13 11

23

19

2

2

5 3 4

20

10

19

17

18

21

22

17

18

8

9

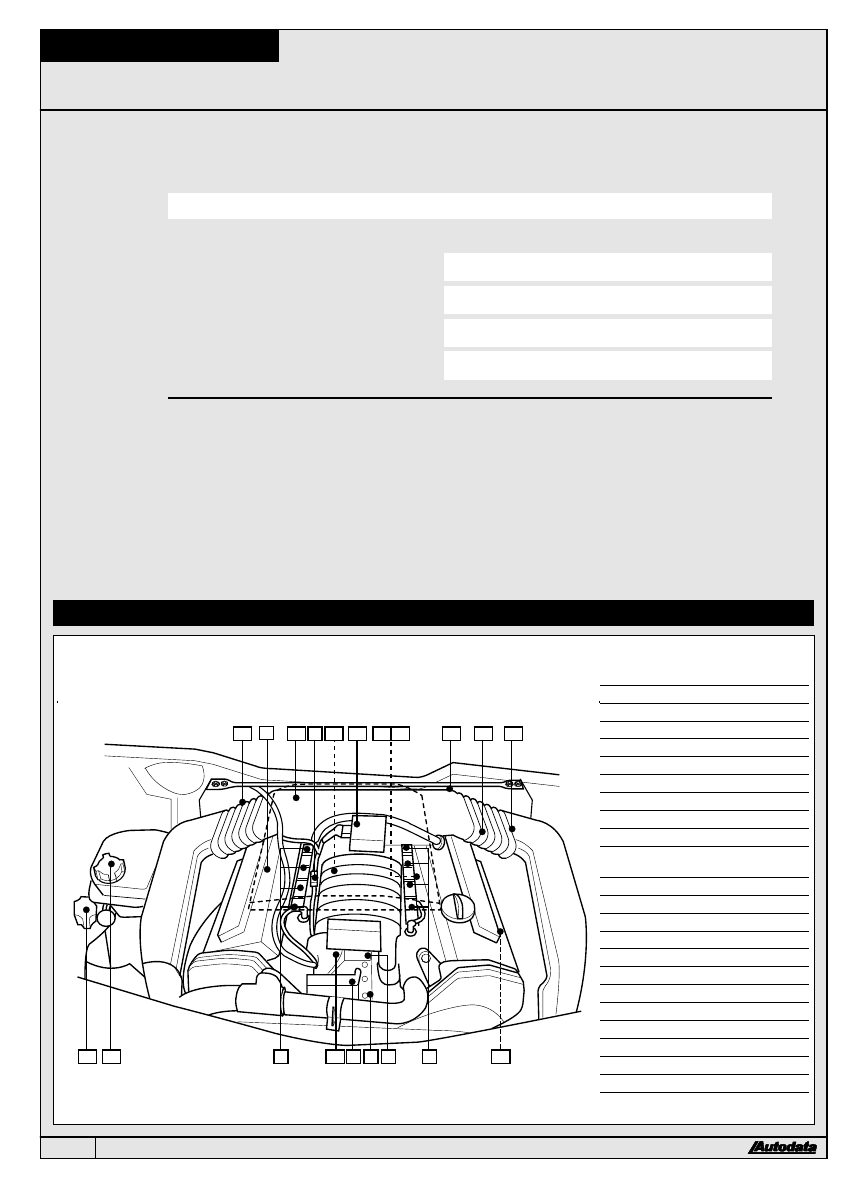

AD91368

all models

&

1 Engine control module (ECM) ± above pedals

&

2 Injectors

&

3 Throttle body

&

4 Throttle position (TP) sensor

&

5 Idle air control (IAC) valve

&

6 Fuel pump ± in tank

&

7 Fuel filter ± tank exterior

&

8 Fuel pressure regulator

&

9 Engine coolant temperature (ECT) sensor

&

10 Mass air flow (MAF) sensor

&

11 Evaporative emission canister purge

(EVAP) valve

&

12 Heated Oxygen sensor (HO2S) ± front pipes

&

13 Auxiliary starting terminal

&

14 Fuel pump relay I ± RH kick panel

&

15 Fuel pump relay II ± RH footwell relay plate

&

16 Data link connector (DLC) ± LH fascia

&

17 Ignition distributors

&

18 Ignition coils/modules

&

19 Knock sensors (KS)

&

20 Engine speed (RPM) sensor

&

21 Crankshaft position (CKP) sensor

&

22 Sensor multi-plugs

&

23 Intake air temperature (IAT) sensor

Model:

Engine code:

Year:

V8 4.2L

ABH

1992-94

System:

Bosch Motronic 2.4.1

Fuel system type:

Multi-port injection, sequential

Ignition system type:

ECM controlled with Hall effect trigger

Trouble shooter:

2

Engine management system layout and components

120

# 1997 Copyright Autodata Limited

Self-diagnosis

General information

l

Engine control module (ECM) incorporates self-

diagnosis function.

l

Malfunction indicator lamp (MIL) will illuminate if certain

faults are recorded.

l

ECM operates in backup mode if sensors fail, to enable

car to be driven to workshop.

l

Trouble codes can be accessed with suitable code

reader. Refer to Self-diagnosis section 2.

Trouble code identification

Trouble code Fault location

0000

No fault found

1111

Engine control module (ECM)

1231

Vehicle speed sensor (VSS)

2111

Engine speed (RPM) sensor

2112

Crankshaft position (CKP) sensor

2113

Camshaft position (CMP) sensor/Hall sensor

2114

Hall sensor not at reference mark

2121

Closed throttle position (CTP) switch

2141

Knock sensors (KS)

2142

Knock sensors (KS)

2143

Knock sensors (KS)

2144

Knock sensors (KS)

2212

Throttle position (TP) sensor

2231

Idle air control (IAC) valve

2232

Mass air flow (MAF) sensor

2234

Engine control module (ECM), voltage supply

too high

2312

Engine coolant temperature (ECT) sensor

2314

Engine/transmission connection

2322

Intake air temperature (IAT) sensor

2324

Engine control module (ECM)

2341

Heated oxygen sensor (HO2S)

2342

Heated oxygen sensor (HO2S)

2411

Exhaust gas recirculation (EGR) system control

2413

Fuel/air mixture incorrect

4312

Exhaust gas recirculation (EGR) solenoid

4334

Oxygen sensor heating

4343

Evaporative emission canister purge (EVAP) valve

4411

Injector valve No.1

4412

Injector valve No.2

4413

Injector valve No.3

4414

Injector valve No.4

4421

Injector valve No.5

4422

Injector valve No.6

4431

Idle air control (IAC) valve

Service adjustments

Preparatory conditions

i

Engine at normal operating temperature.

i

Engine oil temperature min. 85aC.

i

Ignition system in good condition.

i

Air filter installed and in good condition.

i

Automatic transmission in `P'.

i

All auxiliary equipment, including air conditioning,

switched OFF.

i

Radiator fan must not run during checks and

adjustments.

Idle speed

Adjustment

TECHNICAL DATA

Automatic transmission

710-770 rpm

Manual transmission

650-710 rpm

l

Idle speed electronically controlled.

l

No adjustment possible.

l

If idle speed not as specified, check for air leaks in

intake system.

l

Carry out component and electrical tests.

CO level

Adjustment

TECHNICAL DATA

All models

0.5-0.9% ± at emission port

l

CO level electronically controlled.

l

No adjustment possible.

l

If CO level not as specified, check for air leaks in intake

and exhaust systems.

l

Carry out component and electrical tests.

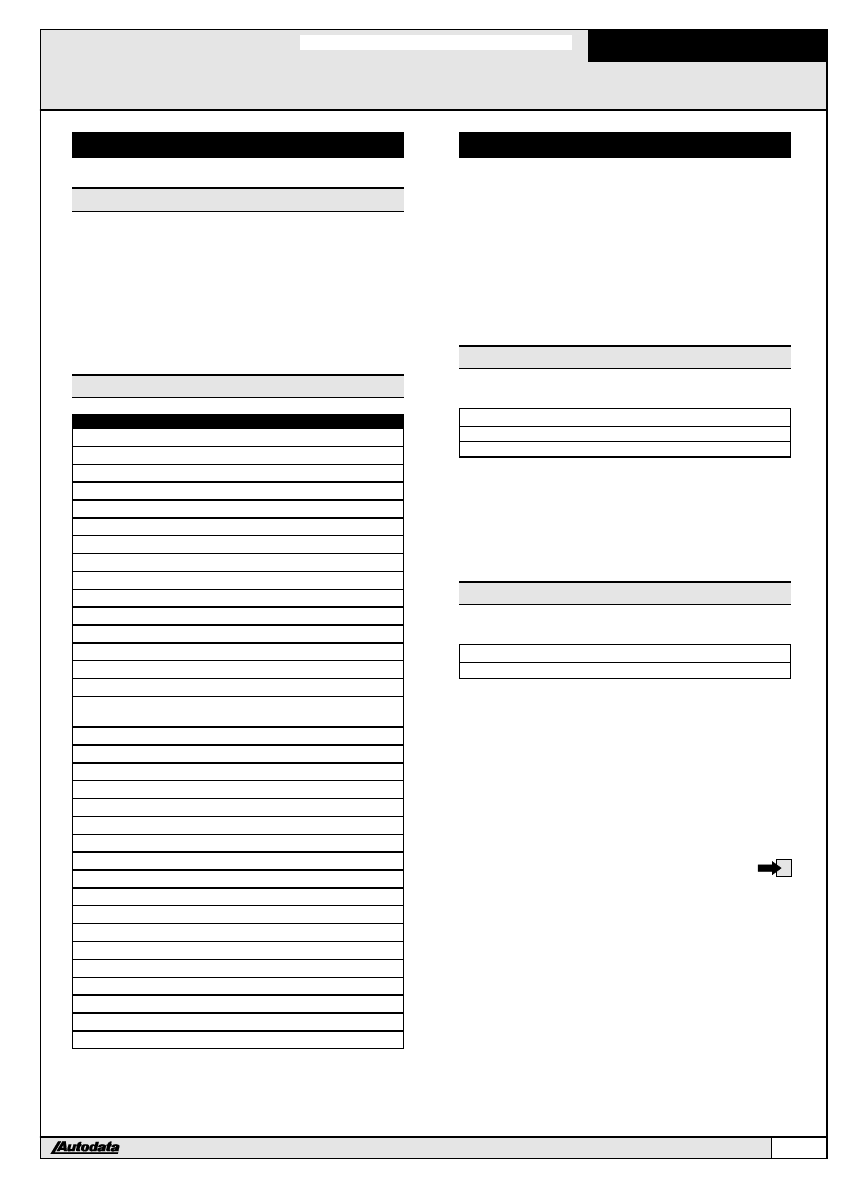

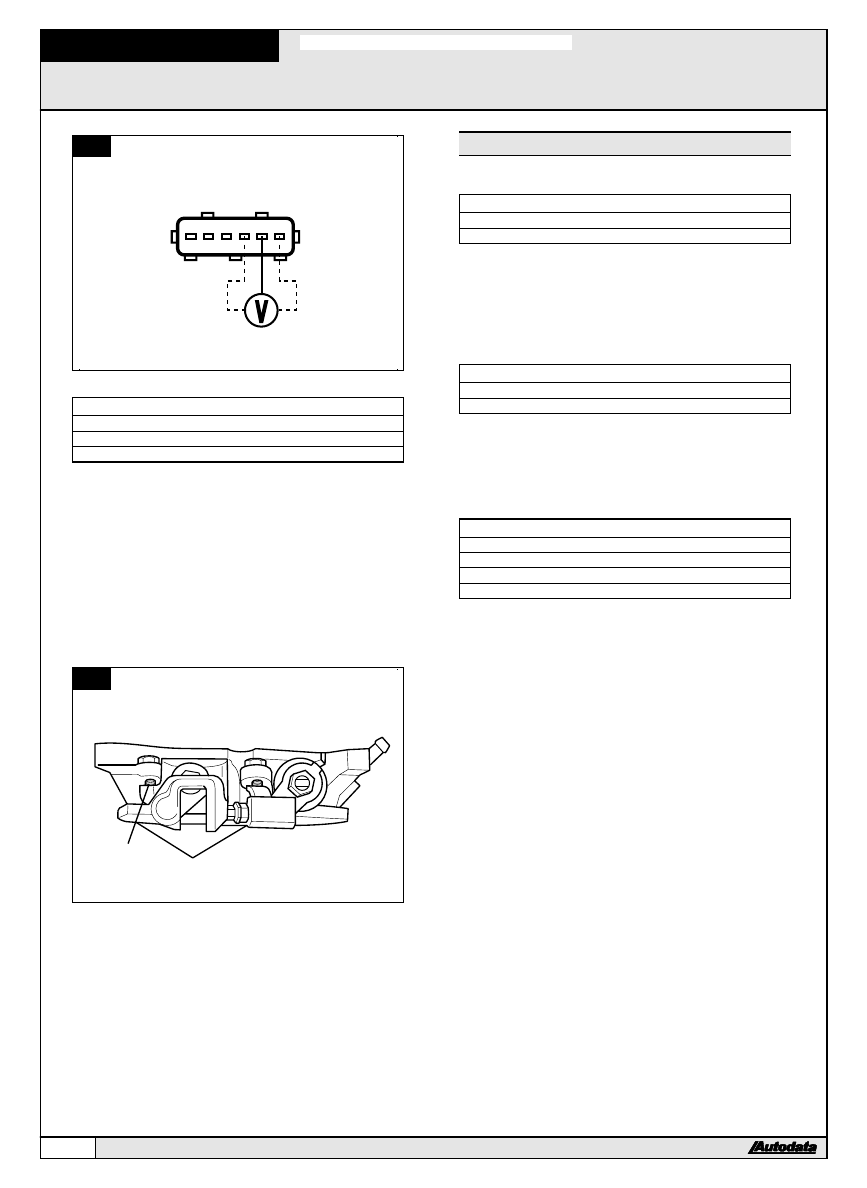

Checking ±

&

1

&

&

2

l

Connect CO meter to CO tap tube

&

1

.

l

Clamp off upper (thicker) carbon canister hose

&

2

.

l

Start engine.

l

Allow to idle.

l

Check CO level.

V8 4.2L

1992-94

AUDI

121

# 1997 Copyright Autodata Limited

1

AD68623

2

AD68624

Throttle initial position

Adjustment

l

Throttle initial position set by manufacturer.

l

No adjustment possible.

Fuel system

CAUTION:

To minimize fire risk, fuel system must be

depressurized before disconnecting any

fuel lines or fuel system components ± refer

to Safety Precautions at the front of this

manual.

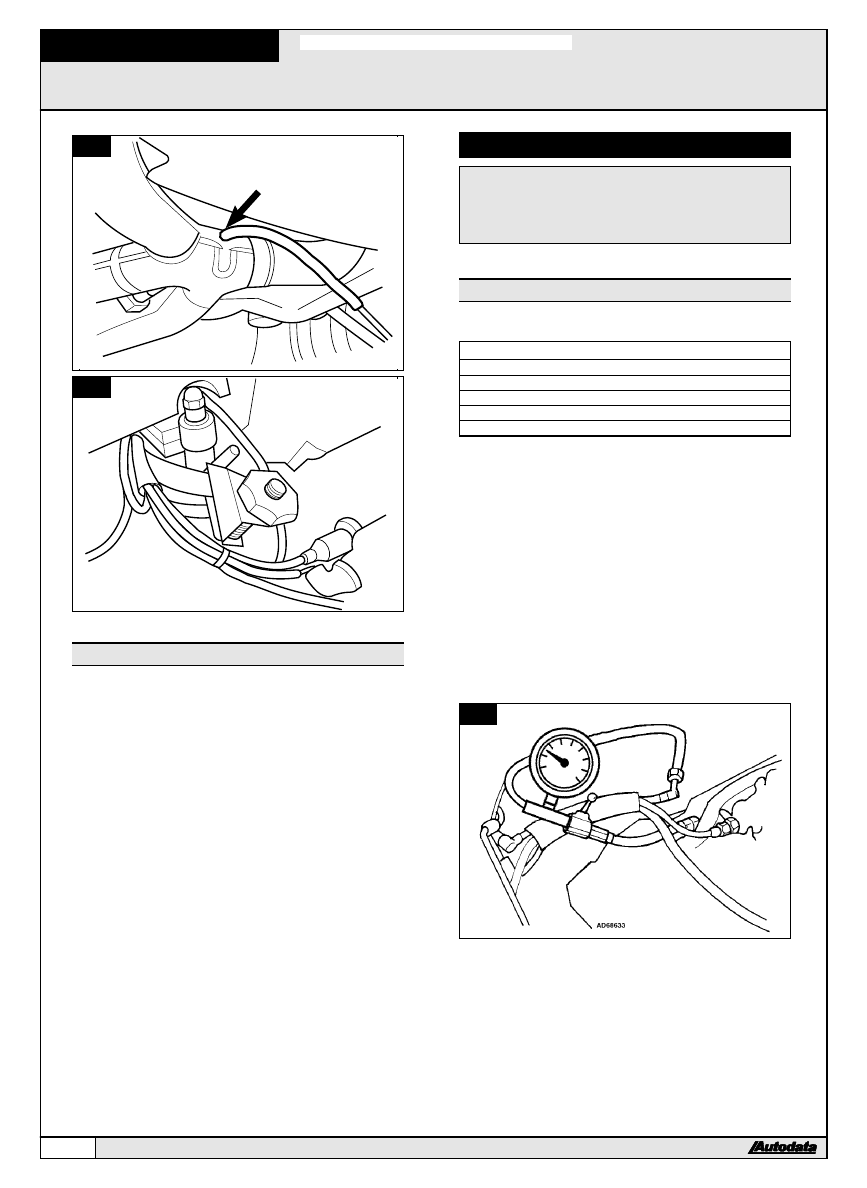

Fuel pressure

Checking ±

&

3

&

&

4

TECHNICAL DATA

Pressure

Condition

Value

System

vacuum OFF

57-61 psi (4-4.3 bar)

Regulated

vacuum ON

48-53 psi (3.4-3.7 bar)

Residual

after 10 minutes (cold)

43 psi (3 bar)

Residual

after 10 minutes (hot)

50 psi (3.5 bar)

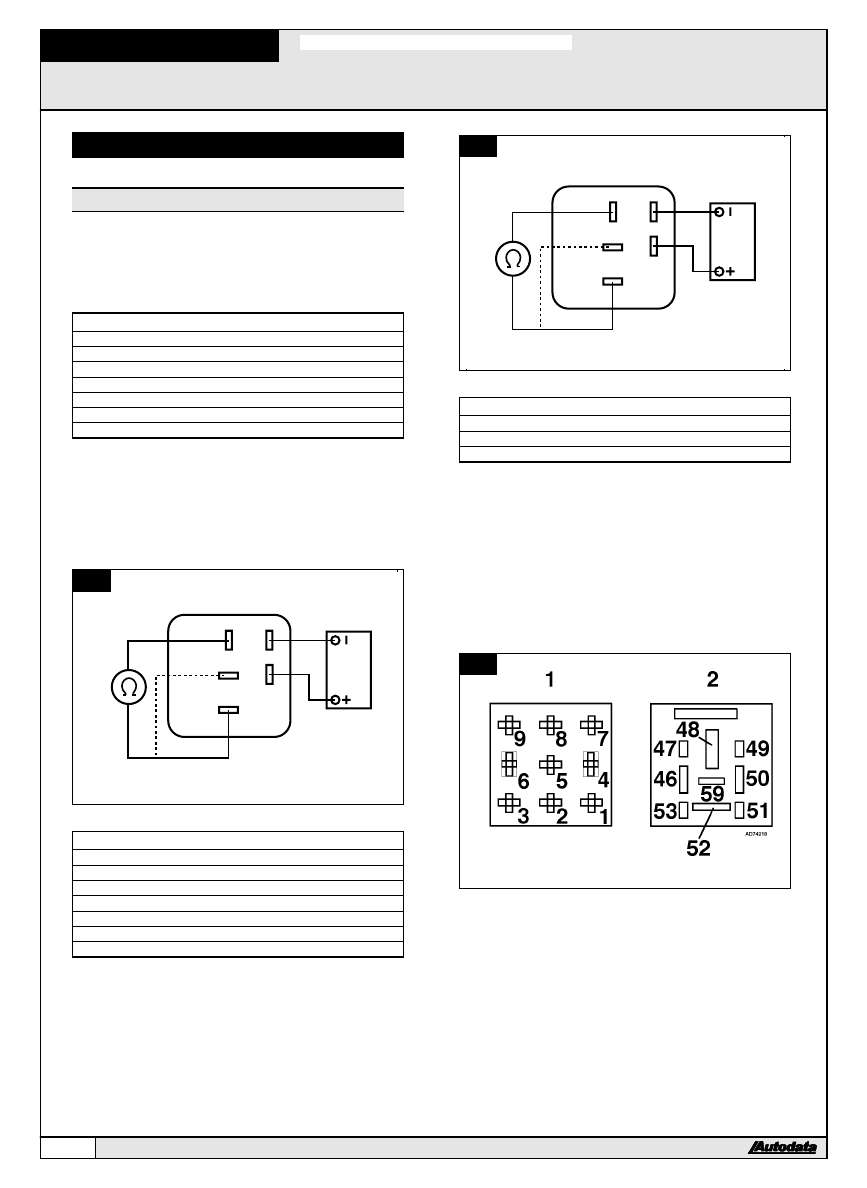

l

Ensure ignition switched OFF.

l

Connect pressure gauge between fuel supply pipe and

fuel manifold

&

3

.

l

Remove fuel pump relay I.

l

Jump fuel pump relay base terminal 52 and auxiliary

starting terminal with a switched lead

&

4

.

l

Operate switch to run fuel pump.

l

Check system pressure.

l

Remove jumper lead.

l

Reinstall fuel pump relay I.

l

Start engine.

l

Allow to idle.

l

Compare regulated pressure indicated with that

specified.

l

Switch ignition OFF.

l

After 10 minutes check residual pressure.

3

V8 4.2L

1992-94

122

AUDI

# 1997 Copyright Autodata Limited

4

50

48

47

46

AD68632

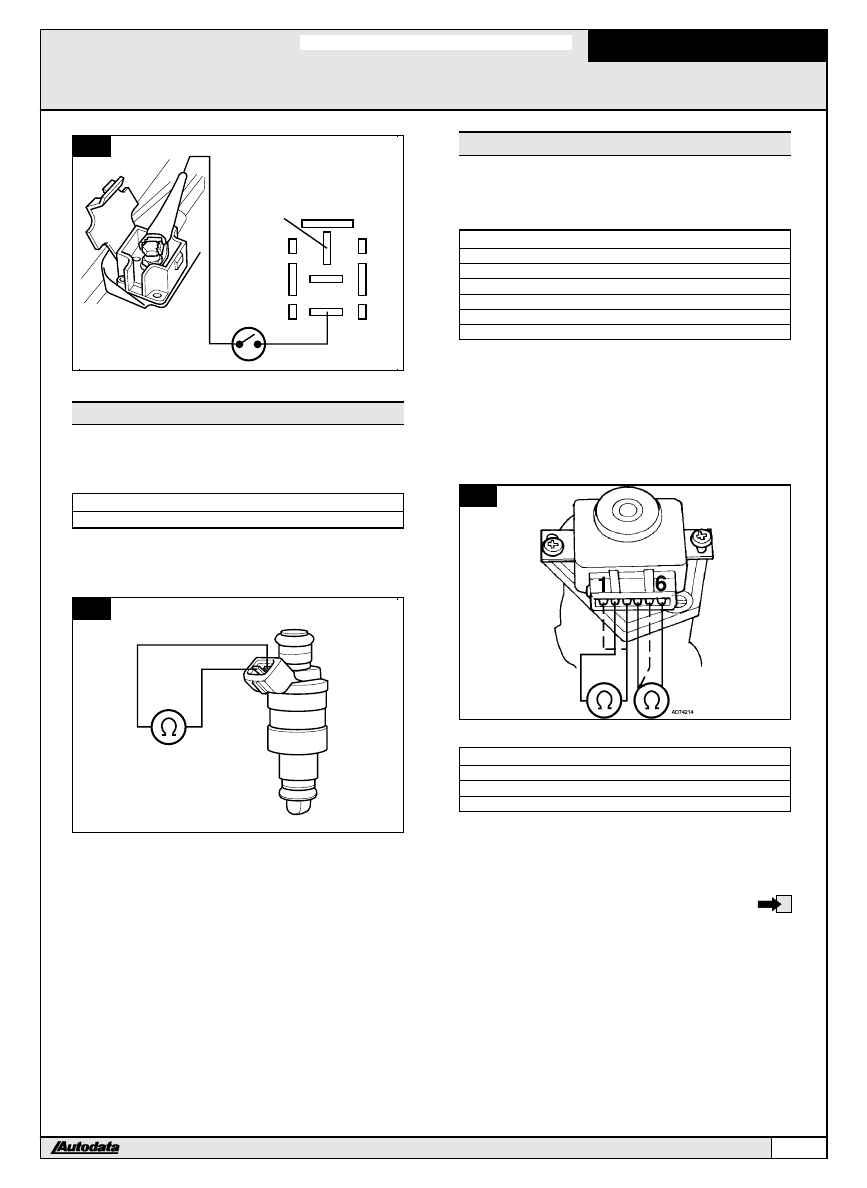

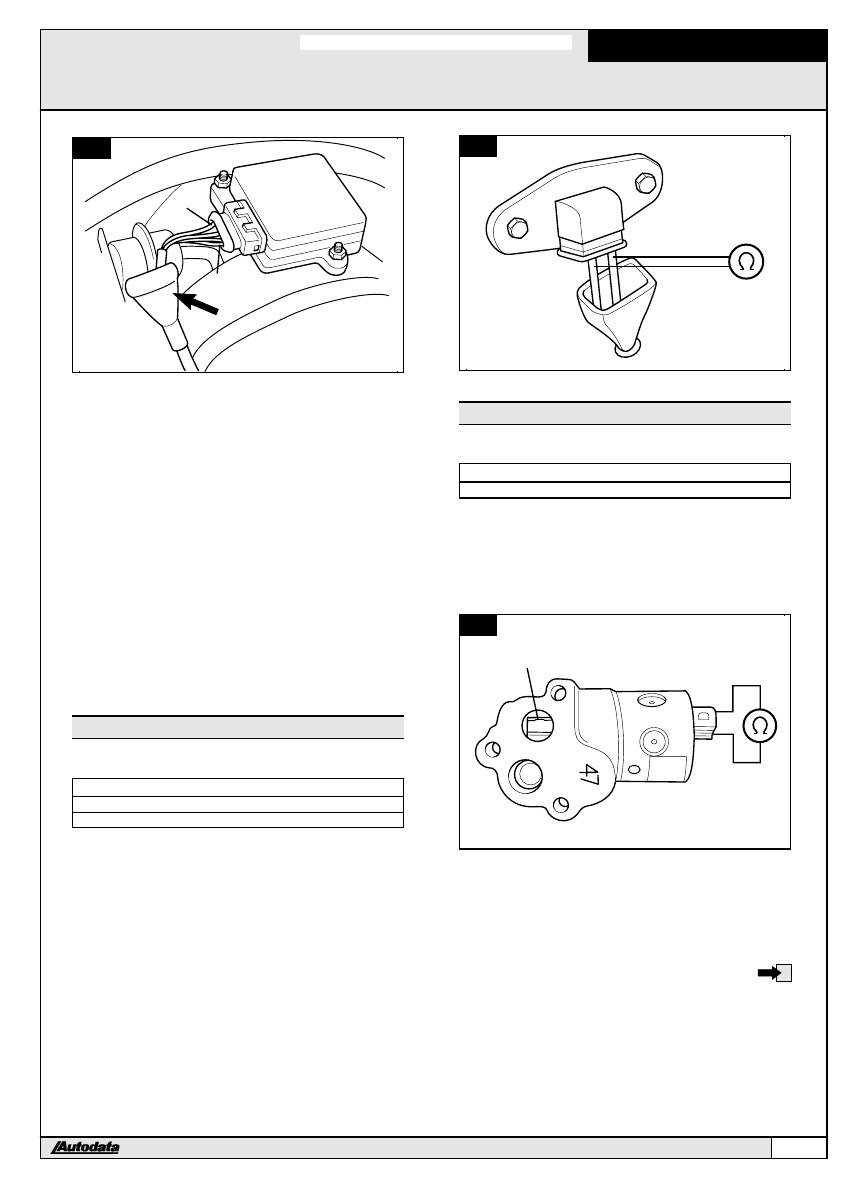

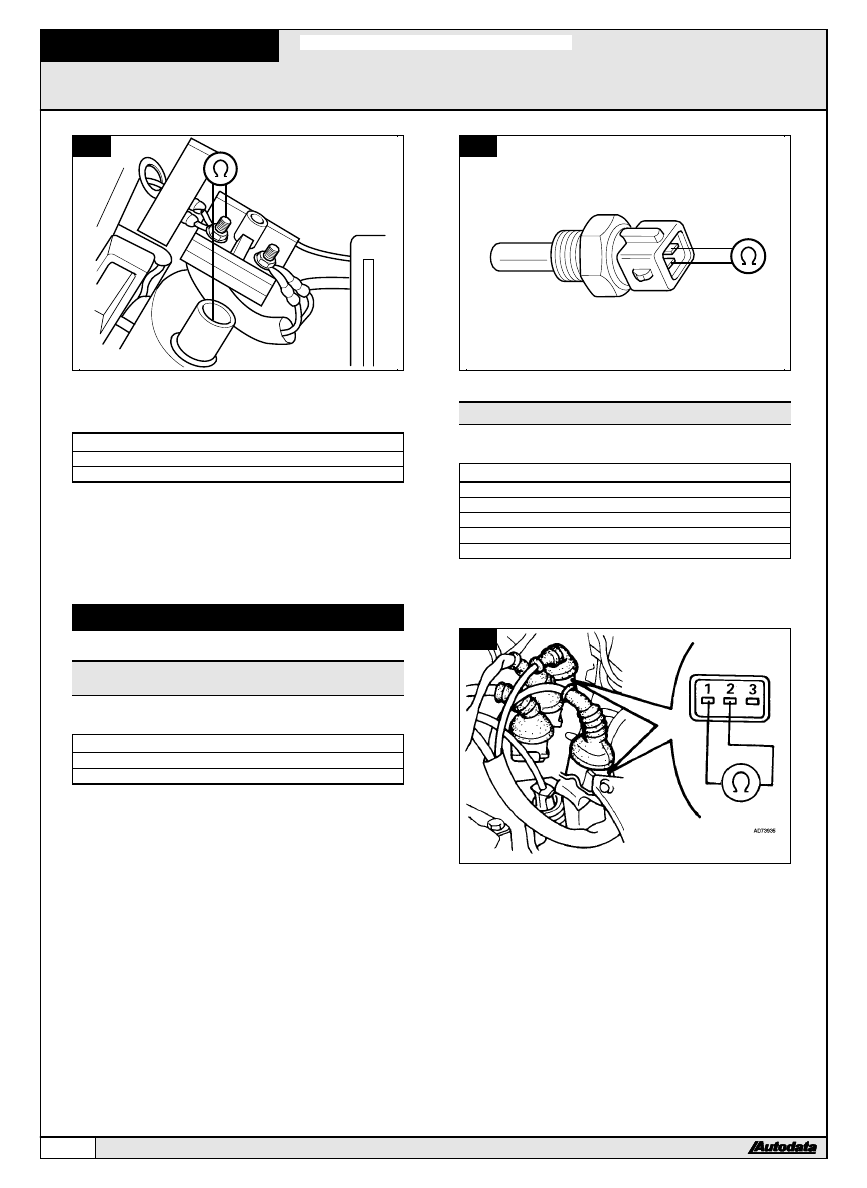

Injectors

Injector spray pattern and leak rate: Refer to General

Test Procedures.

Checking resistance ±

&

5

TECHNICAL DATA

Resistance

15-17 b

l

Ensure ignition switched OFF.

l

Disconnect injector multi-plug.

l

Check resistance between injector multi-plug terminals.

5

AD79117

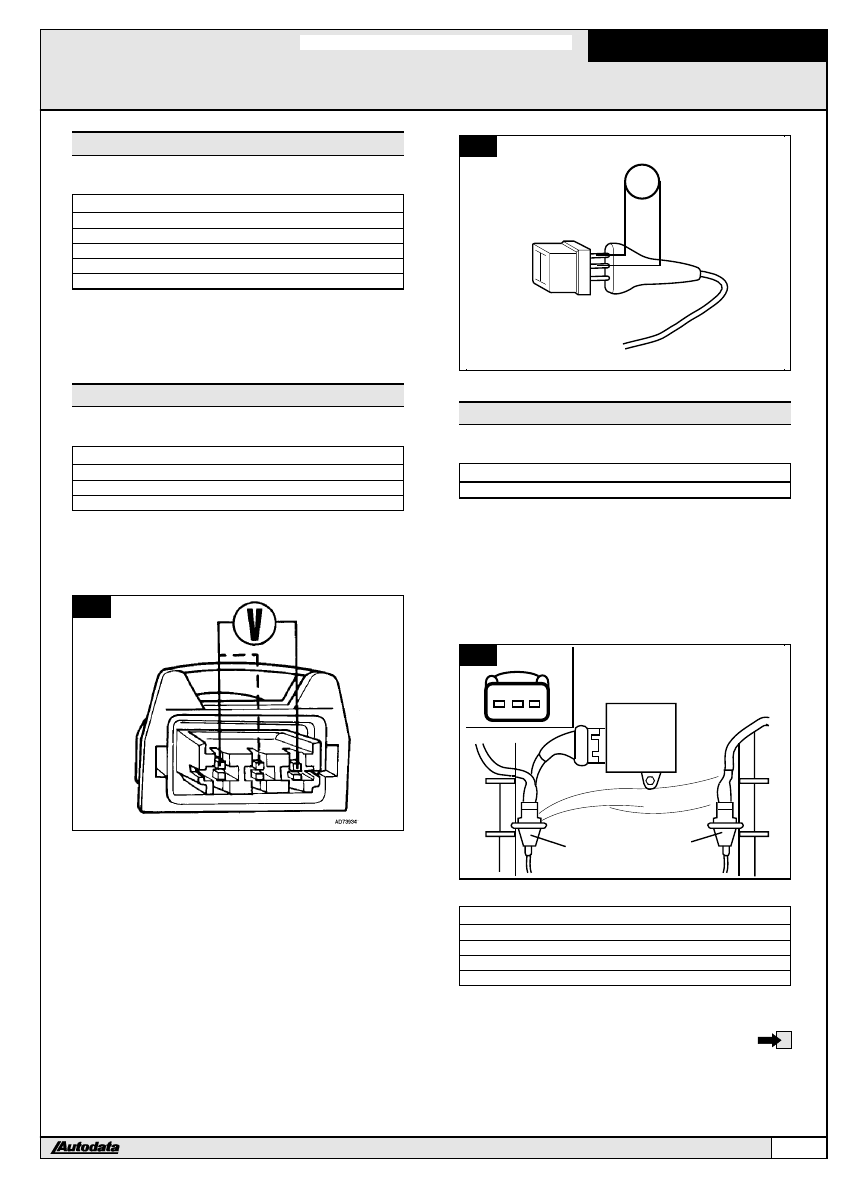

Throttle position (TP) sensor

NOTE: TP sensor incorporates closed throttle position

(CTP) switch.

Checking ±

&

6

TECHNICAL DATA

Terminals

Accelerator

Resistance

1 & 2

-

1500-2500 b

2 & 3

in idle position

750-1300 b

2 & 3

in full load position

2400-3600 b

4 & 6

in idle position

Zero

4 & 6

partly open

u

l

Ensure ignition switched OFF.

l

Disconnect TP sensor multi-plug.

l

Check resistance between TP sensor terminals 1 and 2.

l

Operate accelerator while checking resistance between

terminals 2 and 3.

l

Resistance change should be smooth.

l

Operate accelerator while checking resistance between

terminals 4 and 6.

6

Checking supply voltage ±

&

7

TECHNICAL DATA

Terminals

Voltage

4 & 5

4.5-5.5 V

5 & 6

4.5-5.5 V

l

Ensure ignition switched OFF.

l

Disconnect TP sensor multi-plug.

l

Switch ignition ON.

l

Check voltage between harness multi-plug terminals.

V8 4.2L

1992-94

AUDI

123

# 1997 Copyright Autodata Limited

7

3

2

1

6

5

4

AD74867

Adjustment ±

&

8

TECHNICAL DATA

Terminals Condition

Resistance

4 & 6

0.010 in. (0.25 mm) feeler gauge inserted Zero

4 & 6

0.012 in. (0.30 mm) feeler gauge inserted u

l

Ensure ignition switched OFF.

l

Remove throttle housing.

l

Loosen TP sensor screws.

l

Insert feeler gauge of specified thickness between

throttle lever and stop screw [

1

].

l

Turn TP sensor body counter-clockwise against stop.

l

Turn TP sensor slowly clockwise until resistance

between terminals 4 & 6 as specified.

l

Tighten TP sensor screws.

l

Insert feeler gauge of specified thickness between

throttle lever and stop screw [

1

].

l

Check resistance between terminals 4 & 6.

8

1

AD68629

Mass air flow (MAF) sensor

Checking supply voltage ±

&

7

TECHNICAL DATA

Terminals

Voltage

5 & ground

Battery voltage

l

Ensure ignition switched OFF.

l

Disconnect MAF sensor multi-plug.

l

Switch ignition ON.

l

Check voltage between harness multi-plug terminal and

ground.

Checking ground connection ±

&

7

TECHNICAL DATA

Terminals

Resistance

1 & ground

Zero

l

Ensure ignition switched OFF.

l

Disconnect MAF sensor multi-plug.

l

Check resistance between harness multi-plug terminal

and ground.

Checking voltage ±

&

9

TECHNICAL DATA

Terminals

Condition

Voltage

1 & 3

ignition ON

1.3-1.6 V

1 & 3

engine idling

2.5 V approx.

1 & 3

engine speed raised

3-5 V

l

Ensure ignition switched OFF.

l

Expose MAF sensor multi-plug terminals without

disconnecting multi-plug.

l

Switch ignition ON.

l

Check voltage between multi-plug terminals.

l

Start engine.

l

Allow to idle.

l

Check voltage between multi-plug terminals.

l

Briefly increase rpm.

l

Check voltage between multi-plug terminals.

V8 4.2L

1992-94

124

AUDI

# 1997 Copyright Autodata Limited

9

AD68631

6

1

Checking filament burn off ±

&

9

l

Ensure ignition switched OFF.

l

Engine at normal operating temperature.

l

Expose MAF sensor multi-plug terminals without

disconnecting multi-plug.

l

Connect LED test lamp between multi-plug terminals 1

and 4.

l

Remove fuse No.27.

l

Connect ammeter between fuse terminals.

l

Start engine.

l

Raise engine speed to above 2000 rpm, for more than

3 seconds.

l

Switch ignition OFF.

l

Check filament burn off.

l

If successful burn off indication:

LED illuminates.

ammeter indicates more than 2 A for approximately 1

second.

burn off occurs approximately 3 seconds after engine

stops.

Intake air temperature (IAT) sensor

Checking resistance ±

&

10

TECHNICAL DATA

Temperature

Resistance

68aF (20aC)

450-550 b

l

Ensure ignition switched OFF.

l

Pull back sensor rubber cover.

l

Remove IAT sensor.

l

Check ambient air temperature.

l

Check resistance between IAT sensor terminals.

10

AD73172

Idle air control (IAC) valve

Checking resistance ±

&

11

TECHNICAL DATA

Resistance

7.5-8.5 b

l

Ensure ignition switched OFF.

l

Disconnect IAC valve multi-plug.

l

Remove the IAC valve.

l

Check for high spots on mating faces [

1

].

l

Check for smooth operation.

l

Check resistance between IAC valve terminals.

11

1

AD74215

Checking signal ±

&

12

l

Ensure ignition switched OFF.

l

Disconnect IAC valve multi-plug.

l

Connect LED test lamp between harness multi-plug

terminals.

l

Switch ignition ON.

l

Briefly crank engine.

l

Check that LED flashes.

V8 4.2L

1992-94

AUDI

125

# 1997 Copyright Autodata Limited

12

1

2

AD86786

LED

Ignition system

CAUTION:

To prevent engine starting and to avoid

damaging catalytic converter, disconnect

fuel injector valve multi-plug before

cranking tests ± refer to Safety Precautions

at the front of this manual.

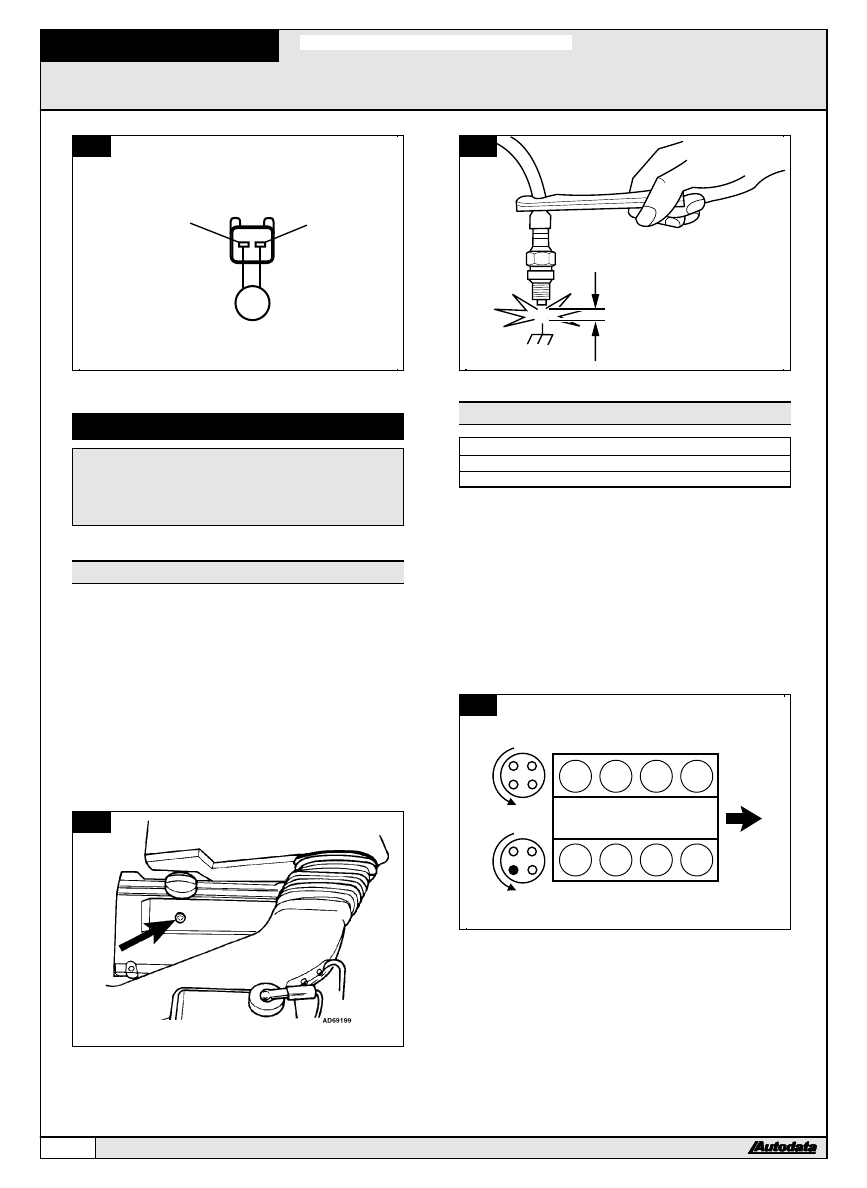

High-tension spark

Checking ±

&

13

&

&

14

l

Ensure ignition switched OFF.

l

Remove upper engine cover

&

13

.

l

Disconnect one high-tension lead from spark plug.

l

Connect test spark plug to high-tension lead.

l

Using insulated pliers, hold test spark plug at 1/4 in.

from suitable ground

&

14

.

l

Briefly crank engine.

l

Check for strong blue spark.

l

Repeat test for each high-tension lead.

l

If no spark is visible, carry out high-tension circuit

component checks.

l

Refer to General Test Procedures.

13

14

AD73908

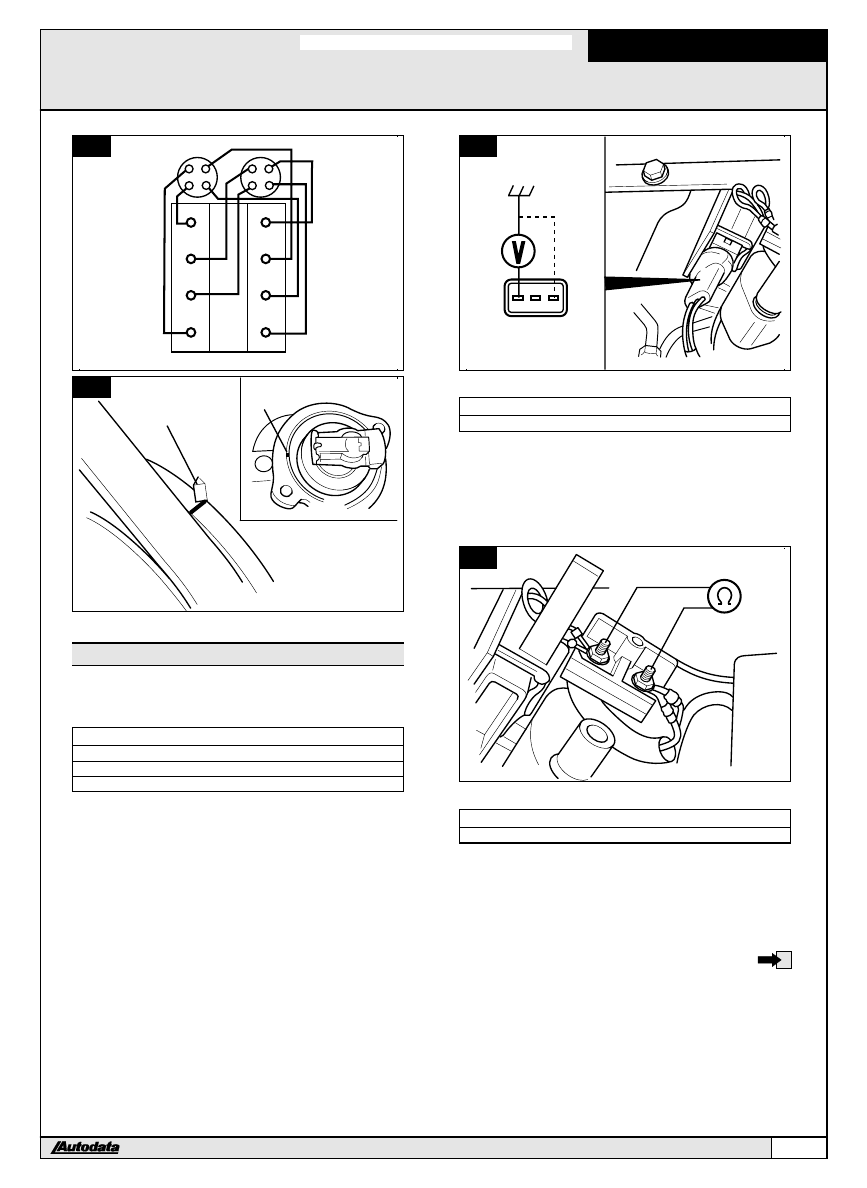

Ignition timing & firing order

TECHNICAL DATA

Firing order

1-5-4-8-6-3-7-2

Distributor rotation

Counter-clockwise

l

Ignition timing electronically controlled.

l

No adjustment possible.

Checking ±

&

15

,

&

16

&

&

17

l

Ensure ignition switched OFF.

l

Check distributor rotor rotation and firing order

&

15

.

l

Ensure high-tension leads are connected correctly

&

16

.

l

Align crankshaft pulley TDC marks

&

17

[

1

].

l

Rotor arms should align with slots in distributor

housings

&

17

[

2

].

NOTE: If rotor arms not aligned turn crankshaft one

further turn clockwise and recheck.

15

4

3

2

1

6

5

7

8

AD75117

V8 4.2L

1992-94

126

AUDI

# 1997 Copyright Autodata Limited

16

4

3

2

1

6

5

7

8

AD73929

17

O

T

1

2

AD73930

Ignition coil

NOTE: Ignition coil incorporates module.

Checking supply voltage ±

&

18

TECHNICAL DATA

Terminals

Ignition

Voltage

1 & ground

ON

Battery voltage

1 & 3

ON

Battery voltage

l

Ensure ignition switched OFF.

l

Disconnect ignition coil multi-plug.

l

Switch ignition ON.

l

Check voltage between harness multi-plug terminal and

ground.

l

Check voltage between harness multi-plug terminals.

l

Repeat test on other ignition coil.

l

If voltage not as specified, check wiring.

18

1

2 3

AD73931

Checking primary resistance ±

&

19

TECHNICAL DATA

Primary resistance

0.5-1 b

l

Ensure ignition switched OFF.

l

Open cover of low-tension terminals.

l

Disconnect ignition coil low-tension leads.

l

Check resistance between ignition coil low-tension

terminals.

l

Repeat test on other ignition coil.

19

AD69206

Checking secondary resistance ±

&

20

TECHNICAL DATA

Secondary resistance

5000-9000 b

l

Ensure ignition switched OFF.

l

Open cover of low-tension terminals.

l

Disconnect ignition coil low-tension leads.

l

Disconnect ignition coil king lead.

l

Check resistance between one ignition coil low-tension

terminal and the high-tension connection.

l

Repeat test on other ignition coil.

V8 4.2L

1992-94

AUDI

127

# 1997 Copyright Autodata Limited

20

AD69207

Checking signal ±

&

18

NOTE: Disconnect injector multi-plugs before cranking

tests,

TECHNICAL DATA

Terminals

Voltage

2 & 3

0.2 V minimum

l

Ensure ignition switched OFF.

l

Disconnect ignition coil/module multi-plug.

l

Briefly crank engine.

l

Check voltage between harness multi-plug terminals.

Engine sensors

Engine coolant temperature (ECT)

sensor

Checking ±

&

21

TECHNICAL DATA

Temperature

Resistance

68aF (20aC)

1500-3000 b

l

Ensure ignition switched OFF.

l

Disconnect ECT sensor multi-plug.

l

Remove ECT sensor from engine.

l

Check resistance between ECT sensor terminals.

l

ECT sensor may be checked in position if engine

temperature and resistance readings are compared.

21

AD52755

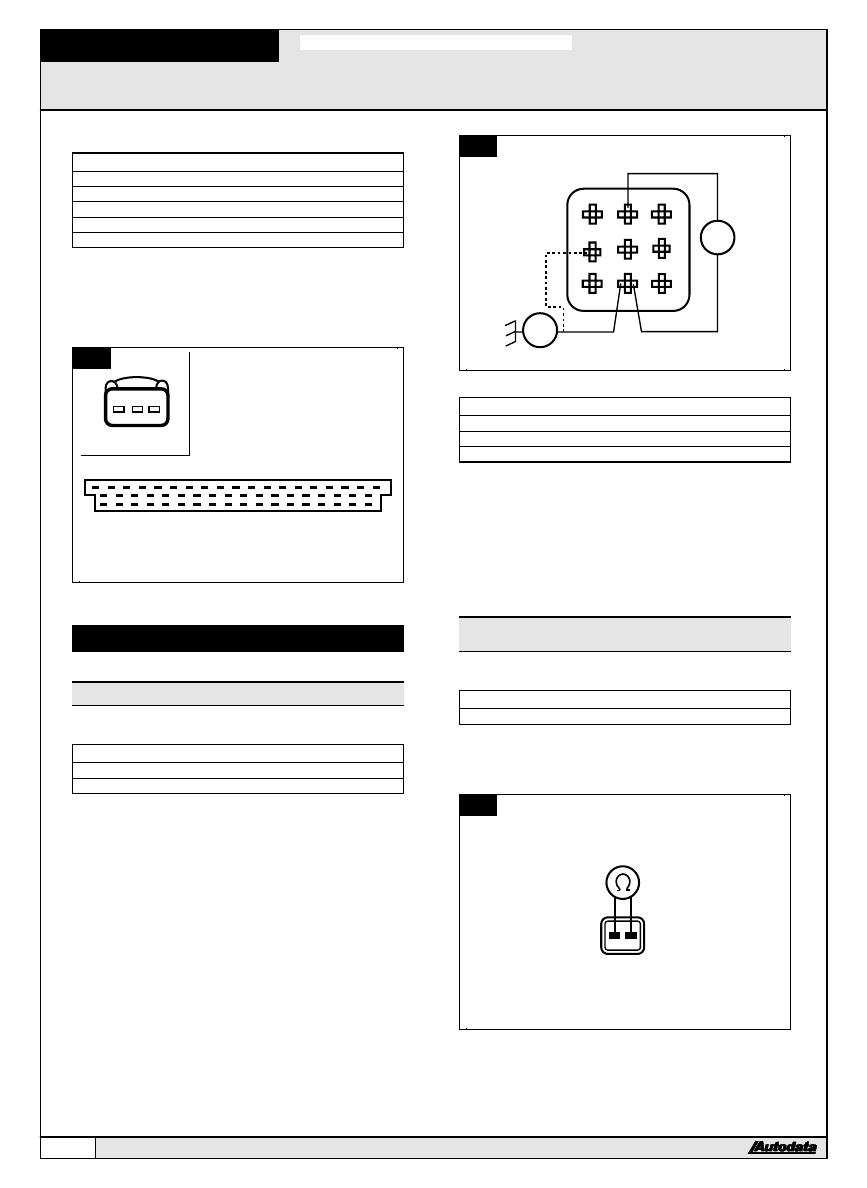

Crankshaft position (CKP) sensor

Checking resistance ±

&

22

TECHNICAL DATA

Multi-plug color

black

Terminals

Resistance

1 & 2

1000 b

1 & 3

u

2 & 3

u

l

Ensure ignition switched OFF.

l

Disconnect CKP sensor multi-plug.

l

Check resistance between CKP sensor terminals.

22

V8 4.2L

1992-94

128

AUDI

# 1997 Copyright Autodata Limited

Engine speed (RPM) sensor

Checking resistance ±

&

22

TECHNICAL DATA

Multi-plug color

gray

Terminals

Resistance

1 & 2

1000 b

1 & 3

u

2 & 3

u

l

Ensure ignition switched OFF.

l

Disconnect CKP sensor multi-plug.

l

Check resistance between CKP sensor terminals.

Camshaft position (CMP) sensor

Checking supply voltage ±

&

23

TECHNICAL DATA

Terminals

Voltage

1 & 3

4.5-5.5 V

2 & 3

4.3-5.2 V

l

Ensure ignition switched OFF.

l

Disconnect distributor multi-plug.

l

Switch ignition ON.

l

Check voltage between harness multi-plug terminals.

23

Checking signal ±

&

24

NOTE: Disconnect injector multi-plugs before cranking

tests, to avoid damage to catalytic converter(s).

l

Ensure ignition switched OFF.

l

Disconnect both module multi-plugs.

l

Expose CMP sensor multi-plug terminals without

disconnecting multi-plug.

l

Connect LED test lamp between multi-plug terminals 1

and 2.

l

Briefly crank engine.

l

Check that LED flashes.

24

LED

1

2

3

AD74065

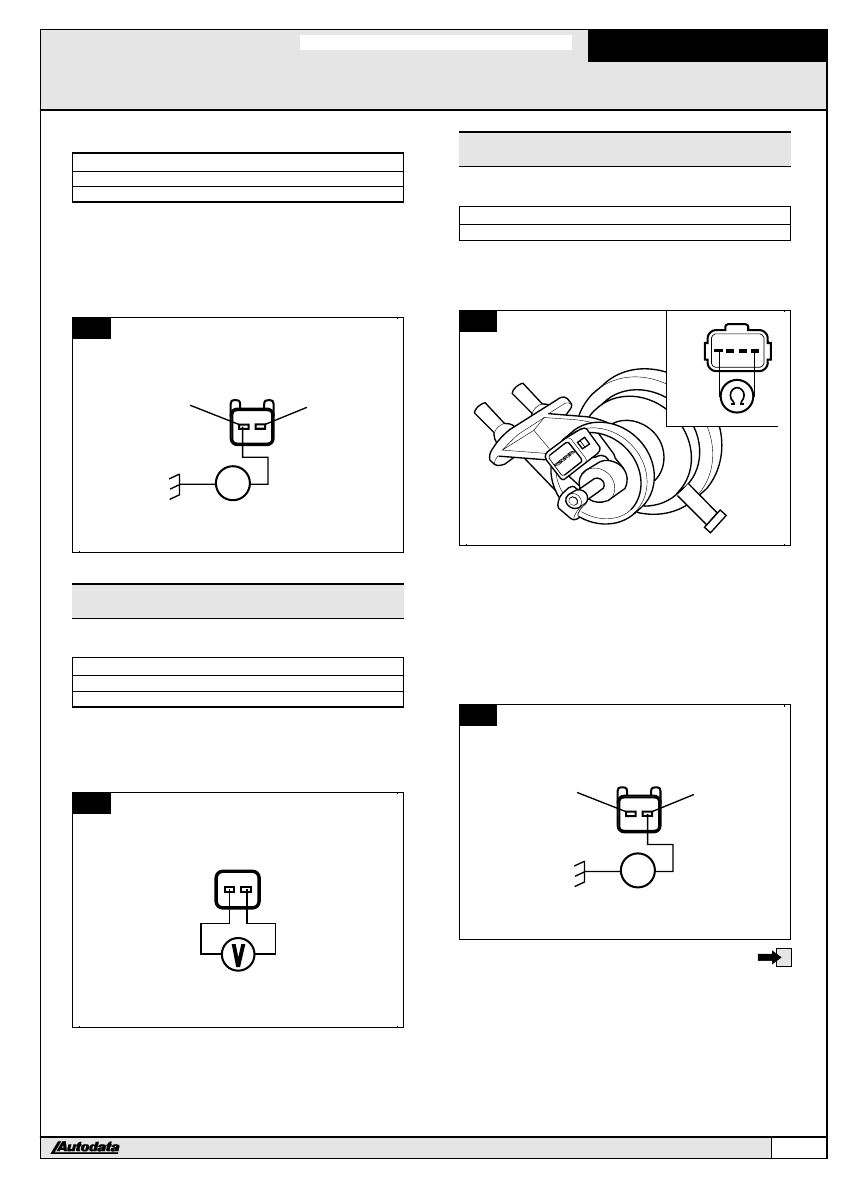

Knock sensor (KS)

Checking ±

&

25

TECHNICAL DATA

Tightening torque

15 ft. lbs (20 Nm)

l

Ensure ignition switched OFF.

l

Disconnect KS multi-plugs [

1

] & [

2

].

l

Remove KS.

l

Ensure cylinder block and KS mating faces are free

from corrosion and clean.

l

Reinstall KS.

l

Tighten bolt to specified tightening torque.

l

Check each KS.

25

1

2 3

AD73936

1

2

Checking resistance ±

&

25

TECHNICAL DATA

Terminals

Resistance

1 & 2

u

1 & 3

u

2 & 3

u

l

Ensure ignition switched OFF.

l

Disconnect KS multi-plugs [

1

] & [

2

].

l

Check resistance between KS terminals.

V8 4.2L

1992-94

AUDI

129

# 1997 Copyright Autodata Limited

Checking wiring ±

&

26

TECHNICAL DATA

Sensor terminal

ECM terminal

Resistance

1 (left)

29

Zero

1 (right)

11

Zero

2

30

Zero

3

19

Zero

l

Ensure ignition switched OFF.

l

Disconnect engine control module (ECM) multi-plug.

l

Check resistance between ECM harness multi-plug

terminals and knock sensor multi-plug terminals.

l

Check each KS.

26

1

2

3

4

5

6

7

8

9

10

11

12

13

15

14

16

17

18

19

20

21

22

23

24

25

35

34

33

32

31

30

29

28

27

26

36

37

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

AD69209

1

2 3

Emission control system

Oxygen sensor heater

Checking heater current ±

&

27

TECHNICAL DATA

Terminals

Current

2 & 8

0.5-4 A

l

Ensure ignition switched OFF.

l

Remove oxygen sensor control unit ± located in RH

footwell.

l

Connect ammeter between control unit base socket

terminals.

l

Switch ignition ON.

l

Check heater current.

27

AD74869

LED

A

1

2

3

4

5

6

7

8

9

Checking signal ±

&

27

TECHNICAL DATA

Terminals

LED

2 & ground

ON

6 & ground

ON

l

Ensure ignition switched OFF.

l

Remove oxygen sensor control unit ± located in RH

footwell.

l

Switch ignition ON.

l

Connect LED test lamp between control unit base

terminals and ground.

l

Check that LED illuminates.

Exhaust gas recirculation (EGR)

solenoid

Checking resistance ±

&

28

TECHNICAL DATA

Resistance

25-35 b

l

Ensure ignition switched OFF.

l

Disconnect EGR solenoid multi-plug.

l

Check resistance between EGR solenoid terminals.

28

AD86047

V8 4.2L

1992-94

130

AUDI

# 1997 Copyright Autodata Limited

Checking supply voltage ±

&

29

TECHNICAL DATA

Terminals

Condition

LED

1 & ground

engine cranking

ON

l

Ensure ignition switched OFF.

l

Disconnect EGR solenoid multi-plug.

l

Connect LED test lamp between harness multi-plug

terminal and ground.

l

Briefly crank engine.

l

Check that LED illuminates.

29

1

2

AD86805

LED

Exhaust gas recirculation (EGR)

temperature sensor

Checking supply voltage ±

&

30

TECHNICAL DATA

Terminals

Voltage

1 & 2

4.5-5.5 V

l

Ensure ignition switched OFF.

l

Disconnect EGR temperature sensor multi-plug.

l

Switch ignition ON.

l

Check voltage between harness multi-plug terminals.

30

AD74133

Evaporative emission canister purge

(EVAP) valve

Checking resistance ±

&

31

TECHNICAL DATA

Resistance

40-50 b

l

Ensure ignition switched OFF.

l

Disconnect EVAP valve multi-plug.

l

Check resistance between EVAP valve terminals.

31

AD74868

Checking supply ±

&

32

NOTE: Disconnect injector multi-plugs before cranking

tests, to prevent engine from starting.

l

Ensure ignition switched OFF.

l

Disconnect EVAP valve multi-plug.

l

Connect LED test lamp between harness multi-plug

terminal 2 and ground.

l

Briefly crank engine.

l

Check that LED illuminates.

32

1

2

AD86787

LED

V8 4.2L

1992-94

AUDI

131

# 1997 Copyright Autodata Limited

Control system

Fuel pump relay

NOTE: This model is fitted with two fuel pump relays

connected in parallel. Fuel pump relay I ± behind

RH kick panel. Fuel pump relay II ± in RH footwell

fuse/relay plate.

Checking operation ± relay I ±

&

33

TECHNICAL DATA

Terminals

Condition

Resistance

48 & 59

battery voltage disconnected

u

48 & 52

battery voltage disconnected

u

48 & 59

battery voltage connected

Zero

48 & 52

battery voltage connected

Zero

(Battery positive to terminal 46)

(Battery negative to terminal 47)

NOTE: Ensure battery voltage supply connected

correctly, otherwise relay could be damaged.

l

Ensure ignition switched OFF.

l

Remove relay.

l

Check resistance between relay terminals.

l

Connect battery supply to specified relay terminals.

l

Check resistance between relay terminals.

33

AD86788

48

59

52

47

46

Checking operation ± relay II ±

&

34

TECHNICAL DATA

Terminals

Condition

Resistance

2 & 5

battery voltage disconnected

u

2 & 8

battery voltage disconnected

u

2 & 5

battery voltage connected

Zero

2 & 8

battery voltage connected

Zero

(Battery positive to terminal 4)

(Battery negative to terminal 1)

NOTE: Ensure battery voltage supply connected

correctly, otherwise relay could be damaged.

l

Ensure ignition switched OFF.

l

Remove relay.

l

Check resistance between relay terminals.

l

Connect battery supply to specified relay terminals.

l

Check resistance between relay terminals.

34

AD86789

2

5

8

1

4

Checking supply voltage ±

&

35

TECHNICAL DATA

Terminals

Ignition

Voltage

46 & ground

ON

Battery voltage

1 & ground

ON

Battery voltage

l

Ensure ignition switched OFF.

l

Remove fuel pump relay I.

l

Switch ignition ON.

l

Check voltage between relay plate terminals and

ground.

l

Switch ignition OFF.

l

Reinstall fuel pump relay I.

l

Remove fuel pump relay II.

l

Switch ignition ON.

l

Check voltage between relay plate terminals and

ground.

35

V8 4.2L

1992-94

132

AUDI

# 1997 Copyright Autodata Limited

Checking relay activation ±

&

35

NOTE: Disconnect injector multi-plugs before cranking

tests, to avoid damage to catalytic converter(s).

TECHNICAL DATA

Terminals

Condition

LED

46 & 47

ignition ON

ON faintly

46 & 47

engine cranking

ON brightly

1 & 4

ignition ON

ON faintly

1 & 4

engine cranking

ON brightly

l

Ensure ignition switched OFF.

l

Remove fuel pump relays I and II.

l

Connect LED test lamp between relay I base terminals

46 and 47.

l

Switch ignition ON.

l

Check that LED illuminates.

l

Briefly crank engine.

l

Check that LED illuminates.

l

Switch ignition OFF.

l

Connect LED test lamp between relay II base terminals

1 and 4.

l

Switch ignition ON.

l

Check that LED illuminates.

l

Briefly crank engine.

l

Check that LED illuminates.

Engine control module (ECM)

Checking supply voltage ±

&

36

NOTE: Due to small size of engine control module (ECM)

harness multi-plug pins it is advisable to use a

breakout box.

TECHNICAL DATA

Terminals

Ignition

Voltage

18 & ground

OFF

Battery voltage

27 & ground

ON

Battery voltage

l

Ensure ignition switched OFF.

l

Disconnect ECM multi-plug.

l

Connect breakout box to ECM multi-plug.

l

Check voltage between breakout box terminal and

ground.

l

Switch ignition ON.

l

Check voltage between breakout box terminal and

ground.

36

1

2

3

4

5

6

7

8

9

10

11

14

18

19

20

21

22

23

24

25

32

29

28

27

36

37

55

54

50

47

46

45

43

42

41

40

39

38

AD86790

Checking ground connections ±

&

36

NOTE: Due to small size of engine control module (ECM)

harness multi-plug pins it is advisable to use a

breakout box.

TECHNICAL DATA

Terminals

Resistance

10 & ground

Zero

14 & ground

Zero

19 & ground

Zero

24 & ground

Zero

l

Ensure ignition switched OFF.

l

Disconnect ECM multi-plug.

l

Connect breakout box to ECM multi-plug.

l

Check resistance between breakout box terminals

and ground.

V8 4.2L

1992-94

AUDI

133

# 1997 Copyright Autodata Limited

SPINE

LEFT HAND PAGE

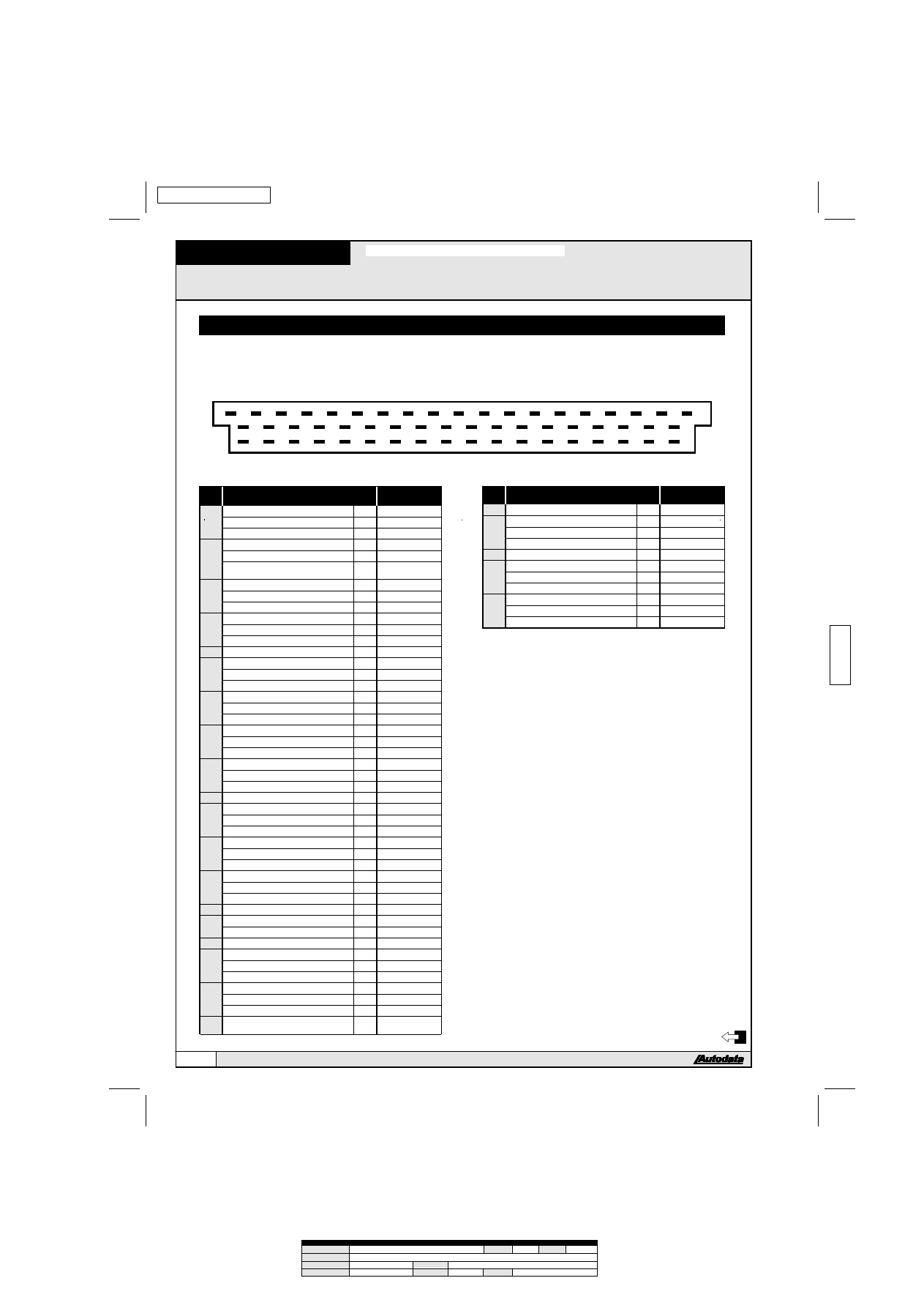

ECM pin diagram

V8 4.2L

1

2

3

4

5

6

7

8

9

10

11

12

13

15

14

16

17

18

19

20

21

22

23

24

25

35

34

33

32

31

30

29

28

27

26

36

37

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

AD72618

ECM

pin

Component

Comp

Description

p

onent

in no.

Wire color

1

Ignition module No.1

2

green

2

Not used

3

Fuel pump relay

T

brown/green

3

Transmission control module

54

brown/green

4

Idle air control (IAC) valve

2

brown/red

5

Evaporative emission canister purge

(EVAP) valve

1

black/white

6

AC control module

12

green/red

7

Mass air flow (MAF) sensor

3

gray/yellow

8

Camshaft position (CMP) sensor

2

black/violet

9

Spare cable

white/violet

10

Ground

brown/black

11

Knock sensor (KS) No.1

1

brown

12

Camshaft position (CMP) sensor

1

black

13

Data link connector (DLC) No.1

1

white/black

14

Ground

brown

15

Injector valve No.3

1

black/green

16

Injector valve No.8

1

black/gray

17

Injector valve No.5

1

black/violet

18

Battery

+

red/brown

19

Ground

brown/black

20

Ignition module No.2

2

green/black

21

EGR system solenoid

2

brown/yellow

22

Data link connector (DLC) No.1

2

white/black

23

Oxygen sensor control module

86

yellow/blue

24

Ground

brown

25

Mass air flow (MAF) sensor

4

gray

26

Mass air flow (MAF) sensor

2

gray/black

27

Ignition switch

15

black

28

Heated oxygen sensor (HO2S)

29

Knock sensor (KS) No.2

1

brown

30

Ground

black/brown

31

Trip computer

7

green/white

32

Injector valve No.2

1

black/yellow

33

Injector valve No.7

1

black/yellow

34

Injector valve No.6

1

black/green

35

Injector valve No.4

1

black/gray

36

Injector valve No.1

1

black/violet

37

Fuel injection relay

87a red/yellow

38

Spare cable

white/yellow

39

Spare cable

gray/green

40

AC refrigerant pressure switch

green/red

41

AC control module

2

red/black

42

Transmission shift position switch

1

green

43

Not used

44

Intake air temperature (IAT) sensor

white/green

45

Engine coolant temperature (ECT)

sensor

violet

ECM

pin

Component

Comp

Description

p

onent

in no.

Wire color

46

EGR temperature sensor

2

white/red

47

Engine speed (RPM) sensor

2

black

48

Engine speed (RPM) sensor

1

brown

48

Crankshaft position (CKP) sensor

1

brown

49

Crankshaft position (CKP) sensor

2

black

50

Instrumentation control module

white/blue

51

Transmission control module

32

blue/green

52

Throttle position (TP) sensor

1

green/violet

53

Throttle position (TP) sensor

2

blue

54

Transmission control module

47

blue/white

55

Data link connector (DLC) No.2

2

blue/yellow

V8 4.2L

1992-94

Autodata Limited

Copyright 1997

File Name:

aud1

Page no:

134

Version:

X

Path:

g:/pchold1/rack1

Description:

Engine Management US

Comments:

Operator:

Eddie

Job Number:

??????

Date:

28-8-97 (Time: 10:50)

134

AUDI

Document Outline

- Untitled

Wyszukiwarka

Podobne podstrony:

akumulator do audi v8 d11 36 quattro 42 quattro

Audi V8 Star

Audi 200 V8

Audi 200 V8

audi 100 klimaautomatik fehlerspeicher v6 v8 mj1997

akumulator do audi a6 avant 4ac4 42 s6 v8 quattro 42 s6 plus q

akumulator do audi a6 4ac4 42 s6 v8 quattro 42 s6 plus quattro

akumulator do audi 100 avant 4a c4 42 s4 v8 quattro

akumulator do audi 100 4a c4 42 s4 v8 quattro

AUDI COUPE GT 1984

Audi 80 Cabriolet

AllRoadFAQ com Audi C5 2 7T 402 AirLoweringMod[1]

AUDI 100 1990

OPONY - oznaczenia, AUDI 80 B4

Readers v8

kluczyk audi scyzoryk

AUDI A4 8E 2005pl

audi A4 6 stala praca wentylatora chlodnicy

więcej podobnych podstron