PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010 187

Irena FRYC

Bialystok University of Technology, Faculty of Electrical Engineering

LED's spectral power distribution under different condition of

operating temperature and driving current

Streszczenie. Jako!" !wiat#a emitowanego przez LED-y zale$y od wielu czynników. Najwi%kszy wp#yw maj& temperatura oraz nat%$enie pr&du

pracy. W zastosowaniach o!wietleniowych jednym z najwa$niejszych parametrów jest utrzymanie sta#ego strumienia !wietlnego oraz barwy

emitowanego !wiat#a. W artykule przedstawione zosta#y dane pomiarowe komercyjnie dost%pnych diod elektroluminescencyjnych. Na podstawie

tych danych przeanalizowana zosta#a mo$liwo!" uzyskiwania z LED !wiat#a o sta#ych strumieniu i barwie w zmieniaj&cej si% temperaturze otoczenia.

(Analiza w!a"ciwo"ci spektralnych LEDów z zale#no"ci od temperatury i nat$#enia ich pr%du pracy)

Abstract. The quality of light emitted by LEDs depends on many factors. The most significant are ambient temperature and driving current. In

lighting application the most important is to have light with constant value of luminous flux and color. In this paper some data taken from

measurement of commercially available LEDs will be presented. Based on those data is possible to make an analysis which can be helpful with

getting constant output of LED luminous flux.

S!owa kluczowe: pomiary promieniowania optycznego, diody elektroluminescencyjne, rozk!ad widmowy mocy promieniowania

optycznego, zale"no#ci temperaturowe.

Keywords: optical radiation measurement, light emitting diodes, spectral power distributions, temperature dependence.

Introduction [1]

The

light-emitting diodes

(LEDs) were discovered by

British radio engineer Henry Joseph Round completely by

accident. While investigating the electrical properties of a

metal semiconductor SiC he witnessed the light emission

from a solid-state material driven by an electrical current.

Round

reported

this

“curious

phenomenon”

of

electroluminescence in 1907. Right now we can see the

scientific and commercial significance of such a discovery,

but the phenomenon of electroluminescence was forgotten

for several years. However, in 1923 it was rediscovered by

Russian scientist Oleg Vladimirovich Lossev. In 1924 he

take the first photograph of electroluminescence from an

LED and he carried out detailed measurements of the

diode’s current-voltage characteristics. Also he showed that

the emission could be switched on and off very rapidly. In

recognition of his accomplishments he was awarded the

PhD degree in 1938. Lossev’s was the first who did detailed

study of semiconductor electroluminescence but he did not

make a correct interpretation physical phenomena of light

emission emitted by this kind of diode. The first correct

interpretation of light emission from a p-n junction was

provided by Kurt Lehovec and colleagues at the Signal

Corps Engineering Laboratories in New Jersey in 1951.

T

he first commercial LED was introduced to the world

only about 40 years ago. Since then, the performance of

LEDs has been improved continuously with a breathtaking

acceleration of progress in the last decade.

These

advances were kick started by replacing SiC with more

efficient materials based on III-V compounds. Key

milestones include the demonstration of single-crystal GaAs

(Welker, 1952), which provides the ideal substrate for many

devices. This platform was used for the initial development

of GaAs LEDs. The first visible LEDs based on III-V

materials were built in 1955 by Wolff and colleagues at the

Signal Corps Engineering Laboratories. This orange-

emitting GaP device generated light through the impact

ionization of carriers at the metal-semiconductor junction.

LED progress followed through the development of new

red, yellow, or

ange and green emitting materials in

the1960s and 70s,which were made from III-V compounds,

such as GaPAs, nitrogen-doped GaP, nitrogen-doped

GaPAs, and zinc and oxygen doped GaP. These LEDs

were far more efficient than Wolff’s metal-semiconductor

structure but they still fall well short of the performance of

today’s high-power LEDs, which are based on AlGaAs and

AlGaInP. But still there was lack of blue LEDs.

In 1969 Paul Maruska made a single-crystalline GaN

film. However, these films were unintentionally n-doped and

the addition of p-type dopant only produced insulating

material. The lack of p-doped material led Maruska’s team

to build metal-insulator-semiconductor diodes, but such

devices are inevitably inefficient and this project was

abandoned in the early 1970s. However, in 1989 Isamu

Akasaki and co-workers from Nagoya in Japan produced

the first p-type doping and conductivity in GaN. An LED with

1% efficiency followed three years later, but this was soon

surpassed by Shuji Nakamura from Nichia, who managed

to fabricate blue and green GaInN double-heterostructure

LEDs that were 10 times as efficient. Further improvements

have continued to this day.

Current interest in single-color LEDs is overshadowed

by their white cousins. One approach to producing white

light involves the mixing of emissions from several different-

colored LEDs. However, the dominant commercial method

that was pioneered by Nichia, which is simpler and

produces a high color rendering index, involves a yellow

phosphor and a blue LED chip. The blue-emitting chip

excites the yellow-emitting phosphor and white light is

created from mixing these two sources.

Scientists and engineers that strive to control and tune

all of the properties of an LED have the unprecedented

challenge of constructing light sources that can be

controlled in terms of spectrum, polarization, color

temperature, temporal modulation and spatial emission

pattern.

The physical mechanism by which semiconductor

LEDs emit light [2]

The spontaneous recombination of electron–hole pairs and

simultaneous emission of photons is the physical

mechanism by which semiconductor LEDs emit light is.

Spontaneous recombination has certain characteristics that

determine the optical properties of LEDs. In an electron–

hole recombination process is electrons in the conduction

band and holes in the valence band are assumed to have

the parabolic dispersion relations.

(1)

!

"

#

$

%

&

'

(

)

*

e

C

m

k

h

E

E

2

2

2

2

(for electrons)

188 PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010

and

(2)

!

"

#

$

%

&

'

(

+

*

h

V

m

k

h

E

E

2

2

2

2

(for holes)

where

!

e

m and

!

h

m are the electron and hole effective

masses, h is Planck’s constant, k is the carrier wave

number, and

V

E and

C

E are the valence and conduction

band edges, respectively.

The requirement of energy and momentum conservation

leads to further insight into the radiative recombination

mechanism. It follows from the Boltzmann distribution that

electrons and holes have an average kinetic energy of kT .

Energy conservation requires that the photon energy is

given by the difference between the electron energy,

e

E

and the hole energy,

h

E , i.e.

(3)

g

h

e

E

E

E

h

,

+

*

-

The photon energy is approximately equal to the

bandgap energy,

g

E , if the thermal energy is small

compared with the bandgap energy

g

E

kT ..

. Thus the

desired emission wavelength of an LED can be attained by

choosing a semiconductor material with an appropriate

bandgap energy. It is helpful to compare the average carrier

momentum with the photon momentum. A carrier with

kinetic energy kT and effective mass

!

m

has the

momentum

(4)

kT

m

m

m

m

p

!

!

!

!

*

-

*

-

*

2

2

1

2

2

The momentum of a photon with energy

g

E can be

derived from the de Broglie relation

(5)

c

E

c

h

k

h

p

g

*

-

*

(

*

2

Calculation of the carrier momentum (using Eq. 4) and

the photon momentum (using Eq. 5) yields that the carrier

momentum is orders of magnitude larger than the photon

momentum. Therefore the electron momentum cannot

change significantly during the transition from the

conduction to the valence band. The transitions are

therefore “vertical” i.e. electrons only recombine with holes

that have the same momentum or k value.

Using the requirement that electron and hole moment

are the same, the photon energy can be written as the joint

dispersion relation:

(6)

!

!

!

"

#

$

%

&

'

(

)

*

"

#

$

%

&

'

(

)

+

"

#

$

%

&

'

(

)

*

r

g

h

V

e

C

m

k

h

E

m

k

h

E

m

k

h

E

E

2

2

2

2

2

2

2

2

2

2

2

2

where

r

m is the reduced mass given by:

(7)

!

!

!

)

*

h

e

r

m

m

m

1

1

1

Using the joint dispersion relation, the joint density of

states can be calculated as:

(8)

/

0

g

/

*

r

E

E

/

h

m

(E)

+

"

"

#

$

%

%

&

'

(

(

*

1

2

3

2

2

2

2

2

1

The distribution of carriers in the allowed bands is given

by the Boltzmann distribution:

(9)

"

#

$

%

&

'

+

*

kT

E

exp

)

E

(

f

B

The emission intensity as a function of energy is

proportional to the product of Eqs. (8) and (9),

(10)

"

#

$

%

&

'

+

+

2

kT

E

exp

E

E

)

E

(

I

g

The maximum emission intensity occurs at:

(11)

kT

E

E

g

2

1

)

*

LED's

photometric

parameters

under

different

condition of operating temperature

All LEDs photometric parameters could be derived

based on measured SPDs. The LED spectral power

distribution depends on many factors but most important is

drive current and junction temperature

j

T . Based on Eqs.

(10) and (11) we can see, that SPDs of an LED depend on

junction temperature

j

T . Also according to manufacturer

data of high power LEDs, reported in Cree® XLamp® Long-

Term Lumen Maintenance [3] there is additional factor that

affects the rate of spectral power distribution and lumen

depreciation for LED. This is the temperature

A

T of the air

surrounding the LED. For this reason is possible to say that

LEDs SPDs depends on the operating temperature. The

term operating temperature means that we take under

consideration

j

T and

A

T

.

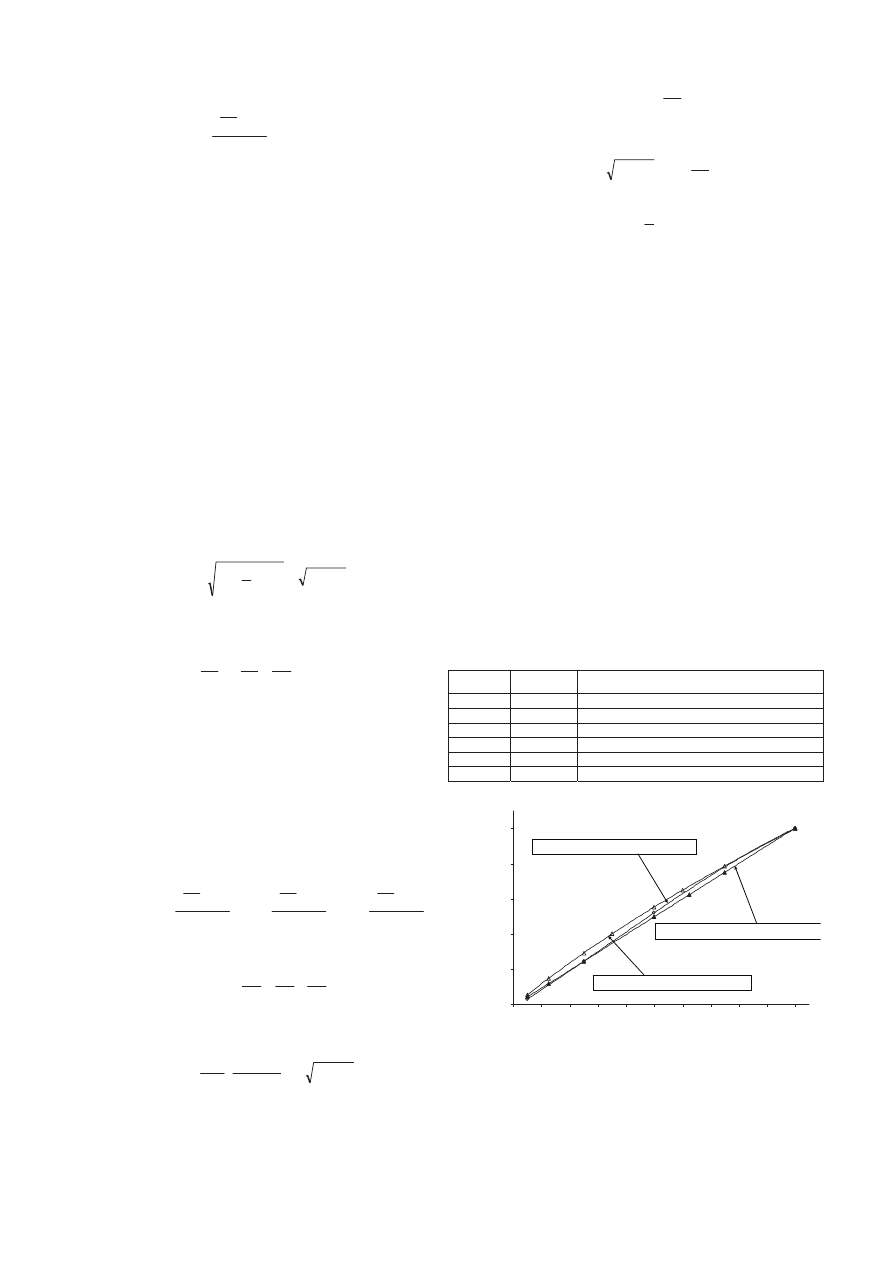

All LEDs photometric parameters were measured

according to recommendations given by CIE 127:2007

document. Figure (1) and (2) show the LEDs luminous flux

relative value versus relative value of drive current. The

measurements

were taken at connstant operating

temperature. Under consideration [4] (Table. 1) were taken

LEDs from blue to red.

Table 1. The LEDs taken under consideration [4]

No.

p

3

[nm]

Part number

1

420.0

LEDREPS UVA-15N20K

2

472.5

SunLED Corporation XLBB12WH

3

504.4

Roithner Lasertechnik 383-2UBGC

4

587.7

LEDTRONICS INC, L200CY5B

5

633.9

LEDTRONICS INC. L200CWR3KH-30D

6

715.0

Roithner Lasertechnik ELD-720-524

Fig. 1. The LEDs luminous flux relative value versus relative value

of drive current [4]

0,0

0,2

0,4

0,6

0,8

1,0

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1,0

current relative value

lu

m

in

o

u

s

f

lu

x

r

e

la

ti

v

e

v

a

lu

e

.

2 - SunLED Corporation XLBB12WH

3 - Roitchner Lasertechnik 383-2UBGC

6 - Roitchner Lasertechnik ELD-720-524

PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010 189

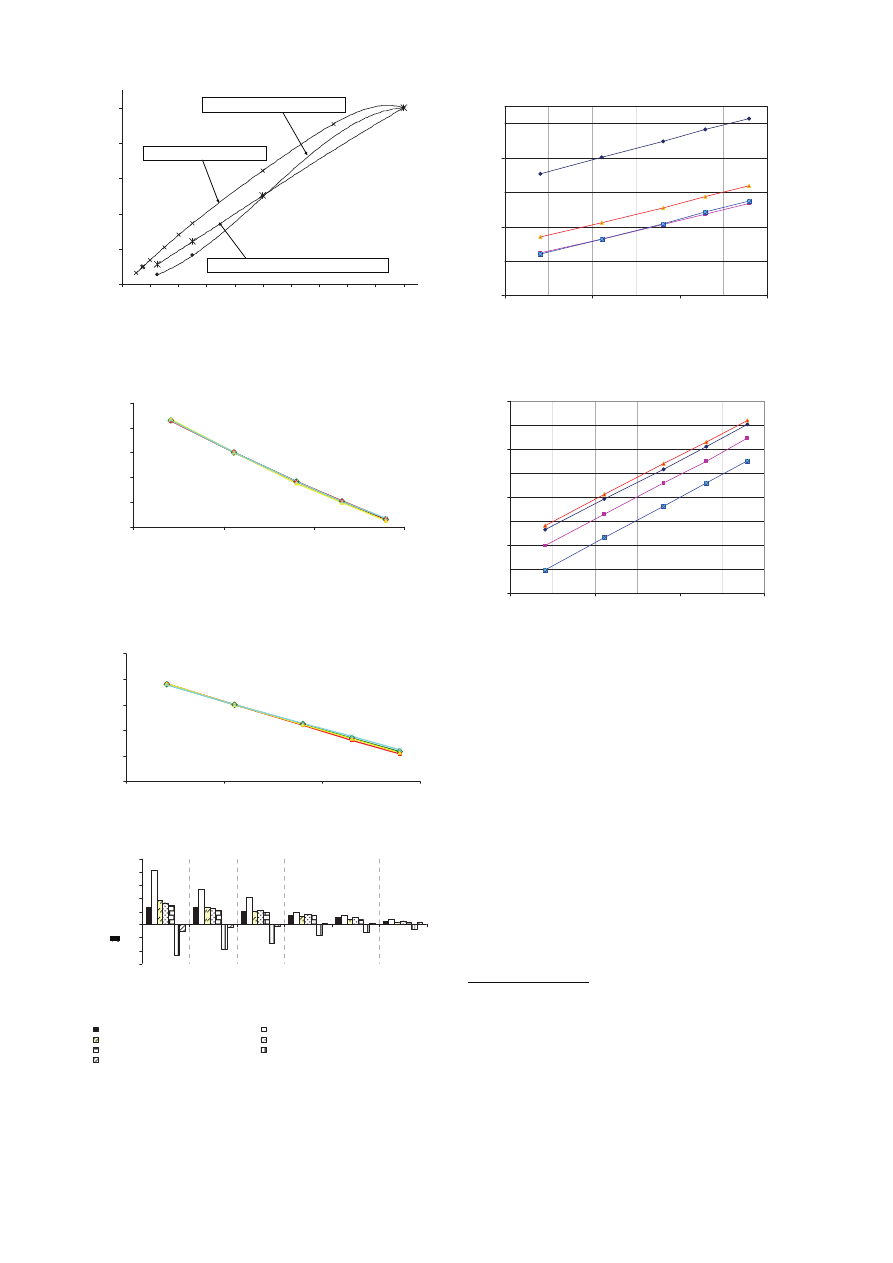

0,0

0,2

0,4

0,6

0,8

1,0

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1,0

drive current relative value

lu

m

in

o

u

s

f

lu

x

r

e

la

ti

v

e

v

a

lu

e

1 - LEDREPS UVA-L5N20K

5 - LEDTRONICS INC. L200CWR3KH-30D

4 - LEDTRONICS INC. L200CY5B

Fig. 2. The LEDs luminous flux relative value versus relative value

of drive current [4]

4 LEDs HLMP-EL30 type with

3

p

= 591 nm

0,7

0,8

0,9

1,0

1,1

1,2

10

20

30

40

Temperature [

o

C]

lu

m

in

o

u

s

f

lu

x

re

la

ti

v

e

v

a

lu

e

Fig. 3. The LED luminous flux relative value versus temperature [4]

4 LEDs HLMP-C116 type with

3

p

= 643 nm

0,7

0,8

0,9

1,0

1,1

1,2

10

20

30

40

Temperature [

o

C]

lu

m

in

o

u

s

f

lu

x

re

la

ti

v

e

v

a

lu

e

.

Fig. 4. The LED luminous flux relative value versus temperature [4]

-6

-4

-2

0

2

4

6

8

10

0.05 Imax, 0.125 Imax, 0.25 Imax,

0.5 Imax,

0.625 Imax, 0.75 Imax,

drive current relative value

s

p

e

c

tr

a

l

s

h

if

t

c

o

m

p

a

re

d

t

o

p

[n

m

]

u

n

d

e

r

I

m

a

x

Roitchner Lasertechnik ELD-720-524

Roitcher Lasertechnik 383 -2UBGC

LEDTRONICS INC. L200CY5B

Roitchner Lasertechnik LED-750-03AU

LEDTRONICS INC. L200CWR3KH-30D

SunLED Corporation XLBB12WH

LEDREPS UVA-L5N20K

Fig. 5. The LEDs spectral shift versus relative value of drive current

at constant temperature [4]

Dominant wavelength vs. temperature

471,50

472,50

473,50

10

20

30

40

Temperature [C]

D

o

m

in

a

n

t

w

a

v

e

l.

[

n

m

]

0.033 nm/ degree C

Fig. 6. The value of dominant wavelength of blue LED versus

temperature

Dominant wavelength vs. temperature

589,50

590,50

591,50

592,50

593,50

10

20

30

40

Temperature [C]

D

o

m

in

a

n

t

w

a

v

e

l.

[

n

m

]

0.096nm / degree C

Fig. 7. The value of dominant wavelength of yellow LED versus

temperature

The LEDs luminous flux relative value versus

temperature are show on Fig. 3 and 4. Figure 5 shows the

LEDs spectral shift versus relative value of drive current at

constant operating temperature. The bigest peak shift was

obserwed for SunLED Corporation XLBB12WH blue and

Roithner Lasertechnik 383-2UBGC green-blue LED.

Figures (6) and (7) shovs dependence of the value of LEDs

dominant wavelength versus temperature.

The work was done in Bialystok University of Technology

under grant S/WE/2/08.

REFERENCES

[1] E. Fred

Schubert and J.K. Kim, 100 years of LEDs, Compound

Semiconductors (2007)

[2] E. Fred Schubert, Light-Emitting Diodes, Cambridge University

Press (2006)

[3] Cree® XLamp® Long-Term Lumen Maintenance (2009)

[4] I. Fryc, Zrodlo swiatla o ksztaltowanej charakterystyce

widmowej, Bialystok University Press (2006)

Author: Irena Fryc, PhD, DsC, Bialystok University of Technology,

Faculty of Electrical Engineering, Department of Optical Radiation,.

Wiejska 45d, 15-351 Bialystok, E-mail: fryc@pb.edu.pl;

Wyszukiwarka

Podobne podstrony:

fairclough semiotic condition of social reproduction and transformation

Colonization with Arbuscular Mycorrhizal Fungi Promotes the Growth of Morus alba L Seedlings under G

Power Distribution Circuit (2 of 5)

Power Distribution Circuit (4 of 5)

Kinetics of scrap tyre pyrolysis under vacuum conditions

Power Distribution Circuit (5 of 5)

Power Distribution Circuit (3 of 5)

Power Distribution Circuit (1 of 5)

Testy Different use of english 10 r bzdak

Iannace, Ianniello, Romano Room Acoustic Conditions Of Performers In An Old Opera House

1 3 16 Comparison of Different Characteristics of Modern Hot Work Tool Steels

Learner differences roles of a teacher

88 1249 1261 Examination of the Real Prestressing Conditions of Tooling Systems

Fidic Conditions Of Contract F

Bille 2010 Different Shades of Blue

Chapter 10 Relation between different kinds of stratigraphic units

The comparison of two different forms of?vertisement

03 Power distribution Power losses

więcej podobnych podstron