Protein Expression and Puri

Wcation 51 (2007) 1–10

www.elsevier.com/locate/yprep

1046-5928/$ - see front matter

© 2006 Elsevier Inc. All rights reserved.

doi:10.1016/j.pep.2006.06.024

Review

Strategies to maximize heterologous protein expression

in Escherichia coli with minimal cost

Wolfgang Peti

a

, Rebecca Page

b,¤

a

Brown University, Department of Molecular Pharmacology, Physiology, and Biotechnology, Box G-E3, Providence, RI 02912, USA

b

Brown University, Department of Molecular Biology, Cell Biology and Biochemistry, Box G-E4, Providence, RI 02912, USA

Received 26 April 2006, and in revised form 20 June 2006

Available online 4 July 2006

Abstract

Automation and miniaturization are key issues of high-throughput research projects in the post-genomic era. The implementation of

robotics and parallelization has enabled researchers to process large numbers of protein targets for structural studies in a short time with

reasonable cost e

Yciency. However, the cost of implementing the robotics and parallelization often prohibit their use in the traditional

academic laboratory. Fortunately, multiple groups have made signi

Wcant eVorts to minimize the cost of heterologous protein expression

for the production of protein samples in quantities suitable for high resolution structural studies. In this review, we describe recent e

Vorts

to continue to minimize the cost for the parallel processing of multiple protein targets and focus on those materials and strategies that are

highly suitable for the traditional academic laboratory.

© 2006 Elsevier Inc. All rights reserved.

Keywords: Structural biology; Heterologous protein expression; Escherichia coli; Cloning

Signi

Wcant amounts of protein, usually between 5 and

50 mg, depending on the protein size and experimental

technique used, are required for every structural biology

project

, independent of the structure elucidation

technique used, including X-ray crystallography, NMR

spectroscopy and cryo-electron microscopy. In general,

Escherichia coli is the preferred host for recombinant pro-

tein expression for structural studies

because it is

rather easy to genetically manipulate, it is relatively inex-

pensive to culture, isotope labeling protocols for NMR

spectroscopy and selenomethionine incorporation for X-

ray crystallography are established, and expression is fast,

typically producing protein in a single day. The impor-

tance of E. coli for heterologous protein production is

perhaps best highlighted by the wide variety of commer-

cial products available for the E. coli expression system.

However, there are disadvantages to using E. coli as an

expression host. Namely, E. coli is not capable of produc-

ing eukaryotic post-translational modi

Wcations, such as

glycosylation, which can be critical for the production of

folded, active protein. Equally important, some proteins,

especially larger proteins and membrane proteins, simply

fail to express in E. coli, or express, but do so insolubly as

inclusion bodies.

To overcome some of these limitations, a large number of

commercial vectors that facilitate soluble expression and sin-

gle step puri

Wcation via the use of diVerent fusion tags have

been developed. In addition, multiple E. coli strains that

facilitate the expression of membrane proteins

, proteins

with rare codons

, proteins with disul

Wde bonds

teins that are otherwise toxic to the cell, among others, are

readily available. This variety of expression vectors and cell

lines now signi

Wcantly enhances the likelihood of designing

an E. coli protein expression protocol suitable for the pro-

duction of the substantial amounts of protein required for

structural studies

. Finally, recently introduced microex-

pression incubator shakers that require as little as 500

l of

expression medium enable researchers to screen for optimal

expression conditions rapidly with reduced costs

. Once

*

Corresponding author. Fax: +1 401 863 9653.

E-mail address:

(R. Page).

2

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

the optimal expression construct is identi

Wed, standard incu-

bator shakers or fermentors are used to produce large

amounts of recombinant overexpressed protein.

During the last few years, both the pharmaceutical indus-

try and the structural genomics community have made signi

W-

cant e

Vorts to develop automated technologies to facilitate the

identi

Wcation and production of proteins suitable for func-

. This has led to new robotic

instrumentation for all steps of the structure determination

process, including rapid cloning systems

, parallel expres-

sion and puri

Wcation technologies

, nanocrystallization

and crystal growth imaging, and robotic crystal di

Vrac-

. Within the NIH Protein Structure Ini-

tiative, implementation of these technologies has resulted in

the determination of more than 1000 new protein structures

deposited in the Protein DataBank (PDB;

). However, academic laborato-

ries that usually focus on a few biologically relevant proteins

typically do not require the high-throughput demanded by

structural genomics centers and pharmaceutical industries.

Moreover, most of these technologies, such as robotics, and

novel strategies, such as commercially available rapid cloning

systems, are cost-prohibitive for most academic laboratories.

Instead, cost-e

Vective alternatives are needed. Fortunately,

during the last 5 years multiple groups have developed and

begun distributing materials that allow for the e

Ycient, paral-

lel screening of multiple constructs with minimal cost. These

techniques and materials use standard molecular biology and

protein puri

Wcation instrumentation that can be found in

most biology and certainly structural biology laboratories.

These new alternatives include new expression vectors

new or revitalized fusion tags to facilitate soluble protein

expression

, new microexpression/solubility screening

protocols

and new macroexpression methods and

instrumentation

. In this review, we describe our recent

experiences transitioning the parallel approach for protein

expression and puri

Wcation screening commonly used in

structural genomics centers to our own academic laboratories

and report on those materials and technologies we have found

most useful for our own projects.

New approaches to construct identi

Wcation

One of the most challenging steps in any structural biol-

ogy project is predicting which protein or protein fragment

will express solubly and purify for subsequent NMR spectro-

scopic or crystallographic studies. Often, small di

Verences in

the amino acid sequence itself, or in the length of the con-

struct, can transform a protein that fails to express into one

that expresses, puri

. In spite

of multiple e

Vorts to analyze the large amounts of data gen-

erated by structural genomics consortia regarding protein

expression, puri

Wcation and crystallization

, we are still

unable to predict, based on sequence alone, which proteins

will express and purify.

As with most laboratories, combined functional and

structural information is used to guide initial attempts to

identify the optimal boundaries (starting and ending resi-

dues) of a protein target/protein domain. We have found

that the ‘Fold and Function Assignment System’ (FFAS;

Vas.ljcrf.edu/Vas-cgi/cgi/Vas.pl

)

1

is a particularly use-

ful program for identifying weak structural homologs to a

sequence of interest. FFAS uses pro

Wle-proWle sequence

alignments and fold recognition to detect remote homolo-

gies not identi

Wed using other sequence comparison meth-

ods

. We use FFAS to identify the closest structural

homologs to various protein domains of interest to facili-

tate the identi

Wcation of appropriate residue boundaries for

primer design. When high resolution structures of homolo-

gous protein/protein domains are not available, we use sec-

ondary structure prediction programs such as PsiPred

to identify which regions of the domain are most likely to

form stable secondary structural elements. We also use the

programs, PONDR

and DisEMBL (HotLoops)

predict regions which are disordered. Both PONDR and

DisEMBL are computational methods based on neural

arti

Wcial networks trained for diVerent deWnitions of disor-

der, including protein sequences not visible in electron den-

sity maps (PONDR) and loops with high B-factors,

indicative of a high intrinsic mobility in these regions (Dis-

EMBL). The results from these analyses are then used to

identify multiple residues as optimal ‘start’ and ‘end’ resi-

dues for the constructs. Typically, we select between 2 and 4

‘start’ residues and 2 and 4 ‘end’ residues and use them

combinatorially to subclone anywhere between 4 and 16

di

Verent constructs of a single domain for expression, puri-

Wcation and structural analysis.

An additional approach that has proven to be success-

ful for the production of proteins for high resolution stud-

ies is ortholog screening

. Orthologs are proteins with

the same function from di

Verent species which, due to

evolution, have small di

Verences in their amino acid

sequences. While these di

Verences do not aVect protein

function, they can have signi

Wcant eVects on the ability of

a protein to express in E. coli, purify and crystallize.

Ortholog screening for high resolution studies have been

successfully used by multiple groups to obtain protein

samples suitable for high resolution studies. For example,

within the mouse homolog group of the Joint Center for

Structural Genomics (JCSG), 14 proteins were selected

for ortholog screening that had either previously failed to

crystallize or failed to express in selenomethionine media.

Using orthologous proteins, the JCSG was able to solve

the high resolution structures of 5 of these 14 protein fam-

ilies. Similarly, the Ontario Center for Structural Genom-

ics found that including even a single ortholog of a target

protein increases the number of samples for structural

studies by a factor of two

1

Abbreviations used: MCS, multiple cloning sites; TEV, Tobacco Etch

Viral; MBP, maltose binding protein; GST, glutathione S-transferase;

IMAC, immobilized metal a

Ynity chromatography; rpm, revolutions per

minute.

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

3

Parallel cloning into new vectors with novel fusion tags to

maximize the likelihood of soluble protein expression in

E. coli

The production of stable, soluble protein is one of the

most important steps in the protein structure determination

process. The experience of others

and ourselves indi-

cate that it is often necessary to express constructs of a pro-

tein of interest in frame with di

Verent protein fusion

partners in order to identify a single construct that is

expressed and soluble in amounts suitable for structural

studies. By using a parallelized matrix approach for clon-

ing, one can complete this expression and solubility screen-

ing in an e

Ycient, timely manner.

A variety of E. coli expression vectors (pET system, pBAD

system) with multiple fusion tags (hexahistidine, maltose-

binding protein, and glutathione S-transferase) under the con-

trol of di

Verent promoters (T7, trc, and araC) are widely

available. However, in many cases, the multiple cloning sites

(MCS) of these vectors often di

Ver from one another, requir-

ing new primers to be ordered and additional PCR ampli

Wca-

tion and restriction digestion steps to be carried out for every

new construct/vector pair. Thus, such vectors are not optimal

for a parallelized matrix approach to cloning. To address this

problem, a number of companies have developed novel, rec-

ombinatorial cloning systems which use recombinase (Gate-

way Technology) instead of the more traditional sticky-end or

blunt-end cloning methods to transfer gene targets from one

vector to another. For example, in the Gateway system, genes

are cloned into an entry (donor) vector which can then be

transferred, via recombination, into a variety of destination

(expression) vectors with the appropriate att recombination

elements. Although the Gateway system provides the

Xexibil-

ity of an extensive set of destination vectors, including multi-

ple E. coli, baculovirus, and mammalian expression vectors,

these systems are proprietary and its routine use can be

expensive for academic laboratories.

Novel expression vectors

We have found the EMBL system of E. coli expression

vectors, available through the European Molecular Biology

Laboratory (EMBL) protein production facility (

www.embl.de/ExternalInfo/protein_unit/draft_frames/index.

html

), most useful for implementing a parallelized matrix

approach to cloning while minimizing the associated costs

. More than 40 di

Verent E. coli expression vectors are cur-

rently available from the EMBL protein production facility.

These vectors have di

Verent promoters (T7, pBAD), include

a variety of fusion tags to facilitate soluble expression and

puri

Wcation (

), and have a choice of intervening pro-

tease sequences for tag removal (thrombin, TEV). The major

advantage of these vectors is that they have nearly identical

MCS sites. Thus, one need only amplify and digest a gene

construct once in order to subclone it into any of the avail-

able EMBL E. coli expression vectors.

The only drawback of these vectors is that they typically

have only a single restriction site for N-terminal cloning.

This is because there are ‘stu

Ver’ sequences present between

the N-terminal cloning site (NcoI) and the C-terminal clon-

ing sites (which have between 6 and 8 di

Verent restriction

sites). Thus, if you have a NcoI site in the DNA sequence of

your “to-be-expressed” protein, then you cannot use these

vectors for cloning unless they are genetically modi

Wed to

incorporate a new restriction site. Because proteins often

have multiple NcoI sites, including proteins we are studying

in our laboratories, we modi

Wed a subset of these vectors to

include an NheI site immediately following the NcoI site,

allowing these modi

Wed vectors to be used to subclone

DNA sequences with NcoI sites. We also developed a set of

our own ‘in-house’ vectors based on the expression vector

typically used in the JCSG for expression in E. coli (pMH1;

). This vector contains a small fusion tag, Thio

6

His

6

,

which includes the

Wrst six amino acids of thioredoxin, to

facilitate expression, followed by six histidine residues, to

facilitate puri

Wcation. Expression in pMH1 is controlled by

the pBAD promoter, which is tightly regulated and pre-

vents leaky expression, allowing for uniform cell culture

growth

. However, as observed by us and others,

Wnal

expression yields of protein under control of the pBAD

promoter are often dramatically lower than those obtained

using vectors under control of the T7 promoter

. Thus,

we developed two new vectors, pETRP1 and pETRP2,

which contain the Thio

6

His

6

tag both with and without a

Table 1

Subset of expression vectors typically used for the production of soluble protein in E. coli

Plasmids used for expression in E. coli; Thio

6

: MGSDKI,

Wrst six residues of thioredoxin; His

6

: HHHHHH, hexahistidine tag; Z-tag: derivative of Staph-

ylococcus protein A binding protein; GST: glutathione S-transferase; MBP: maltose binding protein; GB1: point mutant of the Streptococcus protein G

1 domain.

a

Modi

Wed by the author to include an additional N-terminal restriction site (NheI) for N-terminal cloning.

Vector

Promoter

Residue

Fusion tag

Protease site

Residues remaining

as cloning artifacts

Origin

Source

pETRP1

T7-lac

Kan

N-Thio

6

His

6

TEV

2

pBR322

Page

pETRP2

T7-lac

Kan

N-Thio

6

His

6

None

12

pBR322

Page

pETM-30

a

T7-lac

Kan

N-His

6

GST C-His

6

TEV

4

pBR322

EMBL/Page

pETM-41

a

T7

Kan

N-His

6

MBP

TEV

4

pBR322

EMBL/Page

pETZ2-1a

T7-lac

Kan

N-His

6

Z-domain

TEV

4

pBR322

EMBL

pHIS-GB1

T7-lac

Amp

N-His

6

GB1

TEV

3

pBR322

Gardner

4

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

Tobacco Etch Viral (TEV) NIa protease site, respectively,

and are under control of the T7 promoter. To date, we have

already successfully expressed more than 20 constructs

using these RP vectors, four of which have been success-

fully used for high resolution structure determination (both

NMR spectroscopy and X-ray crystallography

).

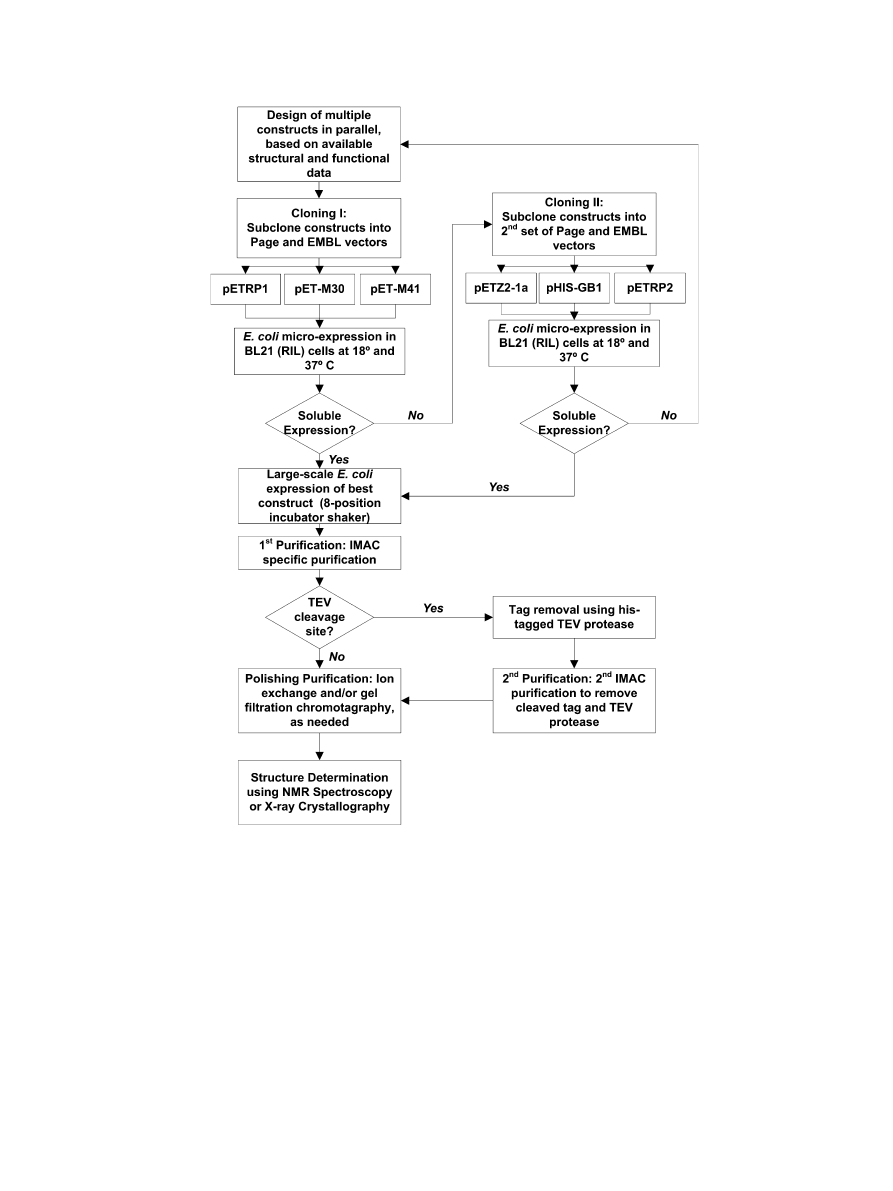

Cloning strategy

For initial cloning and expression tests, we have found it

advantageous to clone our constructs in parallel into three

di

Verent vectors: pETRP1 (N-Thio

6

His

6

, TEV protease

site), pETM-30 (N-His

6

, glutathione S-transferase [GST]

TEV protease site), and pETM-41 (N-His

6

, maltose binding

protein [MBP], TEV protease site). Usually, one of these

three tags results in soluble expression of the construct of

interest. MBP, in particular, has been shown to not only

enhance expression but to also passively promote the fold-

ing of its fused partner, thereby signi

Wcantly facilitating the

production of soluble protein

. Because an N-termi-

nal hexahistidine sequence is present in all of the vectors

(referred to as combinatorial tagging because there are two

expression/puri

Wcation tags present in the expression vector

), an additional advantage of this system is that all of

the expressed constructs can be puri

Wed using standard

immobilized metal a

Ynity chromatography (IMAC). This

makes the expressed proteins straightforward to purify in

parallel in order to rapidly identify which constructs are

suitable for large-scale expression and puri

Wcation.

If these

Wrst-round constructs fail to produce suYcient

amounts of protein for high resolution structural studies, a

second set of vectors that contain more rarely used, but also

e

Vective, fusion tags to facilitate soluble protein expression

and puri

Wcation. These include the Z-tag, a derivative of the

Staphylococcus protein A binding protein

, the GB1-tag,

a point mutant of the Streptococcus protein G

1 domain

, and NusA, the N-utilizing substance A protein

among others. The characteristics of these and other pro-

tein fusion tags are summarized in

. Our typical

work

Xowchart is shown in

TEV protease

The EMBL pETM and our in-house vectors form the

basis of our E. coli expression. These vectors are under

the control of the T7 promoter and have a pBR322 origin

of replication. This allows us to induce protein expres-

sion using IPTG or metabolically when expression is car-

ried out using the recently developed autoinduction

media (described in ‘Microexpression screening prior to

scale-up’). In addition, most of these vectors contain a

Tobacco Etch Virus NIa (TEV) protease cleavage site

between the N-terminal fusion tag and the construct of

interest. This allows us to remove any N-terminal fusion

tag using TEV protease, which can be readily expressed

and puri

Wed in the laboratory. An expression vector for a

his-tagged mutant of TEV NIa protease (His-tagged TEV

S219V), developed by Dr. D. Waugh and colleagues

,

is available from the American Type Culture Collection

(ATCC No. MBA-145). This TEV S219V mutant is

»

100-fold more resistant to auto-inactivation than wild-

type TEV, with the added bene

Wt of slightly better

catalytic activity. Additional TEV protease expression

vectors, including MBP-TEV S219V, are available from

the non-pro

Wt distributor of biological reagents, Add-

Gene (

). Finally, a vector for intracellu-

lar processing of fusion proteins by TEV protease prior

to lysis and puri

Wcation, pRK603, can also be obtained

(D. Waugh, personal communication;

). His-tagged

TEV S219V protease can be puri

Wed following protocols

such as that found at

. This allows investigators to produce

their own protease, resulting in a substantial savings in

reagent costs. In our experience, we have found TEV can

be stored at ¡80 °C for months without a signi

Wcant

decrease in catalytic activity.

Table 2

Expression and puri

Wcation characteristics of commonly used protein fusion tags

Fusion tag

Amino

acids

Size

(kDa)

Puri

Wcation

Comment

Thio

6

His

6

12

1.5

Immobilized metal

chromatography (IMAC)

Thio

6

(

Wrst six residues of thioredoxin) facilitates expression

and His

6

facilitates puri

Wcation using IMAC chromatography

His

6

-glutathione S-transferase (GST)

243

28.1

IMAC or glutathione agarose

GST: enhanced solubility; dimerization can be an issue

His

6

-maltose binding protein (MBP)

390

43.0

IMAC or amylose resin

MBP: enhanced solubility; fusion protein not always soluble

following cleavage from MBP

His

6

-disul

Wde oxidoreductase (DsbA);

disul

Wde isomerase

228

25.4

IMAC

Disul

Wde oxidoreductase (DsbA) and disulWde isomerase

(DsbC), both of which have been shown to have positive

e

Vects on expression levels when used as a fusion partner

His

6

-N-utilizing substance A protein

(NusA)

535

59.3

IMAC

Strong solubility enhancing tag

His

6

-thioredoxin A (TrxA)

135

14.7

IMAC

Solubility enhancing tag

His

6

-Staphylocuccs protein A derived

binding protein (Z-domain)

91

10.6

IMAC; protein A–Sepharose

Solubility enhancing tag

His

6

-point mutant of Streptococcus

protein G

1 domain (GB1)

85

9.7

IMAC; IgG-resins

Highly expressed and soluble; useful for NMR screening of

GB1-fusion proteins prior to tag removal

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

5

Protein coexpression

Finally, the EMBL protein production facility provides a

second series of vectors which is based on the pBAD pro-

moter with a pUC origin of replication. Because each series

of vectors confers resistance to di

Verent antibiotics (the

pETM series confers resistance to kanamycin and the pBAD

series confers resistance to ampicillin), they can also be used

in combination with one another for protein coexpression.

Microexpression screening prior to scale-up

The parallel matrix approach to construct generation

for heterologous protein expression and puri

Wcation tri-

als can rapidly produce large numbers of constructs that

must be tested for expression and solubility, especially

when comparing alternative E. coli expression strains

and/or expression conditions. For example, if four di

Ver-

ent constructs are subcloned into three di

Verent expres-

sion vectors and screened for soluble expression at two

temperatures (37 and 18 °C), 24 di

Verent expression trials

have to be carried out. To minimize the time and expense

of initial expression tests, a number of small-scale screens

have been developed that allow one to rapidly identify

which targets express and are soluble prior to large-scale

expression. Thus, these screens are essential for making

the matrix approach to protein construct generation

e

Ycient and cost-eVective.

Fig. 1. Flowchart depicting the typical protein sample production strategy used by the authors.

6

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

We typically use the E. coli strain BL21 Codon-

Plus(DE3)-RIL (Stratagene) for all initial expression tests.

These cells contain a plasmid that encodes for three tRNA

genes that recognize rare codons (argU: AGA,AGG; ileY:

AUA; leuW: CUA). E. coli strains which contain additional

rare codons (such as BL21-CodonPlus(DE3)-RP/RPIL,

Stratagene; BL21-DE3-Rosetta, Novagen), are also avail-

able, when constructs fail to express in RIL cells. In addi-

tion, for tight regulation of protein expression, as is

necessary when expressing toxic proteins, we use BL21-AI

(Invitrogen) E. coli cells, which contain a chromosomal

copy of the T7 RNA polymerase under control of the arab-

inose-inducible araBAD promoter. A variety of additional

cell lines, which contain di

Verent chaperones (Chaperone

Competent Cell Lines, Takara), mutations in thioredoxin

reductase and glutathione reductase for enhanced disul

Wde

bond formation (BL21-Origami cells, Novagen), and

methionine-auxotrophs for selenomethionine incorpora-

tion for subsequent crystallographic studies (B834, Invitro-

gen), provide important alternatives.

Most microexpression screening is typically carried out

as follows. The proteins are expressed in 96-well (750

l) or

24-well deep-well (2–3 ml) blocks. The cell culture is pel-

leted by centrifugation and resuspended in chemical lysis or

sonication bu

Ver. The cells are then lysed using chemical

lysis, sonication or repeated rounds of freeze–thaw. A sam-

ple of the total lysate is removed for SDS–PAGE gel analy-

sis. The insoluble fraction of the lysate is subsequently

separated from the soluble fraction using either

Wltration or

centrifugation and a sample of the soluble fraction is used

for SDS–PAGE gel analysis. In some laboratories, the solu-

ble fraction is batch puri

Wed using small amounts of aYnity

matrices (i.e., in the EMBL Protein Production Facility,

25

l of immobilized metal aYnity chromatography,

IMAC-resin is used to purify the soluble, expressed protein

from 1.5 ml of cell culture). Finally, the expression and solu-

bility of expressed and puri

Wed proteins are determined

using SDS–PAGE electrophoresis or standard immuno-

chemistry. A number of recent reports describe such meth-

ods

and numerous commercial products, such as

ready-made chemical lysis bu

Vers including B-Per (Pierce),

Bugbuster (Novagen), and 96-well

Wltration plates (multi-

ple vendors), are available to facilitate parallelized expres-

sion screening.

Hand-in-hand with these new technologies, new instru-

mentation capable of facilitating multiple protein construct

screening has also become available

. We previously

adapted a low-cost, high-velocity incubating Glas-Col

(Glas-Col, LLC) Vertiga shaker for e

Ycient, high-through-

put E. coli microliter-scale expression screening that accu-

rately predicts protein behavior expressed in large-scale

(milliliter and liter) fermentation conditions. The apparatus

shakes cultures in three-dimensions at speeds of up to

1000 rpm, allowing small-scale (»500

L) cultures grown in

2 ml deep-well 96-well blocks to achieve optical densities

(OD

600

) of cell culture as high as 10–20. This generates su

Y-

cient material for analysis of expression, solubility and

binding to a

Ynity puriWcation matrices. Using this screen,

we showed that of 34 proteins screened, 33 consistently

expressed (or did not express) in both the small-scale (milli-

liter) and large-scale (liter) fermentation trials. More

recently, we have also shown that this Vertiga shaker can be

used to express and purify proteins in isotopically labeled

media in amounts suitable for initial structural character-

ization using microcoil NMR spectroscopy

Most recently, a novel microexpression screening proce-

dure that does not require culture growth, but instead mon-

itors soluble expression from a single colony, the colony

Wltration blot procedure (Co–Fi), has also been developed

. Rather than growing up milliliter cultures for expres-

sion screening or relying on reporter protein fusions, single

colonies are induced to express protein by transferring the

colonies to plates containing IPTG. After 6 h, the cells are

lysed by three rounds of freeze–thaw, the soluble and insol-

uble fraction separated by

Wltration and the soluble pro-

teins captured on a nitrocellulose membrane for screening

using standard immunochemicals. The Co–Fi blot, which

does not require the growth and expression small-scale cul-

tures, is ideal for screening libraries of thousands of colo-

nies using minimal time and materials.

New methods for increasing cell culture densities during

large-scale expression and improving soluble lysis

Most new expression tools have focused on fermentation

to improve E. coli cell density yields. However, fer-

mentors often require additional optimization of the

expression conditions, e.g. oxygen level, among others.

Moreover, fermentors are typically costly equipment.

Recently, new technologies and strategies have been devel-

oped that increase cell culture densities similar to those

observed with traditional fermentors, but are suitable for

traditional incubator shakers. The Vortexer incubator

shaker (Glas-Col LLC and Thomson Instrument Com-

pany) results in reproducible increases in the cell culture

densities of expressed proteins. A second option is the

BactoLift air spurge fermentor (Lofstand) in which up to

twenty 800 ml cell cultures can be grown in parallel

.

Further, the development of a new media formulation,

autoinduction media, that allows cultures to reach optical

cell densities of 20–40 OD without the need to add external

induction agents, such as IPTG

, shows highly promis-

ing possibilities for simpli

Wed parallel expression. Finally,

high volume homogenizers provide gentle E. coli lysis, max-

imizing the yield of soluble protein.

Vortexer shaker

The new Vortexer incubator shaker combines the ease of

protein expression in an incubator shaker with high

increases in cell culture densities to values typically seen in

fermentor-type setups. Multiple modi

Wcations to the regu-

lar incubator shaker setup have been made. The shaker uses

a high speed (up to 550 rpm) 3-dimensional rocking plat-

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

7

form. The orbit of Vortexer incubator shaker di

Vers from

that of traditional shakers because it rotates not only in the

X- and Y-dimensions, but also rotates in the Z-dimension.

It is temperature controlled, from 15 to 60 °C, and varies in

speed from 10 to 550 revolutions per minute (rpm). In addi-

tion, the Vortexer incubator shaker is also smaller than

more traditional incubator shakers, with dimensions of

only 28 in. (W) £ 26 in. (D) £ 22 in. (H), enabling it to

Wt on

a standard laboratory benchtop. Using the standard plat-

form, the Vortexer incubator shaker can be used to express

eight di

Verent 500–1000 ml cultures using 2.5 L Ultra-Yield

(UY; Thomson Instrument Company)

Xasks. These new

lightweight plastic UY

Xasks, which have six baZes for

increased aeration, are used for expression. Like Fernbach

Xasks, UY Xasks have a broad base 158 mm diameter, but

taper in two-stages to form a narrow neck of also 68 mm

inner diameter, and have six ba

Zes to facilitate mixing. UY

Xasks hold up to 2500 ml and are typically used to express

500–1000 ml of E. coli culture. A specially designed air-

porous seal can be used in conjunction with the UY

Xasks,

which facilitates an increase in the air-exchange compared

with aluminum foil that is usually used to prevent contami-

nation of the shaker cultures during protein expression.

We recently compared the

Wnal cell culture densities of

18 di

Verent proteins and protein domains expressed using

di

Verent media (LB, TB and autoinduction medium), diVer-

ent temperatures (18 and 37 °C), di

Verent Xasks (Fernbach

and UY) and di

Verent shakers (the vortexer incubator and

MultitronII incubator shaker, HT Infors). First, we found

that

Wnal cell culture densities were primarily dependent on

the nature of the protein expressed; i.e., certain proteins

consistently grew to higher (or lower) cell culture densities

than others, in spite of optimization of temperature, shak-

ing speed and media. For example, E. coli cultures express-

ing TEV protease reached a maximum optical cell culture

density (OD

600

) of 7.4 (rich TB medium using ultra yield

Xasks and the Vortexer incubator shaker at 18 °C). How-

ever, in most experiments, TEV cultures reached

Wnal opti-

cal densities of only 2.0 (LB medium, UY or Fernbach

Xasks, MultitronII incubator shaker, 37 °C). In contrast,

cultures expressing di

Verent proteins, such as hematopoi-

etic tyrosine phosphatase (PTN7_2)

or TM0979

were able to consistently reach much higher cell culture

densities, and in the best cases, reached OD

600

’s from 15 to

nearly 30. Second, we found that 62% of the E. coli cultures

expressed in Ultra-Yield

Xasks at 18 °C resulted in higher

Wnal cell culture densities than those expressed at the same

temperature in Fernbach

Xasks. Finally, we found 77% of

the proteins expressed in UY

Xasks at 18 °C had higher

Wnal cell culture densities when expressed in the Vortexer

shaker, while 80% of the proteins expressed in UY

Xasks at

37 °C had higher cell culture densities when expressed in the

MultitronII incubator shaker. In summary, outside of the

importance of the construct actually being expressed, we

found that the most signi

Wcant diVerences in Wnal cell cul-

ture densities depended on the media and temperature, with

the highest overall expression yields obtained for proteins

expressed at 18 °C in rich TB in the Vortexer shaker or

autoinduction medium. Both the MultitronII incubator

and Vortexer shakers are used routinely by the authors for

protein expression in E. coli.

BactoLift air spurge fermentor

While the Vortexer shaker can be used increase

Wnal cell

culture density yields, a second table top fermentor, the

BactoLift, can be used to express up to 20 di

Verent protein

samples simultaneously. The BactoLift is an air spurge fer-

mentor. Agitation is achieved by bubbling sterile air

through the culture using a

Xow-controlled air pump.

Instead of shaker

Xasks, the Bactolift attaches to standard

500 ml and 1 L centrifuge bottles. Cultures are grown

directly in the centrifuge bottles. Twelve 1-L units can be

incubated in a standard 1 £ 1.5 ft. benchtop waterbath, pro-

viding temperature regulation, and can be expanded to

accommodate 20 one-liter units. Following overnight incu-

bation, the bottles are removed from the Bactolift (which

can be repeatedly autoclaved), and are then transferred to

the centrifuge for further processing. This precludes the

need to transfer culture

Xuids from a shaker Xask, eliminat-

ing the possibility of spillage. The BactoLift was originally

developed for the production of plasmid DNA

, but has

more recently been adopted by high-throughput protein

production groups, including those at the Paci

Wc North-

west and Argonne National Laboratories

. In a compre-

hensive work comparing small-scale and large-scale

expression results, Lin and co-workers expressed 47 di

Ver-

ent proteins in 800 ml of media using the BactoLift fermen-

tor. Speci

Wcally, cell cultures were grown at 37 °C to

OD

600

’s of 0.6–0.9, induced and then allowed to express at

30 °C for 3 h, after which the bottles were removed and cen-

trifuged to pellet the cultures. They found that on average,

the

Wnal OD

600

values at harvest were 2.01 § 1.06

. These

average

Wnal cell culture densities are somewhat lower than

those of proteins expressed at 37 °C for 3 h using either the

Infors Multitron II Incubator Shaker (ATR, Laurel, MD)

or the Vortexer Shaker, which were 3.76 § 0.76 and

3.78 § 0.64, respectively. Overnight expression in a Bacto-

Lift, which would require a cooled water bath to maintain

the temperature at 18–20 °C, would likely result in higher

Wnal optical cell densities, but it is not known how they

would compare with those of the Infors Multitron II Incu-

bator Shaker or the Vortexer Shaker.

The primary advantage of the BactoLift fermentor sys-

tem is that the capacity for parallel protein expression is

high, with the ability to express 20 di

Verent proteins on a

1 L scale simultaneously. In contrast, the Infors Multitron

II Incubator and the Vortexer shaker have capacities to

express only 8–12 distinct proteins simultaneously in a

comparable 1 L scale. In addition, there is no need to trans-

fer the cultures to centrifuge tubes once expression is com-

pleted since the cultures are grown directly in the centrifuge

bottles. This is not true of the cultures grown in traditional

shakers, in which

Xasks are used for expression. Finally, it is

8

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

inexpensive, with costs of approximately $2500 for a 6-

place unit and $7500 for a 20-place unit. However, there are

drawbacks of the system. First, it is temperature-controlled

using a water bath. Thus, if expression is to be carried out

at low temperatures, such as 18 °C, to enhance the produc-

tion of soluble protein, the BactoLift fermentor must be

placed in a cold room, which is not always easily available.

Second, it requires a constant in

Xux of air via an air pump,

which occupies additional space and incurs additional rou-

tine-use costs. In general, we have found it optimal to have

at least one traditional temperature-controlled incubator

shaker, such as the Infors Multitron II Incubator, in order

to carry out protein expression on a wide variety of scales

(10 ml culture tubes; 50 ml cultures, 100 ml cultures, 1.0 L

cultures) at any temperature. Instruments like the BactoLift

fermentor or the Vortexer Incubator shaker are then pur-

chased as secondary shakers to provide additional, high-

volume expression throughput. To systematically maximize

Wnal cell culture densities, parallel fermentation systems

such as the Sixfors (HT Infors) is most useful. The Sixfors is

a system with six independent fermentor units, which can

be used to either express six di

Verent proteins or express the

same protein, but under di

Vering conditions (varying tem-

perature, pH, pO

2

, etc.) in order to identify those expression

conditions that maximize the yield of expressed, soluble

protein.

Autoinduction medium produces uniformly high cell culture

densities with strong expression

Autoinduction media can be used to express proteins

under the control of the lacUV5 promoter without the

addition of an external induction agent, such as IPTG

Instead, cultures are simply inoculated in the morning,

grown at 37 °C for 3 h and then transferred to low tempera-

ture (20 °C) for overnight growth and expression. More-

over, using this medium, cultures can repeatedly reach

Wnal

OD

600

of 20–40

. Autoinduction depends on the met-

abolic mechanisms bacteria use to regulate the use of car-

bon and energy sources present in the growth medium.

When glucose is present in the medium, the uptake of lac-

tose is blocked, thereby preventing the metabolic produc-

tion of allolactose, a natural induction agent for proteins

under control of the lacUV5 promoter. Speci

Wcally, the

presence of both glucose (0.05%) and lactose (0.2%) in

autoinduction medium enables cultures to grow to high

optical densities and once the glucose is depleted, lactose is

metabolized to allolactose leading to induction and subse-

quent expression. Because premature induction is pre-

vented by catabolite repression, autoinduction media is also

well-suited for the expression of toxic proteins. Finally,

additional formulations of autoinduction media, which

allow for speci

Wc isotopic-labeling of protein samples

required for multi-dimensional NMR spectroscopy and

enable the incorporation of selenomethionine into protein

samples required for X-ray crystallography, have also been

developed

. Because the cultures do not require the

addition of an external induction agent, the use of this

medium is particularly well suited to high-throughput envi-

ronments in which multiple proteins are expressed in paral-

lel. In particular, the chemically de

Wned autoinduction

medium suitable for isotopic-labeling with

13

C and

15

N has

been implemented for the high-throughput production of

samples suitable for structure determination using NMR

spectroscopy by the Center for Eukaryotic Structural

Genomics

. It should be noted that since the unlabeled

-lactose is also a metabolic source of carbon,

13

C and

15

N-

incorporation was typically not 100% complete, and

observed to be as low as 95%. This was determined to be

su

Ycient for NMR structural investigations.

Cell lysis

Gentle E. coli lysis following expression is essential for

successful puri

Wcation of the expressed protein. Four meth-

ods are generally used, including sonication, enzymatic lysis

using lysozyme, freeze–thaw and homogenization. Sonica-

tion is a popular technique for cell lysis. Ultrasonic probes

rapidly oscillate up and down and at a rate of 20 kHz, the

liquid sample turns into a zone of microscopic shock waves,

resulting in cell lysis by liquid shearing and cavitation. Sig-

ni

Wcant energy is released during this process, and only a

short burst of a sonicator probe can cause water to boil.

Thus, one of the primary drawbacks of sonication is that

protein samples can become overheated, resulting in pro-

tein denaturation. It is typically essential that samples be

kept on ice during the sonication process, preferably with

constant stirring to minimize heat generation near the tip of

the probe. In enzymatic lysis, lysozyme is used to digest the

peptidoglycan layer and permeabilize the outer membrane

of gram-negative bacteria. DNase is also usually added to

cleave the liberated DNA. Enzymatic lysis is a gentle,

e

Vective lysis method, but can become expensive for larger

volume cultures. An alternative to enzymatic lysis is freeze–

thaw, in which cells are resuspended in lysis bu

Ver (typically

with lysozyme and DNase1), frozen using liquid nitrogen

and then stored overnight at ¡20 or ¡80 °C or immediately

thawed at room temperature. Multiple cycles of freeze–

thaw enhance lysis. This is a gentle method, but can often

result in incomplete lysis, leading to protein loss. Notably,

certain E. coli expression cell lines are highly suited for lysis

using the freeze–thaw method. A number of cell lines have

been engineered to express T7 lysozyme, such as BL21

(DE3)pLysS cells, in order to inhibit T7 RNA polymerase

activity prior to induction thereby preventing premature

expression of the pET-derived genes. Because these cells

express lysozyme, cell lysis can be e

Yciently carried out

under milder conditions, such as freeze–thaw, without the

need to add lysozyme.

We have found high volume homogenizers, such as the

Emulsi

Xex-C3 (Avestin, Inc.) or the MicroXuidizer (Micro-

Xuidics), to be ideal for gentle cell lysis for a wide array of

culture volumes (as little as 10 ml to as many as 3 L or

more). A bene

Wt of these systems is that external enzymes,

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

9

such as lysozyme or DNase, are not required to facilitate

lysis. We use the Avestin Emulsi

Xex-C3 (“Cell cracker”) for

lysate volumes greater or equal to 10 ml. It is fast, with a

Xow-through capacity of 3 L per hour. In addition, it can

reach up to 30,000 psi and is thus suitable for lysing not

only E. coli but also yeast. Finally, it can be temperature-

controlled with an appropriate heat exchanger. We typi-

cally use three sequential passes for complete E. coli lysis.

For a 100 ml sample, the entire process, including washing

the system before and after lysis, takes about 30 min. In

between each pass, the lysate is kept on ice to minimize

transient increases in temperature. We have successfully

lysed and puri

Wed multiple proteins using this system

which, when the same cultures were lysed by sonication,

resulted in precipitated protein samples. The primary disad-

vantage of this system is its cost, »$25,000. However, con-

sidering the time and e

Vort that goes into the production of

large-scale protein samples suitable for puri

Wcation, it is

well worth the money and, because of its ease of use, is an

optimal piece of shared instrumentation for a facility or

department.

Conclusions

The production of protein samples in the amounts typi-

cally required for structural biology is often the rate-limit-

ing step of structure determination. The recent introduction

of new, inexpensive technologies and freely available clon-

ing materials have greatly facilitated the abilities of small-

to medium-sized laboratories to rapidly and cost-e

Vectively

identify protein constructs which express to high levels, are

soluble and purify readily. In particular, the EMBL catalog

of E. coli expression vectors is particularly useful because of

the large number of expression and puri

Wcation fusion tags

available and the similarity of the vectors’ multiple cloning

sites. In addition, new technologies and strategies to facili-

tate protein expression, such as the Vortexer shaker in com-

bination with Ultra-yield double-ba

Zed Xasks or the new

autoinduction medium, are resulting in signi

Wcant increases

in the

Wnal cell culture densities of expressed proteins and,

in turn, expression yields of protein in equivalent volumes

of media. Finally, new instrumentation to minimize the

time and e

Vort required for cell lysis by homogenization

have also been introduced, which greatly minimize the like-

lihood a protein sample precipitates during the lysis proce-

dure while also ensuring complete lysis.

Acknowledgments

The authors thank all the members of the Page and Peti

laboratories, especially Barbara Dancheck, Michael Hadley

and Jebecka Hudak for help with experiments, Sam Ellis

(Thompson Instrument Company) for supplies and helpful

advice and James Jacso (Glas-Col Inc.) for technical sup-

port. This work was supported by medical research grants

from the Rhode Island Foundation to R.P. and W.P. and

by a Richard B. Salomon Research Grant from Brown

University to R.P. and W.P. This work was partially sup-

ported by National Institutes of Health (NIH) Grant R01

EB003872-02.

References

[1] A.M. Edwards, C.H. Arrowsmith, D. Christendat, A. Dharamsi, J.D.

Friesen, J.F. Greenblatt, M. Vedadi, Protein production: feeding the

crystallographers and NMR spectroscopists, Nat. Struct. Biol. 7

(Suppl.) (2000) 970–972.

[2] C.W. Goulding, L.J. Perry, Protein production in Escherichia coli for

structural studies by X-ray crystallography, J. Struct. Biol. 142 (2003)

133–143.

[3] F.W. Studier, A.H. Rosenberg, J.J. Dunn, J.W. Dubendor

V, Use of T7

RNA polymerase to direct expression of cloned genes, Methods Enz-

ymol. 185 (1990) 60–89.

[4] P. Braun, J. LaBaer, High throughput protein production for func-

tional proteomics, Trends Biotechnol. 21 (2003) 383–388.

[5] B. Miroux, J.E. Walker, Over-production of proteins in Escherichia

coli: mutant hosts that allow synthesis of some membrane proteins

and globular proteins at high levels, J. Mol. Biol. 260 (1996) 289–298.

[6] U. Brinkmann, R.E. Mattes, P. Buckel, High-level expression of

recombinant genes in Escherichia coli is dependent on the availability

of the dnaY gene product, Gene 85 (1989) 109–114.

[7] W.A. Prinz, F. Aslund, A. Holmgren, J. Beckwith, The role of the thio-

redoxin and glutaredoxin pathways in reducing protein disul

Wde

bonds in the Escherichia coli cytoplasm, J. Biol. Chem. 272 (1997)

15661–15667.

[8] I. Hunt, From gene to protein: a review of new and enabling technol-

ogies for multi-parallel protein expression, Protein Expr. Purif. 40

(2005) 1–22.

[9] R. Page, K. Moy, E.C. Sims, J. Velasquez, B. McManus, C. Grittini,

T.L. Clayton, R.C. Stevens, Scalable high-throughput micro-expres-

sion device for recombinant proteins, Biotechniques 37 (2004) 364,

366, 36.

[10] W. Peti, R. Page, K. Moy, M. O’Neil-Johnson, I.A. Wilson, R.C. Ste-

vens, K. Wüthrich, Miniaturized Structural Genomics Pipeline using

Micro-expression and Microcoil NMR, J. Struct. Funct. Genomics 6

(2005) 259–267.

[11] H. Nguyen, B. Martinez, N. Oganesyan, R. Kim, An automated small-

scale protein expression and puri

Wcation screening provides beneWcial

information for protein production, J. Struct. Funct. Genomics 5

(2004) 23–27.

[12] S.A. Lesley, High-throughput proteomics: protein expression and

puri

Wcation in the postgenomic world, Protein Expr. Purif. 22 (2001)

159–164.

[13] H.E. Klock, A. White, E. Koesema, S.A. Lesley, Methods and results

for semi-automated cloning using integrated robotics, J. Struct. Funct.

Genomics 6 (2005) 89–94.

[14] W.B. Jeon, D.J. Aceti, C.A. Bingman, F.C. Vojtik, A.C. Olson, J.M.

Ellefson, J.E. McCombs, H.K. Sreenath, P.G. Blommel, K.D. Seder,

B.T. Burns, H.V. Geetha, A.C. Harms, G. Sabat, M.R. Sussman, B.G.

Fox, G.N. Phillips Jr., High-throughput puri

Wcation and quality

assurance of Arabidopsis thaliana proteins for eukaryotic structural

genomics, J. Struct. Funct. Genomics 6 (2005) 143–147.

[15] Y. Kim, I. Dementieva, M. Zhou, R. Wu, L. Lezondra, P. Quartey, G.

Joachimiak, O. Korolev, H. Li, A. Joachimiak, Automation of protein

puri

Wcation for structural genomics, J. Struct. Funct. Genomics 5

(2004) 111–118.

[16] B.D. Santarsiero, D.T. Yegian, C.C. Lee, G. Spraggon, J. Gu, D. Scheibe,

D.C. Uber, E.W. Cornell, R.A. Nordmeyer, W.F. Kolbe, J. Jin, A.L.

Jones, J.M. Jaklevic, P.G. Schutlz, R.C. Stevens, An approach to rapid

crystallization using nanodroplets, J. Appl. Cryst. 35 (2002) 278–281.

[17] G. Snell, C. Cork, R. Nordmeyer, E. Cornell, G. Meigs, D. Yegian, J.

Jaklevic, J. Jin, R.C. Stevens, T. Earnest, Automated sample mounting

and alignment system for biological crystallography at a synchrotron

source, Structure (Camb.) 12 (2004) 537–545.

10

W. Peti, R. Page / Protein Expression and Puri

Wcation 51 (2007) 1–10

[18] A.E. Cohen, P.J. Ellis, M.D. Miller, A.M. Deacon, R.P. Phizackerley,

An automated system to mount cryo-cooled protein crystals on a syn-

chrotron beamline, using compact sample cassettes and a small-scale

robot, J. Appl. Cryst. 35 (2002) 720–726.

[19] A. Dummler, A.M. Lawrence, A. de Marco, Simpli

Wed screening for

the detection of soluble fusion constructs expressed in E. coli using a

modular set of vectors, Microb. Cell Fact. 4 (2005) 34.

[20] P.B. Card, K.H. Gardner, Identi

Wcation and optimization of protein

domains for NMR studies, Methods Enzymol. 394 (2005) 3–16.

[21] S. Graslund, M. Eklund, R. Falk, M. Uhlen, P.A. Nygren, S. Stahl, A

novel a

Ynity gene fusion system allowing protein A-based recovery

of non-immunoglobulin gene products, J. Biotechnol. 99 (2002) 41–

50.

[22] R.K. Knaust, P. Nordlund, Screening for soluble expression of recom-

binant proteins in a 96-well format, Anal. Biochem. 297 (2001) 79–85.

[23] F.W. Studier, Protein production by auto-induction in high density

shaking cultures, Protein Expr. Purif. 41 (2005) 207–234.

[24] T. Mustelin, L. Tautz, R. Page, Structure of the hematopoietic tyro-

sine phosphatase (HePTP) catalytic domain: structure of a KIM

phosphatase with phosphate bound at the active site, J. Mol. Biol. 354

(2005) 150–163.

[25] A. Savchenko, A. Yee, A. Khachatryan, T. Skarina, E. Evdokimova,

M. Pavlova, A. Semesi, J. Northey, S. Beasley, N. Lan, R. Das, M.

Gerstein, C.H. Arrowmith, A.M. Edwards, Strategies for structural

proteomics of prokaryotes: quantifying the advantages of studying

orthologous proteins and of using both NMR and X-ray crystallogra-

phy approaches, Proteins 50 (2003) 392–399.

[26] J.M. Canaves, R. Page, R.C. Stevens, Protein biophysical properties

that correlate with crystallization success in Thermotoga maritima:

maximum clustering strategy for structural genomics, J. Mol. Biol.

344 (2004) 977–991.

[27] C.S. Goh, N. Lan, S.M. Douglas, B. Wu, N. Echols, A. Smith, D. Mil-

burn, G.T. Montelione, H. Zhao, M. Gerstein, Mining the structural

genomics pipeline: identi

Wcation of protein properties that aVect high-

throughput experimental analysis, J. Mol. Biol. 336 (2004) 115–130.

[28] L. Jaroszewski, L. Rychlewski, Z. Li, W. Li, A. Godzik, FFAS03: a

server for pro

Wle–proWle sequence alignments, Nucleic Acids Res. 33

(2005) W284–W288.

[29] L.J. McGu

Yn, K. Bryson, D.T. Jones, The PSIPRED protein struc-

ture prediction server, Bioinformatics 16 (2000) 404–405.

[30] K. Peng, S. Vucetic, P. Radivojac, C.J. Brown, A.K. Dunker, Z. Obra-

dovic, Optimizing long intrinsic disorder predictors with protein evo-

lutionary information, J. Bioinform. Comput. Biol. 3 (2005) 35–60.

[31] L.M. Iakoucheva, A.K. Dunker, Order, disorder, and

Xexibility: pre-

diction from protein sequence, Structure 11 (2003) 1316–1317.

[32] L.M. Guzman, D. Belin, M.J. Carson, J. Beckwith, Tight regulation,

modulation, and high-level expression by vectors containing the arab-

inose PBAD promoter, J. Bacteriol. 177 (1995) 4121–4130.

[33] T. Mustelin, L. Tautz, R. Page, The structure of the hematopoietic tyro-

sine phosphatase catalytic domain, J. Mol. Biol. 354 (2005) 150–163.

[34] M.S. Keller, W. Peti, NMR assignment of the Spinophilin PDZ

domain (493–602), J. Biomol. NMR 34 (2006).

[35] S. Nallamsetty, D.S. Waugh, Solubility-enhancing proteins MBP and

NusA play a passive role in the folding of their fusion partners, Pro-

tein Expr. Purif. 45 (2006) 175–182.

[36] R.B. Kapust, D.S. Waugh, Escherichia coli maltose-binding protein is

uncommonly e

Vective at promoting the solubility of polypeptides to

which it is fused, Protein Sci. 8 (1999) 1668–1674.

[37] D.S. Waugh, Making the most of a

Ynity tags, Trends Biotechnol. 23

(2005) 316–320.

[38] G.D. Davis, C. Elisee, D.M. Newham, R.G. Harrison, New fusion pro-

tein systems designed to give soluble expression in Escherichia coli,

Biotechnol. Bioeng. 65 (1999) 382–388.

[39] R.B. Kapust, J. Tozser, J.D. Fox, D.E. Anderson, S. Cherry, T.D.

Copeland, D.S. Waugh, Tobacco etch virus protease: mechanism of

autolysis and rational design of stable mutants with wild-type cata-

lytic pro

Wciency, Protein Eng. 14 (2001) 993–1000.

[40] R.B. Kapust, D.S. Waugh, Controlled intracellular processing of

fusion proteins by TEV protease, Protein Expr. Purif. 19 (2000) 312–

318.

[41] T. Cornvik, S.L. Dahlroth, A. Magnusdottir, M.D. Herman, R.

Knaust, M. Ekberg, P. Nordlund, Colony

Wltration blot: a new screen-

ing method for soluble protein expression in Escherichia coli, Nat.

Methods 2 (2005) 507–509.

[42] S.A. Lesley, P. Kuhn, A. Godzik, A.M. Deacon, I. Mathews, A.

Kreusch, G. Spraggon, H.E. Klock, D. McMullan, T. Shin, J. Vincent,

A. Robb, L.S. Brinen, M.D. Miller, T.M. McPhillips, M.A. Miller, D.

Scheibe, J.M. Canaves, C. Guda, L. Jaroszewski, T.L. Selby, M.A. Els-

liger, J. Wooley, S.S. Taylor, K.O. Hodgson, I.A. Wilson, P.G. Schultz,

R.C. Stevens, Structural genomics of the Thermotoga maritima prote-

ome implemented in a high-throughput structure determination pipe-

line, Proc. Natl. Acad. Sci. USA 99 (2002) 11664–11669.

[43] R.L. Alexander, R.G. Smith, Production of plasmid DNA in a simple,

inexpensive and reusable fermentor, Biotechniques 9 (1990) 358–361.

[44] C.T. Lin, P.A. Moore, D.L. Auberry, E.V. Landorf, T. Peppler, K.D.

Victry, F.R. Collart, V. Kery, Automated puri

Wcation of recombinant

proteins: combining high-throughput with high yield, Protein Expr.

Purif. (2005).

[45] W. Peti, T. Herrmann, O. Zagnitko, S.K. Grzechnik, K. Wuthrich,

NMR structure of the conserved hypothetical protein TM0979 from

Thermotoga maritima, Proteins 59 (2005) 387–390.

[46] H.K. Sreenath, C.A. Bingman, B.W. Buchan, K.D. Seder, B.T. Burns,

H.V. Geetha, W.B. Jeon, F.C. Vojtik, D.J. Aceti, R.O. Frederick, Pro-

tocols for production of selenomethionine-labeled proteins in 2-L

polyethylene terephthalate bottles using auto-induction medium, Pro-

tein Expr. Purif. 40 (2005) 256–267.

[47] R.C. Tyler, H.K. Sreenath, S. Singh, D.J. Aceti, C.A. Bingman, J.L.

Markley, B.G. Fox, Auto-induction medium for the production of [U-

15N]- and [U-13C, U-15N]-labeled proteins for NMR screening and

structure determination, Protein Expr. Purif. 40 (2005) 268–278.

Document Outline

- Strategies to maximize heterologous protein expression in Escherichia coli with minimal cost

- New approaches to construct identification

- Parallel cloning into new vectors with novel fusion tags to maximize the likelihood of soluble protein expression in E. coli

- Microexpression screening prior to scale-up

- New methods for increasing cell culture densities during large-scale expression and improving soluble lysis

- Conclusions

- Acknowledgments

- References

Wyszukiwarka

Podobne podstrony:

Strategies for optimizing heterologous protein expression in E coli

Molecular chaperones involved in heterologous protein expression in E coli

Advanced genetic strategies for recombinant protein expression in E coli

Strategies for achieving high level expression in E coli

Rapid and efficient purification and refolding of a (His) tagged recombinant protein produced in E c

Tuning different expression parametres to achive solube recombinant proteins in E coli

Overview of bacterial expression systems for heterologous protein production from molecular and bioc

Expression of correctly folded proteins in E coli

Method for enhancing solubility of the expressed recombinant protein in E coli

Production of recombinant proteins in E coli

Protein Degradation in the Large Intestine Relevance to Colorectal Cancer

Secretory production of recombinant proteins in E coli

A Guide to the Law and Courts in the Empire

A Surgical Safety Checklist to Reduce Morbidity and Mortality in a Global Population

Natural Strategies to Kill Cancer

Peripheral clock gene expression in CS mice with

How to Change Your Life Around in 30 days

Strategie doboru partnera heteroseksualnego

Zarzadzanie strategiczne - sciaga z wykladow (1), Zarządzanie strategiczne- to dysponowanie zasobami

więcej podobnych podstron