Appl Microbiol Biotechnol (2003) 61:309–313

DOI 10.1007/s00253-002-1213-3

O R I G I N A L P A P E R

I. Roy · A. Gupta · S. K. Khare · V. S. Bisaria ·

M. N. Gupta

Immobilization of xylan-degrading enzymes from

Melanocarpus

albomyces IIS 68 on the smart polymer Eudragit L-100

Received: 4 September 2002 / Revised: 29 November 2002 / Accepted: 29 November 2002 / Published online: 11 February 2003

Springer-Verlag 2003

Abstract

Xylanase of Melanocarpus albomyces IIS 68

was immobilized on Eudragit L-100. The latter is a

copolymer of methacrylic acid and methyl methacrylate

and is a pH-sensitive smart polymer. The immobilization

was carried out by gentle adsorption and an immobiliza-

tion efficiency of 0.82 was obtained. The enzyme did not

leach off the polymer even in the presence of 1 M NaCl

and 50% ethylene glycol. The K

m

of the enzyme changed

from 5.9 mg ml

–1

to 9.1 mg ml

–1

upon immobilization.

The V

max

of the immobilized enzyme showed an increase

from 90.9 mol ml

–1

min

–1

(for the free enzyme) to

111.1 mol ml

–1

min

–1

. The immobilized enzyme could

be reused up to ten times without impairment of the

xylanolytic activity. The immobilized enzyme was also

evaluated for its application in pre-bleaching of eucalyp-

tus kraft pulp.

Introduction

The enzymatic degradation of xylan has a variety of

biological functions. Industrial applications include the

use of xylanases in the paper and pulp industries, as food

additives to wheat flour, for the extraction of coffee and

plant oils, degumming of plant fibre sources and clarifi-

cation of juices and wines (Bajpai 1997; Beg et al. 2001).

One major application of xylanases is as a pre-bleaching

agent in treating Kraft pulps, used in most pulp and paper

mills, for paper manufacture. Such xylanase-pretreated

pulps result in lower generation of toxic, chlorinated

aromatic compounds and are therefore preferred as being

eco-friendly (Viikari et al. 1996; Bisaria et al. 2003).

Recently, purification, characterization and substrate

specificities of xylanase isoenzymes from Melanocarpus

albomyces IIS 68 have been described (Saraswat and

Bisaria 2000). In fact, multiplicity of xylanolytic enzymes

has been reported in several microorganisms. This has a

biochemical basis since degradation of xylan requires the

synergistic action of various xylanolytic enzymes (Beg et

al. 2001). Even in the case of M. albomyces, it was found

that the extent of xylan hydrolysis was higher when all the

isoenzymes were present (Saraswat and Bisaria 2000).

Recently, we reported the immobilization of Aspergil-

lus niger xylanase present in a commercial preparation on

Eudragit L-100, a copolymer of methacrylic acid and

methyl methacrylate (Sardar et al. 2000). Its stability in

aqueous solutions is pH-dependent and this has led to its

use in designing smart macroaffinity ligands (Roy and

Gupta 2002). As an immobilization matrix, its virtue lies

in the fact that it is soluble during catalysis, with its

insolubility below pH 4.0 enabling catalyst recovery by

lowering the pH. The soluble bioconjugate, of course, is

expected to have the considerably reduced mass transfer

constraints associated with enzymes immobilized on solid

supports (Roy et al. 2002).

Materials and methods

Xylan (from oat spelts) was purchased from Sigma, St. Louis, MO.

Eudragit L-100 was a product of Rohm Pharma, Weiterstadt,

Germany, and is a copolymer of methacrylic acid and methyl

methacrylate at a ratio of 1:1. All other chemicals used were of

analytical grade.

Production of xylanase

An ascomycetous fungus, M. albomyces, was isolated from

compost and soil. For xylanase production, the fungus was grown

in a medium containing (per liter): 10.0 g wheat straw, 0.5 g urea,

0.6 g KH

2

PO

4

, 0.4 g MgSO

4

·7H

2

O and 10 g yeast extract (Saraswat

and Bisaria 2000). The pH of the medium was adjusted to 6.0. The

growth temperature was 45C and agitation rate of the incubator

I. Roy and A. Gupta contributed equally to the work described here.

I. Roy · A. Gupta · S. K. Khare · M. N. Gupta (

)

)

Department of Chemistry, Indian Institute of Technology,

Delhi, Hauz Khas, 110016 New Delhi, India

e-mail: mn_gupta@hotmail.com

Tel.: +91-11-26591503

Fax: +91-11-26581073

V. S. Bisaria

Department of Biochemical Engineering and Biotechnology,

Indian Institute of Technology, Delhi, Hauz Khas,

110016 New Delhi, India

shaker was 230 rpm. The broth obtained after removal of mycelial

biomass and unspent wheat straw by centrifugation served as the

crude enzyme preparation (containing 68 U ml

–1

). The free enzyme

itself could be stored at 4C with no loss of activity for up to

16 weeks. Storage stability beyond this point was not checked.

Estimation of protein

Protein was estimated by the dye-binding method (Bradford 1976),

using bovine serum albumin as the standard protein.

Measurement of enzyme activity

Xylanase activity was determined as described by Bailey et al.

(1992) using oat-spelt xylan as the substrate. One unit of xylanase

activity is described as the amount of enzyme required to produce

1 mol reducing sugar (measured as xylose) per minute under assay

conditions (Saraswat and Bisaria 2000). As the polymer-linked

enzyme was soluble at the pH used in the assay (pH 6.0), the

activity of the immobilized preparation could be determined and

expressed in the same manner as the free enzyme.

Preparation of Eudragit L-100 solution

Eudragit L-100 (1 g) was dissolved with constant stirring in 40 ml

distilled water by adding 3 M NaOH dropwise until the pH

increased to 11.0. After the polymer had dissolved completely, the

pH of the solution was decreased to 7.0 by adding 3 M acetic acid

and the total volume made up to 50 ml with distilled water. The

solution was stored at 4C until further use.

Immobilization of xylanase to Eudragit L-100

Varying volumes (0.6–2.7 ml) of the clear culture broth of M.

albomyces IIS 68 were added to 0.75 ml 2% Eudragit L-100 and the

final volume was made up to 5.0 ml with 0.05 M acetate buffer,

pH 6.0. After incubation for 1 h at 25C, the polymer was

precipitated by lowering the pH to 4.0 with 130 l 0.1 N acetic acid.

After 20 min, the suspension was centrifuged at 12,000 g for 20 min.

The precipitate was washed with 4.0 ml acetate buffer (0.01 M,

pH 4.0) until no enzyme activity could be detected in the washings.

Enzyme activity and protein concentration were measured in the

supernatant and washings.

Determination of pH optimum and thermal stability

Effect of pH on free and immobilized xylanase was studied by

assaying both preparations at different pH values. Thermal stability

was studied at 60C by incubating the two enzymes at that

temperature. Appropriate aliquots of free and immobilized xy-

lanases were withdrawn at different time intervals and the activities

were determined.

Reusability of the immobilized preparation

The reusability of the immobilized preparation was assessed at

60C by carrying out the hydrolysis of 36 mg xylan in 4.0 ml 0.05 M

phosphate buffer, pH 6.0 containing 2.6 U immobilized enzyme

activity, and monitoring the amount of reducing sugar liberated

after each cycle. After each cycle of hydrolysis, the undegraded

xylan was removed by centrifugation at 2,000 g for 10 min. The pH

of the supernatant was lowered to 4.0 by the addition of 130 l 0.1 N

acetic acid when the immobilized enzyme precipitated. This was

collected by centrifugation (12,000 g, 20 min), the pH of

supernatant adjusted back to 6.0 and the amount of reducing sugar

estimated using the dinitrosalicylic acid (DNSA) method (Miller

1959). For running the second cycle, the immobilized enzyme was

redissolved in 5.0 ml fresh buffer and added to undegraded xylan

and processed the same way as before.

Hydrolysis of xylan from oat spelt and kraft pulp

by xylanase preparations

Free and immobilized xylanases (2.6 U) were incubated with oat

spelt xylan (1%, in 0.05 M phosphate buffer, pH 6.0) at 60C. The

amount of reducing sugars produced was estimated by the DNSA

method (Miller 1959) by withdrawing appropriate aliquots at

regular time intervals for 6 h.

In the case of kraft pulp, the enzyme was incubated with 5%

pulp (in 0.05 M phosphate buffer, pH 6.0) at 60C and the amount

of reducing sugar formed was estimated as before after 2 h and 5 h

of incubation.

Determination of Km and Vmax

K

m

and V

max

values of free and immobilized xylanases were

determined by measurement of initial rate of xylan hydrolysis at

various concentrations of xylan. The Michaelis constant was

calculated using the Leonora software program (Cornish-Bowden

1995). This software uses the Lineweaver-Burk equation to

calculate the K

m

value. Each experiment was run in duplicate and

the error margin was less than 5% in each case.

Results

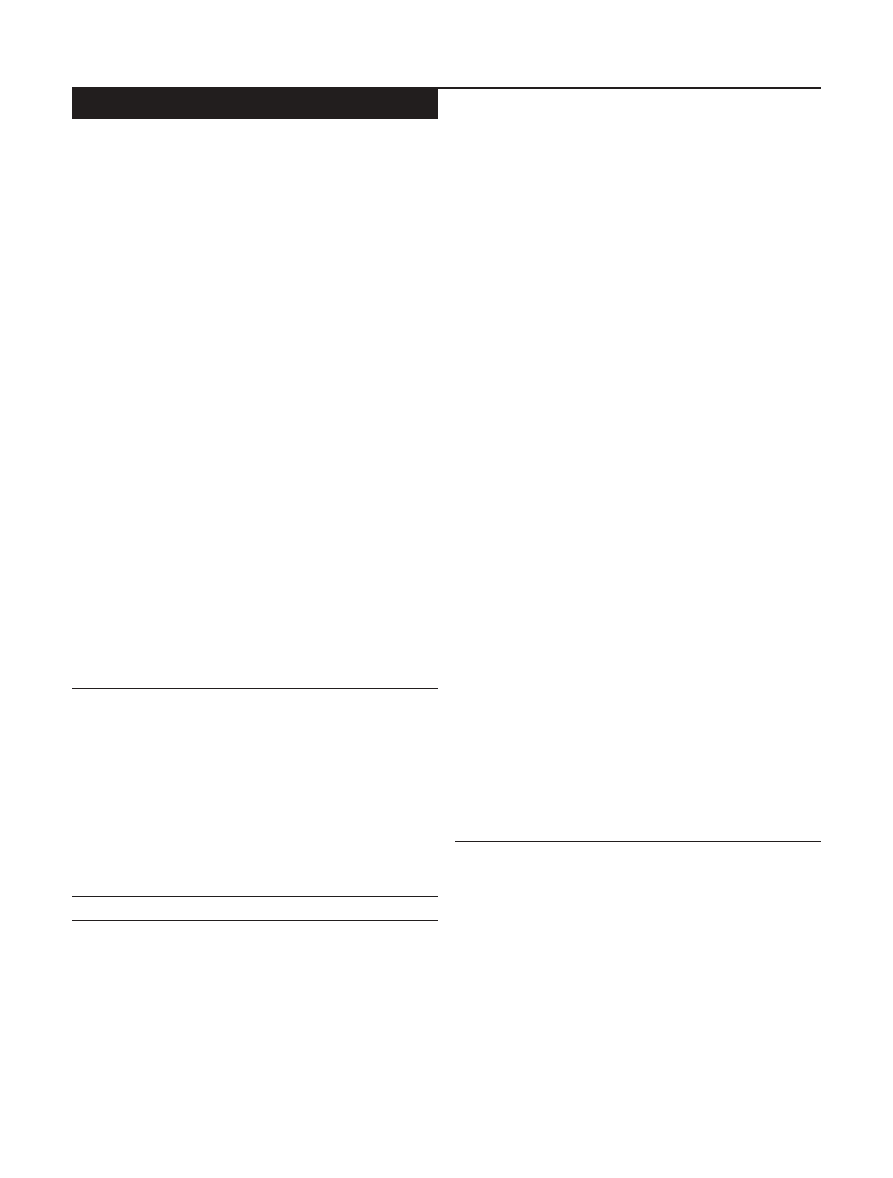

Figure 1 shows (1) that the xylan-degrading activity can

be immobilized on Eudragit L-100 and (2) the variation of

“immobilization efficiency” with the amount of enzyme

adsorbed per unit mass of the polymer. The latter follows

the trend generally observed during immobilization. The

decrease with larger enzyme load is generally attributed

to “overcrowding” of the enzyme on the surface (Sardar

et al. 2000). With a reasonable enzyme load (120 U), an

Fig. 1

Immobilization of xylanase on Eudragit L-100. Various

aliquots of the free enzyme were coupled to the matrix as described

in Materials and methods. A represents the amount of enzyme

theoretically bound to the matrix. This is calculated by subtracting

the unbound activity in the supernatant from the initially added

enzyme. B represents the expressed activity of the particular

immobilized preparation, measured after incubating the immobi-

lized enzyme (after dissolving) with the substrate

310

immobilization efficiency of 0.82 could be achieved. No

detectable activity was found to leach when the immo-

bilized enzyme was washed with 1 M NaCl or 50%

ethylene glycol. This is the preparation that was charac-

terized further.

There was no significant change in the xylan hydrol-

ysis activity versus pH curve upon immobilization (data

not shown). The temperature optimum for xylanolytic

activity also did not change (data not shown).

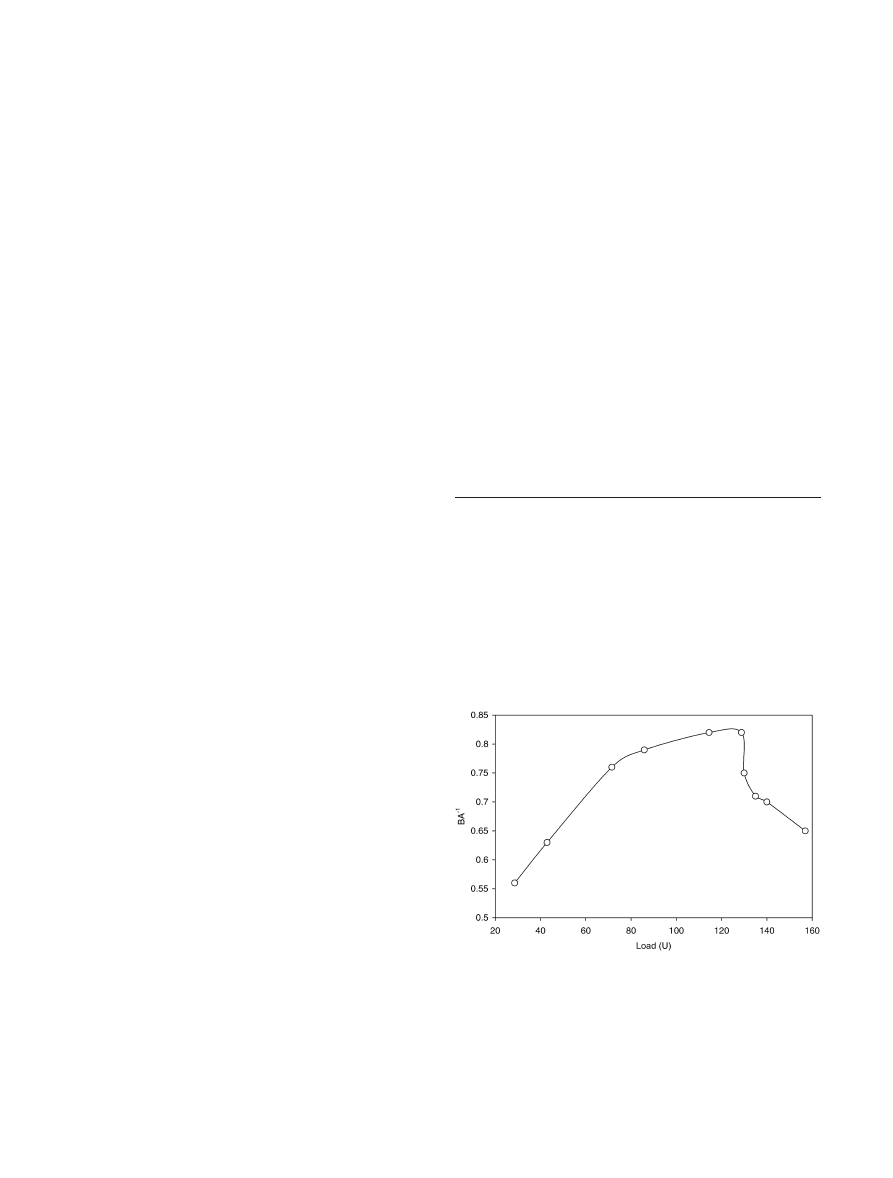

Figure 2 shows that there was no significant change in

the xylanolytic activity of the immobilized preparation up

to ten cycles. It is noteworthy that changing the pH of the

free enzyme to 4.0 destroyed all its activity in a single

exposure. The K

m

changed from 5.9 mg ml

–1

for the free

enzyme to 9.1 mg ml

–1

upon immobilization on the

soluble polymer. V

max

of the immobilized enzyme,

however, showed a marginal increase to 111.1 mol ml

–1

min

–1

(from 90.9 mol ml

–1

min

–1

for the free enzyme).

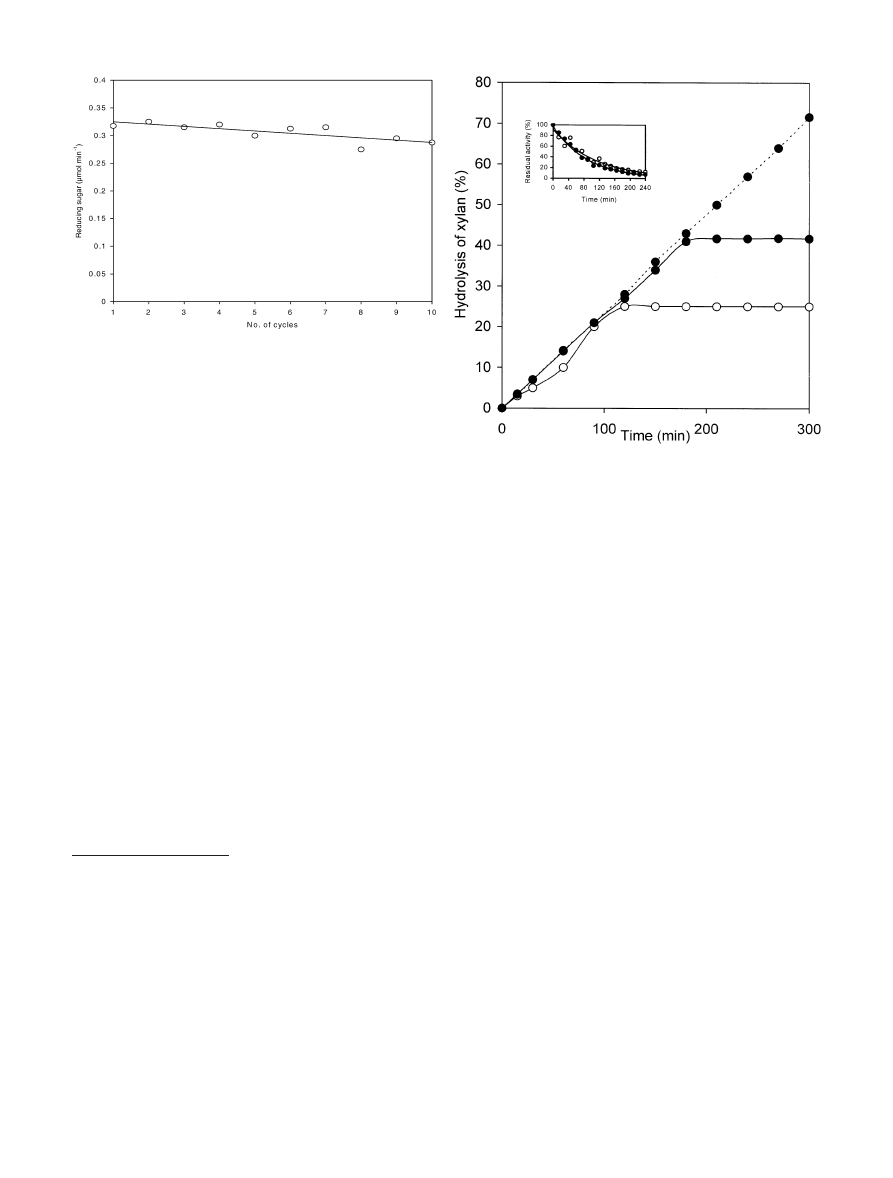

Figure 3 shows a time course hydrolysis by free and

immobilized enzyme. Hydrolysis % was calculated as

follows:

g xylose produced

0:9

g initial xylan

100

ð1Þ

In the case of the free enzyme, there was no further

hydrolysis after 120 min whereas hydrolysis continued up

to 180 min with immobilized enzyme. The final xylan

hydrolysis was 25% for the free enzyme and 42% for the

immobilized enzyme. The reason for the difference in the

performance of the free and immobilized enzymes did not

originate from a difference in thermal stability. Both free

and immobilized enzymes show similar thermal stabilities

at 60C (the temperature used for hydrolysis (inset in

Fig.3). [It should be added that, although the enzyme

alone is not very stable at 60C, its assay in this and

earlier work (Saraswat and Bisaria 2000) has been carried

out at 60C since the presence of xylan, the substrate,

during the assay protects the enzyme from thermoinac-

tivation. This kind of stabilization by the substrate

towards denaturing conditions has been observed in many

cases (Gray 1993)]. Thus, a likely reason for hydrolysis

stopping at 120 min (in the case of free enzyme) is

product inhibition (Hoshino et al. 1989). The immobilized

enzyme presumably has a different K

i

and allows

hydrolysis to proceed further. The broken line in Fig. 3

shows the effect of removing product inhibition factor,

which resulted in 70% xylan hydrolysis compared to 42%

in the case of the product-inhibited reaction. This is

possible only in the case of immobilized enzyme that can

be removed from the hydrolysis system and reintroduced

at any time.

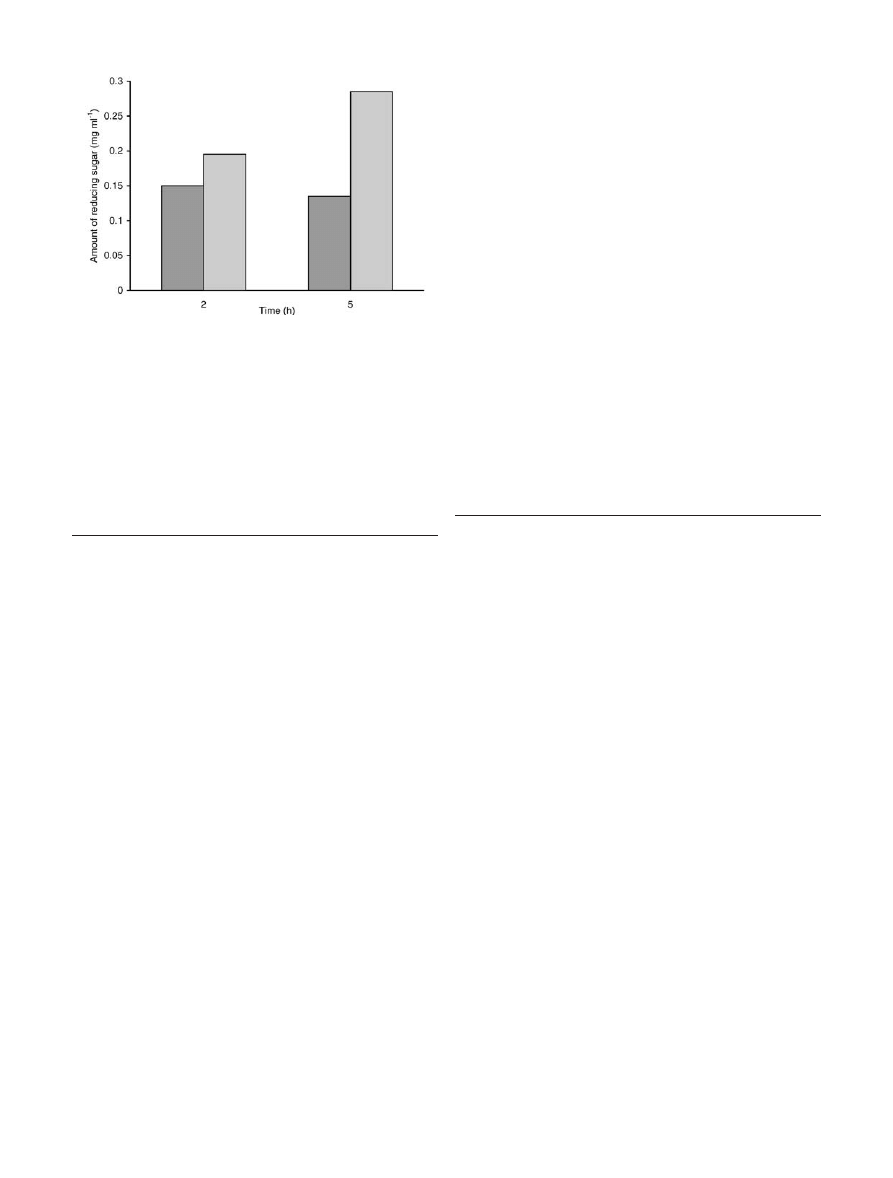

The free and immobilized enzyme preparations were

also evaluated for treatment of kraft pulp. The kraft pulp

(derived from eucalyptus) was treated with either immo-

bilized or free enzyme for 2 h or 5 h. The effectiveness of

the two enzymes was compared in terms of liberation of

sugars from the xylan component of the pulp. As shown

Fig. 2

Reusability of the immobilized preparation. After one cycle

of incubation of the immobilized enzyme and the substrate at 60C,

xylan was removed by centrifugation followed by removal of the

polymer-bound enzyme, as described in Materials and methods.

The immobilized enzyme was redissolved and incubated again with

fresh substrate to initiate the second cycle of hydrolysis. Each

hydrolysis cycle lasted 30 min

Fig. 3

Hydrolysis of xylan by immobilized xylanase. The free (m)

and immobilized (l) xylanases were incubated with xylan under

assay conditions. Aliquots were withdrawn from the suspension

after regular intervals, the pH lowered to 4.0, followed by

centrifugation to remove undegraded xylan and immobilized

enzyme. The amount of reducing sugar was estimated in the

supernatant after increasing the pH to 6.0. In the case of free

enzyme, the degree of hydrolysis was measured without lowering

the pH. The effect of product inhibition was evaluated by carrying

out the hydrolysis as described, except that the pH of the reaction

mixture was lowered and centrifugation carried out to precipitate

xylan and immobilized enzyme (broken line). These were then

redissolved in fresh buffer and the hydrolysis allowed to proceed.

Inset Thermal stability of the free and immobilized enzymes at

60C

311

in Fig. 4, the immobilized xylanase was more effective

for the pre-treatment of kraft pulp, presumably due to its

higher stability under pre-treatment conditions. Thus, the

use of immobilized xylanase may be a better option to

pre-bleach kraft pulps.

Discussion

Simple adsorption is a gentle method for noncovalent

immobilization of enzymes (Gupta and Mattiasson 1992).

The high immobilization efficiency observed in the

present case agrees with this general experience.

As Tischer and Kasche (1999) pointed out recently, the

real advantage of immobilization lies more often in

reusability rather than in stabilization. This stabilization

of the enzyme towards exposure to low pH is obviously

crucial to the reusability of the immobilized preparation.

The strategy of immobilization used in this case will not

be applicable to those enzymes that are not stable at such

low pH or are not stabilized upon immobilization. We

have previously observed similar stabilization of A. niger

xylanase upon immobilization on Eudragit L-100 (Sardar

et al. 2000). Reusable enzyme derivatives immobilized on

Eudragit have also been described with amylase (Cong et

al. 1995) and pectinlyase (Dinnella et al. 1995).

The change in kinetic parameters upon immobilization

is also critical for evaluating the success of an immobi-

lization protocol. Unfortunately, kinetic parameters for

enzymes immobilized on smart polymers have quite often

not been reported (Fujimura et al. 1987; Hoshino et al.

1989). There is some limited data available for compar-

ison. Cong et al. (1995) report marginal changes in K

m

and V

max

upon immobilization of amylase on Eudragit L-

100. Dinnella et al. (1995) report no change in K

m

but a

decrease in V

max

. While more extensive experience with

such systems is required before a clear analysis can

emerge, the increase in K

m

in this case, in spite of the

matrix being a soluble polymer, points towards factors

other than steric ones operating. An increase in V

max

upon

immobilization is generally not observed. However, such

a result is not unprecedented (Suh et al. 1987; Dumitriu et

al. 1989). This marginal increase in V

max

may arise from a

polar product (xylan fragments) being pushed away from

the microenvironment due to the somewhat hydrophobic

nature of Eudragit L-100. Incidentally, this will also

explain the increase in K

m

of the enzyme as the substrate

xylan is also polar in nature.

The soluble and reusable immobilized enzyme de-

scribed here can be used for numerous biotechnological

applications associated with xylanase. As the matrix

Eudragit L-100 is a food grade polymer and the immo-

bilization involves simple adsorption (thus avoiding the

need for toxic and harsh chemicals generally associated

with covalent coupling methods; Williams and Blanch

1994; Tyagi et al. 1998), applications in the area of food

processing can be safely considered.

Acknowledgements

The partial supports provided by the Council

for Scientific and Industrial Research (CSIR) (Extramural Division

and Technology Mission on Oilseeds, Pulses and Maize) and the

Department of Science and Technology, both Government of India

organizations, are gratefully acknowledged. A.G. is grateful to IIT

Delhi for financial support.

References

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of

methods for assay of xylanase activity. J Biotechnol 23:257–

270

Bajpai P (1997) Microbial xylanolytic enzyme system: properties

and applications. In: Neidleman S, Laskin A (eds) Advances in

applied microbiology. Academic Press, New York, pp 141–194

Beg QK, Kapoor M, Mahajan L, Hoondal GS (2001) Microbial

xylanases and their industrial applications: a review. Appl

Microb Technol 56:326–338

Bisaria VS, Mishra S, Sahai V, Jain JK, Mathur RM (2003) Pre-

bleaching of kraft pulp with xylanase enzyme for paper

manufacture. In: Proceedings of the International Symposium

on "New Horizons in Biotechnology", Trivandrum, India, April

2001 (in press)

Bradford MM (1976) A rapid and sensitive method for the

quantitation of microgram quantities of protein utilizing the

principle of protein-dye binding. Anal Biochem 72:248–254

Cong L, Kaul R, Dissing U, Mattiasson B (1995) A model study on

Eudragit and polyethyleneimine as soluble carriers for a-

amylase for repeated hydrolysis of starch. J Biotechnol 42:75–

84

Cornish-Bowden A (1995) Analysis of enzyme kinetic data. Oxford

University Press, Oxford, pp 27–36

Dinnella C, Lanzarini G, Ercolessi P (1995) Preparation and

properties of an immobilized soluble-insoluble pectinylase.

Process Biochem 30:151–157

Dumitriu S, Popa M, Artenie V, Dan F (1989) Bioactive polymers.

56:

Urease

immobilization

on

carboxymethylcellulose.

Biotechnol Bioeng 34:283–290

Fujimura M, Mori T, Tosa T (1987) Preparation and properties of

soluble-insoluble immobilized proteases. Biotechnol Bioeng

29:747–752

Gray CG (1993) Stabilization of enzymes with soluble additives.

In: Gupta MN (ed) Thermostability of enzymes. Springer,

Berlin Heidelberg New York, pp 124–143

Gupta MN, Mattiasson B (1992) Unique applications of immobi-

lized proteins in bioanalytical systems. In: Suelter CH, Kricka,

Fig. 4

Continuous hydrolysis of xylan from kraft pulp by immo-

bilized xylanase. The hydrolysis of kraft pulp was carried out by

free (vertically hatched) and immobilized (cross-hatched) xylanase

preparations as described in Materials and methods

312

L (eds) Bioanalytical applications of enzymes, vol 36. Wiley,

New York, pp 1–34

Hoshino K, Taniguchi M, Netsu Y, Fujii M (1989) Repeated

hydrolysis of raw starch using amylase immobilized on a

reversibly soluble-insoluble carrier. J Chem Eng Jpn 22:54–59

Miller GL (1959) Use of dinitrosalicylic acid reagent for determi-

nation of reducing sugar. Anal Chem 31:426–428

Roy I, Gupta M N (2002) Macroaffinity ligands in bioseparation.

In: Gupta MN (ed) Methods for affinity-based separation of

proteins/enzymes, Birkhauser, Basel, pp 130–147

Roy I, Sharma S, Gupta MN (2002) Smart biocatalysts: design and

applications. Adv Biochem Eng Biotechnol (in press)

Saraswat V, Bisaria VS (2000) Purification, characterization and

substrate specificities of xylanase isoenzyme from Melanocar-

pus albomyces IIS 58. Biosci Biotechnol Biochem 64:1167–

1180

Sardar M, Roy I, Gupta MN (2000) Simultaneous purification and

immobilization of Aspergillus niger xylanase on the reversibly

soluble polymer Eudragit

TM

L-100. Enzyme Microb Technol

27:672–679

Suh WC, Lim BS, Chun M, Sernetz M (1987) Immobilization of

nuclease P1 from Penicillium citrinum and production of 5-

nucleotides by bioreactor. Korean Biochem J 20:17–23

Tischer W, Kasche V (1999) Immobilized enzymes: crystals or

carriers? Trends Biotechnol 17:326–335

Tyagi R, Roy I, Agarwal R, Gupta MN (1998) Carbodiimide

coupling of enzymes to the reversibly soluble-insoluble poly-

mer Eudragit S-100. Biotechnol Appl Biochem 28:201–206

Viikari L, Suurnakki A, Buchert J (1996) Enzyme-aided bleaching

of kraft pulps: fundamental mechanisms and practical applica-

tions. In: Jeffries TW, Viikari L (eds) Enzymes for pulp and

paper processing. ACS Symposium series 665, Oxford Univer-

sity Press, Oxford, pp 15–24

Williams RA, Blanch HW (1994) Covalent immobilization of

protein monolayers for biosensor applications. Biosens Bio-

electron 9:159–167

313

Wyszukiwarka

Podobne podstrony:

Xylan Degrading enzymes from Aspergillus niger

Xylan degrading enzymes from the Yeast

Production of xylan degrading enzymes from Amazon forest fungal

Screening for distinct xylan degrading enzymes in complex shake flask

A xylan degrading strain of Sulfolobus solfataricus

O'Reilly How To Build A FreeBSD STABLE Firewall With IPFILTER From The O'Reilly Anthology

Degradable Polymers and Plastics in Landfill Sites

Estimation of Dietary Pb and Cd Intake from Pb and Cd in blood and urine

pages from xm 754sx 3

Inny świat – hołd złożony człowiekowi i dokument degradacji człowieka, język polski

Does the number of rescuers affect the survival rate from out-of-hospital cardiac arrests, MEDYCYNA,

Test 3 notes from 'Techniques for Clasroom Interaction' by Donn Byrne Longman

How to draw Donkey from Shrek

Mapowanie genów na przykładzie Drosophila melanogaster(1)

big profits from a very dirty business

więcej podobnych podstron