ENERGY CENTER

OF WISCONSIN

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

report

energy

center

Research Report

201-1

Emissions and Economic Analysis

of Ground Source Heat Pumps in

Wisconsin

December 2000

Research Report

201-1

Emissions and Economic Analysis of Ground

Source Heat Pumps in Wisconsin

December 2000

Prepared by

Global Energy Options

4634 Bonner Lane

Madison, WI 53704-1327

608.244.6436

Oak Ridge National Laboratories

1000 Bethel Valley Rd.

Oak Ridge, TN 37831-6070

865.574.2015

Contact: George Penn

Global Energy Options

Prepared for

ENERGY CENTER

OF WISCONSIN

595 Science Drive

Madison, WI 53711-1076

Phone: 608.238.4601

Fax: 608.238.8733

Email: ecw@ecw.org

WWW

.

ECW

.

ORG

Copyright © 2000 Energy Center of Wisconsin

All rights reserved

This report was prepared as an account of work sponsored by the Energy Center of Wisconsin (

ECW

). Neither

ECW

, participants in

ECW

, the organization(s) listed herein, nor any person on behalf of any of the

organizations mentioned herein:

(a) makes any warranty, expressed or implied, with respect to the use of any information, apparatus, method,

or process disclosed in this report or that such use may not infringe privately owned rights; or

(b) assumes any liability with respect to the use of, or damages resulting from the use of, any information,

apparatus, method, or process disclosed in this report.

Project Manager

Craig Schepp

Energy Center of Wisconsin

Acknowledgements

Thanks to Steve Carlson from CDH Energy Corporation and G. Hetherington, A. Hubbard, and E. Mosher from

the Wisconsin Department of Natural Resources.

This report is funded by the Wisconsin Department of Administration, Division of Energy and

Intergovernmental Relations, through the Wisconsin Energy Bureau under the terms and conditions of this

Agreement.

i

Table of Contents

Abstract ........................................................................................................................................... i

Report Summary...........................................................................................................................i i

Introduction....................................................................................................................................1

History.................................................................................................................................1

Approach .............................................................................................................................2

What We Hoped to Learn ....................................................................................................2

Key Findings........................................................................................................................3

Methods...........................................................................................................................................4

Scenarios...............................................................................................................................4

Energy Use Analysis............................................................................................................5

HVAC Equipment Types and Efficiencies..........................................................................6

Systems Modeled.......................................................................................................... 6

Estimated Average Efficiencies ........................................................................................ 7

Emissions Analysis..............................................................................................................7

Daytypes ..................................................................................................................... 9

Sensitivity Analysis .................................................................................................... 10

Customer Economics..........................................................................................................11

Results...........................................................................................................................................13

Emissions Results ..............................................................................................................13

Emissions Breakeven..........................................................................................................19

Economics Results .............................................................................................................19

Discussion.....................................................................................................................................25

Introduction........................................................................................................................25

Interpretation of Results....................................................................................................25

Emissions.................................................................................................................. 25

Breakeven Emissions ................................................................................................... 26

Economics ................................................................................................................. 27

Impactors................................................................................................................... 28

Conclusions........................................................................................................................30

Recommendations ..............................................................................................................30

Limitations and Future Research........................................................................................31

References ....................................................................................................................................32

ii

Appendix A- Emissions Model Input Data..............................................................................A-1

Appendix B- Sample Emissions Results .................................................................................B-1

iii

Tables and Figures

Table 1

Emissions Results – Green Bay..............................................................................iv

Table 2

Energy & Economics Results – Green Bay..............................................................v

Table 3

Scenarios for Which Analyses Were Performed.......................................................4

Table 4

HDD and CDD Estimates........................................................................................5

Table 5

Estimated Average Efficiencies: Commercial Buildings ...........................................7

Table 6

Estimated Average Efficiencies: Residential Type Buildings...................................7

Table 7

Daytypes Used for Emissions Analysis..................................................................9

Table 8

Emissions Sensitivity Analysis..............................................................................10

Table 9

Rates Used for Economic Analysis........................................................................11

Table 10

Blended Rates.........................................................................................................12

Table 11

Large School Emissions Results (Natural Gas Heating).........................................13

Table 12

Small School Emissions Results (Natural Gas Heating).........................................14

Table 13

Office Emissions Results (Natural Gas Heating)...................................................14

Table 14

Commercial Development Emissions Results (Natural Gas Heating) ...................15

Table 15

Residential Emissions Results (Natural Gas Heating) ...........................................15

Table 16

Commercial Development Emissions Results (LP Gas Heating)...........................16

Table 17

Residential Emissions Results (LP Gas Heating)...................................................16

Table 18

Commercial Development Emissions Results (Fuel Oil Heating)..........................17

Table 19

Residential Emissions Results (Fuel Oil Heating)..................................................17

Table 20

Commercial Development Emissions Results (Electric Heating)...........................18

Table 21

Residential Emissions Results (Electric Heating)...................................................18

Table 22

Large School Energy and Economics Results.........................................................20

Table 23

Small School Energy and Economics Results.........................................................21

Table 24

Office Energy and Economics Results ...................................................................22

Table 25

Community Development Energy and Economics Results ...................................23

Table 26

Residential Energy and Economics Results............................................................24

Table A-1

Alliant (WP&L) Power Plant Characteristics ..................................................... A-2

Table A-2

Alliant (WP&L) Emissions Rate Data ................................................................ A-3

iv

Table A-3

Daytype Definitions........................................................................................... A-4

Table A-4

Season Definitions............................................................................................... A-5

Table B-1

Emissions Analysis Sample Output Table: Large School, WPS, Green Bay.......B-1

v

Abstract

A result of the combined sponsorship of the Wisconsin Focus on Energy program, the Wisconsin

Geothermal Association, and the Energy Center of Wisconsin, the research underlying this report

has two main objectives. First, the research team investigated the impact on emissions resulting

from the application of ground source heat pumps (GSHP). Second, the team estimated the

resultant customer economics for application of this technology in new buildings being

constructed in Wisconsin.

We analyzed building energy use for each of the 8760 hours that make up the year. We then

compared this energy use to Wisconsin’s current operation of power plants that provide power

throughout Wisconsin to estimate impacts on several component emissions, assuming economic

dispatch. Finally, we estimated customer economic indicators related to installing GSHPs. Our

investigation included five building types in three different climate regimes, served by three

different utilities.

Based on the energy use of GSHP and conventional HVAC systems, we determined the potential

emissions reductions for each building type in each weather/utility area. For commercial buildings

our calculations indicate significant reductions in CO

2

emissions, as well as reductions in NO

X

and particulates in all but one scenario, while SO

2

emissions always increase. Finally, mercury

(Hg) emissions show less consistency; depending on the building type and weather regime, Hg

either slightly increases or slightly decreases. Conversely, all types of emissions primarily

increased from application of GSHP’s in the residential sector where natural or LP gas is

available. However, GSHPs installed in the residential sector where the home would otherwise be

heated with oil or electricity resulted in emissions reductions.

Finally, we analyzed the economics of this technology compared to conventional systems

appropriate for each building type, from the building owner’s perspective. We have found that

GSHPs can be an economically viable HVAC system for commercial buildings under certain

conditions. The economic viability in the residential sector appears more tenuous.

Our results suggest that designers of Wisconsin Public Benefits programs should consider this

technology in the future for commercial buildings in Wisconsin. For residential buildings Public

Benefits should consider promoting this technology where neither natural gas nor LP gas is

available. Wisconsin Public Benefits initiatives may also consider promotions in the residential

sector if needed to improve economies of scale in Wisconsin markets. In addition, the results also

suggest that electric utilities may want to examine this technology for inclusion in their future

commercial energy efficiency programs.

vi

vii

Report Summary

Introduction

Precedent shows that Ground Source Heat Pumps (GSHP) provide superior HVAC performance

for many buildings, while offering improved efficiency and lower operating costs than

conventional HVAC systems. Further, the EPA has demonstrated significant reductions in most

emissions from the national deployment of this technology. This has led the EPA and DOE to

join forces in a variety of efforts to facilitate the increased application of GSHP technologies.

The Focus on Energy program, the Wisconsin Geothermal Association, and the Energy Center of

Wisconsin seek to learn how the economics and emissions benefits apply to the application of

this technology in new buildings built throughout Wisconsin. Global Energy Options was

retained to develop estimates of economics and emissions impacts for a variety of application

scenarios. Oak Ridge National Laboratory was also a major contributor and partner in this project

providing in-kind support to perform energy and economic analysis for several of the scenarios.

Methods

This report documents the environmental impacts of the technology, in the form of emissions

reductions. We also estimate the typical economic capabilities of this technology, from the

building operator’s perspective. Results outline fifteen scenarios, which are based on three

weather regimes, combined with matching utility generation:

•

Green Bay weather and Wisconsin Public Service

•

Madison weather with Alliant Energy, and

•

Eau Claire weather and Northern States Power

In addition, five “building types” were analyzed against these weather and utility combinations:

•

Large School

•

Small School

•

Office

•

Community Development, and

•

Residential

viii

ORNL and CDH Energy used DOE2 or TRANSYS to estimate energy use for each scenario.

These simulation models are standard and respected tools. Global Energy Options developed a

model in Excel to calculate the emissions for each building, using the annual hourly energy

outputs from ORNL and CDH Energy. This model estimates the emissions from power plants

and from burning natural gas at the site. The emission levels estimated include:

•

Carbon Dioxide – CO

2

•

Sulfur Dioxide - SO

2

•

Nitrous Oxides – NO

x

•

Particulates, and

•

Mercury - Hg

In addition, we have estimated the economics for installing GSHPs in the buildings in lieu of the

most probable conventional technologies. The conventional technologies compared for each of the

building types include:

•

For the school and office scenarios – water-cooled chillers with VAV/reheat distribution

systems and gas boilers for reheat and special heating needs. Gas water heating was also

assumed.

•

For the mixed multifamily and residential scenarios - high efficiency gas furnace and

conventional air conditioning systems. Gas water heating was also assumed.

The results of this research are expressed in indicators that we believe will be useful to a variety

of audiences. We have estimated, for each scenario, the following annual emissions indicators:

•

Building CO

2

, SO

2

, NO

X

, particulate, and mercury savings in pounds

•

Percent CO

2

, SO

2

, NO

X

, particulate, and mercury reductions

•

Savings of CO

2

, SO

2

, NO

X

, particulate, and mercury in pounds per ft

2

We have also estimated the following annual energy and economic indicators:

•

Total kWh, therm and resource energy savings, total energy cost savings and payback

•

Total kWh, therm and resource energy savings, and total energy cost savings as a percent of

the conventional technology application

•

Total kWh, therm and resource energy savings, and total energy cost savings per ft

2

ix

Results

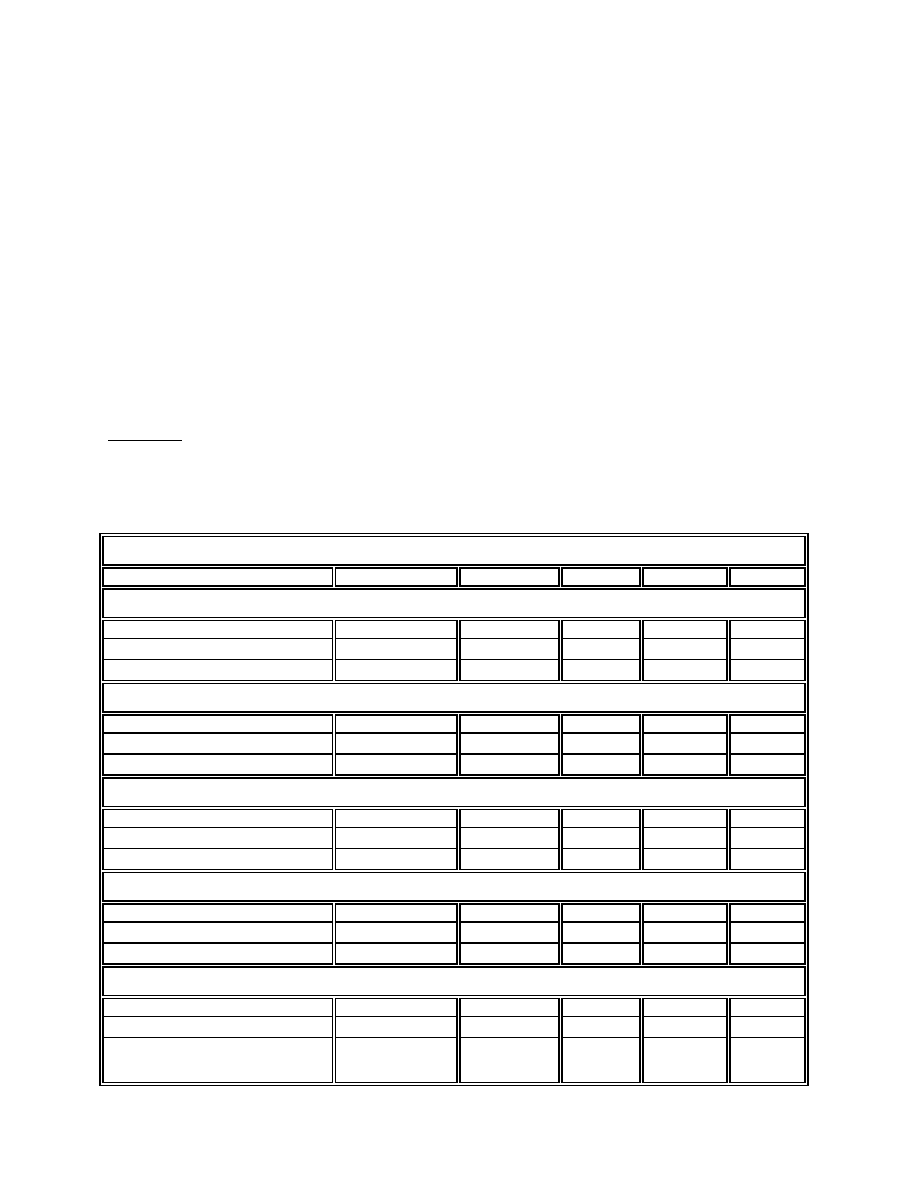

We hope to simplify the presentation of the myriad results for this project with the following

tables. These tables show only the results for the scenario located in the Focus on Energy

territory. The tables for other cities in Wisconsin are shown in the “Results” section of the

report.

The first set of tables frames the environmental impacts. The second set frames the economic

impacts.

Emissions

The following tables show the savings in each emission component from installing GSHPs in lieu

of the conventional alternative. (Note: With all emissions results, a negative number indicates that

there are greater emissions of this component when GSHPs are employed).

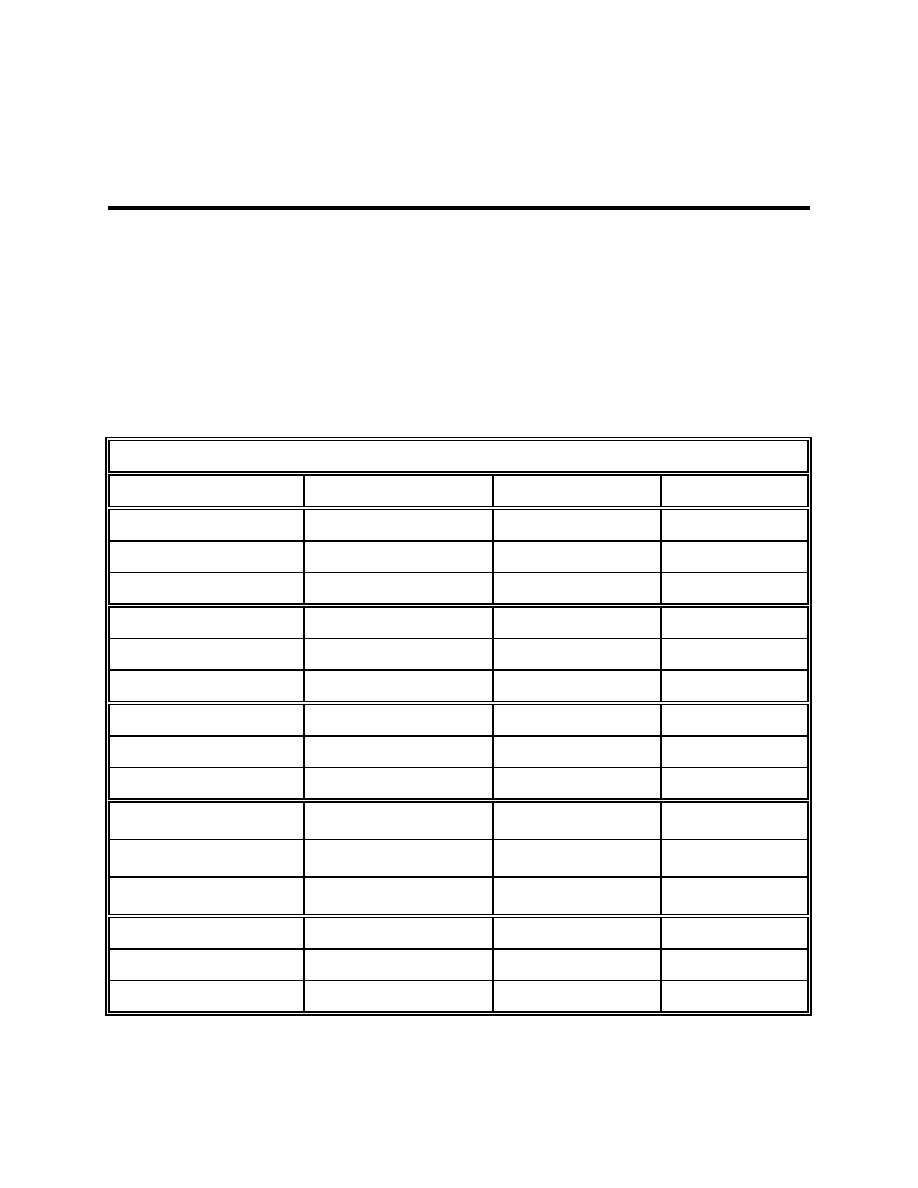

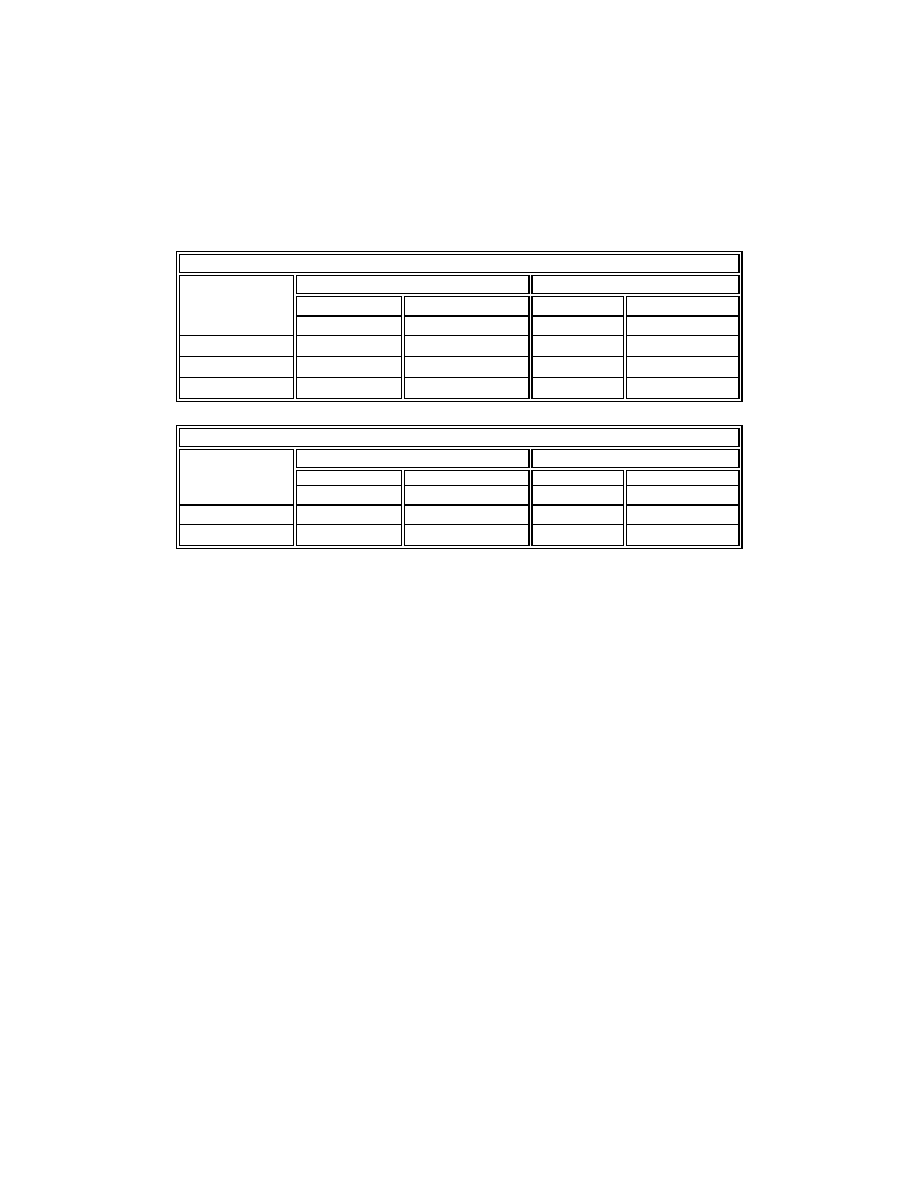

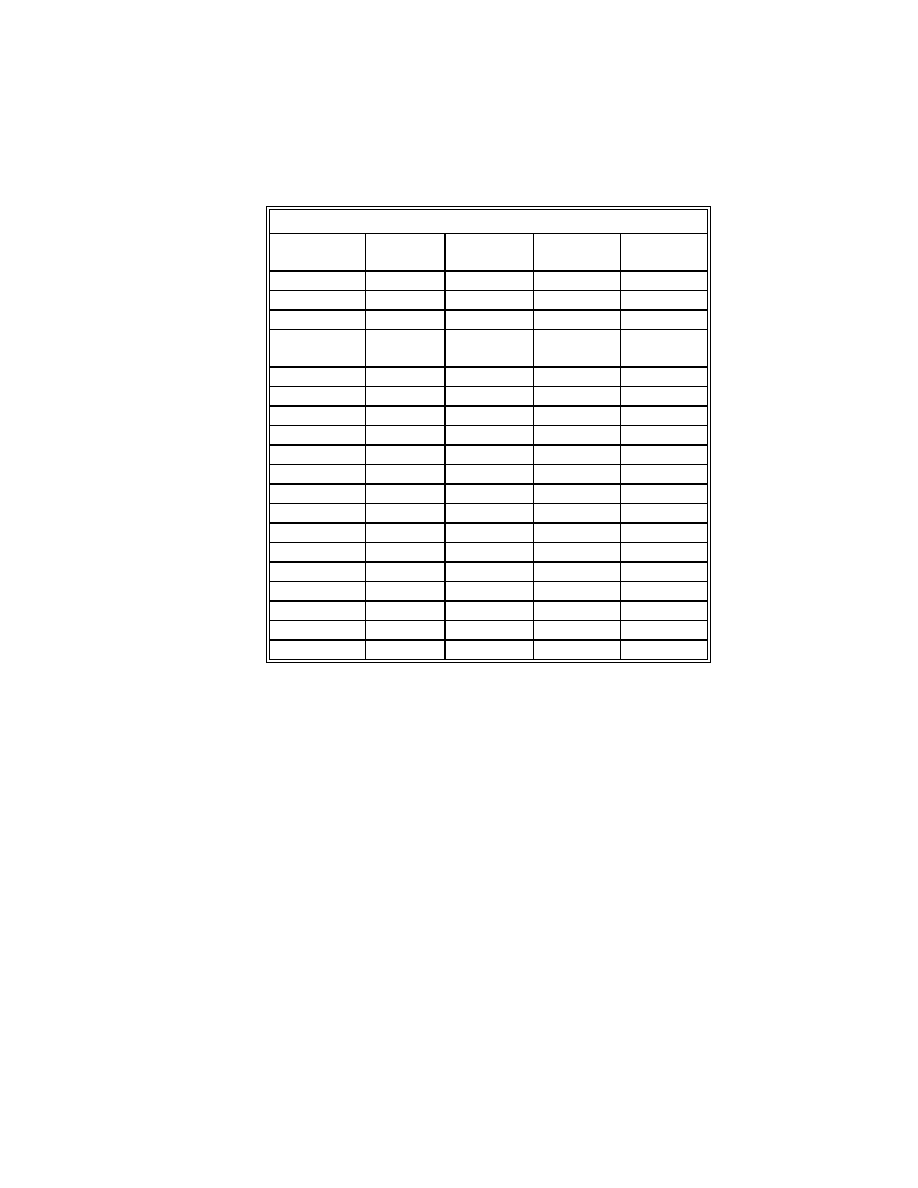

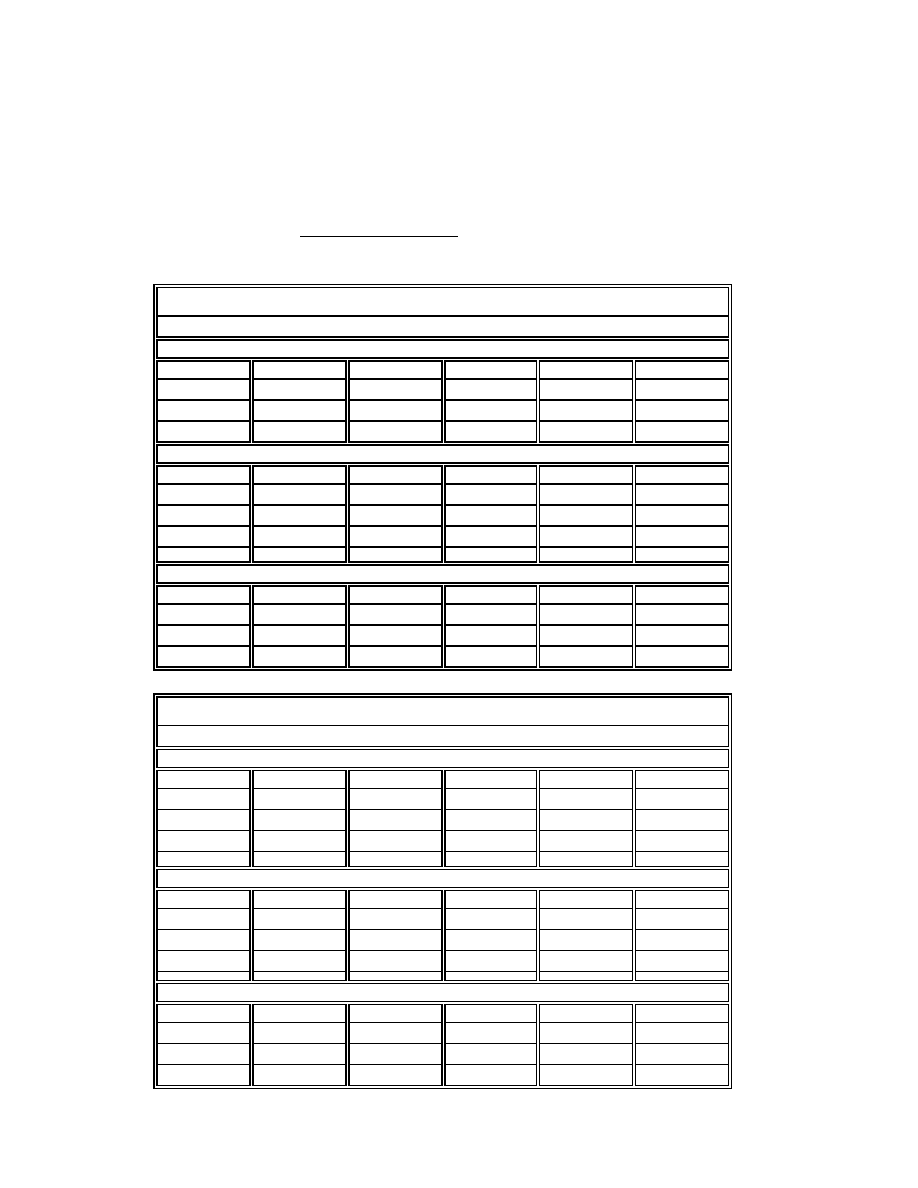

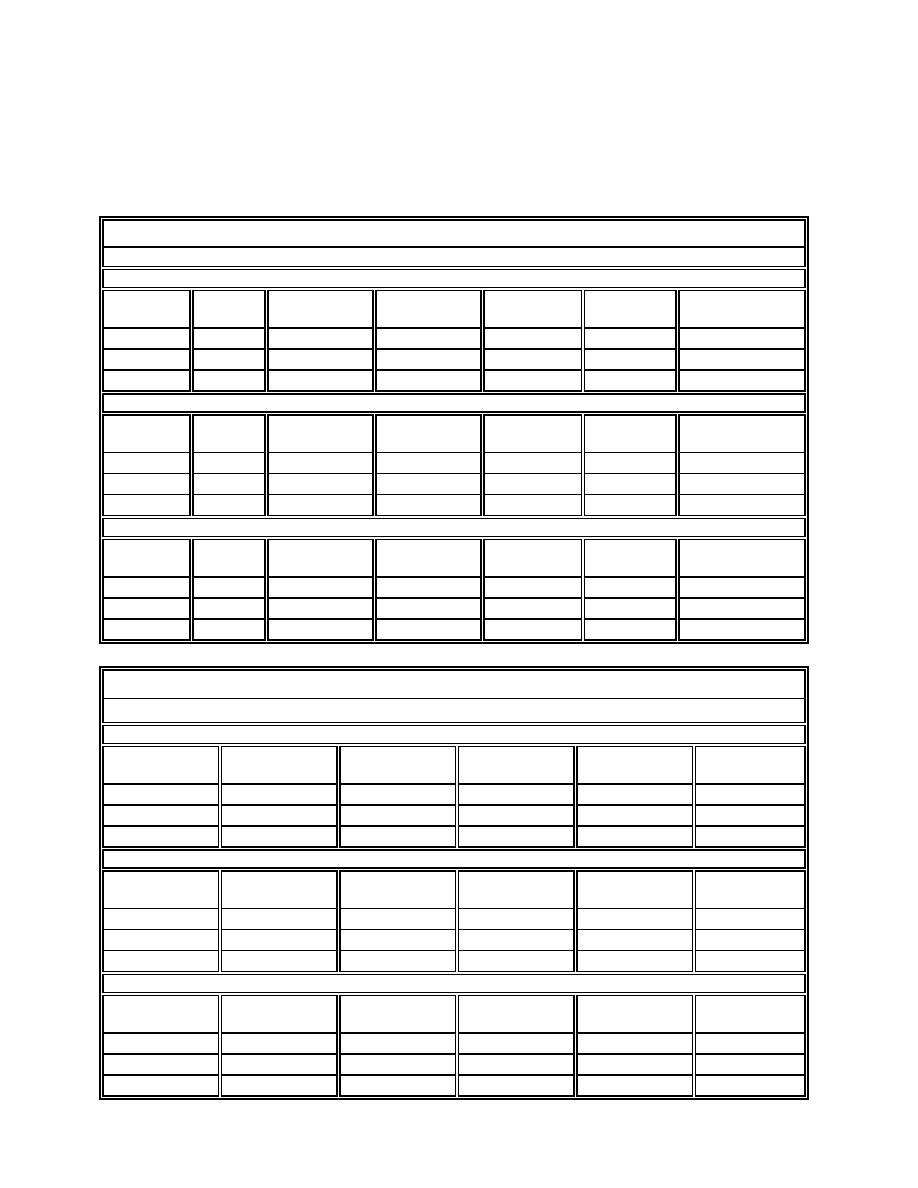

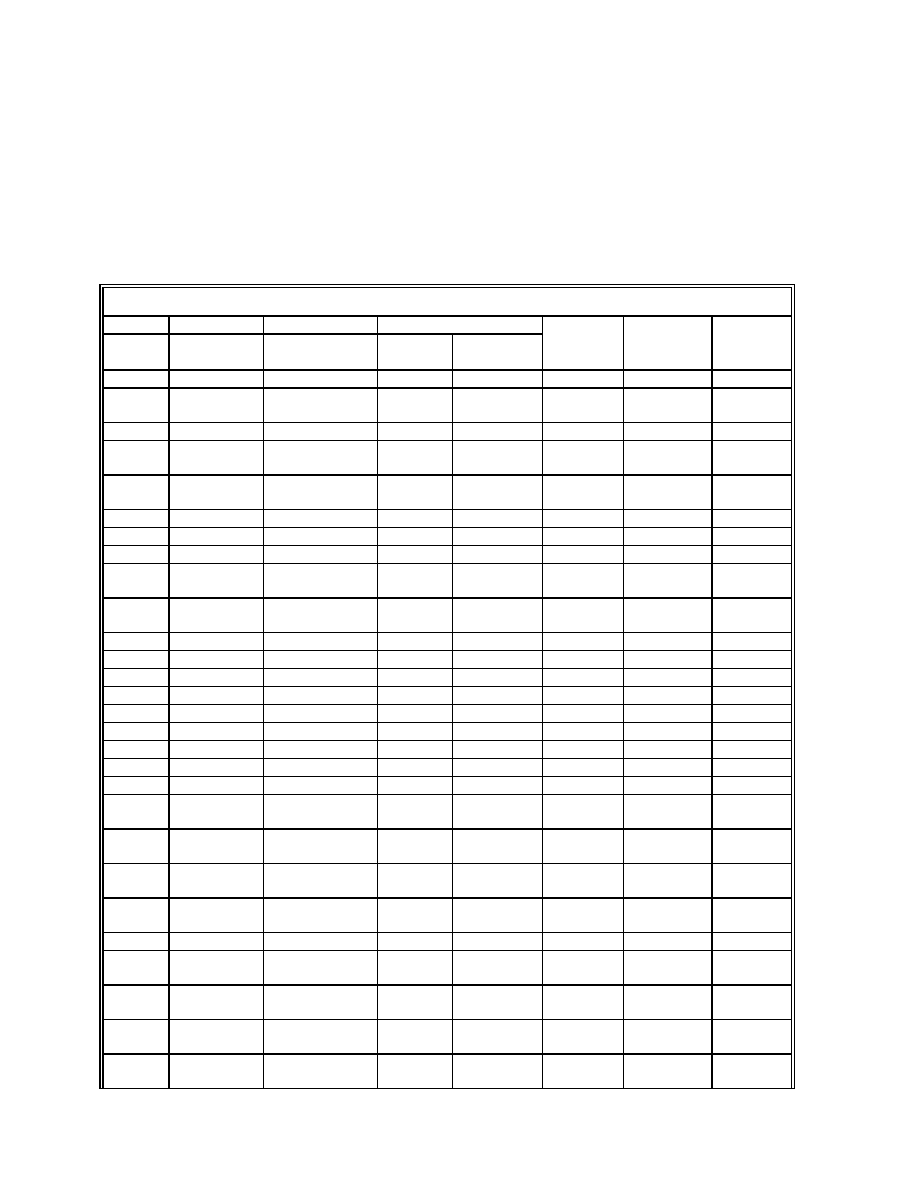

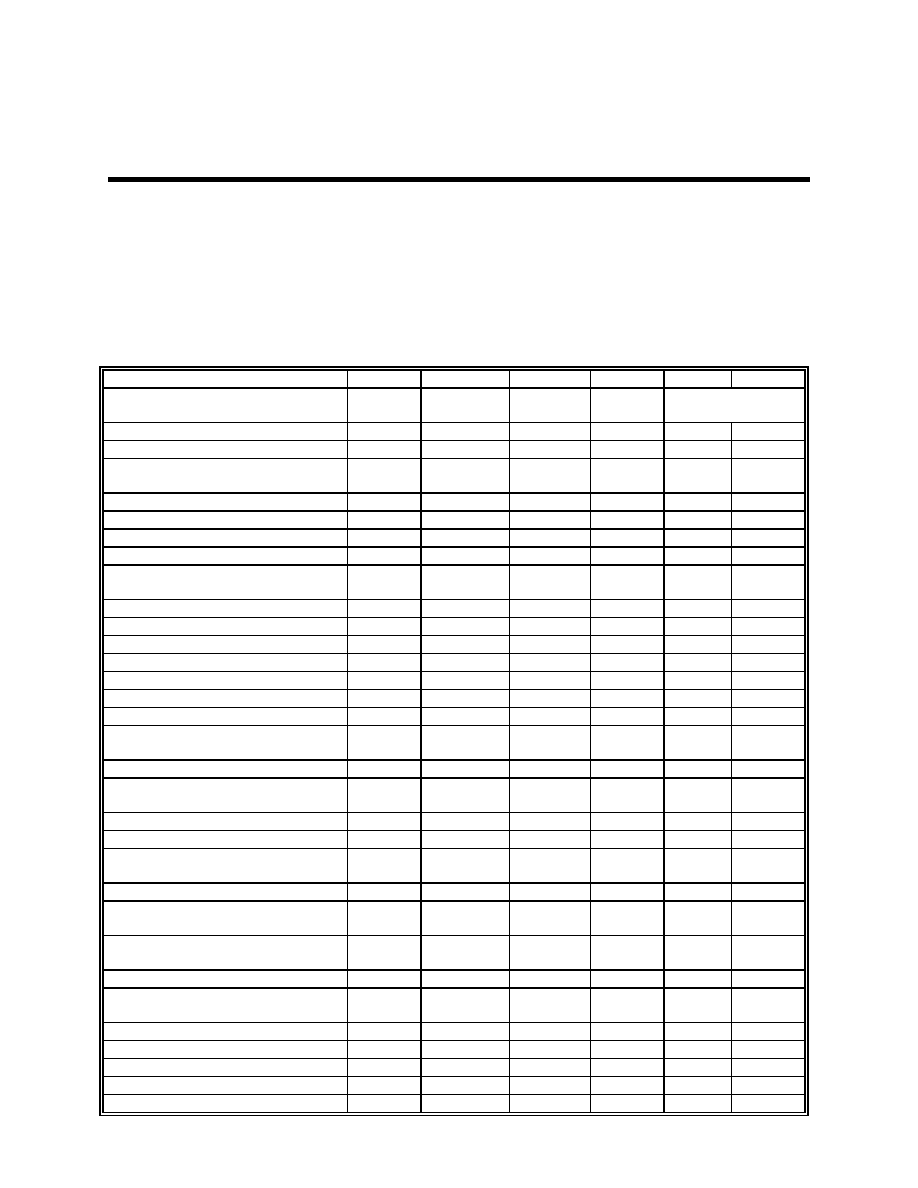

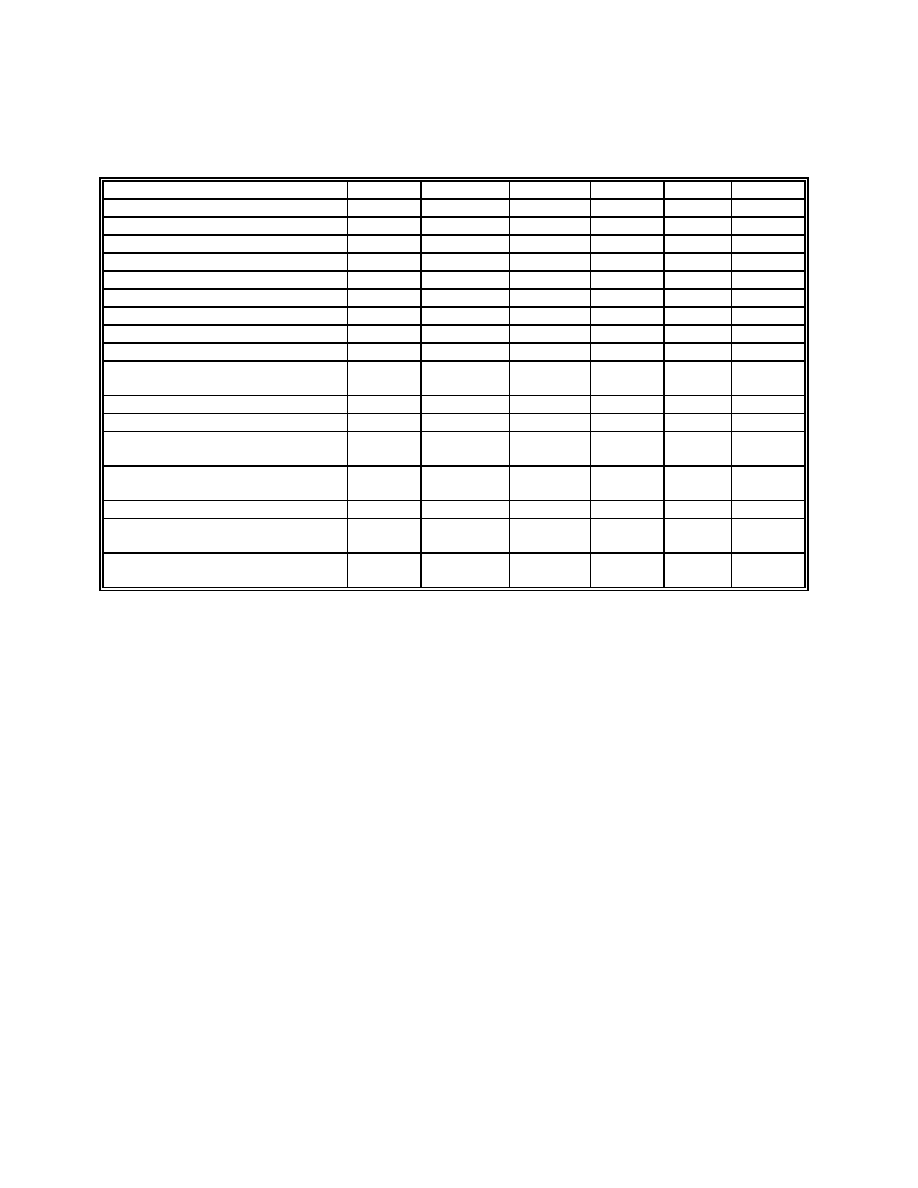

Table 1 – Emissions Results – Green Bay

C O 2

S O 2

N O x

P a r t i c u l a

Hg

Large School

Emissions Reductions

8 5 2 , 3 4 1

- 1 , 1 0 6

1 6 8

- 5

- 0 . 0 0 2 9

Emissions Reductions (%)

13.88%

- 6 . 6 2 %

1 . 2 0 %

- 0 . 4 2 %

- 3 . 4 1 %

Emissions Reductions

2 . 1 9

-2.84 x10

- 3

4.31x10

- 4

-1.33 x

- 7 . 3 4

Small School

Emissions Reductions

1 9 0 , 0 4 5

- 5 2

1 3 6

9

0 . 0 0 0 2

Emissions Reductions (%)

15.40%

- 1 . 6 3 %

4 . 9 7 %

3 . 6 1 %

1 . 1 7 %

Emissions Reductions

2 . 7 5

-7.50 x10

- 4

1.96 x10

-

1.26 x10

- 4

2.74 x

Office

Emissions Reductions

1 4 1 , 8 9 4

- 3 6

1 0 4

7

1.49 x10

-

Emissions Reductions (%)

8 . 8 2 %

- 0 . 7 8 %

2 . 7 1 %

1 . 9 8 %

0 . 6 4 %

Emissions Reductions

2 . 0 6

-5.27 x 10

- 4

1.51 x10

-

9.91 x10

- 5

2.15 x10

-

Community Development (Mixed Residential)

Emissions Reductions

- 2 8 0 , 3 3 8

- 4 , 0 3 1

- 2 , 3 2 2

- 2 2 6

- 0 . 0 1 7 7

Emissions Reductions (%)

- 6 . 5 7 %

- 3 5 . 7 5 %

- 2 4 . 2 3 %

- 2 6 . 5 1 %

- 3 1 . 0 9 %

Emissions Reductions

- 1 . 5 2

-2.18 x10

- 2

- 1 . 2 5

-1.22 x10

-

-

Residential (Home)

Emissions Reductions

- 1 , 3 3 1

- 1 6

- 9

- 1

-

Emissions Reductions (%)

- 5 . 4 5 %

- 2 2 . 6 2 %

- 1 6 . 3 1 %

- 1 7 . 6 2 %

- 2 0 . 0 5 %

Emissions Reductions

( l b s / f t 2 )

- 0 . 9 7

-1.17 x10

- 2

- 6 . 9 0

x10

- 3

- 6 . 6 7 x 1 0

- 4

- 5 . 1 5

x10

- 8

x

Table 2 – Energy & Economics Results – Green Bay

K W h s /

Y e a r

T h e r m s

/ Year

R e s o u r c e

( k B t u h s )

C o s t s

P a y b a

c k

P a y b a c k

w / R e a l

E s t a t e

Large School

Energy and Cost Savings

-

1 0 0 , 6 3 3

8 , 3 5 3 , 8 9 9 $ 3 5 , 5 9

9 . 8

1 . 6

Energy and Cost Savings

- 6 . 6 %

100.0%

23.2%

16.6%

Energy and Cost Savings

- 0 . 4 3

0 . 2 6

2 1 . 4

$ 0 . 0 9

Small School

Energy and Cost Savings

- 7 , 6 5 3

1 7 , 5 4 5

1 , 6 7 6 , 1 4 1

$ 5 , 4 0 6

2 4 . 3

1 4 . 7

Energy and Cost Savings

( % )

- 1 . 6 %

7 1 . 4 %

2 2 . 6 %

1 5 . 6 %

Energy and Cost Savings

(per ft2)

- 0 . 1 1

0 . 2 5

2 4 . 3

$ 0 . 0 8

Office

Energy and Cost Savings

- 5 , 1 5 0

1 2 , 9 9 7

1 , 2 4 6 , 9 6 9

$ 5 , 8 8 1

2 2 . 3

1 3 . 5

Energy and Cost Savings

( % )

- 0 . 7 %

7 0 . 2 %

1 4 . 7 %

1 3 . 2 %

Energy and Cost Savings

(per ft2)

- 0 . 0 7

0 . 1 9

1 8 . 1

$ 0 . 0 9

Community Development (Mixed Residential)

Energy and Cost Savings

-

7 7 , 9 0 1

1 , 5 3 9 , 0 5 7 $ 1 3 , 7 4

1 3 . 9

Energy and Cost Savings

- 3 5 . 6 %

1 0 0 . 0 %

6 . 1 %

8 . 6 %

Energy and Cost Savings

- 3 . 3 0

0 . 4 2

8 . 3 2

$ 0 . 0 7

Residential (Home)

Energy and Cost Savings

- 2 , 4 0 8

2 9 1

4 , 4 4 4

$ 7 5

2 4 . 1

Energy and Cost Savings

- 2 2 . 4 %

1 0 0 . 0 %

3 . 2 %

8 . 2 %

Energy and Cost Savings

- 1 . 7 6

0 . 2 1

3 . 2 4

$ 0 . 0 5

Discussion, Conclusions and Recommendations

The results summarized above imply that emissions reductions and customer economic benefits

depend on a complicated set of factors. These factors are discussed elsewhere in the report.

However, we can make some conclusions about the general viability of GSHPs in Wisconsin

based on the present mix of generation plants (i.e. this analysis is a snapshot in present time).

Economics

xi

Emissions

The results show that there are significant reductions in CO

2

emissions from application of

GSHPs in the commercial sector. There are also typically small reductions in NO

X

and

particulates. However, there are typically small increases in SO

2

emissions. Finally, mercury

emissions are more variable in whether emissions increase or decrease; yet the levels of change are

very small for this pollutant.

The emissions results from use of GSHPs in Community Development and Residential

applications where natural gas is available show a different story. With one exception,

application of GSHPs in residential type buildings results in increased emissions as compared to

the conventional alternatives.

We ran the Community Development and Residential applications scenarios where natural gas is

not available and oil, LP gas or electric heating would be employed. The results of these analyses

are given in more detail later in the report. However, we can note that compared with LP gas the

results are similar to that of natural gas – increased emissions. Compared with oil and electric,

however, there are CO

2

reductions from the application of GSHPs in residential buildings.

Emissions Breakeven

The Center requested that we look at breakeven heating and cooling COP values for GSHPs such

that the CO

2

emissions savings are about zero. We performed a tertiary analysis for the Green

Bay Small School, Office, and Residential scenarios and found the following.

For commercial buildings the analysis shows that CO

2

emissions savings are positive for the

modeled buildings. Therefore, CO

2

emissions savings of zero can be achieved at lower COPs than

those found for our scenarios. The COPs found in our initial research approximate 3.0 for heating

and 3.6 for cooling. Our breakeven analysis suggests that CO

2

emissions savings would be about

zero given GSHP COPs of 2.4 for heating and 2.9 for cooling. This suggests that a reduction of

approximately 20% in heating and cooling COPs for the GSHP system would produce no CO

2

emissions savings for commercial buildings.

For residential buildings the analysis shows that CO

2

emissions savings are negative for the initial

modeling of the home HVAC requirements. In this case we needed to ask how high the heating

COP and cooling EER need to be for there to be no increases in CO

2

emissions. These efficiencies

would have to be raised to a heating COP of 5.1 and a cooling EER of 22.1 to reduce CO

2

emissions increases to zero. This pair of values is not technically achievable with present

technologies.

xii

Economics

For the Large School, the payback periods are good at between 7.1 and 10.5 years depending on

the city. The payback periods for installation of GSHPs in the Small School and the Office

building are two to four times longer (between 15.2 and 27.6 years).

This difference is primarily driven by the loop technology employed. The Large School is being

built in Fond du Lac in the near future and has been analyzed using a pond loop configuration –

the school needs these ponds to meet site drainage requirements. The Small School and Office

buildings were analyzed using vertical loops – which are significantly more expensive to install.

For the commercial type applications considered (schools, offices), we have also calculated the

payback from “real estate savings.” Where building owners see the value in reduced mechanical

room floor space requirements from not installing the conventional system, the payback periods

can be significantly shortened. For this analysis the Large School payback periods went down to

between 1.2 and 1.7 years. For the Small School and Office scenarios, the payback periods went

down to between 9.2 and 16.7 years.

Further, proponents of GSHP systems are confident that there are savings in O&M from

applying this technology. However, we can find no research to support this belief. Therefore, we

have not analyzed the impact of reduced O&M on payback periods.

The Community Development scenario has reasonable economics because the loop costs are

based on costs for an actual installation, in Louisiana. There, a large contract was let for loop

installations and economies of scale resulted in lower loop installation costs. Our analysis

suggests that for this scenario the payback periods range from 9.6 to 13.9 years.

The Residential scenario suggests long payback periods from application of GSHPs. This is due

to the low costs to install a simple furnace and A/C combination. Here the payback periods range

from 24.1 to 26.2 years.

Conclusions

There are significant emissions advantages to using GSHPs in the commercial sector. However,

there appear to be no emissions advantages to replacing efficient natural or LP gas furnaces with

GSHPs in the residential sector. There are emissions advantages in the residential sector when

GSHPs are compared to oil or electric heating in homes. These conclusions are based on current

mixes of utility power plants. Future changes in the power plant mixes will affect the results and

conclusions. In general, the lower the reliance on coal to generate electricity, the better will be the

emissions impact of installing GSHPs.

The payback periods for application of GSHPs in the residential sector are long , exceeding 20 or

xiii

more years in all cases. However, there are situations where GSHPs can be applied to commercial

buildings resulting in reasonable payback periods of less than 15 years. And, where real estate

savings are considered, the payback periods can shorten to less than two years for some

commercial applications.

Recommendations

While there are significant emissions advantages to using GSHPs in commercial buildings, the

economic analysis suggests there will need to be market supports to improve early economics

and develop significant, and possibly sustainable, market penetration.

We recommend that Public Benefits institutions and/or interested utilities provide programs to

help develop the infrastructure and market for GSHPs in the commercial sector.

It is clear the there are no environmental benefits to installing GSHPs in the residential sector in

colder climates where natural or LP gas is the alternative and coal is the primary fuel for power

plants. There are environmental benefits for homes where oil or electricity are the alternatives.

Given our findings, we recommend that Public Benefits institutions not spend much effort on

increasing the market share for GSHPs in the residential sector. However, we note an exception

to this suggestion if facilitating applications in the residential sector is required to build the

infrastructure so that capable contractors are available to install this technology in the commercial

sector. We also recommend this effort if the GSHPs will displace oil or electric heating in the

home.

Introduction

1

Introduction

History

Previous research indicates that Ground Source Heat Pumps (GSHP) provide superior HVAC

performance for all building types, while offering improved efficiency and lower operating costs

than conventional HVAC systems.

Various projects reviewing potential energy and energy cost savings for the installation of

GSHPs, in lieu of conventional technologies, reveal significant benefits. A general consensus in

the GSHP engineering industry indicates savings commonly in the order of 20% for commercial

buildings. Recent work by ASHRAE, the Ground Source Heat Pump Consortium, EPA and

others seems to substantiate this expectation. However, extant research, while conducted

throughout the United States, features fledgling or robust markets for GSHP systems; this does

not yet include Wisconsin.

The research reveals, as with many alternative technologies, a greater cost for installing GSHP

systems than for most conventional systems. While some GSHP proponents are quick to point

out exceptions (in some commercial buildings), the industry generally accepts a higher installation

cost for this less frequently specified technology. Prevailing research suggests an average cost

premium for installing GSHPs in commercial buildings between 10% and 20%. Typical cost

premiums in Wisconsin are uncertain because of limited experience with this technology. Indeed,

because of the lack of infrastructure, and the resultant “fears” of engineers toward applying this

technology, assistance may be initially necessary to ensure the installation of some early,

demonstrative systems.

The EPA has reported significant reductions in most emissions from the national deployment of

this technology, which has led the EPA and DOE to join forces in a variety of efforts to facilitate

the increased application of GSHP technologies. These organizations expect to invest in the

development of this technology in excess of $100 million between 1994 and 2004. Further, they

expect to facilitate an increase in annual installations from about 40,000 heat pumps per year, to

400,000 per year over the same time period.

Reports suggesting national capabilities for emissions reductions are encouraging. However, none

of these estimates apply specifically to Wisconsin. Theoretically, the confluence of weather

regimes and electric generation mixes could result in different emissions savings potential in

Wisconsin than the rest of the country at large.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

2

The Focus on Energy program, the Wisconsin Geothermal Association, and the Energy Center of

Wisconsin seek to learn how the emission and economic benefits apply to the application of this

technology in new buildings built throughout Wisconsin. Global Energy Options was retained to

develop estimates of economics and emissions impacts for a variety of application scenarios.

Approach

This report provides Wisconsin specific estimates of the impact on emissions from installing

GSHPs. It also provides estimates of economic benefits to building owners who install GSHPs

over the most appropriate conventional technology. We focus on the application of this

technology in new buildings.

We analyzed typical hourly energy use by the modeled buildings, and then compared this energy

use to the hourly operation of power plants throughout Wisconsin, assuming economic dispatch.

Our analysis includes buildings in three different climate regimes, served by three different

utilities. Modeling for five different building types results in fifteen scenarios. Our intense hourly

analysis ensures accurate results, hence ensuring a high degree of reliability upon which to base

policy decisions.

While this project was initially commissioned to determine the benefits of applying this

technology in the Focus on Energy territory (23 northeast counties served by WPS), we

ambitiously decided to expand the scope of the work to include the whole state. Today’s

modeling tools allowed us to cost effectively expand the scenarios to other weather regimes and

utility costing structures. And our choice of three different weather/utility points of analysis

allow for the interpolation of the results, somewhat reliably, to other parts of the state.

Originally we chose to analyze only four building types against our weather/utility dimension: a

school, an office, a community development, and a residence. However, CDH Energy was

conducting a feasibility study for a large school in Fond du Lac that is considering the GSHP

option. CDH Energy ran a DOE2 analysis of this building in the two other weather regimes for

us, adding a second school option for us to analyze.

What we Hoped to Learn

We hoped to determine if the application of GSHP technologies to buildings constructed in

Wisconsin offered environmental and economic benefits commensurate with the findings in other

parts of the North American continent.

We also hoped to determine if application of this technology afforded benefits to both the

commercial and residential new construction markets alike, or if application proved more

beneficial to one of these markets than to the other.

Introduction

3

Key Findings

The results show that there are significant reductions in CO

2

emissions from application of

GSHPs in the commercial sector. There are also typically small reductions in NO

X

and

Particulates. However, there are typically small increases in SO

2

emissions. Finally, mercury

emissions are more variable in whether emissions increase or decrease; yet the levels of change are

very small for this pollutant.

The emissions results from use of GSHPs to residential type applications shows a different

story. With one exception, application of GSHPs in residential type buildings results in increased

emissions as compared to the conventional alternatives.

Economics

For the Large School, the payback periods are good at between 7.1 and 10.5 years depending on

the city. The payback periods for installation of GSHPs in the Small School and the Office

building are two to four times longer (between 15.2 and 27.6 years).

This difference is primarily driven by the loop technology employed. The Large School is being

built in Fond du Lac in the near future and has been analyzed using a pond loop configuration –

the school needs these ponds to meet site drainage requirements. The Small School and Office

buildings were analyzed using vertical loops – which are significantly more expensive to install.

For the commercial type applications considered (schools, offices), we have also calculated the

payback from “real estate savings.” Where building owners see the value in reduced mechanical

room floor space requirements from not installing the conventional system, the payback periods

can be significantly shortened. For this analysis the Large School payback periods went down to

between 1.2 and 1.7 years. For the Small School and Office scenarios, the payback periods went

down to between 9.2 and 16.7 years.

Further, proponents of GSHP systems are confident that there are savings in O&M from

applying this technology. However, we can find no research to support this belief. Therefore, we

have not analyzed the impact of reduced O&M on payback periods.

The Community Development scenario has reasonable economics because the loop costs are

based on costs for a project implemented in Louisiana. There, a large contract was let for loop

installations and economies of scale resulted in lower loop installation costs. Our analysis

suggests that for this scenario the payback periods range from 9.6 to 13.9 years. This analysis

does not account for the additional cost of bringing a gas pipeline to the subdivision. If added,

the GHP payback period would be less.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

4

The Residential scenario suggests long payback periods for GSHPs. This is due to the low cost

to install a simple furnace and A/C combination. For the small house (1370 ft2) modeled here,

payback ranges from 24.1 to 26.2 years. Payback improves with increasing house size and loads.

Methods

5

Methods

Scenarios

We selected five building types and three weather regimes for which we have estimated

environmental and economic benefits. For analyzing the customer economics, we used rates for

the utility that serves each weather-regime city. Analyzing these dimensions results in fifteen

scenarios for which we provide results.

These scenarios are shown in the following table.

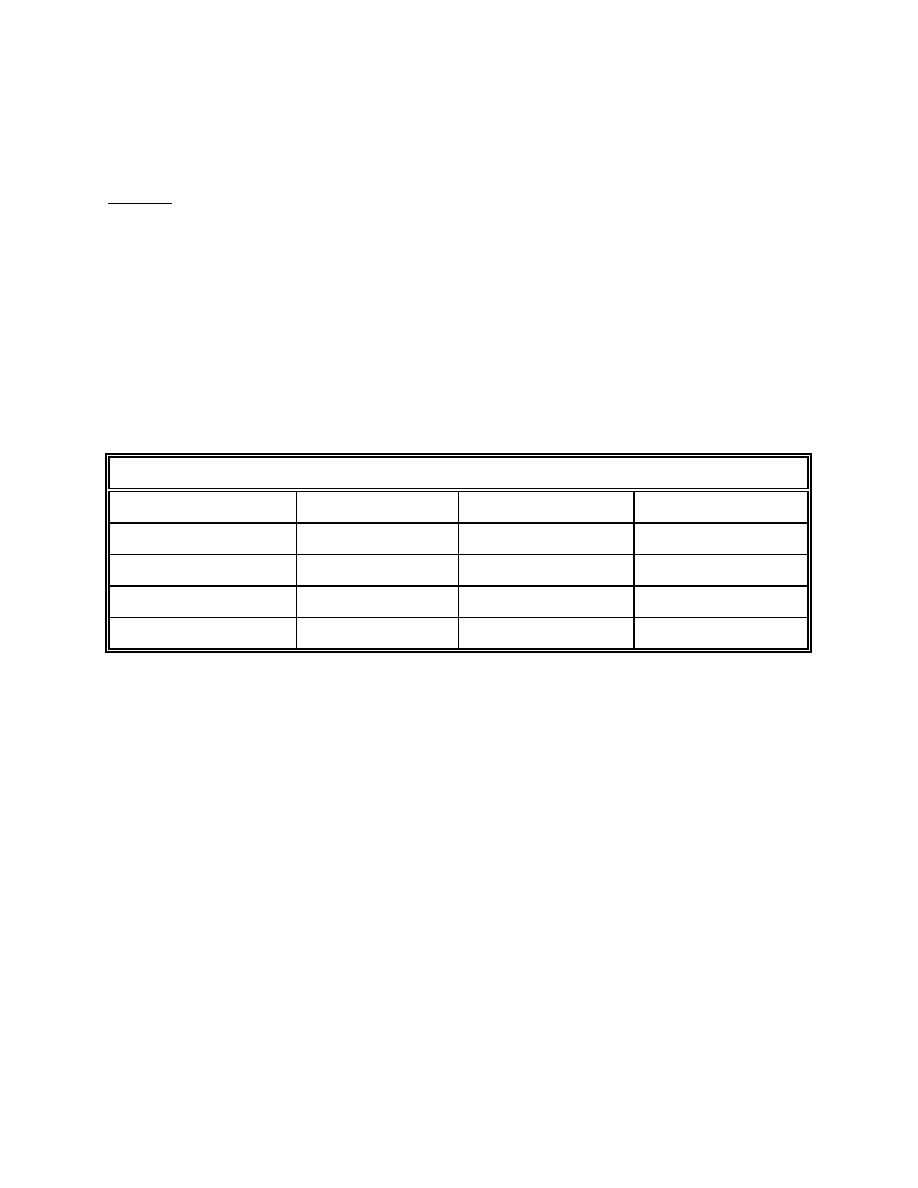

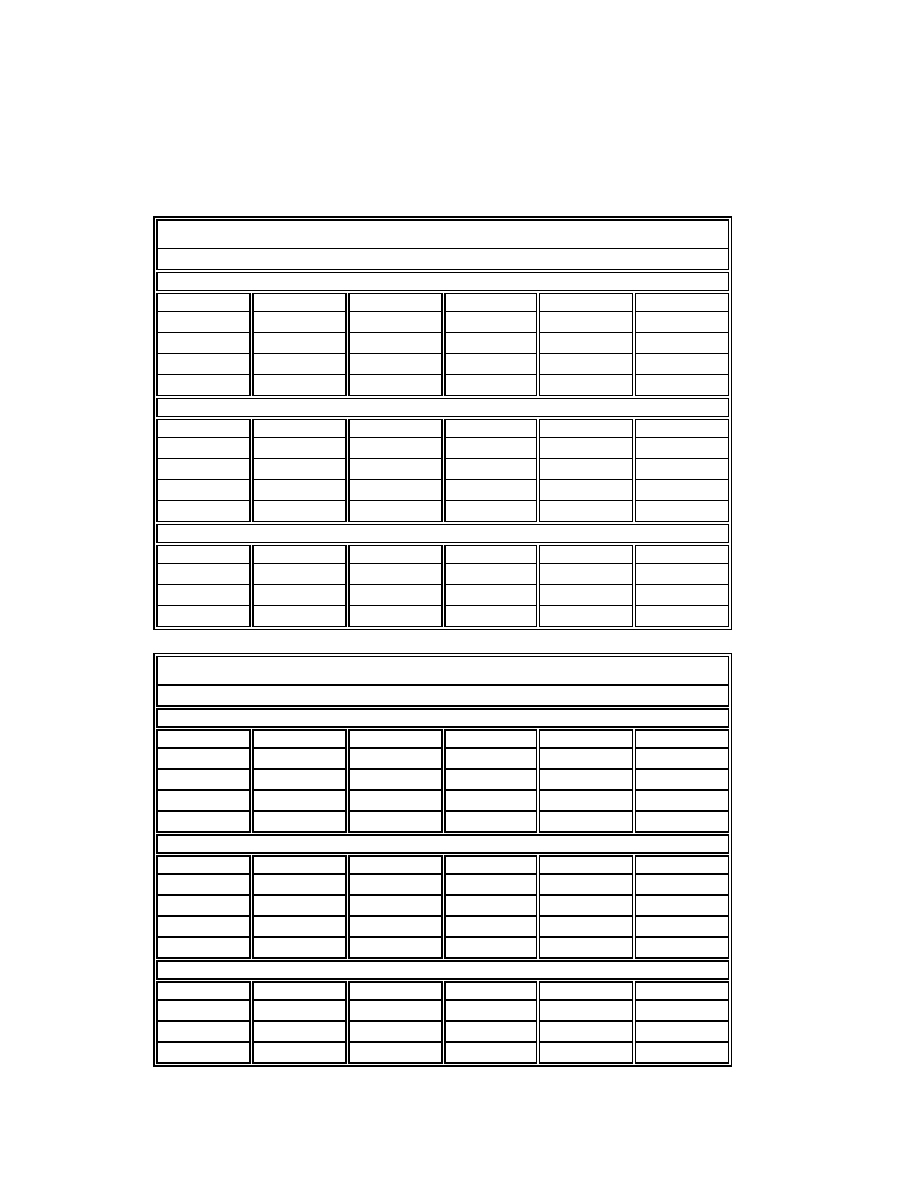

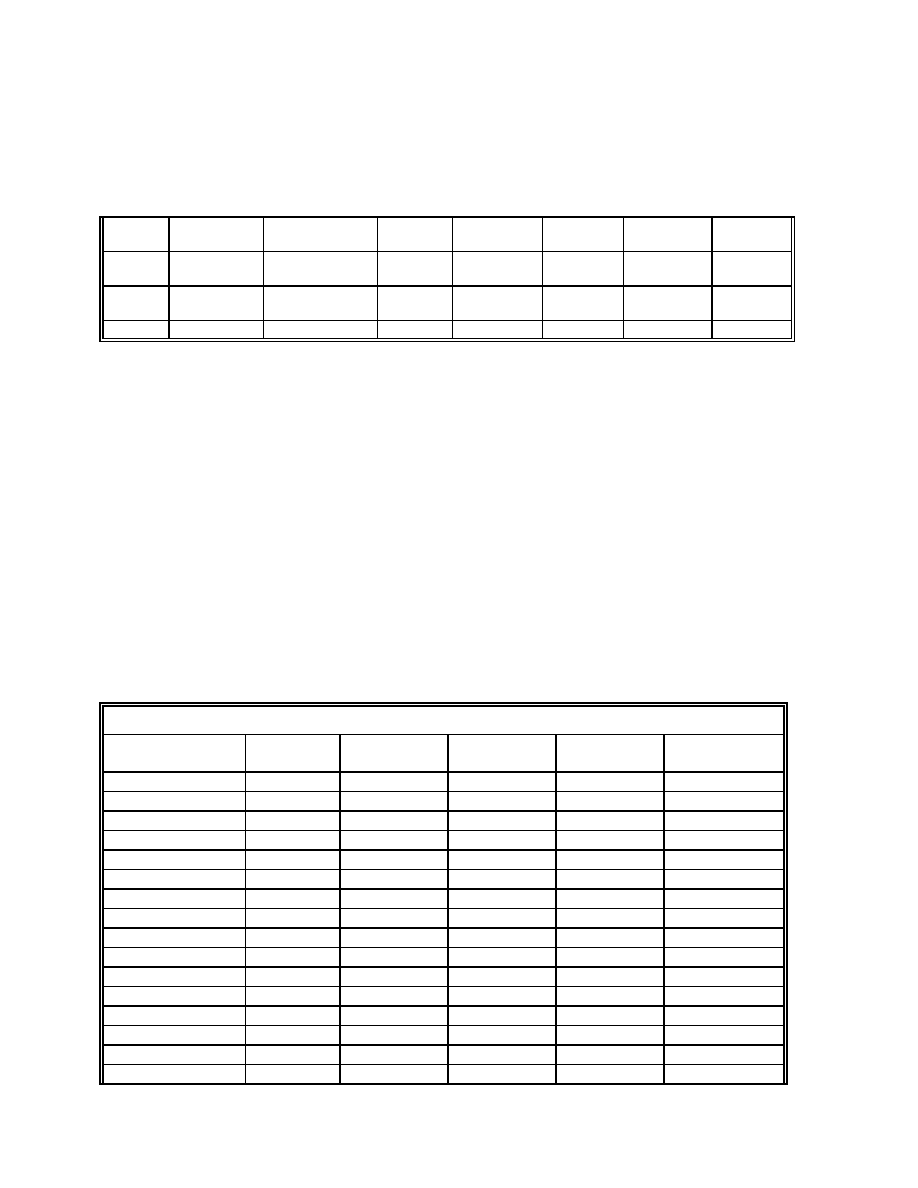

Table 3 - Scenarios for Which Analyses Were Performed

Building Type

Building Size (ft

2

)

Weather Location

Electric Utility

Large School

390,000

Green Bay

WPS

Large School

390,000

Madison

Alliant Energy

Large School

390,000

Eau Claire

NSP

Small School

69,000

Green Bay

WPS

Small School

69,000

Madison

Alliant Energy

Small School

69,000

Eau Claire

NSP

Office

69,000

Green Bay

WPS

Office

69,000

Madison

Alliant Energy

Office

69,000

Eau Claire

NSP

Community

Development

185,000

Green Bay

WPS

Community

Development

185,000

Madison

Alliant Energy

Community

Development

185,000

Eau Claire

NSP

Residence

1,370

Green Bay

WPS

Residence

1,370

Madison

Alliant Energy

Residence

1,370

La Crosse

NSP

The scope of the project did not allow us to model every commercial building type. We selected

schools and offices because these types of buildings are enjoying the most robust application of

GSHPs in other parts of the country.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

6

We added the community development scenario because we are aware of sustainable communities

that are assessing the use of GSHPs. ORNL has done significant analysis of projects of this type

in other parts of the country and found it easy to modify past modeling for Wisconsin building

code and weather parameters. A residential scenario is included to determine the benefits for this

market. The building sizes are functions of existing projects modeled by both ORNL and CDH

Energy.

We chose Green Bay, Madison, and Eau Claire because, from a state perspective, there are

reasonable differences among the weather regimes, and there are ASHRAE TMY (typical

meteorological year) data available for these cities. While a more northerly city like Rhinelander

would provide more diversity, no reliable weather data exists for that or nearby cities. The

heating degree-days (HDD) and cooling degree-days (CDD) estimates for each city are:

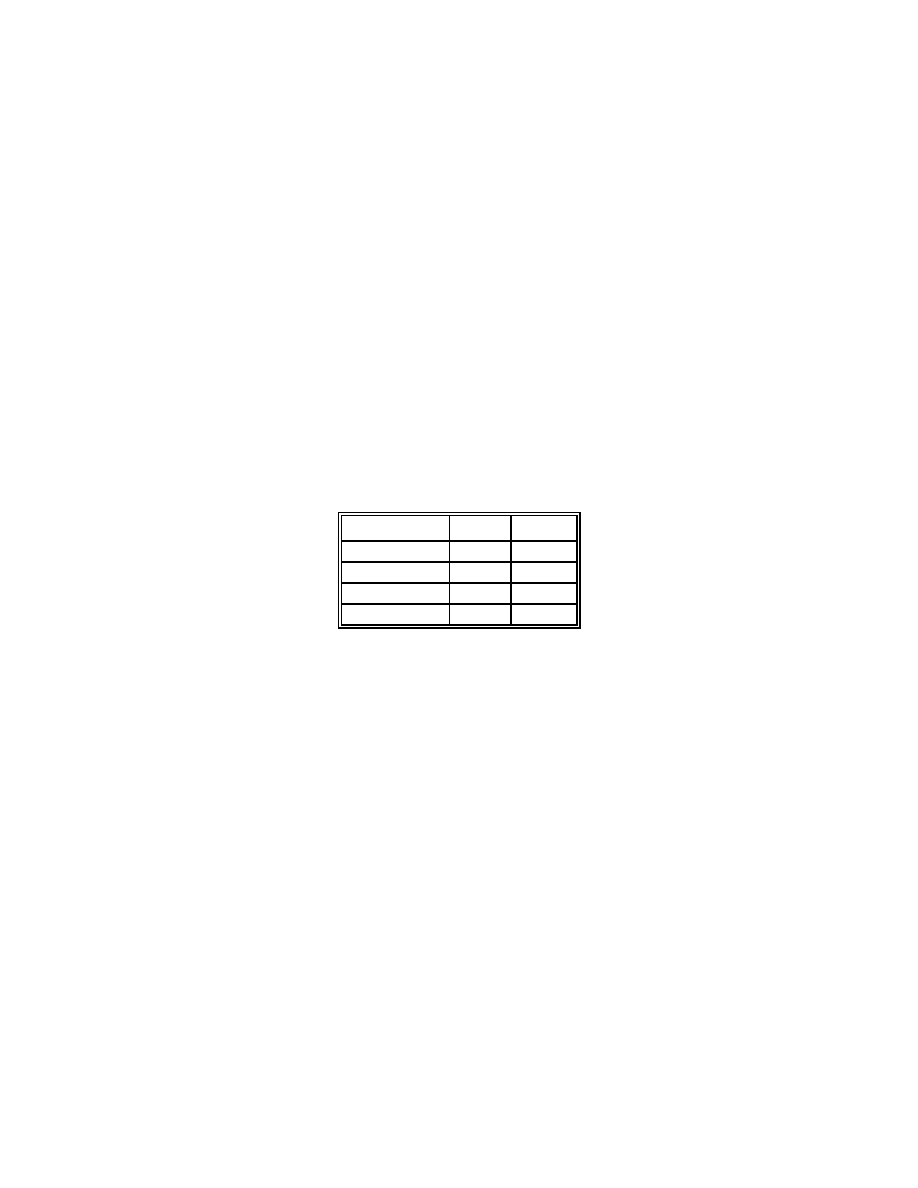

Table 4

C i t y

HDD

CDD

Madison

7 , 3 6 6

5 5 4

Green Bay

8 , 1 6 9

4 1 6

Eau Claire

8 , 4 1 7

5 0 5

La Crosse

7 , 8 1 4

8 3 4

Note: the Residential scenario analysis was conducted using La Crosse weather data because of

technical difficulties in TRANSYS using Eau Claire weather data.

Energy Use Analysis

GEO worked with ORNL and CDH Energy to develop hourly profiles of electric and gas

consumption for each of the scenarios analyzed. The proposed project included analysis from

ORNL for one residential and three commercial scenarios. Coincidentally, CDH Energy was

performing a feasibility analysis for a large school in Fond du Lac that was considering using

GSHPs, and participating in Alliant Energy’s Shared Savings program.

The Center asked GEO to add this school to its list of scenarios and asked CDH Energy to

provide 8760 hour energy use data to GEO. CDH Energy provided the data for the three weather

regimes considered.

Both ORNL and CDH Energy used DOE2 energy simulation software to develop energy use

profiles for the schools and the office. Profiles for the community development and residential

building scenarios were developed using TRANSYS. The building energy simulation industry

commonly uses and respects the reliability of both of these building energy use simulation

software packages.

As suggested earlier, we developed the profiles for the Large School scenarios based on a school

Methods

7

that will be built by the Fond du Lac school district in the next year. An existing school in

Lincoln, Nebraska forms the basis for the Small School scenario. ORNL has performed in-depth

comparisons of the Lincoln school with GSHPs to other identical schools in the Lincoln School

District to develop reliable comparisons of the school economics. ORNL modified the model

developed for this school to apply to Wisconsin commercial building code requirements and the

weather data for the three chosen cities.

For example, the prescriptive UAo values for commercial buildings under the building codes are

about those shown in the table below.

Maximum UAo for WI Commercial Buildings

Madison

Eau Claire

Green Bay

Roof Values

UAo =

0.051

0.047

0.049

R =

19.8

21.5

20.6

Above Grade Wall Values

UAo =

0.121

0.114

0.116

R =

8.2

8.7

8.6

Also, Wisconsin Commercial Building Code requires a minimum of 7.5 CFM per person for most

applications compared to ASHRAE 90.1, which suggests 15 CFM per person.

Similarly, the office building is based on an office in Tennessee for which ORNL has done

extensive HVAC technology comparison analyses. Again, we adjusted this building model for

Wisconsin commercial building code requirements and weather.

The Community Development scenario is based on a GSHP installation in Louisiana, which

includes where a variety of residential building types (mixed residential). The GSHPs replaced

standard air conditioning and gas furnaces. ORNL again chose to model this type of application

because it had done significant modeling and analysis of this project both before and after the

retrofit.

The home used for the residential scenario is located in Sun Prairie, Wisconsin, and was part of an

earlier Center project to look at the feasibility and economics of installing GSHPs in Wisconsin

homes. Data that ORNL could modify were available from earlier analyses of this home.

Using the building simulation models, ORNL and CDH Energy provided GEO with hourly

annual building kWh and therm uses. These two firms also used these energy uses to develop the

customer economics for these scenarios.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

8

HVAC equipment types and efficiencies

Some readers will want to know the efficiency assumptions used for the GSHPs and

conventional systems equipment. With the tools used to analyze HVAC options and energy use,

such as DOE2 and TRANSYS, equipment efficiency is not a single-point input. Instead, building

simulation experts use equipment performance tables from manufacturers.

However, when the simulation is completed, these experts are able to estimate the energy

weighted average efficiencies of the HVAC equipment. Rather than provide these estimates in

another section, we indicate them below.

Systems Modeled

We chose our base conventional system configurations based on what the market would typically

install for each type and size facility.

For the schools and office building, the base system is a water-cooled chiller with VAV/reheat

distribution system. The heating is provided using gas boilers. This includes winter heating load,

reheat as needed year round, and preheating ventilation air.

The GSHPs systems modeled for these buildings have separate heat pumps supplying space

heating and cooling to each defined zone. Most of these heat pumps are between 2 and 6 tons.

Some larger heat pumps are used for larger zones and to boost the temperature of make-up air.

These buildings do contain (smaller) gas boilers. These boilers are primarily needed for preheating

makeup air. This is because heat pumps are typically not designed to provide the necessary

temperature increase for the coldest Wisconsin winter days. The boilers might also provide heat

to some special areas like entrance vestibules if the design engineer uses this approach.

For all commercial buildings, regardless of the HVAC system installed, we assumed gas water

heating.

The Community Development scenario consists of a mix of various single family, duplex and

apartment buildings. The Residential scenario is based on a home in Sun Prairie in which a GSHP

was installed. Therefore, the base technologies for these scenarios are the same. We modeled

these buildings with furnaces and central air conditioning for the conventional base. For the

buildings modeled with conventional HVAC systems, we assumed the water heating is done by

gas. For the GSHP buildings, we assumed water heating is done by electric, with some of this

covered by an on-demand desuperheater.

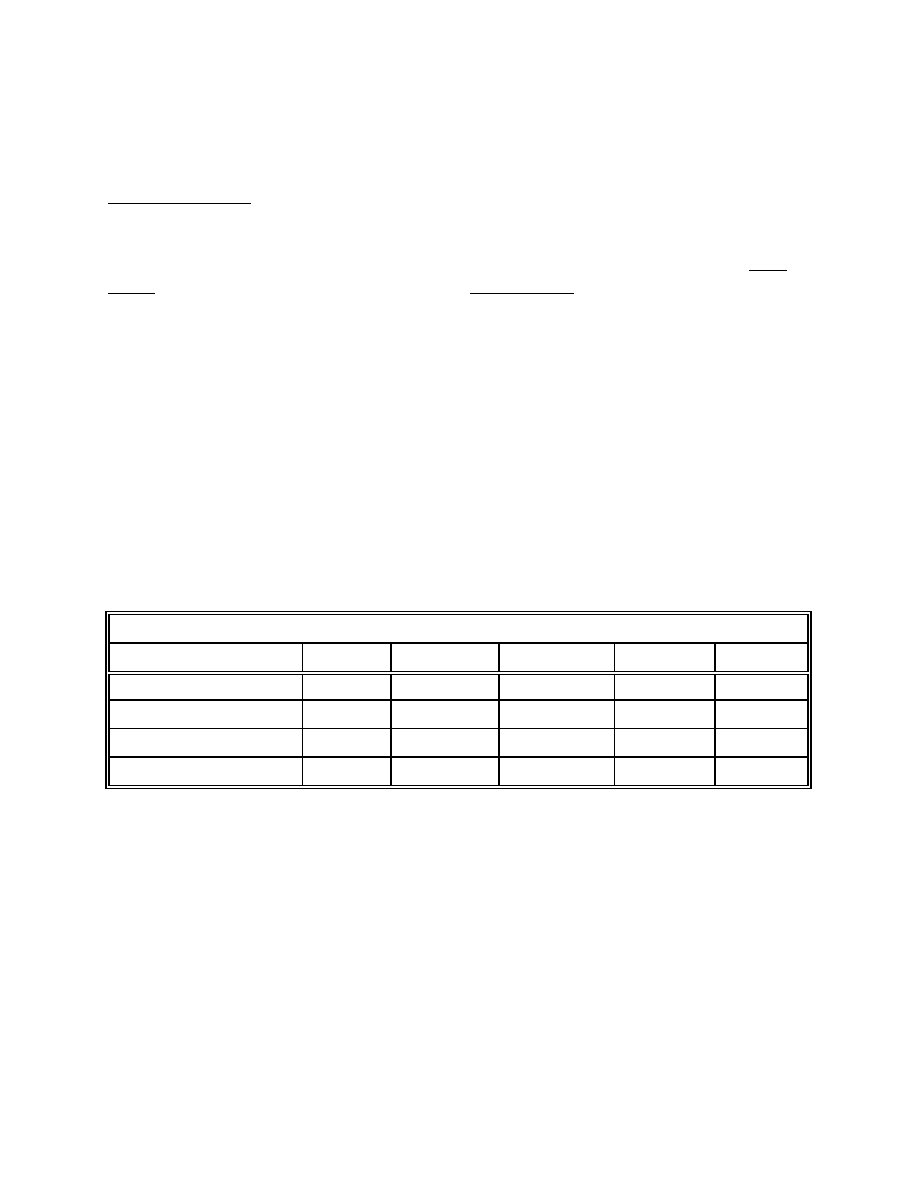

Estimated average efficiencies

We have estimated the average efficiencies for each of the building and system types based on

BTU outputs and kWh or therm inputs (purchased). While there is some variation among the

cities because the weather varies a little over the year, we present an approximate number to

Methods

9

reflect the state average. These estimates are provided to allow the reader to get a sense of the

overall system efficiencies.

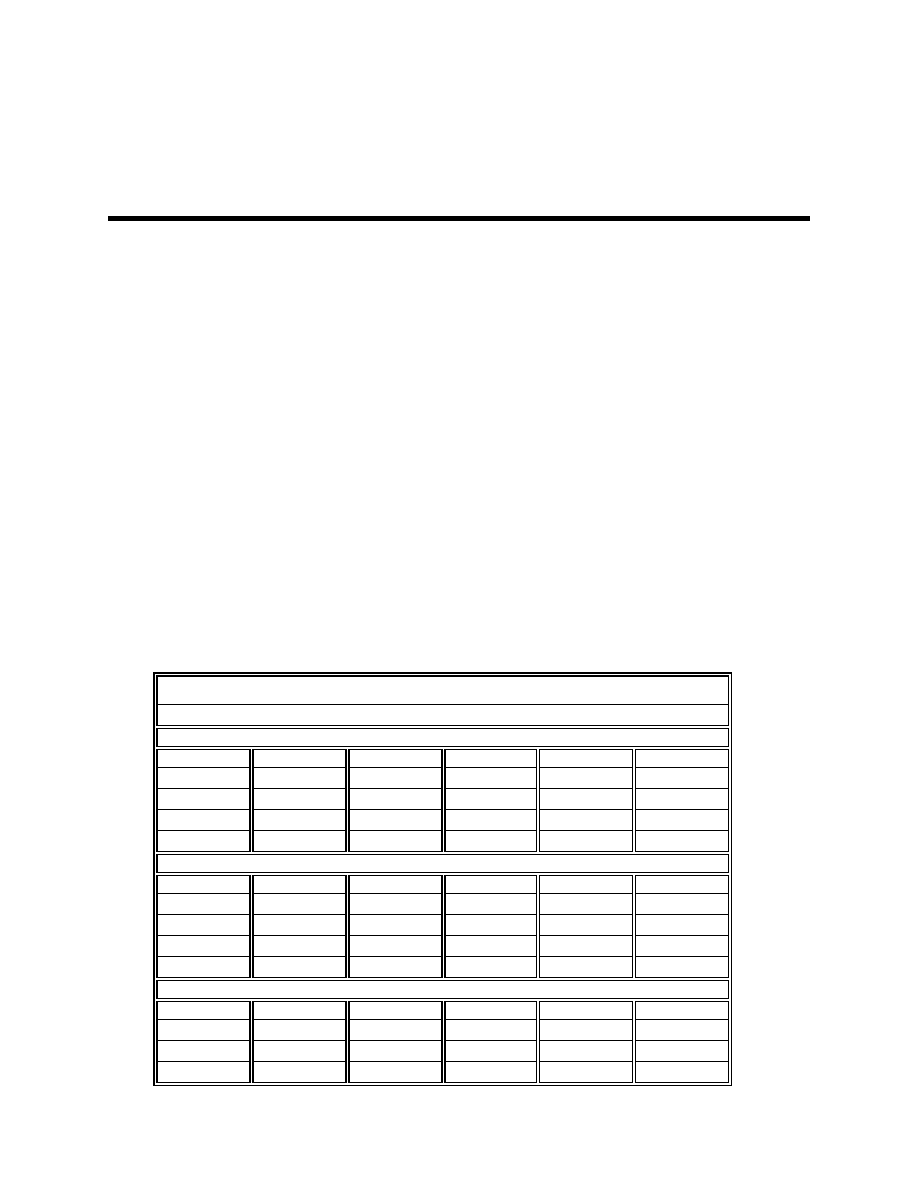

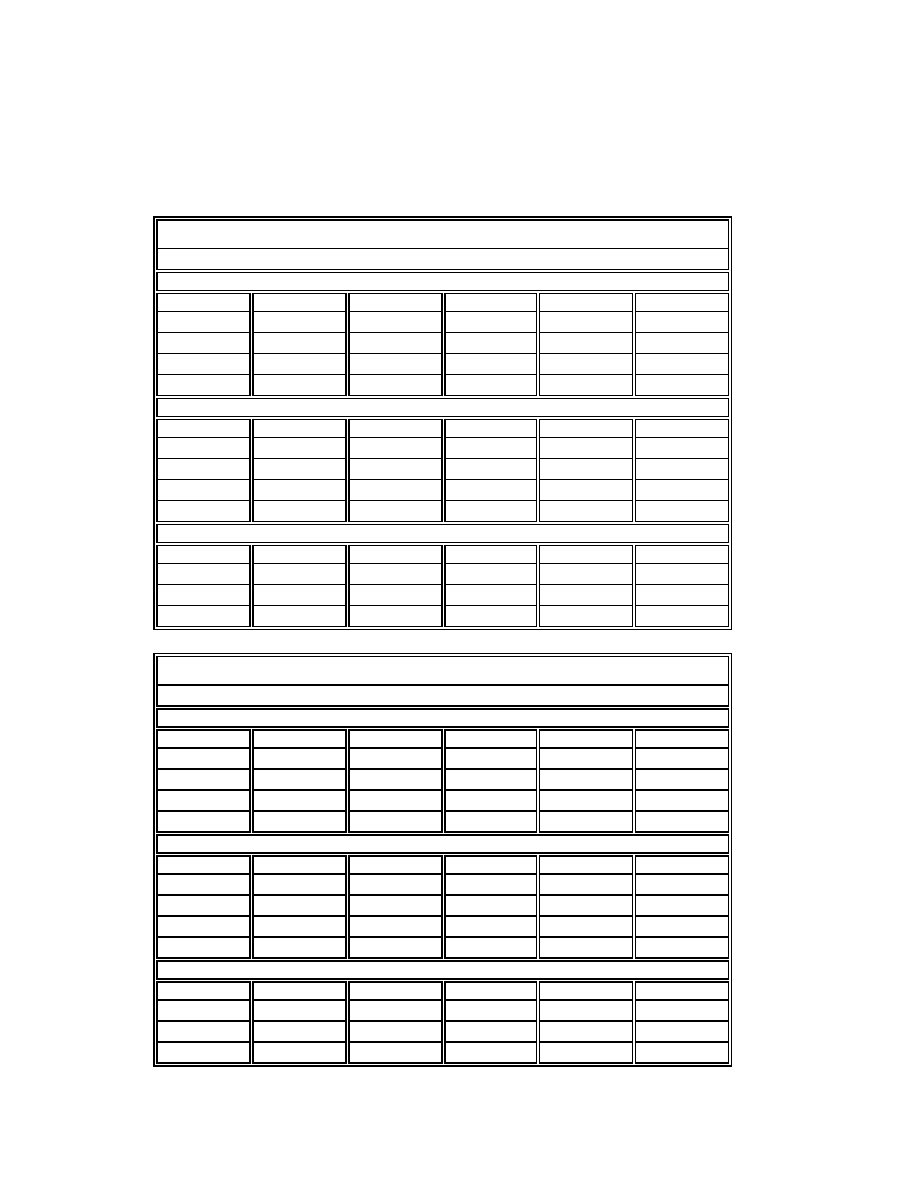

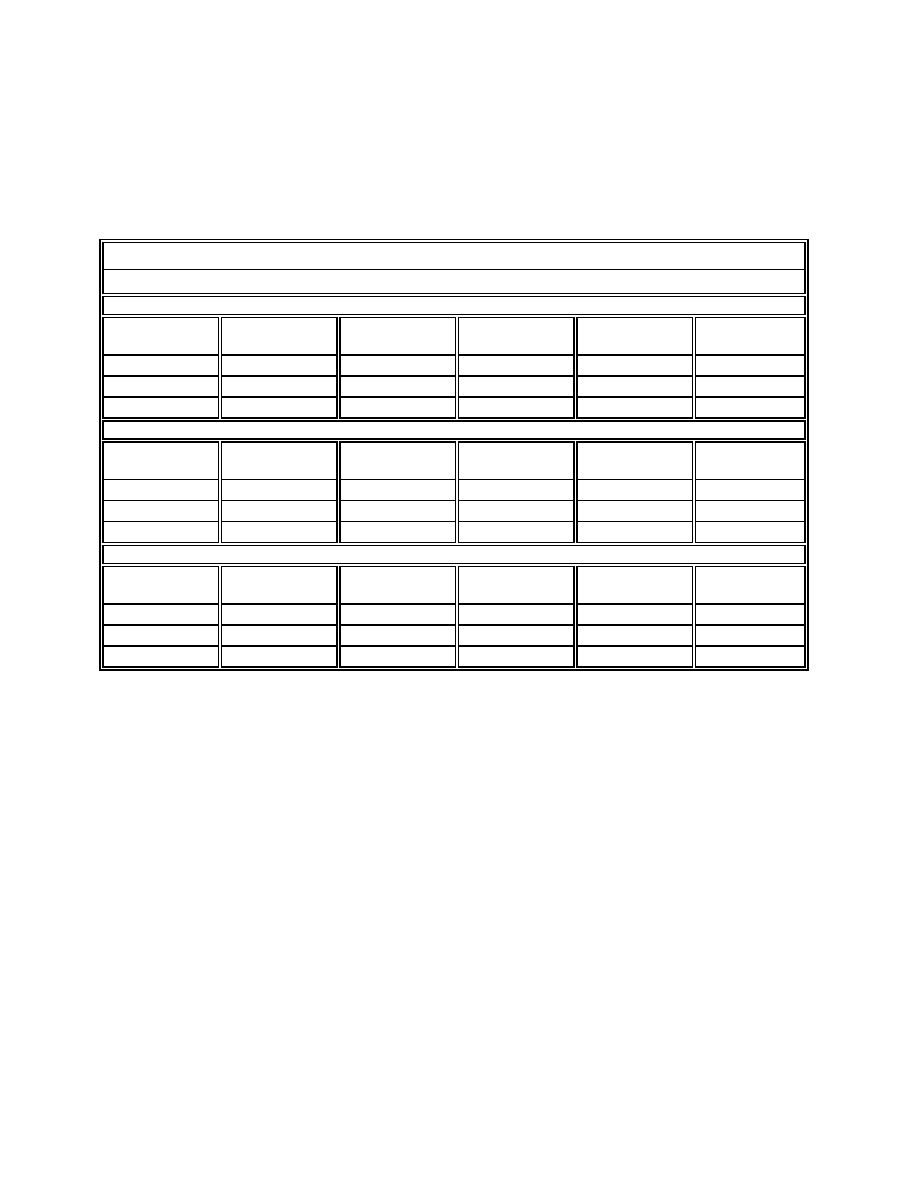

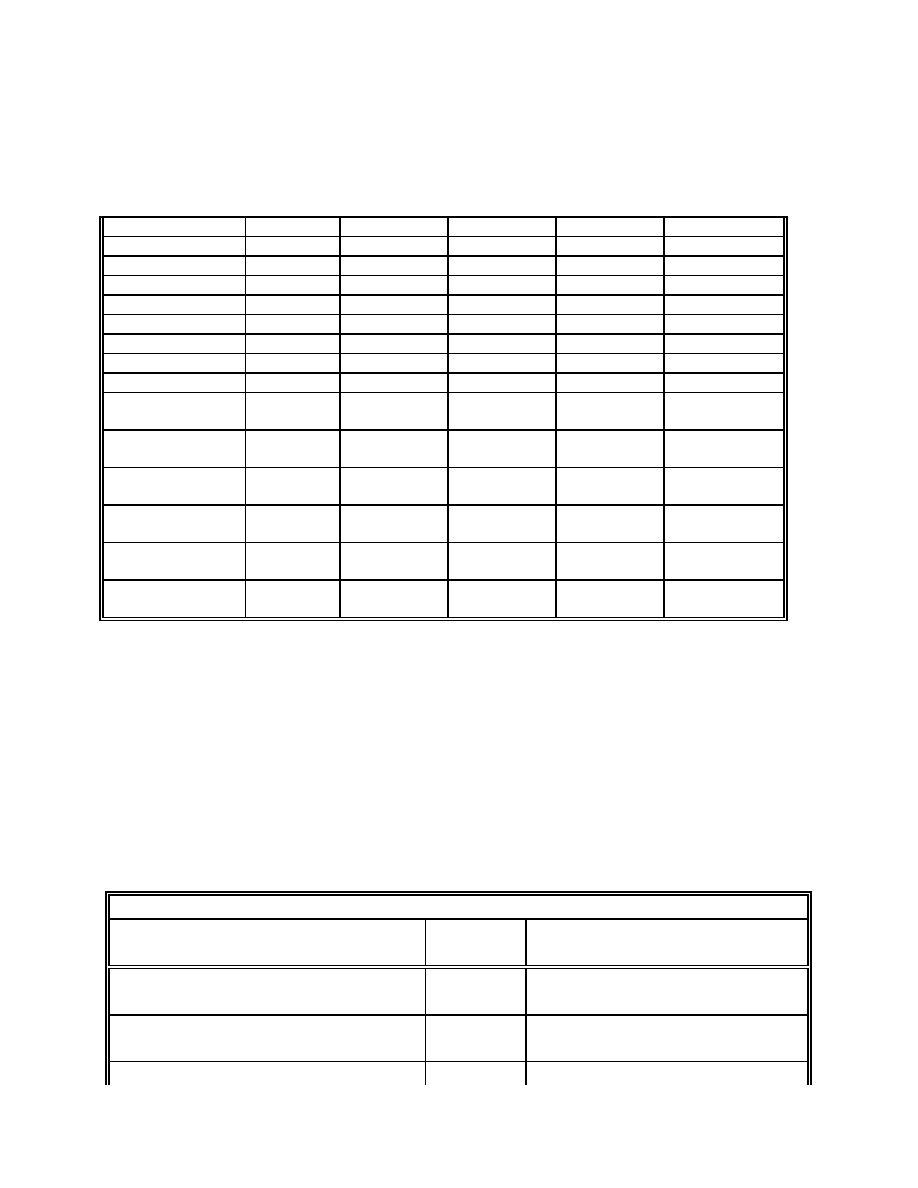

Table 5- Estimated Average Efficiencies: Commercial Buildings

Conventional System Efficiencies

GSHP System Efficiencies

Heating

Cooling

Heating

Cooling

Percent

kW/ton = EER

COP

COP = EER

Large School

7 8 %

1.4 = 8.6

3 . 3

3.1 = 10.6*

Small School

7 8 %

1.6 = 7.5

3 . 4

3.4 = 11.6

Office

7 8 %

1.4 = 8.6

3 . 0

3.6 = 12.3

Table 6- Estimated Average Efficiencies: Residential Type Buildings

Conventional System Efficiencies

GSHP System Efficiencies

Heating

Cooling

Heating

Cooling

Percent

EER

COP

EER

Community

9 2 %

1 2 . 4

3 . 3

1 3 . 2

Residential

9 2 %

1 2 . 0

3 . 5

1 7 . 0

*The CDH report for this building suggests that the modeling underestimates the cooling COP,

and believes that the actual cooling COP is higher than 3.1.

Emissions Analysis

While ORNL and CDH Energy were developing hourly energy use data, GEO developed a model

to estimate the impacts of these energy use profiles on emissions. As stated earlier, we chose to

analyze emissions from electricity use on an hourly basis to ensure confidence and reliability in

the environmental impact implications.

A major part of analyzing the viability of Ground Source Heat Pumps (GSHPs) is to determine

the amounts of pollutants emitted into the air during their use and to compare these emissions to

those of conventional HVAC systems. The aim of the analysis is to discern whether installing a

GSHP system in place of a conventional HVAC system reduces air emissions.

GEO developed three spreadsheet-based air emissions models representing the generation

characteristics of Alliant Energy, Wisconsin Public Service (WPS), and Northern States Power

(NSP) to calculate and compare air emissions between GSHP and conventional HVAC systems.

The models are similar to each other, and each uses the same process to calculate air emissions.

The only differences are the input data that represent a particular utility’s mix of generation, and

the specific hourly demand input data based on weather data for a city within each utility’s

service territory. Each air emissions model works as follows.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

10

Input data are first collected and placed in each model corresponding to the proper utility. The

input data include:

•

power plant unit characteristics such as nameplate capacity (MW), heat rate (Btu/kWh),

fuel cost (cents/kWh), and yearly outage data;

•

power plant air emissions factors in pounds per million Btu (lbs/MMbtu) for carbon

dioxide (CO

2

), sulfur dioxide (SO

2

), oxides of nitrogen (NO

X

), particulate matter, and

mercury (Hg). The model converts the emissions factors to lbs/kWh;

•

utility system hourly load data in MW for one year (8760 hours);

•

air emissions factors for natural gas, LP gas and oil combustion by HVAC equipment for

the above pollutants; and

•

hourly demand data in kW and therms over one year (8760 hours) for the GSHP and

conventional HVAC systems being compared.

More information on model input data is found in Appendix A.

Next, the model calculates how much energy in MWh each power plant unit contributes to

meeting the system demand for each hour of the year. This is done by first modifying the MW

capacity of each unit according to the percentage of generation that the utility owns, and reducing

the capacity according to (planned and unplanned) outage data. Then each power plant unit is

dispatched in order based first on fuel cost, then on heat rate, and then on MW capacity. In some

cases this dispatch order was modified to account for actual MWhs generated by a power plant,

according to historical information. If system demand cannot be met despite dispatching all of the

utility’s power plants, additional power plants representing bulk power purchases by the utility

are added to the dispatch. The characteristics and air emissions factors for these additional plants

are modeled based on a utility’s existing mix of generation. The energy produced due to bulk

power purchases constitute a small percentage of the total energy produced by the utility over

the year, hence they do not have a significant impact on air emissions results.

The energy produced by each power plant unit is then multiplied by the air emission factors to

determine the total amount of air pollutants each plant contributes in the test year. An average air

emission factor in lbs/kWh is then calculated for each pollutant.

The model then takes the hourly kW and therm data for the GSHP and conventional HVAC

systems being considered and calculates total electrical and natural gas energy used by these

systems over the year. The results are multiplied by the average air emissions factors to

determine the total number of pounds of air pollutants produced during the year when the GSHP

and conventional HVAC systems are operated. We then calculate the differences in total air

emissions between the two systems.

Methods

11

Daytypes

The air emissions model calculates the energy produced by the utility, average air emission

factors in lbs/kWh, and the energy used by the GSHP and the conventional HVAC systems

according to daytypes. Daytypes are a means of describing a utility system or demand-side

characteristic that corresponds to certain groups or categories of days during the year. For

example, a daytype called the Summer Weekday High could correspond to the one summer

weekday where system demand was highest.

A list of the daytypes used in the air emissions model and their abbreviations is shown in the

table below. This set of daytypes is one version that has been used by demand-side management

(DSM) planners in the past. Definitions of the daytypes used can be found in Appendix D.

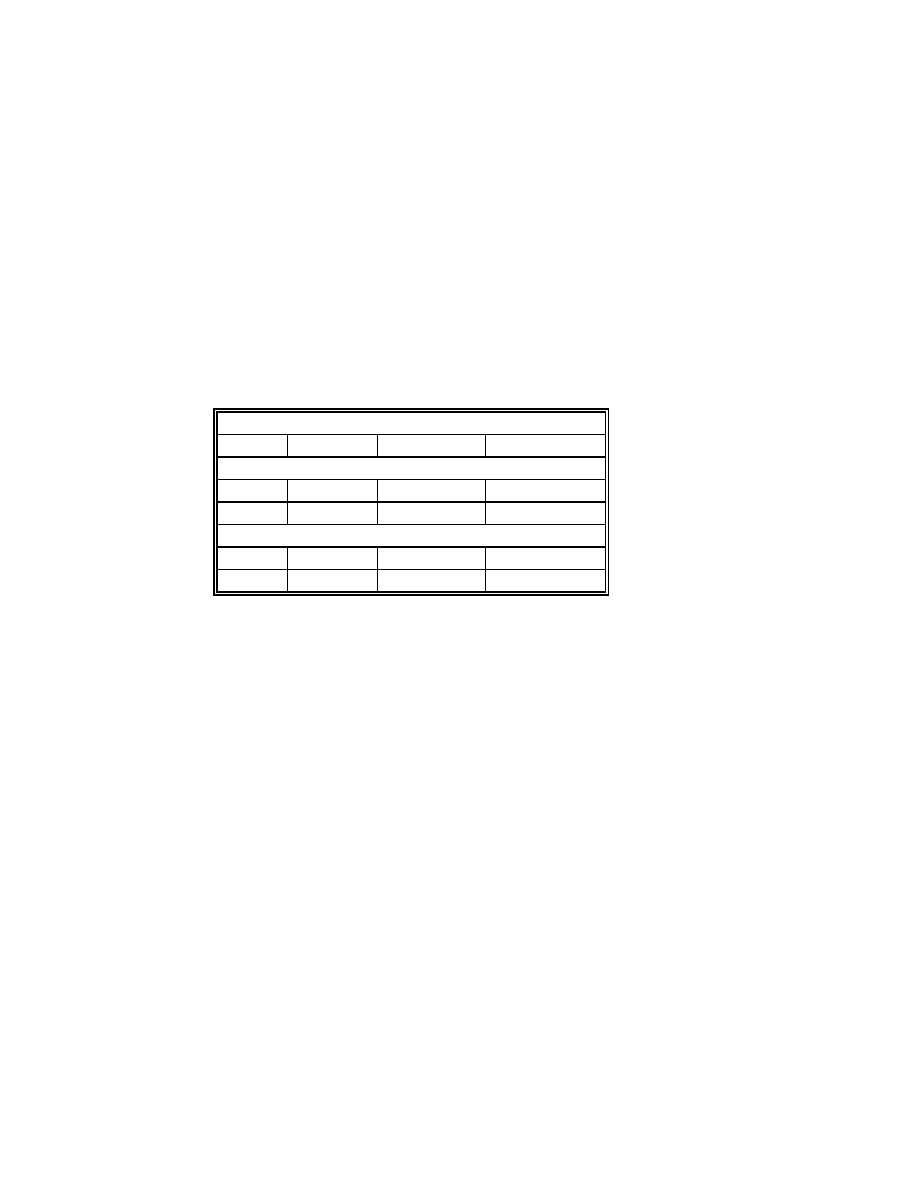

Table 7 - Daytypes Used for Emissions Analysis

Winter

Summer

Spring/Fall

Weekday High

WWHigh

SWHigh

SFWHigh

Weekday Medium

WWMed

SWMed

SFWMed

Weekday Low

WWLow

SWLow

SFWLow

Weekend/Holiday All

WWHAll

SWHAll

SFWHAll

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

12

Sensitivity Analysis

A sensitivity analysis was performed on the electric air emissions model to determine to what

degree differences in air emissions between a GSHP and a conventional HVAC system changed

when the dispatch order of the power plants changed. Two model runs using the original Large

School scenario kW and therm demand data in the Alliant Energy model were performed. The

first run dispatched power plants “properly,” meaning that the plants were dispatched first

according to fuel cost, then heat rate and power plant size. The second run dispatched power

plants “randomly,” without regard to fuel cost, heat rate, or plant size, although an overall

“rough” dispatch order was maintained where hydroelectric and nuclear plants were dispatched

first, followed by coal-fired plants, oil-fired plants, and natural gas-fired plants. This analysis

does not include gas use by the school as it is designed to test the sensitivity to power plant

dispatch assumptions.

The results of the sensitivity analysis shows (Table 8 below) that air emissions do not differ

greatly whether power plants are properly or randomly dispatched. This suggests that, while it is

important that all of a utility’s mix of generation is represented in the model, modeling how

power plants are dispatched with great accuracy (which can present many difficulties) is not

crucial when calculating air emissions.

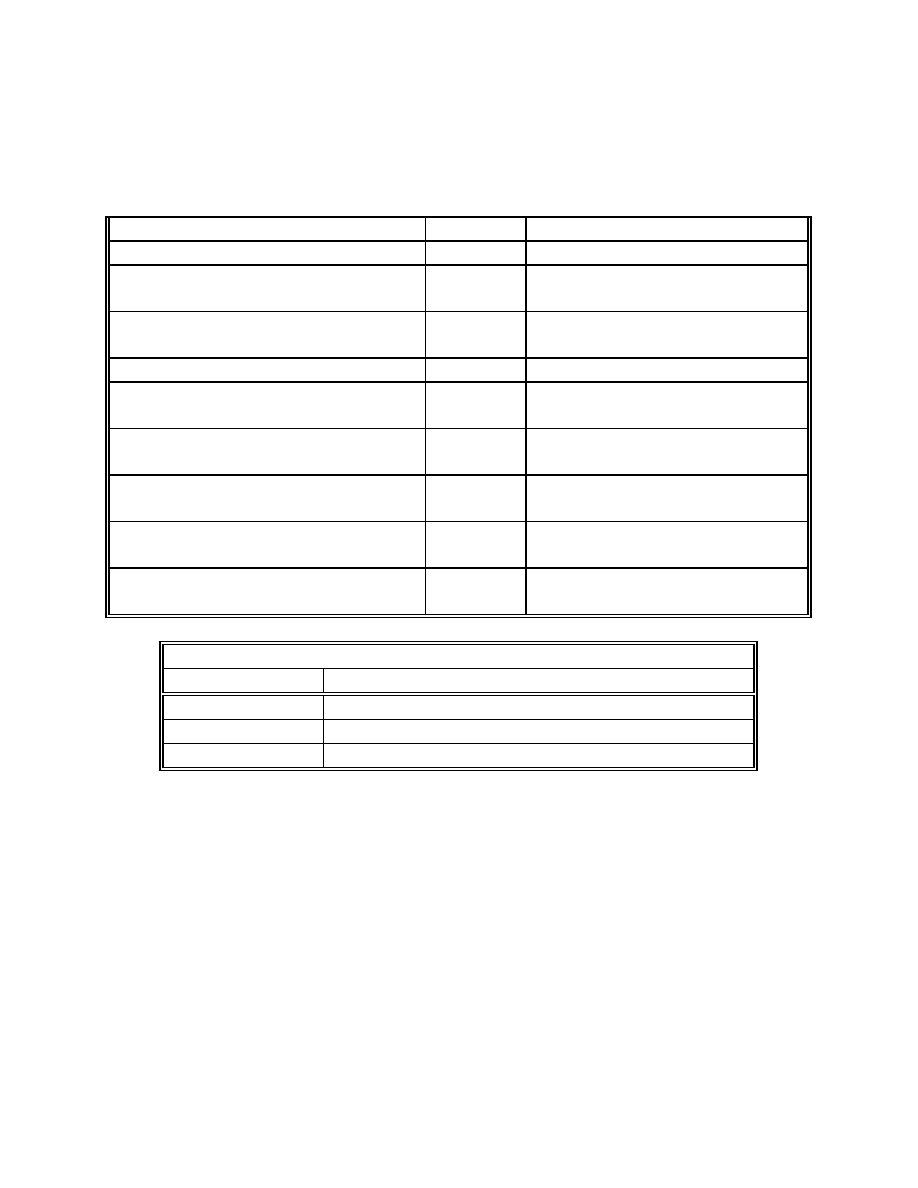

Table 8

- Emissions Sensitivity Analysis

(1)

CO2

SO2

NO

x

Particulate

Mercury

Proper Dispatch

(2)

(lbs)

-317,013

-1,900

-1,298

-57

-0.0069

Random Dispatch

(2)

(lbs)

-317,103

-1,847

-1,332

-59

-0.0069

Difference

(3)

(lbs)

90

-53

34

2

0.00%

Difference (%)

-0.028%

2.79%

-2.62%

-3.51%

0.00%

(1) Electric use considered only; does not include air emissions due natural gas combustion by the VAV Chiller systems

(2) Negative values mean that replacing the VAV Chiller with the GSHP results in increased air emissions.

(3) Differences in air emissions between proper and random dispatch cases are expressed with respect to proper dispatch.

The emission figures above are presented in terms of changes only for each type of pollutant

when comparing GSHPs to VAV/chiller/reheat systems. We simplified here because the tables

would have been too complex to also include totals. These indices will allow a variety of

audiences to gain insights regarding the emissions reductions capabilities of GSHPs in Wisconsin.

For each building/utility/weather scenario we present emissions savings of each type of pollutant.

Further, we estimate emissions reductions as a percentage of the emissions that would be created

by installing the GSHP system. This is provided to assist in comparing savings across building

types. Thus, negative values imply that the GSHP option will result in increased emissions of

that type.

Methods

13

Finally, we calculate emissions reductions per square foot of conditioned space to allow

comparison across building type and size.

Customer Economics

As with the emissions analysis, the economics analysis follows from the energy use analysis.

The 8760 demand profiles allowed us to apply the commercial rates for each utility to each of the

on-peak and off-peak hours for that utility.

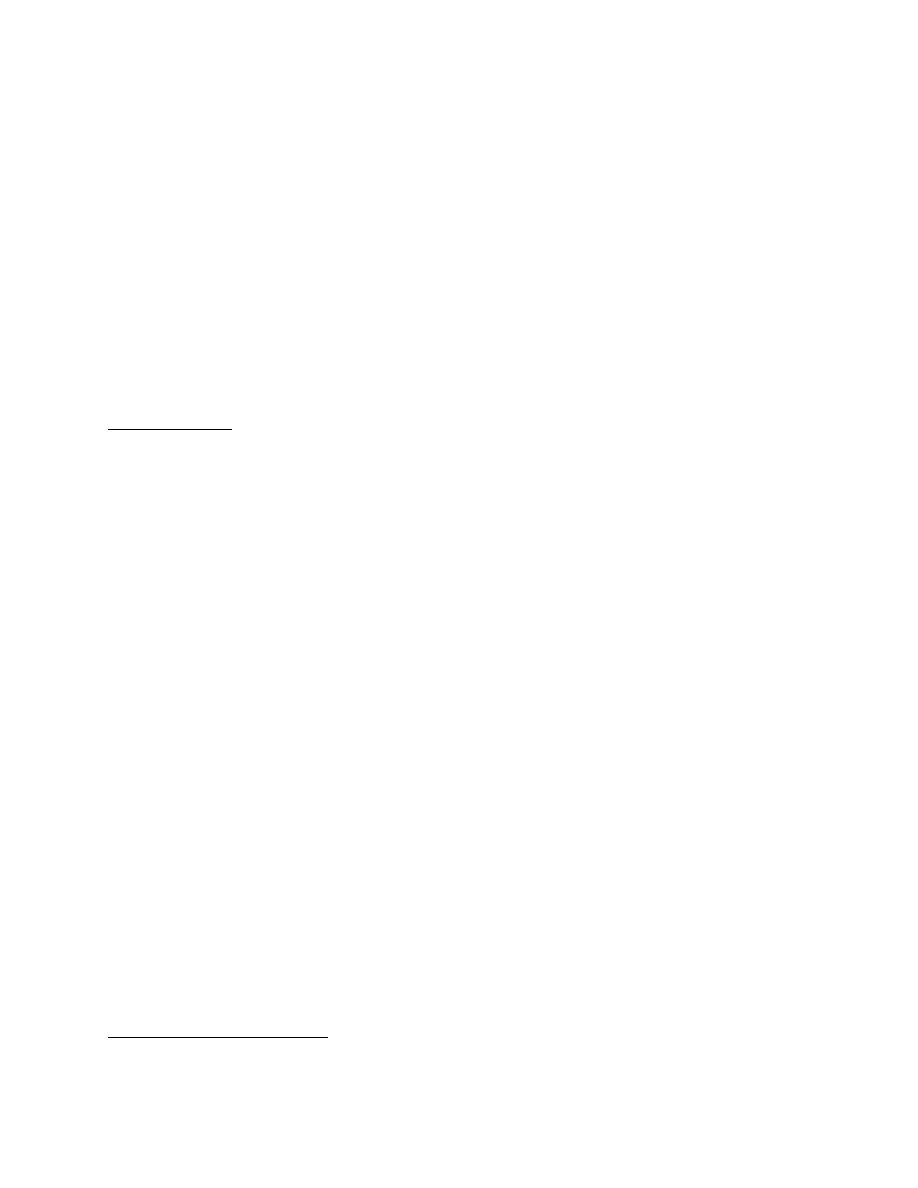

The rates used for each utility are shown in the following table

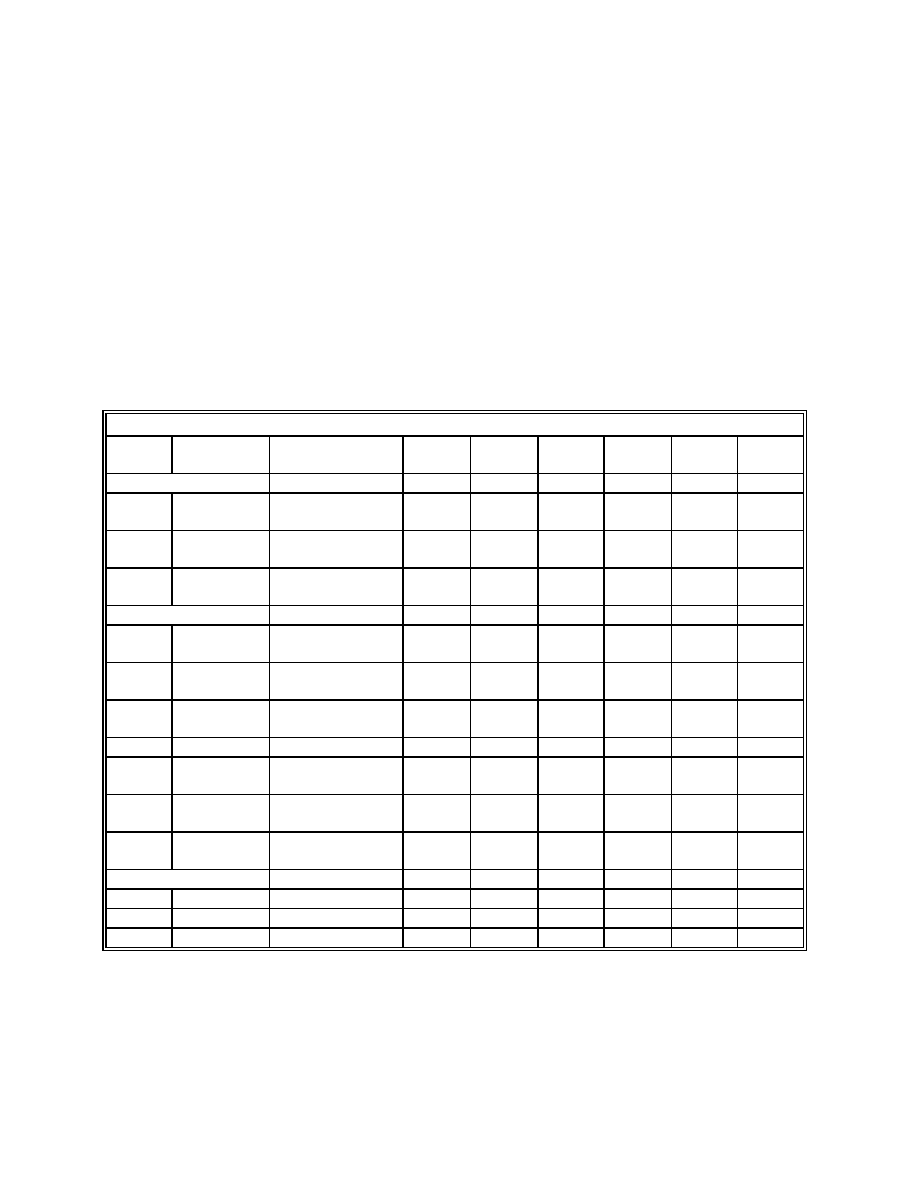

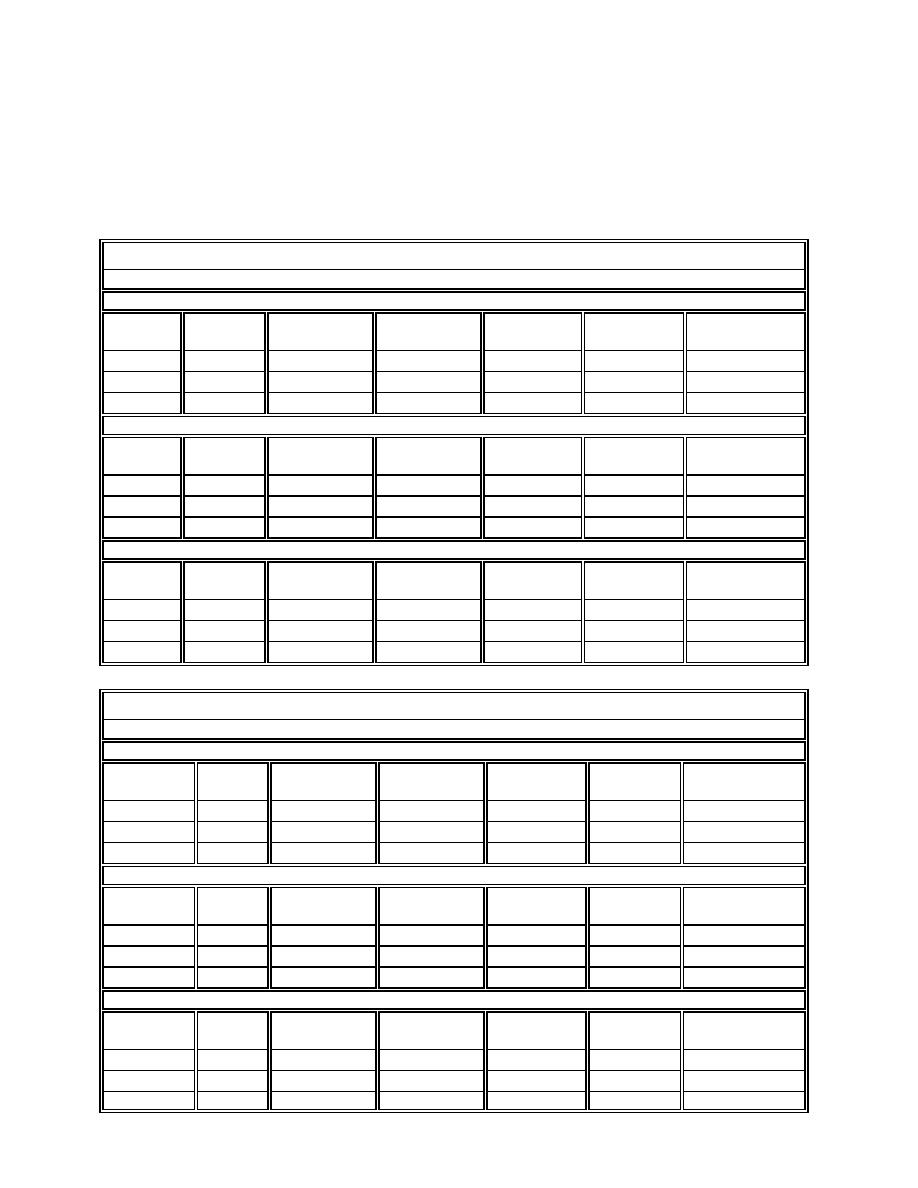

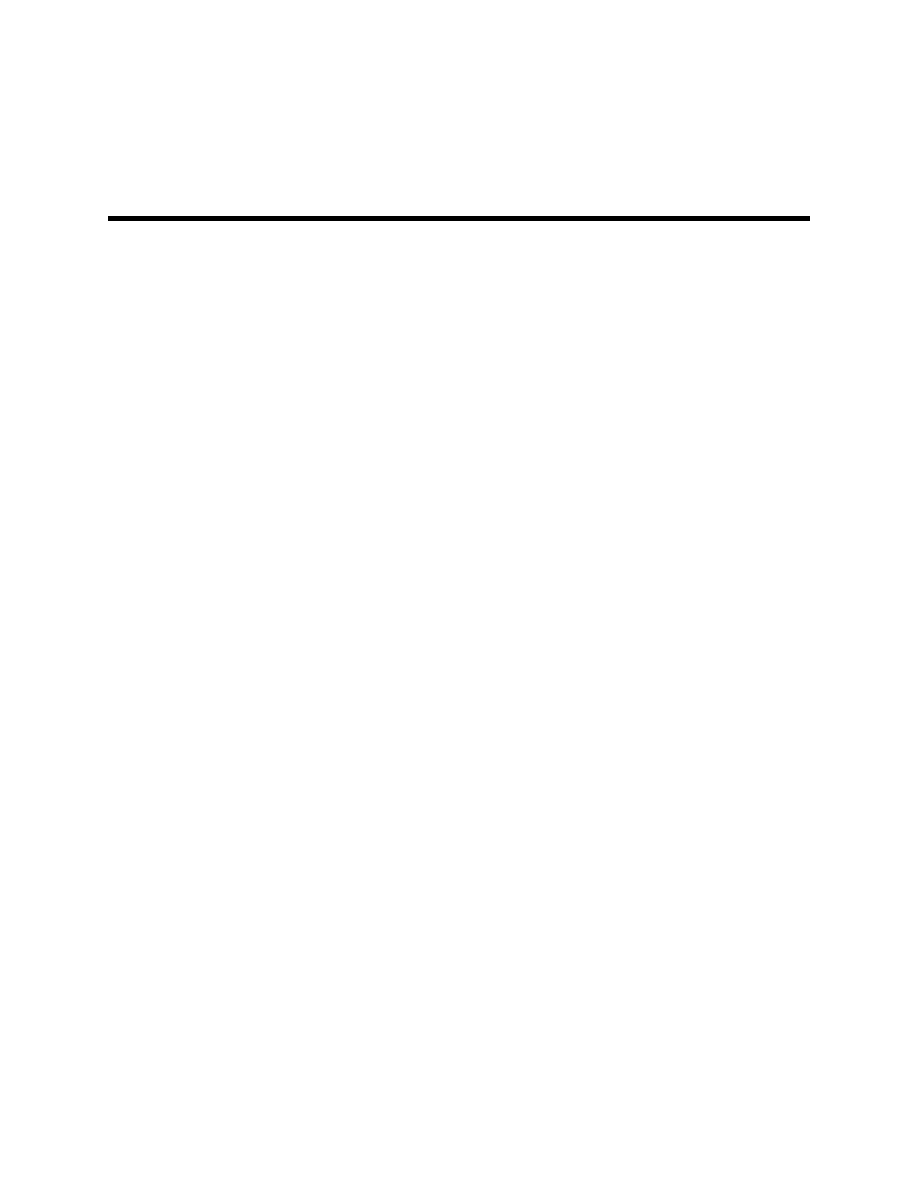

Table 9

-

Rates Used for Economic Analyses

Rates

On-Pk Hrs

Off-Pk

Hrs

On-Pk

$ / k W h

Off-Pk

$ / k W h

On-Pk

$ / k W

Ratchet

$ / k W

$ / t h e r m

Large School

WPS

Estimated

8am-10pm

WkDays

A l l

Others

$ 0 . 0 2 7 3 $ 0 . 0 1 9 3

6 . 8 8

0 . 9 5

$ 0 . 3 8 9 1

Alliant

CP-1/Gc-2

8am-10pm

WkDays

A l l

Others

$ 0 . 0 2 8 8 $ 0 . 0 2 0 3

7 . 2 4

1 . 0 0

$ 0 . 4 5 0 0

NSP

Estimated

8am-10pm

WkDays

A l l

Others

$ 0 . 0 2 9 9 $ 0 . 0 2 1 1

7 . 5 3

1 . 0 4

$ 0 . 5 4 5 6

Small School

WPS

Cg-

1TOU/GRg

~8am-9pm

WkDays

A l l

Others

$ 0 . 0 3 4 7 $ 0 . 0 2 2 3

4 . 7 5

0 . 6 5

$ 0 . 3 6 5 8

Alliant

Cg-2/Gc-2

8am-10pm

WkDays

A l l

Others

$ 0 . 0 2 6 7 $ 0 . 0 2 6 7

5 . 7 5

1 . 0 0

$ 0 . 4 6 0 0

NSP

Cg-9/Gg-1

9am-9pm WkDays

A l l

Others

$ 0 . 0 3 8 5 $ 0 . 0 2 5 6

6 . 1 0

1 . 0 0

$ 0 . 5 2 5 0

O f f i c e

WPS

Cg-

1TOU/GRg

~8am-9pm

WkDays

A l l

Others

$ 0 . 0 3 4 7 $ 0 . 0 2 2 3

4 . 7 5

0 . 6 5

$ 0 . 3 6 5 8

Alliant

Cg-2/Gc-2

8am-10pm

WkDays

A l l

Others

$ 0 . 0 2 6 7 $ 0 . 0 2 6 7

5 . 7 5

1 . 0 0

$ 0 . 4 6 0 0

NSP

Cg-9/Gg-1

9am-9pm WkDays

A l l

Others

$ 0 . 0 3 8 5 $ 0 . 0 2 5 6

6 . 1 0

1 . 0 0

$ 0 . 5 2 5 0

C o m m u n i t y / R e s

WPS

Rg-1/CG-FM

- -

- -

$0.0586 $0.0586

- -

- -

$0.5080

Alliant

Gs-1/Gg-1

- -

- -

$0.0593 $0.0593

- -

- -

$0.5670

NSP

Rg-1/Rg-1

- -

- -

$0.0671 $0.0671

- -

- -

$0.5250

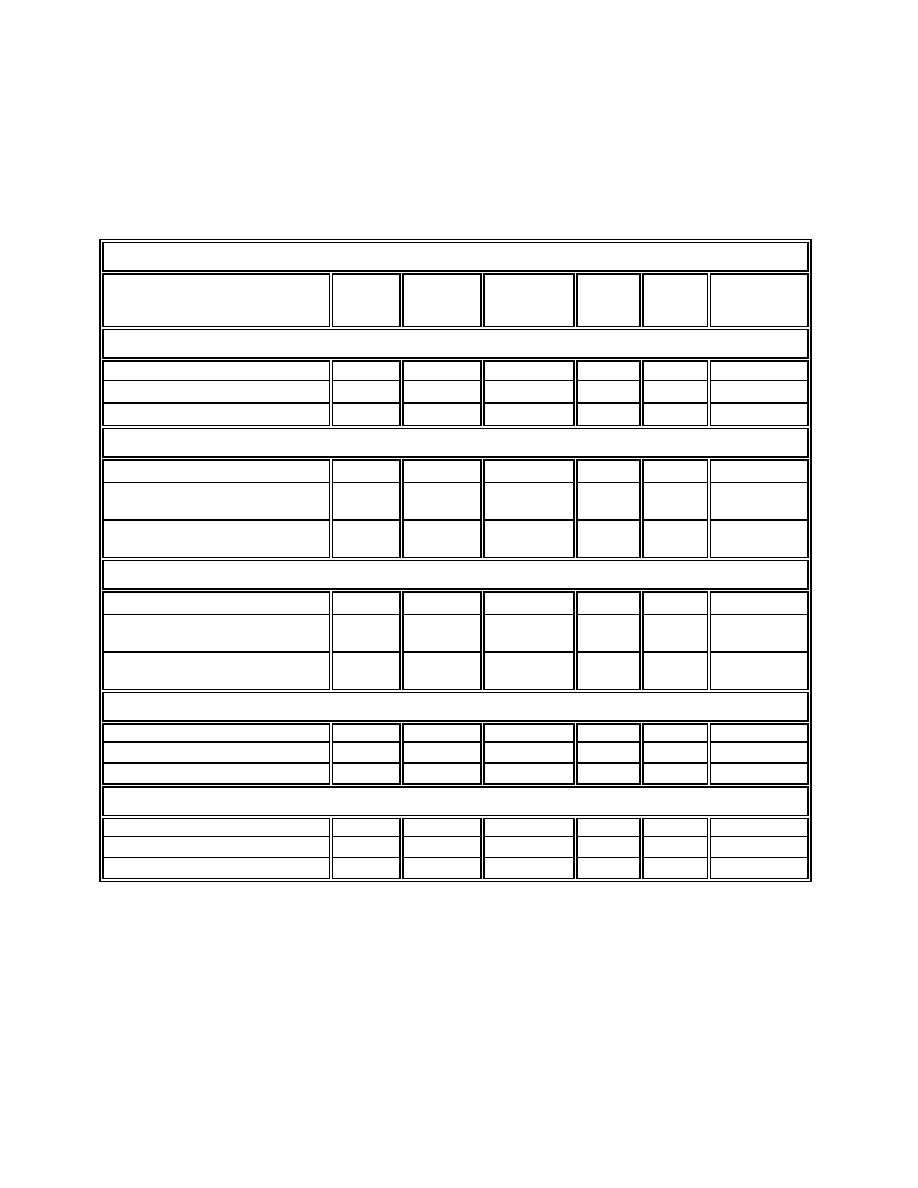

The next table shows the blended equivalent rates for each facility and technology scenario. The

blended rates for GSHPs are typically lower than for VAV/reheat systems because GSHPs have

lower peak monthly demands than VAV/reheat systems during the summer peak periods.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

14

Table 10 - Blended Rates

L a r g e

School

VAV Elect

GSHP Elec

VAV Gas

GSHP Gas

WPS

$ 0 . 0 6 9 0

$ 0 . 0 6 6 1

$ 0 . 3 8 9

$ 0 . 0 0 0

Alliant

$ 0 . 0 7 2 6

$ 0 . 0 6 9 5

$ 0 . 4 5 0

$ 0 . 0 0 0

NSP

$ 0 . 0 7 5 5

$ 0 . 0 7 2 3

$ 0 . 5 4 6

$ 0 . 0 0 0

S m a l l

School

VAV Elect

GSHP Elec

VAV Gas

GSHP Gas

WPS

$ 0 . 0 5 0 4

$ 0 . 0 5 1 7

$ 0 . 4 1 5

$ 0 . 5 3 6

Alliant

$ 0 . 0 5 3 0

$ 0 . 0 5 5 4

$ 0 . 4 8 0

$ 0 . 5 3 5

NSP

$ 0 . 0 5 5 1

$ 0 . 0 5 6 5

$ 0 . 5 8 2

$ 0 . 6 2 3

O f f i c e

VAV Elect

GSHP Elec

VAV Gas

GSHP Gas

WPS

$ 0 . 0 5 0 7

$ 0 . 0 4 9 6

$ 0 . 4 6 3

$ 0 . 5 8 3

Alliant

$ 0 . 0 5 3 6

$ 0 . 0 5 2 1

$ 0 . 5 0 3

$ 0 . 5 5 2

NSP

$ 0 . 0 6 2 9

$ 0 . 0 6 1 2

$ 0 . 6 0 0

$ 0 . 6 1 6

C o m m u n i t y

VAV Elect

GSHP Elec

Furnace Gas

GSHP Gas

WPS

$ 0 . 0 6 4 1

$ 0 . 0 6 2 6

$ 0 . 6 3 4

- -

Alliant

$ 0 . 0 6 4 2

$ 0 . 0 6 3 0

$ 0 . 6 7 0

- -

NSP

$ 0 . 0 7 2 5

$ 0 . 0 7 1 0

$ 0 . 7 3 1

- -

R e s i d e n t i a l

VAV Elect

GSHP Elec

Furnace Gas

GSHP Gas

WPS

$ 0 . 0 6 4 7

$ 0 . 0 6 3 6

$ 0 . 7 4 5

- -

Alliant

$ 0 . 0 6 5 4

$ 0 . 0 6 4 3

$ 0 . 7 7 1

- -

NSP

$ 0 . 0 7 3 2

$ 0 . 0 7 2 2

$ 0 . 8 5 6

- -

The economics presented later in this report are given in terms of savings only in electric and gas

costs, rather than in terms of total or partial facility costs with savings. We did this because

different energy accounting was used by CDH Energy and ORNL. While the modeling was done

differently, the results are equally valid and we report the savings only to prevent confusion.

CDH Energy modeled the energy use of most, but not all, components of the Large School

scenario. That is, they modeled energy use and costs of lighting & equipment, space heating &

cooling, and pumps and fans. However, they did not model water heating because gas would be

used equally to heat water with either HVAC system.

ORNL modeled the energy using systems differently. They modeled total facility energy and

several of the components - including HVAC, water heating, and dehumidification.

We have taken the economics information provided by CDH Energy and ORNL and synthesized

these into indices that we believe allow a variety of audiences to gain insights regarding the

economic viability of GSHPs in Wisconsin.

For each building/utility/weather scenario we analyzed total kWh and therm savings as well as

total annual energy cost savings and payback. Further, we estimate savings as a percentage of the

Methods

15

energy that would be used by the VAV system - including percentage of energy cost savings.

This is provided to assist in comparing savings across building types. Finally, we calculate

savings per square foot of conditioned space to allow comparison across building type and size.

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

16

Results

17

Results

The results of this research are presented as a series of tables showing both the impact on

emissions and the economics of installing GSHPs in each of the five building types. Each table

represents a building type and within the tables the results for each of the city/utility/weather

scenarios are enumerated.

Each table therefore shows results for three sub-scenarios – representing each city/utility pair. In

addition the results are presented in three ways:

•

First we show the absolute emissions, energy and cost savings, and payback for each scenario

•

Below this, the results are presented in terms of percentage savings compared to the

conventional system emissions or energy and cost requirements

•

Finally, the results are presented on a square foot of conditioned space basis

We believe these presentation approaches will facilitate useful policy discussion.

Emissions Results

The following tables show the results of the emissions impacts where natural gas is the

alternative fuel for heating energy. These five tables are followed by tables showing the emissions

analyses where LP, oil, and electricity are assumed as the alternative heating fuel.

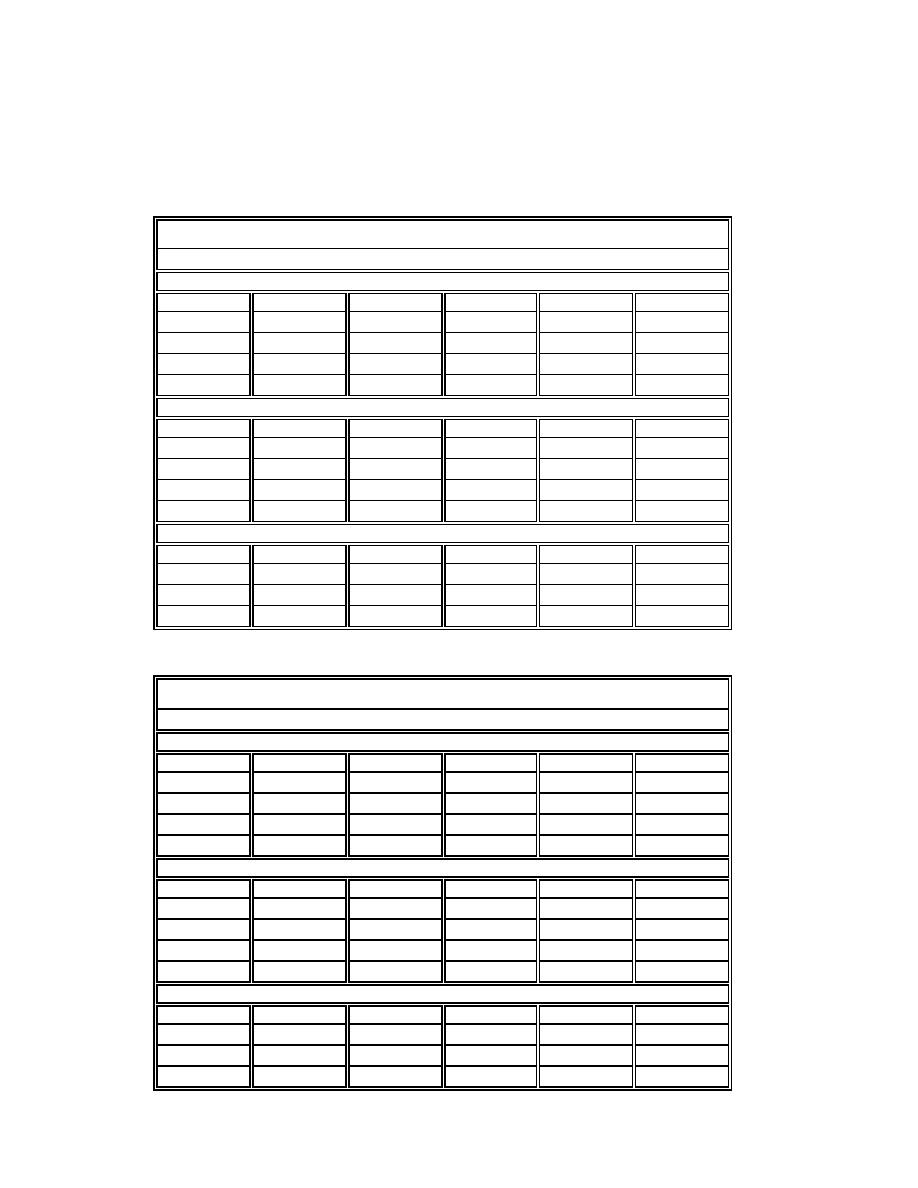

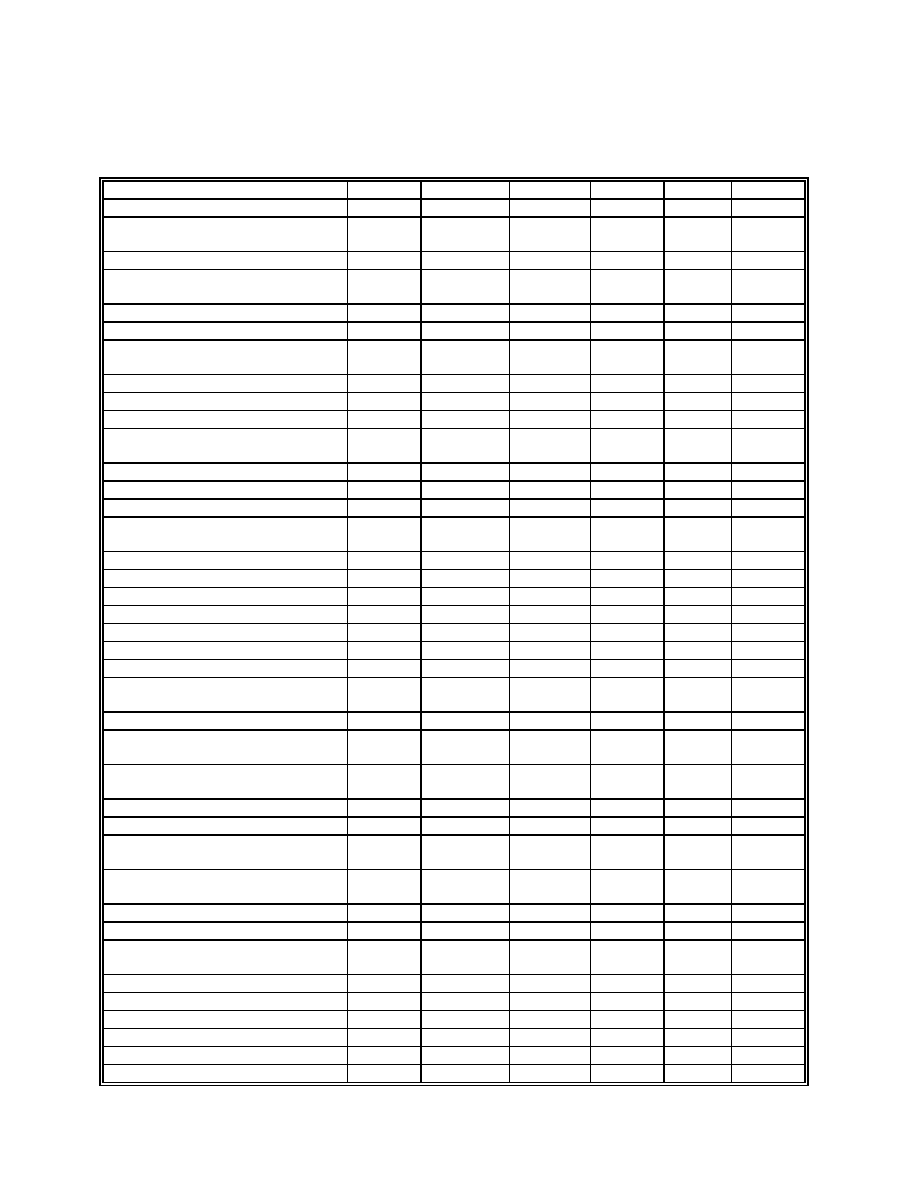

Table 11 - Large School Emissions Results

Natural Gas Heating

Sq. Ft. =

3 9 0 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

8 5 2 , 3 4 1

- 1 , 1 0 6

1 6 8

- 5

- 0 . 0 0 2 9

Madison

6 5 1 , 5 3 3

- 1 , 5 0 7

- 2 6 3

9

- 0 . 0 0 3 5

Eau Claire

9 1 0 , 7 4 2

- 3 5 2

5 1 9

2 7

- 0 . 0 0 0 6

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

1 3 . 8 8 %

- 6 . 6 2 %

1 . 2 0 %

- 0 . 4 2 %

- 3 . 4 1 %

Madison

1 1 . 5 6 %

- 5 . 4 1 %

- 1 . 3 1 %

0 . 9 8 %

- 3 . 4 3 %

Eau Claire

1 9 . 5 0 %

- 4 . 0 6 %

5 . 1 2 %

3 . 0 4 %

- 0 . 9 0 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

2 . 1 9

- 2 . 8 4

4.31 x10

-

- 1 . 3 3

- 7 . 3 4

Madison

1 . 6 7

- 3 . 8 6

- 6 . 7 3

2.23 x10

-

- 9 . 0 7

Eau Claire

2 . 3 4 -9.0 x10

- 4

1.3 x10

- 3

6.9 x10

- 5

-1.5 x10

- 9

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

18

Table 12 - Small School Emissions Results

Natural Gas Heating

Sq. Ft. =

6 9 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

1 9 0 , 0 4 5

- 5 2

1 3 6

9

0 . 0 0 0 2

Madison

1 7 0 , 6 0 7

- 7 0

1 0 6

9

0 . 0 0 0 1

Eau Claire

1 9 2 , 9 3 4

- 7

1 5 8

1 1

0 . 0 0 0 3

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

1 5 . 4 0 %

- 1 . 6 3 %

4 . 9 7 %

3 . 6 1 %

1 . 1 7 %

Madison

1 4 . 7 0 %

- 1 . 3 0 %

2 . 7 1 %

5 . 0 5 %

0 . 7 0 %

Eau Claire

1 9 . 8 3 %

- 0 . 4 4 %

7 . 8 7 %

6 . 2 0 %

2 . 6 5 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

2 . 7 5

- 7 . 5 0

1.96 x10

-

1.26 x10

-

2.74 x10

-

Madison

2 . 4 7

- 1 . 0 1

1.54 x10

-

1.29 x10

-

2.03 x10

-

Eau Claire

2 . 8 0

- 1 . 0 7

2.30 x10

-

1.57 x10

-

4.72 x10

-

Table

13 - Office Emissions Results

Natural Gas Heating

Sq. Ft. =

6 9 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

1 4 1 , 8 9 4

- 3 6

1 0 4

7

1.49 x10

-

Madison

1 2 4 , 2 4 2

2 2

1 1 8

8

3.37 x10

-

Eau Claire

1 3 4 , 8 3 5

- 5

1 1 0

7

1.84 x10

-

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

8 . 8 2 %

- 0 . 7 8 %

2 . 7 1 %

1 . 9 8 %

0 . 6 4 %

Madison

8 . 0 7 %

0 . 2 7 %

2 . 0 7 %

3 . 1 5 %

1 . 1 5 %

Eau Claire

1 0 . 9 9 %

- 0 . 2 0 %

3 . 9 0 %

2 . 9 6 %

1 . 0 5 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

2 . 0 6

- 5 . 2 7

1.51 x10

-

9.91 x10

-

2.15 x10

-

Madison

1 . 8 0

3.12 x10

-

1.71 x10

-

1.14 x10

-

4.89 x10

-

Eau Claire

1 . 9 5

- 7 . 3 1

1.59 x10

-

1.05 x10

-

2.67 x10

-

Results

19

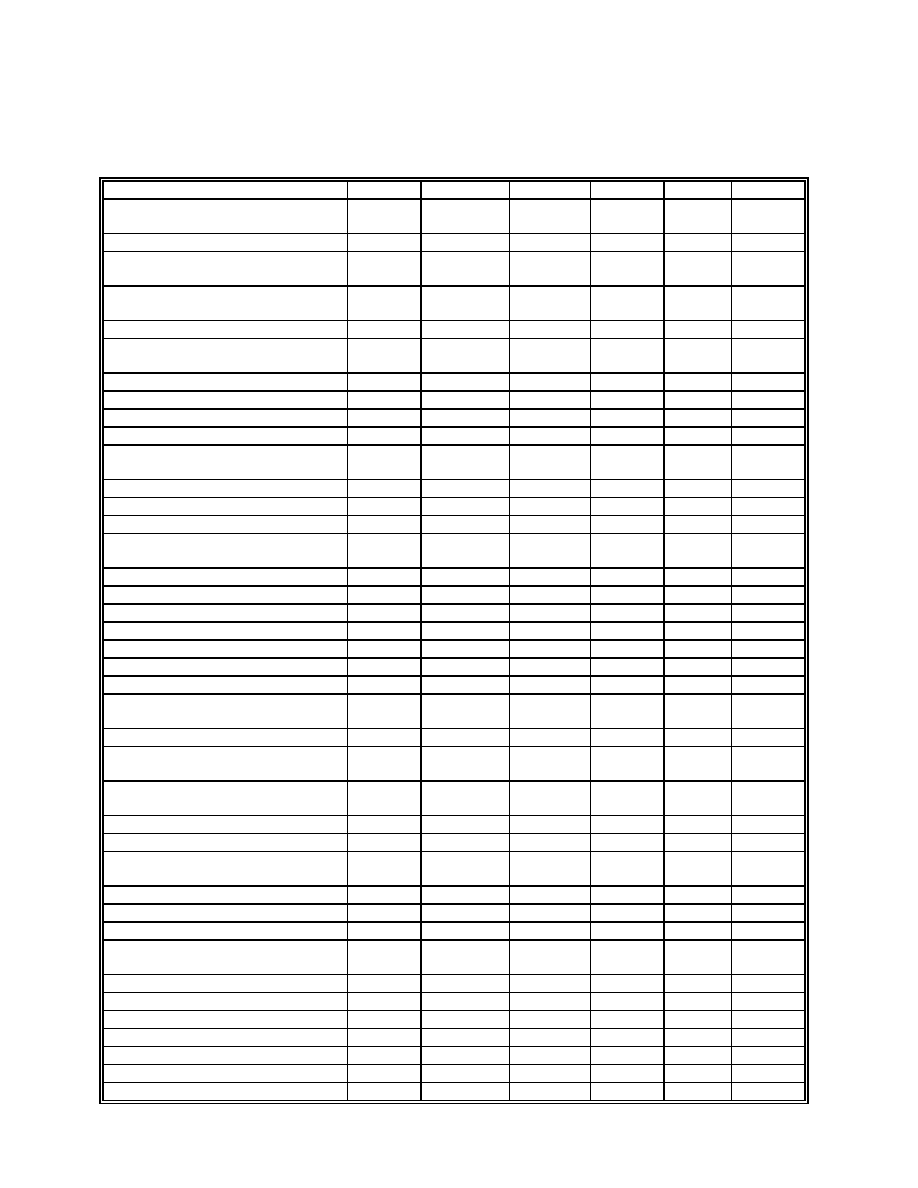

Table 14 – Community Development Emissions

Natural Gas Heating

Sq. Ft. =

1 8 5 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 2 8 0 , 3 3 8

- 4 , 0 3 1

- 2 , 3 2 2

- 2 2 6

- 0 . 0 1 7 7

Madison

- 2 2 5 , 8 2 0

- 6 , 4 6 3

- 3 , 7 2 3

- 1 4 3

- 0 . 0 2 1 7

Eau Claire

5 7 , 9 4 2

- 2 , 0 4 6

- 1 , 4 1 5

- 1 4 4

- 0 . 0 1 3 1

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 6 . 5 7 %

- 3 5 . 7 5 %

- 2 4 . 2 3 %

- 2 6 . 5 1 %

- 3 1 . 0 9 %

Madison

- 5 . 4 2 %

- 3 3 . 5 0 %

- 2 6 . 3 4 %

- 2 2 . 5 1 %

- 3 0 . 0 3 %

Eau Claire

1 . 7 0 %

- 3 3 . 9 5 %

- 1 9 . 7 4 %

- 2 3 . 3 0 %

- 3 0 . 0 2 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 1 . 5 2

- 2 . 1 8

- 1 . 2 5

- 1 . 2 2

- 9 . 5 6

Madison

- 1 . 2 2

- 3 . 4 9

- 2 . 0 1

- 7 . 7 1

- 1 . 1 7

Eau Claire

0 . 3 1

- 1 . 1 1 x

- 7 . 6 5

- 7 . 8 0

- 7 . 0 9

Table 15 - Residential Emissions Results

Natural Gas Heating

Sq. Ft. =

1 , 3 7 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 1 , 3 3 1

- 1 6

- 9

- 1

- 7 . 0 5

Madison

- 1 , 2 1 4

- 2 5

- 1 5

- 1

- 8 . 5 7

La Crosse

- 1 1 5

- 7

- 5

- 1

- 4 . 7 2

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 5 . 4 5 %

- 2 2 . 6 2 %

- 1 6 . 3 1 %

- 1 7 . 6 2 %

- 2 0 . 0 5 %

Madison

- 5 . 1 4 %

- 2 1 . 1 5 %

- 1 7 . 3 7 %

- 1 5 . 2 1 %

- 1 9 . 3 0 %

La Crosse

- 0 . 6 3 %

- 2 0 . 0 3 %

- 1 2 . 8 8 %

- 1 4 . 5 7 %

- 1 7 . 8 0 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 0 . 9 7

- 1 . 1 7

- 6 . 9 0

- 6 . 6 7

- 5 . 1 5

Madison

- 0 . 8 9

- 1 . 8 5

- 1 . 0 9

- 4 . 2 3

- 6 . 2 5

La Crosse

- 0 . 0 8

- 5 . 4 3

- 3 . 9 4

- 3 . 9 0

- 3 . 4 5

Emissions and Economic Analysis of Ground Source Heat Pumps in Wisconsin

20

Residential options

where LP, oil, and electricity are assumed as the heating fuels for the

conventional systems.

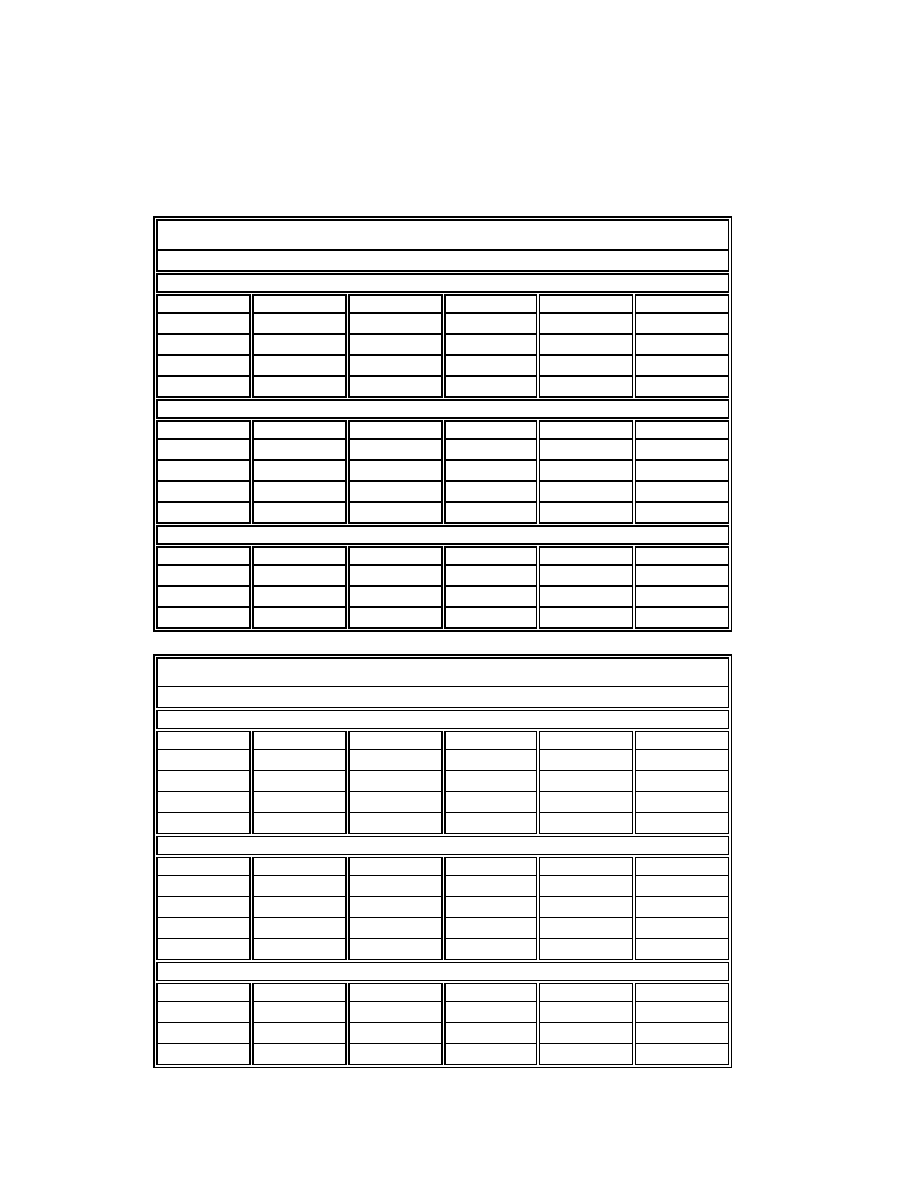

Table 16 - Community Development Emissions Results

LP Gas Heating

Sq. Ft. =

1 8 5 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 1 2 7 , 5 5 7

- 4 , 0 3 4

- 1 , 9 0 9

- 2 4 6

- 0 . 0 1 7 7

Madison

- 8 0 , 4 6 9

- 6 , 4 6 6

- 3 , 3 3 0

- 1 6 2

- 0 . 0 2 1 7

Eau Claire

2 1 5 , 6 6 2

- 2 , 0 4 9

- 9 8 8

- 1 6 5

- 0 . 0 1 3 1

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 2 . 8 8 %

- 3 5 . 7 9 %

- 1 9 . 1 0 %

- 2 9 . 6 3 %

- 3 1 . 0 9 %

Madison

- 1 . 8 7 %

- 3 3 . 5 2 %

- 2 2 . 9 2 %

- 2 6 . 3 9 %

- 3 0 . 0 3 %

Eau Claire

6 . 0 5 %

- 3 4 . 0 2 %

- 1 3 . 0 2 %

- 2 7 . 6 5 %

- 3 0 . 0 2 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 0 . 6 9

- 2 . 1 8

- 1 . 0 3

- 1 . 3 3

- 9 . 5 6

Madison

- 0 . 4 3

- 3 . 5 0

- 1 . 8 0

- 8 . 7 6

- 1 . 1 7

Eau Claire

1 . 1 7

- 1 . 1 1

- 5 . 3 4

- 8 . 9 4

- 7 . 0 9

Table 17 – Residential Emissions Results

LP Gas Heating

Sq. Ft. =

1 , 3 7 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 7 6 1

- 1 6

- 8

- 1

- 7 . 0 5

Madison

- 6 9 5

- 2 5

- 1 4

- 1

- 8 . 5 7

LaCrosse

3 9 3

- 7

- 4

- 1

- 4 . 7 2

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 3 . 0 4 %

- 2 2 . 6 4 %

- 1 3 . 3 0 %

- 1 9 . 3 8 %

- 2 0 . 0 5 %

Madison

- 2 . 8 8 %

- 2 1 . 1 6 %

- 1 5 . 4 8 %

- 1 7 . 3 5 %

- 1 9 . 3 0 %

LaCrosse

2 . 0 9 %

- 2 0 . 0 6 %

- 9 . 3 0 %

- 1 6 . 7 4 %

- 1 7 . 8 0 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

- 0 . 5 6

- 1 . 1 7

- 5 . 7 7

- 7 . 2 3

- 5 . 1 5

Madison

- 0 . 5 1

- 1 . 8 5

- 9 . 8 7

- 4 . 7 3

- 6 . 2 5

LaCrosse

0 . 2 9

- 5 . 4 4

- 2 . 9 4

- 4 . 4 0

- 3 . 4 5

The following tables show the emissions analyses for the Community Development and

Results

21

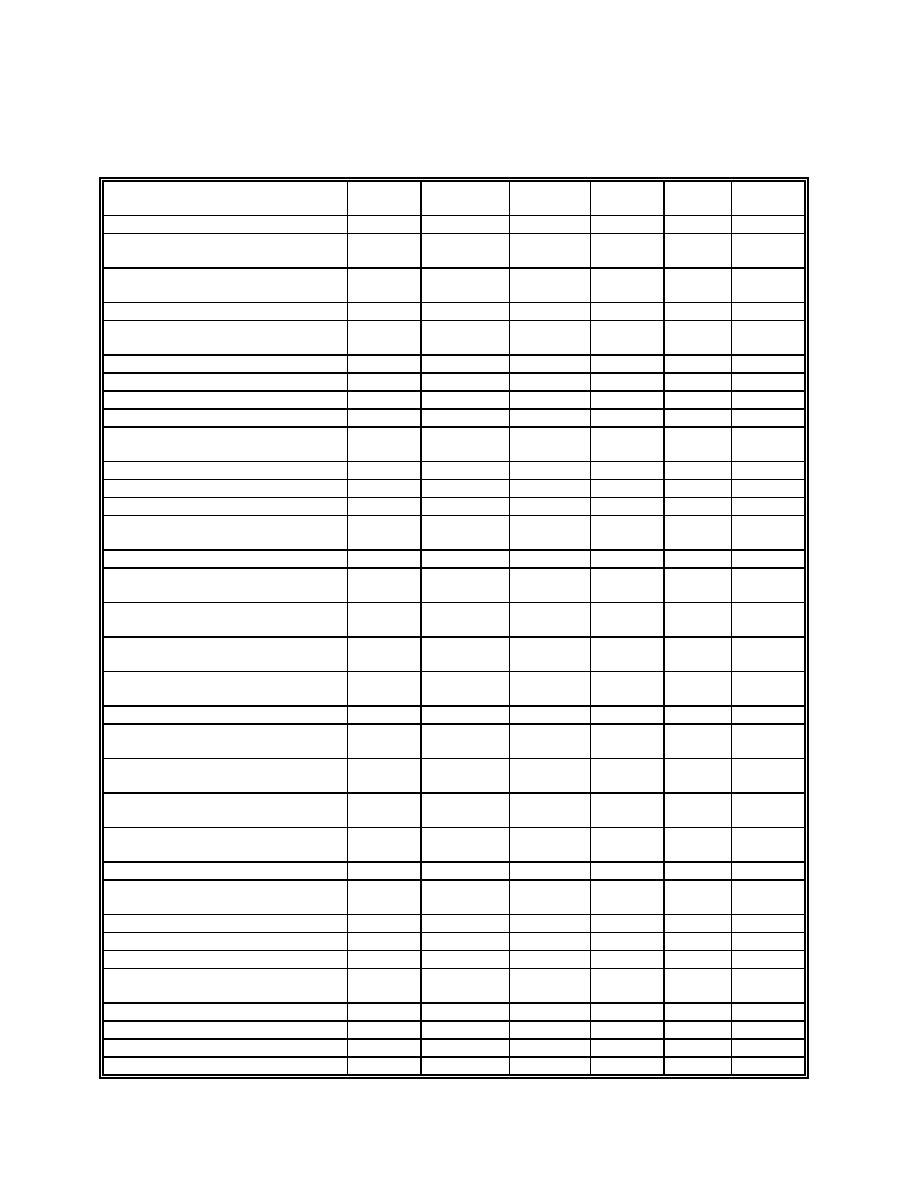

Table 18 – Community Development Emissions

Fuel Oil Heating

Sq. Ft. =

1 8 5 , 0 0 0

Emissions Reductions (pounds/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

4 9 , 0 7 4

- 8 5

- 2 , 0 9 9

- 2 5 8

- 0 . 0 1 3 4

Madison

8 7 , 5 7 2

- 2 , 7 0 9

- 3 , 5 1 1

- 1 7 3

- 0 . 0 1 7 6

Eau Claire

3 9 8 , 0 0 4

2 , 0 2 8

- 1 , 1 8 5

- 1 7 8

- 0 . 0 0 8 7

Emissions Reductions (%)

CO2

SO2

NOx

Particulate

Hg

Green Bay

1 . 0 7 %

- 0 . 5 6 %

- 2 1 . 4 1 %

- 3 1 . 5 0 %

- 2 1 . 8 8 %

Madison

1 . 9 6 %

- 1 1 . 7 5 %

- 2 4 . 4 8 %

- 2 8 . 7 4 %

- 2 3 . 0 5 %

Eau Claire

1 0 . 6 3 %

2 0 . 0 8 %

- 1 6 . 0 2 %

- 3 0 . 3 1 %

- 1 8 . 0 2 %

Emissions Reductions (pounds/ft2/year)

CO2

SO2

NOx

Particulate

Hg

Green Bay

0 . 2 7

- 4 . 6 0

- 1 . 1 3

- 1 . 4 0

- 7 . 2 4

Madison

0 . 4 7

- 1 . 4 6

- 1 . 9 0

- 9 . 3 7

- 9 . 4 9

Eau Claire

2 . 1 5

1.10 x10

-

- 6 . 4 0

- 9 . 6 0

- 4 . 6 9

Table 19 - Residential Emissions Results

Fuel Oil Heating

Sq. Ft. =

1 , 3 7 0