Energy performance and ef

ficiency of two sugar crops for the biofuel

supply chain. Perspectives for sustainable

field management in

southern Italy

Pasquale Garofalo

,

, Laura D'Andrea

, A. Vittorio Vonella

, Michele Rinaldi

,

A. Domenico Palumbo

a

Consiglio per la Ricerca in Agricoltura e l'Analisi dell'Economia Agraria

e Centro di Ricerca per la Cerealicoltura (CRA-CER), S.S. 673 km 25,200,

Foggia, Italy

b

Consiglio per la Ricerca in Agricoltura e l'Analisi dell'Economia Agraria

e Unita di Ricerca per i Sistemi Colturali degli Ambienti Caldo-Aridi (CRA-SCA),

via Celso Ulpiani, 5, Bari, Italy

a r t i c l e i n f o

Article history:

Received 3 May 2015

Received in revised form

6 August 2015

Accepted 11 October 2015

Available online 19 November 2015

Keywords:

Bioethanol

Fertilization

Soil tillage

Sweet sorghum

Sugar beet

a b s t r a c t

Improvement of the energy balance and ef

ficiency for reduced input of cropping systems is one of the

main goals for the cultivation of energy crops. In this

field study, two sugar crops for bioethanol pro-

duction were cultivated under different soil tillage management (conventional; no tillage) and mineral

nitrogen application (0, 75, 150 kg N ha

1

): sweet sorghum and sugar beet. The energy performance and

ef

ficiency along the bioethanol supply chain were analysed and compared. Both of these crops showed

good growth adaptation to the different soil and nitrogen management, and thus the energy return,

resource and energy ef

ficiencies were significantly improved in the low-input system. Sweet sorghum

provided better responses in terms of water and nitrogen use ef

ficiency for biomass accumulation, as

well as its energy yield and net gain, compared to sugar beet, whereas sugar beet showed higher energy

ef

ficiency than sorghum. According to these data, both of these crops can be cultivated in a Mediter-

ranean environment with low energy input, which guarantees good crop and energy performances for

biofuel strategy planning.

© 2015 Elsevier Ltd. All rights reserved.

1. Introduction

European countries are largely dependent on imported fossil

fuels, and the transport sector accounts for more than 30% of the

imported energy

. Most greenhouse gas emission is due to the

transport industry, and CO

2

emission into the air has risen by 90%

over the last two decades (Biofuels Advisory Council,

). To cope

with further increases in greenhouse gas emission, the EU

Renewable Energy Directive

de

fined a framework for the pro-

motion of energy from renewable sources. The target of this

Directive is that by 2020 with the use of biofuels, it will be possible

to achieve a 20% share of energy from renewable sources, and a

reduction of 20% in greenhouse gas emissions, with 10% of this

being renewable in the transport sector. Moreover the

“Climate

Action and Renewable Energy Package

”

has been proposed to

save energy use through an improved energy ef

ficiency of 20% by

2020. In view of these policy targets, some investigations have

focused on the role of the agricultural sector for biofuel production

and the energy ef

ficiency of different cropping systems

,

while others have focused on the reduction of greenhouse gas

emission through the introduction of biofuels and the replacement

of fossil fuel use

.

Some studies have reported that crop productivity of several

species (e.g., wheat, corn, soybean) is not compromised when the

energy input is reduced at the

field level (mainly through soil tillage

and nitrogen management), to improve the energy balance and

ef

ficiency

. Other studies have instead indicated signi

ficant

reductions in crop and energy performance with reduced energy

input applied at the

field level

, as also observed for the pro-

ductivity of winter sorghum

, where a reduced tillage system

lowered the water-use ef

ficiency of the crop, and consequently the

grain yield.

* Corresponding author. Consiglio per la Ricerca e la Sperimentazione in Agri-

coltura

e Centro di Ricerca per la Cerealicoltura (CRA-CER), S.S. 673 km 25,200,

Foggia, Italy. Tel.:

þ39 0881742972; fax: þ39 0881713150.

E-mail address:

(P. Garofalo).

Contents lists available at

Energy

j o u r n a l h o me p a g e :

w w w . e l s e v i e r . c o m/ l o ca t e / e n e r g y

http://dx.doi.org/10.1016/j.energy.2015.10.031

0360-5442/

© 2015 Elsevier Ltd. All rights reserved.

e1557

Currently, the debate on second-generation biofuels remains

open

, and their energy and environmental performance are

under study, although they are unlikely to have any effective impact

before 2020

. The conversion tecnologies are well known for

the

first generation of biofuels

, whereas for second generation

biofuels, these are still under development

. Moreover, the

advantage in terms of energy performance and climate impact of

second generation biofuels is achieved through low-input peren-

nial crops

. Recently, the CAP reform 2014-2020 (EU Regulation

1307/2013)

established that two or more crops should be

cultivated on farms to allow the claiming of subsidies (i.e., crop

diversi

fication as a ‘greening’ measure). Thus, herbaceous crops

with a short growing cycle and high biomass production (e.g.,

sorghum) or high sugar content (e.g., sugar beet) can satisfy both

the greening measure and the biofuel planning strategy.

Crops like sugar beet are not suitable for second-generation

biofuels, because the accumulation of large amounts of lignocel-

lulose can delay the harvest time, with the consequent loss of

biomass (i.e., dead leaves and relocation of sugar from roots to new

leaves). For other crops such as sorghum, the harvest time at full

maturity can compromise the

field operations and/or the sowing

time of the autumn species that follows. Finally, the cultivation of

sucrose crops for feed has dramatically declined in Italy over past

years (72% decrease from 2001 to 2012; ISTAT 2015,

), because

of the European policies (EU Regulation 320/2006); however, the

use of these crops can provide diversi

fication of the farm income

using the expertise and machinery available on the farm.

Assessment of the energy performance of various crops has

been carried out using different parameters and/or at different

stages of the supply chain. Koga (2008)

reported the energy

balance at the

field scale as the difference between the gross energy

output from sugar beet and the energy cost for its cultivation. Other

studies

have de

fined the EROI (energy return on the energy

investment) as the ratio of the quantity of energy delivered by a

biofuel society to the energy used as an input in the process to

produce the energy, with a comparison of EROI of bioethanol ob-

tained from corn and lignocellulose materials.

Most of the studies that have analysed energy crop perfor-

mances have been limited to a single species

or a single

growing season

, or have been based on literature data

rather than applied to a speci

fic environment. Moreover, in Italy,

field experiments have been mainly carried out in central or

northern regions

, with pedo-climatic condition that are

relatively dissimilar to the typical climate of the Mediterranean

area of the present study. In addition, the system boundaries are

often limited to the farm, thus excluding the cost of transportation

and the conversion of biomass into biofuel, although the energy for

transport is not negligible and can reach up to 23% of the total

energy cost

Comparisons of the energy performances of sucrose crops for

bioethanol production under different cropping systems (e.g., with

modulation of soil tillage and nitrogen supply) under speci

fic pedo-

climatic conditions that are prolonged over several years need to be

investigated. Thus, the present study was designed to: (i) determine

the biomass and sugar yield of sweet sorghum and sugar beet in

southern Italy cultivated for

first-generation biofuel; and (ii)

compare the energy performances between these two crops under

different management (i.e., conventional and no tillage practices, and

different nitrogen levels), with consideration also of the

flow along

all of the supply chain (i.e., from farm to bioethanol conversion plant).

2. Materials and methods

The

field experiment was carried out over a 3-year period from

2009 to 2012 in Foggia (latitude, 41

88

0

7

00

N; longitude, 15

83

0

05

00

E;

altitude, 90 m a.s.l.), in the Apulia region of southern Italy. The soil

was a vertisol of alluvial origin, Typic Calcixeret

classi

fied as

silty-clay, with the following characteristics: organic matter, 2.1%;

total nitrogen, 0.122%; NaHCO

3

-extractable phosphorus, 41 ppm;

NH

4

OAc extractable K

2

O

, 1598 ppm; pH (water), 8.3;

field capacity

water content, 0.396 m

3

m

3

; permanent wilting point water

content, 0.195 m

3

m

3

; and available soil water, 202 mm m

1

. The

climate was

‘accentuated thermo-Mediterranean’

, with tem-

peratures below 0

C in winter and above 40

C in summer. The

annual rainfall (mean, 550 mm) was mostly concentrated in the

winter months. The class

‘A pan’ evaporation was 1033 mm over

the year, and 657 mm from May to August. The daily meteorological

data of temperature, humidity, rainfall, wind velocity, and solar

radiation were recorded at a meteorological station located at the

same experimental farm.

2.1. Field experiment

Sweet sorghum (cv

‘Sucro 506’) was sown at the beginning of

May, in rows 0.5 m apart and at a distance of 0.08 m between the

seeds in each row (i.e., 250,000 seeds per hectare). The crop was

harvested before heading (mid-August) to maintain an adequate

plant water content (75%), as necessary for the fermentation pro-

cess. Sugar beet (cv

‘Autave’) was sown between late November and

early December, with row spacing of 0.5 m, and plant-to-plant

spacing of 0.20 m (i.e., 100,000 seeds ha

1

). The crop was harvest

at the beginning of August, when the plant achieved a good

compromise between water content and root sugar content.

Irrigation of both of these crops was managed according to the

water consumed by the plants, as estimated by the gravimetric

method (at 0

e0.8 m soil depth). Each time the water used by the

sweet sorghum and sugar beet reached 60 mm and 30 mm,

respectively, the irrigation was triggered. To ensure uniform water

distribution, a drip irrigation system was used, with one line for

each plant row, and drippers with a 4 L h

1

flow. The total amount

of water applied for the irrigation of the sorghum was 120 mm,

176 mm and 300 mm for the

first, second and third experimental

years, respectively, with rainfall of 79 mm, 73 mm and 68 mm

during the growing seasons in 2010, 2011 and 2012, respectively.

For the sugar beet, 90 mm, 65 mm and 108 mm of irrigation water

were applied in the

first, second and third growing seasons,

respectively, with the total rainfalls of 473 mm, 399 mm and

236 mm during the growing seasons in 2010, 2011 and 2012,

respectively.

For both of these crops, the soil management was carried out

according to CT (conventional tillage) and NT (no tillage). For CT,

shallow ploughing (soil depth, 25 cm) was performed with a

five-

furrow plow, followed by disc harrowing, power harrowing, and

seeding with a precision driller. For NT, no soil practice was

scheduled, with only direct seeding with a Gaspardo No-Till 1040,

which ensured light and shallow tillage in the strip area affected by

the furrowers. For NT, before seeding, 5 L ha

1

glyphosate was

applied for weed control.

Mineral nitrogen fertilisation was managed with 75 kg ha

1

(N75) and 150 (N150) kg ha

1

nitrogen in the form of ammonium

nitrate (34%), as compared with no nitrogen fertilisation (N0). The

nitrogen fertilizer was split into two doses, one as basal dressing

before sowing, and the second as top dressing in the middle of May

for sugar beet, and between the end of June and the beginning of

July for sorghum. Phosphate fertilizer was applied before sowing

(100 kg ha

1

P

2

O

5

).

The main treatment of these crops was related to soil tillage,

while the secondary treatment was for the different nitrogen

supplies. The experimental design was a split-plot design with

three replications. The area of each subplot was 84 m

2

. In the 2-year

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1549

rotation, the farm was split into two halves, with one crop for each

half. In the following year, the crop placings were inverted.

Diesel consumption was measured directly at the farm, as the

difference between the amount of fuel necessary to re

fill the tractor

tank after one soil operation and the following one. The time to

fully complete each

field operation was also recorded.

At harvest, a range of parameters were determined: the weight

of the total fresh and dry biomass (sweet sorghum, leaves and

stems; sugar beet, roots and leaves); the soluble solids content in

Brix (PR model 32 ATAGO Palette digital refractometer), with the

Brix multiplied by the fresh biomass/roots for the TSS (total soluble

solid); the potential sugar yield from the biomass and roots, as

reported by Wortmann et al. (2010)

(see also

); and the

WUE (crop water) and nitrogen (NUE) use ef

ficiency, calculated as

the ratio between the water used by the crop (i.e., irrigation plus

rainfall), the nitrogen applied, and the parameters analysed.

2.2. Energy balance and ef

ficiency

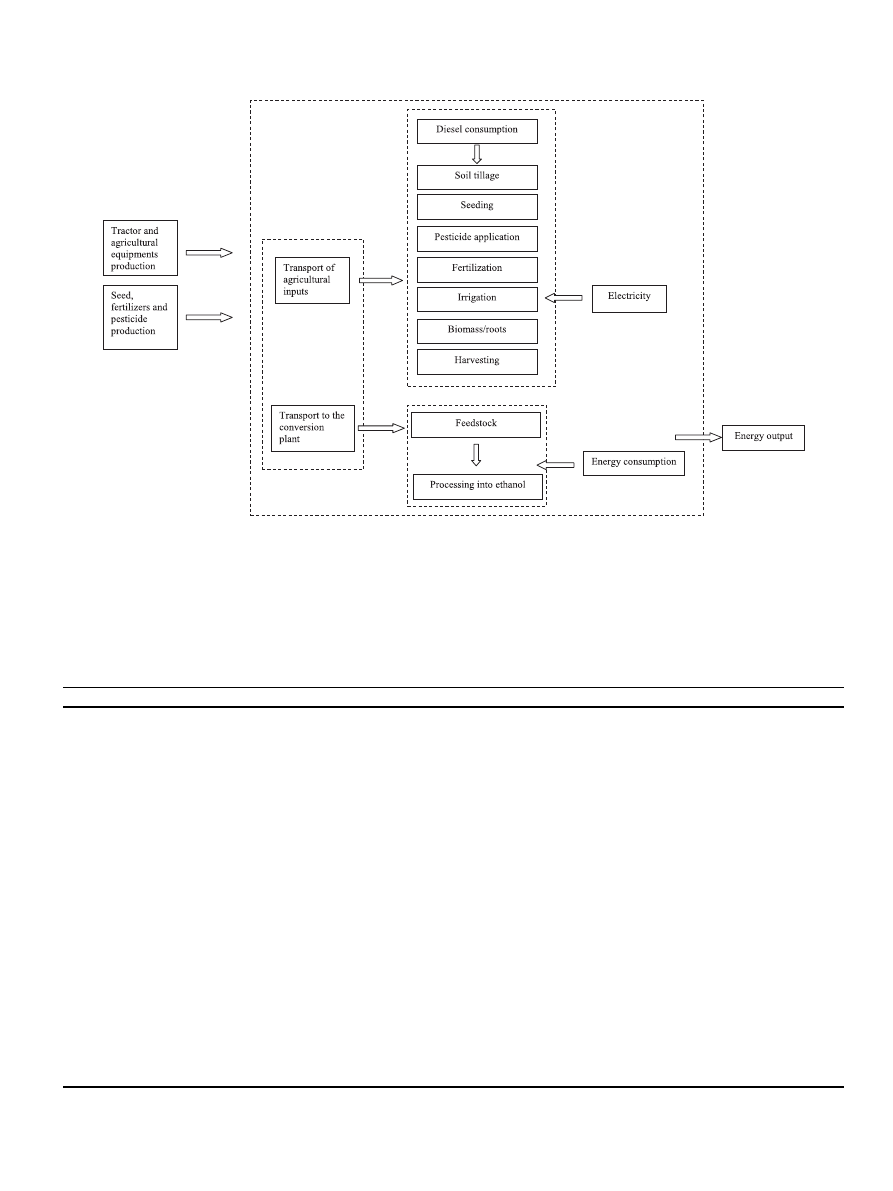

To determine the energy

fluxes for the input and output of the

product systems analysed, the system boundaries were established

(

). The energy input at the

field level was calculated separately

for the tractor, implements, fuel, seed, and chemicals used during

crop management, taking into account the direct and indirect in-

puts. The indirect input included the materials to build the tractor,

and the machinery and implements, and their maintenance. To

follow all the energy cost along the bioethanol supply chain, the

estimations were performed as reported in

For a full overview of the energy performance and ef

ficiency,

several indicators were used. The EY (energy yield) provided the

gross energy output for the potential bioethanol production, minus

the cost to convert the sugar into biofuel, but not including the

transport, and hence indicating the effective energy deliverable by

the power plant. In the NEG (net energy gain), the direct and in-

direct costs for crop cultivation, transport of materials, and biomass

and sugar-bioethanol conversion were subtracted from the EY to

indicate the energy that was effectively gained from the biofuel

supply chian. Finally, to determine how much of the production

process of the biofuel was energy advantageous, and to quantify the

positive returns on investment obtained, the EROI was calculated.

All of the equations necessary for these parameter calculations are

reported in

, and the parameters are reported fully in

The ratio between NEG and the sum of the rainfall plus the

irrigation, and between NEG and the N applied, provided the water

energy use ef

ficiency (EWUE; MJ m

3

) and the nitrogen energy use

ef

ficiency (ENUE; MJ kg

1

)

2.3. Statistical analysis

The analysis was performed using the statistical analysis soft-

ware SAS/STAT

®

(SAS Institute Inc., Cary, NC, USA). The data un-

derwent ANOVA (analysis of variance), considering the Year as the

random effect and the appropriate error test for the soil manage-

ment (in the main plot), nitrogen (in the sub-plot) and their in-

teractions. Differences among treatments were assessed using

Tukey

eKramer tests and significance was accepted at P ¼ 0.05.

3. Results

3.1. Crop productivity

The crop performances for sweet sorghum and sugar beet are

reported in

. For the soil management, there were no

differences across all of the analysed parameters for either of the

crops. On average over the 3-year experimental period, the fresh

biomass of sweet sorghum was 99.9 t ha

1

, and the water content at

harvest was 25%. The

Brix was a little higher for NT (

þ4%)

compared to CT, although compared to NT, CT promoted a better

response in terms of TSS (

þ6%). The water and nitrogen use effi-

ciencies were slightly improved for CT over NT, but globally, these

parameters were not statistically different between CT and NT.

Sweet sorghum saw little bene

fit of the increased nitrogen

supply, with an increase in fresh biomass from 98.1 t ha

1

with N0

to 102.4 t ha

1

with N150, and for dry biomass from 23.4 t ha

1

to

25.4 t ha

1

. These productivity levels are comparable with those

reported by Habyarimana et al. (2004)

for sorghum biomass,

where they showed dry biomass accumulation (20

e29 t ha

1

) close

to the experimental values in the present study, under similar

environmental and rainfall conditions.

The sweet sorghum

Brix was more stable among the nitrogen

treatments, whereas TSS was improved with N150 when compared

to the lower nitrogen levels (

þ12%). However, the differences in

productivity and the WUE indicators did not reach statistical sig-

ni

ficant. On the other hand, with the doubling of the nitrogen dose,

NUE was halved for the fresh and dry biomass and TSS parameters.

In comparison to sweet sorghum, the sugar beet growth was

more dependent on the different nitrogen supplies. Indeed, the

differences in the fresh and dry roots as well as TSS indicated a

Table 1

Estimation of direct and indirect energy input for crop cultivation, transport, sugar-bioethanol conversion, energy performance and ef

ficiency indicators.

Equation

No

Unit

Description

CSY

¼ ðFMY DMYÞ*

Brix

*0:75

(1)

t ha

1

Conservative sugar yield

JY

; 80%extracted ¼ ½FMY ðDMY CSYÞ*0:8

(2)

t ha

1

Juice yield

SY

¼ JY*

Brix

*0:75

(3)

t ha

1

Sugar yield

E

ct

¼

E

e

*M

w

L

(4)

MJ ha

1

Energy coef

ficient for each implement

E

l

¼ T

l

*H

c

(5)

MJ ha

1

Energy coef

ficient for human labour

E

s

¼ E

ps

*S

r

(6)

MJ ha

1

Energy coef

ficient for seed

E

N

;P;G

¼ EC

N

;P;G

*R

N

;P;G

(7)

MJ ha

1

Energy coef

ficient for materials

I

c

¼

d*g*H*Q

n

1

*n

o

*10

6

(8)

MJ ha

1

Energy input for the irrigation

E

t

ðI;IIÞ

¼

D

t

*D

ðI;IIÞ

*

W

m

Pl

*D

ef

(9)

MJ ha

1

Energy for transportation

EY

¼ ðBE*BYÞ ðCE*BYÞ

(10)

MJ ha

1

Energy yield

NEG

¼ EY ðEFI þ ET

I

þ ET

II

Þ

(11)

MJ ha

1

Net energy gain

EFI

¼ ðEt

ðI;IIÞ

þ D

c

*D

ef

þ E

ct

þ E

l

þ E

s

þ E

N

;

P

;

G

þ I

c

Þ

(12)

MJ ha

1

Total energy input

EUE

¼

BY

EFI

(13)

kg ha

1

Energy use ef

ficiency

EROI

¼

NEG

ðEFIþE

t

ðI;IIÞ

Þ

(14)

Energy return on energy invested

a

Sugar concentration of juice is 75% of Brix expressed in g kg

1

sugar juice and 95% of the extracted sugar is converted to ethanol.

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1550

different pattern of plant responses according to the nitrogen dose.

Here, N150 showed the best response for fresh (38.1 t ha

1

) and dry

(10.5 t ha

1

) roots, and TSS production (7.7 t ha

1

), with these data

signi

ficantly worst for N0 (decreases, 23%, 31%, 25%, respectively),

with intermediate data for the N75 treatment. A similar response

was observed for water use ef

ficiency, with the same trend re-

ported under the same environment conditions by Rinaldi and

Vonella (2006)

, although they reported higher water

Fig. 1. Flow diagram (input and output) and system boundaries of the bioethanol production in sweet sorghum and sugar beet.

Table 2

Variables and parameters, and their values as used in the equations given in

Symbol

Description

Unit

Value

Reference

FMY

Fresh matter yield

t ha

1

See text

DMY

Dry matter yield

t ha

1

See text

BY

Bioethanol yield

t ha

1

See text

E

e

Energy cost for building, maintenance, transport for

the machineries and implements

MJ kg

1

See

M

w

Mass

kg

See

L

Lifespan

h

See

T

l

Human labour

h

See text

H

c

Human energy consumption

MJ h

1

1.08

E

ps

Energy value for the seed production,

MJ kg

1

36.98 for sugar beet; 54 MJ kg

1

for sweet sorghum

S

r

Seed rate

kg

1 for sugar beet; 14 MJ kg

1

for sweet sorghum

N, P, G

Nitrogen, phosphorous, glyphosate

EC

Energy coef

ficient of materials

MJ kg

1

48.89 for N, 15.23 for P, 268.4 for G

R

Application rate of materials

kg

See text

d

Water density

kg m

3

1000

H

Total dynamic head

m

5

Q

Water applied

m

3

ha

1

See text

n

1

Pump ef

ficiency

0.65

n

0

Ef

ficiency of the electric motor

0.22

E

t(I)

Transport of materials from the factory to the farm

MJ ha

1

See text

E

t(II)

Transport of biomass from the farm to the conversion plant

MJ ha

1

See text

D

t

Diesel consumption of the truck

l km

1

or kg km

1

0.34 l or 0.27

Pl

Payload

t

27

D

(I)

Distance from the factory (materials) to the farm

km

100

D

(II)

Distance from the farm to the conversion plant

km

70

W

m

Weight of the mass transported

t

See text

D

ef

Energy density of diesel

MJ kg

1

43.1

BE

Energy density of bioethanol

MJ kg

1

26.8

CE

Energy to convert biomass in anhydrous ethanol

MJ kg

1

18.33

a

Differences between the level of water suction in the well (10 m) and the level of the water surface in the collecting basin (5 m).

b

70 km as maximum distance in the short supply chain for the Apulia region; Reg. No 42/2012.

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1551

availability (mean irrigation, 249 mm; mean rainfall, 353 mm) and

crop productivity (fresh roots, 38.2

e60.0 t ha

1

).

Finally, the halving of the nitrogen dosing from N150 to N75

resulted in large difference in nitrogen use ef

ficiencies (i.e., almost a

doubling;

).

3.2. Energy input

shows the amount of energy required for crop man-

agement of the sorghum and sugar beet. The highest impact of the

energy needed was due to the diesel used for the movement of

tractors and equipment, as well as the nitrogen fertilizer applica-

tions. The diesel input for cultivation accounted for 37% and 49% for

sorghum and sugar beet, respectively for the CT_N0 treatment,

although these values dropped to around 15% when compared to

the full nitrogen supply management in the NT treatment. Indeed,

the nitrogen fertilizer required an energy cost of 3647 MJ ha

1

and

7349 MJ ha

1

, when passing from the N75 to the N150 treatments,

with a minimum effect of 25% (sweet sorghum, CT_N75) to a

maximum effect of 50% (sugar beet, NT_N150) of the total energy

use.

The indirect input due to the tractors and implements used was

between 1% for sorghum (NT_N150) to 7% for sugar beet (NT_N0), of

the total energy use. In sweet sorghum the cost for seeding and

irrigation accounted for 750 MJ ha

1

and 933 MJ ha

1

respectively,

with the maximum percentage of 9% for the irrigation cost at the

lowest energy use. In sugar beet, the input due to the seed and

irrigation supply was negligible, as it was constantly below 6% of

the total energy budget. Generally, the estimated energy input at

field scale is higher in northern European countries than in

southern European countries. Indeed, in the UK, the total energy

cost for sugar beet was reported to be up to 26.8 GJ ha

1

, and in

Germany, 29.7 GJ ha

1

. On the other hand, in Greece, the en-

ergy input for sun

flower cultivation was reported as 10.5 GJ ha

1

Table 3

Energy coef

ficients for the indirect energy input used for the machinery for the sorghum and sugar beet

Item

Mass (kg)

Life (h)

Energy cost

Energy coef

ficient

(MJ h

1

)

Materials (MJ kg

1

)

Assembly (MJ kg

1

)

Transport (MJ kg

1

)

Maintenance (MJ kg

1

)

Tractor (132 kW)

6300

12,000

35.2

18.7

1.9

29.6

44.8

Tractor (51 kW)

4000

12,000

35.2

18.7

1.9

29.6

28.5

Plough

1000

3000

34.5

12.3

1.3

25.7

24.6

Disk harrow

1200

3000

34.5

12.3

1.3

25.7

29.5

Fertilizer distributor

100

3000

34.5

12.3

1.3

25.7

2.5

Sprayer

200

2000

34.5

12.3

1.3

25.7

7.4

Power harrow

500

3000

34.5

12.3

1.3

25.7

12.3

Seeder (sorghum)

800

3000

34.5

12.3

1.3

25.7

19.7

(Sugar beet)

1000

3000

34.5

12.3

1.3

25.7

24.6

Harvester (sorghum)

8000

3000

41.3

14.8

1.5

30.9

354.0

Harvester (sugar beet)

8500

3000

41.3

14.8

1.5

30.9

250.8

Trailer

1000

3500

34.5

12.6

1.3

25.9

22.3

a

Mass and life based on local survey.

b

For fertilizing, spraying and for the trailer.

Table 4

Biomass performance, and water and nitrogen use ef

ficiency of sweet sorghum, as affected by soil tillage and nitrogen fertilization during the experimental trial (2009e2012).

Treatment Parameter

FB (t ha

1

) DB (t ha

1

)

Brix TSS (t ha

1

) WUEfb (kg m

3

) WUEdm (kg m

3

) WUEtss (kg m

3

) NUEfb (kg kg

1

) NUEdb (kg kg

1

) NUEtss (kg kg

1

)

CT

101.9

24.8

8.9

8.7

39.9

9.8

3.6

1007.1

244.5

85.4

NT

97.7

24.6

9.3

8.2

37.8

9.5

3.3

995.4

262.2

81.7

N0

98.1

23.4

9.1

8.3

38.2

9.2

3.4

e

e

e

N75

99.0

25.3

9.1

8.2

38.3

9.8

3.4

1319.6 a

337.5 a

108.8 a

N150

102.4

25.4

9.2

8.8

40.1

9.9

3.7

682.8 b

169.1 b

58.3 b

Mean

99.8

24.7

9.1

8.4

38.9

9.6

3.5

1001.3

253.3

83.6

FB, fresh biomass; DB, dry biomass; TSS, total soluble solid; WUE, water use ef

ficiency for fresh biomass (fb), dry biomass (db) and total soluble solid (tss); NUE, nitrogen use

ef

ficiency for biomass (fb), dry biomass (db) and total soluble solid (tss); CT, reduced tillage; NT, no tillage; N0, N75, N150, nitrogen application (0, 75, 150 kg ha

1

).

Different letters indicate different means at P

¼ 0.05 (TukeyeKramer tests).

Table 5

Biomass performance, water and nitrogen use ef

ficiency of sugar beet as affected by soil tillage and nitrogen fertilization during the experimental trial (2009e2012).

Treatment

Parameter

FR (t ha

1

)

DR (t ha

1

)

Brix

TSS (t ha

1

)

WUEfr (kg m

3

)

WUEdr (kg m

3

)

WUEtss (kg m

3

)

NUEfr (kg kg

1

)

NUEdr (kg kg

1

)

NUEtss (kg kg

1

)

CT

35.8

8.8

20.1

7.2

7.5

1.8

1.5

378.1

93.5

76.7

NT

33.4

9.0

20.9

6.8

6.9

1.9

1.4

360.9

97.2

74.1

N0

29.3 b

7.2 b

20.2

5.8 c

6.0 b

1.5 b

1.2 b

e

e

e

N75

36.4 ab

9.0 ab

20.8

7.5 a

7.6 a

1.9 ab

1.6 a

485.2 a

120.6 a

99.4 a

N150

38.1 a

10.5 a

20.5

7.7 a

8.0 a

2.3 a

1.6 a

253.8 b

70.1 b

51.4 b

Mean

34.6

8.9

20.5

7.0

7.2

1.9

1.5

369.5

95.3

75.4

FR, fresh biomass; DR, dry root biomass; TSS, total soluble solid; WUE, water use ef

ficiency for fresh root (fr), dry root (dr) and total soluble solid; NUE, nitrogen use efficiency for

fresh root (fr), dry root (dr) and total soluble solid (tss); CT, reduced tillage; NT, no tillage; N0, N75, N150, nitrogen application (0, 75, 150 kg ha

1

).

Different letters indicate different means at P

¼ 0.05 (TukeyeKramer test).

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1552

, and in Italy, for giant reed cultivation, this value has oscillated

from 4 GJ ha

1

to 18 GJ ha

1

. Despite this large variability

across these studies, they all agreed that diesel consumption and

nitrogen supply are the components that have the greatest effects

on the energy

flux.

For the transport of feedstock from the farm to the plant con-

version platform, the mean energy costs were 3123 MJ ha

1

and

1082 MJ ha

1

, for the biomass of sorghum and the roots of sugar

beet, respectively. This was mainly due to the fresh biomass weight

(three-fold greater in sorghum than beet). Finally, passing from the

highest to the lowest energy intensity treatment, the energy saving

was 6720 MJ ha

1

for sorghum (reduction, 38%) and 7011 MJ ha

1

for sugar beet (reduction, 48%), when compared to CT_150.

3.3. Energy performance

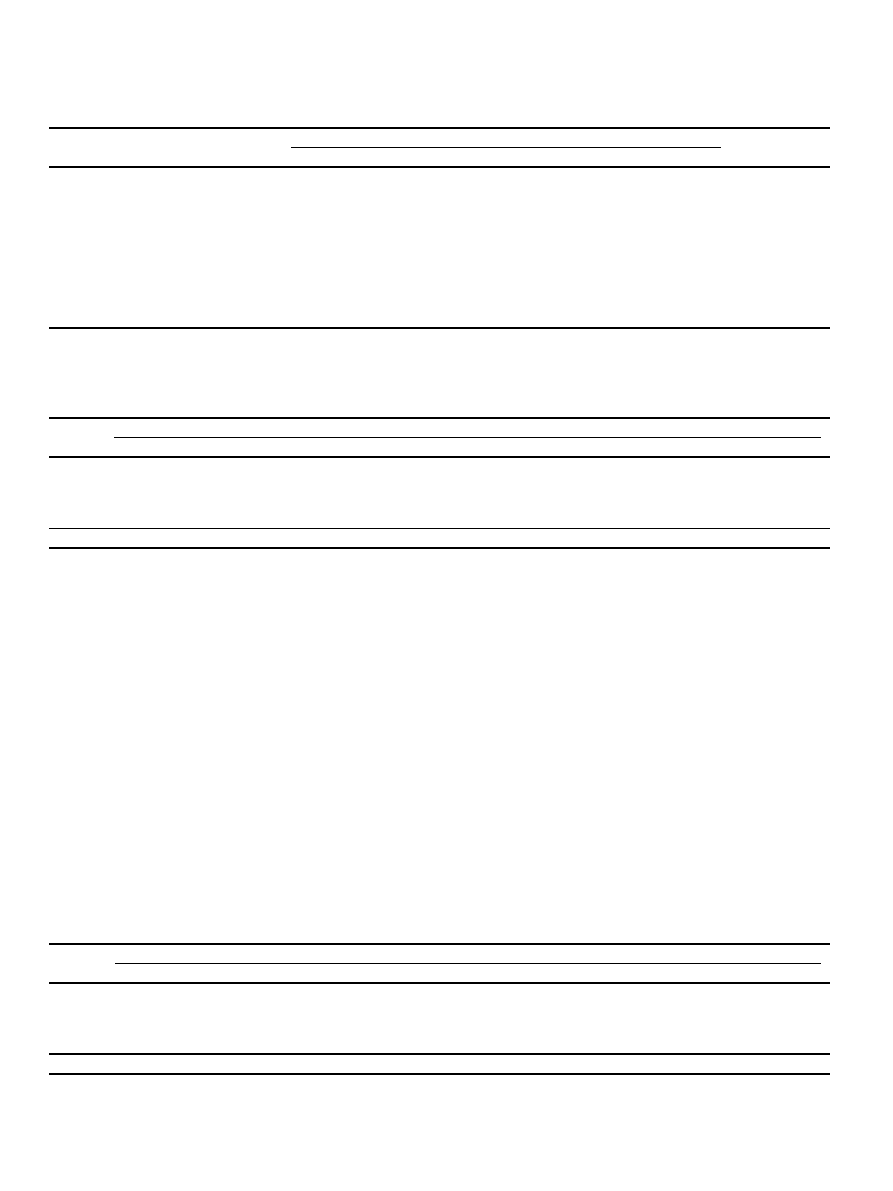

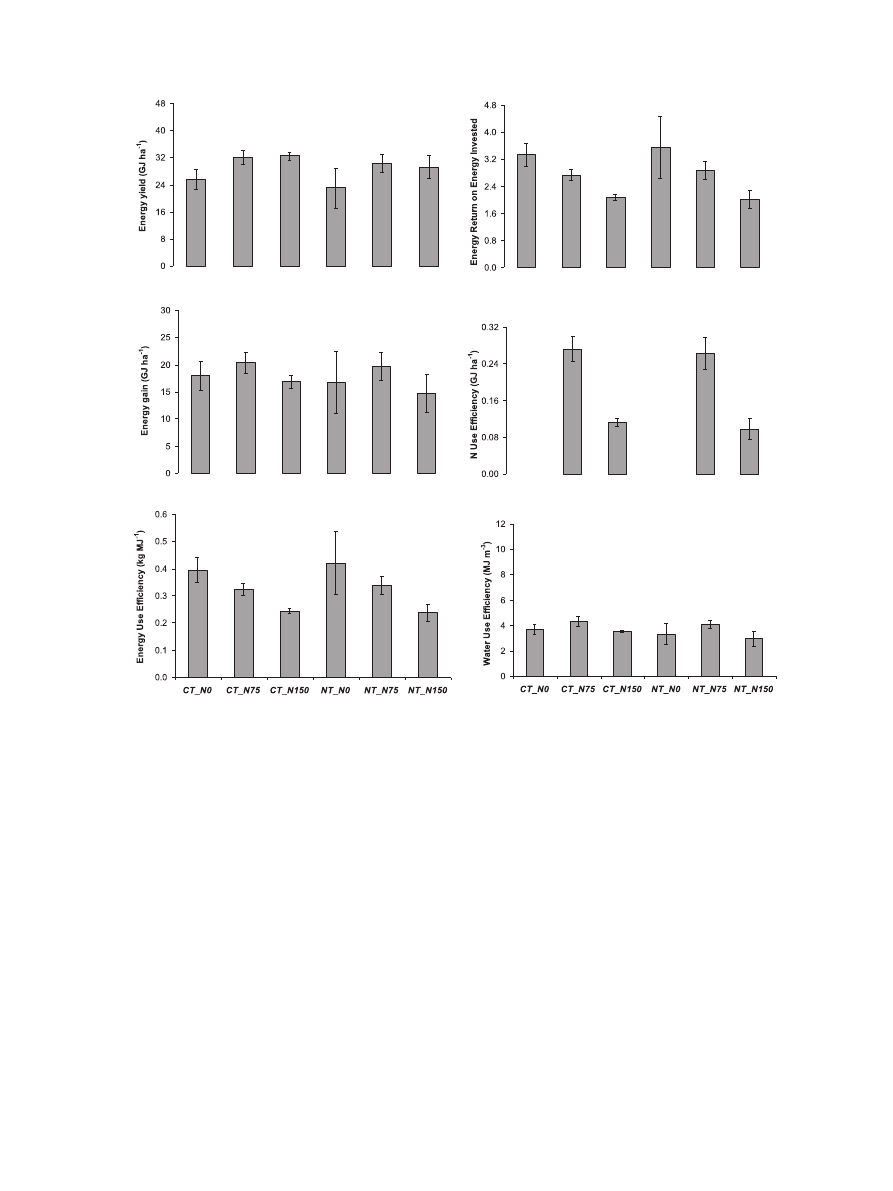

The energy yield, or EY, for sweet sorghum oscillated between

35.2 GJ ha

1

(CT_N150) and 30.0 GJ ha

1

(NT_N75), as shown in

, although no statistically signi

ficant differences were

observed among the treatments. For the sweet sorghum NEG,

although the unfertilized treatments (N0) provided the highest

values (mean, 21.9 GJ ha

1

;

þ35%) with respect to the other treat-

ments, there were no statistical differences in the responses across

all of the treatments for NEG. Consequently, sweet sorghum

showed a relatively stable response for NEG (mean, 17.7 GJ ha

1

)

across the different management practices, which is in line with

data reported in other studies

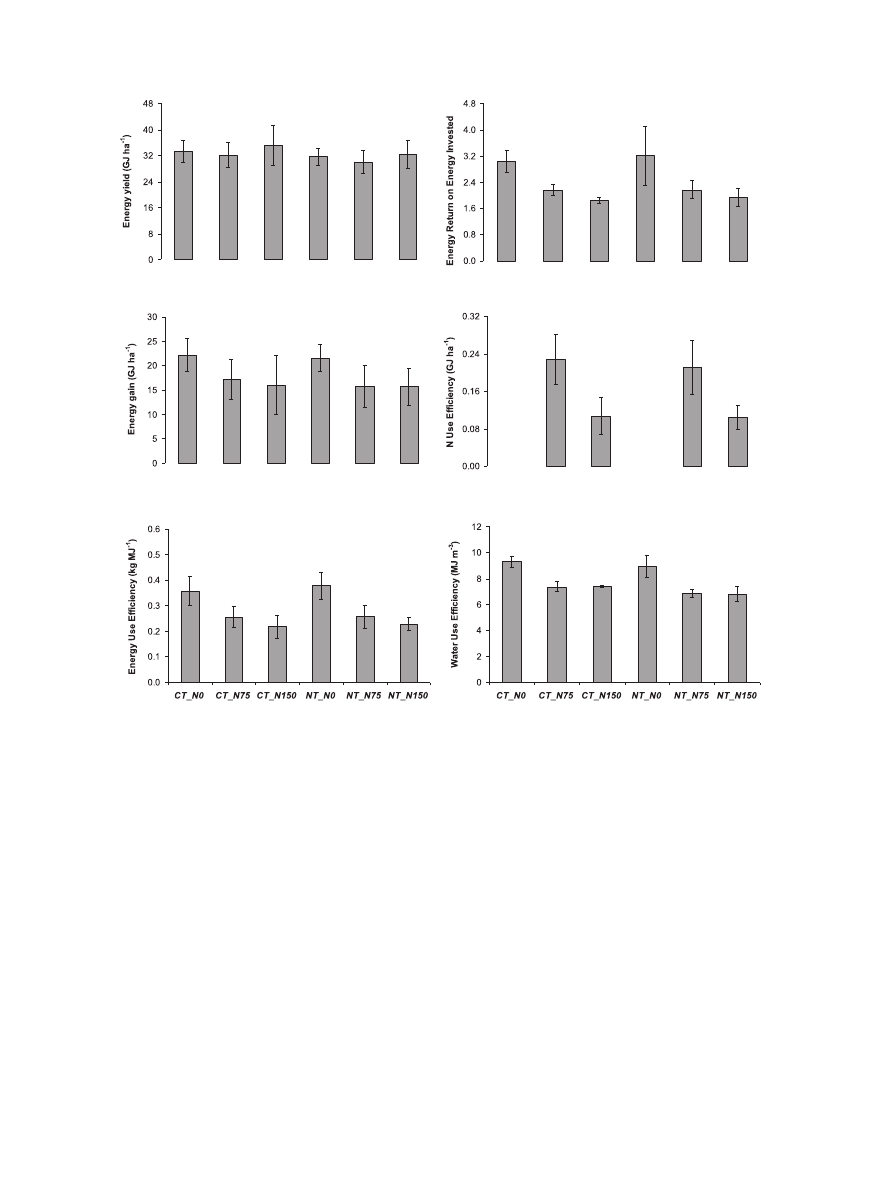

For sugar beet, compared to the unfertilized treatment, EY was

improved by the N75 to N150 change, with an increase of 28% (24.3

vs. 31.0 GJ ha

1

). However, these differences did not reach statistical

signi

ficance among the treatments, and unlike for sweet sorghum,

the performances among the years were more stable. The sugar

beet NEG was 17.3 GJ ha

1

, 20.1 GJ ha

1

, and 15.6 GJ ha

1

for the N0,

N75, and N150 treatments, respectively (

), and CT provided a

small advantage over the NT treatment of 8%, although globally the

net energy returns were comparable for all of the soil and nitrogen

management treatments.

3.4. Resource ef

ficiency

In sorghum, the nitrogen application rather than the soil man-

agement (

) improved WEUE. Indeed, for N0, there was 9.2 MJ

of energy gain per m

3

water used by the crop, followed by the N_75

and N_150 treatments (mean, 7.1 MJ m

3

), with small changes due

to soil management (

þ6% for CT treatment) that did not reach

statistical signi

ficance. The halving of the nitrogen that was applied

to the sweet sorghum provided strongly improved bene

fits in terms

of energy gain, as when the nitrogen supply was reduced from

150 kg ha

1

to 75 kg ha

1

, the ENUE increased from 0.11 GJ kg

1

to

0.23 GJ kg

1

.

Compared to sweet sorghum, for sugar beet, the best energy

return per m

3

water used was for the N75 treatment (mean,

4.2 MJ m

3

), with the lowest for N150 (3.3 MJ m

3

) (

). As for

sorghum, CT slightly improved WEUE, enhancing the value from

3.7 GJ ha

1

for NT to 3.8 GJ ha

1

for CT, as the means of all of the

nitrogen fertilizer treatments. Finally, ENUE more than doubled

when the nitrogen application was halved (0.11 MJ kg

1

for N150 vs.

0.27 MJ kg

1

for N75).

3.5. Energy ef

ficiency

The reduction in energy input intensity together with no

meaningful biomass yield reduction led to a signi

ficant increase in

energy ef

ficiency for sweet sorghum. Indeed, as shown in

,

NT_N0 and CT_N0 provided the best EUE, with the mean production

of 0.37 kg ethanol per MJ energy applied in the

field, followed by

Table 6

Energy input at the

field level for the different soil and crop management for the sweet sorghum and sugar beet.

Crop

Parameter

Energy input according to soil tillage management and nitrogen application in the

field (MJ ha

1

)

Conventional tillage

No tillage

N0

N75

N150

N0

N75

N150

Sorghum

Seed

750

750

750

750

750

750

Pesticide

0

0

0

1342

1342

1342

Nitrogen

0

3674

7349

0

3674

7349

P

2

O

5

1523

1523

1523

1523

1523

1523

Transport (I)

7

18

25

5

18

25

Machinery

242

255

255

163

171

172

Tractor

408

476

476

114

115

115

Labour

11

12

12

3

3

3

Diesel

4079

4271

4508

2260

2560

2526

Irrigation

933

933

933

933

933

933

Transport (II)

3198

3088

3276

2939

3105

3133

Total

11151

15000

19107

10032

14194

17871

Sugar beet

Seed

37

37

37

37

37

37

Pesticide

0

0

0

1342

1342

1342

Nitrogen

0

3674

7349

0

3674

7349

P

2

O

5

1523

1523

1523

1523

1523

1523

Transport (I)

5

17

24

10

17

24

Machinery

517

518

518

427

427

427

Tractor

468

483

483

114

122

123

Labour

13

13

13

4

4

4

Diesel

3662

3902

4122

1663

1978

2287

Irrigation

369

369

369

369

369

312

Transport (II)

965

1154

1240

867

1123

1142

Total

7559

11,690

15,678

6356

10,616

14,570

Data are means over the three experimental years (2009

e2012).

N0, N75, N150, nitrogen application in the

field (0, 75, 150 kg ha

1

); Transport (I), energy input for transport of seed, fertilizers and herbicides at the farm (100 km); Transport

(II), energy input for transport of sorghum biomass or sugar beet root to the conversion plant (70 km).

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1553

the N75 and N150 treatments (0.26 and 0.22 kg MJ

1

, respectively).

N0 provided the highest EROI for the bioethanol supply chain, at

3.2, which was 44% and 65% greater than for N75 and N150,

respectively.

For sugar beet, the analysis of EUE showed different ef

ficiencies

as a consequence of the nitrogen doses applied. Indeed, lowering

the energy input (essentially due to lowering the nitrogen levels),

the ef

ficiency for potential bioethanol production per energy

applied in the

field increased (

), with the lowest for N150

(0.24 MJ kg

1

), followed by N75 (

þ37%), and the highest for N0

(

þ69%). These differences were confirmed also in the EROI analysis,

which indicated that the highest energy return in terms of bio-

ethanol energy output per unit energy used was for N0 (3.5), then

N75 (2.8), and

finally N150 (2.0), with NT slightly better than CT

(

þ4%).

4. Discussion

The soil management had a small impact on the crop produc-

tivity response for both of these crops for this mid-term period,

whereas the nitrogen management indicated greater growth of

sugar beet with increasing nitrogen doses. The nitrogen also

in

fluenced the water use efficiency differently between these two

crops: the water use ef

ficiency remained unchanged for sorghum,

irrespective of the nitrogen management, while it increased for

sugar beet as the nitrogen availability increased. Our

findings are in

line with those reported by Ceotto et al. (2014)

, who indicated

that the productivity of sorghum under N0 treatment was com-

parable to that for partial and fully fertilized sorghum even after 5

years. For sugar beet, a signi

ficant growth reduction was observed

as a consequence of reduced nitrogen supply

, even if in the

present study these differences emerged between N0 and N150,

rather than between N0 and N75. Thus, these data indicated that

soil with good nutrient availability provides good and stable re-

sponses for sweet sorghum in terms of nitrogen use ef

ficiency and

plant growth (with reduced or even no nitrogen supply) for several

years, while for sugar beet, the productivity is more susceptible to

the nitrogen doses.

However, in sugar beet, the increase in energy intensity at the

field scale did not lead to dramatic increases in terms of the root

and potential bioethanol production, as indicated above. This will

be due to the very deep root system of both of these crops, which

will allow greater soil exploration when compared to other crops

(i.e., wheat), in which the different nitrogen doses can have an

appreciable effect on plant growth

. As a consequence, the best

energy performances were achieved by reducing the energy

Fig. 2. Energy balance and ef

ficiencies for the sweet sorghum (as indicated). Data are means ± standard errors over the three experimental years (2009e2012).

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1554

intensity at the

field scale, for both of these crops. This was espe-

cially the case when accounting for the nitrogen supply, high-

lighting nitrogen as the key factor for improvement in the energy

gain. Also, the coupling of wise fertilization management with

conservative tillage practices has been shown to reduce the fossil

energy requirements and greenhouse gas emission in previous

investigations

. These bene

fits can be further emphasized

when the reduced input to the cropping system does not dramat-

ically affect the crop production, as con

firmed in the mid-term in

the present study. These data are, however, in contrast to those of

Ceccon et al. (2003)

, who indicated that the gross energy

output and ef

ficiency that was achievable in their crops was

improved, as the input increased due to better productivity in

comparison with the low-input treatment at the

field scale.

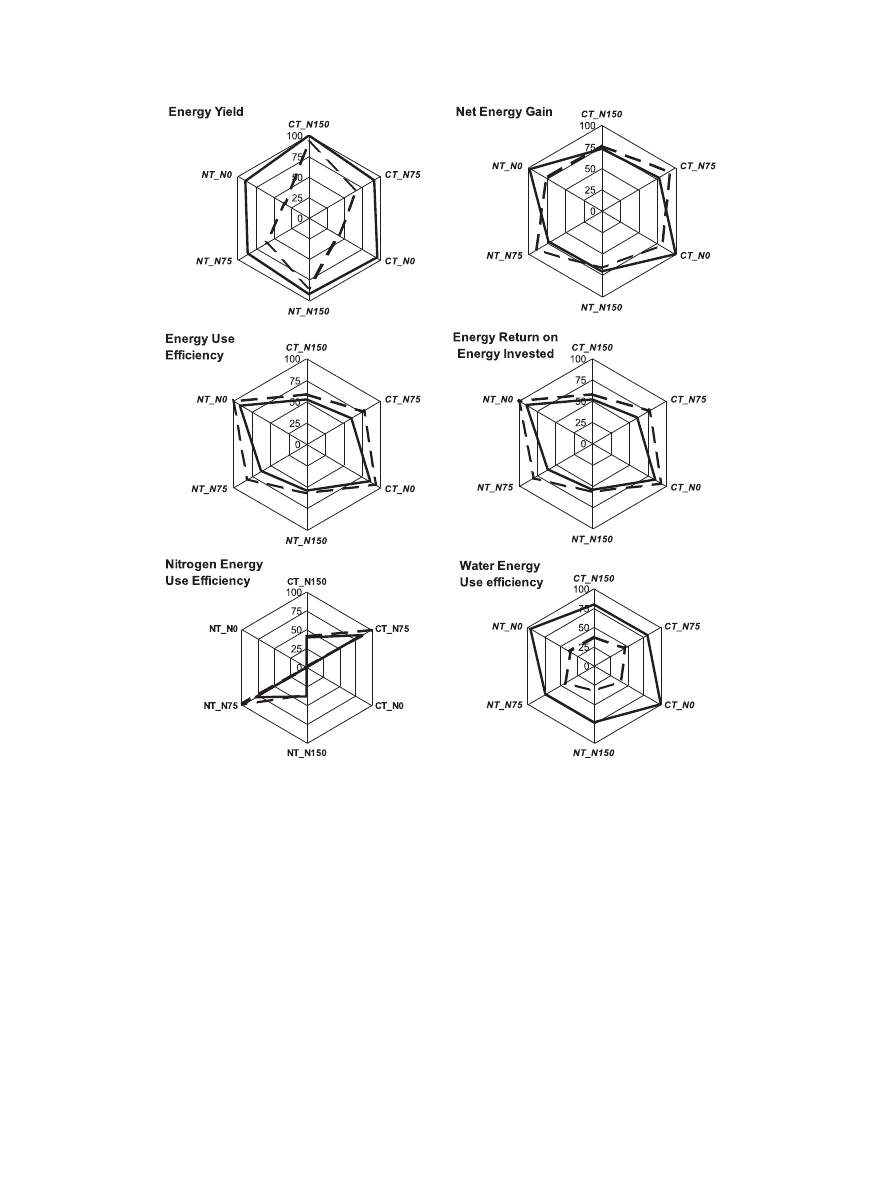

For the biomass production, TSS and potential sucrose yield,

these data indicate that sorghum provides greater improvements

for the resource ef

ficiency than sugar beet. This is true at the farm

scale, where different energy patterns were seen when analysing

the whole supply chain, and thus with the introduction of the

transport costs. This direct comparison between sweet sorghum

and sugar beet gave a mixed response in terms of the most suitable

species for energy purposes according to the bioethanol supply

chain, as also illustrated by the spider plots in

. For the energy

achievable from the potential bioethanol production (i.e., EY),

sweet sorghum and sugar beet gave comparable values at the

highest energy intensity, although a better response emerged with

sorghum compared to sugar beet with the reduction in the nitrogen

and soil-tillage input. With the subtraction of the cost for cultiva-

tion and transport from EY, to obtain NEG, the best energy return

was for sweet sorghum with the N0 management and for both soil

treatments.

Some studies have indicated that the minimun threshold of the

net energy achievable by a crop suitable for energy purposes is

20 GJ ha

1

, a value that was reached only by sweet sorghum at

the lowest energy management. However, this estimation was

based on the low heating value of the biomass and only considered

the cost at the

field scale. This means that in the present study, the

NEG would have far exceeded 20 GJ ha

1

if it had relied on the low

heating value and included only the energy needed at the

field

scale, which is also the case for the sugar beet for the mid-input

management.

With sorghum, the high amounts of biomass that need to be

moved from the farm to the plant added from 17% to 29% onto the

total energy costs, which thus negatively affected the EUE and EROI

of sorghum with respect to sugar beet (i.e., with lower biomass

production but higher sugar content than sorghum); the greater

Fig. 3. Energy balance and ef

ficiencies for the sugar beet (as indicated). Data are means ± standard errors over the three experimental years (2009e2012).

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1555

the energy saving at the

field scale, the greater the advantage of the

sugar beet over the sorghum (see

). This was based on a dis-

tance from the farm to the conversion plant of 70 km (i.e., the

maximum distance for the short supply chain in the Apulia region),

although with a smaller distance (e.g.,

<25 km) the efficiency pa-

rameters become more comparable between these crops (data not

shown).

These

findings are in line with those reported by de Vries et al.

(2010)

, who indicated that crops with high energy yields (e.g.,

sweet sorghum) do not necessarily have the highest energy ratios.

However, both sorghum and sugar beet gave higher energy yields

(i.e., the energy content of the bioethanol minus the cost to convert

the sugar into bioethanol) from 2.2-fold (i.e., the mid-energy in-

tensity for sweet sorghum) to 3.5-fold (i.e., the lowest energy

management for sugar beet) the total energy costs, with the values

over the minimum threshold of 2.0 indicated by Venturi and

Venturi (2003)

.

Moreover, although ENUE was similar or slightly better for sugar

beet (i.e., for the mid-input treatment), WEUE underlined that

sweet sorghum (a C4 species) can produce higher amounts of

biomass per water used by the crop

, with respect to sugar beet

(see

), with this also coupled to a shorter and faster growing

cycle. This is a crucial point for the selection of energy crops in an

environment with reduced water availability and/or with the need

to introduce summer-energy crops in rotation with, rather than

substitution of, winter-food crops.

5. Conclusions

In the present study, both sweet sorghum and sugar beet

showed good potential as energy crops in southern Italy, as they can

maximize the energy balance (sweet sorghum) or the energy ef

fi-

ciency (sugar beet) with lowered energy input.

Due to its deep roots and drought resistance, sweet sorghum

showed favourable exploitation of the water resource and nitrogen

availability, which allows signi

ficant energy saving with stable

productivity under reduced energy intensity. However, when tak-

ing into account the energy costs due to transport of the sorghum

Fig. 4. Relative sustainabilities (as indicated) of the assessed cropping systems for the sweet sorghum (continuous lines) and the sugar beet (dotted lines). Data are percentages

relative to the highest value for the energy balance and ef

ficiencies.

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1556

biomass to the biofuel conversion plant, the results are reversed,

due to the better energy use ef

ficiency for sugar beet than sweet

sorghum.

When the land that can be dedicated to energy crops is limited,

then the goal is to achieve the greatest energy return from a

cropped unit to ful

fil energy demands, and hence sweet sorghum

will be the most suitable crop. However, vice versa (i.e., no limits in

the land available), the crop with the higher energy ef

ficiency

should be preferred (i.e., sugar beet), to achieve improved energy

output with reduced fossil energy use during the crop cycle.

The overall result here, which highlights that conservative

agriculture allows energy saving and improvements in energy ef-

ficiency, should be considered valid in the short-term to mid-term,

as carried out in the present study. A long-term approach is needed

to determine for how long the soil fertility can satisfy the crop ni-

trogen requirements, and to validate the effects of conservative

tillage on the water and nutrient dynamics.

Finally, other factors other than the energy performance and

ef

ficiency might lead to a different approach in the selection of one

crop over another, such as the available technologies on the farm

(i.e., a beet harvester rather than a forage harvester), the expertise

of the farmer relative to a speci

fic crop, or the different income

levels (i.e., due to the selling price of the raw materials, and to the

costs of the starting materials and the transport).

References

[1]

[2] RED;

2009/28/EC;

http://eur-lex.europa.eu/legal-content/EN/ALL/?

. [accessed 13.07.15].

[3]

.

[4]

de Vries SC, van de Ven GWJ, van Ittersum MK, Giller KE. Resource use ef

ciency and environmental performance of nine major biofuel crops, processed

by

first-generation conversion techniques. Biomass Bioenerg 2010;34:

.

[5]

Nassi o Di Nasso N, Bosco S, Di Bene C, Coli A, Mazzoncini M, Bonari E. Energy

ef

ficiency in long-term Mediterranean cropping systems with different

management intensities. Energy 2011;36:1924

[6]

e9

.

[7]

ficiency and greenhouse gas emissions of

corn-ethanol. J Ind Ecol 2009;13:58

[8]

e5

.

[9]

[10]

.

[11]

Patil SL. Winter sorghum (Sorghum bicolor) productivity as in

tillage practices and nitrogen management in Vertisol of SAT, India. Soil Till

Res 2013;126:183

[12]

e80

.

[13] Jesse JH, van der Linde C. Oil turbulence in the next decade: an essay on high

oil prices in a supply-constrained world. CIEP Energy Paper 2008/03. 2008,

June

[accessed

13.07.15],

http://www.feelingeurope.eu/Pages/Oil%

20turbulence%20in%20the%20next%20decade%20(Clingendael%20juli%

202008).pdf

.

[14]

e76

.

[15]

Naik SN, Goud VV, Rout PK, Dalai AK. Production of

ation biofuels: a comprehensive review. Renew Sustain Energy Rev 2010;14:

578

e97

.

[16]

Karp A, Richter GM. Meeting the challenge of food and energy security. J Exp

Bot 2011;62(10):3263

e71

[17] EU Reg. 1307/2013 (art. 43-47)

http://ec.europa.eu/agriculture/newsroom/

. [accessed 13.07.15].

[18] ISTAT, 2015.

http://seriestoriche.istat.it/

. [accessed 13.07.15].

[19]

[20]

[21]

e97

[22]

Monti A, Venturi G. Comparison of the energy performance of

sweet sorghum and wheat monocultures in Northern Italy. Eur J Agron

2003;19(1):35

[23]

e55

.

[24]

e26

.

[25]

Spugnoli P, Dainelli R, D'Avino L, Mazzoncini M, Lazzeri L. Sustainability of

sun

flower cultivation for biodiesel production in Tuscany within the EU

Renewable Energy Directive. Biosyst Eng 2012;112:49

[26]

.

[27]

USDA. Keys to soil taxonomy. 11th ed. 2010. p. 346

[28]

fic and Cultural Organization; 1962

[29]

[30]

& biomass engineering. In: CIGR Handbook of agricultural

[31]

& biomass engineering. In: CIGR handbook of agricultural

engineering. Energy and biomass engineering, vol. V. CIGR

Commission of Agricultural Engineering. American Society of Agricultural

Engineers; 1999. p. 351

[32]

e9

.

[33]

[34]

ciency. Field Crops Res 2006;95:103

e14

.

[35]

[36]

[37]

Kallivroussis L, Natsis A, Papadakis G. The energy balance of sun

duction for biodiesel in Greece. Biosyst Eng 2002;81(3):347

e54

.

[38]

.

[39]

.

[40]

Reddy BVS, Rames S, Reddy PS, Ramaih B, Salimath M, Kachpur R. Swee

tsorghum

e a potential alternate raw material for bioethanol and bioenergy.

Int Sorghum Millets Newsl 2005;2005(46):79

e86

.

[41]

ficiency. Ind Crop Prod 2014;62:380e6

.

[42]

e201

[43]

[44]

e89

[45]

e83

[46]

Garofalo P, Rinaldi M. Water-use ef

ficiency of irrigated biomass sorghum in a

Mediterranean environment. Span J Agric Res 2013;11(4):1153

e69

.

[47]

ficient for agriculture inputs in Western Canada. Canada:

Canadian Agricultural Energy End-Use Data Analysis Centre (CAEEDAC); 1999.

p. 41

P. Garofalo et al. / Energy 93 (2015) 1548

e1557

1557

Document Outline

Wyszukiwarka

Podobne podstrony:

Performance and evaluation of small

Simulation, construction and testing of a two cylinder solar Stirling engine powered by a flat plate

Tale of Two Cities Essay on the Roots of Revolution

The Code of Honor or Rules for the Government of Principals and Seconds in Duelling by John Lyde Wil

Design and construction of three phase transformer for a 1 kW multi level converter

Command and Control of Special Operations Forces for 21st Century Contingency Operations

Sexual behavior and the non construction of sexual identity Implications for the analysis of men who

Barwiński, Marek Reasons and Consequences of Depopulation in Lower Beskid (the Carpathian Mountains

Islamic System Of Practising Social Security For The Needy

(IV)The effect of McKenzie therapy as compared with that of intensive strengthening training for the

Energy and CO2 analysis of poplar and maize crops for biomass production in Italy Włochy 2016

Can we accelerate the improvement of energy efficiency in aircraft systems 2010 Energy Conversion an

Bearden Misc Moore Relationship between Efficiency and Coefficient of Performance (www cheniere o

Induction of two cytochrome P450 genes, Cyp6a2 and Cyp6a8 of Drosophila melanogaster by caffeine

A Tale of Two Cities Summary and Themes of the Book

EFFECTS OF EATING AND NOT EATING ON ENERGY STORES AND BODY WEIGHT

William Pelfrey Billy, Alfred, and General Motors, The Story of Two Unique Men, a Legendary Company

więcej podobnych podstron