Biomaterials 23 (2002) 1353–1357

Bioactive titania gel layers formed by chemical treatment of Ti

substrate with a H

2

O

2

/HCl solution

Xiao-Xiang Wang

a,

*, Satoshi Hayakawa

b

, Kanji Tsuru

b

, Akiyoshi Osaka

b

a

Department of Materials Science and Engineering, Zhejiang University, Hangzhou 310027, China

b

Biomaterials Laboratory, Faculty of Engineering, Okayama University, Tsushima-Naka, Okayama-shi 700-8530, Japan

Received 30 January 2001; accepted 11 July 2001

Abstract

An amorphous titania gel layer was formed on the titanium surface after the titanium specimen was treated with a H

2

O

2

/0.1 m

HCl solution at 801C. The thickness of the gel layer increased almost linearly with the period of the treatment. A subsequent heat

treatment above 3001C transformed gradually the amorphous gel to the anatase crystal structure and the rutile started to appear

after heat treatment at 6001C. Meanwhile, the densification of the gel occurred significantly after heat treatment above 7001C.

Similar to the sol–gel derived titania gel coatings, titania gel layers obtained in the present study exhibited in vitro apatite deposition

ability after the gel layers exceeded a minimum thickness (0.2 mm) and was subsequently heated in a proper temperature range (400–

6001C). r 2002 Elsevier Science Ltd. All rights reserved.

Keywords:

Titanium; Surface modification; Apatite deposition; Bioactivity; Titania gel

1. Introduction

Titania and silica gels were able to induce the

formation of apatite when soaked in a simulated body

fluid (SBF) [1–4]. This property was considered as an

indication of bioactivity, the ability to bond with living

bone. Because the formation of a thin layer of apatite on

the implant surface was observed in in vivo experiments

and believed to be the first step of the bone bonding

process for the bioactive implants including silica and

titania gels [5,6]. Titania gel coating was therefore

considered to be one of the potential surface modifica-

tion techniques to improve the bioactivity of the

titanium implant and has been studied by several

researchers both in vitro and in vivo [1–3,6]. The

conventional sol–gel derived coatings are usually pro-

vided by dip-coating method that consists of several

coating–heating cycles to obtain necessary thickness for

apatite deposition and, thus, is quite time consuming

[1,2]. On the other hand, it was reported that titanium

could react with a H

2

O

2

solution and formed titania gel

[7,8]. Obviously, it could be a more convenient

technique for providing titania gel coating on titanium

substrate. The purpose of the present study was to

examine the microstructure and the in vitro bioactivity

of this gel layers.

2. Materials and methods

Specimens of 10 10 1 mm

3

in size were cut from a

sheet of commercially pure titanium and chemically

washed [9]. They were then chemically treated with a

solution containing 8.8 m H

2

O

2

and 0.1 m HCl (10 ml for

each specimen) at 801C for various time up to 1 h and

subsequently treated at various temperatures up to

8001C for 1 h in air atmosphere. Each of thus obtained

titanium specimens was immersed in 20 ml SBF of

Kokubo’s recipe [9–11] in a polystyrene vial. pHvalue

of the SBF was adjusted at 7.4 at 36.51C. After soaking

for various periods up to 7 days at 36.51C, the specimens

were gently washed with distilled water and dried in an

oven at 601C. The open surface of the specimen [11] was

examined by Fourier transform-infrared (FT-IR) reflec-

tion spectroscopy, scanning electron microscopy (SEM)

and low angle X-ray diffractometry (XRD). The FT-IR

reflection spectra were collected on a JASCO FT/IR-300

spectrometer with 100 scans at 4 cm

1

resolution using a

*Corresponding author. Fax: +86-571-795-1358.

E-mail address:

mse wangxx@dial.zju.edu.cn (X.-X. Wang).

0142-9612/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 2 5 4 - X

Spectra Tech attachment Model 501. Low angle XRD

patterns were recorded with a Rigaku RAD-II diffract-

ometer using Cu K

a

radiation operating under 40 kV

and 25 mA acceleration at an angle of incidence of 11.

SEM photographs were taken using a JEOL JSM-6300

microscope with the specimens being sputter coated with

a 20 nm gold layer.

3. Results

3.1. The formation of titania gel layers

The reaction between the Ti specimen and the H

2

O

2

solution resulted in the formation of a layer of

amorphous titania gel on the Ti surface. Shorter

chemical treatment time yielded a thinner gel layer with

premature porosity. After 20 min chemical treatment, a

titania gel layer of about 0.3 mm in thickness and with

mature porosity was obtained (Fig. 1a). The pores were

in the size of submicrometer. Further extending the

treatment time to 1 h resulted in a cracked thicker gel

layer with thickness of about 1 mm (Fig. 1b). The

thickness of the titania gel layers depended almost

linearly on the period of time of the chemical treatment

at the present treatment temperature (801C), as in-

dicated in Fig. 2. Subsequent heat treatment above

3001C transformed gradually the gel from amorphous to

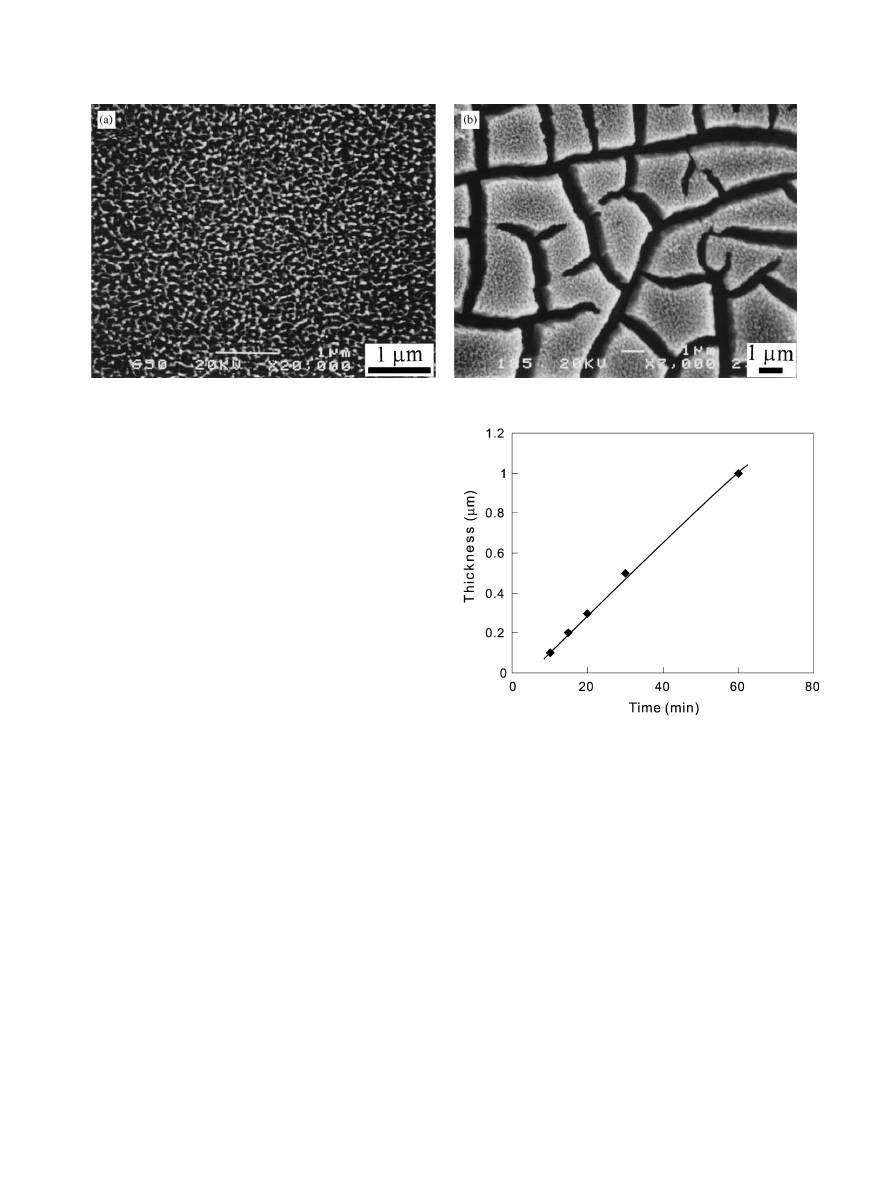

crystalline state. The XRD patterns in Fig. 3 exhibit the

transformation: the as-chemically treated amorphous

gel layer transformed mainly to anatase as the heat

treatment temperature was below 6001C while the rutile

became dominant above 7001C. The SEM observation

revealed that the subsequent heat treatment at tempera-

tures lower than 6001C hardly changed the morphology

of the pore of the gel layer. Large spherical particles of

titania started to appear after heat treatment at 7001C

(Fig. 4a), apparently due to the coalescence of small

particles. Further increasing the heating temperature to

8001C resulted in a fully densified titania layer (Fig. 4b).

3.2. The apatite deposition on the titania gel layers

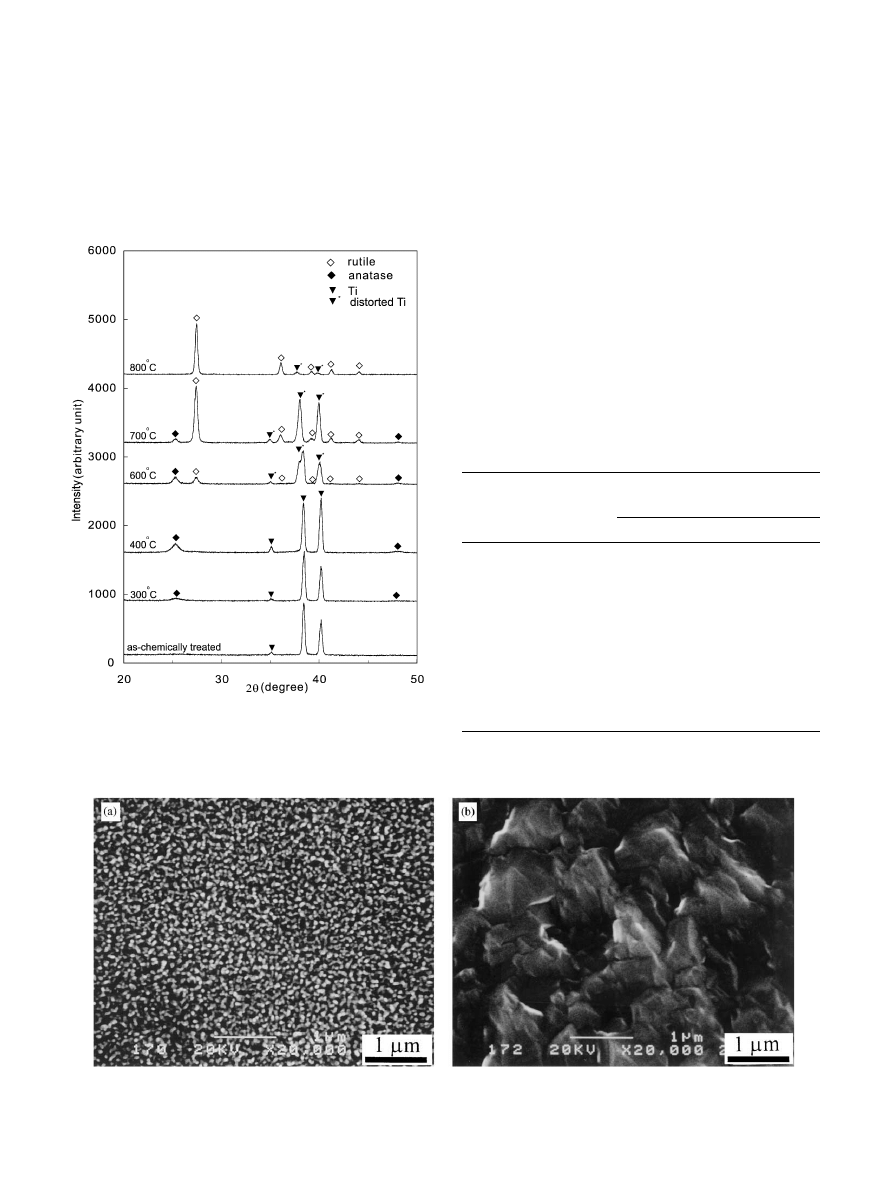

The correlation of apatite deposition ability with the

period of the chemical treatment and the temperature of

heat treatment is summarized in Table 1. Apatite

deposition was observed only with the specimens

chemically treated for longer than 15 min and heat

treated subsequently between 4001C and 6001C. Fig. 5

shows the SEM images of the apatite deposited on the

specimen subjected to the chemical treatment for 30 min

and subsequent heating at 4001C for 1 h. As we can see,

apatite particles scatter on the gel layer after 2 days of

soaking (Fig. 5a) and cover the whole surface after 5

days of soaking (Fig. 5b). These apatite particles have

the SEM morphology same as those deposited on

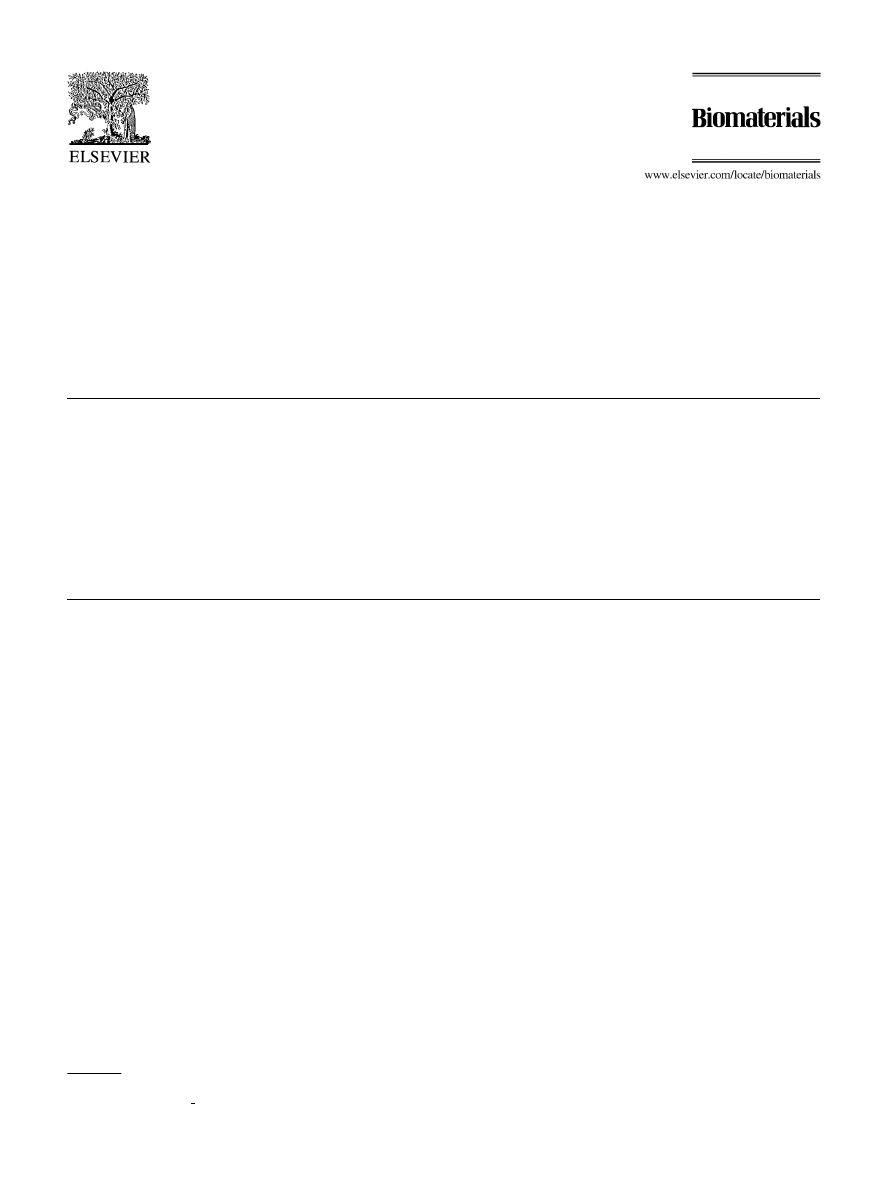

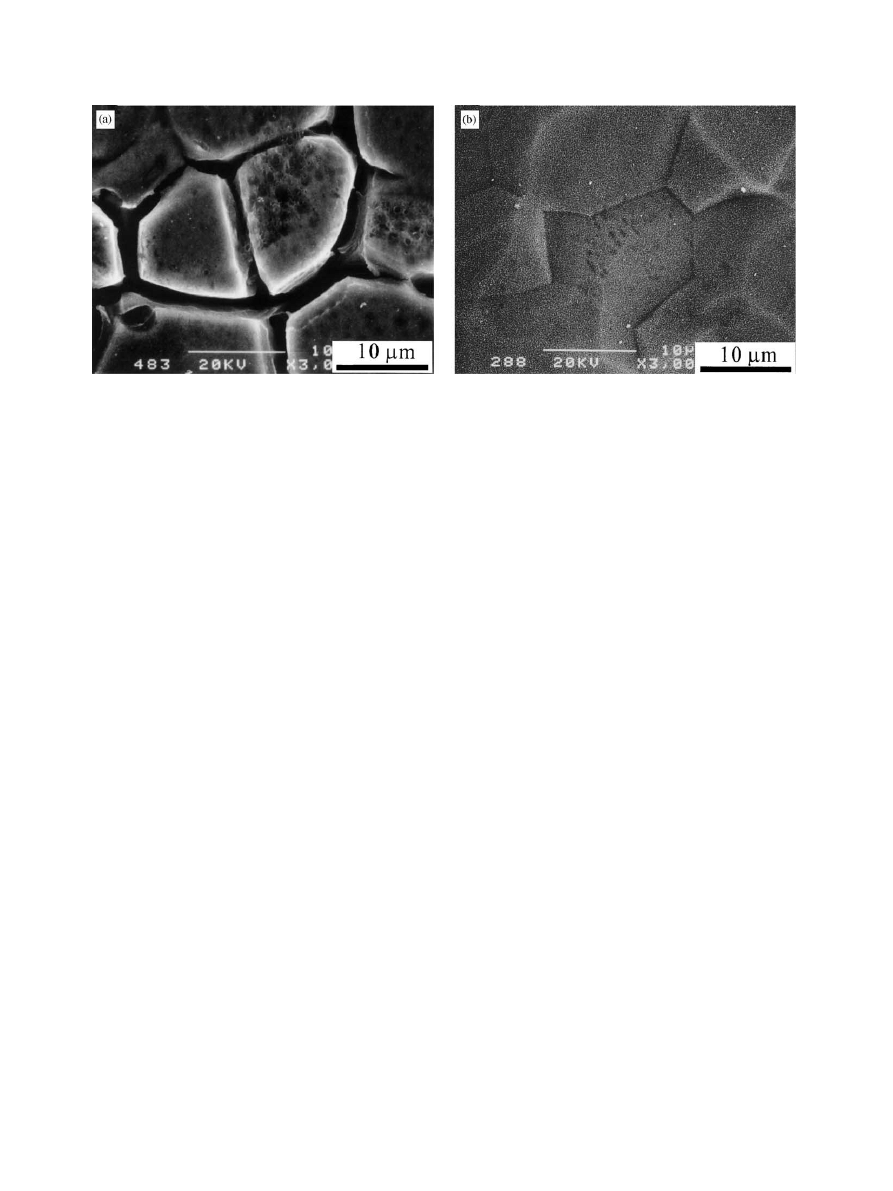

Fig. 1. SEM images of the titania gel layers formed on the Ti surfaces after treatment with the H

2

O

2

/HCl solution at 801C for (a) 20 min; (b) 60 min.

Fig. 2. The plot of the thickness of titania gel layers against the

periods of chemical treatment with H

2

O

2

/HCl solution at 801C.

X.-X. Wang et al. / Biomaterials 23 (2002) 1353–1357

1354

bioactive glass and conventional titania gel layers

[3,4,12]. XRD experimental results in Fig. 6 and FTIR

spectra (see Ref. [9]) indicate they are carbonate-

incorporated hydroxyapatite with low crystillinity, that

is bonelike apatite.

4. Discussion

The titania gel coatings, which are traditionally

derived by the sol–gel technique by hydrolysis of

titanium alkoxides, have been widely studied with

respect to bioactivity in recent years. Those sol–gel

derived coatings can induce apatite deposition in SBF if

the coating exceeds a certain thickness (about 200 nm

[2,13]) and experiences a subsequent heat treatment at a

proper temperature range (400–5501C [2]). In the

present study, we showed that the titania gel coatings

could be produced by the chemical treatment of

titanium with the H

2

O

2

/HCl solution. This titania gel

layers exhibited a similar behavior with respect to the

apatite deposition: a certain thickness and a subsequent

heat treatment are necessary for apatite to deposit. The

present technique is much simpler than the sol–gel

Fig. 4. SEM images of the titania gel layers on the Ti surfaces treated with the H

2

O

2

/HCl solution at 801C for 30 min and subsequently heat treated

at (a) 7001C and (b) 8001C for 1 h, indicating the change in morphology of the gel layers.

Fig. 3. XRD patterns of the specimens treated with the H

2

O

2

/HCl

solution at 801C for 30 min and subsequently heat treated at various

temperatures for 1 h, indicating the transformation of crystal structure

of the gels.

Table 1

Summary of apatite deposition, assessed with FTIR technique, on the

titanium surfaces after soaking in SBF for various time

Periods of

chemical

treatment (min)

a

Heat

treatment

(1C at 1 h)

Periods of soaking in SBF (days)

1

2

3

5

7

5

400

n

n

n

n

n

10

400

n

n

n

n

n

15

400

n

n

n

y

y

20

400

n

y

y

y

y

60

400

n

y

y

y

y

30

No

n

n

n

n

n

30

300

n

n

n

n

n

30

400

n

y

y

y

y

30

500

n

y

y

y

y

30

600

n

n

y

y

y

30

700

n

n

n

n

n

30

800

n

n

n

n

n

a

The chemical treatment was conducted with the H

2

O

2

/0.1 m HCl

solution at 801C.

X.-X. Wang et al. / Biomaterials 23 (2002) 1353–1357

1355

processing in which the reactions are difficult to control

due to the fast kinetics of the alkoxides of transition

metals and it would take several cycles of coating and

heating to attain a required thickness. In addition,

cracking and chipping prevailed in a sol–gel derived

titania gel coating of about 380 nm in thickness [2,13]

whereas the gel layers of less than 0.5 mm in thickness

formed after the chemical treatment of shorter than

30 min in the present study did not show any cracking

and chipping, suggesting that the gel layer derived by the

chemical treatment in the present study may have

stronger adhesion to the titanium substrate than the

sol–gel-derived coating. Therefore, it may be concluded

that the H

2

O

2

treatment is a superior technique over the

traditional sol–gel coating technique in producing

bioactive titania gel coatings on titanium surfaces.

The present experimental results showed that the

titania gel heated between 4001C and 5001C and thus

with anatase crystal structure exhibited excellent bioac-

tivity. Increasing heating temperature resulted in in-

creasing amount of rutile in the gel and the deterioration

of the bioactivity. This phenomenon, however, does not

necessarily mean the titania gel with rutile crystal

structure would lack bioactivity because the densifica-

tion of the gel occurred concurrently when the heat

treatment temperature was raised above 6001C. It is well

known that the porosity is critical for a gel to show

bioactivity. Li [3] has shown that dense single crystal

anatase lacked bioactivity although the porous one

could induce apatite deposition. It follows that the

densification of the gel after the heat treatment above

6001C should contribute to the deterioration of the

bioactivity in the present case. Under this condition, it is

unclear how and to what extent the formation of rutile

in the gel affected the bioactivity. In this regard, further

investigation is required into the effect of crystal

structure of the titania gel on the bioactivity.

Although the mechanism of the titania gel formation

through the reaction between titanium metal and H

2

O

2

solution has not been studied yet in present study and

thus is not well understood, we found the value of pHof

the H

2

O

2

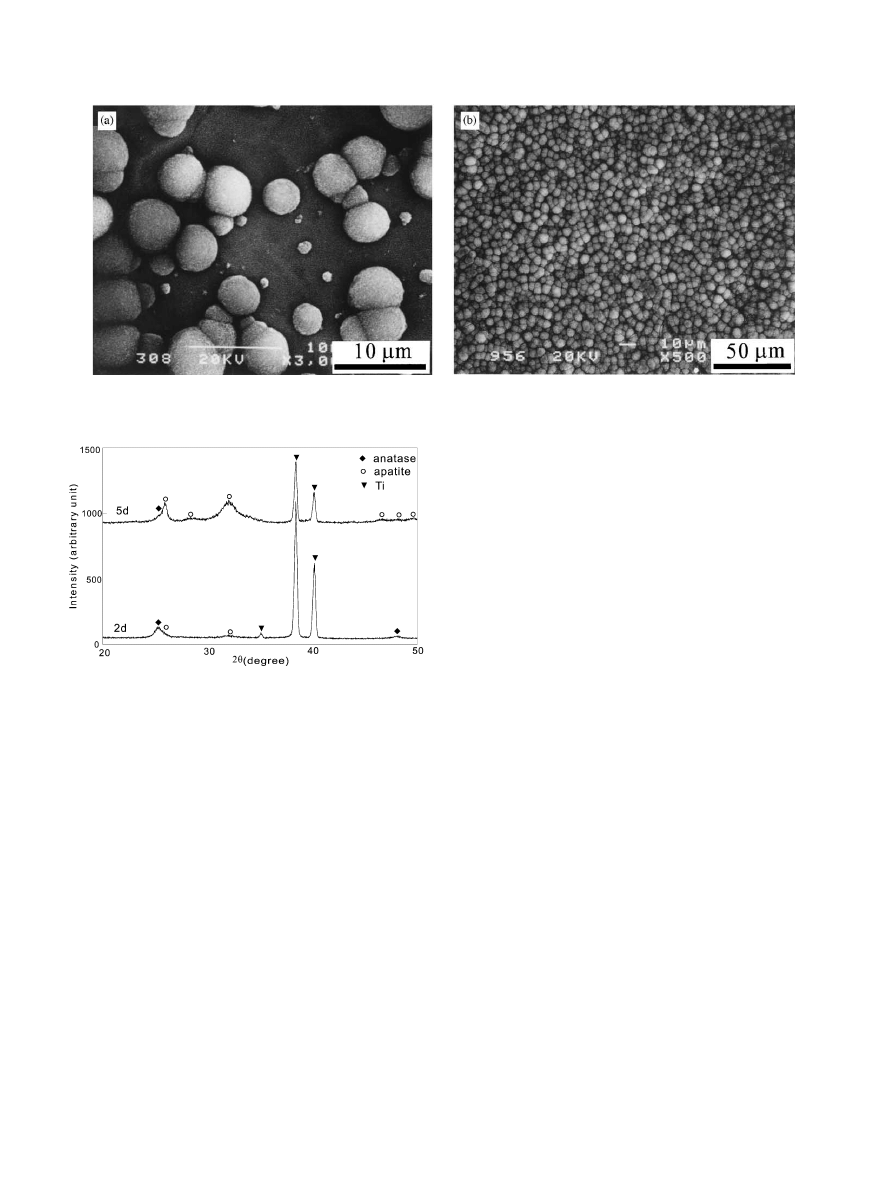

solution had an effect on the gel formation. An

acidic H

2

O

2

solution by addition of HCl could speed up

the reaction and produce a clear gel morphology with

the pore size uniform all over the specimen surface (see

Figs. 1 and 7b). Another important factor involved in

this treatment is temperature. Lower temperature

tended to cause intergranular corrosion of the titanium

substrate before a certain thickness of titania gel layer

was formed, as shown in Fig. 7a in which the specimen

was treated at 251C for 1 day in the same solution. In

contrast, higher temperature can ensure the reaction to

take place uniformly all over the titanium surface, as

shown in Fig. 7b. Because intergranular corrosion on

the surface will damage severely the fatigue property of

the titanium implants, a higher temperature, as the

temperature of 801C chosen in the present study, was

Fig. 5. SEM images of apatite particles deposited on the Ti surfaces after soaked in SBF for (a) 2 days and (b) 5 days. The Ti surfaces have been

treated with the H

2

O

2

/HCl solution at 801C for 30 min and subsequently heat treated at 4001C for 1 h.

Fig. 6. XRD patterns of the specimens after soaking in SBF for 2 and

5 days. The Ti specimens have been chemically treated with the H

2

O

2

/

HCl solution at 801C for 30 min and subsequently heat treated at

4001C for 1 h.

X.-X. Wang et al. / Biomaterials 23 (2002) 1353–1357

1356

critical for the treatment of titanium implant in the

practical application of this treatment.

5. Conclusions

An amorphous titania gel layer was formed by the

treatment of Ti with the H

2

O

2

/0.1 m HCl solution. The

thickness of the gel layer was controllable through the

periods of the treatment. The subsequent heat treatment

above 3001C transformed the gel to anatase. Rutile was

dominant as the heating temperature was raised to

between 7001C and 8001C, meanwhile the densification

of the gel occurred significantly. The minimum thickness

of the titania gel layer and the optimal temperature of

heat treatment are about 0.2 mm and 400–5001C,

respectively, with respect to bioactivity.

Acknowledgements

One of the authors, X.X. Wang, gratefully acknowl-

edges the financial support of the Venture Business

Laboratories (VBL) in the Graduate School of Natural

Sciences of Okayama University. This work was

performed when XXW was on leave from Department

of MSE of Zhejiang University, China. A part of this

work was supported by Mikiya Science Foundation and

RSP-activity of Okayama Prefecture, sponsored by the

Science and Technology Agency of Japan.

References

[1] Li P, Kangasniemi I, DeGroot K, Kokubo T. Bone hydro-

xyapatite induction by a gel-derived titania on a titanium

substrate. J Am Ceram Soc 1994;77:1307–12.

[2] Peltola T, Patsi M, Rahiala H, Kangasiemi I, Yli-Urpo A.

Calcium phosphate induction by sol–gel-derived titania coatings

on titanium substrates in vitro. J Biomed Mater Res 1998;41:

504–10.

[3] Li P, Ohtsuki C, Kokubo T, Nakanishi K, Soga N, DeGroot K.

The role of hydrated silica, titania, and alumina in inducing

apatite on implants. J Biomed Mater Res 1994;28:7–14.

[4] Peltola T, Jokinen M, Rahiala H, Levanen E, Rosenholm JB,

Kangasiemi I, Yli-Urpo A. Calcium phosphate formation on

porous sol–gel-derived SiO

2

and CaO–P

2

O

5

–SiO

2

substrates

in vitro. J Biomed Mater Res 1999;44:12–21.

[5] Li P, Ye X, Kangasniemi I, DeBlieck-Hogervorst JMA,

Klein CPAT, DeGroot K. In vivo calcium phosphate formation

induced by sol–gel-prepared silica. J Biomed Mater Res

1995;29:325–8.

[6] Li P, DeGroot K. Calcium phosphate formation within sol–gel

prepared titania in vitro and in vivo. J Biomed Mater Res 1993;

27:1495–500.

[7] Tengvall P, Lundstrom I, Sjoqvist L, Elwing H. Titanium–

hydrogen peroxide interaction: model studies of the influence of

the inflammatory response on titanium implants. Biomaterials

1989;10:166–75.

[8] Tengvell P, Elwing H, Lundstrom I. Titanium gel made from

metallic titanium and hydrogen peroxide. J Colloid Interface Sci

1989;130:405–13.

[9] Wang XX, Hayakawa S, Tsuru K, Osaka A. Improvement of

bioactivity of H

2

O

2

/TaCl

5

-treated titanium after subsequent heat

treatments. J Biomed Mater Res 2000;52:171–6.

[10] Hench LL. Characterization of bioceramics. In: Hench LL,

Wilson J, editors. An introduction to bioceramics. Singapore:

World Science, 1993. p. 319–34.

[11] Wang XX, Hayakawa S, Tsuru K, Osaka A. A comparative study

of in vitro apatite deposition on heated-, H

2

O

2

-, and NaOH-

treated titanium substrates. J Biomed Mater Res 2001;54:

172–8.

[12] Vallet-Regi M, Romero AM, Ragel CV, LeGeros RZ. XRD,

SEM-EDS, and FTIR studies of in vitro growth of an apatite-like

layer on sol–gel glasses. J Biomed Mater Res 1999;44:416–21.

[13] Jokinen M, Patsi M, Rahiala H, Peltola T, Ritala M, Rosenholm

JB. Influence of sol and surface properties on in vitro bioactivity

of sol–gel-derived TiO

2

and TiO

2

–SiO

2

films deposited by dip-

coating method. J Biomed Mater Res 1998;42:295–302.

Fig. 7. SEM images of the Ti surfaces after treatment with the H

2

O

2

/HCl solution at (a) 251C for 1 day and (b) 801C for 30 min, showing the severe

intergranular corrosion for the former and uniform titania gel layer without intergranular corrosion for the latter.

X.-X. Wang et al. / Biomaterials 23 (2002) 1353–1357

1357

Wyszukiwarka

Podobne podstrony:

Osteoinduction of porous bioactive titanium metal

Preparation of bioactive titanium metal via anodic oxidation

[38]QUERCETIN AND ITS DERIVATIVES CHEMICAL STRUCTURE AND BIOACTIVITY – A REVIEW

titanic wordsearch

Titanic Secondclass crossword

Titanic?cts and Figures

titanik plyvet

Titanic

Informacje o titanicu i jego katastrofie

Titanic Firstclass Passengers

MECHANICAL PROPERTIES TITANIUM

Nowy Titanic

Titanic Lifeboats crossword

Titanic Blame crossword

titanic quiz

was titanic unsinkable

titanic crossword

Ladley, Titania You’ve Got Irish Male!

Titanic bogów atlantyda, Atlantyda

więcej podobnych podstron