XXIV

awarie budowlane

XXIV Konferencja Naukowo-Techniczna

Szczecin-Międzyzdroje, 26-29 maja 2009

D

AISUKE

Y

AMAOKA

, yamaoka_dai_ssd@yahoo.co.jp

Kansai University, Osaka, Japan

K

AZUYA

B

ESSHO

, bessho_ssd@yahoo.co.jp

Y

OSHIHIKO

T

AKADA

Hanshin Expressway Management Technology Center, Osaka, Japan

Prof. M

ASAHIRO

S

AKANO

, peg03032@ipcku.kansai-u.ac.jp

Kansai University, Osaka, Japan

FATIGUE TEST OF AN URBAN EXPRESSWAY STEEL GIRDER

BRIDGE CONSTRUCTED IN 1964

BADANIA ZMĘCZENIOWE STALOWEGO MOSTU BELKOWEGO,

NA MIEJSKIEJ AUTOSTRADZIE, WYBUDOWANEGO W 1964 R

Abstract In Japan, infrastructure, including numerous highway and railway bridges, was intensively constructed

during the rapid economic growth era from 1960's to 1970's. We are warned that those structures are now aged

and may deteriorate

in

the

near future.

Since fatigue design had not been applied to highway bridges

until 2002,

there is a high possibility that

fatigue cracking will

occur frequently in the future. In this study, we try to grasp

fatigue behavior and fatigue strength characteristics of the fatigue weak points in the actual bridge through

fatigue tests of steel girders which had been used on an urban expressway for more than 40 years and removed in

2005. As the result,

it was confirmed that the fatigue strength of web gusset welded joint with fillet satisfies JRA

Fatigue Category E which is two-rank higher than that of web gusset joint without fillet.

Streszczenie W Japonii, infrastruktura bogata w mosty kolejowe i autostradowe była intensywnie rozbudowywa-

na podczas gwałtownego wzrostu ekonomicznego przypadającego na lata 1960-1970. Pojawiają się ostrzeżenia,

ż

e te konstrukcje starzeją się

i ich stan może się pogorszyć w najbliższej przyszłości. Ponieważ testy zmęcze-

niowe nie były stosowane do 2002 roku, istnieje duże prawdopodobieństwo, że uszkodzenia zmęczeniowe będą

coraz częstsze w przyszłości. W pracy scharakteryzowano zachowanie i wytrzymałość najsłabszych punktów

w rzeczywistym moście, przez testy zmęczeniowe stalowych belek, które były eksploatowane na miejskiej

autostradzie przez ponad 40 lat i zostały usunięte w 2005 roku.

1. Introduction

In Japan, infrastructure, including numerous highway and railway bridges, was intensively

constructed during the rapid economic growth era from 1960's to 1970's. We are warned that

those structures are now aged and may deteriorate in the near future. Since fatigue design had

not been applied to highway bridges until 2002

[1]

, there is a high possibility that fatigue

cracking will occur frequently in the future.

In this study, we try to grasp fatigue behavior and

fatigue strength characteristics of the fatigue weak points in the actual bridge through fatigue

tests of steel girders which had been used on an urban expressway for more than 40 years and

removed in 2005.

Mosty, drogi i koleje

396

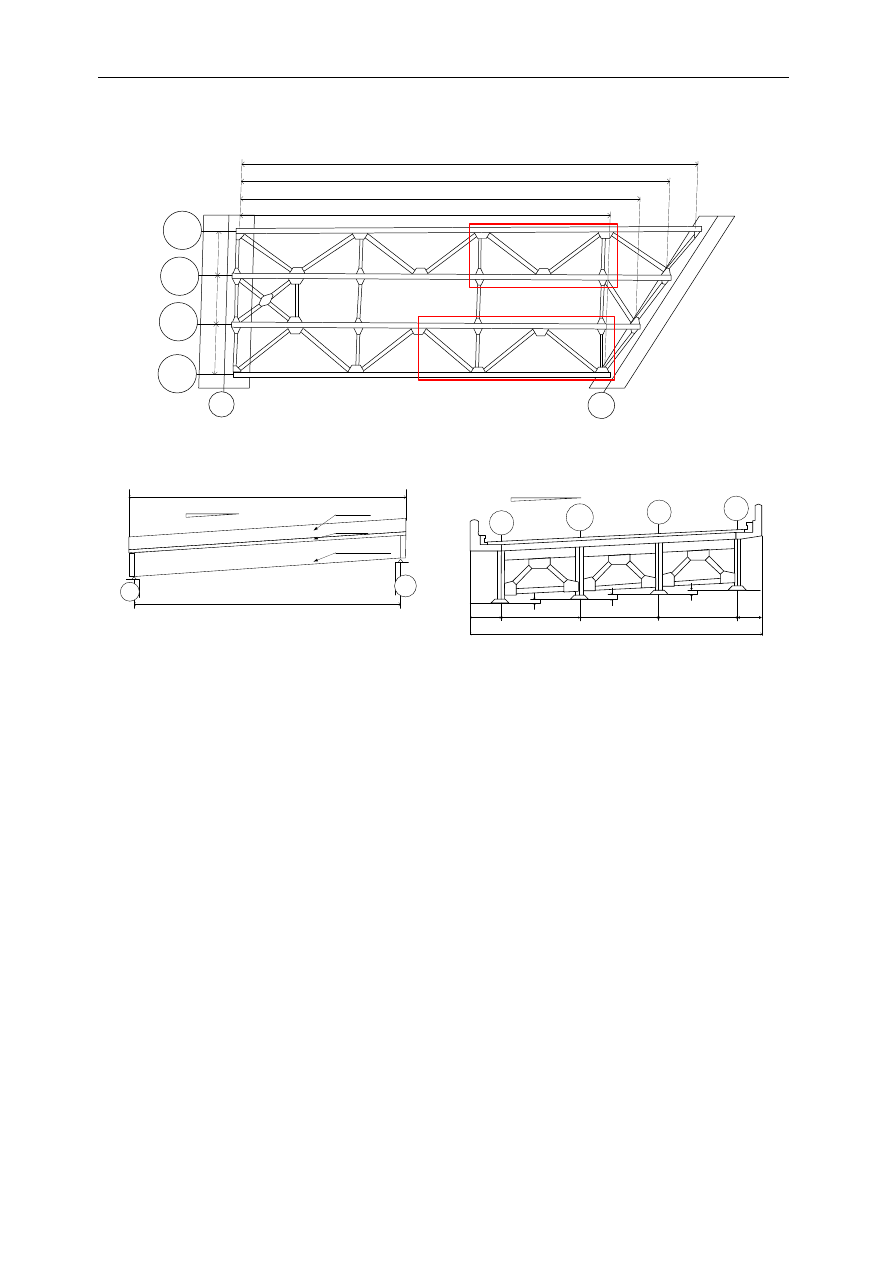

2. Bridge and girders

15830

17128

18425

19718

1

8

9

8

2

1

2

1

2

1

2

1

G- 1

G- 2

G- 3

G- 4

P2

P1

North side

South side

Unit

:

:

:

:

mm

Fig. 1. Plan of Minato-machi Ramp Bridge

16349

15830

Main girder

Slab

Railing

P1

P2

1.001513

1.000000

0.055022

2468

2468

2464

817

994

1

1

8

1

3

0

1

0

7

9211

0.047812

1.000000

1.001142

G- 1

G- 2

G- 3

G- 4

Fig. 2. Elevation of Minato-machi Ramp Bridge

Fig. 3. Cross section of Minato-machi Ramp Bridge

The object of study is the Minato-machi Ramp Bridge, which was real urban expressway

ramp girder bridge constructed in 1964, and removed in 2005. The bridge was a simply-sup-

ported composite main girder bridge. Girders have a web plate and a bottom flange with

welded vertical stiffeners and gusset plates which connect cross frames and lateral bracings to

main girders. Figs.1~3 shows the plan, elevation and cross section of the bridge. Test pieces

were cut out from the red areas shown in Fig. 1.

3. Cracks inspection

3.1. Method

Before the fatigue tests, magnetic particle tests are conducted to detect the fatigue cracks

which could have occurred under service loading. Toes of turn-round weldment are inspected

in the welded joint which connects the gusset plate to the web of the main girder. The total

number of inspected toes of turn-round weldment is 53 in 15 gusset plates. Fig.4 shows

locations of gusset plates and inspected areas.

At first, to confirm the shape and length of paint cracks, the paint cracks are inspected.

Next, the paint is removed by hammer. Finally, we tried to detect the fatigue cracks by

magnetic particle test.

Yamaoka D. i inni: Fatigue test of an urban expressway steel girder bridge constructed in 1964

397

○

:

Inspected

Areas

G- 1

G- 3

G- 4

P1

G- 2

Center side

Edge side

G1- 2

G1- 1

G2- 4

C SC

E

SE

C SC

E

SE

G2- 3W

G2- 3E

C

E

G2- 2

C SC

E

SE

C SC

E

SE

C SC

E

SE

C SC

E

SE

G2- 2E

G2- 2W

C SC

E

SE

C SC

E

SE

G3- 3W

C

E

G3- 3E

G3- 2

C SC

E

SE

C SC

E

SE

C SC

E

SE

G3- 1E

G3- 1W

C SC

E

SE

G4- 1

G4- 2

Fig. 4.

Locations of gusset plates and inspected areas

3.2. Paint cracks inspection

Table 1.

Result of paint cracks inspection

C

12,7,7

C

33

SC

0

SC

0

E

B urne d

E

0

SE

D e te rio ratio n

SE

0

C

83,65

C

0

SC

0

SC

0

E

B urne d

E

0

SE

0

SE

3

C

0

C

13

SC

0

E

27

E

0

C

0

SE

0

SC

0

C

5

E

0

SC

0

SE

0

E

0

C

0

SE

0

SC

17

C

13

E

0

E

12,9

SE

0

C

23

C

23

SC

0

SC

12

E

6

E

D e te rio ratio n

SE

0

SE

B urne d

C

0

C

20,18

SC

0

SC

0

E

0

E

17,9

SE

0

SE

27

G2-4

35,32

G2-3W

G3-1E

G3-1W

G us s e t

P late

Ins pe c te d

A re a

P aint C rac k

L e ngth (mm)

G3-2

G4-2

G2-1W

N o te

G1-1

G2-2

G2-3E

G1-2

G2-1E

G3-3E

G4-1

G3-3W

G us s e t

P late

Ins pe c te d

A re a

P aint C rac k

L e ngth (mm)

N o te

Table 1 shows the result of the paint cracks inspection. Red and yellow areas show paint

crack occurrence areas. There were 18 paint crack occurrence areas in the 53 inspected areas.

Paint cracks in the red areas are along the toes of turn-round weldment which are fatigue

weak points. Paint cracks in the yellow areas are not along the toes of turn-round weldment.

Mosty, drogi i koleje

398

In the 5 blue areas we could not judge the shape and length of the paint crack because of

burning and deterioration.

3.3. Magnetic particle test

Fig. 5 shows the result of magnetic particle tests. MT signs that may indicate fatigue cracks

were observed at 2 weldments among the 18 turn-round weldments with paint cracks. Several

paint cracks were observed at the G1-2-C gusset plate.

G2- 2

G2- 3W

G3- 3E

G3- 1E

G2- 1E

G2- 4E

G1- 2

G1- 1

G4- 1

G4- 2

G- 1

G- 3

G- 4

G3- 3W

G3- 1W

G2- 1W

P1

G3- 2

G- 2

G2- 3E

○

:

With Paint crack

●

:

With MT sign

Fig. 5. Results of magnetic particle test

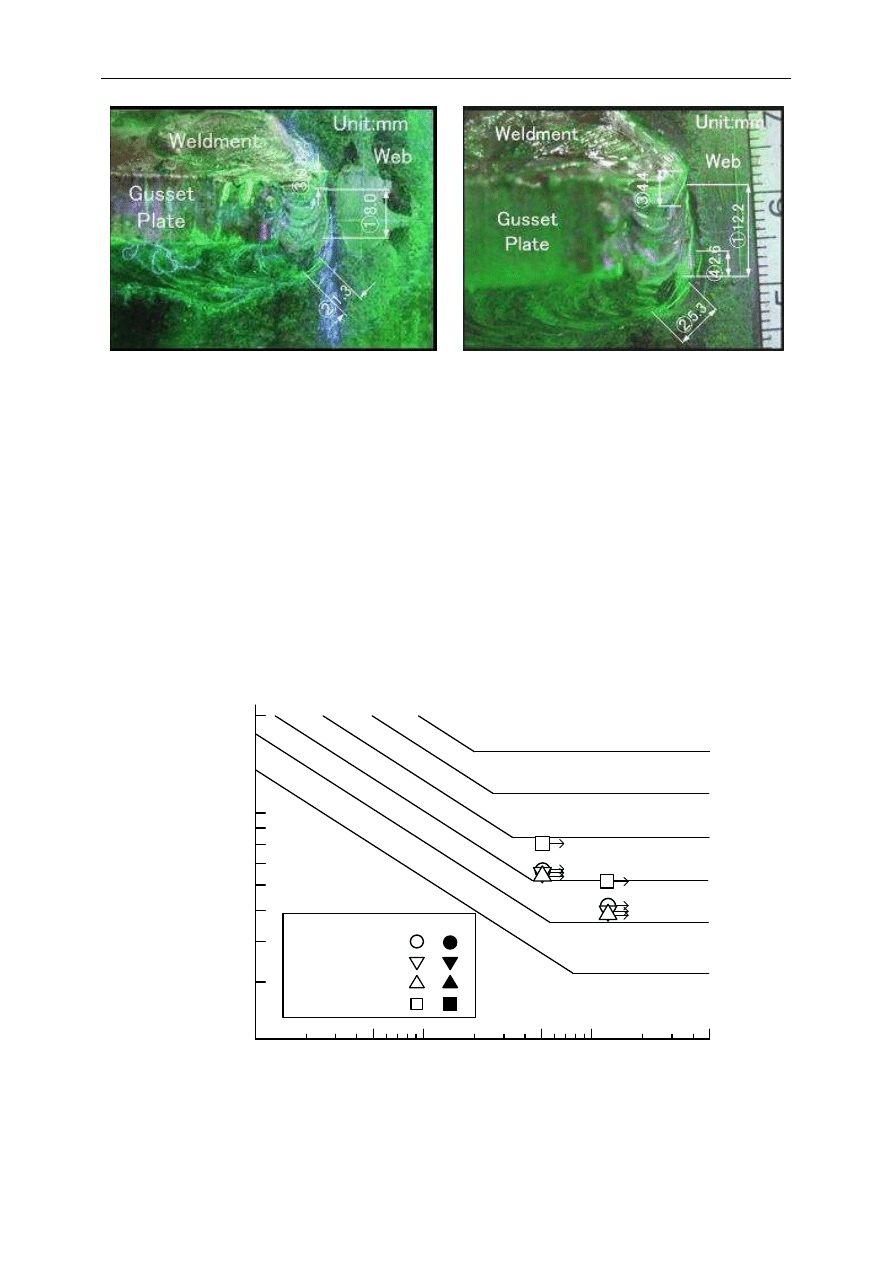

A MT signs of 8 mm and 1.3 mm length were observed under a 83 mm paint crack at the

G1-2-C gusset plate. A MT sign of 4mm length was observed under a 23 mm paint crack at the

G4-1-C gusset plate. Photos 1~4 shows paint cracks and MT signs in the G1-2-C and G4-1-C

gusset plates.

There are no MT signs in the inspected areas that have no paint cracks, or that have paint

cracks in places other than along the toes of turn-round weldment which are fatigue weak

points.

Photo 1. Paint cracks on G1-2-C

Photo 2. MT sign on G1-2-C (N=0cycle)

Yamaoka D. i inni: Fatigue test of an urban expressway steel girder bridge constructed in 1964

399

Photo 3. Paint crack on G4-1-C

Photo 4. MT sign on G4-1-C

4. Experimental method

4.1. The configurations and dimensions of specimen

Fig. 6 shows the configurations and dimensions of G1 girder specimen. Due to the capacity

of the testing machine, the depth of girder was reduced by cutting off the upper part of the

girder and welded a new top flange. Photo 5 shows the gusset plate in G1 girder specimen.

The gusset plate has fillets at its both ends.

C

L

5210

680

3

6

0

3

0

0

9

R=30

200

9

150

1319

1319

1111

1111

11

700

9

11

11

11

9

5210

1

08

2

2

2

1

1

7

5

2

9

150

1319

1319

1111

200

a

b

GUSS PL

360× 9× 680

340

1

4

9

680

SOLE PL

300× 15× 200

1

1

3

0

2

0

0

1

3

0

6

6

6

6

6

6

A

A

A

A

C

700

6

1111

A

A

A

A

C

B

B

9

9

11

11

11

11

1

6

5210

680

3

6

0

3

0

R=30

1319

1111

200

9

1000

1319

1111

2

30

150

1000

6

6

6

9

350

890

400

890

2

30

4860

SOLE PL

300× 15× 200

b’

a’

(b) Elevation

(a) a- a’ Plan

(c) b- b’ Plan

Unit:mm

Fig. 6.

Configurations and Dimensions of G1 Girder Specimen

Photo 5. Configuration of Gusset

Plate

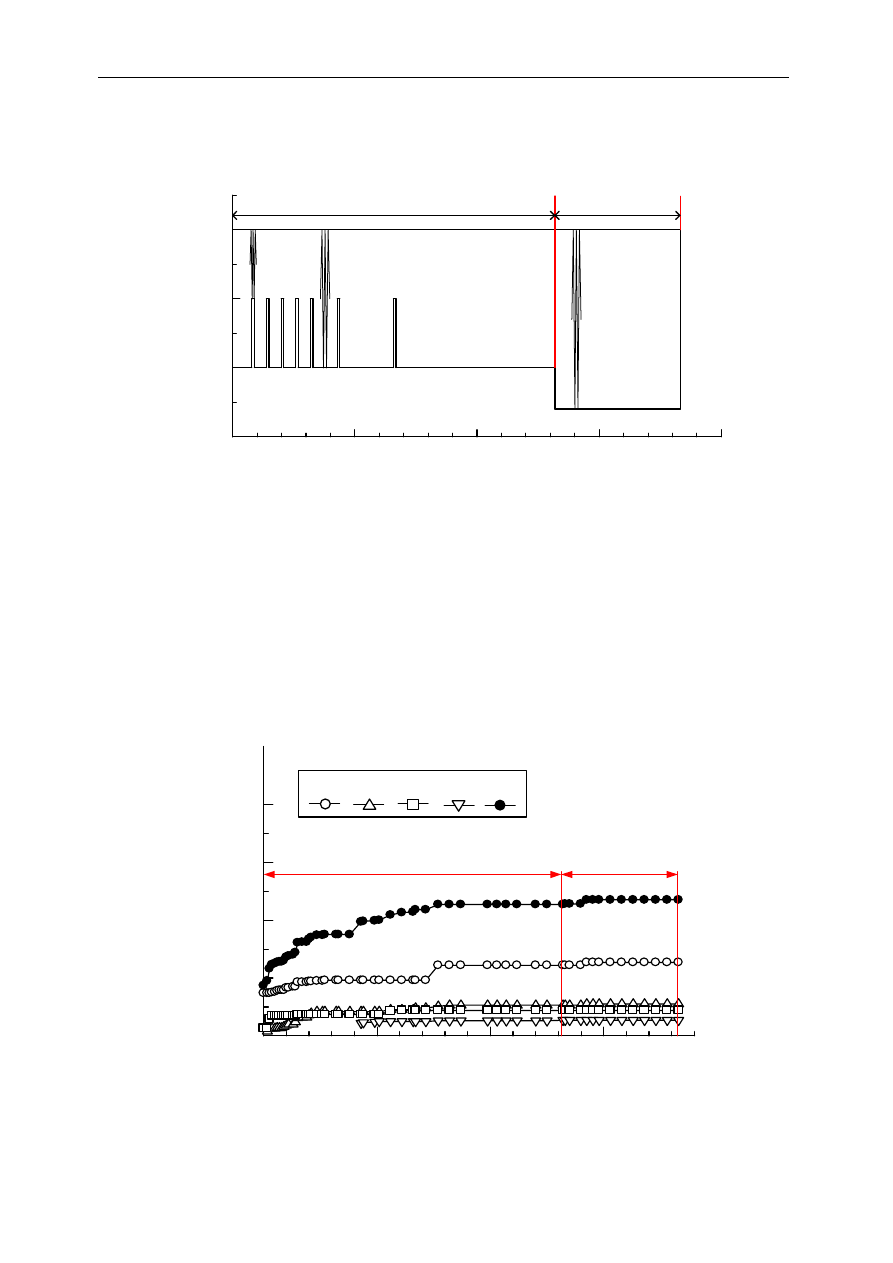

4.2. Fatigue Test Method

Fatigue test was conducted in 4-point bending condition with a loading beam. Loading rate

was 3 Hz. Fig. 7 shows fatigue loading history. After ∆P = 200 kN fatigue loading of

Mosty, drogi i koleje

400

12.5 Mcycles, MT signs at the gusset plate end was propagated so little that. The load range

(∆P) was increased to 260 kN.

5

10

15

20

0

100

200

300

L

oa

d M

a

guni

tude

P

(

kN

)

Total Number of loading cycles Nt (Mcycles)

∆ P=200kN

∆ P=260kN

B.M:100,000cycles

B.M

① ② ③ ④ ⑤

⑥

⑦

18.3

13.2

Fig. 7. Fatigue Loading History

5. Experimental Results

5.1. Fatigue Crack development and Propagation Behavior

Fig. 8 shows the relationship between the length of MT sign and the number of loading

cycles. Photo 6, 7 show MT signs at the G1-2-C gusset plate. A MT sign of 0.8 mm length

was detected after ∆P=200 kN loading of 0.16 Mcycles at the upper part of G1-2-C weldment.

The remarkable propagation of MT signs could not be observed after ∆P = 200 kN loading of

12.5 Mcycles and ∆P = 260 kN loading of 5.1 Mcycles.

5

10

15

0

10

20

30

40

L

e

n

g

th

o

f

M

T

S

ig

n

s

2

a(

m

m

)

Number of loading cycles N (Mcycles)

⊿P=200kN

⊿P=260kN

Sign.2 Sign.3

Sign.1

Sign.4 ∑ 2a

Fig. 8.

Relationship between Length of MT Sign and Number of Loading Cycles

Yamaoka D. i inni: Fatigue test of an urban expressway steel girder bridge constructed in 1964

401

Photo 6 MT sign at G1-2-C (P=200kN,N=0.16Mcycles) Photo 7 MT sign at G1-2-C (P=200kN,N=8.1Mcycles)

5.2. Fatigue Strength

Fig. 9 shows fatigue test results and fatigue design curves after JRA (Japan Road

Association) Fatigue Design Recommendations for Highway Bridges (2002)

[1]

. The vertical

axis represents the maximum principal stress range (∆), while the horizontal axis represents

the fatigue life Nd and Nf. Nd is fatigue crack detection life as the number of stress cycles

until fatigue cracks are detected. Nf is fatigue life defined as the number of stress cycles until

the fatigue crack propagates until the web depth.

No fatigue crack propagation was observed in the gusset plate welded joint after

12.5Mcycles loading under ∆σ = 51MPa and 5.1Mcycles loading under ∆σ = 62MPa.

The fatigue strength of this type of web gusset welded joint with fillet satisfies JRA Fatigue

Category E which is two-rank higher than that of web gusset welded joint without fillet.

100

10

5

10

6

10

7

G

F

E

D

C

JRA-B

20

30

40

50

M

a

x

im

u

m

P

ri

n

ci

p

al

S

tr

e

ss

R

an

g

e

⊿

σ

(M

P

a)

Fatigue Life Nd,Nf(

cycles)

200

G1-2-C

G1-2-E

G1-2-SC,SE

Nf

Nd

Flange-web

Fig. 9. Fatigue Test Results

Mosty, drogi i koleje

402

6. Conclusions

The principal results obtained through this study are as follows.

1) MT signs that may indicate fatigue cracks were observed at 2 weldments from among 18

turn-round weldments with paint cracks.

2) A MT sign of 8mm length was observed under a 83mm paint crack at the G1-2-C gusset

plate. A MT sign of 4mm length was observed under a 23mm paint crack at the G4-1-C

gusset plate.

3) There are no MT signs in the inspected areas which have no paint cracks, or that have paint

cracks in places other than along the toes of turn-round weldment which are fatigue weak

points.

4) The remarkable propagation of MT signs could not be observed after ∆P = 200kN loading

of 12.5Mcycles and ∆P = 260kN loading of 5.1Mcycles

5) It was confirmed that the fatigue strength of this type of web gusset welded joint with fillet

satisfies JRA Fatigue Category E which is two-rank higher than that of web gusset welded

joint without fillet.

References

1. Japan Road Association, “Fatigue Design Recommendations for Highway Bridges”, 2002

(in Japanese).

2. M. Sakano, M. Hozumi, T. Shimora and I. Mikami, "Long Term Fatigue Strength of a Web

Gusset Joint in Floor-Beam-to-Main-Girder Connection", Steel Construction Engineering,

Vol.5, No.18, pp 31–41, June 1998 (in Japanese).

3. M. Sakano, D. Nimura, K. Matumoto, A. Isoda, N. Kondo, K. Arimochi, and N. Konda,

„Improving Fatigue Strength of Welded Beams by Using Fatigue Crack Arresting Steel”,

Euro Steel 2005, Volume B, pp 1.11-25–1.11-32, 2005.

Wyszukiwarka

Podobne podstrony:

Karen MacInerney Tales of an Urban Werewolf 3 Leader of the Pack

11 Yamaoka D i inni Effect of reinforcing method against fatigue cracking of orthotropic steel deck

Design Fatigue Test and NDE of a Sectional Wind Turbine Rotor Blade

05 DFC 4 1 Sequence and Interation of Key QMS Processes Rev 3 1 03

Pancharatnam A Study on the Computer Aided Acoustic Analysis of an Auditorium (CATT)

Congressional Research Services, 'NATO in Afghanistan, A Test of the Transatlantic Alliance', July 2

Sinners in the Hands of an Angry GodSummary

2D Analysis of an Aluminum Bracket

Autopsy of an Egyptian mummy (Nakht ROM I)

ESL Seminars Preparation Guide For The Test of Spoken Engl

comment on 'Quantum creation of an open universe' by Andrei Linde

Summary of an artice 'What is meant by style and stylistics'

Breakdown of an?ucated person

Evidence of an oscillating peripheral clock in an equine fib

formation of an individual

A systematic review and meta analysis of the effect of an ankle foot orthosis on gait biomechanics a

Ćw 05 Antygeny zgodności tkankowej Test mikrolimfocytotoksyczny

więcej podobnych podstron