1

Electric Automatic

Temperature Regulating Valve

(PID Control)

NT2.120.001JS

INSTRUCTION MANUAL

Nanjing TP Thermal Engineering CO.,LTD.

2

Table of Contents

Chapter1 General Specification

Chapter2 Structure and Function

Instrumentation and Wiring

Operation Mechanism

Main Technical Parameters

Chapter3 Specification of Main Devices

Valve Body

Sensor

Electric Temperature Controller

Notice of Installing

Chapter4 System Operation

Starting

Method of Change Set Temperature

Operating process

Chapter5 Maintenance

Chapter6 Trouble Shooting

Chapter1 General Specification

Electric Automatic Temperature Regulating Valve (briefly called as Elect. Valve) are mainly used for

temperature auto-control of lubricant or fresh water in cooling system of power units in marine and other kinds

of ships, and also widely used in diesel engine, air compressors, lubricating equipment, generator sets etc. Our

products have the features of high accuracy, setting temperature easily, having alarm function. It is easy to be

centralized controlled by computer.

Chapter2 Structure and Function

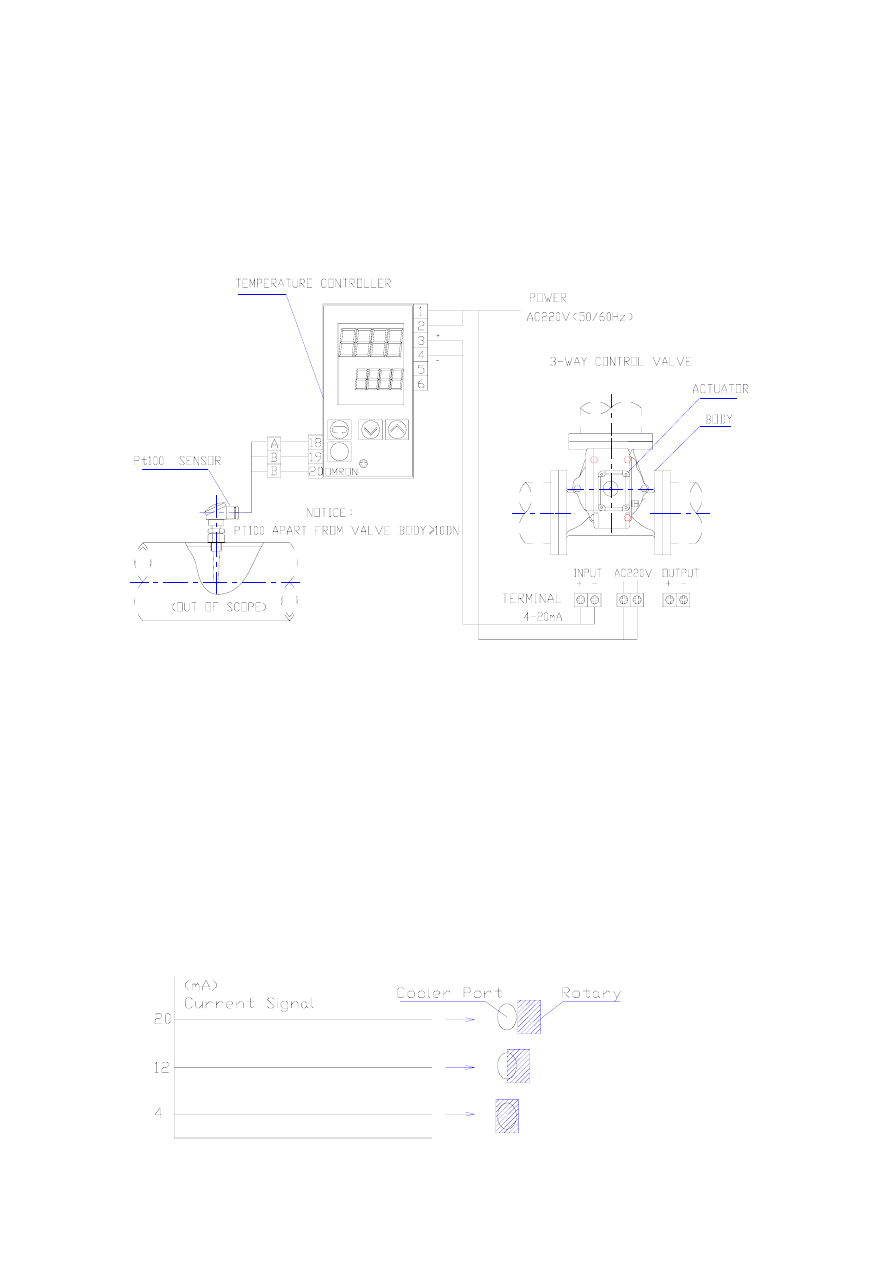

1. Instrumentation and Electrical Wiring Diagram

2. Operation Mechanism

The sensor (Platinum Resistance Thermometer) installed to the particular position for the desired control

in the piping detected the temperature of applied fluid to generate the resistance the which corresponds to each

temperature controller. The resistance value thus reaching the temperature controller causes the output current

4 mA to 20 mA to be delivered to the electrical motor. The signal current is then input to the positioner at the

main body driving section.

The rotor of the driving section is rotated in proportion to the signal currents, so that the flow rates on

both side B and side C are changed by the aperture adjustment at the said two sides made every moment in

accordance with the temperature variation.

As for the control by the temperature controller, advanced PID control with two degrees of freedom is

employed. The controller needs the shortest rise time, does not allow overshooting, and resumes a stabilized

condition very fast in the event of disturbance.

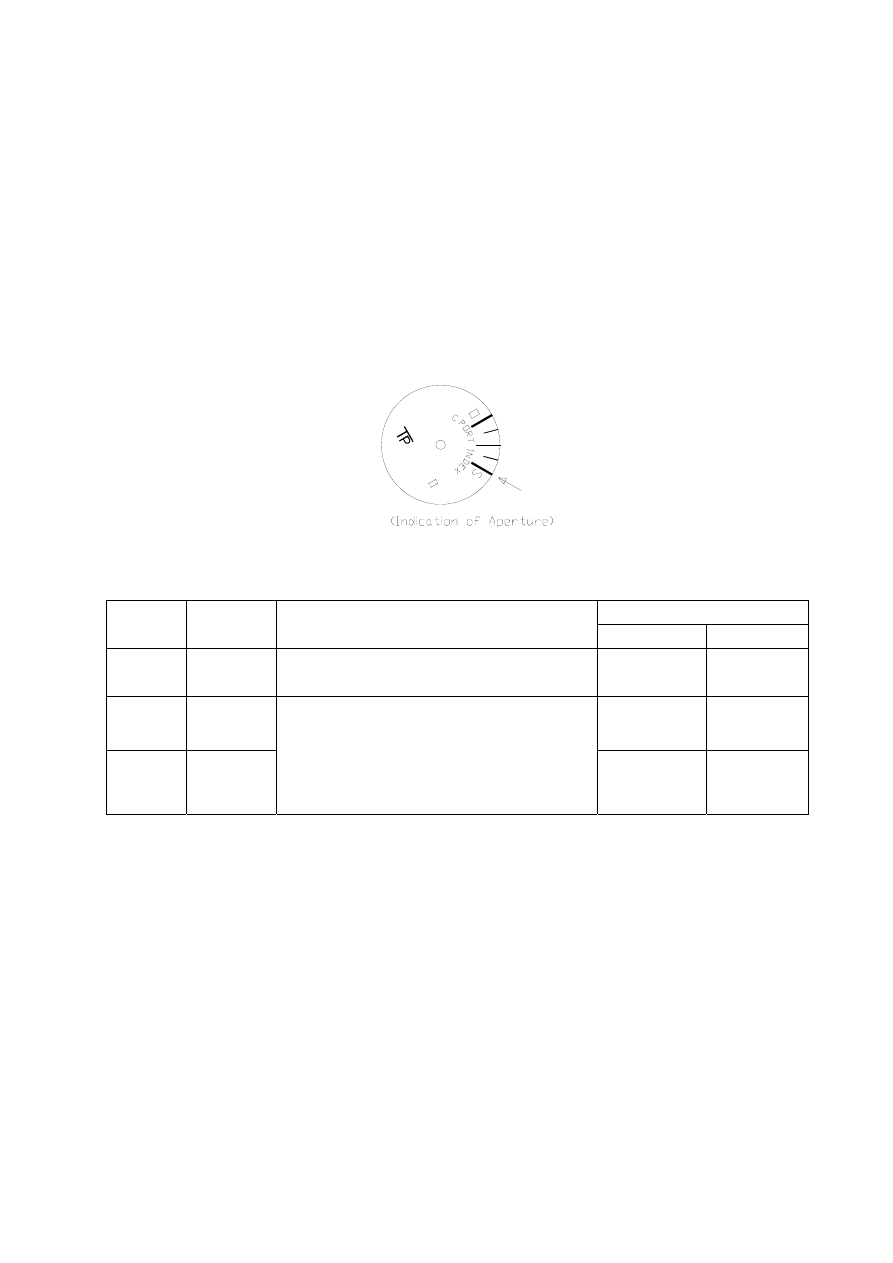

(*)Relationship Between Signal Currents and Aperture(In Case of Reverse Action)

3

3.

Main Technical Parameters

3.1 Working medium: Fresh water, Lubricant, Seawater;

3.2 The insensitivity of the Elect. Valve is not than 1℃;

3.3 The relative leakage of the Elect. valve for rotating type isn’t more than 3%;

3.4

The max working pressure of the Elect. valve is 1.0Mpa;

3.5 The Elect. Valve can be controlled manually;

3.6 The Elect. Valve works under the conditions:

a. Ambient Temperature:0~+55℃;

b. Ambient Humidity: 95%±3%;

c. Fog of oil and salt;

d. The rake and swing of each direction 22.5°,cycle 10s;

e. Shaking:frequency 2~13.2Hz,range 1mm;frequency 13.2~100Hz,acceleration 1G。

Chapter3 Specification of Main Devices

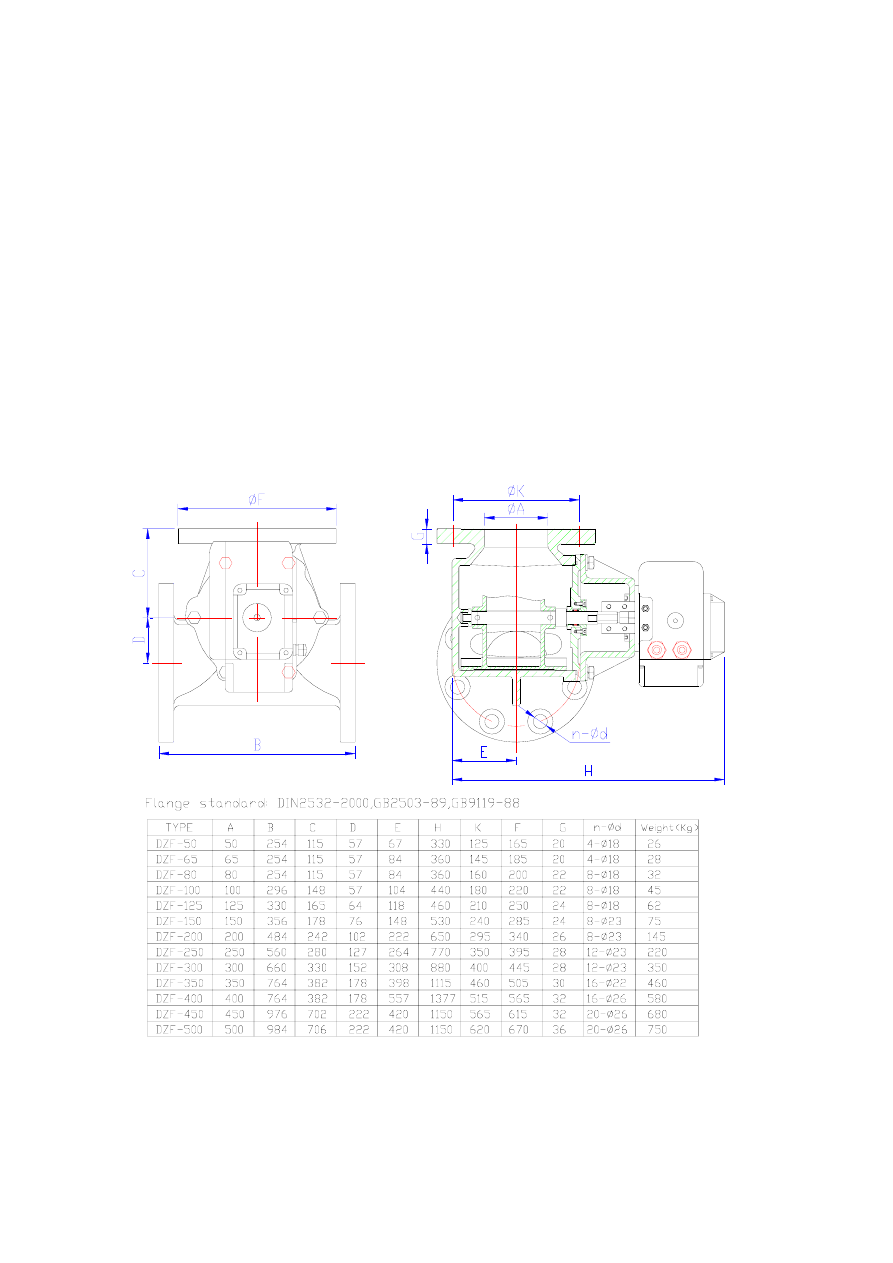

1. Valve Body

1.1 Outline, Installation and Main Sizes

4

1.2 The rated pressure of body is 1.0MPa,the pressure of test is 1.5MPa(5min)。

1.3 The main technical parameter of the electronic actuator:

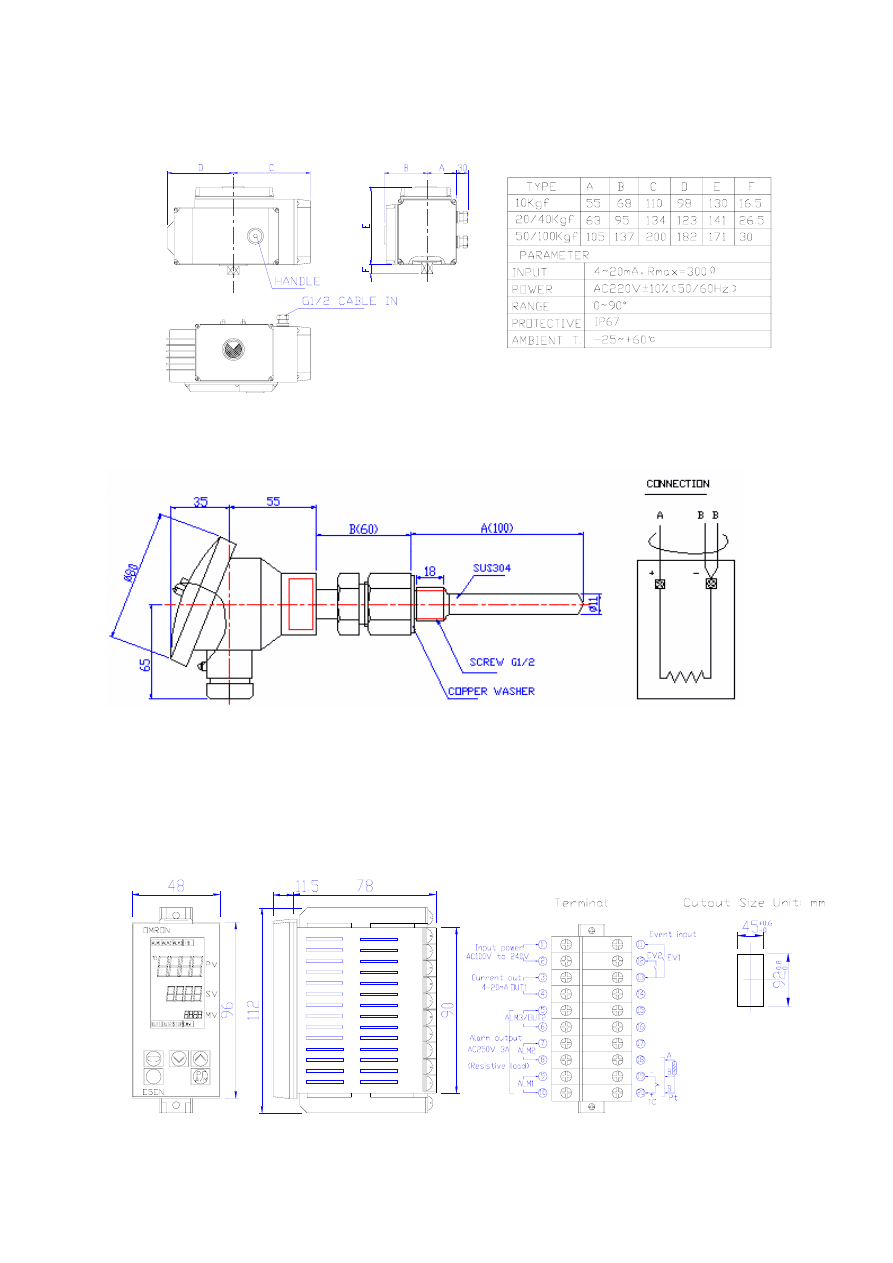

2. Sensor

2.1 Sensor is imported from Japan (PT100), with stainless steel socket. It’s outline is:

2.2 Technical parameter:

a. Range of temperature:0~+200℃;

b. Class of accuracy:B, △t=±(0.3+0.005|t|) ;

c. Class of protective: IP65;

3. Electric Temperature Controller

5

6

※NOTICE OF INSTALLING:

1. For installation in pipeline, over-force of pipe should be avoided in case the valve deformed.

2. The situation of valve is benefit to operate and service.

3. The pipe that the valve wants to be fixed must be thoroughly cleaned, and have no any foreign matter.

4. The electrical wire is must correct fully, otherwise maybe cause another component damaged.

Chapter4 System Operating

1. Starting

※Before turning on power, correct wiring and power type must be confirmed!

After turning on power, the temperature controller displays the previous value of temperature (PV) and

the setting value (SV).

NOTICE: According to “the temperature controller setup table (apex 1)”, the basic parameters of

temperature controller have been setup and locked before delivery. User do not setup it again, otherwise it

could cause the system to be out of order.

2. Method of Change Set Temperature

If the setting value of temperature needs changing, only push “↑” or “↓” key, OK!

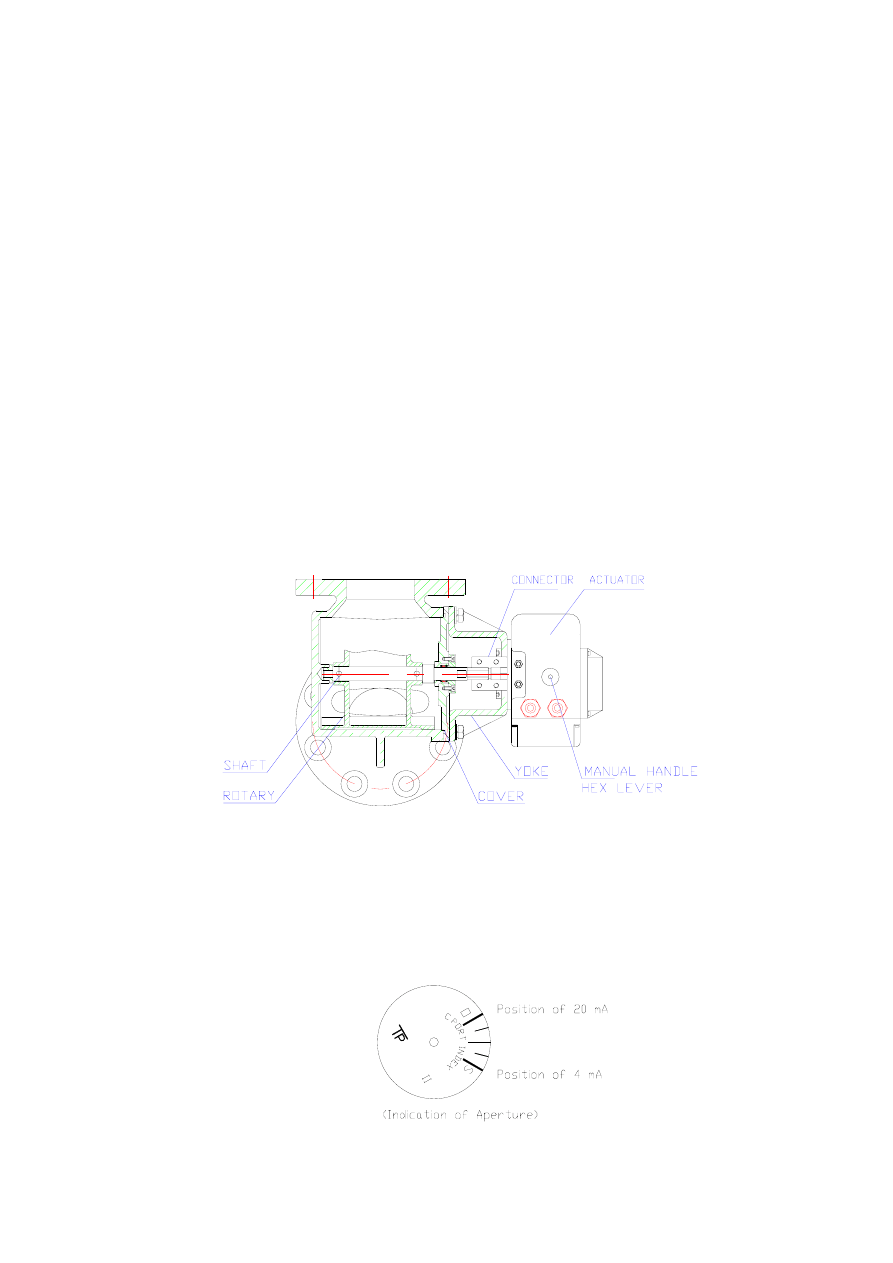

3. Actuator’s indication of opening degree

It indicates the relation of rotary to port C. “S”is port C closed fully. “O”is port C opened fully. The

middle indication is port C and port B opens half each other.

4. Working process

At beginning, the temperature of liquid is lower. PV<SV, port C is closed fully. Liquid flows from port A

to port B.

With the temperature rising, PV>SV, port C opens a little slowly and port B closes a little slowly. Liquid

flows from port A=port (B+C).

At last, PV is approaching SV. The system is stable.

Chapter5 Maintenance

Regular inspection

For keeping stable performance for years it is necessary to regularly inspect the valve system in the following

manner.

(1)Shutting off power ,regularly inspect the valve system using the manual lever(once a month). (The

manual lever must turn lightly with the valve gully open or closed.)

(2)Regularly overhaul the inside of the valve(once a year). In the case of seawater specifications, conduct

overhaul inspection twice a year to check conditions of rust. An O-ring (The bye ton) is used for sealing the

shaft. Change the O-ring when occurs water leakage due to its qualitative deterioration or wearing.(For its size,

see the last page.)

Method to overhaul the side of valves

(1)Seeing the opening degree indication of the electronic actuator, set Ⅰ-type to “S” side and Ⅱ-type to

“O” side . This can be done either by changing set values of the electronic temperature regulator or by

operating the manual lever, shutting off the power for the electronic actuator.

(2)Shut off the power for the electronic actuator and drain off the water inside the valve.

(3)Remove all 4 connecting metal fastening bolts.

(4)Remove yoke fitting bolts(valve side).

(5)Remove the electronic actuator together with yoke.

(6)Remove all cover fastening bolts.

(7)Take out the inner assembly together with the upper cover. Thus, disassembling the inside is completed.

So, follow the procedures given the below.

(8)Check if there is any rust or foreign matter inside the main unit. If any, take it out.

(9)Check if there is any foreign matter or abnormality on the upper cover and inner assembly.

(10)Check if there is any other abnormality(e.g. bending of shaft defective bearings, etc.).

(11)Insert the inner assembly together with the upper cover into the main unit.(Be sure to insert the cover

seal together).

(12)Fit cover fastening bolts(excluding bolts for the yoke).

(13)Install the electronic actuator and yoke and fasten their bolts.

(14)Turning the shaft, adjust the setting mark “.” of the shaft setting mark “.” of the electronic actuator.

(15)Fasten the connecting metal with 4 bolts.

(16)Turn on the power switch and the valve will function again with opening degrees to automatically

respond to signals and regulate the temperature accordingly.

The way of operating an drive part lever

When the temperature rises, it I possible to do manual lever operation in the time with power supply

malfunction, others malfunction.

(1)It makes a power supply off.

(2)It puts hexagon wrench in the manual operation part (the 6 corner hole) of actuator and it operates it.

Because it maintains in the fixed position, turn a lever in opening degrees with the temperature to want to

control.

(3)On the power supply when automatic results when extraordinary cause is removed and when results,

valve opening degrees does a temperature control in opening degrees which followed a signal automatically

about any position by the manual operation.

Chapter 6 Trouble shooting

When the temperature is abnormally high (for the case of reverse function)

(1)Is the electronic temperature controller transmitting control output? If transmitted, it must be less than

20mA. If it stays unchanged at 20mA,it can be said that the electronic temperature controller is out of order

and needs checking. (See the item concerning “Abnormality of the electronic temperature controller” in last

page)

(2)If the electronic temperature controller does not function properly while its control output is normal , it

7

can be considered that it is malfunctioning because of foreign matter, rust, etc. In such a case, follow the

instructions of Chapter 5 (Maintenance and Inspection.)

When it is found that the malfunction is not attributable to foreign matter or rust, it can be considered that

there exits some abnormality in the cooling capacity or the circulating water. So, check both accordingly.

Further, in case of the emergency it is possible to regulate temperature using the manual lever (see

“Method to handle the driving part lever” Chapter 5)

When the temperature is abnormally low (for the case of reverse function)

(1)Is the electronic temperature controller transmitting control output? If transmitted, it must be over than

4mA. If it stays unchanged at 4mA,it can be said that the electronic temperature controller is out of order and

needs checking. (See the item concerning “Abnormality of the electronic temperature controller” in last page)

(2)When the temperature is low while the opening degree indication is “S”, it can be considered that there

exist some other some other causes(in the piping system, etc.) So, check such accordingly.

When it is suspected that there has occurred a failure

Phenomenon: Nothing is indicated while the power switch is turned on.

Output (failure)

Display 1

Cause

Countermeasure

Control signal

Alarm output

5Err

Input

failure

Check the connection wiring of the sensor, and

check the type of the sensor.

no

High Temp.

yes

E111

Memory

failure

no no

HErr HB

failure

Turn off the power switch, and turn on again, if

failure code displays stilly. Thus the electronic

temperature controller needs checking.

If display is correctly, it can be said that

because of the noise, and check it.

no no

Nanjing TP Thermal Engineering CO.,LTD.

Adress:Nanjing Economic & Technological Development Zone No.6-1 Xingwen Road

Tel:025-85803553,85804180

Fax:025-85803776,85804180

P.C.:210038

8

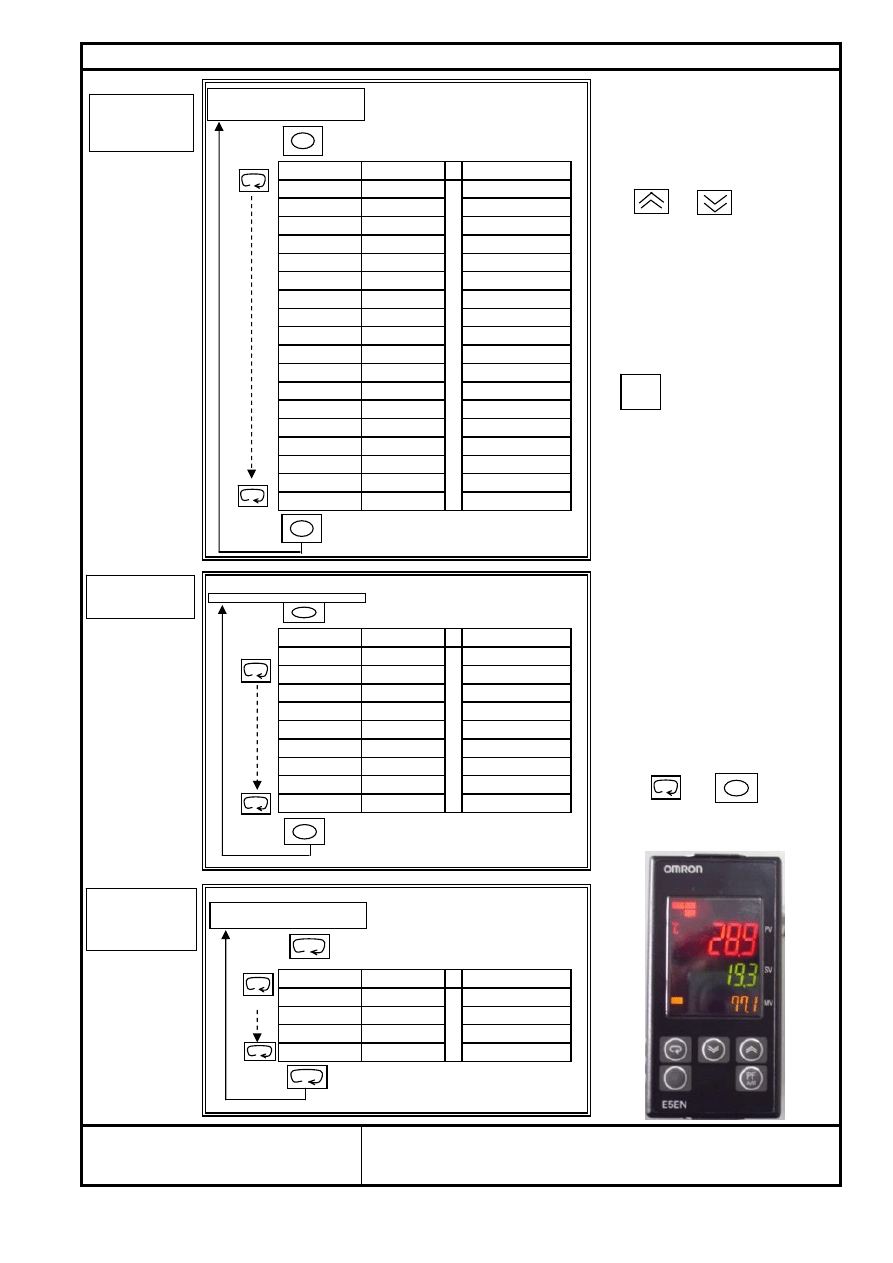

Temp. Controller Initial Setting(before delivery)

Note:

1、Each setting value varied by

display code

setting value

meaning

“upper”“down”key;

IN-t

3

input type

d-U

C

unit ℃/F

SL-H

500

upper limit

SL-L

-199.9

lower limit

2、Display value is setting value,

CNtL

PId

control type

and do not press any key to approval.

S-HC

StNd

standard

St

oFF

self-turning

3、Commissioning is prohibited in

PtRN

oFF

program pattern

the course of the two keys at the same

OREV

oR-d

direct operation

same time, otherwise they will enter

ALt 1

2

alarm 1 type

the state Dead.

ALH1

0.2

alarm 1 hysteresis

ALt 2

2

alarm 2 type

4、 Function key/auto/manual

ALH2

0.2

alarm 2 hysteresis

ALt 3

2

alarm 3 type

key press this function key to operate

ALH3

0.2

alarm 3 hysteresis

the function set with the PF setting .

tR-t

oFF

transfer output type

o1-t

4-20

liner output type

AMoV

0

5、In the initial interface.Regulate

"upper" and "down" key to Change

the temperature setting SV.

6、MV,Shows that the percentage

output.

display code

setting value

meaning

7.(protect level)

L.AdJ

adjustment level

1.OAPT(operation/adjustment): 2

At

oFF

AT cancel

2.ICPT(initial/communication): 2

IN5

0

input shift

3.WTPT(setting change): off

P

15

proportional band

4.PRLP(move to protect level): 0

I 100

integral

time

d

25

derivative time

SPRt

oFF

SP ramp set value

8、Unlock:

OL-H

105

Press and 3 seconds

OL-L

-5

1.OAPT(operation/adjustment): 0

2.ICPT (initial/communication): 0

display code

setting value

meaning

R-5

RUN

run/off

AL-1

5.0

deviation limit

AL-2

5.0

deviation limit

AL-3

5.0

deviation limit

CO.,Ltd

Temp.Controller Type:

E5EN-C3T-N

Nanjing TP Thermal Engineering

Hold down for at least 1 second

Hold down for at least 3 seconds

Press less than 1 second

Press less than 1 second

Press less than 1 second

Press less than 1 second

operation level

Initinal

setting

Adjustment

level

ti

l

l

operation level

Alarm value

setting

PF

A/M

Document Outline

Wyszukiwarka

Podobne podstrony:

08 INSTRUCTION MANUAL TEMPERATURE CONTROL VALVE 12160 3078

DJ F1 S1 Instruction Manual

Electrical Safety Student Manual

Electronic Flight Instruments System, Lotnicze różności

BSA Instruction Manual D14

Instruction Manual

ICOM instruction manual[1]

DJ F1 S1 Instruction Manual

09 INSTRUCTION MANUAL OIL PUMP 12143 3055 E

MALOWANIE LINJI easylineedge instruction manual

Electrolux ER 7326 C Manual

Electrolux ER 9096 B Manual

Instrukcja (manual) wymiany linek hamulca ręcznego (pomocniczego, awaryjnego) fiat punto I (1,1)

Electrolux ERB4010AC Instrukcja

102003BGA Reballing Instruction Manual

Electrolux ERB 4032 Manual

#0449 – Using an Instruction Manual

06 INSTRUCTION MANUAL FUEL OIL FILTER 12153 3188 E

07c John Ashbery The Instruction Manual

więcej podobnych podstron