P R O D U C T I O N P R O C E S S

Material-related aspects of the machinability of Austempered

Ductile Iron

F. Klocke

•

M. Arft

•

D. Lung

Received: 19 January 2010 / Accepted: 16 April 2010

Ó German Academic Society for Production Engineering (WGP) 2010

Abstract

The exceptional properties of Austempered

Ductile Iron (ADI) are widely known and can be ascribed

to its austenitic-ferritic microstructure. Strain hardening of

this material is exceptional and an advantage for many

applications where high wear resistance is required, as well

as the extraordinary combination of ductility and tensile

strength. One reason which restricts the introduction of this

material in practical applications is its poor machinability.

This paper describes the material-sided influences on

machinability, especially on the acting wear mechanism.

The heat treatment factor austempering time, ADI grade

and the alloying elements nickel and molybdenum are

varied and investigated in external longitudinal turning

operations.

Keywords

Production technology

Machinability

Austempered Ductile Iron

Austempering time

1 Austempered Ductile Iron: an introduction

Austempered Ductile Iron (ADI) is one opportunity to

respond to the increasing industrial demand for cost- and

weight-efficient constructional materials. The advantages

are well known and the wide fields of applications for this

material are growing fast. The excellent mechanical prop-

erties of ADI, in particular the favourable combination of

high tensile strength, wear resistance and ductility, pre-

destine this material to act as a substitute for forged or

case-hardened materials and Ductile Iron (DI). For Ductile

Iron components, of which improved tensile strength is

required, the crank shaft is a well known example [

], ADI

presents a suitable solution, obtaining the freedom in

designing, typical for cast components, by offering an

enhanced tensile strength [

,

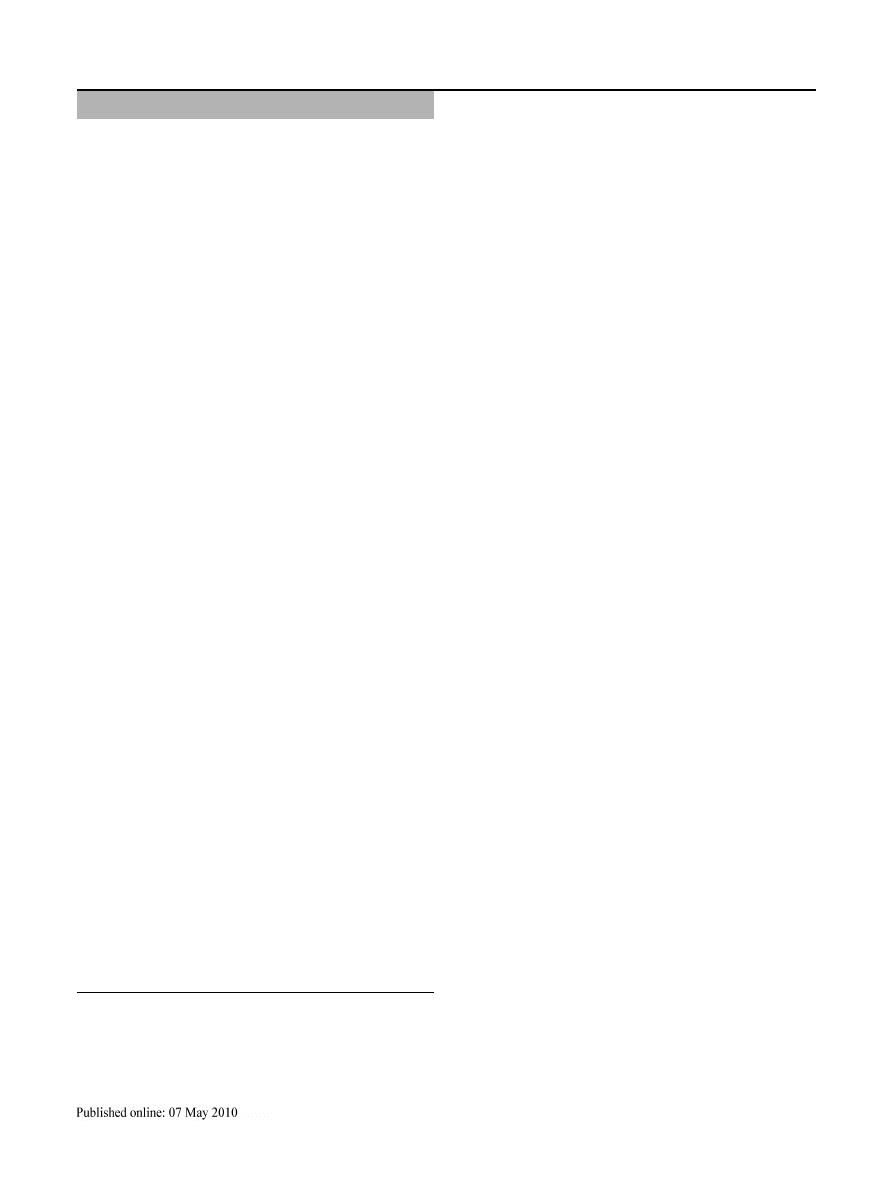

]. ADI is a heat treated cast

Ductile Iron. During the heat treatment process the either

ferritic or pearlitic Ductile Iron is first austenitized and then

austempered. Due to this treatment, the microstructure

changes into a mixture of stabilized austenite, acicular

ferrite and residual austenite, defining its mechanical

properties (Fig.

).

Tensile strength and ductility of ADI materials can be

varied in a wide range due to the austenitic-ferritic

microstructure generated during the heat treatment process

[

]. Besides those metallographic constituents, carbides

can be found at the grain boundaries, related on alloying

elements.

2 Production of Austempered Ductile Iron

and its influences on machinability

For the manufacturing of components made of ADI,

sophisticated processes are required. The first step for ADI

components is the casting process of a Ductile Iron. This

process must be conducted carefully. Deviations in mate-

rial properties, such as deterioration of the graphite and

material inhomogeneities could be carried along the heat

treatment process and influence the mechanical properties

of the work piece. In addition a high nodule count and

nodularity and a stable chemical composition of the alloyed

cast iron is required [

].

F. Klocke

M. Arft (

&) D. Lung

Werkzeugmaschinenlabor WZL der RWTH Aachen,

Aachen, Germany

e-mail: m.arft@wzl.rwth-aachen.de

URL: www.wzl.rwth-aachen.de

123

Prod. Eng. Res. Devel.

DOI 10.1007/s11740-010-0227-4

2.1 Heat treatment process

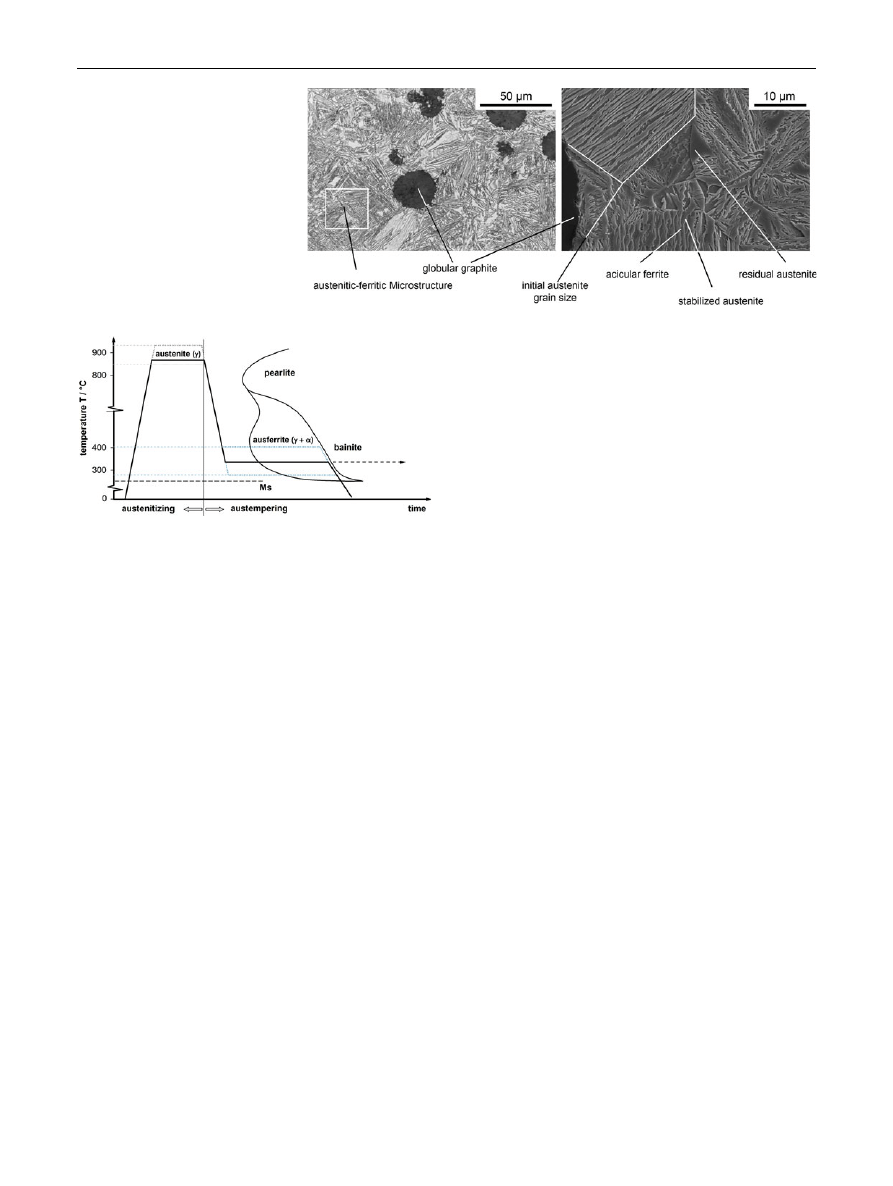

The heat treatment process consists of an austenitizing and

an austempering process (Fig.

). In the austenitizing pro-

cess, the work piece is heated up to a temperature between

875 and 920

°C and the cubic body centred microstructure

changes into cubic face centred. Maintaining at this tem-

perature, the austenitic metallic matrix is enriched with

carbon coming from the globular graphite pebble. In the

directly following austempering process the work piece is

cooled down quickly to its austempering temperature. An

insufficient cooling rate results in pearlitic structures in the

austenitic-ferritic microstructure, affecting the materials

mechanical properties tremendously. In the isothermal

austempering process, acicular ferrite arises, setting carbon

free which diffuses into the austenitic-structure and

increases the carbon content in the residual austenite.

The transformation of austenite into martensite is hindered

by an increasing level of carbon in the austenitic structure. The

ratio of austenite and acicular ferrite depends directly on the

temperature of the heat treatment process. Increasing aus-

tempering temperatures (up to 390

°C) effect a stronger dif-

fusion of carbon and therefore lead to larger areas of ferrite,

typical for ductile ADI grades like EN-GJS-900-8. On the

other side, a reduced austempering temperature, as low as to

230

°C, results in a very fine austenitic-ferritic matrix, hence

the ductility is reduced, but strength is increased up to

1,600 N/mm

2

. In addition to the temperature, the duration of

the austempering process influences the metallic matrix. If the

austempering time is too short, the austenitic-ferritic structure

is not completely enriched with carbon, and if the material is

austempered too long, bainitic structures arise in the micro-

structure of the ADI material [

].

2.2 Influence of alloying elements on material

properties

The transformation of the metallic microstructure in ADI

materials during the heat treatment process is influenced

decisively by the alloying elements Nickel and Molybde-

num. With increasing wall thickness of the ADI material,

the duration of the heat treatment process as well as the

content of alloying elements have to be adapted to guarantee

constant material properties along the whole cross section of

the material. Both Nickel and Molybdenum constrain the

transformation of austenite into pearlite in the austenitizing

process and prolong the arising of bainitic structures in the

austempering process. The duration of the heat treatment

process can be enlarged due to the alloyed elements, so that

for components with a stronger wall thickness a homoge-

nous microstructure can be produced [

,

,

The machinability of cast iron is influenced decisively

by the chemical composition [

,

]. The impact of

Molybdenum, forming carbides at the grain boundaries, and

Nickel, located intercrystalline in the microstructure, are

investigated. Varied alloying contents of Molybdenum

and Nickel, adapted on different wall thicknesses, are

considered.

3 Test facility

The external longitudinal turning tests were conducted on a

turning lathe ‘Gildemeister NEF 660’. While other cutting

Fig. 1

Microstructure of

austempered Ductile Iron

Fig. 2

Heat treatment of Ductile Iron to create austempered Ductile

Iron

Prod. Eng. Res. Devel.

123

materials, like diamond and ceramics are under investiga-

tion for the machining of cast iron [

–

], coated carbide

is still a superior cutting material. For the cutting tests, a

carbide insert K-20 coated with an Al

2

O

3

top-layer and a

Ti(C, N) bond coat with negative geometry (CNMA

120408) was used. The turning tests were conducted with

flood cooling using a 6% Rhenus FU 50 emulsion.

4 Investigated materials

For the investigation of material-related aspects of the

machinability three test series with different material

variations were cast. The influence of the microstructure

hardness on the machinability, meaning the ADI grades

900 and ADI 1200, were machined in the first series. In

addition to those two ADI grades, a pearlitic cast iron GJS

700-2 with no heat treatment after casting was investigated

in this series. Objective of the second test series was to

evaluate the influence of the austempering time on the

machinability.

For the first two test series tubular rods with an outer

diameter of 200 mm, a length of 300 mm and a wall

thickness of 30 mm were cast. To investigate the influence

of the austempering time, tubular rods from the same batch

were heat treated (ADI 900) for 5 different austempering

times (30, 60, 90, 120 and 180 min).

To investigate the influence of Molybdenum and Nickel

on the machinability in the third test series, 9 samples with

varied chemical compositions were cast and heat-treated.

These variations were subdivided into 4 different wall

thicknesses of 20, 30, 60 and 90 mm with an adapted

content of Molybdenum and Nickel. Due to different wall

thicknesses, the austempering time was varied too. The

samples with a wall thickness of 20 and 30 mm were

tubular rods, the wall thicknesses of 60 and 90 mm were

represented by solid shafts.

5 Influence of the metallic matrix on machinability

and wear mechanisms

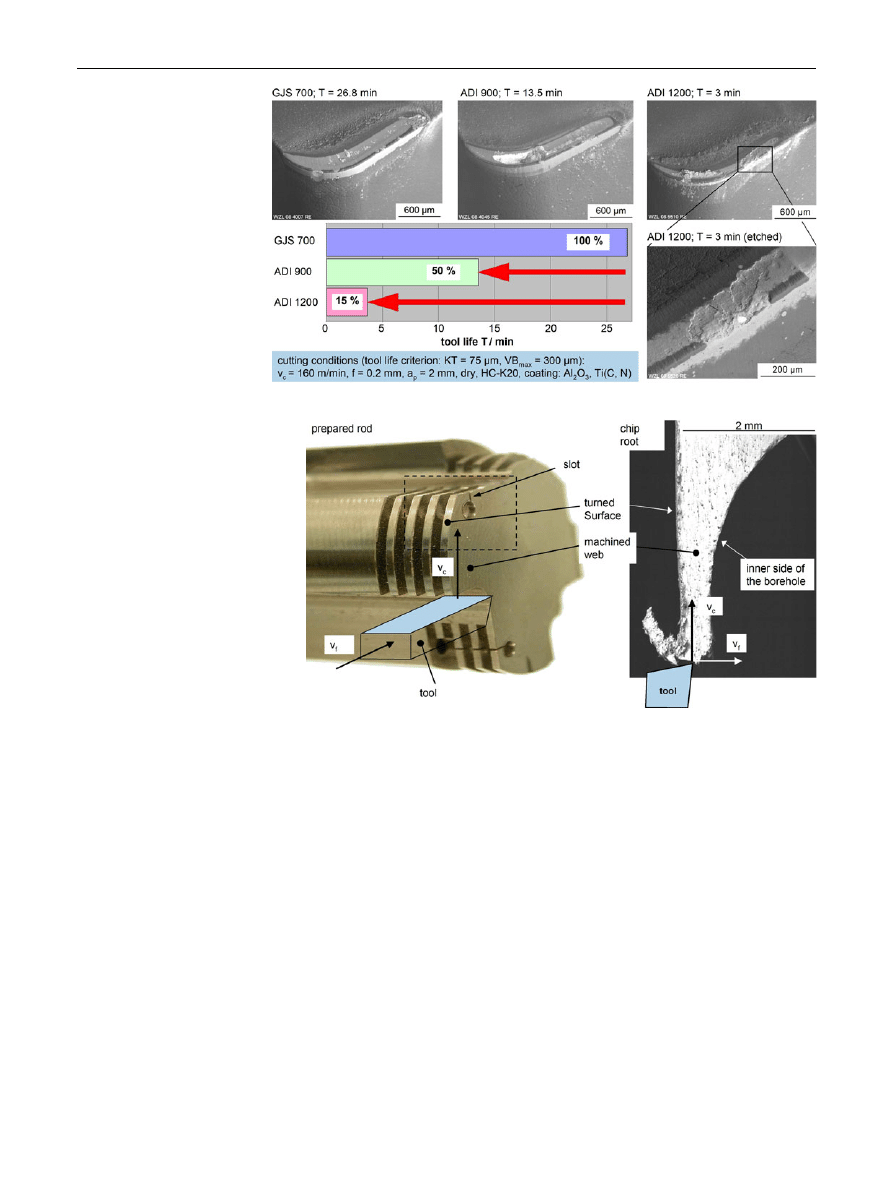

The machining tests were conducted in dry longitudinal

turning operations on pearlitic cast iron EN-GJS 700-2,

austenitic-ferritic EN-GJS 900-8 (ADI 900) and austenitic-

ferritic EN-GJS 1200-2 (ADI 1200) under constant cutting

conditions (v

c

= 160 m/min, a

p

= 2 mm, f = 0.2 mm).

The three investigated materials for the first test series are

shown in Table

On the applied tools (HC-K20, CNMA 120408) differ-

ent wear mechanisms could be observed. Tool life in dry

machining GJS 700 was determined by abrasive flank wear

(T = 27 min). In machining ADI 900, strong crater wear

close to the cutting edge, as it was already mentioned by

Klo¨pper [

,

], was found and tool life was reduced by

50% (13.5 min) in comparison to EN-GJS-700-2. On tools

which were used for the machining of ADI 1200, delami-

nation of the coating takes place, setting particularly the

carbide substrate free, resulting finally in breakage of the

cutting edge. Therefore tool life was reduced tremendously

down to T = 3 min (Fig.

By reducing the cutting speed in machining ADI 1200

(80 m/min and 120 m/min), delamination of the coating

could be averted and tool life was increased up to 20 and

8 min. In consequence, crater wear close to the cutting

edge, comparable to the wear mechanism when machining

ADI 900, arises. When using coolant, the crater wear

caused by thermal effects on the tool rake face is avoided

for both ADI 900 and ADI 1200. Due to the use of coolant

in machining ADI 1200 tool life was increased by 100% or

the applicable cutting speed for the same tool life was

increased by 33%. Although coolant was used, the thermal

load on the cutting tool was still high and plastic defor-

mation of the cutting edge with increasing wear was

observed. Overall, flank wear was identified as main wear

mechanism if plastic deformation of the cutting edge could

be avoided. For a closer consideration of the influence of

the ADI grade on machinability, chips and chip roots were

investigated. Chip roots were produced by using the

method according to Buda [

]. In this method, chip roots

were generated in an orthogonal turning process of a web

(Fig.

).

To conduct those tests, a special preparation of the

machined rod is needed. A borehole is drilled in the web

with a defined distance from the outer diameter. In addi-

tion, a slot from the outer web-contour of the rod into the

drilled borehole is cut. In an orthogonal turning operation,

the remaining material of the machined web between the

machined surface of the web and the borehole decreases

with each rotation in the direction of the feed speed. Under

Table 1

Investigated materials

GJS-700, ADI 900 and ADI

1200

Material

Mo-content/%

Ni-content/%

Wall thickness/mm

Hardness/HB

Test series 1: machinability of ADI and Ductile Iron

GJS 700-2

0

0

30

HB 236–HB245

ADI 900

0

0.3–0.4

30

HB285

ADI 1200

0

0.3–0.4

30

HB350

Prod. Eng. Res. Devel.

123

consideration of constant cutting forces and the decreasing

material cross-section between borehole and machined web

surface, stresses in this cross-section are increasing, and the

remaining material in front of the cutting edge is pushed

away in the direction of the cutting speed. At this material,

which is pushed away from the rod, the chip root in the

cutting zone can be found (Fig.

). To minimize plastic

deformation in the moment when the material in front of

the cutting edge is ripped away from the rod, the drilled

borehole in the web is sealed with a splint.

During the machining of ADI 900 under dry conditions

(v

c

= 160 m/min, a

p

= 2 mm, f = 0.2 mm), segmented

chips were observed. The chips consist of single chip

segments, which were welded together on the bottom side,

where a strong plastic deformation of the material occurs.

In Fig.

, for both ADI 900 and ADI 1200 materials some

generated chips were shown, and for each material chips

produced with a new and a worn tool. With increasing

crater wear, a stronger plastic deformation of the chip took

place, resulting in higher temperatures and in a slightly

increase of chip length.

While machining of ADI 1200 discontinuous chips were

observed, irrespective of the usage of lubricoolant. The

chip root analysis supports this conclusion, showing a

strong mechanical deformation in the shear zone in

machining ADI 900 and hardly any plastical deformation

in machining ADI 1200 and hence the chip length varies.

Furthermore, on the chip root from machining ADI 1200 it

is obvious that the spheroidical graphite grains interrupt the

metallic matrix which support chip breakage.

6 Influence of the austempering time on machinability

The influence of the austempering time on machinability

was investigated by machining 5 ADI 900 samples

Fig. 4

Chip roots according to

Buda [

Fig. 3

Wear mechanism and

tool life in dry longitudinal

turning

Prod. Eng. Res. Devel.

123

(Table

) from the same batch, each heat treated for a

different time (30, 60, 90, 120 and 180 min).

It is assumed, that due to a longer austempering time the

level of carbon in the austenite increases and therefore the

transformation of the austenite into martensite is hindered.

On the samples which were heat treated for the shortest

time, meaning 30 min, pearlitic structures in the matrix

could be observed. This could be traced back to an insuf-

ficient cooling rate between the austenitizing and the aus-

tempering process.

The machining tests were conducted under the same

cutting conditions as mentioned above (dry, v

c

= 160

m/min, f = 0.2 mm, a

p

= 2 mm). The chip shape was

comparable for all material variations in this test series,

meaning short segmented chips, and with increasing tool

wear a slightly increase of chip length. Tool life when

machining the ADI 900 grades, which were heat treated for

60 min and longer (90, 120 and 180 min) was comparable by

round about 13 min. Due to pearlitic grains in the micro-

structure of the ADI 900 samples, which were heat treated

for 30 min, tool life was reduced by 20%.

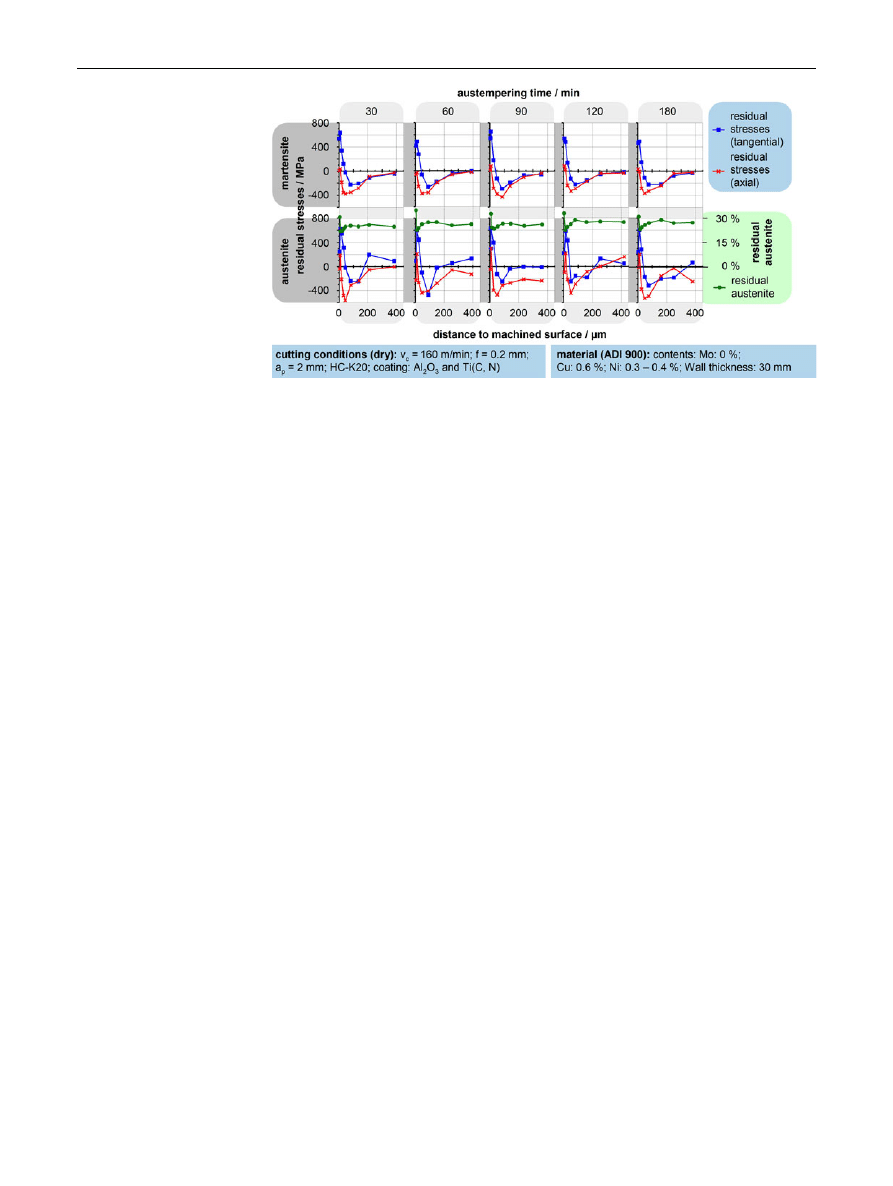

For a closer consideration of the machined surface and

the acting strain hardening mechanism, residual stresses in

both tangential and axial direction and the carbon content

of the retained austenite in the boundary zone were

measured by X-ray diffractometry. Alternatives for the

Fig. 5

Chip roots of ADI 900

and ADI 1200

Fig. 6

Chips when machining

ADI 900 and 1200 with new and

worn tools

Table 2

Investigated materials

for test series 2

Material

Mo-content/%

Ni-content/%

Wall thickness/mm

Austempering time/min

Test series 2: Influence of austempering time on machinability

ADI 900

0

0.3–0.4

30

30

ADI 900

0

0.3–0.4

30

60

ADI 900

0

0.3–0.4

30

90

ADI 900

0

0.3–0.4

30

120

ADI 900

0

0.3–0.4

30

180

Prod. Eng. Res. Devel.

123

characterization of the ADI microstructure are metallo-

graphic methods, In-Situ-dilatometry, neutron diffractom-

etry and magnetic and ultrasonic methods [

–

The X-ray diffraction can be traced back to the law of

Bragg:

k

¼ 2 d sin H

with k as the X-ray wave length, d as the lattice space, and

H as diffraction angle. If the crystal structure of the

material is deformed, than the lattice space d changes and

as a result of this the diffraction angle H. The X-ray

measurements were conducted in axial and tangential

direction and in both directions in the austenitic and in the

martensitic structure (Fig.

).

In the tangential direction of the martensitic structure,

tensile stresses within a depth of up to 50 lm were mea-

sured. Then the stresses change into compressive stresses,

reaching a level of up to r = -200 N/mm

2

in a depth of

100 lm. Thereupon the stresses decrease back to zero. In

axial direction, hardly any tensile stresses were found in

the boundary zone, but compressive stresses were mea-

sured into a depth of up to 400 lm.

The measurements in the austenitic structure show

comparable results. In tangential direction, tensile stresses

were measured in a depth of 50 lm, changing into com-

pressive stresses with further distance from the surface, but

dropping down to zero within a depth of 400 lm. In axial

direction compressive stresses in the face centred austenite

structure were higher than in the martensite structure, but

still on a low level and only existent within a depth of

10–20 lm.

Those measurements proof, that residual stresses as a

result of the machining operation were observed, however

an influence of the austempering time on residual stresses

could not be confirmed. Overall, it could be concluded that

comparable measurement results were found irrespective

of the austempering time.

For a closer examination of the mechanisms which

occur in the boundary zone, the level of the residual aus-

tenite is considered. Close to the boundary zone, up to a

depth of 80 lm, the content of residual austenite is

reduced. The first measurement of residual Austenite was

located too close to the boundary zone and has to be

neglected. The decrease can be explained by arising mar-

tensite due to the machining. In addition to the X-ray

analysis, the micro hardness in the material boundary zone,

neglecting the hardness of the graphite grains, was mea-

sured, and a hardened boundary zone was observed within

a depth of up to 100 lm.

Finally it can be concluded, that the influence of the

austempering time between 60 and 180 min can be

neglected, but a transformation from austenite into mar-

tensite in the boundary zone takes place and therefore the

machinability is influenced.

7 Influence of alloying elements on the machinability

The properties of ADI materials are affected by the level of

alloyed Nickel and Molybdenum. On the one side, the

transformation of the microstructure is influenced and a

homogeneous austenitic-ferritic microstructure along the

whole cross-section of the material can be produced. On

the other side, the molybdenum forms carbides at the grain

boundaries. The chemical composition and the heat treat-

ment process have to be considered carefully with respect

to the material wall thickness. With increasing wall

thickness, longer austempering times are required and the

thermal distribution in the material gets larger. The mate-

rials for this test series are shown in Table

.

Fig. 7

X-ray analysis of

machined ADI 900 samples

Prod. Eng. Res. Devel.

123

All machining investigations in this topic were con-

ducted in a dry longitudinal turning operation (v

c

=

160 m/min, f = 0.2 mm, a

p

= 2 mm). Due to the dry

cutting operation, strong crater wear close to the cutting

edge, like already mentioned above, was identified in this

test series as main wear mechanism. The chip shape was

comparable to those which were mentioned above and no

influence of the alloying elements on chip shape could be

considered.

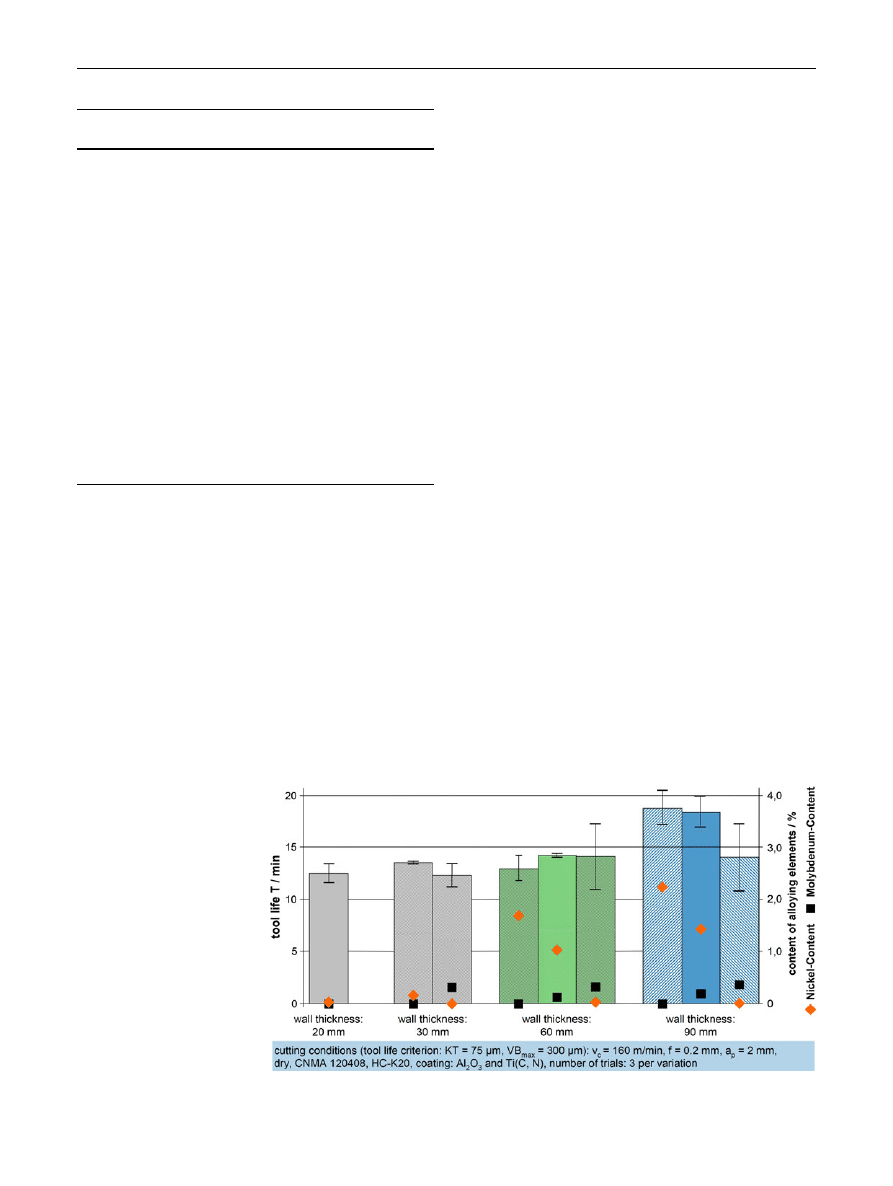

The required amount of Nickel and Molybdenum was

chosen on foundry based experiences. For the samples with

a wall thickness of 20 mm, no additional Nickel or

Molybdenum is required. For the samples with 30 mm wall

thickness, one investigated material variation was alloyed

with Nickel (Ni = 0.3–0.4%, Mo = 0%) and another one

with Molybdenum (Ni = 0%, Mo = 0.1–0.15%). For the

Nickel alloyed material variation with a wall thickness of

30 mm and for the ADI 900 sample with a wall thickness

of 20 mm, average tool life was approximately 13 min.

When machining of the Molybdenum alloyed ADI tool life

was reduced by nearly 10%. The results for the machining

operations are compared in Fig.

.

The investigated samples with a wall thickness of

60 mm were alloyed with a varying content of Molybde-

num and Nickel. The first sample was alloyed without

Molybdenum (Mo = 0%, Ni = 1.6%), the second with a

mixture of both (Mo = 0.15%, Ni = 1%) and the third

sample without Nickel (Mo = 0.3%, Ni = 0%). Average

tool life for those three material variations was comparable

by 13 min. For tool life of each single cutting test, far

scattered results could be found with respect to the chem-

ical composition of the material. While tool life for both

material variations with Molybdenum content below 0.15%

was 13 ± 1.5 min, tool life when machining the ADI 900

grade with the highest Molybdenum content ranged from

11 to 17 min. The strong variance of the tool life can

be traced back to molybdenum carbides at the grain

boundaries.

For the samples with a wall thickness of 90 mm, a

higher level of alloying elements than for the other inves-

tigated materials were required. The first material variation

was alloyed without Molybdenum (Mo = 0%, Ni =

2.2%), the second one was alloyed with both elements

(Mo = 0.2%, Ni = 1.4%) and the third one without Nickel

(Mo = 0.4%, Ni = 0%).

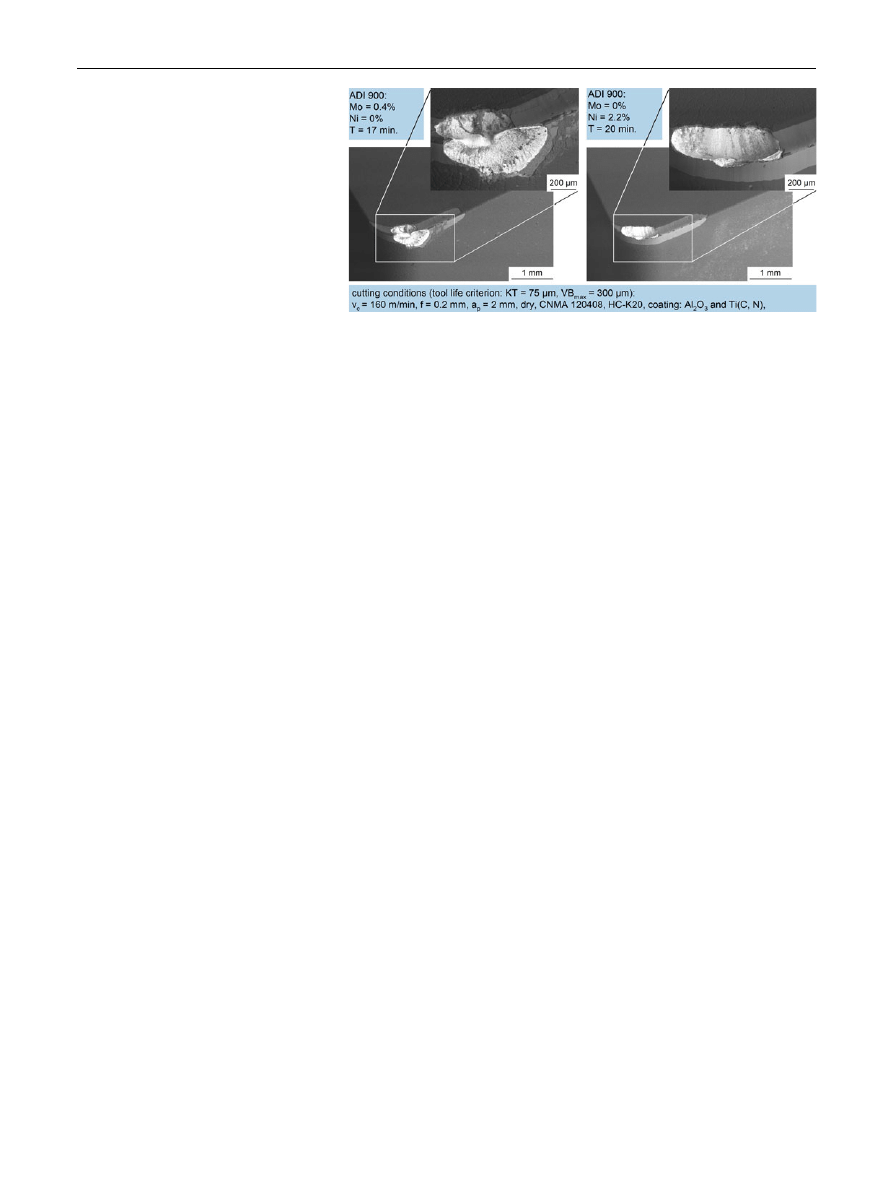

During the machining of these ADI-samples, the influ-

ence of Molybdenum on the machinability becomes more

obvious. An average tool life of 18 ± 1.5 min was

observed when machining the two material variations with

Table 3

Investigated ADI 900 material variations for test series 3

Material Mo-content/

%

Ni-content/

%

Wall

thickness/mm

Austempering

time/min

Test series 3: Influence of alloying elements on machinability

ADI

900

0

0

20

50

ADI

900

0

0.3–0.4

30

90

ADI

900

0.1–0.15

0

30

90

ADI

900

0

1.5–1.8

60

130

ADI

900

0.3–0.35

0

60

130

ADI

900

0.1–0.15

0.9–1.1

60

130

ADI

900

0

2.2

90

170

ADI

900

0.4

0

90

170

ADI

900

0.2

1.4

90

170

Fig. 8

Tool life for machining

of ADI 900 with varied alloying

elements and wall thicknesses

Prod. Eng. Res. Devel.

123

low Molybdenum content (Mo \ 0.2%). Average tool life

and the variance of tool life was decreased significantly

when machining the high Molybdenum alloyed ADI

(14 ± 4 min). Therefore it can be concluded, that due to a

high Molybdenum content ([0.3%) in the ADI 900 mate-

rial, average tool life was reduced and a strong scatter of

tool life was observed. On worn tools, with distinctive

crater wear, extensive chipping on the cutting edge was

observed (Fig.

) when machining Molybdenum alloyed

samples. This occurrence can be ascribed to molybdenum

carbides in the cast iron.

8 Conclusions

Objective of this investigation was to evaluate the mate-

rial related aspects on the machinability of ADI. It was

shown, that with regard to the ADI grade, cutting condi-

tions have to be chosen carefully. The thermal load on the

tool is high and the usage of coolant has to be preferred in

order to suppress crater wear. Flank wear is identified as

major tool life criterion while using lubricoolant as long

as no plastic deformation of the cutting edge takes place.

The shape of the generated chips depends vitally on the

material hardness. Strong plastic deformation takes place

in the shear zone during machining ADI 900 and can also

be detected on the formed chips. In machining ADI 1200

hardly any deformation in the shear zone or on the chips

was observed.

It was proven, that tool life is not influenced by the

austempering time between 60 and 180 min. However,

arising pearlite in the austenitic-ferritic microstructure

reduces tool life by about 20%. The transformation of

austenite into martensite and residual stresses in the

boundary zone could be identified by X-ray analysis.

In ADI materials, which were alloyed with a molybde-

num content of more than 0.3%, machinability is influ-

enced negatively and the risk of a breakout of the cutting

edge with increasing crater wear rises. Furthermore,

average tool life is reduced with a molybdenum content of

more than 0.3%.

Acknowledgments

The authors would like to thank the Bundes-

ministerium fu¨r Wirtschaft und Technologie for funding the project

15308 N ‘‘Machinability of ADI’’ in the program of ‘‘Industrielle

Gemeinschaftsforschung’’ (IGF).

References

1. Neugebauer

R,

Stoll

A,

Roscher

H-J

(2009)

Ultra-

schallunterstu¨tzung verbessert Tiefbohren in hochfesten Guss.

MM Das IndustrieMagazin 28:24–27

2. Rimmer A, Schiweck A (2008) ADI 101—what do the ADI

treatments do?, Seminar-Paper ‘‘Ausferritisches Gusseisen mit

Kugelgraphit ADI’’ III/13–III/31

3. Ro¨hrig K (2003) 2.Europa¨ische ADI-Entwicklungskonferenz –

Eigenschaften, Bauteilentwicklung und Anwendungen. Kon-

struieren ? Giessen I:2–14

4. Herfurth K et al (2007) Wa¨rme- und Oberfla¨chenbehandlung.

Konstruieren ? Giessen 2:27–37

5. Krause F (1989) Zerspanbarkeit von zwischenstufenvergu¨tetem

Gusseisen mit Kugelgraphit, Dissertation TU Clausthal

6. Cakic M, Baryram A, Isik Y, Salar B (2005) The effects of

austempering temperature and time onto machinability of aus-

tempered ductile iron. Mater Sci Eng A 407:147–153

7. Yang J, Putatunda S (2005) Effect of microstructure on abrasive

wear behaviour of austempered ductile iron (ADI) processed by a

novel two-step austempering process. Mater Sci Eng A 406:217–228

8. Klocke F, Klo¨pper C, Fallbo¨hmer M (2000) Fundamentals in

machining of Austempered ductile iron. Prod Eng VII/2:49–52

9. Klo¨pper C (2006) Untersuchungen zur Zerspanbarkeit von aus-

tenitisch-ferritischem Gusseisen mit Kugelgraphit (ADI), Dis-

sertation RWTH Aachen

10. Reuter U (2002) Verschleißmechanismen bei der Bearbeitung

von Gusseisen mit PCBN-Schneidstoffen, Dissertation TU

Darmstadt

11. Podolsky C (2008) Zerspanung von Gusseisen mit Vermikular-

graphit, Dissertation Leibniz Universita¨t Hannover

12. Abele E, Berger C, Scheerer H, Pfeiffer P (2009) Gussbearbei-

tung mit PKD, VDI-Z Special Werkzeuge Mai 18–21

13. Abele E, Schramm B (2007) Einsatz von Diamant zur Zerspa-

nung von Spha¨roguss. wt Werkstatttechnik online 97:41–46

14. Klocke F, Klo¨pper C, Lung D, Essig C (2007) Fundamental wear

mechanisms when machining austempered ductile iron (ADI).

Ann CIRP 56(1):73–76

Fig. 9

Chipping of the cutting

edge when machining ADI with

high level of molybdenum

Prod. Eng. Res. Devel.

123

15. Buda J, Vasilko K, Stranava J (1968) Neue Methode der Span-

wurzelgewinnung zur Untersuchung des Schneidvorganges.

Industrie-Anzeiger 90.Jg.(Nr.5):78–81 S.78

16. Hoffmann H, Meier L, Schaaf P, Cusenza S, Ho¨che D, Bam-

berger M, Amran Y, Weiss K, Hofmann M (2010) Monitoring

phase transition kinetics in austempered ductile iron (ADI). Mater

Sci Forum 638–642:3394–3398

17. Hoffmann H, Meier L (2008) Gusseisen—ein Werkstoff mit

Geschichte und Zukunft. Tagungsband Mu¨nchener Kolloquium

449–458

18. Brinksmeier E, Cammett JT, Ko¨nig W, Leskovar P, Peters J,

To¨nshoff HK (1982) Residual stresses–measurement and causes

in machining processes. Ann CIRP 31(2):491–510

19. Hoffmann H, Wasmuth U, Meier L, Hofmann M, Mu¨hlbauer M,

Stege V (2008) Optimisation of composite castings by means of

neutron measurements. Ann CIRP 57(1):579–582

Prod. Eng. Res. Devel.

123

Document Outline

- Material-related aspects of the machinability of Austempered Ductile Iron

- Abstract

- Austempered Ductile Iron: an introduction

- Production of Austempered Ductile Iron and its influences on machinability

- Test facility

- Investigated materials

- Influence of the metallic matrix on machinability and wear mechanisms

- Influence of the austempering time on machinability

- Influence of alloying elements on the machinability

- Conclusions

- Acknowledgments

- References

Wyszukiwarka

Podobne podstrony:

Aspects of Britain and the USA(1)

Presentation 5 Psychological Aspects of Treatment of the S

Aspects of the development of casting and froging techniques from the copper age of Eastern Central

Racism, Racial Discrimination, Xenophobia and Related Forms of Intolerance, Follow up and Implementa

Liberman, Anatoly Some Controversial Aspects of the Myth of Baldr

30 Pragmatic Aspects of Grammatical Constructions The Handbook of Pragmatics Blackwell Reference O

Greg Bear The Machineries of Joy

Pearl, The Aspect of Evil in the Novel doc

Sipperl The Machine in the Pastoral Imagery of 18th century utopia

The Pulse of the Machine Nina Kiriki Hoffman

Racism, Racial Discrimination, Xenophobia and Related Forms of Intolerance, Follow up and Implementa

The Dual Aspect of Wisdom by H P Blavatsky

Antheil Sonatina (Death of the Machines)

Eizo Matsuki The Crimean Tatars and Their Russian Captive Slaves An Aspect of Muscovite Crimean Rela

Jeri Smith Ready Aspect of Crow 03 The Reawakened

The Very Pulse of the Machine Michael Swanwick

Bear, Greg The Machineries of Joy, Redux

Dion Fortune The Machinery of the Mind

SCHECHNER the performance aspects of agni

więcej podobnych podstron