Biomaterials 23 (2002) 313–317

Apatite formation on zirconium metal treated with aqueous NaOH

Masaki Uchida

a,

*, Hyun-Min Kim

a

, Fumiaki Miyaji

b

, Tadashi Kokubo

a

,

Takashi Nakamura

c

a

Department of Material Chemistry, Faculty of Engineering, Graduate School of Engineering, Kyoto University, Sakyo-ku, Kyoto 606-8501, Japan

b

Department of Material Science, Faculty of Science and Engineering, Shimane University, Matsue 690-8504, Japan

c

Department of Orthopaedic Surgery, Graduate School of Medicine, Kyoto University, Sakyo-ku, Kyoto 606-8507, Japan

Received 21 July 2000; accepted 7 March 2001

Abstract

Previous studies by the authors have shown that titanium metal, titanium alloys and tantalum metal which were subjected to

aqueous NaOHsolution and subsequent heat treatments form an apatite surface layer upon immersion in a simulated body fluid

(SBF) with ion concentrations nearly equal to those in human blood plasma. These metals form the apatite surface layer even in

living body, and bond to living bone through the apatite layer. In the present study, the apatite-forming ability of NaOH-treated

zirconium metal in SBF has been investigated. A hydrated zirconia gel layer was formed on the surface of the zirconium metal

on exposure to 1–15 m NaOHaqueous solutions at 958C for 24 h. It was observed that the metals treated in NaOHaqueous

solutions with concentrations above 5 m form an apatite layer on their surface in SBF. This indicates that the Zr–OHgroup of the

zirconia gel induces apatite nucleation. The present study points to the possibility of obtaining bioactive zirconium after treatment

by NaOH. # 2001 Elsevier Science Ltd. All rights reserved.

Keywords:

Zirconium; Alkali treatment; Bioactivity; Simulated body fluid (SBF); Apatite; Zirconia gel

1. Introduction

An essential requirement for an artificial material to

bond to living bone is the formation of a bonelike

apatite layer on its surface in body environment [1,2]. In

earlier works, we reported that titanium metal [3–9],

titanium alloys [10,11] and tantalum metal [12–14]

which were exposed to NaOHaqueous solution and

subjected to subsequent heat treatments form a bonelike

apatite layer on their surfaces in a simulated body fluid

(SBF) with ion concentrations nearly equal to those

found in human blood plasma. As in SBF, these NaOH-

and heat-treated metals form the apatite in the living

body, and bond to bone through the apatite layer. They

are now expected to be useful as bone substitutes even

under highly loaded conditions such as is found in

femoral and tibial bones since they exhibit high fracture

toughness as well as high bone-bonding ability [15].

It is scientifically and technically interesting to know

to what other metals the NaOHtreatment can be

applied to induce apatite-forming ability. In this view,

zirconium metal is worthy of note, since it shows high

mechanical strength and good biocompatibility, thereby

being a material of interest as surgical implant [16–18].

More practically, this metal is considered as an

important alloying component for titanium metal to

improve its mechanical properties [19,20].

In this present study, the apatite-forming ability of

zirconium metal treated with aqueous NaOHhas been

investigated in SBF. It is known that materials that form

a bonelike apatite layer on their surfaces in SBF form

the same apatite layer even in the living body, and they

can chemically bond to living bone thorough the apatite

layer [21–23].

2. Materials and methods

2.1. NaOH treatment of zirconium metal

Plates of commercially pure zirconium metal (Kobe

Steel Ltd., Japan) with dimensions 10 10 1 mm

3

were

abraded using #400 diamond plate, and washed with

*Corresponding author. Tel.: +81-75-753-5537; fax: +81-75-753-

4824.

E-mail address:

uchida@sung7.kuic.kyoto-u.ac.jp (M. Uchida).

0142-9612/02/$ - see front matter # 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 1 1 0 - 7

acetone and distilled water in an ultrasonic cleaner.

They were then immersed for 24 h in 5 ml of 1–15 m

NaOHaqueous solutions at 958C. The metal plates

were then gently washed with distilled water, and dried

at 408C for 24 h.

2.2. Immersion of the specimens in SBF

The zirconium plates untreated and treated with

NaOHaqueous solutions were immersed in 30 ml of

SBF with ion concentrations nearly equal to those in

human blood plasma (Table 1) at 36.58C for various

periods. The SBF was prepared by dissolving reagent-

grade NaCl, KCl, K

2

HPO

4

3H

2

O, MgCl 6H

2

O, CaCl

2

,

and Na

2

SO

4

in distilled water, and buffering the solution

to

pH7.4

with

tris-hydroxymethyl-aminomethane

((CH

2

OH)

3

CNH

3

) and hydrochloric acid at 36.58C.

After a set time period up to 28 days, the zirconium

plates were removed from the SBF, washed with distilled

water, and dried in a clean bench.

2.3. Surface analysis of the specimens

The structural changes occurring on the surface

of the zirconium metal due to the NaOHtreatment

and subsequent immersion in the SBF were investigated

using thin-film X-ray diffractometry (TF-XRD; RINT-

1400, Rigaku Co., Japan) and scanning electron

microscopy (SEM, S2500CX; Hitachi Co., Japan). The

TF-XRD was performed on the metals using a step rate

of 2y=28/min, with a 18 glancing angle against the

incident beam. Some TF-XRD were performed on the

metal samples using a scanning rate of 2y=0.028 step,

followed by 10 s hold time, with a 0.18 glancing angle

against the incident beam. X-ray photoelectron spectro-

scopy (XPS; MT5500 ULVAC-PHI Co. Ltd., Japan)

measurements were carried out on the metals that had

been subjected to the NaOHtreatment. The photoelec-

tron take-off angle was set at 458, and MgK

a

radiation

was used as the source. In order to remove potential

contamination of the metal surfaces, Xe-ion sputtering

was carried out at 3 keV for 1 min before a measurement

was taken. As a standard, the observed binding energies

were corrected from comparison with the binding energy

of C

1s

in CH

2

(284.6 eV).

3. Results

SEM observations showed no structural changes on

the surface of the zirconium metal after immersion in

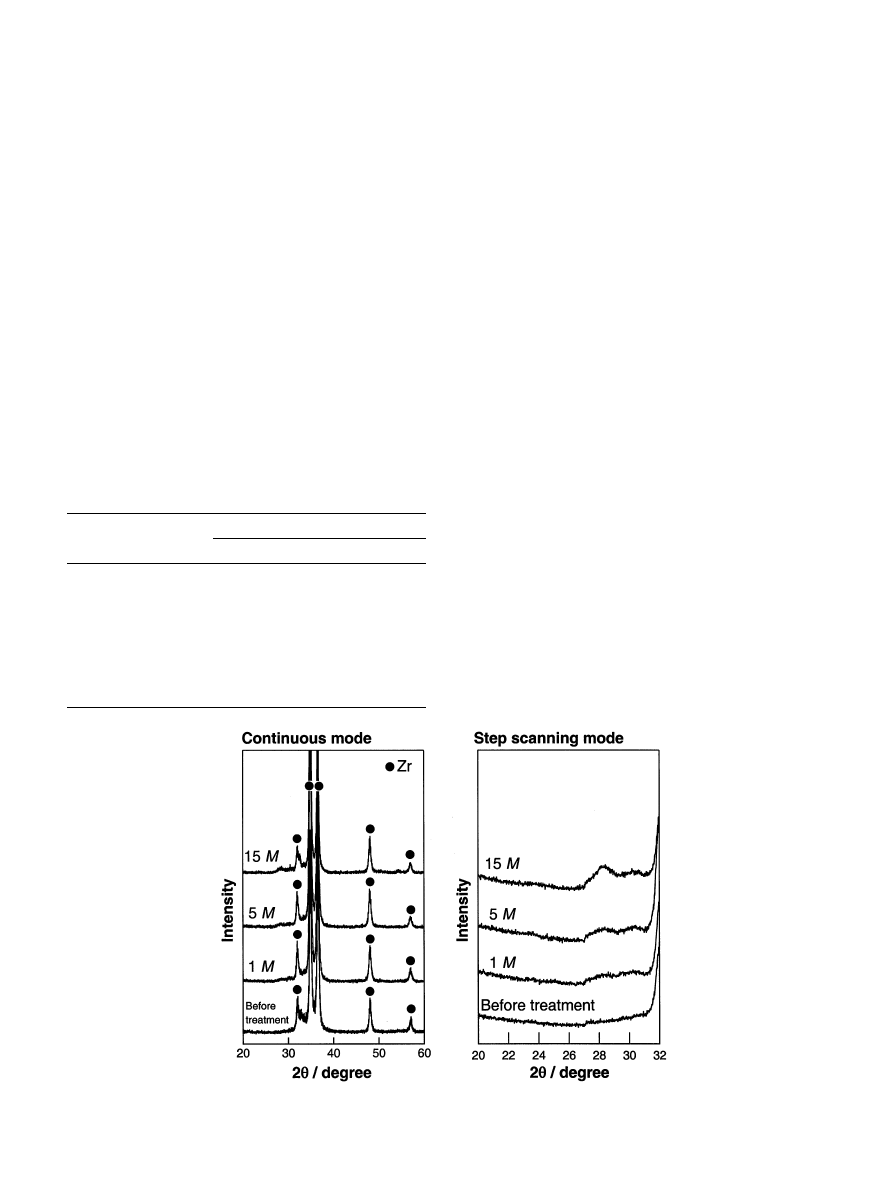

1–15 m NaOHaqueous solutions at 958C for 24 h. Fig. 1

shows the TF-XRD patterns of the surfaces of

zirconium metals before and after 1–15 m-NaOHtreat-

Table 1

Ion concentrations of human blood plasma and SBF

Ion

Concentration/mm

Blood plasma

SBF

Na

+

142.0

142.0

K

+

5.0

5.0

Mg

2+

1.5

1.5

Ca

2+

2.5

2.5

Cl

103.0

147.8

HCO

3

27.0

4.2

HPO

4

2

1.0

1.0

SO

4

2

0.5

0.5

pH7.20–7.40

7.40

Fig. 1. TF-XRD patterns of the surfaces of zirconium metals treated with NaOHsolutions with various concentrations at 958C for 24 h.

M. Uchida et al. / Biomaterials 23 (2002) 313–317

314

ment at 958C for 24 h. In all the NaOH-treated samples,

a broad peak was observed between 288 and 308 in 2y, in

addition to the sharp peaks ascribed to zirconium. The

intensity of this broad peak increased with increasing

NaOHconcentration. This broad peak is ascribed to an

amorphous phase formed on the metal by the NaOH

treatment.

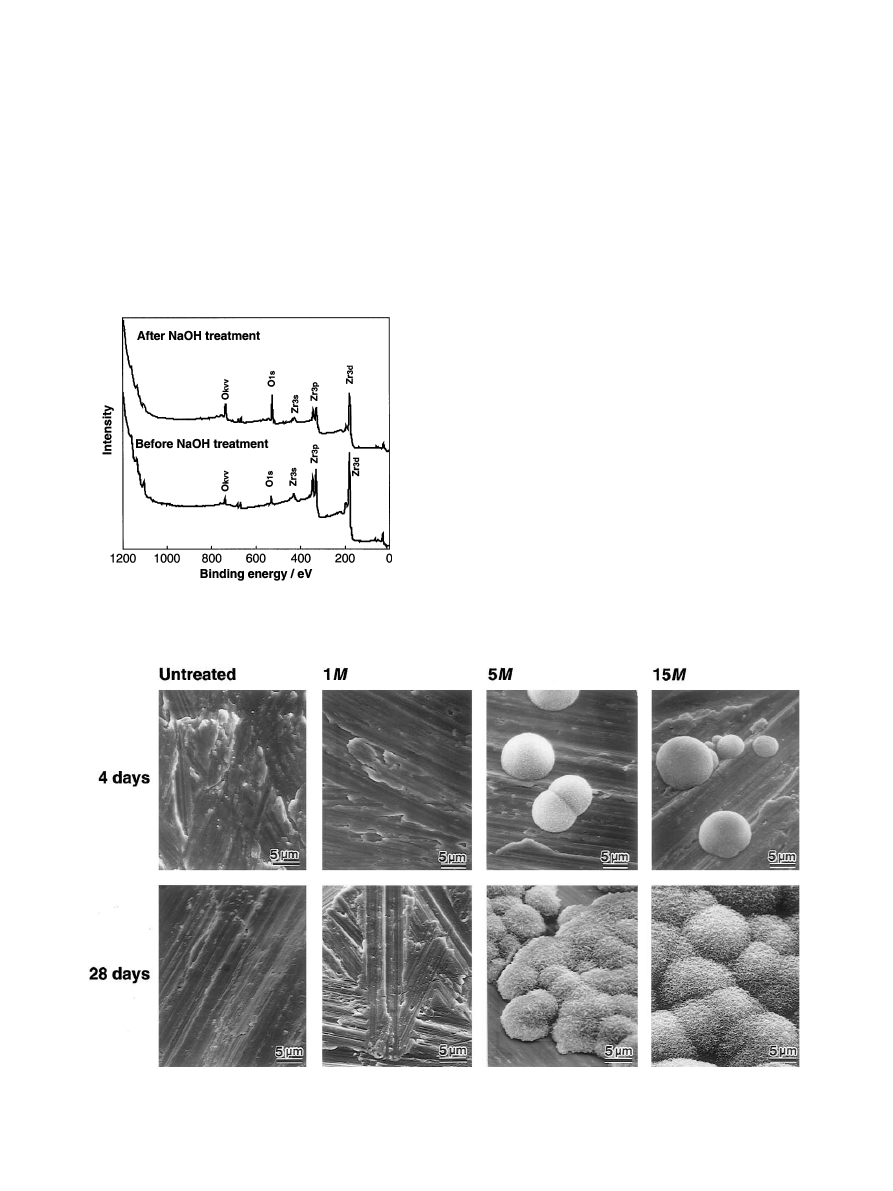

Fig. 2 shows the XPS survey spectra of the surfaces of

zirconium metals before and after 15 m-NaOHtreat-

ment at 958C for 24 h. After the NaOHtreatment, the

intensity of the O

1s

peaks increased, while that of the

Zr

3d

and Zr

3p

peaks decreased. No peak assigned to Na

was detected after the NaOHtreatment.

Fig. 3 shows SEM photographs of the surfaces of

zirconium metals which were untreated and treated with

the NaOHsolutions and then immersed in the SBF for 4

and 28 days, respectively. There were no precipitations

on the surface of zirconium substrates which were

untreated or treated with 1 m NaOHsolution. On the

other hand, island-like spherulites were observed on

parts of the zirconium metals treated with a NaOH

solution greater than 5 m after immersion for 4 days.

The spherulites were observed on the lower surface of

the zirconium substrate, where the metal surface was

faced to the bottom of the vessel, but not on the upper

surface of the zirconium substrate.

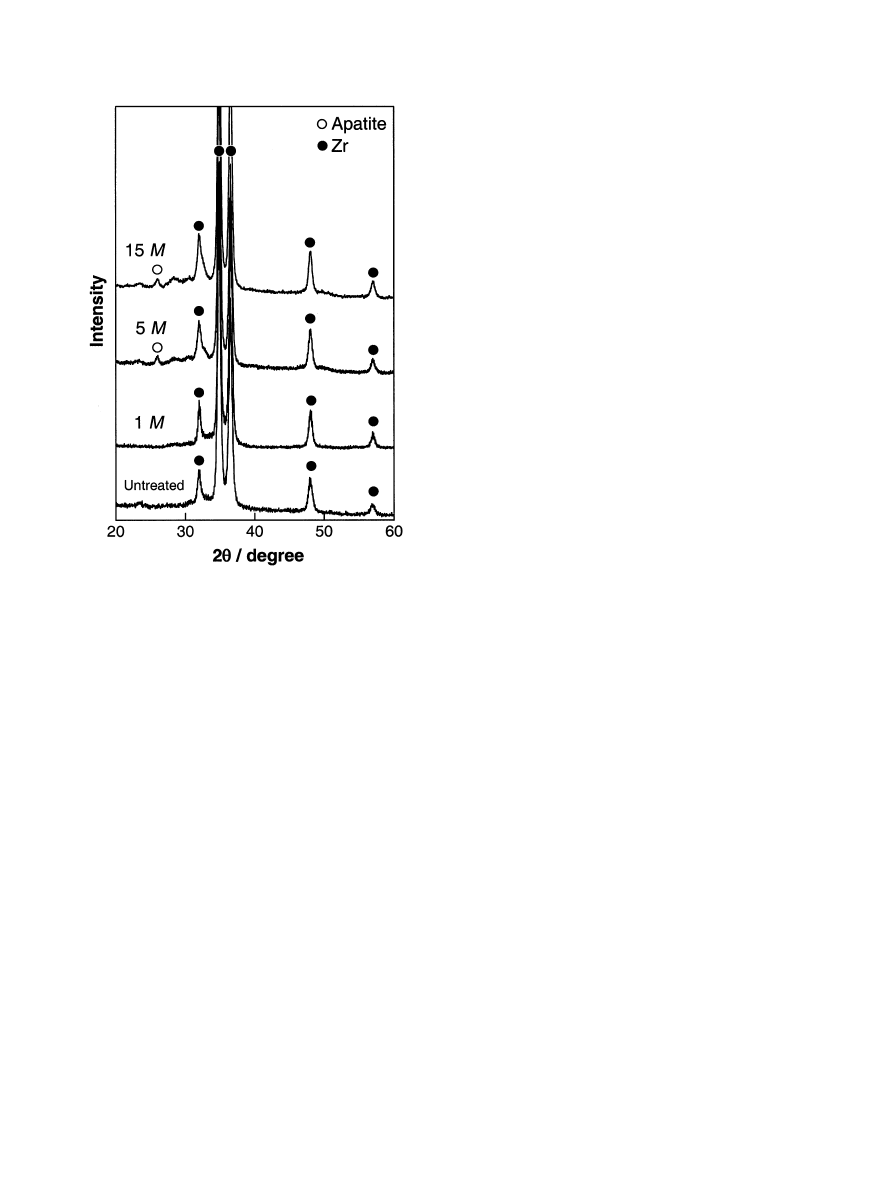

Fig. 4 shows the TF-XRD patterns of the lower

surfaces of the zirconium metals in contact with the

bottom of the vessel, which were untreated and treated

with NaOHsolutions and then immersed in the SBF for

28 days. It can be seen from Figs. 3 and 4 that the

spherulites observed by SEM and TF-XRD are crystal-

line apatite.

4. Discussion

It is clear from the above results that zirconium metal

can form an apatite layer on its surface in SBF when it

Fig. 2. XPS survey spectra of the surfaces of zirconium metals before

and after 15 m-NaOHtreatment at 958C for 24 h.

Fig. 3. SEM photographs of the surfaces of zirconium metals which were untreated and treated with NaOHsolutions, and then immersed in SBF for

4 days and 28 days.

M. Uchida et al. / Biomaterials 23 (2002) 313–317

315

has been previously treated with NaOHsolution with a

concentration greater than 5 m, at 958C for 24 h. This

can be explained as follows.

It is well known that zirconium metal is usually

covered with a passive zirconium oxide layer, and this

passive layer can react with the NaOHsolution. It has

been reported that, when zirconium metal is immersed

in aqueous NaOHsolutions with concentrations higher

than 1 m, hydration of the passive layer occurs [24]. Our

observations, as presented in Figs. 1 and 2, are

consistent with this previous report. Figs. 1 and 2 show

that the hydrated zirconium oxide layer exists as an

amorphous structure, with its thickness increasing with

increasing NaOHconcentration. This amorphous layer

is considered to be a zirconia hydrogel layer. In the case

of NaOH-treated titanium and tantalum metals, Na

+

ions are incorporated into the gel layers, which are

formed by the NaOHtreatment [3,4,12]. In contrast to

these metals, Fig. 2 shows that zirconium metal forms a

Na-free zirconia hydrogel layer.

Titanium and tantalum metals form HTiO

3

nH

2

O or

HTa

2

O

6

H

2

O when they exposed to NaOHsolution

[4,12]. These negatively charged hydrates react with

positively charged Na

+

ions to form sodium titanate or

sodium tantalate hydrogel. In contrast, zirconium metal

is assumed to rarely form such anion species, because of

its higher corrosion durability than titanium and

tantalum metals in NaOHsolution, thereby forming

merely a thin Na-free zirconia hydrogel layer on its

surface [24]. With an aid of this gel layer, the NaOH-

treated zirconium metal forms an apatite surface layer in

SBF (see Figs. 3 and 4). This is attributed to a catalytic

effect of the Zr–OHgroups, abundant on the surface of

the zirconia gel, for apatite nucleation, similar to that

which has been shown in Si–OH[25], Ti–OH[26] and

Ta–OHgroups [27]. The present authors have already

shown that zirconia hydrogel, prepared by hydrolysis

and polycondensation of zirconium-alkoxide, forms an

apatite on its surface in SBF [28]. This indicates that the

surface Zr–OHgroups abundant on the gel can be

effective centres for apatite nucleation.

In the case of NaOH-treated titanium and tantalum

metals in SBF, their surfaces were fully covered with an

apatite layer within 28 days [3,4,12]. In contrast to these

metals, the NaOH-treated zirconium metal formed a

small amount of apatite on its surface even after

immersion in SBF for 28 days. Phenomenally, the

apatite was formed on the bottom surface of the

substrate. Similar apatite formation was observed on

simply heat-treated titanium metal immersed in SBF by

Wang et al. [29]. They assumed that the surface

surrounded with a small closed space is favorable for

apatite formation.

Low apatite-forming ability of NaOH-treated zirco-

nium metal is attributed to the lack of Na

+

ions in the

surface gel layer on the zirconium metal. Titanium and

tantalum metals form sodium titanate hydrogel, and

sodium tantalate hydrogel layers, respectively, on their

surfaces after NaOHtreatment. These metals release

Na

+

ions from the surface gel layers into the SBF, via

an ion-exchange with H

3

O

+

ions present in the SBF. As

a result, the ionic activity product of the apatite in the

surrounding SBF is increased by the increase in

concentration of OH ions. The increased ionic activity

product accelerate apatite nucleation on the Ti–OHor

Ta–OHgroups. In the case of NaOH-treated zirconium,

apatite nucleation, catalysed by the Zr–OHgroups,

cannot be enhanced by the release of the Na

+

ion from

its surface.

Once the apatite nuclei are formed, they can

spontaneously grow by consuming the calcium and

phosphate ions in the SBF, as the SBF is already

supersaturated with respect to the apatite even before

immersion of the metal [30].

5. Conclusions

Zirconium metal forms an apatite on its surface in

SBF after previous treatment with NaOHsolutions with

concentrations above 5 m. The apatite nucleation is

Fig. 4. TF-XRD patterns of the surfaces of zirconium metals which

were untreated and treated with NaOHsolutions, and then immersed

in SBF for 28 days.

M. Uchida et al. / Biomaterials 23 (2002) 313–317

316

induced by Zr–OHgroups in a zirconia hydrogel layer,

which forms on the metal on exposure to NaOH

solution. The result indicates the possibility of obtaining

bioactive zirconium metal by a simple chemical treat-

ment. The apatite-forming ability of NaOH-treated

zirconium metal is, however, lower than those of

NaOH-treated titanium and tantalum metals.

Acknowledgements

This work was supported by Grant-in-Aid for

Scientific Research, the Ministry of Education, Science,

Sports and Culture, Japan.

References

[1] Kokubo T. Biocative glass ceramics: properties and application.

Biomaterials 1991;12:155–63.

[2] Hench LL. Bioceramics: from concept to clinic. J Am Ceram Soc

1991;74:1487–510.

[3] Kokubo T, Miyaji F, Kim HM, Nakamura T. Spontaneous

formation of bone like apatite layer on chemically treated

titanium metals. J Am Ceram Soc 1996;79:1127–9.

[4] Kim HM, Miyaji F, Kokubo T, Nakamura T. Apatite-forming

ability of alkali-treated Ti metal in body environment. J Ceram

Soc Jpn 1997;105:111–6.

[5] Kim HM, Miyaji F, Kokubo T, Nakamura T. Effect of heat

treatment on apatite-forming ability induced by alkali treatment.

J Mater Sci Mater Med 1997;8:341–7.

[6] Kim HM, Miyaji F, Kokubo T, Nakamura T. Bonding strength

of bonelike apatite layer to Ti metal substrate. J Biomed Mater

Res (Appl Biomater) 1997;38:121–7.

[7] Yan WQ, Nakamura T, Kobayashi M, Kim HM, Miyaji F,

Kokubo T. Bonding of chemically treated titanium implants to

bone. J Biomed Mater Res 1997;37:267–75.

[8] Yan WQ, Nakamura T, Kawanabe K, Nishiguchi S, Oka M,

Kokubo T. Apatite layer-coated titanium for use as bone bonding

implants. Biomaterials 1997;18:1185–90.

[9] Nishiguchi S, Nakamura T, Kobayashi M, Kim HM, Miyaji F,

Kokubo T. The effect of heat treatment on bone-bonding ability

of alkali-treated titanium. Biomater 1999;20:491–500.

[10] Kim HM, Miyaji F, Kokubo T, Nakamura T. Preparation of

bioactive Ti and its alloys via simple chemical surface treatment.

J Biomed Mater Res 1996;32:409–17.

[11] Nishiguchi S, Nakamura T, Kato H, Fujita H, Kim HM, Miyaji

F, Kokubo T. Enhancement of bone bonding strength of titanium

alloys by alkali and heat treatment. In: LeGeros RZ, LeGeros JP,

editors. Bioceramics 11. Singapore: World Scientific Publishing

Co. Pte. Ltd., 1998. p. 675–8.

[12] Miyazaki T, Kim HM, Miyaji F, Kokubo T, Kato H, Nakamura

T. Bioactive tantalum metal prepared by NaOHtreatment.

J Biomed Mater Res 2000;50:35–42.

[13] Miyazaki T, Kim HM, Kokubo T, Miyaji F, Kato H, Nakamura

T. Effect of thermal treatment on apatite-forming ability of

NaOH-treated tantalum metal. J Mater Sci Mater Med,

submitted.

[14] Kato H, Nakamura T, Nishiguchi S, Fujita H, Miyazaki T,

Miyaji F, Kim HM, Kokubo T. Bonding of alkali- and heat-

treated tantalum implants to bone. J Biomed Mater Res (Appl

Biomater) 2000;53:28–35.

[15] Long M, Rack HJ. Titanium alloys in total joint replacement}a

materials science perspective. Biomaterials 1998;19:1621–39.

[16] Hanawa T, Masuhara E, Ohkawa S, Sugawara T, Kondou S, Ota

M. Change in surface layer of zirconium in electrolyte solution. J J

Dent Mater 1992;11:469–74.

[17] Jonansson CB, Wennerberg A, Albrektsson T. Quantitative

comparison of screw-shaped commercially pure titanium and

zirconium implants in rabbit tibia. J Mater Sci Mater Med

1994;5:340–4.

[18] Thomsen P, Larsson C, Ericson LE, Sennerby L, Lausmaa J,

Kasemo B. Structure of the interface between rabbit cortical bone

and implants of gold, zirconium and titanium. J Mater Sci Mater

Med 1997;8:653–65.

[19] Kobayashi E, Matsumoto S, Doi H, Yoneyema T, Hamanaka H.

Mechanical properties of the binary titanium–zirconium alloys

and their potential for biomedical materials. J Biomed Mater Res

1995;29:943–50.

[20] Kobayashi E, Doi H, Yoneyama T, Hamanaka H, Gibson IR,

Best SM, Shelton JC, Bonfield W. Influence of aging heat

treatment on mechanical properties of biomedical Ti–Zr based

ternary alloys containing niobium. J Mater Sci Mater Med

1998;9:625–30.

[21] Kokubo T, Kushitani H, Sakka S, Kitsugi T, Yamamuro T.

Solution able to reproduce in vivo surface-structure change in

bioactive glass-ceramic A-W. J Biomed Mater Res 1990;24:

723–34.

[22] Ohtsuki C, Kokubo T, Takatsuka K, Yamamuro T. Composi-

tional dependence on bioactivity of glassed in the system CaO–

SiO

2

–P

2

O

5

: its in vitro evaluation. J Ceram Soc Jpn 1991;99:1–6.

[23] Ohtsuki C, Kushitani H, Kokubo T, Kotani S, Yamamuro T.

Apatite formation on the surface of ceravital-type glass-ceramic in

the body. J Biomed Mater Res 1991;25:1363–70.

[24] Gadallah AG, Mazhar AA, El-Taib Heakal F, Ameer MA.

Formation and dissolution of anodic oxide films on zirconium in

NaOH: kinetic studies. J Appl Electrochem 1989;19:213–8.

[25] Li P, Ohtsuki C, Kokubo T, Nakanishi K, Soga N, Nakamura T,

Yamamuro T. Apatite formation induced by silica gel in a

simulated body fluid. J Am Ceram Soc 1992;75:2094–7.

[26] Li P, Ohtsuki C, Kokubo T, Nakanishi K, Soga N, Nakamura T,

Yamamuro T. A role of hydrated silica, titania and alumina in

forming biologically active apatite on implant. Berlin, Germany:

Transactions of Fourth World Biomaterials Congress, 1992.

p. 5.

[27] Miyazaki T, Kim HM, Kokubo T, Miyaji F, Kato H, Nakamura

T. Induction and acceleration of bonelike apatite formation of

tantalum oxide gel in simulated body fluid. J Sol-Gel Sci Tech,

submitted.

[28] Uchida M, Kim HM, Miyaji F, Kokubo T, Nakamura T.

Apatite-forming ability of zirconia gel in modified SBF solutions.

In: LeGeros RZ, LeGeros JP, editors. Bioceramics 11. Singapore:

World Scientific Publishing Co. Pte. Ltd., 1998. p. 77–80.

[29] Wang XX, Hayakawa S, Tsuru K, Osaka A. A comparative study

of in vitro apatite deposition on heat-, H

2

O

2

-, and NaOH-treated

titanium surfaces. J Biomed Mater Res 2001;54:172–8.

[30] Ohtsuki C, Kokubo T, Yamamuro T. Mechanism of apatite

formation on CaO–SiO

2

–P

2

O

5

glasses in simulated body fluid. J

Non-Cryst Solids 1992;143:84–92.

M. Uchida et al. / Biomaterials 23 (2002) 313–317

317

Wyszukiwarka

Podobne podstrony:

Biomimetic apatite formation on chemically treated titanium

Prezentacja formatka

Formaty plików dźwiękowych

Przekroje Format A2

h 1 formatka 2012 budowa hv

P3 PLAN KONSERWATORSKI (FORMAT 2000x2500)

Formatki do zaj z OC Cwiczenie Nieznany

Automatyczne formatowanie dokumentu, informatyka, grafika

Formatowanie(1), Edukacja, Informatyka

2013.09.17 FORMATKA RYSUNKOWA A4

format[1], Szkoła, Systemy Operacyjnie i sieci komputerowe, systemy, semestr I

Przenoszenie formatu z komórki na komórkę, excel

sciaga format normalny

Formatka!!!

WORD FORMATION PRACTICE N 1

Format scenariusza(1)

word formation od EXTEND

4 Formatowanie zaawansowane punktury i numeratory Cwiczenie 4

17 Money Making Candle Formations

więcej podobnych podstron