22

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 84 NR 8/2008

Sandra TABI

ŠOVA

Slovak University of Technology in Bratislava

LEDs and their application in practice

Abstract. This paper handles with the properties and application of nowadays most forwarding light source, LED, particularly from the point of view

of lightning technology. There were done measurements on white, red and blue diodes.

Streszczenie.

W artykule przedstawiono problematykę cech i zastosowań obecnie najbardziej rozwijających się źródeł światła, LED, zwłaszcza z

punktu widzenia techniki świetlnej. Wykonano pomiary diod białych, czerwonych i niebieskich. (Diody elektroluminescencyjne i ich praktyczne

zastosowanie).

Keywords: light, LED, measurements, lifetime, luminaire.

Słowa kluczowe: światło, diody elektroluminescencyjne, pomiary, trwałość, oprawa oświetleniowa.

Introduction

LED was used more than 30 years only in special

applications as: signal-technique. The reason of their thin

application area was their low specific output and their

colour rendering. In the last years this light source features

beating up lighting and technical parameters, such as a

specific output, luminance and low consumption. LEDs are

moderately efficient, the average outputs is about 32 lm/W,

new technologies deliver specific output up to 80-100 lm/W.

Advantages and disadvantages of LED

LEDs are typically much smaller than conventional light

sources, allowing for dramatically different lighting designs

capitalizing on the unobtrusiveness of the source.

Designing with LED for example, can enable completely

hidden sources of light, eliminating large visual luminaries,

and creating a magical effect when illuminated.

Fig. 1. One Chip LED lamps.

In figure 1 there are two LED lamps which can be used

instead of standard bulbs or halogen lamps. Every lamp

consists of LED with power of 3W. The construction of

these lamps has also the function of cooling system.

Light emitting diodes provide the lighting designer with

additional options and choices compared to conventional

technologies. Instead of taking one very bright source and

mounting it in a reflector optic to distribute light, LEDs can

enable alternative lighting concepts where the light source

can be divided into multiple points of light, distributed

across a surface, or placed in multiple planes. What is listed

in figure 3.

These devices have no moving parts, no fragile glass

environments, no mercury, no toxic gasses, and no

filament. There is nothing to break, rupture, shatter, leak, or

contaminate. Unlike typical conventional light sources,

LEDs are not subject to sudden failure or burnout. There is

no point in time at which the light source ceases to function;

instead, LEDs gradually degrade in performance over time.

Conventional light sources (as well as some LEDs) contain

invisible radiation as well as the visible component of light in

the beam. This radiation can be very short wavelength blue,

known as ultraviolet light, or long wavelength red, known as

infrared, which causes heat. Ultraviolet light can, and will,

damage materials, cause colour changes and eventually

breakdown

many

materials.

Museums

and

other

applications where ultraviolet light is a liability use

expensive low flexibility light pipes to filter out this harmful

component of the generated light. Frequently the light

source used for these light pipes is a very bright, hot,

incandescent or halogen sources, generating most of their

light as heat. Infrared light can damage displayed objects,

increases air conditioning costs, decreases environmental

comfort, and when reflected off reading surfaces increases

eyestrain.

Since LED based light sources last at least 10 times

longer than a normal light source, there is no need to

replace the light source, reducing or even eliminating

ongoing maintenance costs and periodic relapsing

expenses. Because if we use LED instead of a conventional

light source, there we have to replace online one piece of

LED, not all LEDs which are in this lamp.

Light emitting diodes provide even greater advantages

in applications where location makes replacement difficult.

Radio towers, offshore marine buoys, aircraft warning lights,

and bridge and tunnel lights all require expensive

maintenance fees due to their prohibitive location.

Eliminating or dramatically reducing the frequency of

required maintenance can save thousands of euros per

maintenance call in these applications.

The long life of a LED solution also allows for trouble

free designs. For example, even with the temperature

extremes, high shock and vibration environment of trucks

and cars.

Light Emitting Diodes require no filters to create

coloured light, resulting in deeper saturated colours without

wasted light. Deep reds, greens, blues and other colours

can be produced in monochromatic form directly from the

solid state element. Many lighting applications, such as

signs, signals, and warning lights, are coloured. Usually this

light is created through filtering. These filters block the

undesirable portions of the white light and let only the

desired wavelengths through. The blocked light that is not

of the correct colour is therefore lost energy.

Therefore, to make a red sign, one can use a

monochromatic LED that generates only red light and

therefore does not require an additional colour filter. There

is no need for expensive filters, and there is no wasted

energy.

The light emitted from an LED is directional. Typical

conventional sources such as incandescent, halogen, or

fluorescent lights are omnidirectional, emitting light in all

directions. In order to direct the light onto the object to be

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 84 NR 8/2008 23

illuminated, light that is not directed toward the desired

location must be redirected using secondary optics. Each

time a light beam is reflected and some of its intensity is

lost, resulting in a fixture loss. Typical fixture losses range

from 40 to 60%, meaning that in some cases less than half

of the light generated by the source is directed in the

desired direction. The directed nature of LEDs can result in

fixture efficiencies of 80 to 90%, requiring less total lumens

to provide the same level of illuminance. When considering

LEDs as a light source it is important to consider all factors

in determining the appropriate solution. For example, if you

are replacing a 500 lm source in a fixture with 50%

efficiency with an LED based source in a fixture with 85%

efficiency, less than 300 lm will be required from the LED

source for an equivalent illuminance. A side benefit from the

directionality of light emitted from the LED solution is the

reduction of light pollution.

Light emitting diodes are solid state devices containing

no moving parts and no filaments to break. As such, LEDs

handle rough environments including heavy vibration and

impact. Unlike conventional light sources, which typically

contain a fragile filament enclosed in a breakable glass

enclosure. The solid state natures of LEDs make them

extremely rugged and durable and excellent choice for

applications where reliability and dependability are

paramount.

Colour LEDs can be used for dynamic colour changing

applications. With fast turn on times (measured in

microseconds) it is easy to instantly change from one hue to

another. Further, you can generate more brilliant colours

than are currently possible on conventional LCD or CRT

monitors, these LEDs offers a larger colour range than is

possible using conventional lighting technologies. Not only

can you use LEDs for viewing applications (such as TVs or

computer screens); the endless choices of colour are

available for almost any application. Imagine everything

from a stadium replay panel, laptop screen, wall up lighters,

pools and fountains. As white light is the combination of red,

green, and blue (RGB), we can easily create any colour of

white (CCT) from warm to cool blue by changing the relative

intensity of each colour component.

LEDs switch on and off so quickly and have an

exceptional dimming range. Light emitting diodes are fully

dimmable with straightforward driver topologies. This

dimming ability, through the common technique of pulse

width modulation (PWM) of the drive current, allows for

environmentally friendly illumination without sacrificing

either the Colour Acceptance Index (CAI) or the Colour

Rendering Index (CRI). With PWM control, the colour

provided is independent of the set intensity. Therefore it is

easy to optimize the desired colour and then adjust the

intensity to suit the needs of virtually any application. The

use of an LED based lighting system enables a wide colour

gamut of saturated static and dynamic lighting effects.

Whether the desired effect is a tunable white source or a

single light capable of digitally producing any colour.

Many light sources in use today are not well suited to

cold environments. In some cases, such as walk in

refrigerators, cool outdoor climates, or automotive

applications expensive drivers are required to enable

ignition at low temperatures. LEDs do not require any

special equipment or drivers, regardless of the temperature.

Cold start is not a problem for this solid state technology,

down to -

40°C. This cold start ability allows for instant on/off

control without specially designed circuitry, simplifying

system design while lowering the cost of the electronic

driver [1].

Street lighting

For public lighting there are used high pressure lamps.

In older lighting systems are used mostly mercury high

pressure lamps. In this pressure lamp, like in every

pressure lamp is the generation of light based on another

principle than it is at the solid state device LED. Mercury

pressure lamps have relatively bad colour rendering Ra=40-

60, lifetime 8-12 000 hours and luminous efficiency 40-60

lm/W. High pressure mercury lamps are replaced by high

pressure sodium lamps, which have better technical

properties. The tube in this lamp is filled except other

materials mostly with sodium. This lamps have higher

lifetime up to 32 000 hours, high luminous efficiency 60-130

lm/W though the colour rendering is very low. In the past

few years there have been developed high pressure sodium

lamps with a good colour rendering Ra=30-80.

For public lighting is also possible to use fluorescent or

compact fluorescent lamps. These are low pressure lamps

with lifetime about 8000 hours under service with

conventional ballast. If we use electronic ballast, the lifetime

of a low pressure lamp is ca.18 000 hours. Colour rendering

of these light sources is very good it is between Ra=80-100.

Problem on this lamp is the dependence luminous flux on

the surround temperature. In the summer and winter

months there decreases the luminous flux. This problem is

solved by a specific construction of fluorescent lamps. The

luminous flux is not adequate for lighting of motorways. This

light source is better to use for lighting of parks or

pedestrian zones. Adequate light source for public lighting

is the metal halide lamp, which has a better colour

rendering and higher lifetime than high pressure sodium

lamp. Nowadays there are some lamp producers, which

produce and sell luminaries for street lighting with LEDs. In

figure 2 is an example for such street luminaire.

Fig. 2. MILLENIO LED street luminaire [2].

As I ment

ioned in paper from Lumen V4: „LED lamp for

public lighting” it would be much more expensive using the

LEDs instead of high pressure lamps. But now, there are

produced LEDs with higher outputs for lower prices per

piece then it was two years ago. Because of the sinking

price, there is given a possibility to produce exterior

luminaries for lower prices as it was mentioned in that

paper.

Fig. 3. LED exterior luminary and conventional used exterior

luminaries [4].

24

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 84 NR 8/2008

In figure 3 it is shown a LED exterior luminaire. This

luminaire was designed and produced by our student Ing.

František Fülöp within the frame of his master thesis. As

we can see in the picture there were used only 20 LEDs,

what means a constant lighting even if one of them is no

more functioning. This luminaire can be used in parks,

these more sources in one luminaire provide more safety

for the pedestrians. The price for such luminaire is about

two times higher than a price for a standard street

luminaire. This diodes should light 100 000 hours, what is

given by the producer of this devices. This means almost no

costs for the service.

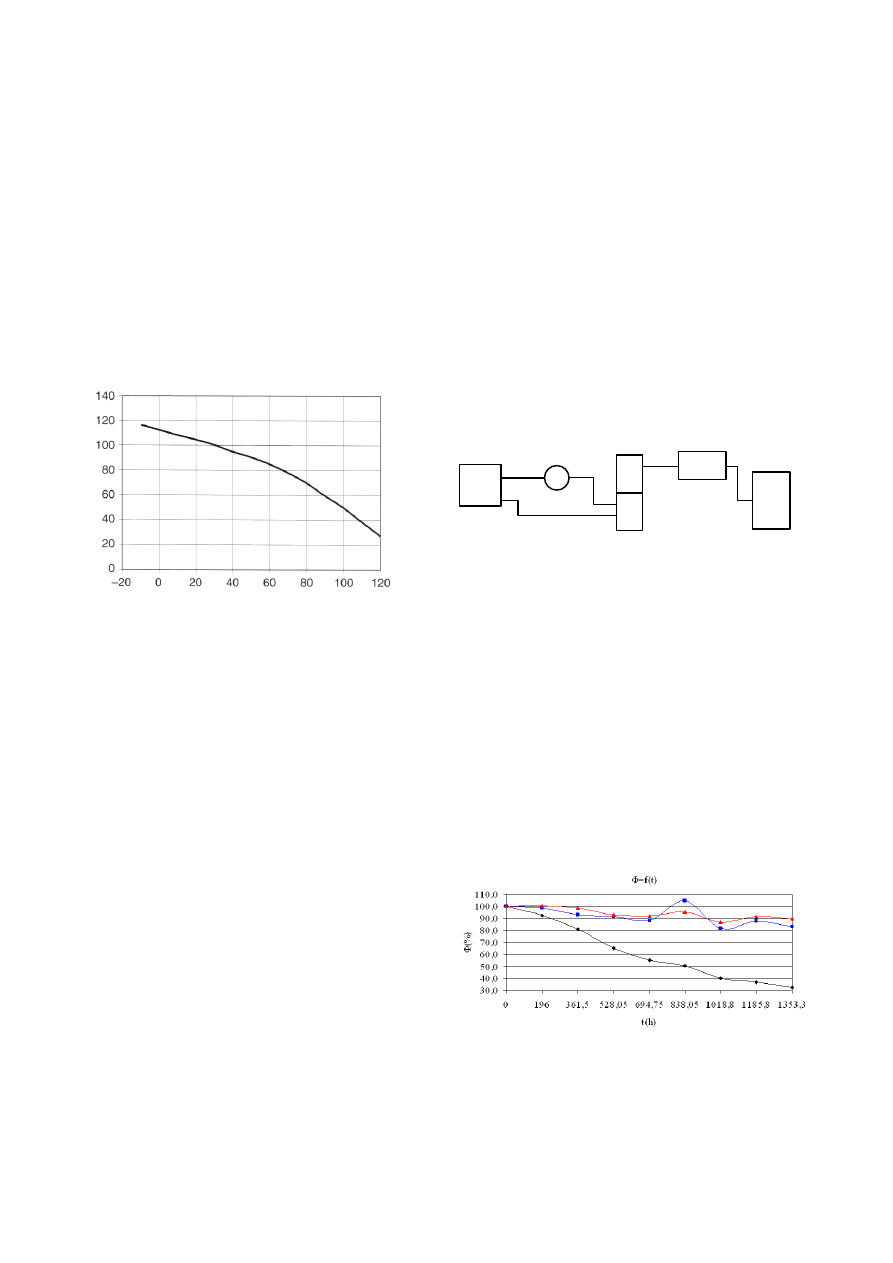

Factors influencing the lifetime of LED

To the factors which affect reliability and therefore also

the lifetime of LED is especially temperature. With the

increase of the temperature is the specific output sinking.

Maximum allowable temperature of the junction T

J

should

not be during the operation overruned (figure 4).

Junction Temperature T

J

(

°C)

R

e

la

ti

v

e

l

u

m

in

o

u

s

f

lu

x

Fig. 4. Relative luminous flux versus junction temperature of the

source [3].

Operating temperature is the primary condition,

depending on the surrounding. LED performance largely

depends on the ambient temperature of the operating

environment. "Driving" a LED "hard" in high ambient

temperatures may result in overheating of the LED

package, eventually leading to device failure. Adequate

heat-sinking is required to maintain long life. This is

especially important when considering automotive, medical,

and military applications where the device must operate

over a large range of temperatures, and are required to

have a low failure rate.

Another influence of the lifetime of a LED is for example:

mechanical influence as

a pressure or drawing force, which

increase mechanical tension in light emitting diode. Also

infrared radiance means always a supplementary heating

up of the source, whereby it is possible to overrun the

temperature range, at which can LED emit light. Ultraviolet

radiation is also unsuitable effect for the quality of radiance

of LED, because it is rich of energy and the consequence is

quenching of the resinous cover. Same like by virtue of IR

and UV radiance, comes by the contact of LED with

chemical gases to the decrease of the lifetime. Depending

of the used material can the lifetime through the service in

surrounding with a high dampness and temperature

drastically shorten.

Measurement

We decided to measure if there is any decrease in

luminous flux through the lifetime of LEDs, because this is

one important factor influencing the application in street

luminaires, as well as in another then only in street

luminaires.

We used 30 LED for the measurement of the lifetime.

These LED had different colour, there had ten pieces blue

colour, ten had red colour and ten were white. Every diode

was in the circuit with a resistance. Used were LEDs which

has these properties, given by the manufacturer:

-operating temperature range: -

30 °C to +80°C,

- red LED was made of AlGaInP, blue and white

semiconductor material was InGaN,

-luminance of red and blue LED was between 3000-4000

mcd and the white had 11 500-16 500 mcd,

- power is 100 mW at the white, at the blue and red LED is

10 mW.

This circuit consisting of 30 LEDs and 30 resistances

was connected to constant-current supply. At this way

connected LEDs did light constantly. Their lighting was

stopped only during the measurement, which took about

one hour. Measurement on LED was done in different time

periods. Through spectrophotometer USB 2000, notebook

and multimeter. LED was positioned in a measurement

apparatus, which was connected to the spectrophotometer.

The ambient temperature was also marked, it moved in the

temperature interval 21,5-

25ºC. Scheme during the

measurement is in figure 5.

Source

A

R

I

S

PC

+

-

Fig. 5. Scheme during the measurement (S- spectrophotometer, A -

multimeter, I - integrator, where the LED was inserted and R - serial

integ

rated resistance R=300 Ω, PC - notebook).

Up to this day were done ten measurements for each

type of used LED, together we collected more than 300

values. From the tables we can identify, that the decrease

of the luminous flux is visibly at every diode but the most

visible decrease of the flux is measured at the white LEDs,

as we can see in figure 7. Luminous flux did sink at these

diodes less than 60%, even on the LED was this decrease

near to eighty percents, what some manufacturer describe

as the end of the lifetime of light source.

The lowest decrease at the red LED was on the red

LED, it was 25% toward to the initial luminous flux.

Accordingly relative low decrease of the luminous flux

measured at the red LED, was on the blue diodes, where

the biggest ultimate decrease was 38%. One blue LED

diode at the last measurement ended her life after 1336,8

hours of lighting.

Fig. 6. Percentage luminous flux versus time.

Conclusion

From the measured values we did find out, that the

decrease at the white LED was average 60% of their

beginning luminous flux. At the similar, how were used LED

diodes for measurement, the producers indicate the lifetime

between 8000 to 10 000 hours. A good question is, if for

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 84 NR 8/2008 25

selling bidden diodes really do satisfy the demand of

maximum decrease of the luminous flux by 20% through

their lifetime, as many producer of lighting sources indicate,

seeing that after 1336 hours of lighting is the decrease of

luminous flux at the majority of LED bigger than 20% and it

was even showed, that one lighting source would be no

more useful in the practice. Interesting would be

measurements with more than 30 LEDs, as well as with

power LEDs.

LED could be effectively used in areas, where is not

heavy traffic, for example in the villa areas or in the

communities in switching schedule, as a reaction for coming

vehicle or pedestrian. Zero time of switching on and minimal

costs for such lamp by using LED as light source, would be

in this lighting system a great benefit opposite high pressure

lamps, which have a longer time for start and they cognize

of failing by switching service. Nowadays we provide

measurements on the university with LEDs, which are in

switching schedule. These results will be interesting for the

using in exterior lighting luminaires.

LED lighting can ensure a safe traffic and for pedestrian

can sink risk of crime delinquency.

Through this lighting which uses a tight viewing angle

will decrease in many incidents glare for the pedestrians

and it will decrease the values of luminance in

today’s often

bad illuminated parts of city communications.

REFERENCES

[1] Philips Lumileds lighting company,Benefits of Philips Lumileds

Solid State Lighting vs. Conventional Lighting. [online].

Available on internet: <http://www.luxeon.com/pdfs/AB17.pdf>,

2006

.

[2] HESS. Available on internet: <http://pdf.archiexpo.de/pdf/hess-

form-licht/millenio-led-strassenleuchte/9916- 1665.html>, 2008.

[3] GEMMER,W.: Light emitting diodes

. In: Handbuch für

Beleuchtung. Horst Lange, 5.Auflage, 2005. I - 6.13.1

– I –

6.13.8. ISBN 3-609-75390-0.

[4]

SITECO.Product

catalogue.

Available

on

internet:

<.http://www.siteco.de/de/produkte/aussenleuchten/chapter/15

46/category/6910/family/6920.html>, 2008.

Author:

M. Sc. Sandra Tabišová, Slovak University of Technology

in Bratislava, Faculty of Electrical Engineering and Information

Technology, Department of Electrical Power Engineering,

Ilkovičova

3,

812

19

Bratislava,

Slovak

Republic,

Wyszukiwarka

Podobne podstrony:

Bauman, Paweł Vilfredo Pareto – Biography, Main Ideas and Current Examples of their Application in

74 1053 1066 Hard PVD Coatings and Their Perspectives in Forming Tool Applications

54 767 780 Numerical Models and Their Validity in the Prediction of Heat Checking in Die

Software Vaccine Technique and Its Application in Early Virus Finding and Tracing

MRS and its application in Alzheimer s disease

Bacterial spore structures and their protective role in biocide resistance

Eizo Matsuki The Crimean Tatars and Their Russian Captive Slaves An Aspect of Muscovite Crimean Rela

Bradley Using ISO 3382 measures, and their extensions, to evaluate acoustical conditions in concert

Cooper and Hawthorne woman in their writing

Green tea and its polyphenolic catechins medicinal uses in cancer and noncancer applications

Signs of the Zodiac and the Planets in their exaltations

Synchronous Generator And Frequency Converter In Wind Turbine Applications System Design And Efficie

więcej podobnych podstron