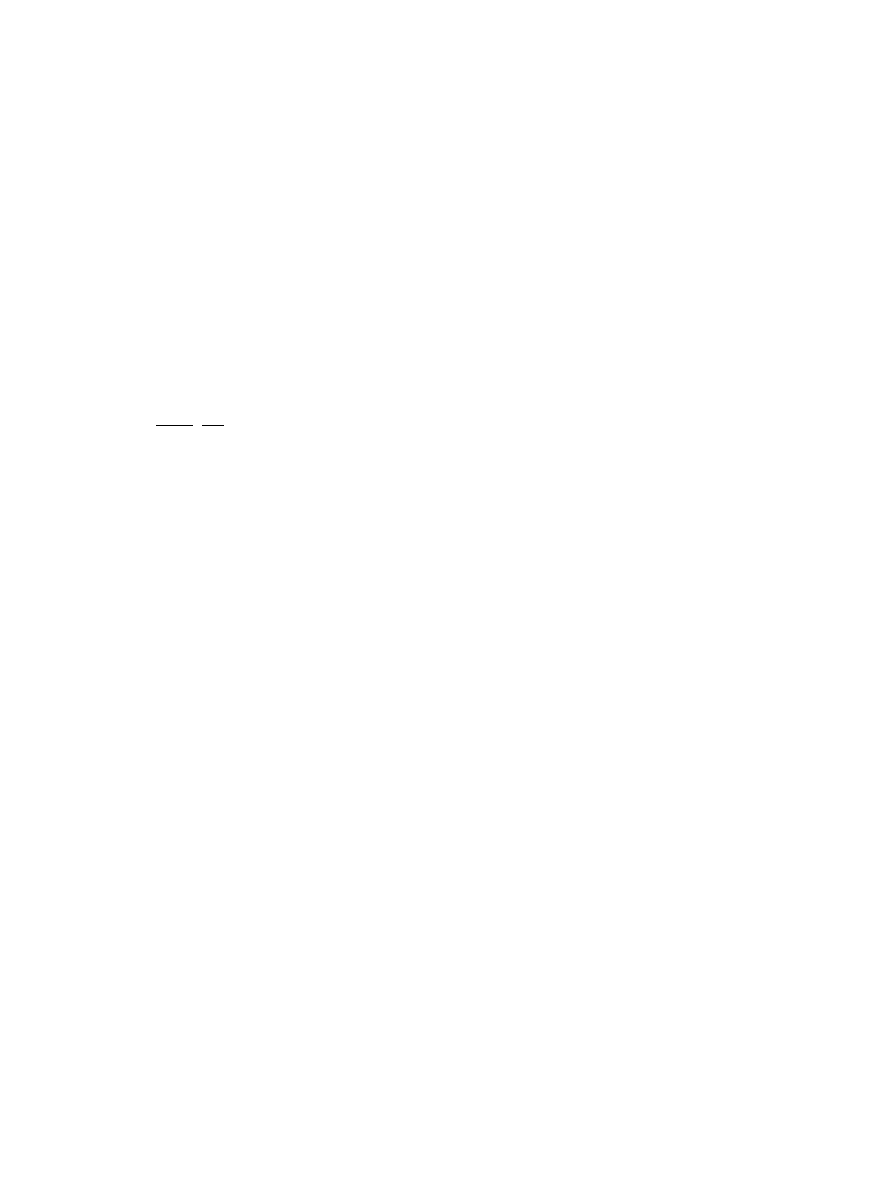

The correlations reported in

present different

coefficients and therefore yield different results for the same

composition. Comparing these correlations is difficult because

the authors report different accuracies based on different samples

and composition ranges. Therefore, a comparison of the average

results obtained using these correlations to estimate the HHV of

the raw samples belonging to the ‘biomass database’ considered

in this study is carried out and reported in

. Most of the cor-

relations accurately reproduce the average HHV of the biomass

samples.

Table 1

Average composition and HHV of different types of biomass on a dry basis. The number of samples of each biomass type is presented in parenthesis.

Hardwood (33)

Softwood (16)

Mix (3)

SRC & SRF (11)

Ag. Biomass (23)

Av.

r

Av.

r

Av.

r

Av.

r

Av.

r

Carbon (wt%)

49.7

1.0

51.2

1.3

50.8

1.0

49.1

0.3

46.8

1.4

Hydrogen (wt%)

5.8

0.1

5.9

0.2

5.9

0.1

6.0

0.1

5.8

0.2

(%wt)

42.7

1.1

41.9

1.3

40.8

1.3

41.9

1.1

42.3

2.4

Nitrogen (wt%)

0.2

0.1

0.1

0.1

0.2

0.0

0.3

0.2

0.8

0.5

Sulfur (mg kg

1

)

171.2

133.7

270.9

443.8

243.3

108.7

609.3

673.8

1,355.5

645.1

Ash, 550

°C (wt%)

1.74

0.64

0.99

0.65

2.33

1.31

2.88

1.08

5.14

2.08

HHV

db

(kJ kg

1

)

19811

448.4

20331

704.3

19947

480.9

19552

612.6

18458

703.8

LHV

db

(kJ kg

1

)

18612

442.5

19128

707.2

18740

477.5

18321

614.4

17263

703.2

a

Mix refers to hardwood and softwood samples.

b

Oxygen is calculated by difference.

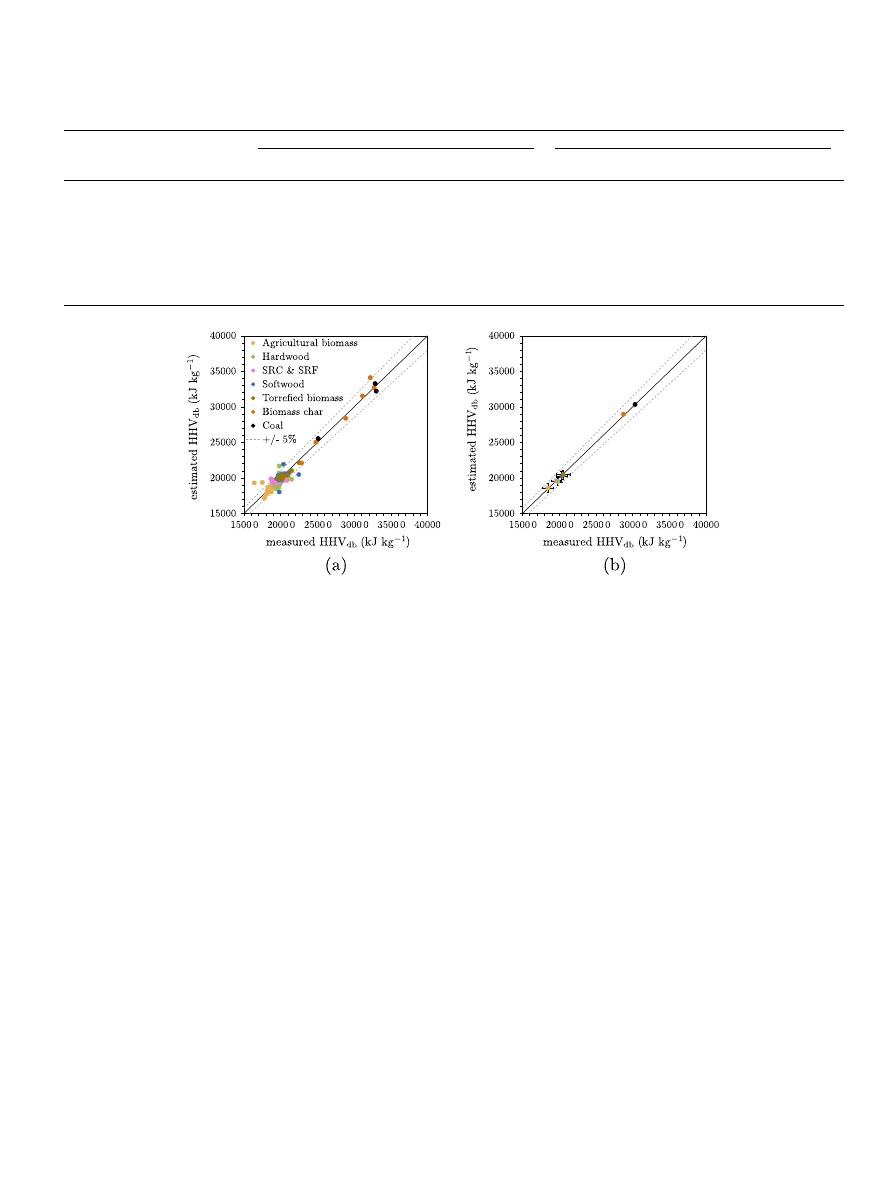

Fig. 1. Evaluation of the performance of literature correlations estimating the HHV

with respect to the measured values of the ‘biomass database’ considered in this

study. The bars represent the difference between the average HHV calculated using

the different correlations and the average HHV measured. The average measured

value is 19.7 MJ kg

1

. The grey bars represent correlations originally developed for

coal and hydrocarbons whereas the green bars represent correlations originally

developed for or including biomass. The red lines represent the standard deviation

of the measured HHV, the error bars represent the standard deviations obtained

using the correlations. (For interpretation of the references to colour in this figure

legend, the reader is referred to the web version of this article.)

Table 2

Survey of correlations estimating the HHV from the elemental composition

Authors (year)

Correlations: HHV (kJ kg

1

), dry basis

Dulong (1880)

338

:29 C þ 1442:77 H þ 94:2 S 180:36 O

(3)

Mott-Spponer (1940)

336

:20 C þ 1419:33 H þ 94:2 S ð153:24 72:01 O=ð100 AÞÞ O

(4)

Boie (1953)

351

:70 C þ 1162:49 H þ 104:67 S 110:95 O þ 62:80 N

(5)

IGT (1973)

341

:7 C þ 1322:1 H 119:8 ðO þ NÞ 123:2 S=10000 15:3 A

(6)

Tillman (1978)

437

:3 C 1670:1

(7)

Grabosky and Bain (1981)

328

C þ 1430:6 H þ 92:9 S 23:7 N 40110 ð1 A=100Þ H=C

(8)

Channiwala and Parikh (2002)

349

:1 C þ 1178:3 H þ 100:5 S 103:4 O 15:1 N 21:1 A

(9)

Sheng and Azevedo (2005)

1367:5 þ 313:7 C þ 700:9 H 31:8 O

0

(10)

Friedl et al. (2005)

3

:55 C

2

232 C 2230 H þ 51:2 ðC HÞ þ 131 N þ 20600

(11)

a

C, H, O, N, S, A represent respectively the carbon, hydrogen, oxygen, nitrogen, sulphur, and ash content expressed in % by mass on a dry basis.

b

A conversion factor of 2.326 kJ kg

1

per 1 BTU lb

1

was considered to adapt the correlation as reported by Mason and Gandhi

c

As reported by Channiwala and Parikh

d

Here O

0

is the sum of oxygen and other elements in the organic matter (S, N, Cl, etc.) and is calculated by difference O

0

= 100

C H A.

1

As far as the authors know this is the only correlation, considered in this study, for

which a validity range is specified.

210

E. Peduzzi et al. / Fuel 181 (2016) 207–217

The accuracy of the correlations has been evaluated using the

raw and torrefied samples belonging to the representative

‘biomass database’ presented above. Biomass char is considered

separately from the database as its ultimate analysis and heating

values were taken from the literature. The performance has been

evaluated considering the error between experimental and

computed HHV according to the root mean square error RMSE,

mean absolute error (MAE) and MBE as defined in the

. The

MBE represents the bias error of the correlation: a positive value

indicates that the correlation generally overestimates the observed

value. The correlations have also been evaluated considering the

percentage of predictions below 5% error and the coefficient of

determination R

2

. The values of these parameters for all correla-

tions listed in

are listed in

for the ‘biomass data-

base’ excluding char on the left and including char on the right.

Excluding char from the ‘biomass database’, the MAE, obtained

using the correlations is in the range of 1.93–2.38% (excluding

Dulong’s correlation). These values are slightly higher than the

reproducibility limit of 1.5% specified by the European Standard

(EN) for the measurement by bomb calorimetry (XP CEN/TS

14918) which shows the high accuracy of the correlations. The best

performing correlations are the most recent ones, Eqs.

by Friedl et al.

and Sheng and Azevedo

. However,

considering only biomass and torrefied biomass, the coefficient of

determination is low for all the correlations ranging from 0.54 to

0.64. Including char significantly increases the range of the HHVs

with respect to the scattering of the measurements. This, therefore,

drastically improves this coefficient with values ranging from 0.92

to 0.94. The accuracy remains similar for most correlations with a

significant increase in the RMSE for the correlations by Sheng and

Azevedo

and Tillman

The equation that best fits the experimental data available in

this study is the Eq.

by Friedl et al.

(Section

). However,

this correlation features a second order dependency to the compo-

sition which is not compatible with the general approach proposed

in this study that requires a first order polynomial to describe bio-

mass properties as a linear function of its elemental composition.

The correlation retained to model biomass in this study is Eq.

,

by Boie

which is linear with respect to the biomass con-

stituents and presents low MBE. This correlation has been used

in previous studies describing biomass thermochemical conver-

sion, for example, by Gassner and Maéchal

and Tock et al.

As shown in

, Boie’s relationship can represent the HHV

over the range of compositions of the ‘biomass database’ including

torrefied wood and chars, and coal as well as the differences

between biomass types when considering the average values.

5. Biomass thermodynamic properties model

The model presented in this study is general and can be used in

numerical simulations and any flowsheeting software which

allows the definition of new pseudo-compounds to represent sub-

stances not present in the internal database. The pseudo-

compounds chosen here are the most abundant elemental con-

stituents of biomass, which are carbon, hydrogen, oxygen, sulphur,

nitrogen, and bound water. This study provides the thermodynamic

properties to be assigned to these pseudo-compounds to have a

representation of biomass yielding coherent mass and energy

balances.

Using this approach it is possible to model any biomass as a

mixture of these pseudo-compounds provided that partial flows

Table 3

Accuracy of correlations in literature estimating the HHV for the ‘biomass database’ considered in this study.

Excluding char

Including char

RMSE

(kJ kg

1

)

MAE (%)

MBE (%)

<

D5% (%)

R

2

RMSE

(kJ kg

1

)

MAE (%)

MBE (%)

<

D5% (%)

R

2

Dulong (1880)

2176

10.51

10.38

4.6

0.54

2148

10.23

10.07

7.9

0.92

Mott-Spooner (1940)

671

2.20

0.76

90.7

0.56

691

2.26

0.58

91.2

0.92

Boie (1953)

656

2.28

0.42

89.8

0.58

669

2.28

0.37

89.5

0.93

IGT (1978)

672

2.38

0.56

88.9

0.58

681

2.40

0.62

89.5

0.92

Tillman (1978)

665

2.43

1.73

89.8

0.68

1185

2.97

2.31

86.0

0.94

Grabosky et al. (1981)

658

2.29

1.56

90.7

0.64

681

2.31

1.33

90.4

0.93

Channiwala and Parikh (2002)

663

2.20

0.81

91.7

0.58

668

2.19

0.79

91.2

0.93

Sheng and Azevedo (2005)

611

2.08

0.26

94.4

0.62

989

2.56

0.83

89.5

0.92

Friedl et al. (2005)

577

1.93

0.06

92.6

0.66

592

1.93

0.04

93.0

0.94

Fig. 2. Use of Boie’s correlation to predict the HHV of different types of biomass, torrefied biomass from the biomass database as well as char and coal: (a) predicted vs

experimental values, (b) average predicted vs average experimental values and relative standard deviation. Error bands of ±5% are displayed.

E. Peduzzi et al. / Fuel 181 (2016) 207–217

211

(or the ultimate composition) is given. The pseudo-compounds are

considered to be solid except for the bound water that will behave

as normal water in the liquid and the gas phase. The thermody-

namic properties of the biomass pseudo-compounds, which are

necessary in flowsheeting tools, are:

The enthalpy of formation of the elemental constituents, to

coherently represent the energy balances of biomass thermo-

chemical transformations.

The heat capacity of the solid, in order to take into account the

sensible heat of biomass.

The enthalpy of formation of bound water (optional), to coher-

ently assess the energy balances during drying processes.

The Gibbs free energy (optional), to define the ‘available energy’,

or ‘exergy’ of biomass.

In this study, the properties of the pseudo-compounds are

defined as being independent of the composition considered. This

feature makes the model very flexible and simple as, once the

properties are implemented, the only information required to rep-

resent biomass is its average elemental composition (and moisture

content) that can be obtained experimentally for a specific biomass

considered.

5.1. The enthalpy of formation

Although biomass is not a pure substance and does not have a

standard value for the enthalpy of formation, it is possible to com-

pute the value of

D

H

f

;BM

from the HHV. Given the combustion reac-

tion stoichiometry, Eq.

the HHV may be defined as the

additive inverse of the enthalpy of reaction of combustion,

D

H

r

, as

expressed in Eq.

. Combining Eqs.

, and considering

water in its liquid state (H

2

O

l

) it is therefore possible to calculate the

enthalpy of formation of biomass

D

H

f

;BM

.

CH

x

O

y

N

z

S

w

þ 1 þ

x

4

þ w

y

2

O

2

!

x

2

H

2

O

ðlÞ

þ CO

2

þ

z

2

N

2

þ w SO

2

ð12Þ

HHV

¼

D

H

r

¼

x

2

D

H

f

;H

2

O

ðlÞ

þ

D

H

f

;CO

2

þ

z

2

D

H

f

;N

2

þw

D

H

f

;SO

2

D

H

f

;BM

1 þ

x

4

þ w

y

2

D

H

f

;O

2

ðkJ mol

1

Þ ð13Þ

When defining the

D

H

f

;BM

, the normalisation used to define bio-

mass composition should always be specified. In this study compo-

sition is referred to 1 mol of carbon. Other studies use 6 mol of

carbon with reference to the structure of glucose. Furthermore, it

should be underlined that a small error on the HHV directly affects

the

D

H

f

;BM

for which it becomes relatively more important (a 5%

error on the HHV can represent a 20% difference on the

D

H

f

;BM

).

A general linear correlation relating HHV and composition can

be expressed in the form of Eq.

~

HHV

¼ eA C þ eB H þ eC O þ eD N þ eE S ðkJ kg

1

Þ

ð14Þ

C, H, O, N and S are the mass percentages of carbon, hydrogen, oxy-

gen, nitrogen and sulphur. For simplicity, these values are here

taken on a dry ash free basis and the corresponding HHV is there-

fore also on the same basis.

The general linear relationship between the higher heating

value of biomass and its composition, Eq.

, may be re-written

on a molar basis. Considering 1 mol of carbon as reference for

the molar composition of biomass, the molar HHV of biomass

may be expressed by Eq.

, where x

; y; z and w are expressed

in mol and M

m

in g mol

1

HHV

ðCH

x

O

y

N

z

S

w

Þ ¼ ~A M

m

;C

þ x ~B M

m

;H

þ y ~C M

m

;O

þz ~D M

m

;N

þ w ~E M

m

;S

1

10

ðkJ mol

1

Þ

ð15Þ

By equating Eqs.

, and solving for the

D

H

f

;BM

a lin-

ear correlation is obtained, Eq.

, relating directly the

D

H

f

;BM

to

the elemental composition of biomass.

D

H

f

;BM

ðCH

x

O

y

N

z

S

w

Þ ¼ ~A

M

m

;C

10

þ

D

H

f

;CO

2

þ x ~B

M

m

;H

10

þ

1

2

D

H

f

;H

2

O

ðlÞ

þ y ~C

M

m

;O

10

þ z ~D

M

m

;N

10

þ w ~E

M

m

;S

10

¼

D

H

f

;C

BM

þ x

D

H

f

;H

BM

þ y

D

H

f

;O

BM

þ z

D

H

f

;N

BM

þ w

D

H

f

;S

BM

ðkJ mol

1

Þ

ð16Þ

The coefficients of Eq.

represent the partial derivatives of

D

H

f

;BM

with respect to the variations in biomass composition,

they can be used to obtain the enthalpies of formation of the

pseudo-compounds that describe biomass.

As shown in Section

, Boie’s HHV relationship may be consid-

ered valid over a wide range of compositions. It is therefore

possible to use the same pseudo-compounds to describe raw and

torrefied biomass. The HHV relationships provide a general way

to describe biomass, which may be acceptable for engineering

applications. The outlined procedure allows to consistently

model the HHV and the enthalpies of formation involved in the

torrefaction and gasification of biomass.

5.2. Gibbs free energy of formation

The Gibbs free energy of formation of biomass can be expressed

in terms of its enthalpy and entropy of formation according to Eq.

D

G

f

;BM

¼

D

H

f

;BM

T

D

S

f

;BM

ðkJ mol

1

Þ

ð17Þ

D

S

f

;BM

can be expressed in terms of the absolute entropy S

BM

and the entropy of the atomic constituents of biomass as shown in

Eq.

.

D

S

f

;BM

¼ S

BM

X

S

atoms

ðJ mol

1

K

Þ

ð18Þ

Unlike the HHV, from which it is possible to calculate the

D

H

f

;BM

, experimental values of entropy of complex organic mole-

cules are rarely available in the literature. Battley

proposes a

correlation, Eq.

, based on the experimental values of entropy

of solid organic substances of biological interest, including cellular

data from previous studies.

S

BM

¼ ð1 K

B

Þ

X

S

atoms

ðJ mol

1

K

Þ

ð19Þ

B

is the constant reported by Battley

with a value of 0.813 and

S

atoms

are the atomic absolute entropies which can be determined

from the reference substances (carbon, H

2

, O

2

, N

2

, sulphur), avail-

able for example in

and reported in the

.

In subsequent studies, Battley and Stone

show that Eq.

is especially accurate for high molecular weight substances, with

an error of ±1% for substances having a molecular weight higher

than 300 g mol

1

. Whereas for lower molecular weight substances

the error generally lays within ±3% even though some outliers are

2

A complete combustion reaction is presumed with all nitrogen completely

transforming to N

2

during combustion.

3

DH

f

;H

2

and

DH

f

;O

2

and

DH

f

;N

2

are omitted as they are equal to zero.

212

E. Peduzzi et al. / Fuel 181 (2016) 207–217

present (at ±30%). Alternatively, the S

of a complex organic mole-

cule can be computed by a group contributions method taking into

account basic structural information and functional groups, as for

example the Joback’s method

. Nevertheless, given the difficul-

ties in pinning down the exact structures of the main molecular

components of biomass (for example lignin and hemicellulose)

the application of a group contribution method results difficult.

In the context of this study Battley’s method is used to determine

the entropy of biomass, S

BM

, because of the relatively good results

obtained in comparison with Joback’s method for simple organic

molecules and its simplicity. An alternative to Battley’s method is

the correlation proposed by Song et al.

, linearly relating

entropy to elemental composition, statistically based on the data

of a set of biologically important molecules.

Given the correlation expressing the enthalpy of formation, Eq.

, and the entropy of formation, Eq.

, it is possible to express

the Gibbs free energy as shown in Eq.

.

D

G

f

;BM

ðCH

x

O

y

N

z

S

w

Þ ¼

D

H

f

;C

BM

þ T

K

B

S

C

1

1000

þ x

D

H

f

;H

BM

þ T

K

B

S

H

1

1000

þ y

D

H

f

;O

BM

þ T

K

B

S

O

1

1000

þ z

D

H

f

;N

BM

þ T

K

B

S

N

1

1000

þ w

D

H

f

;S

BM

þ T

K

B

S

S

1

1000

¼

D

G

f

;C

BM

þ x

D

G

f

;H

BM

þ y

D

G

f

;O

BM

þ z

D

G

f

;N

BM

þ w

D

G

f

;S

BM

ðkJ mol

1

Þ

ð20Þ

The Gibbs free energy of formation assigned to the pseudo-

compounds and therefore to biomass can optionally be taken into

consideration in the thermochemical modelling of biomass

conversion.

It should be underlined however that the pseudo-compounds

are ‘artificial’ elements designed to reproduce the properties of

biomass and biomass itself cannot be considered as a substance

at equilibrium. Therefore, the values of Gibbs free energy are not

intended to be used in equilibrium calculation involving Gibbs free

energy minimisation. Nevertheless, these values can be used to

represent the ‘available energy’ or ‘exergy’ value of biomass coher-

ently as it is shown in the next section.

5.3. Exergy of biomass

The exergy concept is often used in the literature to analyse the

performance of thermal and chemical processes. Exergy is defined

as the maximum amount of work that can be obtained by bringing

a system to a state of thermodynamic equilibrium with the

common components of the environment by means of a reversible

process. Examples related to the conversion of biomass are the

analysis by Van Rens et al.

on biomass to fuel plants, the study

of the role of torrefaction for biomass gasification by Prins et al.

, the comparison of different types of gasifiers by Gassner

and Maréchal

and several others.

In these studies the definition of the exergy of biomass relies on

correlations expressing exergy as a function of composition. The

most cited correlations are the ones proposed by Szargut and

Styrylska

based on regression equations of the exergies of

standard organic substances. Different correlations are proposed

by Kotas

and Song et al.

. Other methods based on group

contributions are proposed by Shieh and Fan

.

Given the correlations presented in the previous sections of this

study, it is interesting to calculate the exergy of biomass starting

from its thermochemical properties. Taking into consideration

the combustion reaction, expressed in Eq.

, and the Gibbs free

energy, as shown in Eq.

, the standard chemical exergy of a fuel

can be expressed by Eq.

B

ch

¼

D

G

f

;BM

þ 1 þ

x

4

þ w

y

2

D

G

O

2

D

G

CO

2

x

2

D

G

H

2

Ol

z

2

D

G

N

2

w

D

G

SO

2

þ B

ch

;CO

2

þ

x

2

B

ch

;H

2

O

ðlÞ

þ

z

2

B

ch

;N

2

þ w B

SO

2

1 þ

x

4

þ w

y

2

B

ch

;O

2

ðkJ mol

1

Þ

ð21Þ

The standard chemical exergy, B

ch

;k

of the reference species is

related to their concentrations in the environment, considered at

standard temperature and pressure. Two alternative models often

used to represent the standard environment are the ones

developed for example by Szargut et al.

and Ahrendts

,

as reported by Bejan and Tsatsaronis

For gases belonging to the atmosphere it is possible to calculate

the standard chemical exergy, under the assumption of ideal

gas behaviour, considering their mean partial pressures (or

concentrations), P

0n

, as shown by Eq.

B

ch

¼ R T

n

ln

P

n

P

0n

ðkJ mol

1

Þ

ð22Þ

R is the ideal gas constant equal to 8.314 J mol

1

K

1

, reference

mean partial pressures, P

0n

, are reported in

The environment is considered at normal temperature and

pressure: T

n

= 298.15 K, P

n

= 101.325 kPa.

It is possible to express the exergy of biomass, again in terms of

a linear correlation of its elemental composition, in the form of

Eq.

. This equation is obtained given (i) Eq.

, (ii) the partial

pressures of the reference species in the atmosphere and (iii) the

standard chemical exergies of the reference species in the

environment

B

ch

;BM

ðCH

x

O

y

N

z

S

w

Þ ¼

D

G

f

;C

BM

D

G

f

;CO

2

þ B

ch

;CO

2

þ

D

G

f

;O

2

B

ch

;O

2

þ x

D

G

f

;H

BM

þ

1

4

D

G

f

;O

2

1

2

D

G

f

;H

2

O

ðlÞ

þ

1

2

B

ch

;H

2

O

ðlÞ

1

4

B

ch

;O

2

þ y

D

G

f

;O

BM

1

2

D

G

f

;O

2

þ

1

2

B

ch

;O

2

þ z

D

G

f

;N

BM

1

2

D

G

f

;N

2

þ

1

2

B

ch

;N

2

þ w

D

G

f

;S

BM

D

G

f

;SO

2

B

ch

;O

2

þ B

ch

;SO

2

¼ B

ch

;C

BM

þ x B

ch

;H

BM

þ y B

ch

;O

BM

þ z B

ch

;N

BM

þ w B

ch

;S

BM

ðkJ mol

1

Þ

ð23Þ

As for the correlations for the enthalpy of formation and the

Gibbs free energy of formation presented in this study, it is possible

to assign a value of standard chemical exergy to the pseudo-

compounds of biomass to represent its exergy.

5.4. Water content

Biomass, wood in particular, is a hygroscopic material and its

water content is generally expressed in terms moisture content

(MC) (water content on a dry basis).

Water molecules are adsorbed

on biomass surfaces (bound water) up to MC corresponding to the

4

The standard chemical exergies of the reference species in the environment can

be taken for example from Szargut et al.

or Ahrendts

, and reported in the

5

Sometimes the water content is expressed in terms of humidity

U

(water content

on an as received basis).

E. Peduzzi et al. / Fuel 181 (2016) 207–217

213

fiber saturation point (fsp), which for most wood species falls

between 25% and 30%

. For higher MC, water exists in cell

cavities and within the pores (free water) and its thermodynamic

properties are essentially the ones of liquid water

. In this sec-

tion the new pseudo-compound H

2

O

bound

is defined in analogy with

the previous sections, in the attempt to represent the thermody-

namic properties of bound water in biomass.

The enthalpy of formation of (bound) water can be described with

respect to the enthalpy of liquid water by the differential heat of sorp-

tion,

D

H

sorp

,

. As a first approximation the enthalpy of formation

of bound water (H

f

;H

2

O

bound

) can therefore be defined by Eq.

.

H

f

;H

2

O

bound

¼ H

f

;H

2

O

ðlÞ

þ

D

H

sorp

ðkJ mol

1

K

Þ

ð24Þ

where

D

H

sorp

is an average value of

D

H

sorp

between 0 and the fsp

water content

Stanish et al.

proposed an approximation assuming

D

H

sorp

varies quadratically with the bound water content (M

b

) and it is

40% of the latent heat of liquid water (

D

H

v

ap

) when the water

content is 0%. This approximation is expressed by Eq.

D

H

sorp

¼ 0:4

D

H

v

ap

1

M

b

M

fsp

2

ðkJ mol

1

K

Þ

ð25Þ

From Eq.

it is possible to calculate the value of

D

H

sorp

. For

example, at 298.15 K (25

°C), neglecting the temperature depen-

dence of

D

H

v

ap

and considering a fsp of 30%,

D

H

sorp

is of

6.348 kJ mol

1

.

The Gibbs free energy of bound water can be described in terms

of its enthalpy and entropy of formation. The considerations car-

ried out by Dunitz

in the context of ice, crystalline salts, pro-

teins and bio-molecules, show that the entropy cost of transferring

a water molecule from the liquid state to a surface,

D

S

sorp

can vary

in

the

range

between

0

and

7 cal mol

1

K

1

(0

and

29.288 J mol

1

K

1

). Considering the entropy cost from liquid

water to ice,

28.95 J mol

1

K

1

as the

D

S

sorp

, and the

D

H

sorp

esti-

mated before, the

D

G

sorp

, with respect to liquid water, at

298.15 K, is 2.272 kJ mol

1

.

The Exergy of bound water in biomass can be estimated consider-

ing its formation as a phase change with respect to water in its refer-

ence conditions in the environment, as shown in general by

Hinderink et al.

. In this case the phase change is from vapour

to liquid,

D

G

cond

, and from liquid to bound,

D

G

sorp

, which results in

Eq.

B

H

2

O

bound

¼ B

ch

;

v

þ

D

G

cond

þ

D

G

sorp

ðkJ mol

1

Þ

ð26Þ

Considering again the properties of the reference species in the

environment, taken from

and reported in

and the thermodynamic properties of water, as reported in

the estimate of B

f

;H

2

O

bound

is 3.19 kJ mol

1

.

5.5. Heat capacity

Another property required for the description of the pseudo-

compounds is the heat capacity (c

p

;dry

). The heat capacity of

biomass is considered independent of its elemental composition

and dependent on its temperature T on the basis of the model pro-

posed by Kollman

, Eq.

, which therefore applies to each of

the solid pseudo-compounds considered.

c

p

;dry

¼ 0:00486 T 0:21293 ðkJ kg

1

K

1

Þ

ð27Þ

The coefficients for heat capacity of the solid are not reported here,

they can be obtained by multiplying the coefficients of Eq.

by

the molar mass of each pseudo-compound. Alternatively, other

correlations are available in the literature which are reviewed by

Radmanovic´ et al.

. These correlations are generally valid in a

temperature range varying between 273 and 373 K. For higher tem-

peratures, between 313 and 513 K, the heat capacity measurements

for 21 biomass types and fast pyrolysis chars, are reported by

Dupont et al.

To obtain the heat capacity on a wet basis, it is possible to con-

sider the wet biomass as a mixture of dry biomass and water

as shown in Eq.

.

c

p

;wet

¼

U

c

p

;H

2

O

ðTÞ þ ð1

U

Þ c

p

;dry

ðkJ kg

1

K

1

Þ

ð28Þ

where c

p

;water

ðTÞ represents the heat capacity of water at the tem-

perature T.

6. Discussion

6.1. The biomass model

The model presented in this study provides a set of linear corre-

lations relating the enthalpy of formation, the Gibbs free energy and

the exergy of biomass to its composition. The coefficients of these

correlations are summarised in

and they can be used to

express the enthalpy of formation, the Gibbs free energy and the

exergy of the pseudo-compounds representing the C, H, O, N, S

and bound water content of biomass. The numerical values are

obtained by taking into consideration Boie’s and Battley’s correla-

tions, thermodynamic properties and standard chemical exergies

(as calculated by Szargut et al.

) of the reference substances

as reported in

.

The results obtained in terms of

D

H

f

;

D

G

f

, and S

, for several

molecules relevant to biomass are displayed in

and

when possible, compared to literature values showing a good

agreement of the proposed correlations.

To complete the biomass model so it can be used, for example,

for a preliminary analysis of a thermochemical conversion process,

it is necessary to fix a reference composition of the inherently vari-

able biomass. For this purpose, and in the absence of experimental

values,

it is possible to use the average value of woody biomass

composition of the ‘biomass database’. Averaging the elemental

composition for hardwood, softwood, SRC and SRF, represented in

, and normalising it to a dry ash free basis, yields:

C

6

H

8

:40

O

3

:76

N

0

:02

(or equivalently C

1

H

1

:40

O

0

:64

N

0

:003

corresponding to

mass percentages of 50.81% carbon, 5.96% hydrogen, 43.05% oxygen,

0.18% nitrogen). The average ash content amounts to about 1.3%.

Applying the correlations proposed in this study using the

numerical values of the coefficients as summarised in

,

the properties of the average biomass, C

1

H

1

:40

O

0

:64

N

0

:003

, are

(normalised

to

1 mol

of

carbon):

D

H

f

¼ 120:49 kJ mol

1

,

D

G

f

¼ 80:95 kJ mol

1

, HHV = 442.10 kJ mol

1

(or 19.959 MJ kg

1

),

LHV = 442.29 kJ mol

1

(or 18.659 MJ kg

1

) and B

ch

¼ 495:82 kJ mol

1

(or 20.918 MJ kg

1

).

It should be underlined that this study does not take into

account the effect of the ash content and composition and only

attempts to consider the effect of moisture (free water has the same

properties as water). This is because the biomass types taken into

consideration are generally relatively dry and have low ash

content.

6.2. The representation of exergy

This study proposes a model for the representation of the

exergy of biomass based on its thermochemical properties. It is

6

An overview of the chemical composition of different types of biomass is carried

out by Vassilev et al.

214

E. Peduzzi et al. / Fuel 181 (2016) 207–217

therefore interesting to compare the results obtained with the

method proposed by Szargut et al.

and widely used in the

literature.

Eq.

represents the correlations proposed by Szargut and

Styrylska

, as reported by Szargut et al.

, to express the

chemical exergy of a fuel with respect to its LHV as a function of

the elemental composition. Eq.

concerns wood and Eq.

concerns bituminous coal, lignite, coke, and peat.

b ¼

B

ch

LHV

ð29Þ

b

wood

¼

1

:0412þ0:2160

H

C

0:2499

O

C

1þ0:7884

H

C

þ0:0450

N

C

1

0:3035

O

C

ð30Þ

b

coal

¼ 1:0437þ0:1896

H

C

þ0:0617

O

C

þ0:0428

N

C

ð31Þ

C, H, N, O are the mass percentages of carbon, hydrogen, oxygen

and nitrogen. The correlations for wood is valid for O/C

6 2.67 with

a mean accuracy of ±1.5% whereas the correlation for coal is valid

for O/C

6 0.667 and ±1%.

These types of correlations are used because biomass, and many

industrial technical fuels such as coal and other hydrocarbons, are

solutions of numerous and often unknown chemical compounds,

for which it is difficult or even impossible to accurately determine

the thermochemical properties.

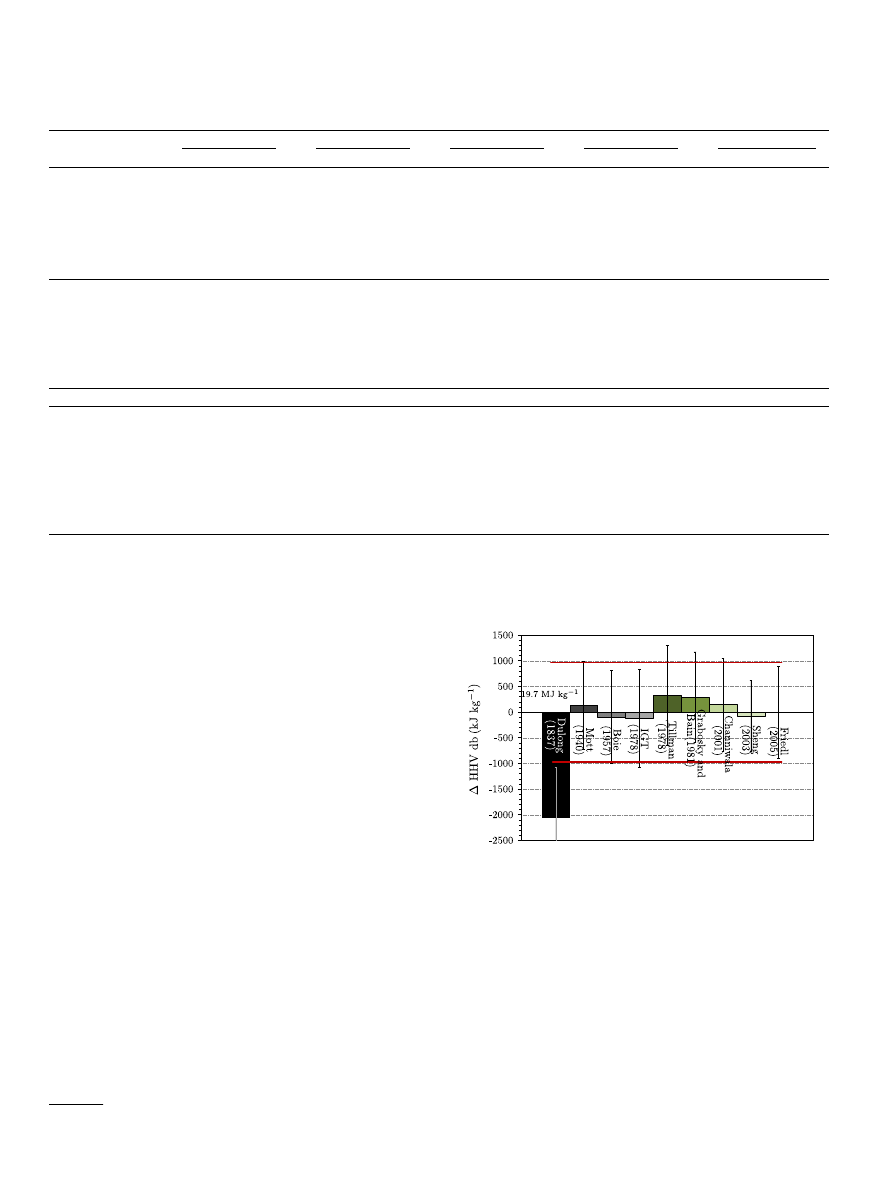

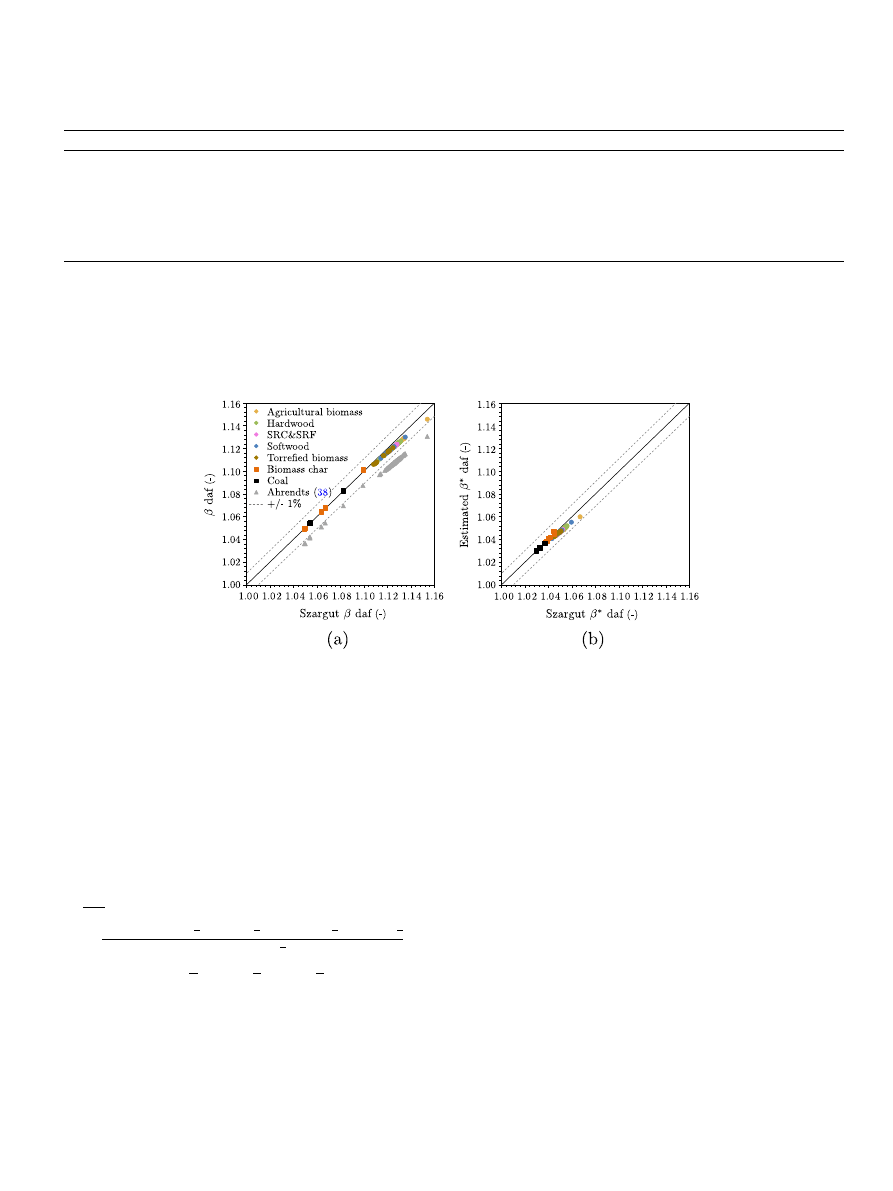

The comparison between the correlations proposed in this study

and the ones proposed by Szargut and Styrylska

is carried out

considering the elemental compositions of the sample belonging to

the biomass ‘database’ enriched with biomass char and coal sam-

ples and described in Section

. For the sake of simplicity and for

the comparison carried out in this study all biomass compositions

taken into account are normalised to the dry ash free basis. The

ratios between exergy (Eq.

) and the heating values as esti-

mated in this study against the ratios obtained considering Szar-

gut’s correlations are displayed in

. On the right side of this

Figure (a) the heating value is represented by the LHV

(

b ¼ B

ch

=LHV), whereas on the left side (b) the heating value is rep-

resented by the HHV (

b

¼ B

ch

=HHV). The relationship between LHV

and HHV is reported by Eq.

. For char and coal samples the exergy

values according to Szargut are calculated with Eq.

whereas for

all the other samples they are calculated with Eq.

As mentioned before, the correlations presented in this study are

evaluated considering the composition of the reference environ-

ment as considered by Szargut et el.

. Results are compared

with the values obtained considering a different set of standard

chemical exergies of the reference species, as for example the one

proposed by Ahrendts

, which are displayed in grey in

.

This comparison shows that the correlation presented in this

study is closely related to the one proposed by Szargut et al.

Table 4

Summary of the numerical values of the coefficients of the model presented in this study.

M

m

(g mol

1

)

DH

f

(kJ mol

1

)

DG

f

(kJ mol

1

)

B

ch

(kJ mol

1

)

Carbon: C

BM

12.0107

28.89(4308300)

30.28(5661053)

440.545

Hydrogen: H

BM

1.008

25.74(4998820)

9.90(6362655)

108.121

Oxygen: O

BM

15.999

177.51(3343000)

152.65(1032805)

150.664

Nitrogen: N

BM

14.007

87.96(2076000)

111.18(4819990)

111.545

Sulphur: S

BM

32.06

38.76(202000)

46.53(1779781)

593.100

Bound water

: H

2

O

bound

18.01528

DH

f

;H

2

O

ðlÞ

6:438

DG

f

;H

2

O

ðlÞ

þ 2:294

3.076

Free water

: H

2

O

free

18.01528

DH

f

;H

2

O

ðlÞ

DG

f

;H

2

O

ðlÞ

B

ch

;H

2

O

ðlÞ

a

The number of significant figures is limited by the ones of the HHV correlations reported in the literature. However, if these values are intermediate results, all digits

(reported in brackets) should be used to obtain the same values of the initial correlations considered.

b

The properties

DH

f

;H

2

O

ðlÞ

and

DG

f

;H

2

O

ðlÞ

can be found in thermodynamic properties tables. In this study the values of

285.830 kJ mol

1

and

237.141 kJ mol

1

K

1

are

used, as reported by Atkins and de Paula

.

c

The properties of free water are equivalent to those of liquid water at standard conditions. The standard chemical exergy of liquid water is taken from

B

ch

;H

2

O

ðlÞ

¼ 0:9 kJ mol

1

.

Fig. 3. Ratio between the exergy and the heating value as estimated in this study against the ratios obtained considering the correlations by Szargut et al.

for wood

(circles) and for coal (squares). The data is relative to different types of biomass, torrefied biomass char and coal. The ratio is reported in (a) with respect to the LHV and in (b)

with respect to the HHV. Grey points represent values obtained considering the reference environment defined by Ahrendts

, whereas all other values are obtained taking

into consideration the reference environment defined by Szargut et al.

.

E. Peduzzi et al. / Fuel 181 (2016) 207–217

215

Results are very similar and, in the range of compositions

considered in this study, lay within ±1% to those obtained using

Eq.

for dry biomass. This result is expected as the same refer-

ence environment composition has been assumed.

In contrast to previously published correlations,

which assume the exergy of biomass to be independent from the

environmental parameters, the approach proposed in this study

can take directly into account the level of components of the envi-

ronment. The results show that the exergy variations are indeed

small.

Furthermore, within the range of compositions considered, the

values of exergy vary between about 105% and 115% of the LHV

whereas they display a smaller variation, between 103% and

107% with respect to the HHV. This justifies the approximation of

the chemical exergy of a fuel with its HHV as it is often observed

in the literature

7. Conclusions

The biomass model presented in this study allows a coherent

description of the mass and energy balances in the modelling of

biomass thermochemical conversion processes, such as torrefac-

tion, pyrolysis, combustion and gasification. The main contribu-

tions of this study are:

The evaluation of the accuracy of correlations available in the

literature relating biomass elemental composition to its heating

value on a large and consistent database of woody, straw and

torrefied biomass samples.

Given the evaluation of the literature correlations for the HHV, a

flexible and accurate definition of biomass in terms of heat of

formation is proposed.

The method for the estimation of the entropy of complex

organic molecules by Battley

is extended to biomass.

Gibbs free energy is represented using entropy and enthalpy of

formation correlations.

Exergy is represented given the Gibbs free energy correlation,

which conveniently allows directly taking into consideration

the reference composition of the environment.

A complete and coherent biomass model is presented (sum-

marised in

). The model is implemented in the software

Vali

Ò

but that could also be used in other calculation procedures.

The approach used in this study is based on the elemental com-

position of biomass and all information relative to structure and

molecular composition is not taken into consideration. Further

study regarding biomass characterisation and the definition of its

properties would be required to fully take into account and estab-

lish the importance of structure with respect to composition, in

terms of enthalpy, entropy, Gibbs free energy and exergy. The

structure information may be useful to model and highlight the

differences between biomass conversion pathways to obtain differ-

ent molecules, for example, in the context of biorefineries. Never-

theless, the elemental composition of biomass can be used to

predict reasonably well the thermodynamic properties of biomass,

most importantly the enthalpy of formation and also give an esti-

mate of its Gibbs free energy of formation and its exergy. Further

investigation is also required to take into better account the effect

of ash and moisture content. It would be interesting in fact to

extend the results and the approach developed in this study to

highly wet and high ash content biomass, as for example animal,

agricultural or food waste. Furthermore the same approach could

be extended to the representation of coal.

The model developed is suitable, given the information

generally available for biomass properties, for the accurate

representation of biomass, and in particular woody biomass, in

the context of the modelling and evaluation of thermochemical

conversion process chains.

Acknowledgements

The research for this paper was in part financially supported by

the Swiss Competence Center for Energy Research BIOSWEET - Bio-

mass for Swiss Energy Future and in part by the Commissariat à

l’énergie atomique et aux énergies alternatives of Grenoble (CEA-

Grenoble) in France. In particular the authors would like to

acknowledge Capucine Dupont (Biomass Technology Laboratory,

CEA-Grenoble) who provided most of the experimental data used

in this study as well as helpful discussion.

Appendix A. Supplementary material

Supplementary data associated with this article can be found, in

the online version, at

http://dx.doi.org/10.1016/j.fuel.2016.04.111

.

[1]

[2] AspenTech. Aspen physical property system, physical property model; 2012.

[3]

.

[4] Belsim SA. Belsim Vali; 2013.

[5]

.

[6] EC, Directive 2009/28/EC of the European Parliament and of the Council of 23

April 2009 on the promotion of the use of energy from renewable sources and

amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC,

Official Journal of the European Union (L 140/16).

[7]

.

[8] Laguerre D. Mesure du pouvoir calorifique des gaz. In: Techniques de

l’Ingénieur, Éditions Techniques de l’Ingénieur; 2005.

[9]

.

.

.

.

.

Boie W. Fuel technology calculations. Energietechnik 1953;3:309–16

.

.

[20] IGT. Coal conversion systems technical data book. Institute of Gas Technology,

United States Dept of Energy; 1978.

Tillman DA. Wood as an energy resource. New York: Academic Press, Inc.;

1978

216

E. Peduzzi et al. / Fuel 181 (2016) 207–217

.

.

Atkins P, de Paula J. Physical chemistry. W.H. Freeman; 2007

.

[27] NIST. Chemistry WebBook, NIST standard reference database number 69,

National Institute of Standards and Technology, Gaithersburg MD; 2013.

.

Kotas TJ. Exergy method of thermal plant analysis. Krieger Publ; 1995

.

[36] Shieh HJ, Fan T. Energy and exergy estimation using the group contribution

method. Efficiency and costing; 1983 [chapter 17]. p. 351–71.

[37]

.

[38]

Ahrendts J. Reference states. Energy 1980;5:666–77

[39]

Bejan A, Tsatsaronis G. Thermal design and optimization. John Wiley & Sons;

1996

[40]

Reed JE. Wood and moisture relationships Tech. rep.. Oregon State University;

2009

.

[41]

.

[42]

.

[43]

[44]

Dunitz JD. The entropic cost of bound water in crystals and biomolecules.

Science 1994;264(5159):670

[45]

[46]

Kollman F. Technologie des Holzes und der Holzwerkstoffe. Heidelberg: Springer;

1982

.

[47]

Radmanovic´ K, Dukic´ I, Pervan S. Specific heat capacity of wood. Drvna

industrija 2014;65(2):151–7

.

[48]

.

[49]

.

[50]

.

E. Peduzzi et al. / Fuel 181 (2016) 207–217

217

Document Outline

- Biomass modelling: Estimating thermodynamic properties from the elemental composition

Wyszukiwarka

Podobne podstrony:

Identyfikacja cementów portlandzkich produkowanych w Polsce na podstawie zawartości składników akces

Mit Wielkiej Brytanii w literackiej kulturze polskiej okresu rozbiorow Studium wyobrazen srodowiskow

Współczesny sport, jego istota, elementy i obraz na podstawie lektury

DAF, Na podstawie powyższych danych zaksięgować operacje gospodarcze, zakła¬dając, że na kontach są

Podstawy fizyki z elementami biofizyki, zagadnienia na egzamin

Podstawy fizyki z elementami biofizyki zagadnienia na egzamin

Klasyfikacja i oznaczanie minerałów na podstawie ich właściwośći, Studia TOŚ, geochemia

6i8 Badanie podstawowych przemian termodynamicznych Wyznaczanie wielkości kappa Wyznaczanie ciepła p

23597 problem właściwości organów oraz wyłączenie pracownika i organu na podstawie przepisów w kodek

ING Lojalność wobec klientów na podstawie ING Banku Śląskiego S A

PDW na podstawie obserwacji pedagogicznej

Lęk i samoocena na podstawie Kościelak R Integracja społeczna umysłowo UG, Gdańsk 1995 ppt

Prognozowanie na podstawie modeli autoregresji

Podstawy fizyki z elementami biofizyki mat 02d

Uczucia Juliusza Słowackiego na podstawie utworów, Notatki, Filologia polska i specjalizacja nauczyc

Status producenta na podstawie przepisów prawa w oparciu o praktykę, BHP I PRAWO PRACY, PORADY PRAWN

więcej podobnych podstron