Types of Cylinders

There are two basic types of compressed gas cylinders. Non-refillable cylinders are designed for one-time use and should never be refilled or reused. Refillable cylinders are made of steel or aluminum, and are designed for refilling and repeated use. Some cylinders have been in service for over 40 years! Most refillable cylinders have an open interior with walls of 1/4 inch steel and a reinforced neck and bottom. Because commonly used gases are highly pressurized (between 1,500 psig and 2,500 psig), cylinders must be maintained in good condition and protected from accidental damage at all times.

A compressed gas cylinder that has been accidentally knocked over and damaged at the valve can result in extensive property damage and personal injury. Never attempt to stop a damaged cylinder that is spinning in place due to rapid release of pressurized contents! Leave the area until the contents are dispelled and the cylinder has stopped.

Refillable cylinders also come in three different types:

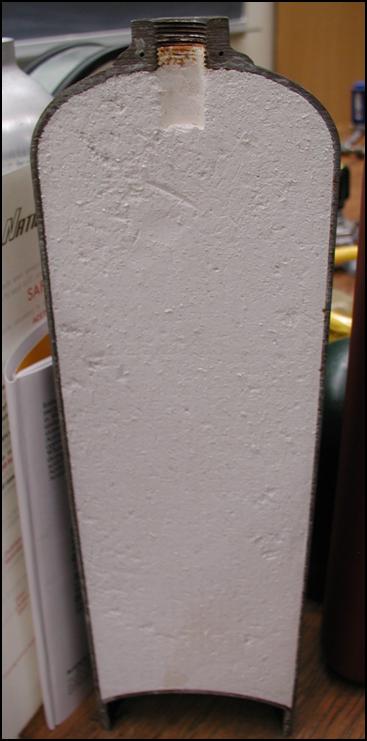

Acetylene cylinders have a porous filler material that helps stabilize the

extremely volatile gas. Acetone is used to stabilize the acetylene, but pockets of pure acetylene can develop at the valve stem if the cylinder is not kept in an upright position, or if the cylinder is dented or damaged. Acetylene is pressurized at 250 psig, but free acetylene is highly unstable at 15 psig. The maximum flow rate on acetylene cylinders is 15 psig. Always keep acetylene cylinders in an upright position! If a cylinder is found that is not in an upright position, put it in an upright position and let it sit for at least 24 hours before using or contact the supplier for guidance.Some gases, such as carbon dioxide, are commonly used in both a liquid and gas form. Cylinders designed for such use have a siphon, or "dip", tube. A siphon serves as a drinking straw to pull the liquid from the bottom of the cylinder when needed. The valve pulls the gas vapors from the top of the cylinder when the gas form is required.

Cylinder Damage

Cylinders can be damaged in several ways:

Effects of heat can cause the cylinder to expand and contract with pressure changes. Cylinders are designed, to some degree, to handle such pressure changes, however, cylinders made of aluminum are affected by heat more than cylinders made of steel and can rupture. Some suppliers use invisible heat strips on the cylinders to identify damage from heat. Strips are invisible under normal temperatures, but will turn orange or brown if exposed to more than 120 degrees F.

Arcing damage from welding operations can result in a heat rise sufficient enough

to cause a pressure explosion or the pressure relief device to activate. When this occurs on a fuel gas cylinder, such as acetylene, it can cause rapid dissociation within the cylinder resulting in greater destruction and/or injuries. This occurs most frequently on argon, carbon dioxide, helium, and inert mixture cylinders used in heliarc welding when the torch is left dangling on top of the cylinder. For this to happen, the cylinder must be part of the electrical circuit connecting the work to the welding machine. This is highly dangerous even without the arc burn and must not be permitted. Arc burns are easily recognized by a spot, or series of spots, of freshly burned paint, exposing bare metal. When caused by a stick electrode, there can be a deposit of filler metal on the cylinder where the electrode dragged.

Never allow the cylinder to become part of an electrical circuit. Do not place the torch or electrode holder on the cylinders for any reason.

Arc-damaged cylinders must be removed from service and returned to the supplier, who often charges the customer for the cost of the cylinder.

Dents can occur from impact or mishandling, which can weaken the walls of the cylinder making it more susceptible to rupture.

Corrosion from moisture, salt, corrosives, and other materials can corrode cylinders, especially the bottom of the cylinder where stored on the ground. Always store cylinders in a dry location, preferably on a concrete surface.

Cylinder Labeling

Cylinders must contain the following information:

DOT or ICC (prior to 1968) identification number - ex. DOT3AA2265. This identifies the cylinder material and the service pressure in pounds per square inch.

Cylinder serial number - ex. SG12152A. The letters "SG" may precede the serial number to indicate a specialty gas cylinder.

Original owner of the cylinder - ex. APROINC

Date of maintenance to indicate the original hydrostatic test (month/year).

Current owner of the cylinder will appear on the neck ring.

Retest markings (month, facility, year, rating, stamp). A "+" indicates the cylinder qualified for a 10 percent overfill. A star stamp on the end of the marking indicates the cylinder meets the requirements for a 10-year retest.

CylinderTrak bar code provides a unique identifier and is used by computer systems to track cylinders through the filling process.

Cylinder manufacturer's inspection marking, which is unique to the inspector.

Cylinder tare weight, i.e. the weight of the cylinder plus the valve without product, preceded by the letters "TW".

Cylinders must also identify their contents, which is typically in the form of a

sticker applied near the neck of the cylinder. This is the only acceptable means of identifying non-medical-grade cylinder contents! There are only five medical grade gases that are permitted to be identified by color. All others are not required to be color-coded, and color codes may vary from one supplier to another.

Leaking Cylinders

If a leaking cylinder is detected during delivery from the supplier, the cylinder should be rejected and/or returned to the supplier. For other situations, consider the following:

The nature of the operation.

The potential location of a release or spill.

The quantity of material that might be released and the type of contaminant.

The chemical and physical properties of the gas.

The hazardous properties of the gas.

The availability and locations of emergency supplies.

The department's emergency action plan recommendations.

Minor (Non-Hazardous) Leaks

For cylinders with minor leaks:

Verify the leak with a flammable gas detector, or an approved leak test solution.

Try tightening the valve gland or packing nut.

Place a plastic bag, rubber shroud, or similar device over the top and duct tape it to the cylinder to confine the leaking gas.

Contact EHSS at 231-2982 or call 911.

Major Leaks

Call 911 immediately.

For fuel gases or highly toxic gases, be sure to turn off any machinery or open flames in the area.

Activate building and area fire alarms.

Evacuate the area and secure the entrances.

Do not re-enter the building until the local fire official give an "all clear".

Wyszukiwarka

Podobne podstrony:

Types of syllabuses

Types of regimes in Plato s thought

Part12 Types of Verbs, Verb Endings

Types of?et

Types of A V Aids and relevance for LT

Język angielski Types of English

Types of Verbs

Functional types of subordinate clauses

The Various Types of Skiing

Description Types of Latches

Types Of Martial Arts

Types of transfer (1)

types of transport

The?sic Poetic Metres and Types of Rhymes Smutek

What types of foundations should I consider

Types of syllabuses

więcej podobnych podstron