Journal of Archaeological Science (1999) 26, 1127–1133

Article No. jasc.1999.0408, available online at http://www.idealibrary.com on

Determining the Technological Origins of Iron and Steel

David Starley

Ancient Monuments Laboratory, English Heritage, 23 Savile Row, London, WIX 1AB, U.K.

The potential for identifying the technology of production of iron artefacts is investigated through the examination of

two series of well-dated iron samples. Compositional variations were investigated in both the metal matrices, using

scanning electron microscope (SEM)-based wavelength dispersive analysis, and in the slag inclusions by an energy

dispersive detector. This combination of data allowed the partitioning of elements between the two phases to be

calculated, providing a measure of furnace conditions. A first study looked at high quality iron and steel from the Late

Mediaeval and Renaissance, through the analysis of 60 samples from 44 plate armours. A change to the use of superior

steels by south German and English armourers from

1500 is suggested to derive from the high bloomery smelting

process, on the basis of the partitioning of manganese. More recent work examined architectural ironwork with the aim

of investigating 18th and 19th century innovative coke-fired reverberatory processes for the conversion of cast iron to

wrought iron. The results have now been tested against previously suggested models for the composition of these alloys.

1999 Academic Press

Keywords: IRON, SLAG, INCLUSION, ARMOUR, ARCHITECTURAL, FINING, PUDDLING.

Introduction

F

rom the Late Mediaeval through the industrial

period, iron and steel production and trade were

of major importance to the economies of both

the increasingly specialized iron-producing regions of

Europe and the many nations heavily dependent on

imports. This continent-wide trade pattern shifted,

often as a result of technological innovations. Two

particularly significant changes were the move from

direct (bloomery) iron and steel to indirect (blast

furnace/finery) alloys and the change from charcoal to

coke as fuel for furnaces and hearths of the industry.

Iron smelting technology in Europe followed three

broad traditions. The bloomery or ‘‘direct’’ process.

had developed from, but retained essentially the same

principles as, the earliest furnaces. This was a batch

operation in which each smelt was terminated to

remove the solid bloom. The iron, although containing

considerable slag as inclusions, was su

fficiently low in

carbon (ferritic iron or steel) that it could be worked

without further treatment, apart from the expulsion of

slag during forging. From the Late Mediaeval period

the blast furnace became increasingly important with

the sole product being cast iron; this typically had a

much higher carbon content, above 2·5% and was not

malleable. The third technique, often considered as

intermediate between the other two, was the high

bloomery (stu¨ckofen) which allowed the flexibility to

produce either cast iron or malleable alloys, the latter

being noted (

) for their steely nature.

Whilst the casting of objects direct from the furnace

was often an attractive option, the greater need

continued to be for malleable iron and a series of

conversion processes were developed to decarburize

cast iron. Until the 18th century this was achieved by

remelting in a finery, a highly oxidizing charcoal-fired

hearth. However, through that century other tech-

niques were developed based on the use of reverber-

atory furnaces which, by separating the fuel and iron,

allowed coal or coke to be used as fuel without

excessive transfer of sulphur to the metal (

). A patent by John Wood in 1761

involved fining of cast iron with coal followed by

granulation and heating with flux in crucibles in a

reverberatory furnace. The term stamping and potting

was applied to this and similar processes operating

around this date. In 1783 Cort patented what became

known as the dry puddling process. This dispensed

with use of a separate finery hearth and decarburized

the cast iron on a bed of sand in a reverberatory

furnace. The originality of his method was the subject

of a lawsuit and there is reason to believe aspects of his

process were not without precedent (ibid.). A further

development, beyond 1816, was wet puddling, in which

the furnace bottom was lined with iron plates protected

by furnace cinder. This allowed a slag bath to build up

which very e

ffectively oxidized elements from the cast

iron. These developments, together with the use of

coke in blast furnaces, were crucial for the continued

expansion of the British iron industry, previously

hindered by high charcoal costs. From 1720, when

more bar iron was imported than produced, the

country had become a net exporter by the end of the

century (

Despite the diversity of production methods, the

range of ‘‘wrought iron’’ products have proved

remarkably di

fficult to differentiate. Reasons include

1127

0305–4403/99/081127+07 $30.00/0

1999 Academic Press

the heterogeneity within samples, the very low levels of

trace elements which might be co-smelted with the

iron, and the great variation in the composition of

ores, fluxes and inadvertently added compounds, such

as those deriving from furnace linings. Previous

approaches to the subject have compared slag inclu-

sions within the iron to bulk slags recovered from

production centres (

) and

against archival iron samples (

). How-

ever, for many of the less well-known processes, reli-

ably identified residues are not yet available. Without

such material of known technological provenance, the

work described below adopted a methodology of

examining large groups of artefacts, reliably dated

across a broad period of time. Compositional changes

observed in the data were matched against historically

known details of production methods.

Partitioning of Elements

The approach of this study is to consider the behaviour

of di

fferent elements in the alternative processes,

particularly those elements which tend to partition

between the metal and slag phases. This di

fference is

unlikely to a

ffect those elements which always pass into

the slag: potassium, sodium, calcium and magnesium,

or those that are invariably reduced into the iron:

copper, nickel and cobalt. However, for certain ele-

ments (phosphorus, manganese, sulphur and silicon)

the degree to which they are reduced into the metal will

depend on furnace temperature. Sulphur’s detrimental

e

ffect on iron is such that high-sulphur raw materials

were avoided by smelters. Silicon is only likely to be

reduced into the cast iron at high temperatures, cer-

tainly when coke is used as fuel, but is removed rapidly

during the early stages of fining. A large proportion of

phosphorus will be reduced into the iron but the

tendency for the element to di

ffuse between metal and

inclusions during hot working makes it a less suitable

identifier of smelting technology.

Manganese is potentially a reliable indicator of

smelting conditions. The e

ffect of temperature on

the reduction of manganese has been discussed by

. Their calculations, which

assume the activity of carbon to be unity and the

partial pressure of carbon monoxide to be one atmos-

phere, suggest that a rise from 1327 to 1527

C would

increase the recovery of manganese 11-fold. Hence,

given similar ores, cast iron from the higher tempera-

ture blast furnace might be expected to contain levels

of manganese an order of magnitude greater than

would be expected from a bloomery.

The subsequent e

ffect of the fining processes on the

dissolved elements is dramatic. In the conversion pro-

cesses silicon in the pig iron oxidizes most rapidly;

followed in succession by manganese, phosphorus then

carbon. Thus, a high proportion of any manganese and

phosphorus present will oxidize into the finery/

puddling slag. Their final content there will be depen-

dent not only on the amount of the two elements in the

cast iron but also on the bulk of slag present and

the extent to which other materials were added (par-

ticularly hammerscale and haematite ore during wet

puddling). However, it would appear likely that slag

from the decarburizing processes would contain

very significantly elevated levels of manganese and

phosphorus.

Examination and Analysis

After mounting and preparation, metallographic

examination was carried out to allow carbon content,

grain size, inclusion content and any heat treatment of

samples to be assessed.

shows a typical

microstructure of wrought iron, with a high slag inclu-

sion content and little if any carbon in the metal.

Microanalysis of the samples used scanning electron

microscope (SEM) based techniques. The metal

matrices were analysed using a wavelength dispersive

detector, which with detection limits such as 0·004 wt%

for phosphorus and 0·009 wt% for manganese was

su

fficiently sensitive to detect trace levels of impurities

present. Slag inclusion analysis utilized a faster but

less sensitive energy dispersive detector to provide

quantitative analysis of all elements present with

atomic number greater than oxygen. Inclusion size was

recorded during analysis to enable a check on one

possible source of error; elements such as phosphorus

are known to di

ffuse between inclusions and the metal

during hot working and it might be expected that the

composition of small inclusions, with high surface area

to volume ratio, would be more significantly changed

as a result. However, no significant link between

inclusion size and composition was identified.

Study 1. Technological Origins of Iron and

Steel in European Plate Armour

This research (

investigated 44 plate

armours of 14th to 17th century date from the

Figure 1. Micrograph of sample from staircase upright, Coventry

Hall, Streatham 1800. Etched in nital

100.

1128 D. Starley

collections of the Royal Armouries in HM Tower of

London. The project aimed to use this well-preserved,

remarkably closely dated, material to identify a change

from the use of bloomery iron to blast furnace/finery

products. The research was carried out against the

widely held view of art historians that the 15th century

comprised the ‘‘great period’’ of plate armour and that

little significant later development occurred. Metallo-

graphic examination revealed a di

fferent picture. The

major armour-producing centre of south Germany

(together with the English Greenwich Armoury

which employed German craftsmen) began, from the

early 16th century, to utilize remarkably homogenous

steel, subsequently heat treated to optimize its

e

ffectiveness.

Microanalyses of the iron show this later German

material to be uniformly high in manganese (averaging

0·04 wt%) and low in phosphorus compared with ear-

lier German and Italian material of both periods

). The date for this change coincides with the

expansion of the blast furnace, particularly in the Low

Countries (

). However the data from analy-

sis of more than 700 inclusions show that manganese

levels in inclusions from these late German armours

are not significantly higher than those for other

samples, giving rise to relatively low partition coef-

ficients (wt% in slag/wt% in metal). These results

suggest that the final process in which the slag inter-

acted with the metal was, relative to the bloomery,

more reducing. It was therefore concluded that this

material most probably derived from the high

bloomery rather than the highly oxidizing finery. For

this specialized product at least, the demand for high

quality metal took precedence over any economic

incentive to use mass produced iron from the indirect

process.

Study 2. Converting Processes for

Architectural Wrought Iron

Architectural ironwork shares two advantages with

armour as a source of samples. Firstly, samples may be

dated with precision unattainable in archaeologically

recovered artefacts and secondly, corrosion is rarely a

problem. Furthermore, it is more representative of

bulk iron production, importation and use than

specific artefacts and it potentially provides a very wide

date range. In this study samples of ‘‘wrought iron’’,

mainly from the Architectural Study Collection of

English Heritage, were investigated for compositional

changes, particularly those which could be associated

with the innovative 18th and 19th century conver-

sion processes which had such a dramatic e

ffect on

the expansion of the British iron industry and the

industrial revolution in general.

discuss the characteris-

tics of bulk slags from the wide range of iron conver-

sion processes operating through this period.

examined dry puddling slags and con-

cluded that it was possible to distinguish these from

finery and bloomery slags on the basis of microstruc-

tural constituents. Neither of these studies extended to

the consideration of the evidence for stamping and

potting, although the economic importance of these

processes was recognized in stating that they were

responsible for half the production of bar iron in

Britain by 1780 (ibid.).

A major di

fficulty with any study of historical iron-

working debris is the scarcity of reference material

for which the production process is known with

certainty. Like the study of armour this research used

samples, for which the technology of production was

unknown, but which were closely dated; in this case

from their architectural contexts. It is strictly only

possible to say whether a sample predates a specific

technique. The recycling of old iron and the continued

supply of iron from more traditional techniques will

inevitably lead to a blurred transition rather than an

immediate displacement of old by new. However,

unlike the study of the specialized production of steel

armour the choice of architectural ironwork should

more closely reflect the availability of bulk iron at

any particular time. Considering the major economic

importance of the processes of interest, very extensive

sampling should not be necessary to ensure that

material from the full range of techniques will be

represented.

A large proportion of the samples reported on here

are from the later 18th century but some undoubted

bloomery samples date from as early as 1200 and some

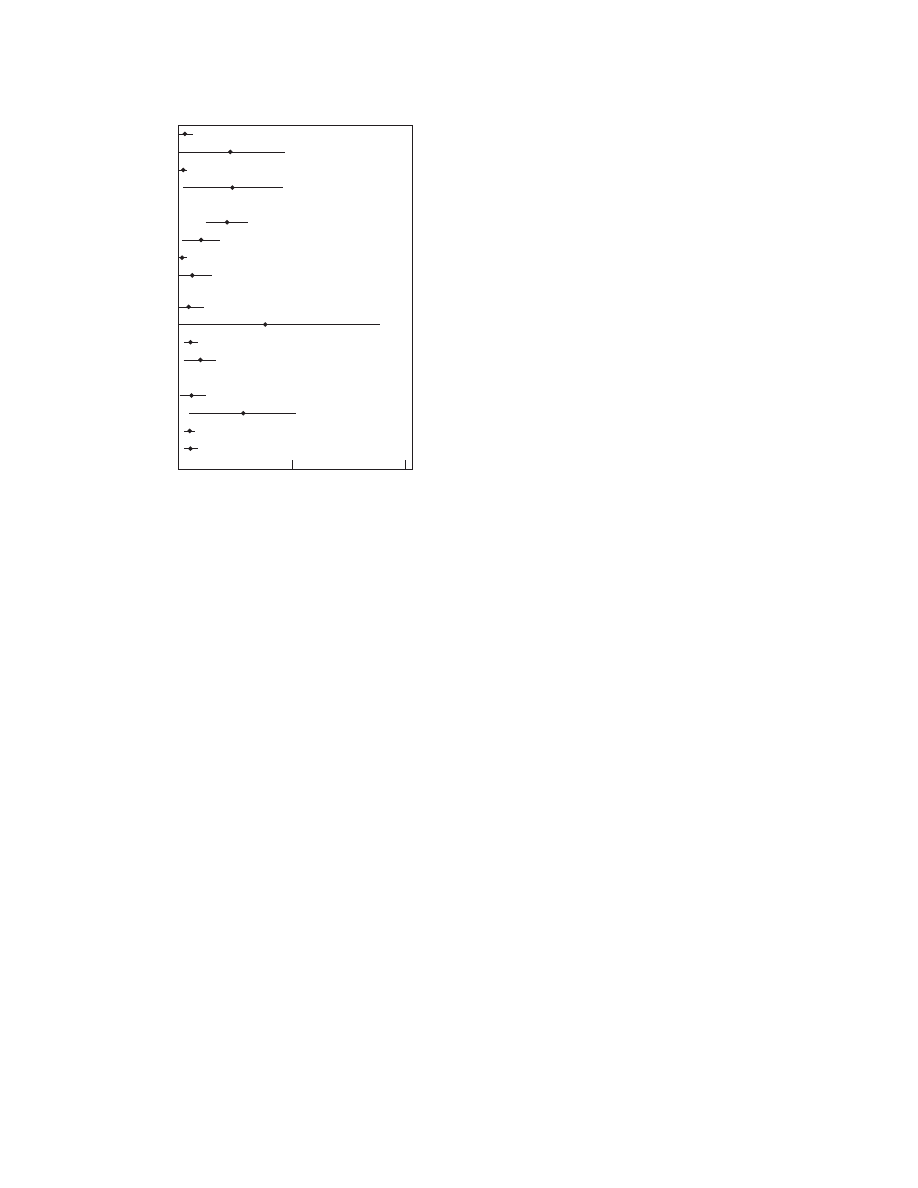

Mn

Mean matrix analysis (wt%)

±

1

σ

North Italian

P

S

Ni

South German

and Greenwic

h

0

0.1

0.2

Before

1500

After

1500

Mn

P

S

Ni

Mn

P

S

Ni

Before

1500

After

1500

Mn

P

S

Ni

Figure 2. Mean (

one standard deviation) levels of manganese,

phosphorus, sulphur and nickel in the metal of the armour samples.

Determining the Technological Origins of Iron and Steel 1129

ornamental ironwork is from the last decade of the

19th century. Material was generally obtained from

buildings whose history was well documented and a

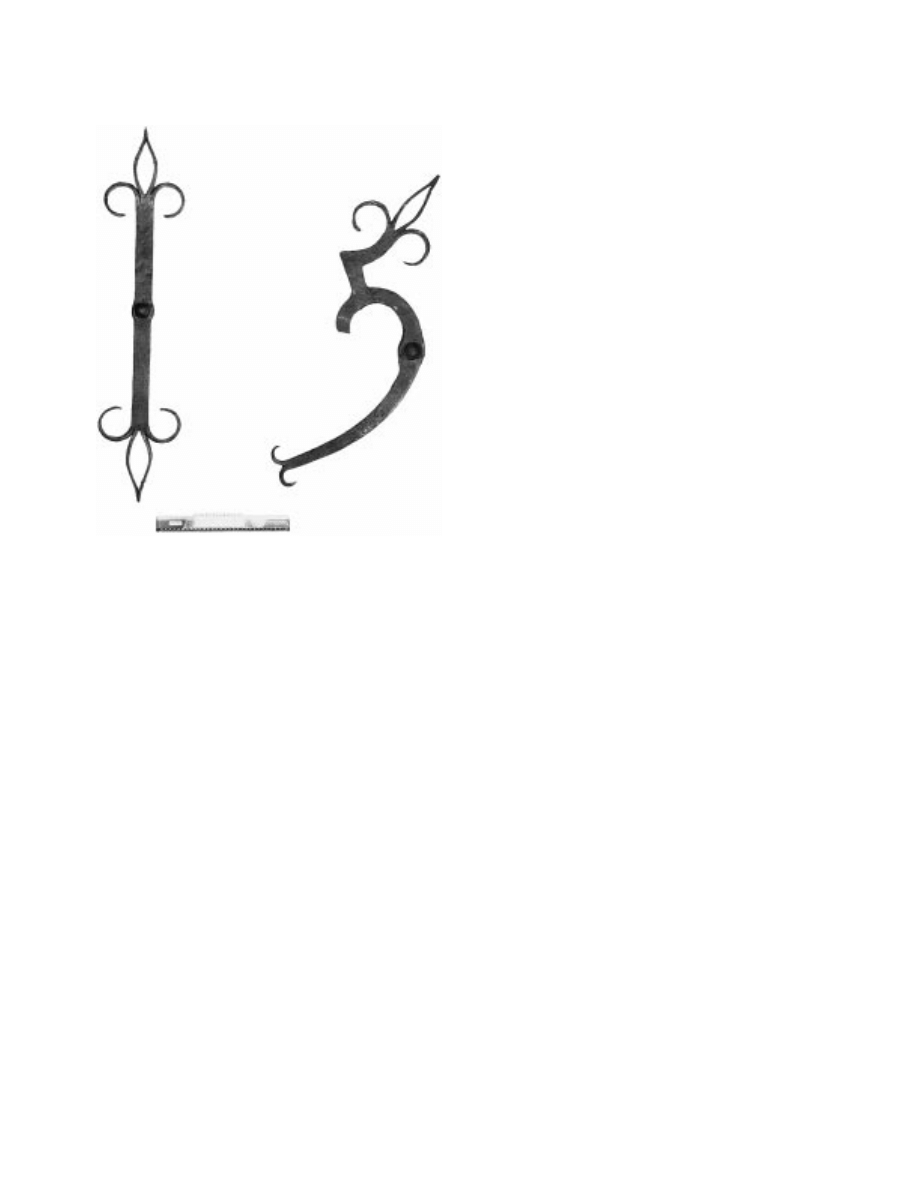

series of short wall ties (

) which incorporated

the year of construction were a very welcome addition.

The 26 samples studied can only be considered as a

pilot project. However, the results do show patterns in

composition which are interesting to compare with

suggestions made by other workers for determining the

technology used to produce artefacts.

Low sulphur levels have generally been regarded as

indicative of bloomery iron and charcoal fined iron.

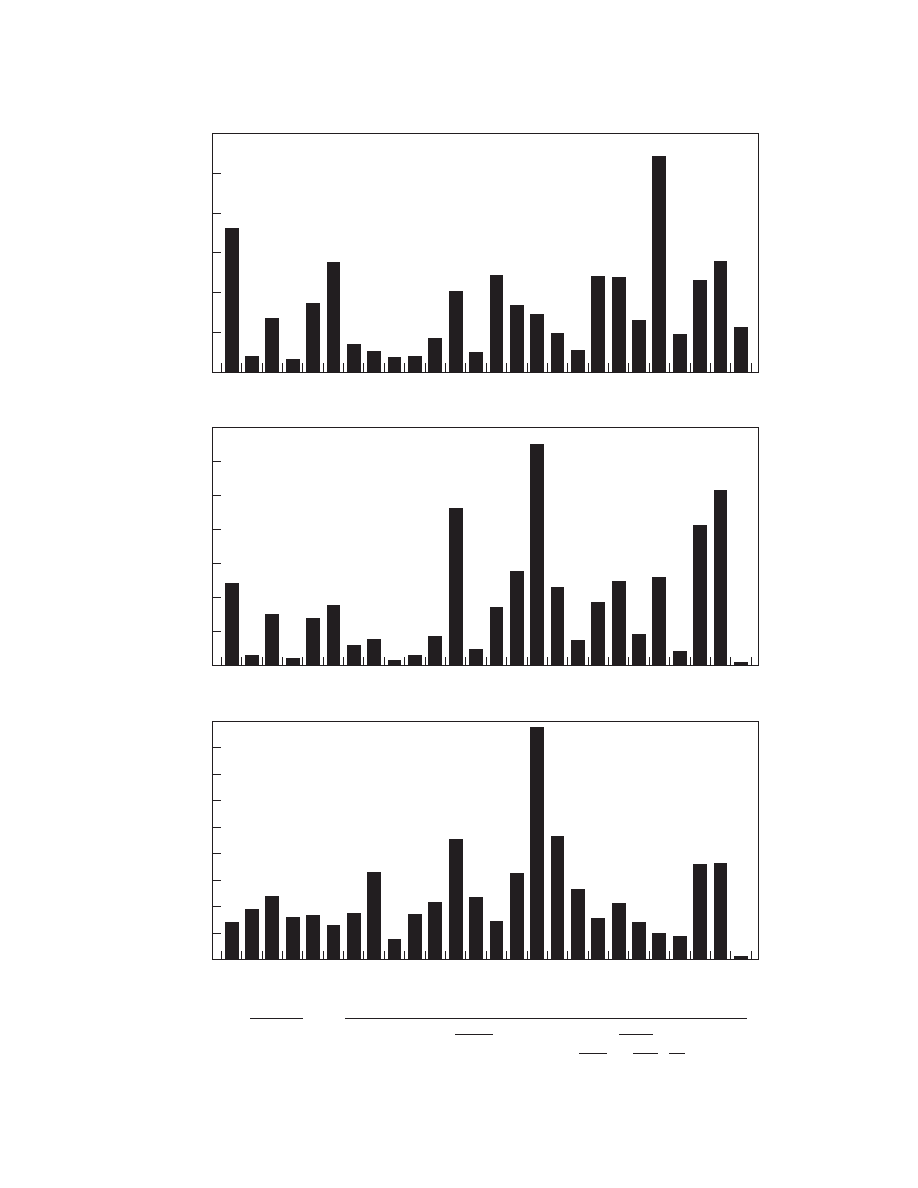

The inclusion data in

show the changing

levels of sulphur in inclusions with time. For clarity

only the latest possible dates for the samples were

plotted on the x-axis. Generally, values show an

upward trend, with values above 0·4% all dating to

1799 or later and exceptionally high levels from a

‘‘wrought iron’’ gate of 1891. Despite this trend, ab-

solute di

fferences over the entire period are narrow and

it would appear that little confidence can be placed

in sulphur as a discriminator for the fuel used in

conversion processes.

The alkalis, potash and soda, originate from either

charcoal or coke ash.

note

that very low levels of Na

2

O and K

2

O occur in dry

puddling slags, where the reverberatory furnace kept

the fuel separate from the iron and slag. This contrasts

to bloomery and finery slags which form in contact

with fuel ash.

looked at

inclusions and extended this argument to suggest that

low alkali content of inclusions could be used as a

discriminator of process. In

it can be seen

that slag inclusions in late 18th and 19th century

samples are generally low in Na

2

O and K

2

O and so

conform to this model (a small staple of 1825 may well

be one example of recycled iron).

‘‘probable upper limit’’ of 1% alkali certainly fits

most of the ironwork used in the period when

puddling was at its height. However, low alkali con-

tents also appear to characterize iron from the decade

before Cort’s patent for the puddling process of 1784.

These are unlikely to derive from the stamping and

potting process which, although it also used reverber-

atory furnaces, also used highly alkaline fluxes to

remove sulphur picked up in an earlier refining stage.

Several much earlier samples also contain only low

alkali concentrations. Thus, whilst earlier researchers

are correct in stating that puddled iron normally

contains low alkali inclusions, the presence of low

alkali inclusions cannot be cited as proof of this

process.

The value of manganese partitioning in the architec-

tural samples is limited by the very low concentrations

of the element in the metal and inclusions and so this is

not discussed further here. By contrast most of the

samples from early to late contained significant levels

of phosphorus (

. This provided an oppor-

tunity to test the findings of

who

suggested, on the basis of inclusion and bulk metal

analyses, that distinctly higher proportions of phos-

phorus pass into the slag of fined and puddled iron

than bloomery iron. Whilst some di

ffusion of phos-

phorus will occur during hot working, this will be

relatively minor in comparison to the changes taking

place during the high temperature, highly oxidizing

conditions of the decarburizing processes.

shows very considerable variation between the mean

phosphorus content of inclusions, demonstrating the

quantities of this element which could be stored up in

the non-metallic phases. However, it is di

fficult to

discern patterns in the data until the partitioning data

is displayed (

. Values on the y-axis are

calculated as percentage phosphorus pentoxide in the

slag divided by mean percentage phosphorus in the

iron. Early samples, at least before the late 17th

century, are relatively consistent and set a baseline for

what might be expected from the bloomery process. In

fact many later samples show very similar levels.

However, a scattering of samples dated as widely as

1699 to 1876 show a technique or techniques which

were able to extract greater proportions of phosphorus

from the metal into the slag. Wet puddling, from 1816

or slightly later (

), had a reputation for

the superior removal of phosphorus (and silicon) from

cast iron. Five samples date beyond this introduction

but none show greater partitioning of phosphorus than

Figure 3. Two ‘‘short wall ties’’, Great Yarmouth, 156 . . . The final

digit was missing from this oldest and largest known set of wall

anchors from the town. Copyright English Heritage Photographic

Library.

1130 D. Starley

several late 18th century samples. Whilst initial indi-

cations, based on so few samples should be treated

with some caution, given the apparent rapidity with

which wet puddling became the standard technique for

the production of wrought iron in Britain it would be

unlikely that none of these five samples derived from

the process.

Conclusions

Metallography and microanalysis are powerful tech-

niques for characterizing ferrous alloys and determin-

ing the later working and heat treatment histories of

artefacts. This study extended these techniques to the

investigation of iron production technology, particu-

larly with the aim of di

fferentiating the products of

direct process from those of indirect production.

Microanalysis of both inclusions and metal matrices

allowed quantification of elemental partitioning be-

tween the two phases which reflects the conditions in

the furnace or hearth. The methodology was tested on

two groups of material. Firstly, samples from the

specialized manufacture of defensive armour showed

a shift in the use of materials, identifiable by metal-

lography and microanalysis. The partitioning behav-

iour of the element manganese suggested a specific, if

unexpected, technological source: the high bloomery.

The second group of material comprised samples of

architectural ironwork covering a much wider date

range. Of particular interest were the origins of mid- to

late 18th century material. Hopes of identifying

less well documented conversion processes such as

stamping and potting were not fulfilled. Whether this is

due to methodological weakness or poor choice of

Dry

/

Wet puddling

4.5

0.0

1200

Sample date

P

ercentage of K

2

O + Na

2

O in inc

lusions

2.0

4.0

3.5

3.0

2.5

1.5

1.0

0.5

1400

1569

1601

1637

1651

1691

1699

1729

1729

1743

1770

1775

1779

1779

1782

1800

1822

1825

1872

1876

1891

(b)

1779

1799

1799

1799

5.2

0.0

1200

P

ercentage of sulphur in inc

lusions

0.2

5.0

0.8

0.6

0.4

1400

1569

1601

1637

1651

1691

1699

1729

1729

1743

1770

1775

1779

1779

1782

1800

1822

1825

1872

1876

1891

(a)

1779

1799

1799

1799

Fining

?

Potting and stamping

?

Figure 4. Concentrations of (a) sulphur and (b) oxides of potassium and sodium in architectural iron inclusions.

Determining the Technological Origins of Iron and Steel 1131

180

0

1200

Sample date

P

ercentage of phosphorus pentoxide (slag)/

percentage of P (iron)

80

160

140

120

100

60

40

20

1400

1569

1601

1637

1651

1691

1699

1729

1729

1743

1770

1775

1779

1779

1782

1800

1822

1825

1872

1876

1891

(c)

1779

1799

1799

1799

14.0

0.0

1200

P

ercentage of phosphorus pentoxide in inc

lusions

4.0

12.0

10.0

8.0

6.0

2.0

1400

1569

1601

1637

1651

1691

1699

1729

1729

1743

1770

1775

1779

1779

1782

1800

1822

1825

1872

1876

1891

(b)

1779

1799

1799

1799

0.300

0.000

1200

P

ercentage of phosphorus in iron

0.050

0.250

0.200

0.150

0.100

1400

1569

1601

1637

1651

1691

1699

1729

1729

1743

1770

1775

1779

1779

1782

1800

1822

1825

1872

1876

1891

(a)

1779

1799

1799

1799

Fining

?

Dry

/

Wet puddling

Stamping and potting

?

Figure 5. The distribution of phosphorus in architectural iron samples (mean values). (a) Elemental phosphorus in iron matrix. (b) Phosphorus

pentoxide in slag inclusions. (c) Partitioning of phosphorus between slag inclusions and iron.

1132 D. Starley

samples is unclear and will need to be tested by

more specific sampling as the project moves beyond

the pilot stage. Meanwhile it would appear that the

identification of production processes of ‘‘wrought

iron’’ alloys by quantification of the sulphur or alkali

content of their inclusions should be viewed with some

caution.

Acknowledgements

Many thanks to those who provided samples, in par-

ticular the sta

ff of the Royal Armouries and those

associated with English Heritage’s Architectural

Collections and Study Centre. The work on armour

was undertaken as a Ph.D. at Bradford University,

funded by the Science and Engineering Research

Council. Wavelength dispersive analysis was under-

taken by Chris Salter at The Research Laboratory

for Archaeology and the History of Art, Oxford

University.

References

Awty, B. G. (1981). The continental origins of Wealden ironworkers,

1451–1544. Economic History Review 34(4), 524–539.

Bodsworth, C. & Bell, H. B. (1972). Physical Chemistry of Iron and

Steel Manufacture. 2nd edn. London: Longman.

Gordon, R. B. (1983). English iron for American arms: laboratory

evidence on the iron used at the Springfield Armoury in 1860.

Historical Metallurgy 17(2), 91–98.

Gordon, R. B. (1984) The quality of wrought iron evaluated by

microprobe analysis. In A. D. Romig Jr. & J. I. Goldstein, Eds)

Microbeam analysis 1984. Proceedings of the 19th annual confer-

ence of the Microbeam Analysis Society, Bethlehem, Pennsylvania

1984. San Franscisco: San Francisco Press, pp. 231–234.

Killick, D. J. & Gordon, R. B. (1987). Microstructures of puddling

slags from Fontley, England and Roxbury, Connecticut, U.S.A.

Historical Metallurgy 21 (1), 28–36.

Morton, G. R. & Mutton, N. (1967). The transition to Cort’s

puddling process. Journal of the Iron and Steel Institute 205,

722–728.

Morton, G. R. & Wingrove, J. (1969). Slag, cinder, and bear. Bulletin

of the Historical Metallurgy Group 3 (1), 55–61.

Mott, R. A. (1977–78). Dry and wet puddling. Transactions

Newcomen Society 49, 153–158.

Percy, J. (1864). Metallurgy: Iron and Steel. London: John Murray.

Rostoker, W. & Dvorak, J. R. (1990). Wrought irons: distinguishing

between processes. Archeomaterials 4 (2), 153–166.

Starley, D. (1992). Medieval iron and steel production. Unpubl. Ph.D.

Thesis. Bradford University.

Tylecote, R. F. (1976). A History of Metallurgy. London: Metals

Society.

Determining the Technological Origins of Iron and Steel 1133

Document Outline

Wyszukiwarka

Podobne podstrony:

Serneels Archeometallurgy of Iron and Steel

[2007] Hoffmann, T Aquinas And Intellectual Determinism; The Test Case Of Angelic Sin

Kissinger and Rockefeller the Origins of AIDS and Ebola

We have the widest range of equipment and products worldwide

Best Available Techniques for the Surface Treatment of metals and plastics

The Intellectual Origins Of Modern Catholic Social Teaching On Economics

The Pernicious Blend of Rumination and Fearlessness in NSSI

The Cambodian Campaign during the Vietnam War The History of the Controversial Invasion of Cambodia

Chavda The hidden power of prayer and fasting

The Inner Nature of Music and the Experience of Tone

The Specious Origins of Liberalism Anthony Ludovici (1967)

Hoppe Hans H The Political Economy of Democracy and Monarchy and the Idea of a Natural Order 1995

Yasunari Kawabata The Dancing Girl of Izu and Other Stories (rtf)

Волощук Medieval Slovakia and Croatia as the second homeland of nobility and peoples from the Rus’ i

the illict preparation of morphine and heroin from pharmaceutical products containing codeine homeba

British Patent 6,481 Improvements relating to the Electrical Transmission of Power and to Apparatus

Technologie w Hearts of Iron II

Virato, Swami Interview With Sogyal Rinpoche On The Tibetan Book Of Living And Dying (New Frontier

więcej podobnych podstron