Assessment of the fertiliser potential of digestates from farm

and agroindustrial residues

Jose´ Antonio Alburquerque

, Carlos de la Fuente

, Alicia Ferrer-Costa

, Lucı´a Carrasco

Juan Cegarra

, Manuel Abad

, Marı´a Pilar Bernal

a

Department of Soil and Water Conservation and Organic Waste Management, Centro de Edafologı´a y Biologı´a Aplicada del Segura,

CSIC, P.O. Box 164, 30100 Murcia, Spain

b

Instituto Agroforestal Mediterra´neo, Universidad Polite´cnica de Valencia, P.O. Box 22012, 46071 Valencia, Spain

a r t i c l e i n f o

Article history:

Received 22 February 2011

Received in revised form

11 February 2012

Accepted 22 February 2012

Available online 14 March 2012

Keywords:

Anaerobic co-digestion

Digestate composition

Agroindustrial residues

Biodegradability

Phytotoxicity

a b s t r a c t

The sustainability of biogas production systems depends greatly on the appropriate

disposal of the digestates produced. The main agrochemical characteristics of 12 digestates

from the anaerobic co-digestion of farm and agroindustrial residues were determined and

compared with quality standards to assess their potential use as fertilisers. The digestates

have a high fertilising potential, associated mainly with their contents of NH

4

-N; however,

their recycling in agriculture might be restricted by their Cu and Zn contents, salinity,

biodegradability, phytotoxicity and hygiene characteristics, which must be addressed to

obtain the maximum benefits. Such characteristics determine the need for applying pre- or

post-treatments to increase digestate quality until acceptable levels. Therefore, digestate

quality must be taken into account when managing the co-digestion process, including

substrate selection, in order to use digestates as fertilisers without the additional cost of

post-digestion conditioning treatments.

ª 2012 Elsevier Ltd. All rights reserved.

1.

Introduction

The non-renewable nature of fossil energy sources and their

contribution to global warming have caused a great, world-

wide interest in the development and implementation of

renewable energy programmes. In this context, technologies

such as anaerobic digestion - for which the share of the

renewable energy market is increasing - play a major role,

leading to benefits for residue management, energy supply

and the environment

.

The vast amounts of biodegradable residues and by-

products produced by the livestock and agroindustrial

sectors have a large potential for biogas production through

co-digestion. This constitutes a great incentive for the

implementation of the anaerobic co-digestion of animal

manures and slurries with other residues, as put forward in

the Spanish Slurry Biodigestion Plan

.

Anaerobic digestion produces biogas and a very-wet

residue called digestate which is a mixture of partially-

degraded organic matter (OM), microbial biomass and inor-

ganic compounds. The direct application of digestates to soil

is currently considered an inexpensive means for their

disposal and for recovery of their mineral and organic

constituents for agricultural systems. During anaerobic

digestion, labile organic constituents are mostly degraded,

leading to an increase in the stability of the remaining OM

contained in the digestate

. However, the prevalence of

efficiency criteria for energy production (biogas) at an

* Corresponding author. Tel.:

þ34 968 396313; fax: þ34 968 396213.

E-mail addresses:

(J.A. Alburquerque).

Available online at

http://www.elsevier.com/locate/biombioe

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

0961-9534/$

e see front matter ª 2012 Elsevier Ltd. All rights reserved.

industrial scale can lead to a limited residence time of the

material in the digester (after which energy efficiency starts to

decline); this can produce a digestate that is not completely

exhausted in terms of easily-degradable organic compounds.

This may generate problems during storage (odour emission,

production of toxic compounds, pathogen re-growth and

phytotoxicity) and cause unfavourable impacts on the soil-

plant system, thus limiting the potential fertilising value of

digestate when unstable materials are added to soil

.

These can cause an extensive range of deleterious effects on

crops, such as prevention or delay of seed germination, plant

death or marked reductions in growth, which must be

addressed. Bioassays incorporating plant material are simple,

reproducible, rapid and economic tests that identify phyto-

toxic materials.

On the other hand, the agricultural use of digestates should

be considered as a recovery process instead of a simple

disposal method. But, the market demand for digestates as

soil conditioners or fertilisers depends on the compliance with

quality standards, as regulated by European and national

guidelines

as well as by quality protocols for digestate

application in Germany

and the United Kingdom

. In

Spain, no specific, applicable standards for digestates, which

would favour their use in agriculture, have been developed -

which represents a major barrier for the development of

anaerobic digestion.

In this study, the main agrochemical characteristics of

a number of digestates, including phytotoxicity, have been

determined, by analysing twelve samples from several,

representative co-digestion processes carried out in Spain,

and then compared to the quality criteria established in order

to assess their potential use as fertilisers in agricultural

systems.

2.

Materials and methods

2.1.

Digestate origin and sampling

After the anaerobic co-digestion of twelve mixtures incorpo-

rating pig (PS) or cattle (CS) slurries as major components, the

corresponding,

representative

digestate

samples

were

collected for analysis. According to the origin of the digestate,

the samples were classified into the following four groups

(on a fresh mass basis):

- From PS plus energy crop residues (PS-EC):

þ9.6% rape

residue (PS-EC1),

þ4.5% sunflower residue (PS-EC2) and

þ5.4% corn residue (PS-EC3).

- From PS plus animal by-products (PS-AB):

þ0.6% pasteurised

slaughterhouse

residues

(PS-AB1),

þ3.8% pasteurised

slaughterhouse residues (PS-AB2) and

þ1.0% sludge from

a slaughterhouse wastewater treatment plant

þ6.5% bio-

diesel wastewaters (PS-AB3).

- From CS plus glycerine (CS-G):

þ4% glycerine (CS-G1) and

þ6% glycerine (CS-G2 and CS-G3).

- From CS plus agroindustrial residues (CS-AW):

þ5% orange

peel residue (CS-AW1),

þ10% orange peel residue (CS-AW2)

and

þ4.3% cattle manure þ11.6% maize-oat silage

(CS-AW3).

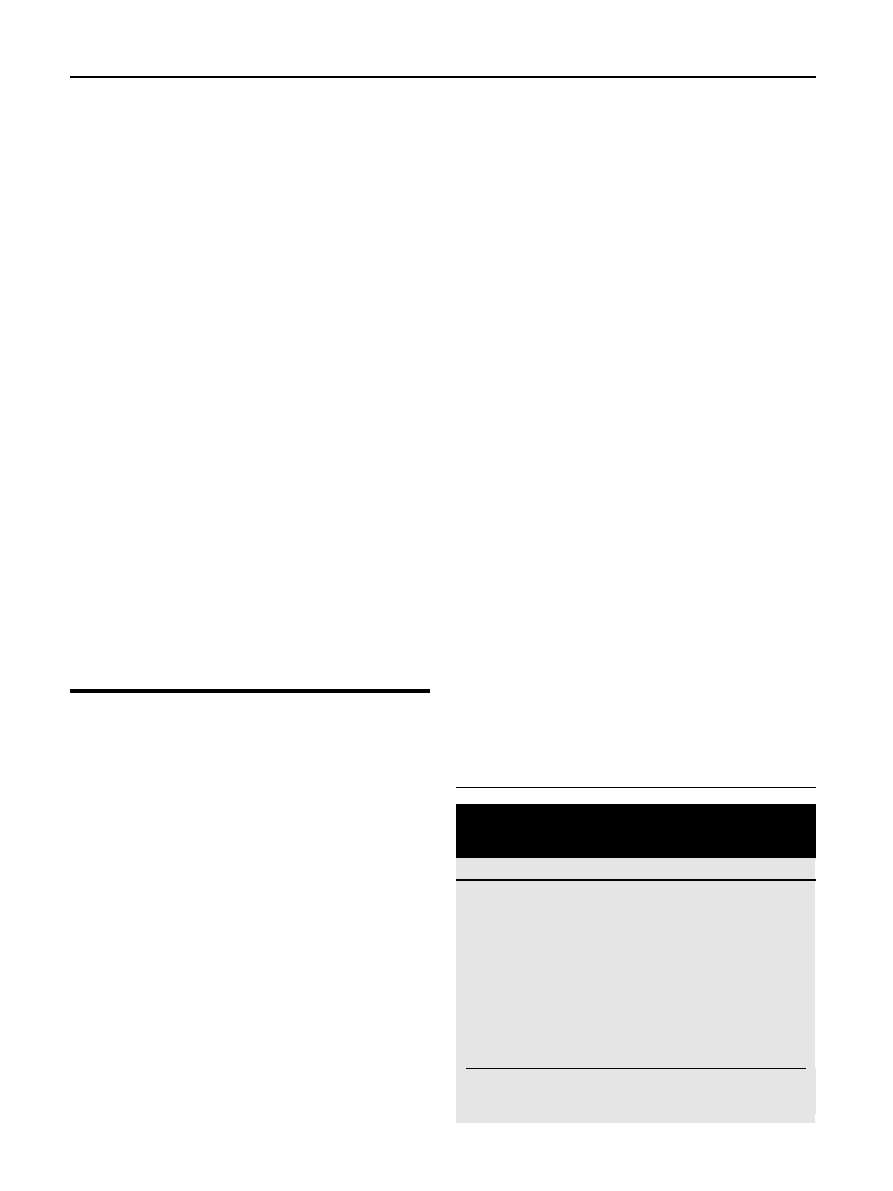

As shown in

, these samples included two diges-

tates derived from industrial processes (PS-AB3 and CS-AW3),

while the rest came from laboratory-scale experiments run in

order to optimise biogas production by using co-substrates

such as glycerine or orange peel residues (for CS) and

slaughterhouse or energy crop residues (for PS). The diges-

tates were sampled directly after anaerobic digestion

processes (without post-treatments), stored at a temper-

ature

< 4

C and processed quickly to prevent chemical or

biological alterations.

2.2.

Analytical methods for digestate characterisation

The following parameters were determined in the fresh

digestate samples: electrical conductivity (EC) and pH; dry

matter content (DM) after drying the digestate sample at

105

C for 24 h; the volatile solids, which reflect the OM

content, by loss on ignition at 500

C for 24 h. The total organic

carbon (TOC) and total nitrogen (TN) were measured in freeze-

dried samples, by automatic microanalysis (EuroVector

elemental analyser). The dissolved organic carbon (DOC) was

measured after filtration of the fresh digestate (through

a synthetic filter with a pore diameter of 0.45

mm), using an

automatic analyser for liquid samples (TOC-V CSN Analyzer,

Shimadzu). Ammonium was determined by steam-distillation

from alkalised fresh samples with MgO, and chloride (Cl) by

potentiometry with silver nitrate. After HNO

3

/HClO

4

(2:1 v/v)

digestion, the following elements were determined by induc-

tively coupled plasma-optical emission spectrometry (ICP-

OES, Thermo Elemental Co. Iris Intrepid II XDL): P, K, S, Na, Ca,

Mg, Fe, Cu, Mn, Zn, B, Pb, Cd, Cr and Ni. The 5 d biochemical

oxygen demand (BOD

5

) was determined, with respirometric

Oxitop

IS 6 equipment (WTW, Germany), based on pressure

measurement, which is automatically computed as an oxygen

value with units of mg L

1

. In the Oxitop

equipment, the

cumulative oxygen consumption was recorded each day

during a period of 5 d. Salmonella spp. and Escherichia coli were

determined according to the modified method of the USEPA

Table 1

e The main technical aspects of the anaerobic co-

digestion processes which produced the 12 digestates

studied.

Digestate

Operation

Scale

Temperature (

C)

HRT (d)

PS-EC1

CONT

LS

35

30

PS-EC2

CONT

LS

35

30

PS-EC3

CONT

LS

35

30

PS-AB1

CONT

LS

35

20

PS-AB2

CONT

LS

35

30

PS-AB3

CONT

IS

37

21

CS-G1

DISCONT

LS

35

40

CS-G2

DISCONT

LS

35

40

CS-G3

CONT

LS

55

22

CS-AW1

DISCONT

LS

38

28

CS-AW2

DISCONT

LS

38

40

CS-AW3

CONT

IS

38.5

25

CONT: continuous operation, DISCONT: discontinuous operation,

LS: laboratory-scale (2 L to 6 L digester), IS: industrial-scale (3000 m

3

digester), and HRT: hydraulic residence time.

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

182

and the most probable number (MPN) method

,

respectively.

2.3.

Potential phytotoxicity

To obtain homogeneous samples, the 12 digestate samples

were sieved (0.25 mm mesh-size) and then centrifuged. The

supernatants thus obtained were shaken and tested in

bioassays involving seed germination and seedling growth,

with both cress (Lepidium sativum ‘Alenois’) and lettuce (Lac-

tuca sativa ‘Bionda degli Ortelani’).

2.3.1.

Seed germination bioassays

In these bioassays, the Petri dishes used (8.5 cm diameter)

each contained 2 filter papers (base and cover), which were

moistened with 1 mL of the digestate. Digestate samples were

tested at concentrations of 100% (pure), 20%, 10%, 1% and 0.1%

(volume fraction), which were prepared with distilled water.

Ten seeds per dish were sown and each experimental treat-

ment was replicated 5 times. The dishes were transferred to

a germination chamber under controlled conditions of

temperature (17

C and 23

C for lettuce and cress, respec-

tively) and darkness for 3 d (cress) or 5 d (lettuce). After this

period, the number of germinated seeds was counted, the

radicle lengths of these seeds measured and the germination

index (GI) calculated as a percentage of the control (distilled

water), according to Zucconi et al.

2.3.2.

Plant growth bioassays

Plastic cell trays (10 cells/tray and 33 mL/cell), with a drainage

hole in the bottom of each cell, were filled with horticultural

perlite (1 mm

e2 mm in diameter) and used for these bioas-

says. Trays (in triplicate for each treatment tested) were

placed in a holder vessel (18 cm

6.5 cm 5 cm) - containing

400 mL of distilled water - for 24 h, until the perlite was

saturated by capillarity. Then, 2 seeds of cress or lettuce per

cell were sown and maintained under the same wetting

conditions for 9 d or 13 d, respectively, until seed germination

and seedling emergence occurred (and only 1 seedling/cell

was left). After this period, the water in the holder vessel was

replaced completely by 200 mL (equivalent to the perlite

container volume) of the digestate concentrations to be

examined: 20%, 10%, 1% and 0.1%, keeping trays without

digestate addition as a control. Pure digestate was not tested

for plant growth bioassays since GI was 0% for all the digestate

samples. In these bioassays, and due to the limited availability

of adequate volumes of the samples obtained from the raw

digestates, only 7 co-digestion mixtures were studied: PS-EC1,

PS-EC2, PS-EC3, PS-AB2, PS-AB3, CS-G3 and CS-AW3. Imme-

diately following the sowing, the trays and their holder vessels

were transferred to a growth chamber with controlled condi-

tions: 17

C (lettuce) and 23

C (cress) during the first

week, followed by 19

C (lettuce) and 21

C (cress)

during the remaining 3 weeks. During the bioassay, the daily

photoperiod was 16 h at a photosynthetic irradiance of

250

mmol m

2

s

1

provided by fluorescent tubes (Sylvania Cool

White VHO). Solution losses from the holder vessels (by plant

uptake

þ evaporation) were restored periodically using

distilled water. From the second week, a liquid, mineral

compound fertiliser (Hesi Coco

, The Netherlands; N-P

2

O

5

-

K

2

O 24:21:27, at 3 or 1.5 mL per L distilled water for cress and

lettuce, respectively) was added (in 3 successive applications)

to the digestate solutions to maintain seedling growth. At the

end of the experiment (4 weeks from sowing), 5 seedlings per

tray were harvested and their total dry mass (shoot

þ roots)

determined after drying at 105

C.

2.4.

Statistical analyses

Basic statistical analyses of data, correlation coefficients and

regression models were produced using the SPSS 18.0 program

for Windows. The normal distribution of the data was checked

by the Shapiro-Wilk’s test, and failed data were adjusted to

a normal distribution through logarithmic transformation.

3.

Results and discussion

3.1.

Physico-chemical characterisation

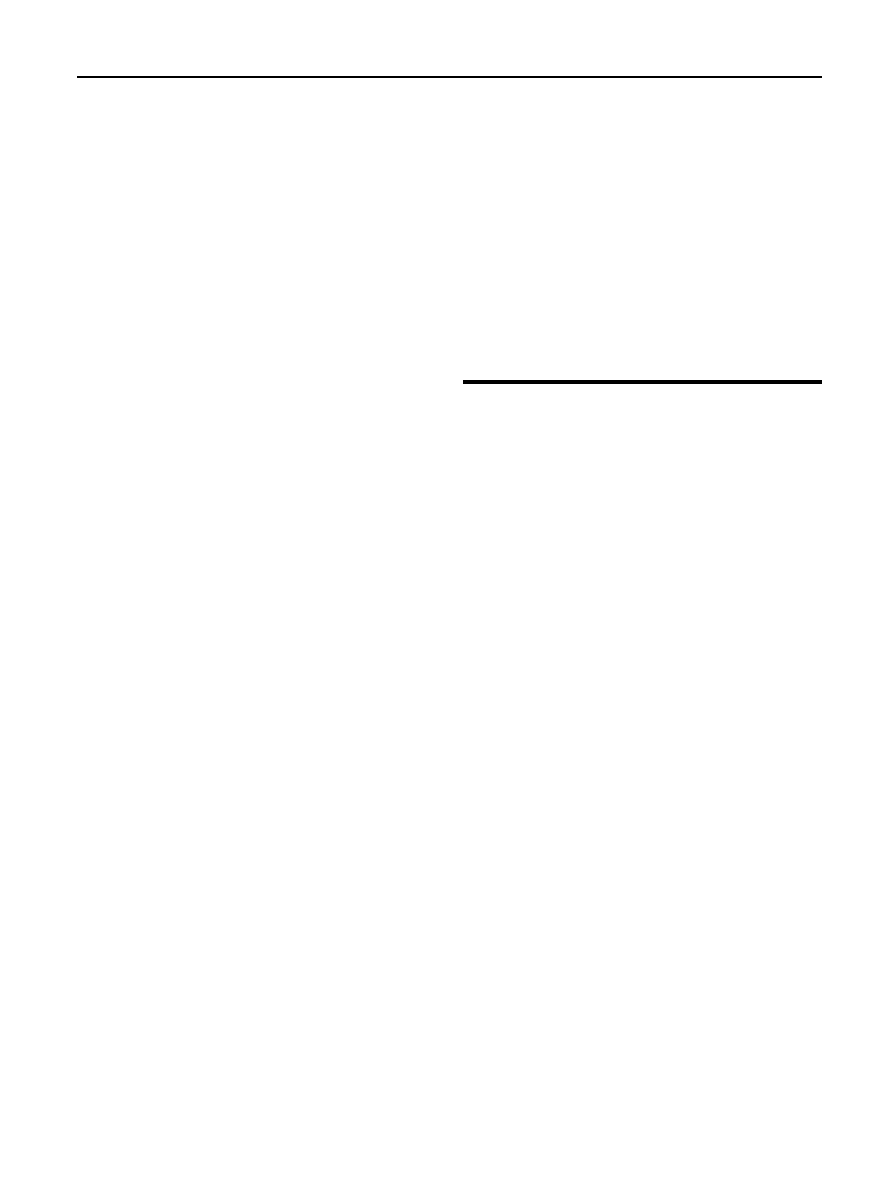

All digestate samples had low dry matter contents (

these

being

classified

as

liquid

products

(DM

mass

fraction

15%

). They were characterised by slightly-

alkaline pH values (

> 7.5), except in the case of CS-G1 and

CS-G3. The trend is for the pH to increase as anaerobic

digestion progresses, due to volatile fatty acid degradation

and ammonia production

. In addition, the pH is also

conditioned by the addition of strong bases or carbonates to

control pH and the buffer capacity of the system during

anaerobic digestion

. Generally, the pH of digestates derived

from animal slurries is in the alkaline range, around 8

.

The highest EC values were found in the PS digestates and

the CS-AW3 sample (

> 20 dS m

1

,

), which also had the

highest concentrations of Cl, while CS-G1, CS-G2 and PS-AB2

exhibited the highest Na concentration (

). Therefore,

special care must be taken since excessive doses or continued

applications of digestates rich in Cl and Na to soils could lead

to an increase in soil salinity and inhibit plant growth.

Regarding the plant nutrient content and hence the fertil-

iser value, the most-significant property of the digestates was

that a large proportion of the N occurred as inorganic forms

(

), representing NH

4

-N more than 70% of the TN (on

a mass basis) in the PS mixtures and 39%

e61% in mixtures

with CS. This form of N can be easily lost by ammonia vola-

tilisation during storage and land spreading due to the alka-

line pH of the digestates

. In addition, NH

4

-N is nitrified

rapidly in soil under favourable conditions, this form being

highly available to crops but also subjected to leaching

through the soil profile, which may result in groundwater

pollution. Therefore, storage and land spreading operations

with digestates must be carefully controlled to avoid negative

environmental impacts.

The TOC/TN ratio was highest for CS-AW3, CS-G1, CS-G2

and CS-G3 (

> 8), clearly higher than the mean value of 4

reported by Siebert et al.

for digestates from different

sources. Unbalanced C/N ratios in digestates can limit their

use in agriculture, as an excess of degradable organic

substrate for microorganisms with respect to N leads to

immobilisation of this nutrient in the microbial biomass and

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

183

to crop deficiency, while excess N causes losses through

ammonia volatilisation, nitrate leaching, etc.

.

The nutrient concentrations of the digested materials were

within the range found by other authors

. As a whole, the

major elements were N and K, followed by P and Ca (

). PS-EC1, PS-EC2 and PS-EC3 together with PS-AB2 and

CS-AW3 showed the highest concentrations of P, K, Ca and

Mg, whereas the S concentration was generally higher in PS

samples than in those from CS mixtures (

). From the

standpoint of quality criteria for digested materials

, no

limits have been established for their nutrient contents,

although a number of parameters should be declared,

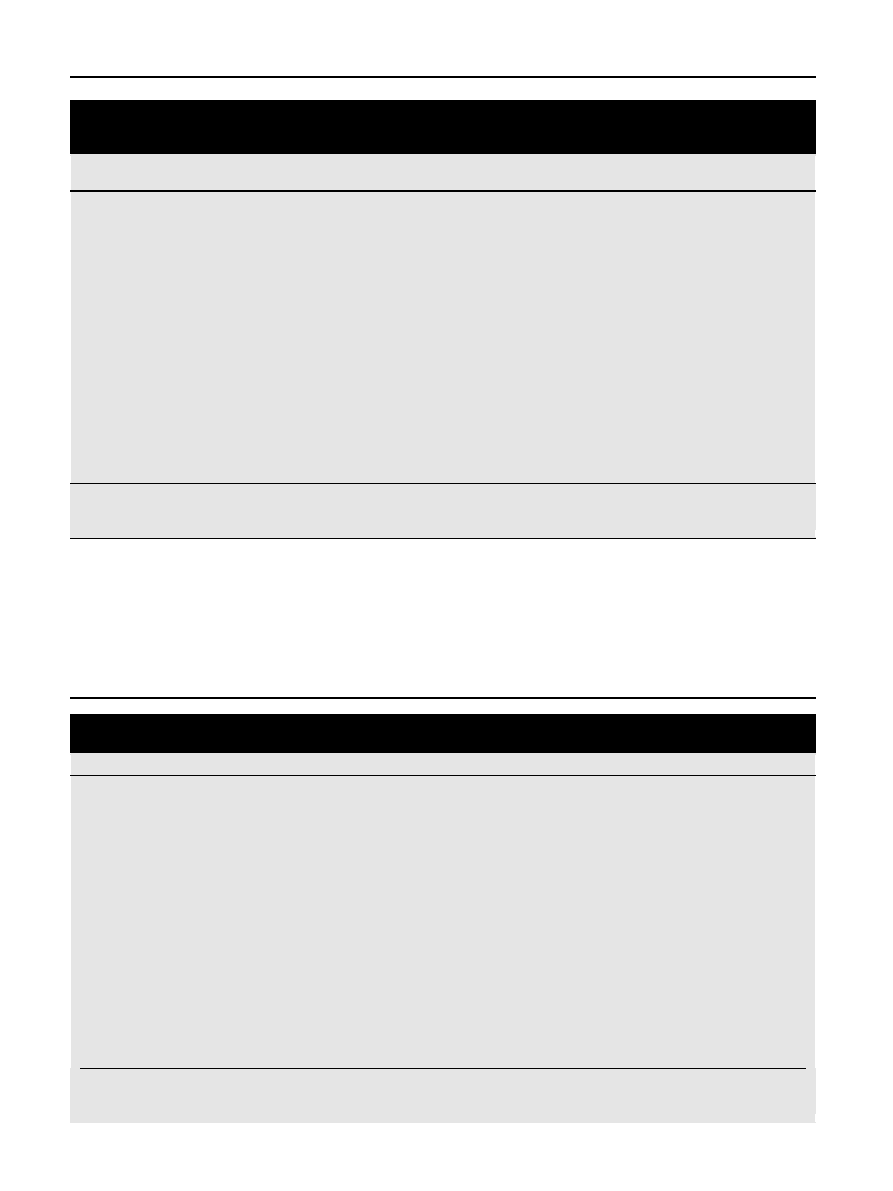

Table 3

e The concentrations (mg L

L1

) of elements in the 12 digestate samples (mean value, expressed on a fresh mass

basis). CV: coefficient of variation.

Digestate

S

Ca

Mg

Na

Cl

Fe

Mn

Zn

Cu

B

Pig slurry

PS-EC1

401

1993

633

666

1574

155

22.9

49.2

8.4

3.2

PS-EC2

367

1970

721

699

1495

143

23.4

45.9

7.0

3.2

PS-EC3

417

1863

698

697

1613

224

31.0

62.5

7.8

2.7

PS-AB1

219

799

324

696

1598

51

11.4

84.4

14.3

2.2

PS-AB2

302

828

365

995

2120

63

15.4

140.2

15.1

3.1

PS-AB3

680

218

67

726

1993

22

2.9

34.7

4.0

2.3

Median

384

1345

499

698

1606

103

19.1

55.8

8.1

2.9

(CV)

(39.3)

(59.4)

(55.4)

(16.5)

(14.9)

(69.9)

(56.1)

(55.6)

(46.2)

(16.5)

Cattle slurry

CS-G1

180

1550

267

1164

685

117

13.7

18.1

10.8

1.8

CS-G2

265

1753

333

1842

665

165

17.1

28.3

13.0

4.8

CS-G3

48

192

79

66

448

95

3.2

10.6

1.4

1.3

CS-AW1

113

1008

257

276

366

30

6.0

7.7

2.8

1.7

CS-AW2

131

1035

314

303

452

39

6.9

8.0

3.1

3.5

CS-AW3

457

4026

698

746

1418

301

27.5

27.7

10.8

3.4

Median

155

1293

290

525

558

106

10.3

14.4

6.9

2.6

(CV)

(73.2)

(82.1)

(62.8)

(91.6)

(57.6)

(80.4)

(72.8)

(56.8)

(72.8)

(49.4)

ANOVA

a

NS

NS

NS

NS

**

NS

NS

*

NS

NS

NS: not significant. * and **: significant at probability level P

< 0.05 and P < 0.01, respectively.

a considering the following grouped mixtures: pig slurry

þ energy crop residues (PS-EC1, -2 and -3), pig slurry þ animal by-product (PS-AB1, -2

and -3), cattle slurry

þ glyceryne (CS-G1, -2 and -3) and cattle slurry þ agroindustrial residues (CS-AW1, -2 and -3).

Table 2

e The main characteristics and composition of the 12 digestate samples (mean value, expressed on a fresh mass

basis). EC: electrical conductivity, DM: dry matter, TOC: total organic carbon, DOC: dissolved organic carbon, BOD

5

: 5

d biochemical oxygen demand, TN: total nitrogen and CV: coefficient of variation.

Digestate

pH

EC

(dS m

1

)

DM

(g L

1

)

TOC

(g L

1

)

DOC

(g L

1

)

BOD

5

(g L

1

)

TN

(g L

1

)

NH

4

-N

(g L

1

)

P

(g L

1

)

K

(g L

1

)

TOC/TN

Pig slurry

PS-EC1

7.82

26.0

43.9

14.7

4.3

6.5

3.6

2.9

1.1

3.1

4.1

PS-EC2

7.92

24.1

38.3

12.2

3.7

4.0

3.5

2.6

1.1

3.1

3.5

PS-EC3

7.90

23.3

28.3

8.3

3.7

4.7

3.4

2.7

1.2

2.7

2.4

PS-AB1

7.95

21.1

21.0

5.8

1.2

2.3

2.9

2.2

0.5

2.2

2.0

PS-AB2

7.86

30.8

29.5

8.4

3.5

6.2

4.9

3.4

0.8

3.1

1.7

PS-AB3

8.20

30.3

19.5

5.9

2.4

2.2

4.0

3.5

0.2

2.0

1.5

Median

7.91

25.0

28.9

8.4

3.6

4.4

3.6

2.8

0.9

2.9

2.2

(CV)

(1.7)

(15.2)

(31.8)

(38.6)

(35.6)

(43.7)

(18.2)

(16.9)

(50.9)

(18.2)

(40.9)

Cattle slurry

CS-G1

5.64

14.5

38.3

17.8

10.6

37.5

1.9

1.0

0.5

1.8

9.5

CS-G2

7.35

11.7

72.9

42.8

27.6

52.5

2.3

0.9

0.4

1.6

18.5

CS-G3

6.35

5.2

17.6

8.3

8.2

10.6

0.6

0.4

0.1

0.8

13.6

CS-AW1

7.86

8.7

24.4

9.4

1.2

1.3

1.4

0.8

0.2

1.1

6.6

CS-AW2

7.90

10.0

17.6

5.8

1.0

1.2

1.5

0.9

0.2

1.2

3.8

CS-AW3

7.50

25.7

90.1

33.7

5.4

5.9

4.0

2.4

0.8

3.1

8.5

Median

7.42

10.9

31.4

13.6

6.8

8.3

1.7

0.9

0.3

1.4

9.0

(CV)

(12.8)

(56.2)

(71.0)

(77.5)

(109.6)

(118.9)

(58.0)

(67.1)

(71.9)

(49.8)

(52.2)

ANOVA

a

*

*

NS

NS

*

**

NS

**

*

NS

***

NS: not significant. *, ** and ***: significant at probability level P

< 0.05, P < 0.01 and P < 0.001, respectively.

a considering the following grouped mixtures: pig slurry

þ energy crop residues (PS-EC1, -2 and -3), pig slurry þ animal by-product (PS-AB1, -2

and -3), cattle slurry

þ glyceryne (CS-G1, -2 and -3) and cattle slurry þ agroindustrial residues (CS-AW1, -2 and -3).

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

184

including: bulk density, DM, OM, pH, salt content, TN, P

2

O

5

,

K

2

O, CaO, MgO, S, NH

4

-N, NO

3

-N, micronutrients, Cl and Na.

In the current Spanish legislation for fertilisers

,

minimum limits for N, P and K contents are specified for

marketable

liquid

organo-mineral

fertilisers.

However,

according to the legal requirements, digestates cannot be

considered balanced fertiliser products and they must be

complemented with other inorganic fertilisers. Another

significant limitation is the digestate TOC content, generally

lower than the required concentration (

> 4% on a mass basis).

Therefore, the inclusion of a new fertiliser category in the

current Spanish legislation, specifically considering digestate

composition, may be advisable.

The most-abundant micronutrient in the digestates was Fe

(

), CS-AW3 having the highest value due to the use of Fe

salts during its anaerobic digestion. High concentrations of Cu

and Zn were found in the digestates due to the use of pig and

cattle slurry as the major co-digestion substrates, since these

two elements are frequently used as additives - to prevent pig

and cattle diseases and to stimulate livestock growth. The Cu

and Zn concentrations were especially high in digestates

arising from PS mixtures (on a dry mass basis): (76

e682)

mg kg

1

, with a median value of 173 mg kg

1

for Cu, and

(222

e4757) mg kg

1

with a median value of 446 mg kg

1

for Zn.

Some values were higher than the established limits

, so

special care must be taken with respect to Cu and Zn

concentrations, especially for digestate produced from PS.

With respect to heavy metals, the concentrations on a dry

mass basis in some digestate samples for Ni (n

¼ 7, 6 mg kg

1

to 36 mg kg

1

), Pb (n

¼ 7, 11 mg kg

1

to 46 mg kg

1

), Cr (n

¼ 2,

3 mg kg

1

and 55 mg kg

1

) and Cd (n

¼ 6, 0.1 mg kg

1

to

1.0 mg kg

1

) were lower than both the limits established by the

cited Spanish legislation and the quality protocols for the

production and use of digestates

. The concentrations of

heavy metals found in this study were similar to those

reported previously for digested materials from substrates of

different origin

.

Our results reveal the influence of the raw materials on the

digestate characteristics. The coefficients of variation (

) of most of the parameters analysed reveal, in general,

a high degree of variability. Thus, digestates should be ana-

lysed fully before use. However, highly-significant correla-

tions between the DM and parameters such as TOC, Ca and Fe

were found, while TN, NH

4

-N, K, S, Zn and Cl were correlated

significantly with EC (

), indicating their preferential

association with the solid or liquid digestate fraction,

respectively.

The use of regression equations based on highly-

significant correlations between EC and ionic species (NH

4

þ

,

K

þ

, etc.) resulted in a reliable tool for providing a quick esti-

mation of nutrient contents in animal slurries

. As

a result, the EC and DM of digested materials can be used

successfully to estimate other valuable and useful parameters

which are much-more difficult and time-consuming to

analyse (

) and which, together with BOD or DOC data,

characterise the quality of digested materials, as discussed in

the following section.

3.2.

Digestate biodegradability

The digestate samples showed a great variability in their

degree of stability, according to the BOD

5

values (

These results indicate the great influence on digestate

stability not only of the raw materials used as co-digestion

substrates but also of the co-digestion process, as shown by

the clear differences in the organic load and its biodegrad-

ability among digestate samples from cattle slurry

þ glycerine

mixtures (CS-G). The CS-G digestates showed BOD

5

values

that were clearly higher than those of the other digestates

tested (

), indicating that they had the lowest degree of

microbial stability, associated with the presence of easily-

degradable compounds. The industrial digestate sample

(CS-AW3) had the highest DM content of all the digestates

produced from CS mixtures, but only 16% of the TOC occurred

as DOC, which led to a higher degree of stability (less biode-

gradable material) than for the digestates from CS-G mixtures.

This is related to the use of cattle manure and, especially,

silage (solid lignocellulosic materials) as co-substrates for

Table 4

e Correlation matrix between selected parameters related to the digestate composition (n [ 12).

Parameters

DM

EC

TOC

TN

NH

4

-N

P

K

Ca

Mg

Fe

Mn

Zn

Cl

DM

1

EC

NS

1

TOC

0.946***

NS

1

TN

NS

0.973***

NS

1

NH

4

-N

NS

0.984***

NS

0.951***

1

P

NS

0.607*

NS

0.644*

0.599*

1

K

NS

0.875***

NS

0.900***

0.837**

0.878***

1

Ca

0.856***

NS

0.725**

NS

NS

0.612*

0.577*

1

Mg

0.584*

NS

NS

NS

NS

0.923***

0.780**

0.800**

1

Fe

0.789**

NS

0.705*

NS

NS

0.655*

NS

0.886***

0.752**

1

Mn

0.684*

NS

NS

NS

NS

0.932***

0.787**

0.806**

0.941***

0.859***

1

Zn

NS

0.814**

NS

0.836**

0.813**

0.649*

0.793**

NS

NS

NS

NS

1

Cl

NS

0.968***

NS

0.936***

0.979***

NS

0.814**

NS

NS

NS

NS

0.888***

1

NS: not significant. *, ** and ***: significant at probability level P

< 0.05, 0.01 and 0.001, respectively.

EC: electrical conductivity (dS m

1

). DM: dry matter, TOC: total organic carbon, TN: total nitrogen. NH

4

-N, P, K, Ca, and Mg in g L

1

on a fresh

mass basis. Fe, Mn, Zn and Cl in mg L

1

on a fresh mass basis. The DM, TOC and Zn data were adjusted to a normal distribution (Shapiro-Wilk’s

test) through logarithmic transformation.

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

185

anaerobic digestion, which enriched the digestate in OM of

low biodegradability.

The CS-AW1 and CS-AW2 samples had the lowest BOD

5

values and percentages of DOC with respect to TOC (

<16%),

indicating a high stability degree. By contrast, digested

materials where PS was the main substrate showed an inter-

mediate behaviour, with BOD

5

values between 2 g L

1

and

7 g L

1

and DOC values between 1 g L

1

and 4 g L

1

, repre-

senting from 20% to 40% of the TOC in the digestates.

Therefore, differences in stability degree between diges-

tates were related directly to the concentration of DOC, readily

available for microorganisms. The BOD

5

was correlated

significantly with both TOC (r

¼ 0.722; P < 0.01) and, especially,

DOC (r

¼ 0.960; P < 0.001), which demonstrates the strong

influence of DOC on digestate biodegradability characteristics.

A significant regression equation was obtained for BOD

5

and

DOC (g L

1

fresh digestate mass): lgBOD

5

¼ 1.172lgDOC þ 0.057,

which allows cautious prediction of BOD

5

from DOC data.

Considering the BOD data after 24 h, which corresponds to

the period of maximum biological activity, and expressing

them as the average oxygen uptake rate (on an organic

matter basis), only the CS-AW3 sample satisfied the respira-

tion index (

<1 mg g

1

h

1

) proposed for stabilised biowastes

. On the other hand, using the criterion established by

Ponsa´ et al.

, the digestates can be classified as follows

(on a dry mass basis): 1) low biodegradability (

<2 mg g

1

h

1

):

PS-AB3, CS-AW1, CS-AW2 and CS-AW3 (1.4, 0.9, 1.0

and 0.8 mg g

1

h

1

, respectively); 2) moderate biodegradability

(2 mg g

1

h

1

e5 mg g

1

h

1

): PS-AB1, PS-AB2, PS-EC1, PS-EC2

and PS-EC3 (2.1, 3.2, 2.4, 2.2 and 2.6 mg g

1

h

1

, respectively);

and 3) high biodegradability (

> 5 mg g

1

h

1

): digestates from

CS-G mixtures (8.2, 20.0 and 11.8 mg g

1

h

1

for CS-G1, CS-G2

and CS-G3, respectively). The procedure for certifying the

quality of digestates in the United Kingdom

establishes

a dissolved chemical oxygen demand (COD) lower than

0.43 g g

1

OM as a stability requirement. In our study, the CS-G

digestates did not meet this requirement, assuming that DOC

contributes greatly to COD, thus underlining the high biode-

gradability of the CS-G digestates. In such cases, a longer

residence time during anaerobic co-digestion, further pro-

cessing or post-treatment stabilisation is recommendable

before digestate application to soil, in order to obtain the

maximum agricultural and environmental benefits.

Among the quality criteria defined for digestates, biode-

gradability or the degree of stability is the parameter for

which there is least agreement. As a result, different

threshold values have been established as quality criteria,

based on respiration indices

, volatile fatty acid contents

or chemical oxygen demand

. In our previous work

, digestate composition parameters such as DOC, BOD

and DOC/TN were related to the C and N dynamics in a soil

amended with digestates. In this case, a digestate suitable

for use as a fertiliser was defined based on DOC

< 1.5 g L

1

,

BOD

5

< 2.5 g L

1

and DOC/TN

< 1, while digestates showing

characteristics such as DOC

< 5.5 g L

1

, BOD

5

< 6.0 g L

1

and

DOC/TN

< 1.5 were established as less-appropriate for fer-

tilisation purposes, with a curing or maturation period being

required in order to increase digestate stability. Highly-

biodegradable

digested

materials,

such

as

the

CS-G

samples, were not suitable for agricultural use as they

caused a high CO

2

-C production and led to N-immobilisation

in soil, thus greatly limiting their N-fertilising potential in

the short-term.

3.3.

Evaluation of the potential phytotoxicity of digestates

and their hygiene

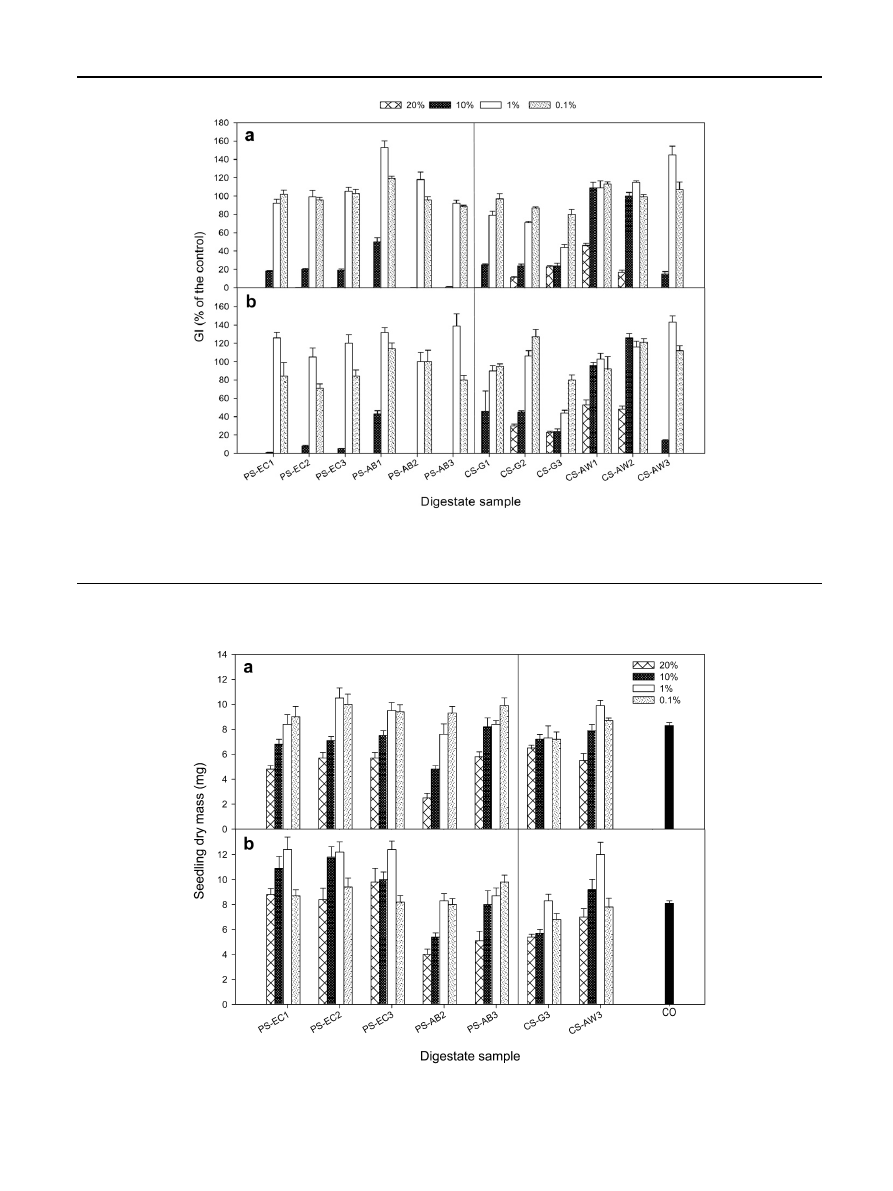

The effects of the 12 digestates and 5 digestate concentrations

studied (100% -pure-, 20%, 10%, 1% and 0.1%) on the GI,

expressed as a percentage of the control (distilled water), of

cress and lettuce seeds (germination bioassays) are shown in

(a) and (b), respectively. Notable and highly-significant

effects of both digestates and concentrations were found.

Among the 12 digestates examined, the average GI ranged

from 34% (CS-G3) to 75% of the control (CS-AW1) for cress and

from 34% (CS-G3) to 82% (CS-AW2) for lettuce and, with regard

to the concentration tested, from 0% (100% digestate concen-

tration, both cress and lettuce) to 102% (1% digestate

concentration, cress) or 110% (1% digestate concentration,

lettuce). At a digestate concentration of 1%, various digestates,

particularly PS-AB1 and CS-AW3, exceeded the threshold

value for GI of 125% (of the control), in both the cress and

lettuce bioassays; thus, these two digestate solutions could be

considered to have plant nutrient or plant growth stimulant

attributes, as suggested by Emino and Warman

and

Moldes et al.

The GI of both cress and lettuce at the digestate concen-

trations of 20% and 10% were inversely correlated with the EC

values (P

< 0.01) of the digestates (an indicator of their salt

content) and also with the concentrations of TN (P

< 0.01),

NH

4

-N (P

< 0.05), K (P < 0.01), S (P < 0.05), Zn (P < 0.01) and Cl

(P

< 0.01). McLachlan et al.

obtained similar results when

they studied the potential phytotoxicity of digestates

produced from municipal solid wastes, high soluble salt

concentrations being the major reason for phytotoxicity. Tam

and Tiquia

related the phytotoxic effects of spent pig litter

to its salt, NH

4

-N, Cu and Zn contents.

For concentrations of 1% and, especially, 0.1%, TN, NH

4

-N,

K, S, Zn and Cl were not correlated significantly with the GI for

cress, but the latter was correlated positively with EC, TN,

Table 5

e The linear regression equations (y [ Ax D B)

calculated for selected parameters determined in the

digestates (

n [ 12).

y

x

A

B

r

lgTOC

lgDM

1.176***

0.708**

0.946***

Ca

3.807***

4.286**

0.856***

Fe

289.6**

318.4*

0.789**

TN

EC

0.141***

0.117

NS

0.973***

NH

4

-N

0.124***

0.431*

0.984***

K

0.084***

0.543

NS

0.875***

lgZn

0.037**

0.764**

0.814**

Cl

0.070***

0.144

NS

0.968***

NS: not significant, *, ** and ***: significant at P

< 0.05, 0.01 and 0.001,

respectively.

TOC: total organic carbon, TN: total nitrogen, DM: dry matter, NH

4

-

N, K, Ca, and Cl in g L

1

(fresh mass basis). Fe and Zn in mg L

1

(fresh mass basis). EC: electrical conductivity in dS m

1

.

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

186

Fig. 1

e The effects of digestates and concentrations on the germination index (GI, expressed as percentage of the control) of

cress (a) and lettuce (b) seeds. Each value is the mean of five replications ± the standard error of the mean. GI was 0% for all

the pure (100%) digestate samples studied.

Fig. 2

e The effects of digestates and concentrations on the biomass accumulation (expressed as total dry mass, shoot D roots,

in mg) of cress (a) and lettuce (b) seedlings. Each value is the mean of three replications ± the standard error of the mean. Control

(without digestate addition): CO.

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

187

NH

4

-N and S for lettuce at 1% concentration (P

< 0.05). Indeed,

parameters related to digestate stability (DOC, DOC/TN and

BOD) correlated negatively with GI, especially for cress at both

concentrations of 1% and 0.1% (P

< 0.05). Several authors

related decreases in the phytotoxic effects of digestates to

reductions in the amount of easily-biodegradable organic

compounds.

The influence of digestates PS-EC1, PS-EC2, PS-EC3, PS-AB2,

PS-AB3, CS-G3 and CS-AW3, at the concentrations of 20%, 10%,

1% and 0.1%, and of the control (without digestate addition), on

biomass accumulation in cress and lettuce plants - expressed

as total dry mass (shoot

þ roots) per seedling - is presented in

(a) and (b), respectively. Significant differences in seedling

dry mass among both digestates and concentrations were

found, the best results (on average) being obtained with PS-

AB3, PS-EC1, PS-EC2, PS-EC3 and CS-AW3 in cress and with

PS-EC1, PS-EC2 and PS-EC3 in lettuce; the concentrations of 1%

(cress and lettuce) or 0.1% (cress) yielded the greatest seedling

biomass. In addition, most of the best treatments indicated

above were as efficient as the untreated controls, or even more

so, with regard to seedling biomass accumulation. This indi-

cates - as do the seed germination results - plant nutrient,

growth stimulant or even phytohormone-like effects of these

digestate solutions.

Therefore, agricultural uses of stable digestates can be

conditioned by their phytotoxic effects during early growth

(germination), due mainly to salinity. Thus, digestate appli-

cation rates must consider the concentrations of Na and Cl,

and also heavy metals (especially Cu and Zn), in order to

avoid any risk of metal accumulation in soil as well as sali-

nisation or phytotoxic effects, already detected following

excessive application of animal manure and slurries

.

In order to avoid phytotoxicity, digestate application to soil

should be done well in advance of sowing, avoiding direct

contact with young plants or germinating seed. The

maximum benefit from the nutrients provided can be

obtained if digestate is applied together with the irrigation

water, acting as a dilutor.

Another significant biological aspect of digestate quality

is hygiene. In Spain, the RD 824/2005

states the

requirements for fertilisers prepared from certain organic

residues, which must not exceed the following maximum

levels of micro-organisms: Salmonella spp., absent in 25 g of

product, and E. coli,

< 1000 MPN g

1

fresh product. In the

present study, E. coli was detected in most digestate samples

at levels lower than 1000 MPN g

1

fresh digestate, but

Salmonella spp. was present in 25 g fresh digestate in some

samples (data not shown). This must be related to the fact

that most digestate samples were derived from mesophilic

processes (with the exception of CS-G3) without post-

treatment, where hygiene is not guaranteed. So, further

treatment for inactivation of pathogens is required, to avoid

health risks. Both the European legislation

and

quality standards for certification of digestates

are

severe, focusing on three aspects in the case of anaerobic

digestion: process management (thermophilic temperature,

retention time, etc.), pre- or post-treatments (pasteurisation,

steaming, sterilisation, etc.) and end-product requirements

that ensure the sanitation of the digested materials accord-

ing to the source of the feedstocks.

4.

Conclusions

The digestates had a high potential fertiliser value due to their

contents of N, P, K and micronutrients. However, their high

variability and unbalanced contents necessitate their analysis

before they can be integrated into fertilisation programmes.

Together with the sanitary quality of the digestates,

a minimum degree of stability of their OM is required to obtain

the maximum benefits of digestate recycling in agriculture,

which must be harmonised at an international level. There-

fore, digestate characterisation is an unavoidable task, to

determine the application rates, phytotoxicity risk and need

for a safety period, before sowing, or a stabilisation treatment,

before soil application.

Acknowledgements

This research was funded by the “Ministerio de Ciencia e

Innovacio´n, Plan Nacional I

þDþI 2008-2011” and EU through

FEDER Funds “Fondo Europeo de Desarrollo Regional, una

manera de hacer Europa”, in the framework of the project

“singular estrate´gico PROBIOGAS” (Refs.: PSS-120000-2008-58;

PSS-120000-2008-62). The authors thank all the research

groups involved in the project PROBIOGAS (

), especially the GIRO and AINIA Technological

Centres, the University of Oviedo, San Ramo´n Group and

Treatments of Juneda Society (Tracjusa), for providing the

digested materials used in this work. The authors also thank

Dr. D.J. Walker for the English revision.

r e f e r e n c e s

[1] Al Seadi T. Good practice in quality management of AD

residues from biogas production. Esberg, DK. University of

Southern Denmark. 2002, 32 p. Report for IEA Bioenergy task

24: energy from biological Conversion of organic waste.

[2] Ward AJ, Hobbs PJ, Holliman PJ, Jones DL. Optimisation of the

anaerobic digestion of agricultural resources. Bioresour

Technol 2008;99(17):7928

e40.

[3] Real Decreto 949/2009, de 5 de junio, por el que se establecen

las bases reguladoras de las subvenciones estatales para

fomentar la aplicacio´n de los procesos te´cnicos del Plan de

biodigestio´n de purines. BOE 2009; 151:52291

e301.

[4] Grigatti M, Di Girolamo G, Chincarini R, Ciavatta C. Potential

nitrogen mineralization, plant utilization efficiency and soil

CO

2

emissions following the addition of anaerobic digested

slurries. Biomass Bioenerg 2011;35(11):4619

e29.

[5] Chadwick DR. Digestate as a fertiliser and environmental

concerns. In: Anaerobic digestion stakeholder workshop.

Session IV: building the market for digestate. UK: Exeter

University; September 3-4, 2007.

[6] Schievano A, Adani F, Tambone F, D’Imporzano G, Scaglia B,

Genevini PL. What is digestate? In: Adani F, Schievano A,

Boccasile G, editors. Anaerobic digestion: opportunities for

agriculture and environment. Milano Italy: Regione

Lombardia Publisher; 2009. p. 7

e18.

[7] Abdullahi YA, Akunna JC, White NA, Hallett PD, Wheatley R.

Investigating the effects of anaerobic and aerobic post-

treatment on quality and stability of organic fraction of

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

188

municipal solid waste as soil amendment. Bioresour Technol

2008;99(18):8631

e6.

[8] Salminen E, Rintala J, Ha¨rko¨nen J, Kuitunen M,

Ho¨gmander H, Oikari A. Anaerobically digested poultry

slaughterhouse wastes as fertiliser in agriculture. Bioresour

Technol 2001;78(1):81

e8.

[9] European Commission. Working document: biological

treatment of biowaste (2nd draft). Directorate-General

Environment A.2-Sustainable Resources. Brussels; 2001. 22 p.

[10] Real Decreto 824/2005 de 8 de julio sobre productos

fertilizantes. BOE 2005; 171: 25592

e669.

[11] Siebert S, Thelen-Ju¨ngling M, Kehres B. Development of

quality assurance and quality characteristics of composts

and digestates in Germany. In: Rodic-Wiersma L, Barth J,

Bidlingmaier W, de Bertoldi M, Diaz LF, editors. 6th

International conference ORBIT 2008-Moving Organic Waste

Recycling Towards Resource Management and Biobased

Economy. Wageningen, The Netherlands; October 13-15,

2008, p. 1

e12.

[12] BSI. PAS 110:2010. Specification for whole digestate,

separated liquor and separated fibre derived from the

anaerobic digestion of source-segregated biodegradable

materials. 60p. British Standards Institution Publications

[accessed 27.01.12] Available at:

downloads/PAS110_vis_10.af954016.8536.pdf

; 2010.

[13] Method 1682 USEPA. Salmonella in sewage sludge (biosolids)

by modified semisolid Rappaport-Vassiliadis (MSRV) medium.

U.S: EPA Office of Water; 2005. 41p. EPA/821/R-04/028.

[14] International Organisation for Standardisation. Detection

and enumeration of presumptive Escherichia coli - most

probable number technique. ISO 7251:2005; 2005. 13p.

[15] Zucconi F, Pera A, Forte M, de Bertoldi M. Evaluating toxicity

of immature compost. Biocycle 1981;22(2):54

e7.

[16] Tambone F, Genevini P, D’Imporzano G, Adani F. Assessing

amendment properties of digestate by studying the organic

matter composition and the degree of biological stability

during the anaerobic digestion of the organic fraction of

MSW. Bioresour Technol 2009;100(12):3140

e2.

[17] Smith KA, Metcalfe P, Grylls J, Jeffrey W, Sinclair A. Nutrient

value of digestate from farm-based biogas plants in Scotland.

ADAS UK Ltd and SAC Commercial Ltd; 2007. 44 p. Report for

Scottish Executive Environment and Rural Affairs

Department-ADA/009/06.

[18] Sommer SG, Husted S. The chemical buffer system in raw

and digested animal slurry. J Agr Sci 1995;124:45

e53.

[19] Bernal MP, Alburquerque JA, Moral R. Composting of animal

manures and chemical criteria for compost maturity

assessment. A Review Bioresour Technol 2009;100(22):

5444

e53.

[20] PRE/630/2011 Orden de 23 de marzo, por la que se modifican

los anexos I, II, III, IV, V, y VI del Real Decreto 824/2005, de 8

de junio, sobre productos fertilizantes. BOE 2011;

72:31871

e31910.

[21] Edelmann W, Baier U, Engeli H. Environmental aspects of the

anaerobic digestion of the organic fraction of municipal solid

wastes and of agricultural wastes. 8p [accessed 27.01.12]

Available at:

http://www.arbi.ch/LCA%2520AD%

; 2004.

[22] Moral R, Perez-Murcia MD, Perez-Espinosa A, Moreno-

Caselles J, Paredes C. Estimation of nutrient values of pig

slurries in southeast Spain using easily determined

properties. Waste Manage 2005;25(7):719

e25.

[23] Suresh A, Choi HL, Oh DI, Moon OK. Prediction of the

nutrients value and biochemical characteristics of swine

slurry by measurement of EC-Electrical conductivity.

Bioresour Technol 2009;100(20):4683

e9.

[24] Ponsa´ S, Gea T, Sa´nchez A. Different indices to express

biodegradability in organic solid wastes. J Environ Qual 2010;

39:706

e12.

[25] Alburquerque JA, de la Fuente C, Bernal MP. Chemical

properties of anaerobic digestates affecting C and N

dynamics in amended soils. Agr Ecosyst Environ in press,

doi:10.1016/j.agee.2011.03.007

).

[26] Emino ER, Warman PR. Biological assay for compost quality.

Compost Sci Util 2004;12(4):342

e8.

[27] Moldes A, Cendo´n Y, Lo´pez G, Barral MT. Biological quality of

potting media based on MSW composts: a comparative

study. Compost Sci Util 2006;14(4):296

e302.

[28] McLachlan KL, Chong C, Voroney RP, Liu HW, Holbein BE.

Assessing the potential phytotoxicity of digestates during

processing of municipal solid waste by anaerobic digestion:

comparison to aerobic composts. Acta Hortic 2004;638:

225

e30.

[29] Tam NFY, Tiquia S. Assessing toxicity of spent pig litter using

a seed germination technique. Resour Conserv Recy 1994;

11(1

e4):261e74.

[30] Drennan MF, DiStefano TD. Characterization of the curing

process from high-solids anaerobic digestion. Bioresour

Technol 2010;101(2):537

e44.

[31] L’Herroux L, Le Roux S, Appriou P, Martinez J. Behaviour of

metals following intensive pig slurry applications to

a natural field treatment process in Brittany (France).

Environ Pollut 1997;97(1

e2):119e30.

[32] Moral R, Perez-Murcia MD, Perez-Espinosa A, Moreno-

Caselles J, Paredes C, Rufete B. Salinity, organic content,

micronutrients and heavy metals in pig slurries from south-

eastern Spain. Waste Manage 2008;28(2):367

e71.

[33] Regulation (EC) No 1774/2002 of the European Parliament and

the Council of 3 October 2002 laying down health rules

concerning animal by-products not indented for human

consumption. Off J Eur Commun 2002;L273:1

e95.

[34] Regulation (EC) No 1069/2009 of the European Parliament and

of the Council of 21 October 2009 laying down health rules as

regards animal by-products and derived products not

intended for human consumption and repealing Regulation

(EC) No 1774/2002 (Animal by-products Regulation). Off J Eur

Commun 2009;L300:1

e33.

[35] Regulation (EC) No 208/2006 of 7 February 2006 amending

Annexes VI and VIII to regulation (EC) No 1774/2002 of the

European parliament and of the council as regards

processing standards for biogas and composting plants and

requirements for manure. Off J Eur Commun 2006;L36:25

e31.

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 8 1

189

Document Outline

- Assessment of the fertiliser potential of digestates from farm and agroindustrial residues

Wyszukiwarka

Podobne podstrony:

Właściwości chemiczne pofermentu i wpływ na dynamikę C i N w glebie Hiszpania 2012

Koszty wytworzenia i wartość nawozowa pofermentu z różnych instalacji Belgia 2014

Wartość nawozowa pofermentu i gnojowicy Włochy 2016

Przestępczość, Przestępczość nieletnich jako problem społeczny zawiera w sobie znacz¬ny potencjał ni

Biokataliza – potencjalne zastosowania w przemyśle chemicznym

Laborki surowce i procesy przemysłu nieorg Skład chemiczny i właściwości nawozów mineralnych nasze

Właściwości nawozowe i skład chemiczny różnych rodzajów pofermentu i kompostu Włochy 2010

Rozwiązania technologiczno aparaturowe do odzyskiwania fosforanów(V) ze ścieku z przemysłu nawozoweg

06 Kwestia potencjalności Aid 6191 ppt

potencjal spoczynkowy i jego pochodzenie

Przemyśl to

3 Prawo własności przemysłowej

Zanieczyszczenia powstające w przemyśle metalurgii żelaza prezentacja

ryzyko zawodowe w przemys

więcej podobnych podstron