Krzysztof ZAREMBA

1

, Andrzej PAWLAK

2

Bialystok Technical University (1), Central Institute for Labour Protection - National Research Institute (2)

Parameters of model luminaire with high power LED diodes

Abstract. Specially manufactured reflectors with limited height were applied in the designed luminaire model. Thanks to that approach, a reduced

luminous flux distribution was achieved along with more appropriate luminous intensity curve, with simultaneous high efficiency reaching 92%.

Application of 30 white and 5 red diodes in the same luminaire provided the resulting optical radiation with the colour temperature of 3702K and

colour rendering index of 81.

Streszczenie. W modelowej oprawie zastosowano specjalnie zaprojektowane i wykonane odbłyśniki o niewielkiej wysokości. Dzięki temu

osiągnięto ograniczony rozsył strumienia świetlnego, krzywą światłości przystosowaną do równomiernego oświetlenia powierzchni roboczej i

jednocześnie wysoką sprawność oprawy wynoszącą aż 92%. Jednoczesne zastosowanie 30 diod barwy białej i 5 diod barwy czerwonej

spowodowało uzyskanie światła o temperaturze barwowej 3702K i wskaźniku oddawania barw 81. (Parametry modelowej oprawy z diodami LED

o dużej mocy)

Keywords: high power LED diode, general lighting, colour rendering index, colour temperature.

Słowa kluczowe: diody LED o dużej mocy, oświetlenie ogólne, wskaźnik oddawania barw, temperatura barwowa.

1. Introduction

In the case of high power LED diodes, it is possible to

assume that their luminous intensity distribution curves are

very similar with the cosine luminous intensity distribution

curve of the Lambertian surface. They should not be

however applied directly in general lighting luminaires [1].

Obtaining the constant illuminance value on the working

surface, which is directly connected with the highest

possible degree of the lighting uniformity, requires

application of a luminaire with the special luminous intensity

curve [2]. Such luminous intensity distribution can not be

obtained in a typical general lighting reflector luminaire with

the

α

ob

cut-off angle ranging from 55° to 65°. A uniform

lighting luminaire must be constructed in such a way, that

the central part of the luminous flux emitted by the diode is

dissipated by an additional reflector module or a lens. That

additionally complicates the construction of such a luminaire

and increases its final price.

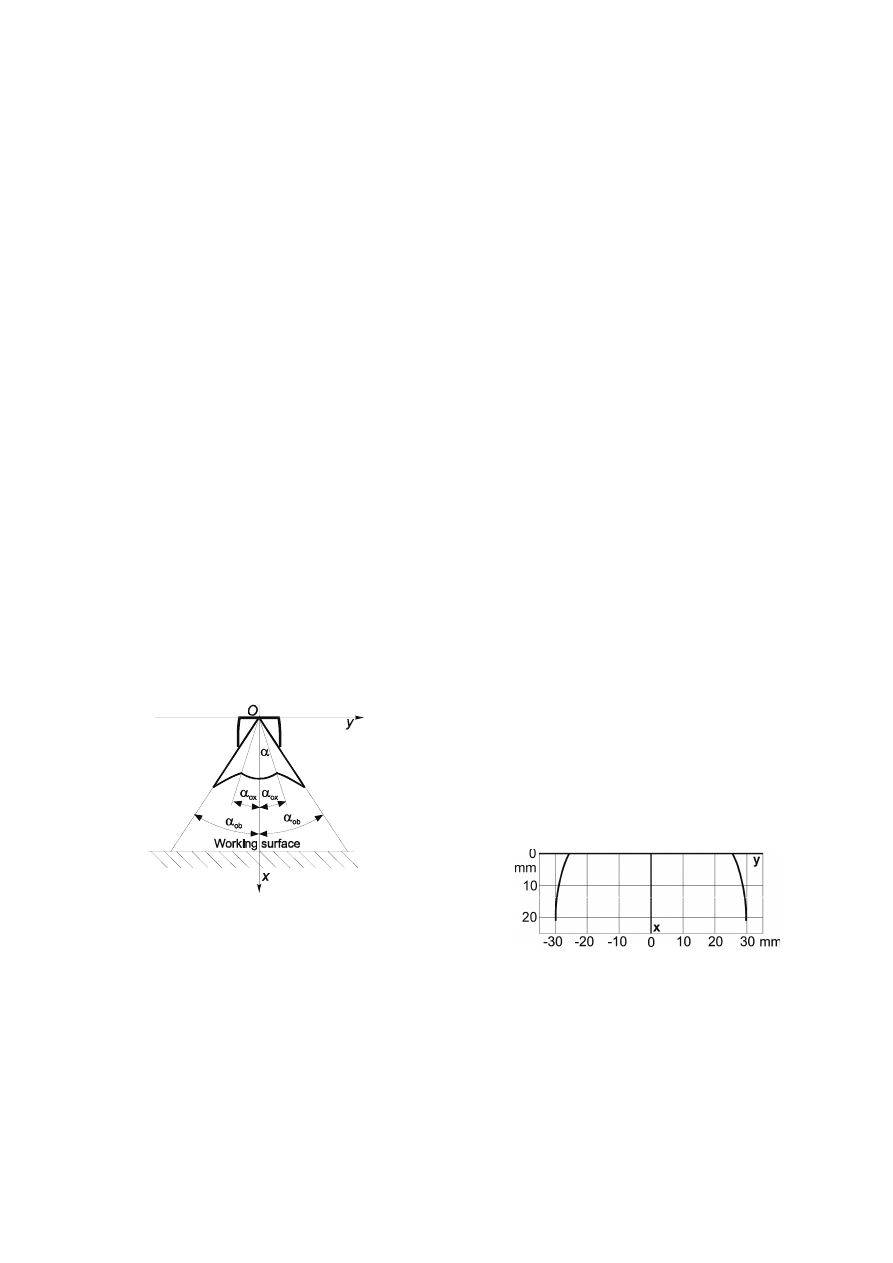

Fig. 1. Geometric layout of the designed luminaire with alternated

luminous intensity curve

In accordance with the standard EN 12464-1:2004 –

Lighting of Indoor Work Places, the uniformity of target area

lighting (calculated as a quotient of the minimum and

average value of the illuminance observed on the given

target area) for continuous work should be estimated at

least 0.7. That is exactly the reason why we decided to

examine the lighting uniformity for luminaires, where the

central part of the luminous intensity distribution curve,

characterized with the

α

ox

angle (Fig. 1), is identical with the

luminous intensity distribution curve of the light source and

then has a constant value of the illuminance. Under the

assumption that the reflection coefficient for the reflector

module was defined at 0.82, the minimal normative lighting

uniformity ratio, defined at 0.7 is achieved for the

α

ob

cut-off

angles lower or equal to 60,4°. Thus, it is possible to design

a single-reflector luminaire module, providing lighting

uniformity ratio better than 0.7. A luminaire with the direct

α

ob

cut-off angle estimated at 60° can theoretically provide

the lighting uniformity ratio of 0.713, while the said ratio

increases to 0,852 with the

α

ob

cut-off angle of 55°.

However, predicting a practical decrease in the estimated

lighting uniformity ratio, the luminaire with the

α

ob

cut-off

angle of 55° was selected for construction. It is

characterized with the

α

ox

angle estimated at 37,6° and the

luminous intensity I

ox

= 252,2 cd/klm.

2. Construction of the luminaire model

The shape of the luminaire reflector was estimated for

the I

o

α

luminous intensity distribution curve using the flux

method (Fig. 2) [2]. The used method for estimation of the

shape of the reflector module does not compensate for the

real size of the light source. Thus, the applicability analysis

for the derived profiles was conducted in systems with the

finite size of the light source. Its results confirm the

applicability of reflectors, designed for the light source with

negligible size, in the lighting systems with the real light

source of finite size. Visible alternations in the luminous

intensity distribution curves are noticeable only when the

size proportion between the light source and the reflector

module reaches the ratio 1:5.

Fig. 2. Calculated shape for the rotationally symmetrical reflector

with the direct irradiation angle

α

ob

equal to 55°

Construction of the model of the examined luminaire,

equipped with the LED diodes type LXHL-LW3C with the

diameter of 5.6 mm, featured a reflector module with the

output diameter of 60 mm (Fig. 2). The LXHL-LW3C diode,

emitting white light, is characterized with the standard

operating current of 700 mA with the operating voltage of

3.7 V, thus dissipating 2.6 W. Under such operating

conditions, the diode emits a luminous flux of 66 lm (with the

minimum value of 60 lm). The diode can also be powered

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

50

with the current of 1000 mA and voltage of 3.9 V,

dissipating 3.9 W and emitting a luminous flux of 80 lm. The

LXHL-LW3C diode, just like most of the currently

manufactured devices of his type, emits the daylight type of

visible radiation. Such diodes produce significant amount of

blue and green - yellow light, thus their colour temperature

is quite high, since it is typically estimated at 5500 K. The

manufacturer allows for a very wide colour temperature

distribution, ranging between 4500 K and 10000 K.

Additionally, the manufacturer does not also provide any

estimation of the colour rendering index, stating only that it

is good. Based on the catalogue – provided spectral

distribution for the LXHL-LW3C diode, its colour

temperature was estimated at 6177 K while the overall

colour rendering index was established at 67. The colour

temperature of 6177 K is too high for the majority of

applications, however, taking into the account the

admissible wide colour temperature distribution provided for

by the manufacturer, it becomes obvious that the target

luminaire should be equipped with a mechanism allowing to

adjust the colour temperature at will [3]. The impact of

applying red LXHL-LD3C diode in order to alter the colour

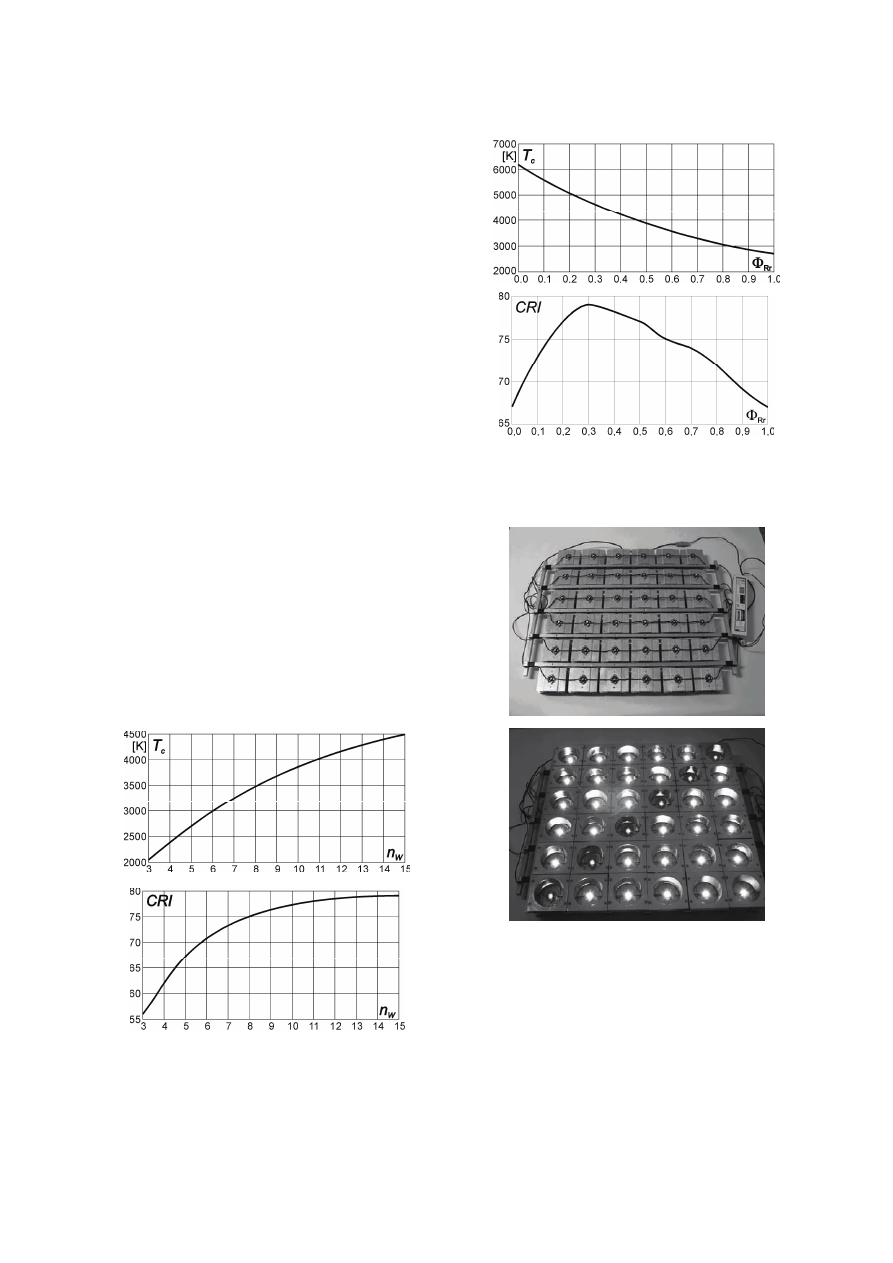

temperature of white diodes, was examined in detail. Fig. 3

present the relation between the colour temperature T

c

and

colour rendering index (CRI) for the resulting mixture of

optical radiation from a single red diode and a varied portion

n

W

of radiation originating from white diodes. Increase in the

number n

W

of white diodes is closely correlated with the

increase in the colour temperature and colour rendering

index of the resulting light. The designed luminaire

contained thus a single, red LXHL-LD3C diode for every 5

white emitting LXHL-LW3C diodes. The optical radiation

emitted by such mixture of diodes is characterized by the

overall colour temperature of 2709 K and the colour

rendering index estimated at 67, which is equal to the ones

of the white LED diodes alone. Selection of such proportion

of diode types was also advantageous in terms of power

budget, since most of the available power supply sources

are characterized with the maximum output voltage of 24 V,

which corresponds to 6 diodes connected in series in a

single branch.

Fig. 3. Calculated colour temperature T

c

and colour rendering index

CRI for radiation mix originating from a single red and n

W

white

diodes

Utilization of such diode proportion can also produce the

output white light with the colour temperature higher than

2709 K and colour rendering index reaching 79 providing

that a regulation circuit is employed in the luminaire,

allowing to decrease the relative quantity of the luminous

flux

Φ

Rr

originating from red diodes. (Fig. 4).

Fig. 4. Calculated colour temperature T

c

and colour rendering index

CRI for radiation mix originating from a single red diode with the

relative quantity of luminous flux

Φ

Rr

and 5 white diodes

a

b

Photo 1. Overall construction of the model luminaire with 36 LED

diodes: (a) – with no attached reflectors, (b) – with attached

reflectors

The target model luminaire was to contain 30 LXHL-

LW3C type LED white light diodes and 6 LXHL-LD3C type

LED red light diodes (Photo 1 – red diodes are located on

the diagonal of the luminaire). Each diode was mounted on

a separate, electrically insulated radiator (Photo 1.a). In the

result of the conducted analysis using the Philips

Xitanium™ 80W/3.15-24V/3150mA power supply system,

assumptions concerning the system power source were

modified. Instead of original two parallel power supplies,

only one was applied. It was decided that at the research

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

51

stage, assuring stable and safe operating conditions for the

diodes is much more important than obtaining their

maximum lighting parameter ratings. Closer analysis of the

power supply system indicated that under failure conditions

(e.g. disconnecting one of the parallel branches), the whole

current provided by the power supply would flow through the

remaining branches, meaning that with a 3 branch design,

most of the diodes would be damaged. Thus, a single power

supply system was connected to 6 parallel diode branches.

It must be noted, that while the average current value in

branches was estimated at 0,537 A, the maximum observed

difference was measured at 0,09 A, providing the relative

value of approximately 20%.

2. Conclusions

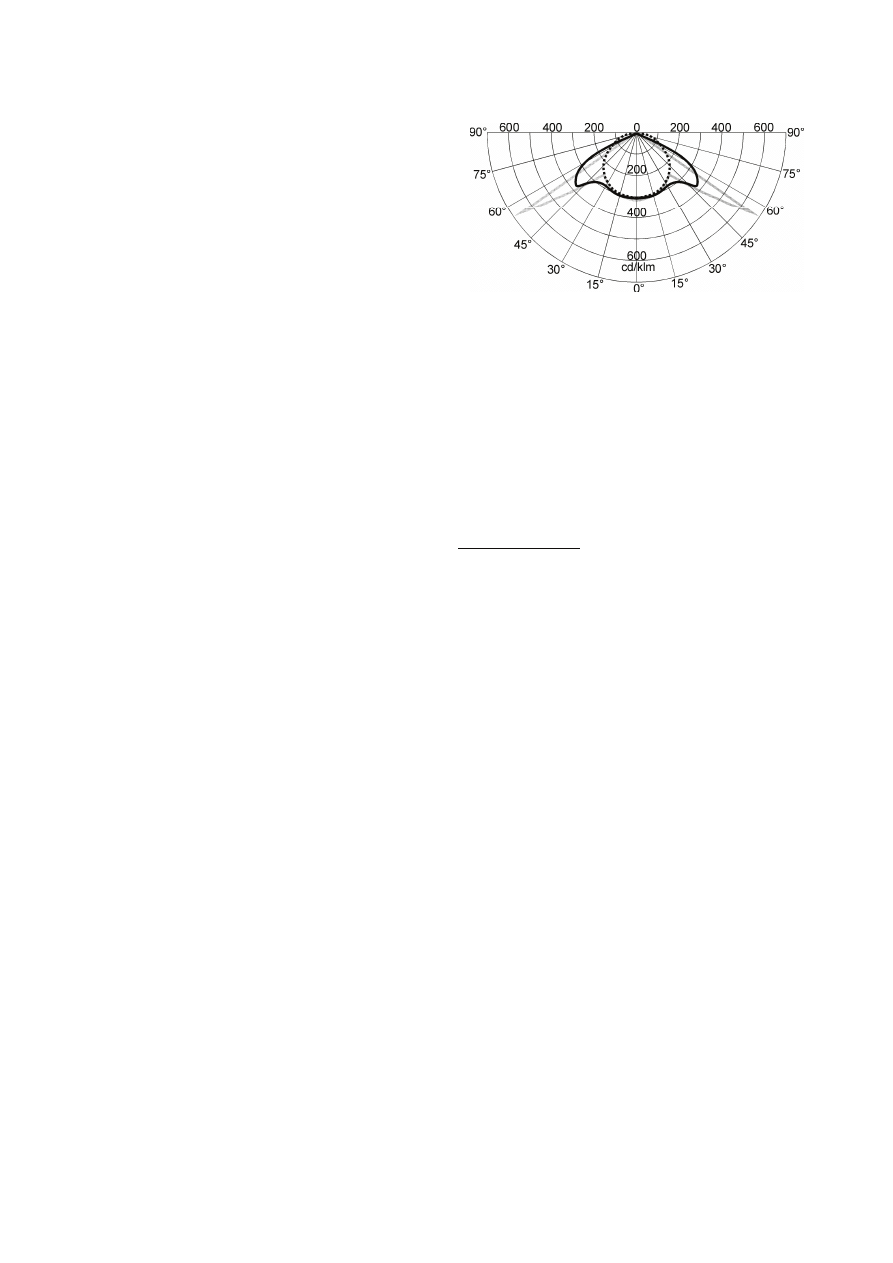

The measured luminous intensity curves for 36 LED

diodes and the model luminaire were depicted in Fig. 5. The

constructed luminaire is characterized by low luminance

value and limited luminous flux distribution. The obtained

luminous intensity distribution curve is characterized by

significantly lower maximum luminous intensity value when

compared with the theoretically estimated one, which

originates from the manufacturing technology for model

reflectors, the surface of which has slightly diffusive

properties. Despite this fact, the model luminaire achieves

significantly improved lighting uniformity when compared

with the application of individual diodes alone. The luminous

flux of all 36 diodes was measured at 1954 lm (on average,

54,3 lm/diode). The model luminaire has very high

efficiency, reaching 92%, which is 15÷20% higher when

compared with other luminaires with similar parameters but

different light sources. The designed luminaire is relatively

low, which is a design target on its own. It could be further

reduced providing that lower profile radiators are used. The

measured colour temperature of the designed luminaire was

estimated at 3702K, which is higher than the theoretically

expected value. The measured colour rendering index was

estimated at 81. It is therefore conclusive that the designed

model luminaire with high power LED diodes may be

successfully applied for general lighting purposes.

Fig. 5. Luminous intensity curve: 36 LED diodes (black dotted

line), luminaire model (black solid line) and calculated theoretically

(grey solid line)

REFERENCES

[1] U c h i d a Y . ; T a g u c h i T . : Lighting theory and luminous

characteristics of white light-emitting diodes, Optical

Engineering. Dec. 2005; 44(12): 124003-1-9

[2] Z a r e m b a K . : A Synthetic Method of Designing Rotational

Reflectors, 13

th

European Simulation Multiconference 1999,

Modelling and Simulation: A Tool for the Next Millenium,

ESM’99, Warsaw, June 1-4 1999, Poland, Volume II, p.307-309

[3] B r o w n D . ; N i c o l D . ; F e r g u s o n I . : Investigation of the

spectral properties of LED-based MR16 bulbs for general

illumination, Optical Engineering. Nov. 2005; 44(11): 111310-1-

4

Autors: Krzysztof Zaremba, Ph.D. (E.Eng), Białystok Technical

University, Chair of Optical Radiation, ul. Wiejska 45D, 15-351

Białystok, Poland; phone 48 85 746 94 47, zaremba@pb.edu.pl;

Andrzej Pawlak, M.Sc. (E.Eng.), Central Institute for Labour

Protection - National Research Institute, ul. Czerniakowska 16, 00-

701 Warszawa, Poland; phone 48 22 623-46-75, fax 48 22 623-

3695, anpaw@ciop.pl;

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

52

Wyszukiwarka

Podobne podstrony:

Lens for luminaires with a high power LED diodes

THREE PHASE 200 KVA UPS WITH IGBT CONSISTING OF HIGH POWER FACTOR CONVERTER AND INSTANTANEOUS WAVEFO

0502 Refrigerant circuit Model 126 with air conditioning system

High Power Car Stereo Amp

dm7407 Hex Buffer Driver with High Voltage Open Collector Outputs

High Power Mini FM Transmitter Shematics (1Km range)

Panel Power LED opis produktu

15 185 196 A ew High Tensile Steel with High Toughness

HIGH POWER 100KW INVERTER

Lampa Power LED opis produktu

A Composite Pwm Method Of Three Phase Voltage Source Inverter For High Power Applications

KB01 HIGH BRIGHTNESS LED 1

Differences in the note taking skills of students with high achievement,

High Power Car Stereo Amp

Preparation of garlic powder with high allicin content by using combined microwave–vacuum and vacuum

6624 Getting started with the Power BI for Android app WSG 2

6623 Getting started with the Power BI mobile app for Windows 10 WSG 2

więcej podobnych podstron