Contents

lists

available

at

Process

Biochemistry

j o

u

r n

a l

h o m

e p a g e :

w w w . e l s e v i e r . c o m / l o c a t e / p r o c b i o

Production

of

xylooligosaccharides

using

immobilized

endo-xylanase

of

Bacillus

halodurans

Yu-Sheng

Lin

,

Min-Jen

Tseng

,

Wen-Chien

Lee

a

Department

of

Chemical

Engineering,

National

Chung

Cheng

University,

Chiayi,

Taiwan

b

Department

of

Life

Science,

National

Chung

Cheng

University,

Chiayi,

Taiwan

a

r

t

i

c

l

e

i

n

f

o

Article

history:

Received

10

June

2011

Received

in

revised

form

10

August

2011

Accepted

12

August

2011

Available

online

19

August

2011

Keywords:

Immobilized

enzyme

Endo-xylanase

Xylooligosaccharides

Bacillus

halodurans

Anionic

exchanger

XOS

Corncob

a

b

s

t

r

a

c

t

Endo-xylanase

secreted

by

the

alkaliphilic

Bacillus

halodurans

was

immobilized

onto

an

anionic

exchange

resin

via

the

ionic

linkage

and

the

highest

immobilized

amount

was

achieved

at

pH

8.

Approximately

0.4

mg

of

enzyme

could

be

coupled

onto

1

g

of

anionic

exchanger.

Time

courses

of

the

xylooligosaccharides

(XOS)

produced

from

corncob

xylan

indicated

that

the

immobilized

enzyme

tends

to

use

shorter

xylan

chains

as

the

substrate

and

to

produce

more

xylobiose

and

xylotriose

initially.

On

the

contrary,

when

free

enzyme

was

employed,

products

at

initial

stage

of

the

reaction

exhibited

higher

level

of

oligomers

with

degree

of

polymerization

greater

than

4,

suggesting

that

free

xylanase

worked

on

both

longer

(insoluble)

and

shorter

(soluble)

xylan

chains.

At

the

end

of

24

h

reaction,

XOS

mixture

contained

a

total

of

25.2%

and

32.5%

(w/w)

of

xylobiose

and

xylotriose

with

immobilized

xylanase

and

free

xylanase,

respectively.

The

conversions

for

converting

substrate

xylan

to

soluble

XOS

with

immobilized

xylanase

was

determined

to

be

80.9%,

which

was

lower

than

the

use

of

free

xylanase

(99.8%).

The

combination

of

free

and

immobilized

xylanase

can

be

employed

to

further

improve

the

conversion

of

XOS.

©

2011

Elsevier

Ltd.

All

rights

reserved.

1.

Introduction

Xylooligosaccharides

(XOS)

are

typically

produced

by

enzy-

matic

approach

using

plant

source

of

xylan

as

raw

material.

The

xylanase-catalyzed

hydrolysis

yields

XOS

products

composed

of

mainly

xylobiose,

xylotriose,

and

a

small

fraction

of

oligosaccha-

rides

with

a

higher

degree

of

polymerization

(DP).

Xylobiose

and

xylotriose

are

the

most

important

components

of

human

probiotic.

Agro-wastes

such

as

corncob

(also

known

as

maize

cores)

have

been

frequently

used

as

the

xylan

source

for

the

production

of

XOS.

Zhu

et

al.

ammonia-pretreated

corncob

as

the

raw

material.

The

enzymatic

reaction

at

pH

5

and

50

◦

C

using

a

dosage

of

0.04

g/g

solids

endoxylanase

X2753

resulted

in

15.74

g/l

XOS

in

72

h.

In

addi-

tion

to

corncob,

Yang

et

al.

bagasse,

wheat

bran,

and

peanut

shell

as

raw

materials.

After

extraction

by

NaOH,

these

materials

were

converted

to

XOS

by

the

action

of

xylanase

from

Thermobi-

fida

fusca

at

pH

7

and

60

◦

C.

The

XOS

yields

after

24

h

reaction

were

29.5%,

23.7%,

7.6%,

and

10.1%,

respectively

from

the

four

raw

corn-

cob,

bagasse,

wheat

bran,

and

peanut

shell.

After

extraction

with

24%

KOH,

cotton

stalk

was

used

as

the

raw

material

to

produce

XOS

by

the

action

of

an

Aspergillus

niger

secreted

enzyme,

Veron

∗ Corresponding

author.

Fax:

+886

5

2721206.

address:

(W.-C.

Lee).

191

(AB

Enzymes

Co.,

Germany),

at

pH

5.4

and

40

◦

C.

An

XOS

yield

of

53%

was

obtained

after

enzymatic

reaction

for

24

h

In

the

present

work,

endo-xylanases

purified

from

alkaliphilic

Bacillus

halodurans

and

immobilized

with

anionic

exchange

resin

were

employed

for

the

production

of

XOS

from

corncob.

This

strain,

which

was

previously

named

as

Bacillus

firmus

rei-

dentified

by

16S

rDNA

gene

sequencing

as

a

B.

halodurans.

Two

endo-xylanases

(endo-1,4-

-xylanase,

EC

3.2.1.8)

purified

from

this

B.

halodurans

have

molecular

weights

of

45

kDa

and

23

kDa,

respectively,

and

both

showed

enzymatic

activity

over

the

pH

range

of

5.0–11.0

at

37

◦

C

the

calculated

pI

value

for

the

dom-

inant

secreted

proteins

in

45

kDa

xylanase

is

4.5,

we

therefore

tried

to

immobilize

the

enzyme

from

B.

halodurans

onto

anionic

exchange

resin

(Lewatit

MonoPlus

MP64)

by

the

ionic

binding

in

this

work.

Like

other

industrial

enzymes,

xylanase

can

be

theo-

retically

immobilized

by

different

methods

with

various

carriers.

Several

conventional

enzyme

immobilization

methods

including

ionic

binding

on

DEAE-Sephadex

resin,

inclusion

in

polyacrylamide,

and

covalent

binding

by

glutaraldehyde

to

chitosan,

chitin,

Amber-

lite,

Duolite,

florisil,

and

gelatin

have

been

examined

for

the

immobilization

of

xylanase

from

Talaromyces

thermophilus

2.

Materials

and

methods

2.1.

Preparation

of

enzyme

B.

halodurans

Thonburi

(deposited

to

Bioresource

Collection

and

Research

Cen-

ter

of

Taiwan

with

a

deposited

number

of

BCRC

910501)

was

cultivated

at

37

◦

C

1359-5113/$

–

see

front

matter

©

2011

Elsevier

Ltd.

All

rights

reserved.

doi:

2118

Y.-S.

Lin

et

al.

/

Process

Biochemistry

46

(2011)

2117–2121

for

5

days

in

Emerson

medium

containing

0.55%

yeast

extract

(Bacto),

0.5%

peptone

(Bacto),

0.02%

MgSO

4

(Merck),

0.1%

K

2

HPO

4

(Merck),

and

2%

corncob

(obtained

from

local

market).

The

initial

pH

was

adjusted

to

10

with

1

M

NaOH

(Showa).

The

5

d

cul-

ture

was

centrifuged

and

the

supernatant

was

precipitated

with

ammonia

sulfate

on

ice.

The

resultant

precipitate

was

dissolved

using

100

mM

Tris–HCl

(J.T.

Baker)

buffer

and

then

dialyzed

against

the

100

mM

Tris–HCl

buffer

containing

10%

glyc-

erol.

The

activity

of

xylanase

was

measured

by

calculating

the

release

of

reducing

sugars

from

birchwood

xylan

via

modified

dinitrosalicylic

acid

approach

l

of

sample

was

mixed

with

160

l

Tris–HCl

buffer

(100

mM,

pH

8.0)

containing

1%

brichwood

xylan

(Sigma).

The

reaction

was

incubated

at

37

◦

C

for

5

min

and

0.4

ml

of

DNS

reagent

composed

of

1%

dinitrosalicylic

acid

(RDH),

0.2%

phenol

(Riedel-de

Haën),

0.05%

sodium

sulfite,

and

1%

sodium

hydroxide

(J.T.

Baker)

was

added

to

stop

the

reaction,

the

solution

was

then

boiled

for

5

min

absorbance

at

500

nm

was

measured

after

adding

2.5

ml

of

water.

One

unit

of

xylanase

was

defined

as

the

amount

of

enzyme

required

to

release

1

mol

of

xylose

from

birchwood

xylan

in

1

min.

2.2.

Enzyme

immobilization

Ion-exchange

resin

Lewatit

MonoPlus

MP64

was

used

for

the

immobilization

of

xylanase

by

ionic

binding.

Macroporous

styrene-divinylbenzene

copolymer

hav-

ing

quaternary

amine

functionality

was

introduced

as

weak

basic

anion

exchange

resin.

As

supplied

by

the

vendor,

this

highly

monodispersive

resin

exhibits

an

aver-

age

particle

size

of

0.59

mm,

and

its

beads

are

highly

chemically

and

osmotically

stable.

Thus,

this

anionic

exchanger

was

used

for

the

immobilization

of

enzyme

at

pH

greater

than

its

pI

value.

The

ion

exchanger

(100

mg)

was

equilibrated

with

1

ml

of

Tris–HCl

buffer

(100

mM,

pH

8.0)

and

incubated

with

various

doses

(1,

2,

3,

5,

9,

and

11

l)

of

concentrated

xylanase

(127.8

U/ml)

under

4

◦

C

for

24

h.

The

unbound

enzyme

was

removed

by

washing

with

the

same

buffer

until

no

activity

or

soluble

protein

was

detected.

The

enzyme

activity

obtained

in

buffer

after

the

washing

was

taken

as

unbound

enzyme.

To

study

the

effect

of

pH

on

enzyme

immobilization,

ion

exchanger

(100

mg)

was

equilibrated

in

buffers

of

different

pH

(5.0–8.0)

and

incubated

with

2

l

of

concentrated

xylanase

(127.8

U/ml)

under

4

◦

C

for

24

h.

Buffers

used

were

citrate–phosphate,

pH

5.0–6.0,

and

Tris–HCl,

pH

7.0–8.0.

2.3.

Operational

stability

of

the

immobilized

xylanase

The

immobilized

enzyme

was

assayed

for

5

cycles,

each

with

a

duration

of

5

min.

For

each

cycle,

500

l

of

2.0%

(w/v)

xylan

in

100

mM

Tris–HCl

buffer

(pH

8.0)

was

added

to

the

immobilized

enzyme

(0.05

g;

0.255

U)

and

incubated

for

5

min

under

continuous

shaking

at

37

◦

C.

At

the

end

of

reaction,

the

immobilized

enzyme

was

collected

by

centrifugation

at

8000

×

g

for

30

s.

The

supernatant

was

assayed

for

reducing

sugars.

For

running

the

succeeding

cycle,

the

immobilized

enzyme

was

redissolved

in

500

l

of

2.0%

(w/v)

xylan

in

100

mM

Tris–HCl

buffer

(pH

8.0)

and

processed

with

the

abovementioned

procedures.

2.4.

Production

of

xylooligosaccharides

Xylan

was

obtained

from

the

alkali

extraction

of

corncob.

Corncob,

which

was

obtained

locally,

was

chopped

and

milled

into

powders.

Powders

of

corncob

were

treated

with

15%

NaOH

with

a

solid–liquid

ratio

of

1:20

(w/v)

at

90

◦

C

for

90

min.

The

resultant

soluble

fraction

was

neutralized

with

acetic

acid

to

a

final

pH

of

5.0.

Three-time

volume

of

95%

ethanol

was

then

added

and

the

resultant

mixture

was

incubated

for

60

min

at

room

temperature.

Xylan,

the

substrate

for

XOS

production,

was

obtained

from

the

recovered

precipitate.

Free,

immobilized

xylanase

and

a

combination

of

free

and

immobilized

xylanase

with

a

total

activity

of

0.255

U

were

added

separately

to

1

ml

of

2.0%

(w/v)

xylan

in

100

mM

Tris–HCl

buffer

(pH

8.0).

The

mixture

was

incubated

at

50

◦

C

with

mild

agi-

tation

(30

rpm).

A

sample

of

100

l

was

taken

at

different

time

intervals

and

diluted

with

D.I.

water

to

10%

prior

to

filtration.

The

filtrate

was

analyzed

by

HPLC

using

a

Biorad

Aminex

HPX-87H

column

(300

×

7.8

mm

i.d.)

to

examine

the

concentrations

of

xylobiose,

xylotriose,

and

xylose.

The

mobile

phase

was

5.0

mM

sulfuric

acid

at

a

flow-rate

of

0.6

ml/min.

The

retention

times

of

hydrolytic

products

(xylose,

xylo-

biose,

and

xylotriose)

were

compared

with

known

standards

(Megazyme)

with

a

refractive

index

detector

at

65

◦

C

column

temperature.

3.

Results

and

discussion

3.1.

Immobilization

of

endo-xylanase

According

to

previous

findings,

the

alkaliphilic

bacterium

B.

halodurans

Thonburi

could

secret

two

xylan-degrading

enzymes

with

molecular

weights

of

45

and

23

kDa,

respectively

The

protein

extracts

of

these

two

enzymes

in

different

ratios

can

be

obtained

by

culturing

B.

halodurans

in

Emerson

medium

supple-

mented

with

different

sources

of

xylan

(corncob,

wheat

bran,

and

0.00

0.05

0.10

0.15

0.20

8

7

6

5

pH value

Immobilized protein

(mg/g resin)

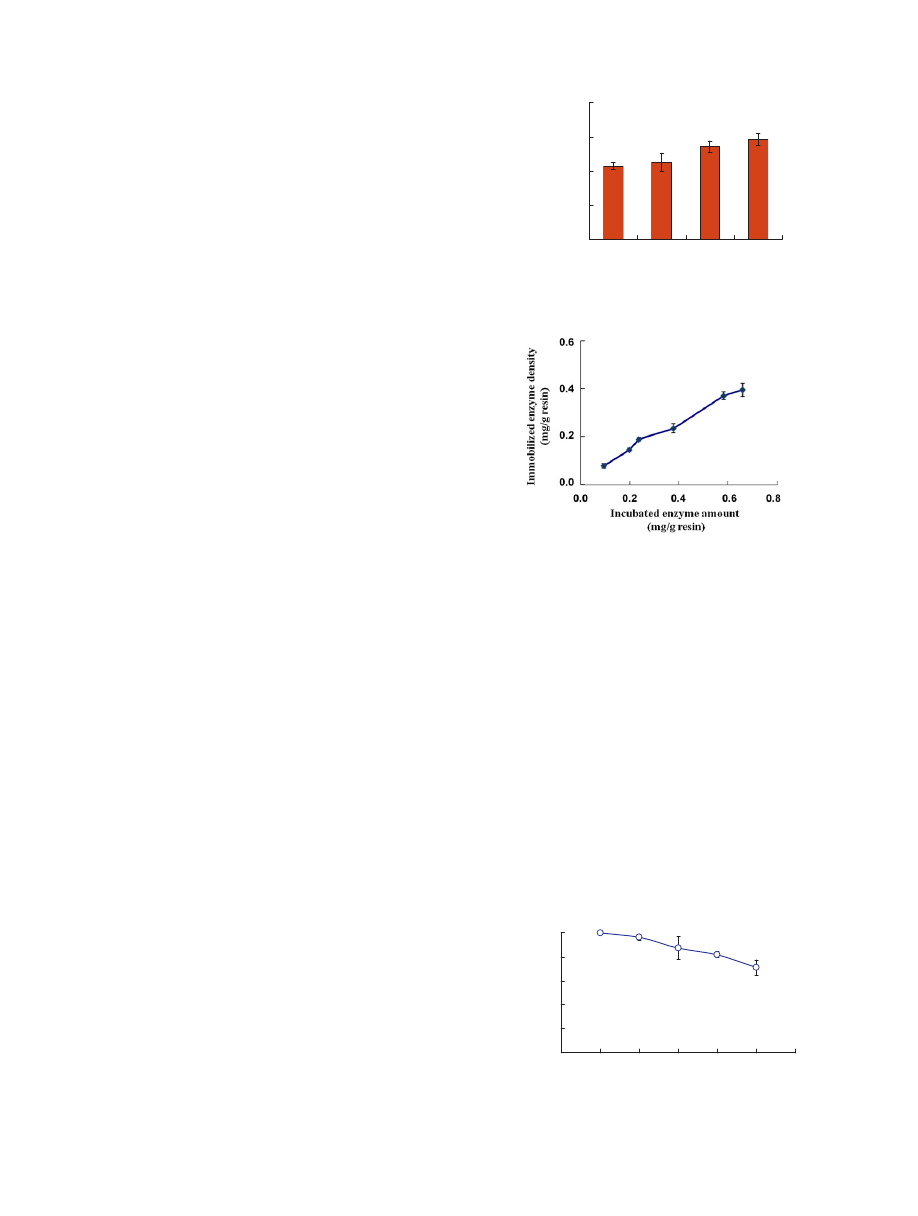

Fig.

1.

Effect

of

pH

on

the

immobilization

of

B.

halodurans

xylanase

onto

anionic

exchange

resin

(Lewatit

MonoPlus

MP64).

Fig.

2.

Effect

of

the

amount

of

added

enzyme

protein

on

the

immobilization

of

xylanase

from

B.

halodurans

on

anionic

exchange

resin.

birchwood

xylan)

as

the

inducer.

As

the

corncob

(2%)

was

used

as

the

inducer

in

the

present

work,

only

one

prominent

band

at

45

kDa

xylanase

was

observed

in

the

SDS-PAGE

(data

not

shown).

The

anionic

exchange

resin

was

thus

used

for

the

immobilization

of

the

endo-xylanase

via

the

ionic

linkage.

The

amount

of

xylanase

bound

onto

anionic

exchanger

varied

with

the

pH

value

of

the

enzyme

solution

in

the

range

between

5

and

8.

The

higher

the

pH

value,

the

stronger

the

anionic

groups

on

the

enzyme.

This

was

attributed

to

the

deprotonization

of

func-

tion

groups

on

enzyme

protein

in

the

conditions

with

pH

value

greater

then

its

pI

value.

As

shown

in

the

highest

immo-

bilized

amount

was

achieved

at

pH

8.

Since

the

45

kDa

xylanase

showed

the

pH

optimum

at

6–8

for

its

enzymatic

activity

immobilization

of

this

enzyme

was

thus

carried

out

at

pH

8

for

further

study.

When

pH

was

set

to

8,

the

immobilized

amount

of

enzyme

increased

with

the

amount

of

enzyme

in

the

solution

applied

for

immobilization.

About

0.4

mg

of

enzyme

could

be

cou-

pled

onto

1

g

of

anionic

exchanger,

as

shown

in

the

work

of

Kapoor

and

Kuhad

series

of

ion

exchangers

(DEAE-sepharose,

Q-S,

CM-sepharose,

Amberlite

IR-120,

and

Amberlite

IR-440)

was

0

20

40

60

80

100

6

5

4

3

2

1

0

Cycle number

Retention of xylanase

activity (%)

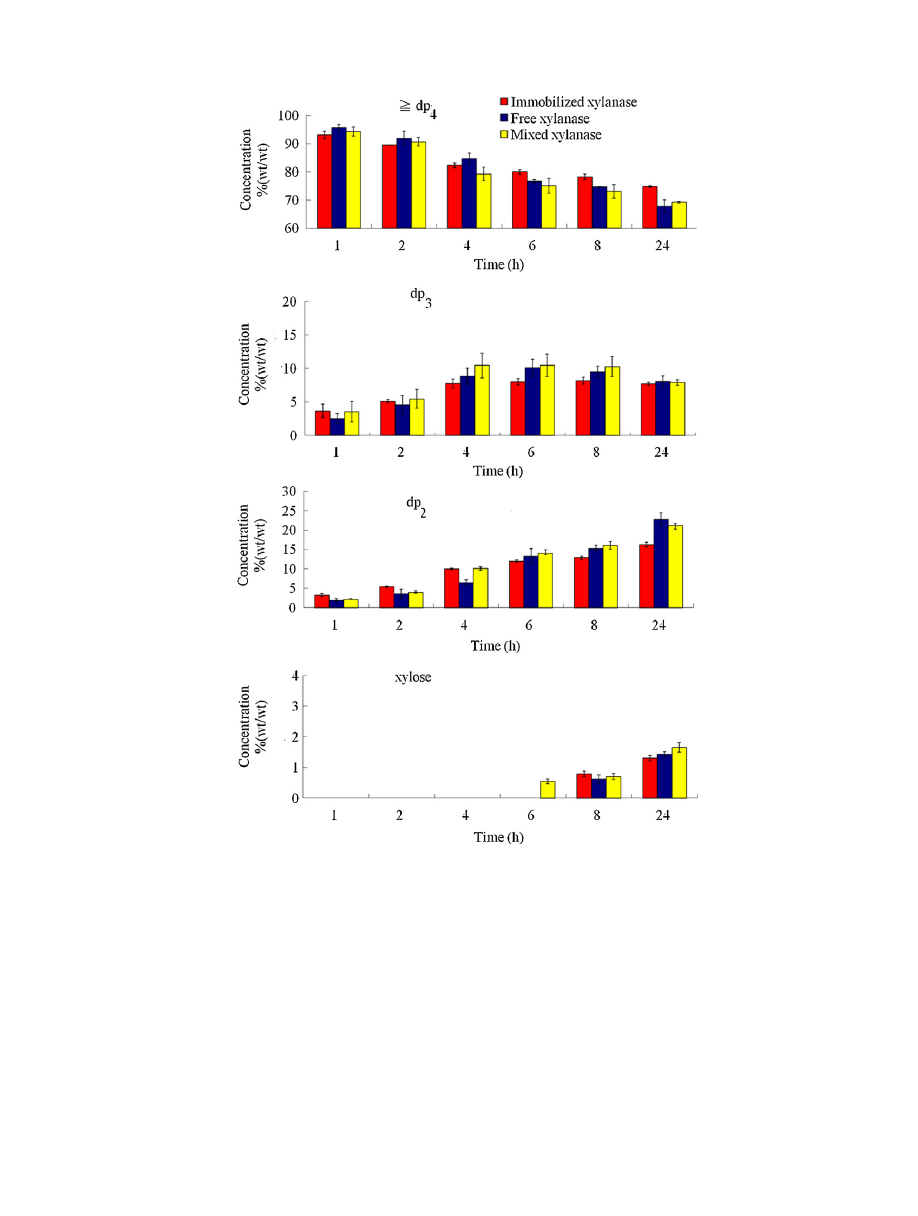

Fig.

3.

Reusability

of

the

B.

halodurans

xylanase

immobilized

on

anionic

exchange

resin.

Y.-S.

Lin

et

al.

/

Process

Biochemistry

46

(2011)

2117–2121

2119

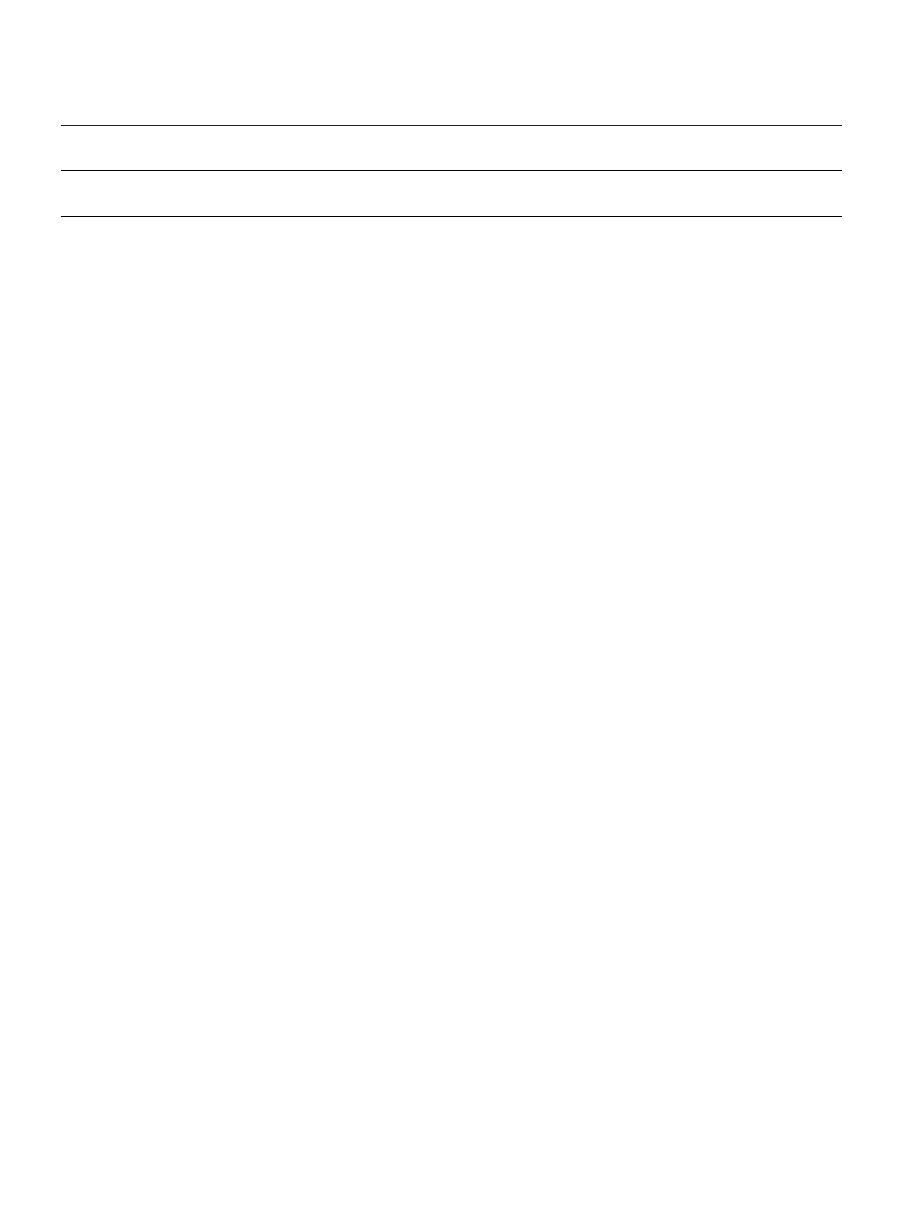

Fig.

4.

Time

courses

of

the

xylooligosacchride

production

from

corncob

xylan

by

free

and

immobilized

xylanase

from

B.

halodurans.

A

combined

use

of

free

and

immobilized

xylanase

was

also

presented.

Each

batch

of

reaction

was

carried

out

with

0.255

U/ml

xylanase

using

2%

corncob

substrate

at

pH

8

and

50

◦

C.

For

each

data

bar,

the

number

of

repeated

runs

ranged

from

3

to

6.

The

concentration

of

each

product

was

expressed

in

term

of

gram

per

100

g

of

total

products,

%

(w/w).

incubated

with

20

mg

lyophilized

xylanase

per

unit

gram

of

ion

exchanger

for

the

immobilization

of

xylanase

by

ionic

binding.

Based

on

the

detection

of

unbound

enzyme

in

washing

buffer,

the

bound

amounts

of

enzyme

was

found

to

range

from

1.2

to

3.8

mg/g-ion

exchange.

Bound

efficiency

was

low

in

the

range

from

6.2

to

19.2%.

For

the

sake

of

reducing

unbound

enzyme,

the

present

work

carried

out

xylanase

immobilization

with

added

enzyme

of

0.7

mg/g-ion

exchanger,

which

resulted

in

the

maximum

bound

enzyme

0.4

mg/g-ion

exchanger.

The

bound

efficiency

was

much

higher

(60.2%).

Anionic

exchanger-bound

xylanase

was

capable

to

be

reused

for

several

times

without

losing

too

much

of

its

enzymatic

activity.

As

shown

in

the

activity

of

immobilized

xylanase

on

anionic

exchange

resin

decreased

gradually

with

number

of

repeated

uses.

The

immobilized

enzyme

retained

about

71%

of

its

original

activ-

ity

after

reuse

for

5

cycles.

Possible

causes

for

the

gradual

decrease

in

enzyme

activity

over

cycling

could

be

owing

to

the

elution

of

enzyme

from

the

carrier

at

high

reaction

temperature

(50

◦

C)

and

clogging

of

carrier

by

macromolecular

xylan

fragments.

However,

this

xylanase-immobilized

preparation

was

found

to

be

superior

or

comparable

to

those

reported

in

the

literature.

According

to

Kapoor

and

Kuhad

in

case

of

xylanase

(from

Bacillus

pumilus

Strain

MK001)

immobilized

on

gelatin

by

entrapment

and

chitin

by

phys-

ical

adsorption,

more

than

half

of

the

activity

was

lost

after

four

cycles.

Xylanase

immobilized

on

Q-sepharose

with

ionic

binding

and

HP-20

beads

with

covalent

binding

showed

better

retention

2120

Y.-S.

Lin

et

al.

/

Process

Biochemistry

46

(2011)

2117–2121

Table

1

Calculation

of

the

conversion

of

xylan

to

soluble

oligomers

by

enzymatic

reaction

for

24

h.

Total

soluble

oligomers

initially

presented

(g/l)

Total

soluble

oligomers

in

the

final

product

(g/l)

Total

fraction

of

xylobiose

and

xylotriose

in

the

product

%(w/w)

Immobilized

xylanase

9.79

16.17

22.5

80.9

62.5

Free

xylanase

9.96

19.96

33.8

99.8

99.6

Combined

preparation

9.60

18.95

27.6

94.8

89.9

a

Based

on

the

total

soluble

oligomers

produced

with

respect

to

the

initial

substrate

concentration

(20

g/l).

b

Based

on

the

soluble

oligomers

produced

from

insoluble

xylan

initially

presented

in

the

substrate.

rate,

with

up

to

70.0%

of

its

original

activity

retained

after

seven

cycles.

3.2.

Production

of

XOS

Xylooligosaccharides

are

usually

produced

from

xylan

by

enzy-

matic

hydrolysis.

Corncob

is

an

ideal

raw

material

for

producing

XOS

due

to

its

relatively

high

hemi-cellulose

(xylan)

content.

The

time

courses

of

XOS

production

by

0.255

U/ml

xylanase

(immobi-

lized,

free,

or

a

combined

use

of

immobilized

and

free

enzyme)

using

2%

corncob

substrate

at

pH

8

and

50

◦

C

are

given

in

When

20

g/l

xylan

was

employed

for

XOS

production,

the

ini-

tial

amount

of

soluble

fraction

with

DP

4

was

9.0–10.0

g/l

in

the

reaction

mixture.

No

XOS

with

DP

less

than

4

was

observed

at

ini-

tial

stage

of

the

reaction.

This

soluble

fraction

was

xylooligomers

produced

due

to

the

autolysis

in

alkaline

conditions.

When

immo-

bilized

xylanase

was

applied

to

the

xylan

solution,

the

soluble

xylooligomers

were

hydrolyzed

into

oligomers

with

low

DP.

Also,

insoluble

xylan

was

digested

to

become

soluble

high

DP

xylooligomers

and

subsequently

degraded

into

oligomers

with

lower

DP.

As

shown

in

the

fraction

of

xylooligomers

with

DP

4

decreased

significantly

in

the

first

hour

and

decreased

to

81.5%,

w/w

at

the

fourth

hour,

followed

by

a

gradual

decrease

to

73.5%

at

the

end

of

24

h

reaction.

On

the

other

hand,

the

fraction

of

xylotriose

increased

gradually

from

3.6

to

8.4%

from

the

first

hour

to

the

eighth

hour,

and

then

decreased

slightly

to

7.9%

at

24

h.

At

the

end

of

24

h

reaction,

the

XOS

mixture

contained

a

total

of

25.2%

(w/w)

of

xylobiose

and

xylotriose

by

using

immobilized

xylanase.

When

free

xylanase

was

used

instead

of

immobilized

enzyme,

the

concentrations

of

xylobiose

and

xylotriose

were

ini-

tially

lower.

Although

the

time

courses

for

xylotriose

and

xylobiose

were

similar,

the

use

of

free

enzymes,

when

compared

with

the

use

of

immobilized

enzyme,

exhibited

higher

concentrations

of

xylotriose

and

xylobiose

after

fourth

and

sixth

hour,

respectively.

At

the

end

of

24

h

reaction,

the

XOS

mixture

contained

a

total

of

32.5%

(w/w)

of

xylobiose

and

xylotriose

when

free

xylanase

was

used.

The

higher

xylotriose

and

xylobiose

concentrations

at

the

initial

stage

of

the

reaction

observed

with

the

immobilized

enzyme

suggest

that

the

immobilized

enzyme

tends

to

act

on

the

termini

of

xylan

chains.

On

the

contrary,

enzyme

molecules

attacked

everywhere

in

the

chains

of

xylooligomers

when

free

enzyme

was

used.

In

addi-

tion

to

the

production

of

xylobiose

and

xylotriose,

xylooligomers

with

lower

DP

were

also

produced

from

the

high

DP

xylooligomers

during

the

enzymatic

reaction

of

free

enzyme.

From

this

point

of

view,

it

seems

that

there

was

a

steric

hindrance

for

immobilized

xylanases

to

access

the

intermediate

portion

of

the

xylan

chain.

A

combined

use

of

half

free

and

half

immobilized

enzyme

led

to

time

courses

with

trend

similar

to

having

trade-off

from

either

free

or

immobilized

xylanase.

Based

on

the

total

amount

of

sub-

strate,

the

amount

of

total

soluble

fraction

in

the

products

from

24

h

reaction

using

immobilized

enzyme

made

of

a

conversion

of

80.9%.

However,

when

free

enzyme

with

the

same

enzymatic

activity

was

used,

the

conversion

could

approach

as

high

as

99.8%.

This

indicates

that

the

final

products

were

almost

soluble.

Since

no

insoluble

mat-

ter

left

after

the

reaction,

we

believe

that

the

xylan

obtained

from

NaOH

extraction

and

ethanol

precipitation

was

very

pure.

A

con-

version

of

94.8%

can

be

achieved

with

the

combinative

approach.

If

the

initial

soluble

fractions

were

exclusive

from

the

calculation,

the

conversions

for

the

insoluble

substrate

to

soluble

XOS

were

deter-

mined

to

be

62.5,

99.6,

and

89.9%

for

the

use

of

immobilized,

free,

and

combined

preparations

of

xylanase,

respectively

(

The

efficiency

for

converting

corncob

xylan

to

XOS

under

the

catalysis

of

endo-xylanase

from

B.

halodurans

was

higher.

If

only

xylobiose

and

xylotriose

were

taken

into

account,

the

use

of

immo-

bilized

xylanase

for

24

h

reaction

led

to

a

product

composing

of

4.5

g

of

xylobiose

and

xylotriose

from

20

g

xylan.

When

free

xylanase

was

used,

product

composed

of

6.8

g

of

xylobiose

and

xylotriose

from

20

g

xylan

was

obtained

after

24

h

reaction.

Recently,

a

two-

stage

process

based

on

a

steam

explosion

pretreatment

followed

by

enzymatic

hydrolysis

was

used

for

XOS

production,

and

a

max-

imum

yield

of

28.6

g

XOS/100

g

xylan

in

corncobs

was

achieved,

in

which

more

than

90%

of

xylobiose

and

xylotriose

were

contained

in

XOS

syrup

The

product

from

the

enzymatic

reaction

was

composed

of

xylo-

biose,

xylotriose,

oligomers

(DP

4),

and

small

amounts

of

xylose.

After

reaction

for

24

h,

the

xylose

content

was

less

than

1.8%

(w/w)

in

the

product

mixture,

regardless

of

whichever

xylanase

was

used

(free

or

immobilized).

In

the

present

work,

alkaline-extracted

corn-

cob

xylan

was

used

as

substrate

for

XOS

production.

When

xylan

with

a

soluble

fraction

(DP

4)

in

the

range

of

9.0–10.0

g/l,

conver-

sions

of

xylan

to

soluble

XOS

with

immobilized

and

free

xylanase

in

24

h

reaction

were

80.9%

and

99.8%,

respectively.

On

the

other

hand,

the

conversion

was

lower

for

xylan

with

lower

soluble

frac-

tion

under

the

same

reaction

time.

For

example,

when

the

initial

concentration

of

soluble

xylan

was

6.9

g/l,

the

XOS

conversion

by

using

immobilized

and

free

xylanase

would

be

50.9

and

65.9%,

respectively

under

the

same

enzyme

dosage.

The

higher

the

ini-

tial

percentage

of

insoluble

fraction

presented

in

the

substrate,

the

harder

the

accession

of

enzyme

molecule

to

longer

xylan.

Thus,

the

conversions

became

lower

due

to

the

slower

degradation

rate.

Although

extraction

of

xylan

with

steam

or

acid

has

been

proven

capable

of

increasing

the

XOS

yield,

large

amounts

of

undesired

products,

such

as

monosaccharides

and

their

dehydration

products

were

produced

4.

Conclusion

Endo-xylanase

secreted

by

B.

halodurans

can

be

well

immo-

bilized

with

0.59

mm

anionic

exchange

resin

(Lewatit

MonoPlus

MP64)

for

repeated

uses

in

the

production

of

XOS

from

alkaline-

extracted

corncob.

Interestingly,

time

courses

associated

with

XOS

production

from

corncob

xylan

by

the

catalysis

of

immobilized

enzyme

differ

slightly

from

those

using

free

forms

of

xylanase.

Xylobiose

and

xylotriose

were

produced

mainly

from

the

solu-

ble

xylan

(xylooligomers)

in

the

first

few

hours

under

the

action

of

immobilized

enzyme.

While

free

enzyme

can

effectively

cat-

alyze

the

hydrolysis

of

glucosidic

bonds

at

every

positions

in

the

xylan

chains;

xylobiose,

xylotriose,

and

xylooligomers

with

lower

DP

were

all

produced

simultaneously

during

the

time

course

of

enzyme

reaction.

Overall

conversions

from

insoluble

substrate

to

Y.-S.

Lin

et

al.

/

Process

Biochemistry

46

(2011)

2117–2121

2121

soluble

XOS

were

80.9

and

99.8%

with

immobilized

and

free

forms

of

xylanase

in

a

24

h

reaction,

respectively.

However,

as

the

immo-

bilized

enzyme

was

used,

the

lower

conversion

for

yielding

XOS

could

be

improved

by

introducing

the

combination

of

free

and

immobilized

xylanase

to

the

reaction.

Acknowledgement

This

study

was

supported

by

the

Ministry

of

Economic

Affairs

(Taiwan)

under

grant

no.

98-EC-17-A-13-S1-116.

References

[1] Zhu

Y,

Kim

TH,

Lee

YY,

Chen

R,

Elander

RT.

Enzymatic

production

of

xylooligsac-

charides

from

corn

stover

and

corncobs

treated

with

aqueous

ammonia.

Appl

Biochem

Biotechnol

2006;129–132:586–98.

[2] Yang

CH,

Yang

SF,

Liu

WH.

Production

of

xylooligosaccharides

from

xylans

by

extracellular

xylanases

from

Thermobifida

fusca.

J

Agric

Food

Chem

2007;55:3955–9.

[3]

Akpinar

O,

Ak

O,

Kavas

A,

Bakir

U,

Yilmaz

L.

Enzymatic

production

of

xylooligosaccharides

from

cotton

stalks.

J

Agric

Food

Chem

2007;55:5544–51.

[4]

Chang

P,

Tsai

WS,

Tsai

CL,

Tseng

MJ.

Cloning

and

characterization

of

two

ther-

mostable

xylanases

from

an

alkaliphilic

Bacillus

firmus.

Biochem

Biophys

Res

Commun

2004;319:1017–25.

[5]

Tseng

MJ,

Yap

MN,

Ratanakhanokchai

K,

Kyu

KL,

Chen

ST.

Purification

and

char-

acterization

of

two

cellulase

free

xylanases

from

an

alkaliphilic

Bacillus

firmus.

Enzyme

Microb

Technol

2002;30:590–5.

[6]

Maalej-Achouri

I,

Guerfali

M,

Gargouri

A,

Belghith

H.

Production

of

xylo-oligosaccharides

from

agro-industrial

residues

using

immobilized

Talaromyces

thermophilus

xylanase.

J

Mol

Catal

B:

Enzymatic

2009;59:

145–52.

[7]

Bailey

MJ,

Beiley

P,

Poutanen

K.

Interlaboratory

testing

of

methods

for

assay

of

xylanase

activity.

J

Biotechnol

1992;23:257–70.

[8]

Kapoor

M,

Kuhad

RC.

Immobilization

of

xylanase

from

Bacillus

pumilus

strain

MK001

and

its

application

in

production

of

xylo-oligosaccharides.

Appl

Biochem

Biotechnol

2007;142:125–38.

[9] Teng

C,

Yan

Q,

Jiang

Z,

Fan

G,

Shi

B.

Production

of

xylooligosaccha-

rides

from

the

steam

explosion

liquor

of

corncobs

coupled

with

enzymatic

hydrolysis

using

a

thermostable

xylanase.

Bioresour

Technol

2010;101:

7679–82.

[10] Yuan

QP,

Zhang

H,

Qian

ZM,

Yang

XJ.

Pilot-plant

production

of

xylo-

oligosaccharides

from

corncob

by

steaming,

enzymatic

hydrolysis

and

nanofiltration.

J

Chem

Technol

Biotechnol

2004;79:1073–9.

[11]

Yang

R,

Xu

S,

Wang

Z,

Yang

W.

Aqueous

extraction

of

corncob

xylan

and

production

of

xylooligosaccharides.

LWT

Food

Sci

Technol

2005;38:

677–82.

Document Outline

- Production of xylooligosaccharides using immobilized endo-xylanase of Bacillus halodurans

Wyszukiwarka

Podobne podstrony:

78 1101 1109 Industrial Production of Tool Steels Using Spray Forming Technology

Production of b xylanase and b xylosidase

~$Production Of Speech Part 2

GB1008594A process for the production of amines tryptophan tryptamine

pair production of black holes on cosmic strings

BoyerTiCS Religious Thought as a By Product of Brain Function

Production Of Speech Part 1

Production Of Speech Part 2

Production of Energy from Biomass Residues 020bm 496 1993

Machine Production of Screen Subtitles for Large Scale Production

~$Production Of Speech Part 2

the production of urban sprawl lepizig

Techniques to extract bioactive compounds from food by products of plant origin

Production of recombinant proteins in E coli

GB1008594A process for the production of amines tryptophan tryptamine

Chiodelli&Tzfadia The Multifaceted Relation between Formal Institutions and the Production of Infor

SMeyer WO8901464A3 Controlled Process for the Production of Thermal Energy from Gases and Apparatus

więcej podobnych podstron