28

Osmotic Dehydration of Fruits

and Vegetables

Piotr P. Lewicki and Andrzej Lenart

CONTENTS

28.1 INTRODUCTION

Water as a main constituent of most foods affects

food stability, microbial as well as chemical, and is

responsible for the consumer perception of many

organoleptic attributes, i.e.,

juiciness,

elasticity,

tenderness, and texture. It is generally accepted that

it is not the quantity of water in food but its thermo-

dynamic state that is responsible for its influence on

food stability and texture. The thermodynamic state

of water in food is expressed by its activity, which is 0

for absolutely dry material and 1 for pure water. The

lower the water activity the more stable is the food,

and the texture changes from juicy and elastic to

brittle and crunchy.

The lowering of water activity can be achieved in

two ways, either by addition of humectants or by

removal of solvent (i.e., water). The first way is mostly

unacceptable by consumers as it needs large amounts

of sodium chloride, sugars, or polyols to be added to

food. Moreover, this way is limited by nutritional

and toxicological restraints. The other way is energy

intensive, hence the final product is expensive.

The use of osmosis allows both ways of decreasing

water activity in food to be applied simultaneously.

The permeability of plant tissue is low to sugars and

high molecular weight compounds; hence, the mater-

ial is impregnated with the osmoactive substance in

the surface layers only. Water, on the other hand, is

removed by osmosis and the cell sap is concentrated

without a phase transition of the solvent. This makes

the process favorable from the energetic point of

view. The flux of water is much larger than the coun-

tercurrent flux of osmoactive substance. For this

reason the process is called osmotic dehydration or

osmotic dewatering.

ß

2006 by Taylor & Francis Group, LLC.

The food pro duced by this method has many

advantag eou s feat ures:

.

It is ready to eat and rehydrat ion is not need ed.

.

The amount of osmoact ive substa nce penetra t-

ing the tissue can be adjust ed to indivi dual re-

quirem ents.

.

The chemical co mposition of the food can be

regula ted acco rding to needs.

.

The mass of the raw mate rial is reduce d, usually

by half.

The os motic deh ydration does not reduce wat er ac-

tivity suffici ently to hinder the proliferation of micr o-

organis ms. The process extends , to some degree, the

shelf life of the mate rial, but it does not preser ve it.

Hence, the app lication of othe r preser vation methods ,

such as freez ing, pa steurizat ion, or drying is necessa ry.

Howev er, pro cessing of os motically dehydrat ed semi -

produc ts is much less ex pensive an d preserves most of

the charact eristics acqu ired dur ing the osmosi s.

28.2 THE NATURE OF OSMOTIC

DEWATERING

28.2.1 O

SMOTIC

P

RESSUR E

The therm odynami c stat e of wat er in solut ion is char-

acterized by wat er intera ctions with solut e. Becau se

each molec ule has its internal e nergy an d inter action s

also need energy e ach substa nce of the solut ion is in

the defi ned en ergetic stat e. This state referred to one

mole of the substa nce is called the chemi cal poten tial.

Chem ical potenti al is a function of concentra tion,

tempe rature, and pressur e. Un der isot hermal co ndi-

tions it is solely determ ined by conce ntration and

pressur e. The increa se of solut e concentra tion de -

crease s the ch emical poten tial of a solvent , which

can also be express ed by its a ctivity acco rding to the

followi ng relat ionshi p:

m

w

¼ m

ow

þ RT ln a

w

(28 : 1)

where m

w

—chemi cal potenti al of water

m

ow

—chemic al potenti al in a standar d stat e

R—gas constant

T—absol ute temperatur e

a

w

—wa ter acti vity coeffici ent

The inter actio n of two systems in different ene rgy

states is manif ested by the energy excha nge. Thi s

exchange proceed s until the equilibrium state is

achieved, which is the state in which chemical potentials

of tw o systems are the same.

The equilibrium state, under isothermal conditio n,

can be achieve d by the change of eithe r co ncentra tion

or pressure. Excess pressure needed to reach the state of

equilibrium between pure solvent and a solution is

called osmotic pressure and is expressed by the formula:

P

¼

RT

V

ln a

w

(28 : 2)

where V is molar volume of wat er.

As water is the solvent in food s, the above equ a-

tion can be sim plified to

P

¼ 4: 6063 10

5

T ln a

w

(28 : 3)

Osm otic pressur e is related to molar mass of the

solute; the smaller the mass , the high er will be the

pressur e at the same concen tration. Electr olytes show

higher osmot ic pressur e than nonelect rolytes because

each ion affects the chemi cal poten tial of a solvent.

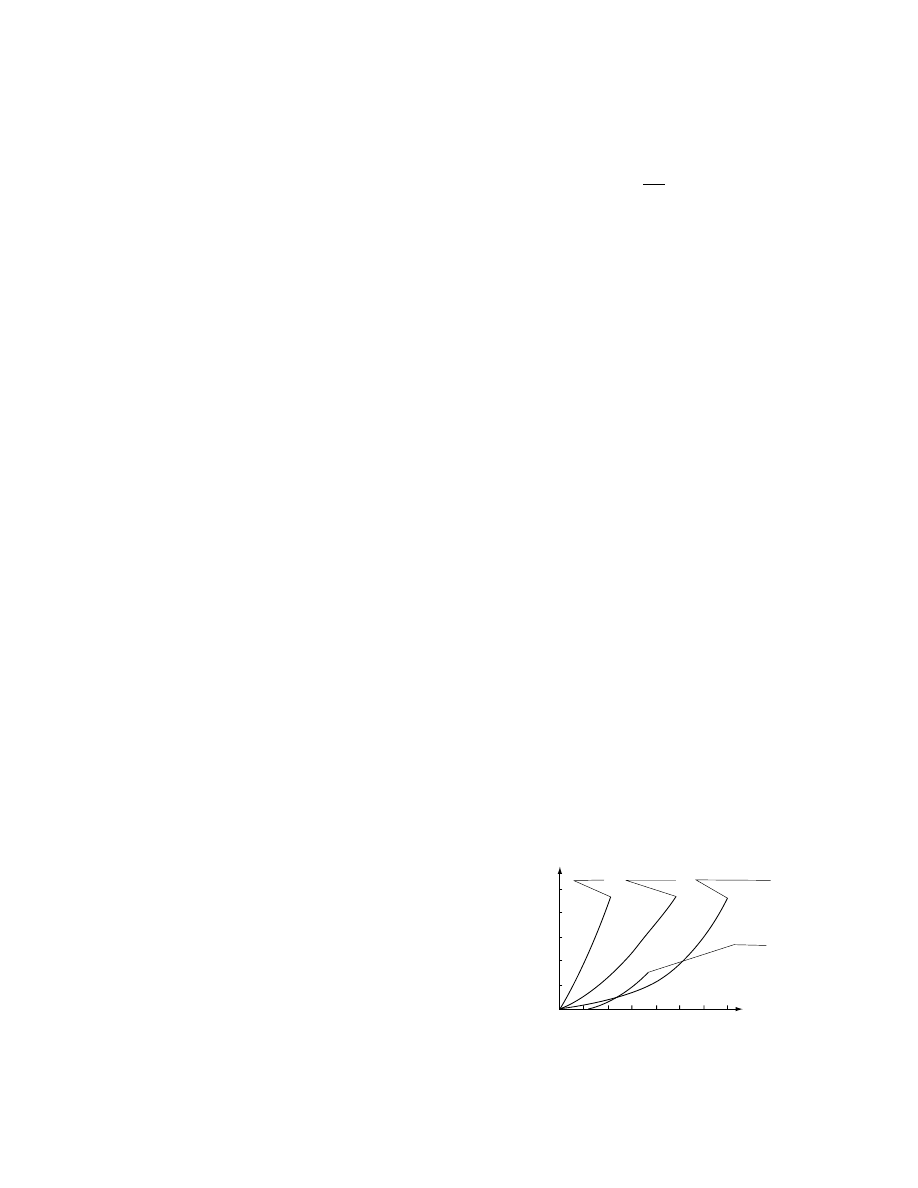

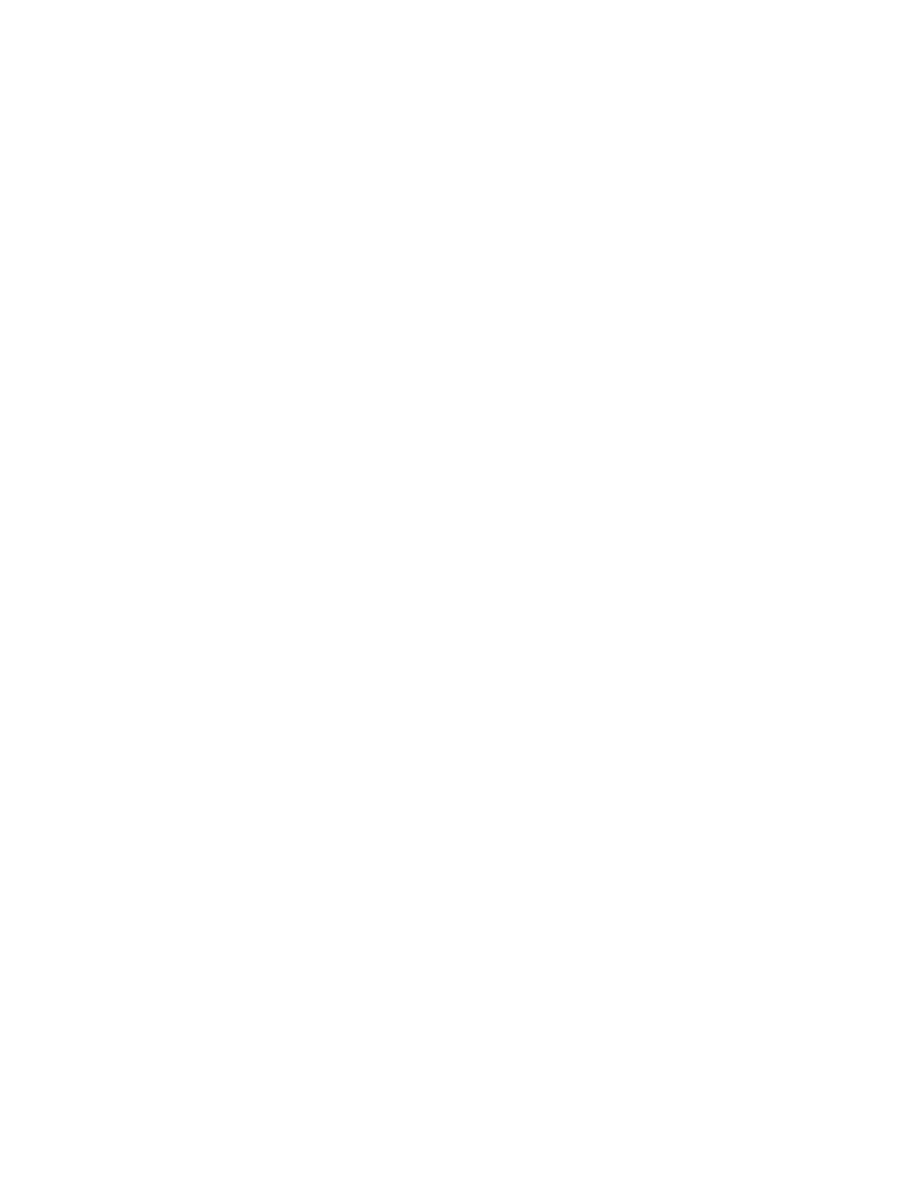

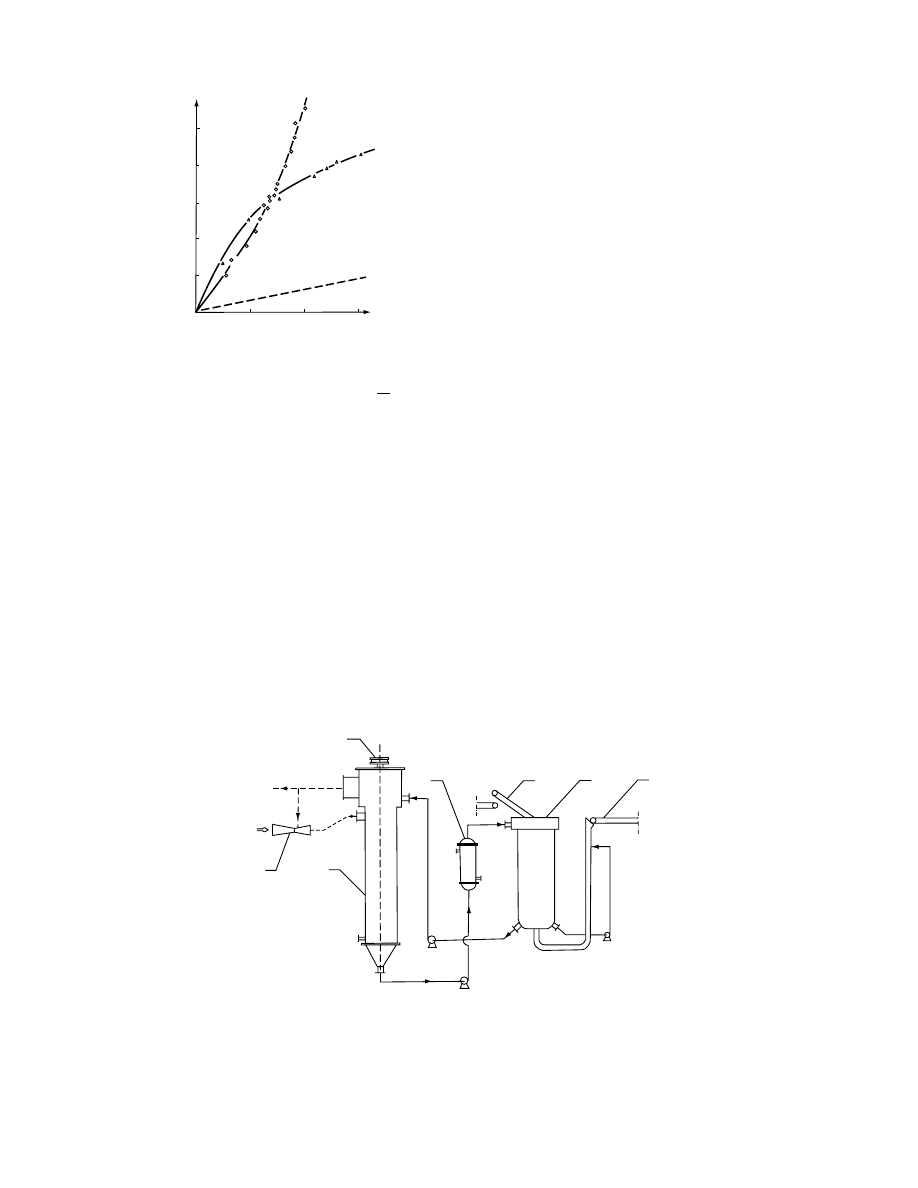

Rel ationsh ip betw een co ncentra tion and osmot ic

pressur e is shown in Figure 28.1. Osmoti c pr essure

has an inhibi tory effe ct on microo rganisms. Mo st

bacter ia, yeasts, an d mo ulds do not proli ferate a t

P >

12.7 MPa , P > 17.3 M Pa, and P > 30.1 M PA,

respectivel y. Hence, the shelf life of foods can be

regula ted by the osmot ic pressur e of the solut ion in

the material.

Difference in osmotic pressure of two systems is a

motive power for mass transfer, if the systems are

separated by a semipermeable membrane, i.e., the

membrane is permeable to solvent and impermeable

to solute molecules. This phenomenon is utilized in

osmotic dewatering of fruits and vegetables.

28.2.2 T

HE

S

TRUCTURE OF

P

LANT

T

ISSUE

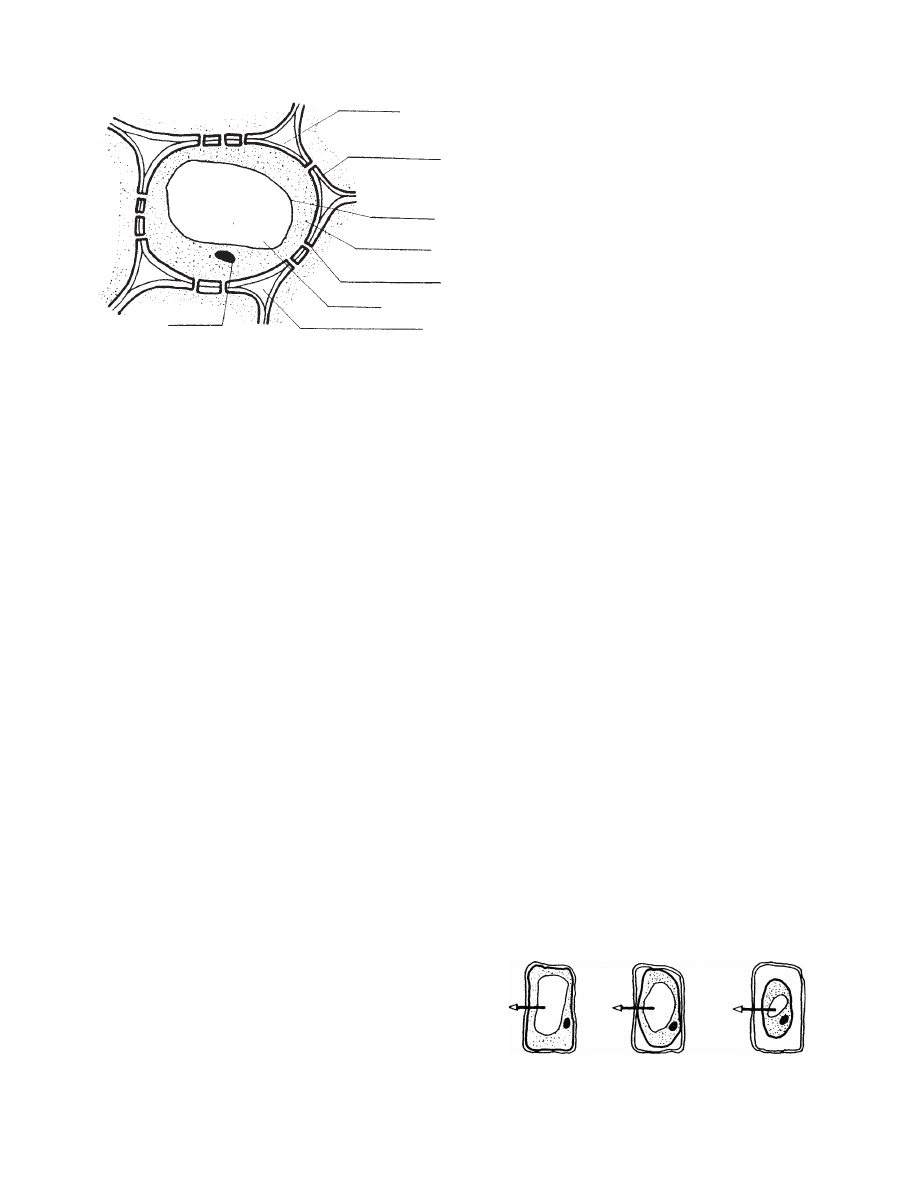

A plant cell can be simply pictured as a unit consisting

of two main components: the cell wall and the proto-

plast (

) . The cell wall is permea ble to wat er

and low molecular weight compounds and is not a

10

20 30

40 50 60 70

Concentration, %

5

10

15

20

25

NaCI

Glycerol

Saccharose

Milk

Osmotic pressure, MPa

FIGURE 28.1 Relationship between concentration and

osmotic pressure of solution.

ß

2006 by Taylor & Francis Group, LLC.

barrier in solute transport from and to the cell. The cell

wall is perforated and the channels are filled with thin

strands of protoplasm, assuring the contact between

protoplasts of neighboring cells. These strands of

protoplasm are called plasmodesmata. The diameter

of the strands is 20–70 nm and the average contact

area can be estimated as 0.2 m

2

/m

2

of the cell wall [1].

The protoplast is composed of protoplasm enclosed

in a membrane called plasmalemma, vacuoles, and

other structural elements such as the nucleus, plastids,

and so on. The plasmalemma is a protein–lipid layer

that regulates the contact between the protoplast

and the environment. It is 7.5–10 nm thick [2], per-

meable to water, and selectively permeable to other

substances. Protoplasm is a colloidal solution of pro-

teins and lipoproteins in water. The vacuole is sus-

pended in protoplasm and is enclosed in a membrane

called the tonoplast. It contains a solution of minerals,

sugars, and other organic compounds in water.

Most cells have dimensions between 10 and 100

m

m. Depending on their function they are loosely or

closely packed in a tissue. Cells are highly specialized.

A group of cells that is designated to play a special

role in a plant is called tissue.

In general, three types of tissues are recognized.

Epidermal tissue forms the outermost layer of cells

that are thick walled and covered, in many cases, with

cuticle containing a waxy substance known as cutin.

Parenchymatous tissue forms the essential part of

organs and serves to produce and store nutritional

substances. The cells are predominantly large, thin

walled, and highly vacuolated. Usually, parenchyma

cells are loosely arranged in the tissue and intercellu-

lar spaces are formed. The volume of intercellular

spaces depends on the kind of plant and its part.

Leaves have large intercellular spaces whereas roots

are little porous. For example, intercellular spaces in

potato tuber occupy about 1% of total volume,

whereas in apple fruit this volume is as large as 20%.

Intercellular spaces form a continuous system of

channels that is filled with air.

A particular type of tissue is the vascular one. It

contains xylem and phloem, which form bundles.

Xylem is present in elongated cells with perforated

end walls that no longer contain viable protoplasm.

Xylem, in other words, forms open dead vessels that

provide a way of transportation for minerals and

water from roots to other parts of a plant. Phloem is

present in elongated viable cells that have sieve end

plates. Phloem translocates a solution of sugars,

amino acids, and other nutritious substances.

A solution in a vacuole has an osmotic pressure

that pushes protoplasm and plasmalemma toward the

cell wall. The protoplast is tightly pressed to the cell

wall and the cell is in a turgor state. The difference

between the osmotic pressure in the cell and in its

surroundings is called the turgor pressure.

28.2.3 M

ASS

T

RANSFER IN

O

SMOTIC

P

ROCESS

If the cell and the surroundings have the same os-

motic pressure then turgor pressure is zero and the

system is in thermodynamic equilibrium. Osmotic

pressure of the surroundings lower than that of the

cell causes transfer of water into the cell. The cell

swells, but the rigid cell wall limits the extent of

swelling. A cell placed in a hypertonic solution

(osmotic pressure higher than that of the cell) will

lose water. The dehydration of a protoplast causes

decrease of its volume and, in consequence, detach-

ment of plasmalemma from the cell wall. This process

is called plasmolysis (Figure 28.3). As the cell wall is

permeable the volume between the cell wall and

plasmalemma fills with the hypertonic solution.

Osmotic dehydration occurs on a piece of material

and not on a single cell. Hence, it should be assumed

that the piece exists in all kinds of plant tissue. As a

rule, a skin is removed from the raw material; there-

fore, epidermal cells and cuticle are absent in most

cases. A piece of fruit or vegetable thus will contain

parenchymatous and vascular tissue and intercellular

spaces, as well.

Cell wall

Plasmalemma

Tonoplast

Protoplasm

Plasmodesmata

Vacuole

Intercellular space

Nucleus

FIGURE 28.2 Plant cell (simplified).

Flux

of water

FIGURE 28.3 Plasmolysis.

ß

2006 by Taylor & Francis Group, LLC.

Fr om the process point of view, a plant material

can be co nsider ed as a cap illary-p orous body that is

divide d inter nally in num erous repeat ing units . Some

capillari es an d por es are filled wi th a solution ,

wherea s others are empty (i.e., contai n air). M ost

capillari es an d pores are ope n. Repeat ing units can

exchange water betwe en ea ch oth er.

The inter nal structure of a body is not a hom oge-

neous one as far as trans port of water is co nsider ed.

Cell walls are built from microfi brils, and intermi-

crofibri llar spaces are some 10 nm in cross section

[3]. These spaces are large enough to allow water,

ions, an d small molec ules to pass through them. As

cell wal ls are interconn ected in the tissue, a c ontinu-

ous matr ix c apable of transp orting wat er and smal l

molec ules is formed. Thi s continuum is call ed the

apoplast . In a major ity of cell s, protopl asm of neigh-

boring cell s is intercon nected through plasm odesmata

and another continuou s ne twork is form ed. The sys-

tem of protopl asts and connec ting plasmo desmata

is wi dely known as sympl ast. Becau se plasmod es-

mata permi t the passage of solut es [1], they un-

doubted ly permi t the pa ssage of water also. The

apoplast an d sympl ast as networks capable of trans -

portin g water are separat ed from each other by plas-

malemma. Eac h vacu ole is enclosed in tonoplas t and

they are not inter connected. Hen ce, vacuoles form a

discont inuity in the syst em.

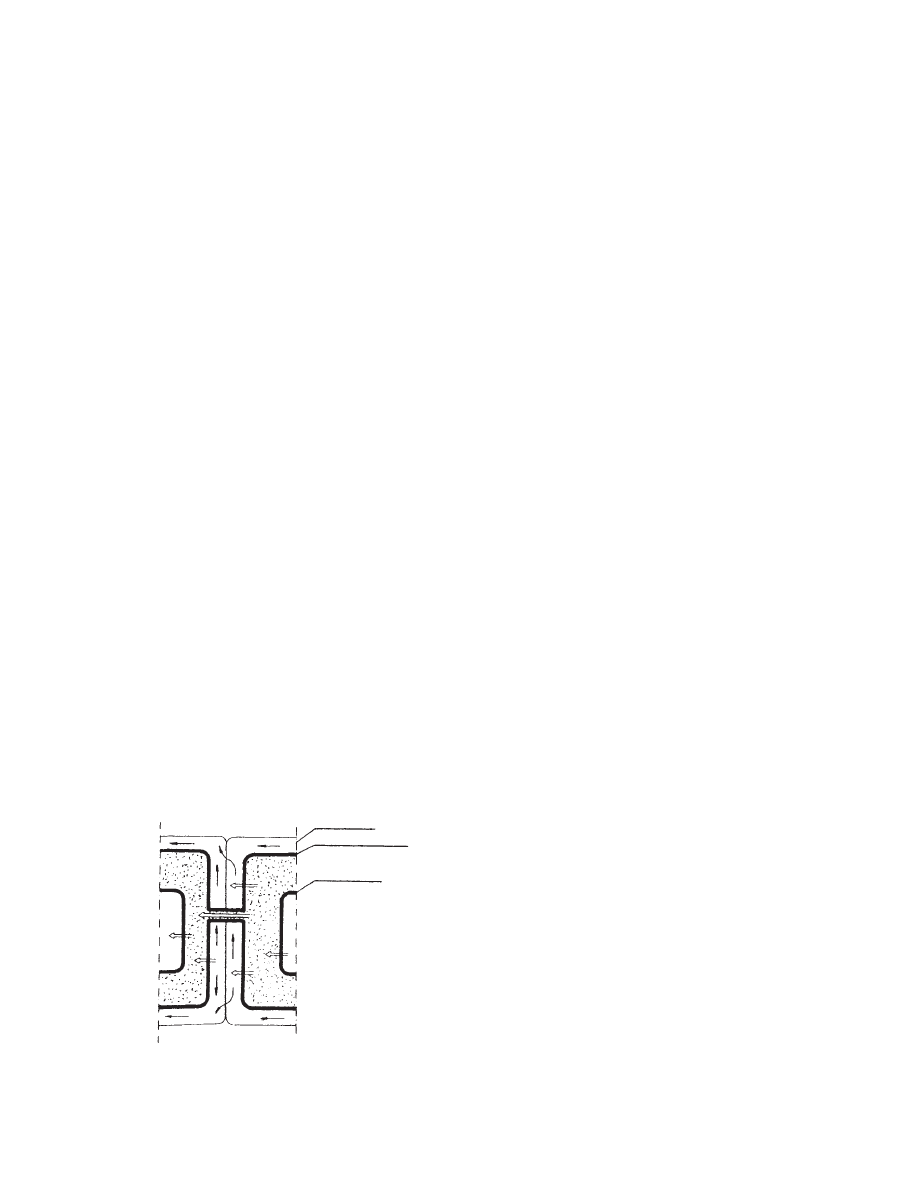

Two ways of wat er trans port in a plant have been

recogni zed: apoplasm ic and symplasmi c (F igure

28.4). It is general ly agreed that the cell walls prov ide

the major pa thway of water movem ent in plant ma-

terial. The rati o of volume flows in the apoplasm ic

and sympl asmic (vacuo le-to-va cuole) pa thways is of

the order of 50:1 in leaf tissue [1]. For the root cortex ,

the rati o is lower.

The capillary and porous system of the body exists

in vascular tissue and intercellular spaces. Xylem forms

an open conduit of relatively low hydraulic resistance

that is filled with diluted mineral solution. Phloem

exists in cells with a width ranging from 10 to 70 mm

and a length from 100 to 500 mm in dicotyledons [4].

Their turgor is around 2 MPa (beetroot is 1.83 MPa)

with a pressure gradient of 0.02–0.03 MPa/m [5,6]. As

phloem transports substances of very different molecu-

lar weight, shape, charge, and surface activity along

with water, it is presumed that the mechanism is an

osmotically driven solution flow [6].

The intercellular system of channels has the vol-

ume dependent on the kind of tissue. In potatoes, it

occupies 1–3%, whereas in beetroot 25% of volume is

attributed to cell walls and intercellular spaces [7].

There is no doubt that all these structures of the

transport system in the plant tissue will participate in

the process of osmotic dehydration.

Contacting plant tissue with the hypertonic solu-

tion, a sequence of mass transfer processes can be

envisa ged (

) as follows :

.

In intercellular spaces a capillary suction will

occur. The channels will fill in with the hyper-

tonic solution and the gas phase will be com-

pressed or pushed out until the equilibrium state

will be achieved.

.

Xylem and phloem containing solutions of

lower osmotic pressure than the hypertonic so-

lution will be penetrated by the osmoactive sub-

stance by diffusion. Osmotic pressure flow can

also take place.

.

Cell walls in contact with hypertonic solution

will lose water due to diffusion and osmotic

flow. Osmoactive substance will penetrate cell

walls by diffusion.

.

Change of osmotic pressure in xylem and

phloem and the dewatering of the cell walls

will initiate the symplasmic movement of water

in the material. The dehydration of the cells will

take place and plasmolysis will be induced.

The sequence presented above also suggests the

kinetics of the osmotic dehydration process. As long

as the mass transfer processes are not strongly depen-

dent on the symplasmic pathway, the water flux will

predominate over the osmoactive substance flux. This

is due to osmotic pressure flow, which will reduce the

countercurrent diffusion of osmoactive substance but

it will not strongly affect the diffusive flux of water as

the self-diffusion of water in a solution is of the same

order of magnitude as that for solute. When plas-

molysis occurs and the hypertonic solution fills in

the volume between cell walls and plasmalemma, the

π

1

π

1

>

π

2

π

2

Cell wall

Plasmalemma

Tonoplast

FIGURE 28.4 Apoplasmic and symplasmic transport

of water.

ß

2006 by Taylor & Francis Group, LLC.

process of dewatering will be substituted by the

impregnation of the tissue. The flux of osmoactive

substance will be equal to or will surpass the flux

of water.

The above picture of the mechanism of osmotic

dehydration suggests that the plasmalemma resist-

ance to mass transfer affects the process to only a

small extent. The process will be rather dependent

on the internal resistance to osmotic flow and apo-

plast dewatering and, to some extent, on external

resistance to mass transfer.

28.2.4 M

ODELING THE

O

SMOTIC

D

EHYDRATION

P

ROCESS

From the previous description of the structure of the

plant material and processes that can be involved in

the mass transfer between plant tissue and the os-

motic solution, it is evident that the modeling of

osmotic dehydration is not simple.

Models have been developed that describe the

behavior of the plant tissue under normal growing

conditions, i.e., when the osmotic pressure in the

tissue is higher than that in the surroundings and

the plant cell is in the turgor state [8–14]. They shed

some light on the possible ways the water and solute

molecules move in a plant tissue during osmotic

dewatering, and that was presented in previous chap-

ter. Moreover, the models were used, in some cases,

to quantify the osmotic dewatering process.

In the last five years a lot of work has been done

on modeling the osmotic dehydration process.

Mostly, the theory of molecular diffusion in the

solid has been used to predict the water loss during

the process. An unsteady unidirectional diffusion de-

scribed by the second Fick’s equation was used to

quantify the process by the effective diffusivity. The

resulting diffusivity is generally correlated with the

concentration and the temperature of the hypertonic

solution [15–28].

The models based on the second Fick’s equation

do not necessarily simulate the osmotic dehydration

process. In this process countercurrent fluxes of water

and the osmoactive substance occur. Moreover, a flux

of soluble solids from the tissue accompanies a flux of

water (Figure 28.6). Hence, there is a simultaneous

mass transfer and probable interactions between

flows cannot be taken into account. The estimated

effective diffusivities are affected by the countercur-

rent flows and they cannot be used to predict the

contribution of each flux to the process. Moreover,

in these models the resistance at the surface of the

Vacuole

Tonoplast

Intercellular space

Air

Plasmalemma

Cell wall

Mass transfer

surface

Hypertonic solution

Cell sap

Vascular

tissue

FIGURE 28.5 Possible ways of transport of water in a plant tissue during osmotic dehydration.

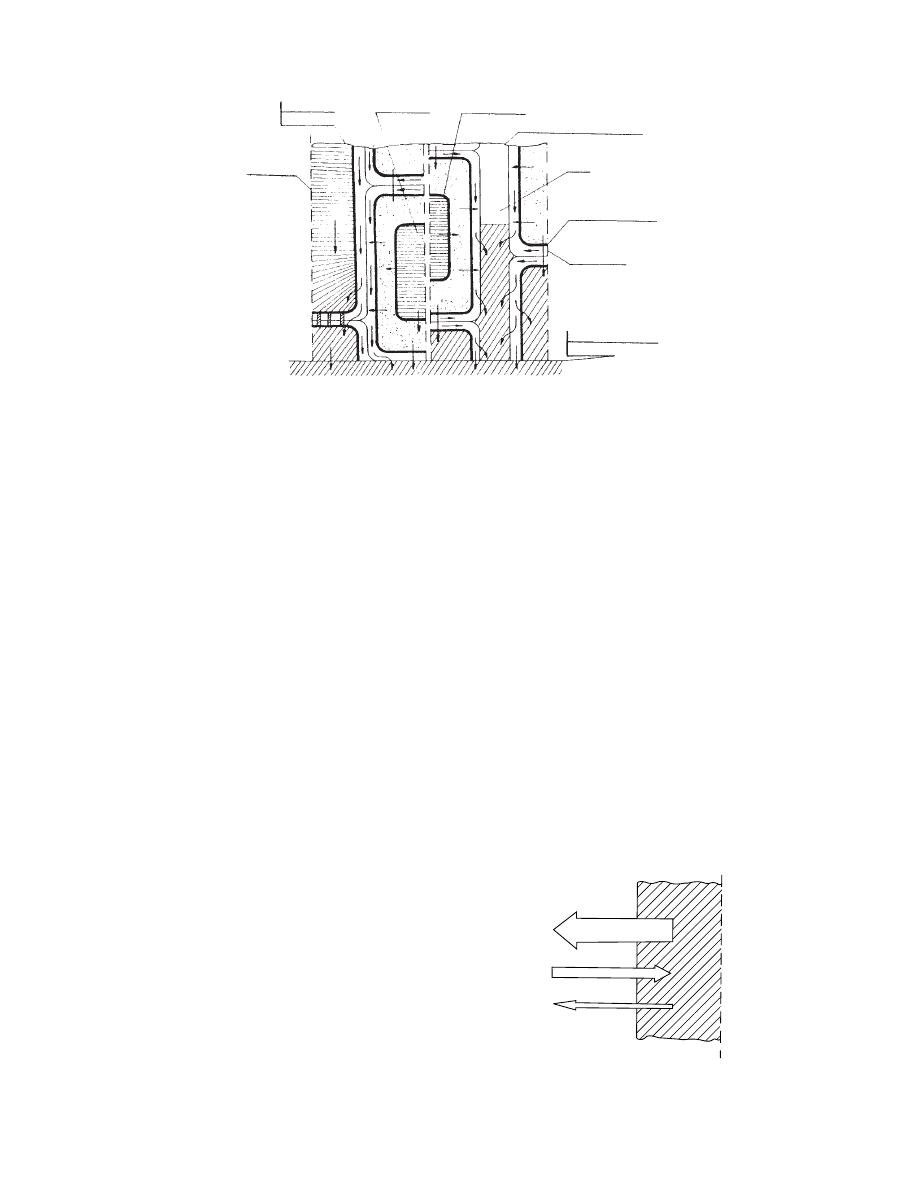

Hypertonic

solution

Water

Material

Osmoactive

substance

Natural

solubles

FIGURE 28.6 Mass transfer in osmotic dehydration.

ß

2006 by Taylor & Francis Group, LLC.

solid is assumed to be negligible, thus the whole re-

sistance to mass transfer is in the solid. Last, the

models do not take into account the possible effect

of the living cell on the mass transfer process.

A pseudo-diffusion approach [29] to model mass

transfer in osmotic dewatering showed that effective

diffusivity was not a unique function of Fourier num-

ber, as it would be expected in pure diffusion. The

developed model had no predictive ability. On the other

hand, experiments done on the frozen apple tissue

showed that mass transfer was only diffusive [30].

Besides all the limits and contradictory results, the

models based on the second Fick’s equation proved to

be quite successful. Hawkes and Flink plotted the

normalized solids content of apple versus the square

root of time and obtained a straight line, the slope of

which was called the mass transfer coefficient [15]. This

approach was used in numerous works [16,31–38].

A model was developed based on the irreversible

process thermodynamics in which the cell membrane

characteristics, the cell volume changes, tissue shrink-

age, internal volumetric rearrangements, and diffu-

sion of nonpermeating and permeating species are

taken into account [39,40]. The set of equations

solved numerically showed the model as satisfactorily

representing the behavior of parenchymatous storage

tissue undergoing osmotic dehydration. Moreover,

the simulations have shown that the cell membrane

represents the major resistance to mass transfer in

such systems. The model needed simultaneous adjust-

ment of four constants to obtain a good fit, hence its

practical usefulness is rather questionable.

Marcotte et al. improved Toupin’s model by giv-

ing a closer thermodynamic description of forces in-

volved in the osmotic dehydration process [41]. The

transmembrane transport is modeled on the basis of

irreversible thermodynamics whereas transport in the

intercellular space is modeled by relations derived

from the second Fick’s equation.

Further development of this model incorporating

diffusion, bulk flow, transmembrane flux, and matrix

shrinkage [42–44] showed that the cell membrane is

the main barrier to mass transfer only for single cells

or thin slices of tissue. When the thickness of the

sample increases, the extracellular space may become

the limiting factor [45].

The models based on the irreversible process

thermodynamics show that the cell membrane (plas-

malemma) represents the major resistance to mass

transfer. This is contradicted by findings of Raoult-

Wack et al. [46–48], who showed that membranes are

not necessary for osmotic dehydration and merely

diffusive properties of the material are responsible

for high water flux with only marginal sugar penetra-

tion. These authors suggest the following mechanism.

At the beginning of the process the removal of

water concentrates the superficial layer of solute

in the surface of the material. This layer is detri-

mental to further solute incorporation but is favor-

able to water removal as it creates a pronounced

concentration gradient [48–50]. The compartmental

model was developed that provided good fit for

the different situations tested. The solution of the

set of differential equations was done by numerical

methods.

The role of intercellular space and capillary flow

in osmotic dehydration was well documented by Fito

et al. [51–53]. On this basis the nondiffusional mass

transfer model was developed incorporating hydro-

dynamic mechanism (HDM). Studies done by the

same group [19,54] showed that long time of osmotic

process is needed to obtain a fully developed water

and sugar concentration profiles. A model based on

the advancing disturbance front (ADF) was proposed

that allows prediction of sample concentration during

osmotic dehydration.

The above models of osmotic dewatering were

developed taking the processes into account that

take place in plant tissue when the tissue is contacted

with hypertonic solution. Empirical models are also

proposed in the literature.

Mass transport during osmotic dehydration was

described by the first order kinetics in which the

rate constant is a function of main process parameters

[55] or by an empirical equation with two para-

meters, which correspond to the initial rate of mass

transfer and to equilibrium conditions, respectively

[56]. A kinetic model based on the theory of the

decreasing nucleus was also proposed to describe the

osmotic process [57].

Phenomenological or empirical models describing

osmotic dehydration are of limited use. The phenom-

enological models try to explain processes taking

place in plant tissue during osmotic dewatering. Be-

cause of that they are general and do not account for

individual response of the tissue to osmotic stress.

And a response of cells to osmotic stress depends on

the origin and morphology of plant tissue [58]. On the

other hand, empirical models are developed for the

investigated product and treatment conditions, and

they cannot be used to model the process in general.

A lot of work has been done to understand osmotic

dewatering of food products. The research done on

micro- as well as macroscopic scale presents fairly

well processes occurring in plant tissue during os-

motic dewatering. However, the great variability of

plant tissue structure and its response to osmotic

stress makes it difficult to control the main variables

of the process. Hence, current technologies are still

somewhat empirical.

ß

2006 by Taylor & Francis Group, LLC.

28.3 DESIGN OF OSMOTIC DEHYDRATION

Osmotic dehydration is a versatile process, which

makes it possible to produce a variety of products

based on the same raw material. By a proper choice

of process parameters, a wide range of products can

be obtained starting with highly dehydrated and low

solute infiltrated products and ending with highly

impregnated and little dehydrated products. If hyper-

tonic solution contains other solutes the chemical

composition of the final product can be formulated,

according to the request [59]. Hence, the design of

the osmotic process depends on the expected quality

attributes of the final product.

28.3.1 P

REDEHYDRATION

T

REATMENT

Fruits and vegetables undergoing processing come

from different parts of a plant. They are roots (car-

rots, parsley, beetroots), stems (kohlrabi, potatoes),

shoots (asparagus, onions), leaves (cabbages, spin-

ach), flowers (cauliflower, broccoli), fruits (tomatoes,

cucumbers, pumpkins, apples, pears, plums, green

bean), and seeds (green peas, beans) and must be

appropriately prepared for the osmotic process.

The epidermal tissue has very low permeability for

water and solutes, hence the skin must be removed

before osmotic treatment. In the case of small fruits

such as berries and grapes the skin permeability must

be increased. It can be done by treatment in NaOH

solution containing ethyl oleate. It proved to be

effective for tomato [60] and strawberries [61].

Most of fruits and vegetables are cut into pieces

before they are contacted with hypertonic solution.

Shape and size of the material pronouncedly affect

the rate of the process. Osmosed fruits and vegetables

have different forms that come from the technology

and consumer requirements [62,63]. Plums were de-

hydrated in whole or in halves [64]; apples were

cutinto 12 segments [65,66] or sliced into 3-mm slices

[67] or 3–4 mm thick [15]. Peaches were cut into 6 or 8

segments and pears into 8 segments [65]. Carrots were

cut into cubes of 5 or 10 mm [68,69]. Potatoes were

sliced 5 and 10 mm thick [70], or diced [20]. Papaya

was cut into cubes.

Lenart and Lewicki have shown that the thickness

of the material should not exceed 10 mm [71,72].

Taking into account further processing following os-

motic dehydration and use of the product, they con-

sidered a cube with a side dimension close to 10 mm

as an optimal size and shape for most materials.

Lewicki et al. [73–77] and Lerici et al. [78] dehydrated

apples, carrots, and potatoes as cubes of 8–10 mm on

a side. Flink, as well as Simal et al. [20], likewise used

this shape in most of his studies [79].

Blanching of fruits and vegetables before osmotic

treatment strongly affects the course of the process.

Blanching of carrots and potatoes reduces water loss

and increases solids gain [73,77,80]. Hence, its effect is

detrimental to osmotic dehydration of these materials.

Steam or microwave blanching of strawberries affected

volatile profile of the product inhibiting formation of

esters of furanones [81]. Steam blanching gave better

results than microwave treatment [82,83]. Blanching of

apple pieces either by high temperature short time

(HTST) or low temperature long time (LTLT) process

resulted in softening of tissue [84] and adversely affected

quality of the dried apricots [85].

It has been reported that immersion of some ma-

terials in CaCl

2

solution prior to osmotic dehydration

affects the properties of the product. Texture of apple

was improved [84]. Brining of cashew apple in NaCl

solution before osmotic dehydration resulted in fir-

mer texture of the candied product [86].

Immersion of cut material in ascorbic acid [87] or

citric acid [88] is used to prevent browning of the tissue.

The effect of high pressure on osmotic dewatering

was studied by Rastogi et al. [89,90]. It was shown

that the treatment has a damaging effect on tissue and

results in higher permeability to water and solutes.

The process of osmotic dehydration is facilitated by

high-pressure pretreatment.

High-intensity electric field pulses accelerated os-

motic dehydration of carrot [18]. A Fickian diffusion

coefficient for water and solute increased exponen-

tially with electric field strength. This effect was at-

tributed to increased cell wall permeability, which was

also manifested by the softening of product.

Most of the above-described treatments are aimed at

increasing permeability of plant tissue and facilitating

the osmotic dehydration. Damage to the tissue structure

results in increased permeability to water as well as to

solute. Hence, the pretreatment has no selective effect

and faster water removal is accompanied by greater

infiltration of solute into osmosed material. In many

cases, it is desirable to reduce infiltration of solute into

tissue as much as possible to obtain dehydrated product

with little or no change in its chemical composition.

The influx of osmoactive substance into the tissue

can be hindered by special pretreatment or by artifi-

cial semipermeable membranes. It was shown that

convective drying of apple cubes for time as short as

10 min forms a type of skin on the surface which does

not affect the flux of water but reduces the flux of

sugar during further osmotic dehydration [91]. Artifi-

cial semipermeable membranes are formed from pec-

tins or starch [91–95], alginate or low-methoxyl pectin

[96]. Coatings significantly reduce solute incorpor-

ation into tissue and result in increased weight loss

during osmotic treatment.

ß

2006 by Taylor & Francis Group, LLC.

28.3.2 O

SMOACTIVE

S

UBSTANCE

Osmoactive substances used in food must comply

with special requirements. They have to be edible

with accepted taste and flavor, nontoxic, inert to

food components, and if possible, highly osmoactive.

Quality of the final product was the main aim of

most experiments testing the suitability of different

osmoactive substances. Their technological applicabil-

ity is estimated on water loss rate and final water con-

tent in the material. Usually, saturated solutions, or the

solutions at the same concentrations, are compared.

Flink [97] used two criteria to rate different osmoactive

substances: water loss and the amount of the substance

penetrating the material that is osmosed. Lowering of

water activity in the material was also used as an

indicator of suitability of an osmoactive substance [98].

Solutions of sugars are mostly used to dehydrate

fruits; and glycerol, starch syrup, and sodium chlo-

ride are used for vegetables [62,73,91,99]. Sucrose is

the most frequently used substance [17,65,100–104].

The control of pH of sucrose solution is recom-

mended for banana slices osmotic dehydration [105].

It was also shown that control of pH of sucrose

solution affects the course of osmotic dehydration of

apple and carrot [106]. Addition of ascorbic acid to

sugar solution is practiced to minimize browning of

fruit pieces during osmotic process [72]. Sucrose can

be substituted in part by lactose [15].

Glucose and fructose give a similar dehydration

effect [107,108]. In other publications it is reported

that fructose increases the dry matter content by 50%

as compared with sucrose. Water activity of the final

product was also lower with fructose as a hypertonic

solution [109]. In apple, banana, and kiwifruit, glu-

cose caused higher water loss and solids gain than

sucrose [102]. Starch syrup makes it possible to have

similar final water content in dehydrated material as

that obtained with sucrose but at a much lower influx

of osmoactive substance into tissue [87,101,110]. The

dextrose equivalent of the syrup strongly affected the

ratio between water loss and solids gain. Corn syrup

solids [111], cane sugar syrup [112], palm sugar syrup

[113], and hydrolyzed lactose syrup [114] were also

used in osmotic dehydration of fruits and vegetables.

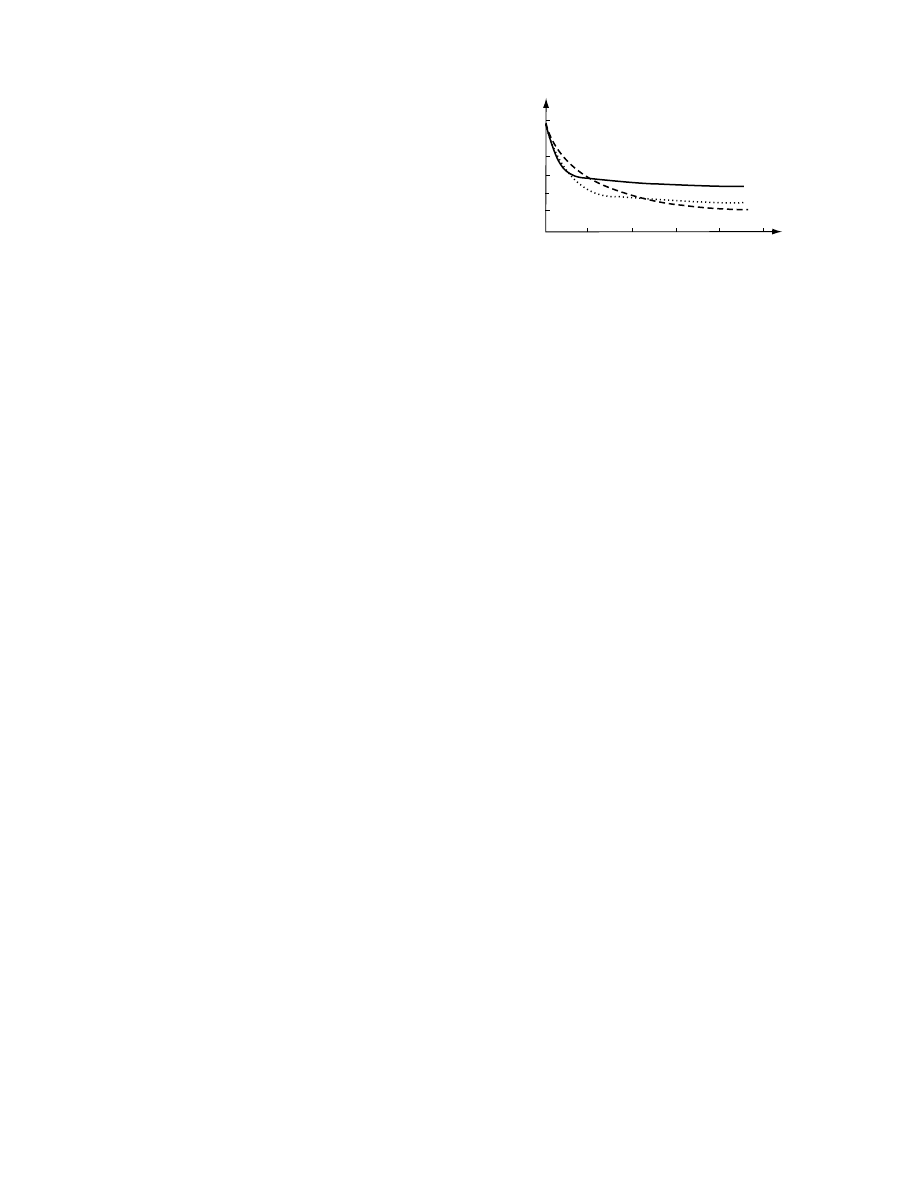

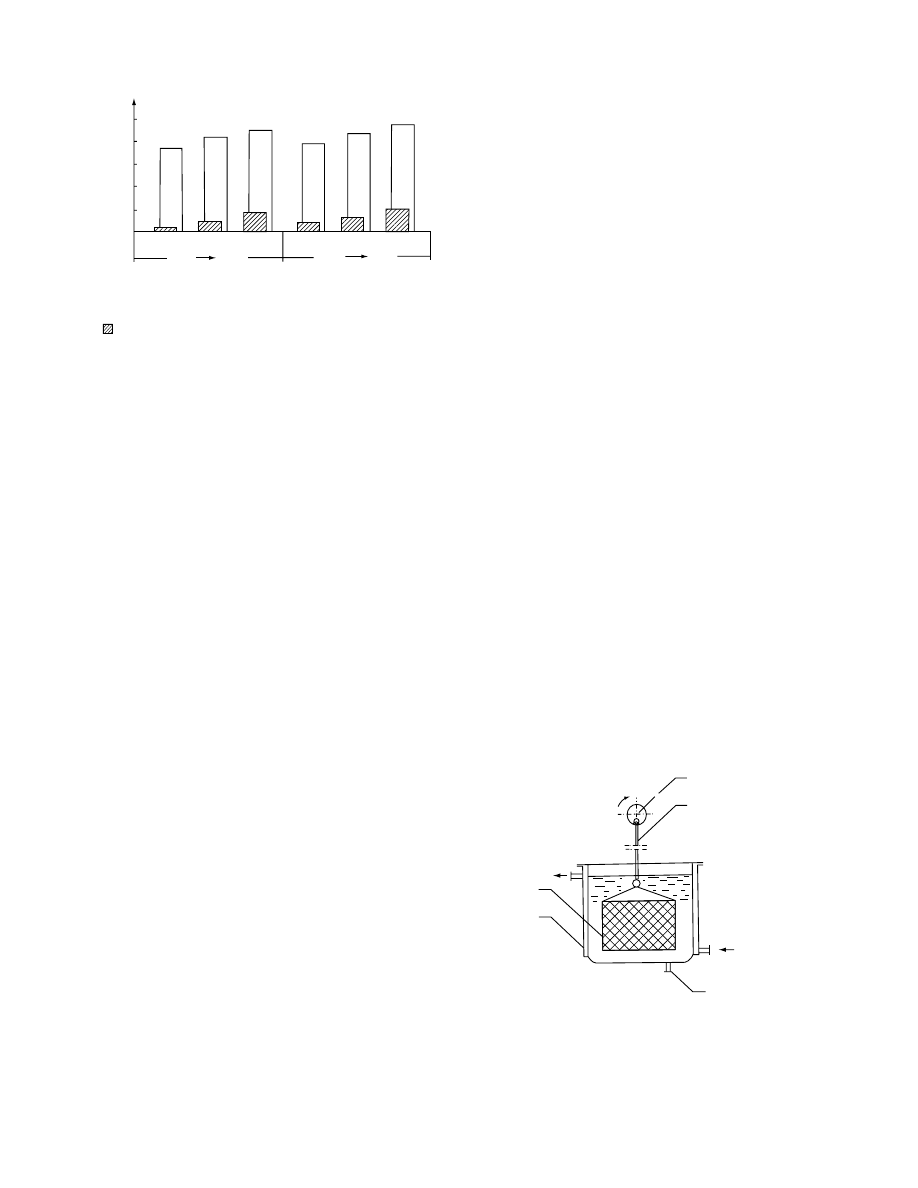

The effect of the kind of osmoactive substance on the

water content of osmosed material is presented in

Figure 28.7 [115].

Mixtures of osmoactive substances are also used.

Maltini et al. [116] used sucrose and starch syrup in

a ratio of 1:1. Lerici et al. [117] dehydrated apples in a

solution containing 42% fructose, 52% sucrose, 3%

maltose, 3% polysaccharides, and 0.5% sodium chlor-

ide in dry matter. Mastrocola et al. [118] used solut-

ions containing sucrose and fructose in varying

proportions. Water loss was similar for all solutions

tested but the penetration of the osmoactive substance

was different. Peaches dehydrated in solutions of glu-

cose and fructose were especially suitable to pasteur-

ization [119]. Solution of sucrose and glucose yielded

high drying rate of apple slices [17]. Mixture of crys-

talline sucrose and glucose lowered water activity of

guava to 0.77 whereas sucrose alone yielded a water

activity of 0.80 [120]. Mixture of sucrose and sodium

chloride is used to osmose fruits and vegetables [121–

123]. The presence of NaCl facilitates the process.

Mixture of sucrose and citrate was used in osmotic

dehydration of peas [124–126] and papaya [127].

Sodium chloride was used to dehydrate vegetables.

Speck et al. [68] used 10% solutions to dehydrate car-

rots. Lewicki et al. [80] used 15% NaCl to dehydrate

carrots and potatoes. Adambounou et al. [128] dehy-

drated paprika, tomatoes, and eggplant in saturated

salt solutions, getting water activity as low as 0.8.

Vijayanand et al. [129] used 5–25% NaCl solution to

dehydrate cauliflower. Use of sodium and potassium

chlorides made it possible to regulate sodium and

potassium content in dehydrated corn and green peas.

It has been found that the addition of low molecu-

lar weight substances such as sodium chloride, malic

acid, lactic acid, and hydrochloric acid in concentra-

tions of 1–5% to sugars or starch syrups improves the

process of osmotic dehydration. In general, they pro-

mote removal of water from the material. Calcium

chloride and malic acid were added to sucrose to

improve the texture of osmosed apples [130].

28.3.3 P

ROCESSING

P

ROCEDURES AND

P

ARAMETERS

Osmotic dehydration can be done basically in two

ways: by static or dynamic process. In a static process,

5

5

4

3

2

1

10

Water content, g/gd·m

Time, h

15

20

25

6

FIGURE 28.7 The effect of osmoactive substance on

the

course

of

osmotic

dehydration

of

apples

at

308C

(. . . . . .,

glucose; ------, saccharose; ........., starch

syrup). (From Lenart, A. and Lewicki, P.P., of in IDS ’89

Mujumdar, A.S. and Roques, M., eds., Hemisphere Publ.

Co., New York, 1990, p. 501.)

ß

2006 by Taylor & Francis Group, LLC.

the material is mixed with an osmoactive substance,

which can be used as crystals or solution, and the

mixture is left motionless until the desired water loss

is achieved. It has been shown that the mass transfer

resistance in this method is higher than that observed

in a dynamic process [131,132].

In a dynamic process, the mixture is mixed; dif-

ferent methods of mixing can be used. Movement of

food particles in a stationary solution, mixing of the

whole suspension, and the flow of the osmoactive

substance through the stationary layer of food pieces

are the commonly used designs of the dynamic pro-

cess. If crystals of the osmoactive substance are

used, the fluidized bed is the solution for the dynamic

process. It has been shown that the rate of motion

has little effect on the rate of osmotic dehydra-

tion [71,133]. It is just sufficient to induce motion of

particles or solution in the system to have increased

mass transfer rates. Moreover, it was shown that the

motion of osmotic solution in a turbulent region

affected water flux but no difference in solids gain

occurred in comparison with laminar flow [134].

Azuara et al. [121] applied centrifugal force to

suspension of potato and apple slices in hypertonic

solution. The force affected solids gain much more

than the water loss. In comparison with static

method, the application of centrifugal force resulted

in larger water flux and smaller solids gain.

Reduction of pressure during osmotic dehydra-

tion increases the rate of the process [115,135]. It

has also been observed that low pressure facilitates

penetration of the osmoactive substance into the tis-

sue [136,137]. Osmotic dehydration under reduced

pressure is done in two ways: reduced pressure is

kept continuously or reduction of pressure is done

in pulses [83,127,137–139]. In general, pulsed vac-

uum osmotic dehydration gives better results than

vacuum osmotic dewatering.

Apple cubes subjected to osmotic process and

treated by ultrasound, dewatered faster than the

nontreated ones [20]. Water and solute transport

rates were significantly higher in sonicated samples in

comparison with those not sonicated during osmosis.

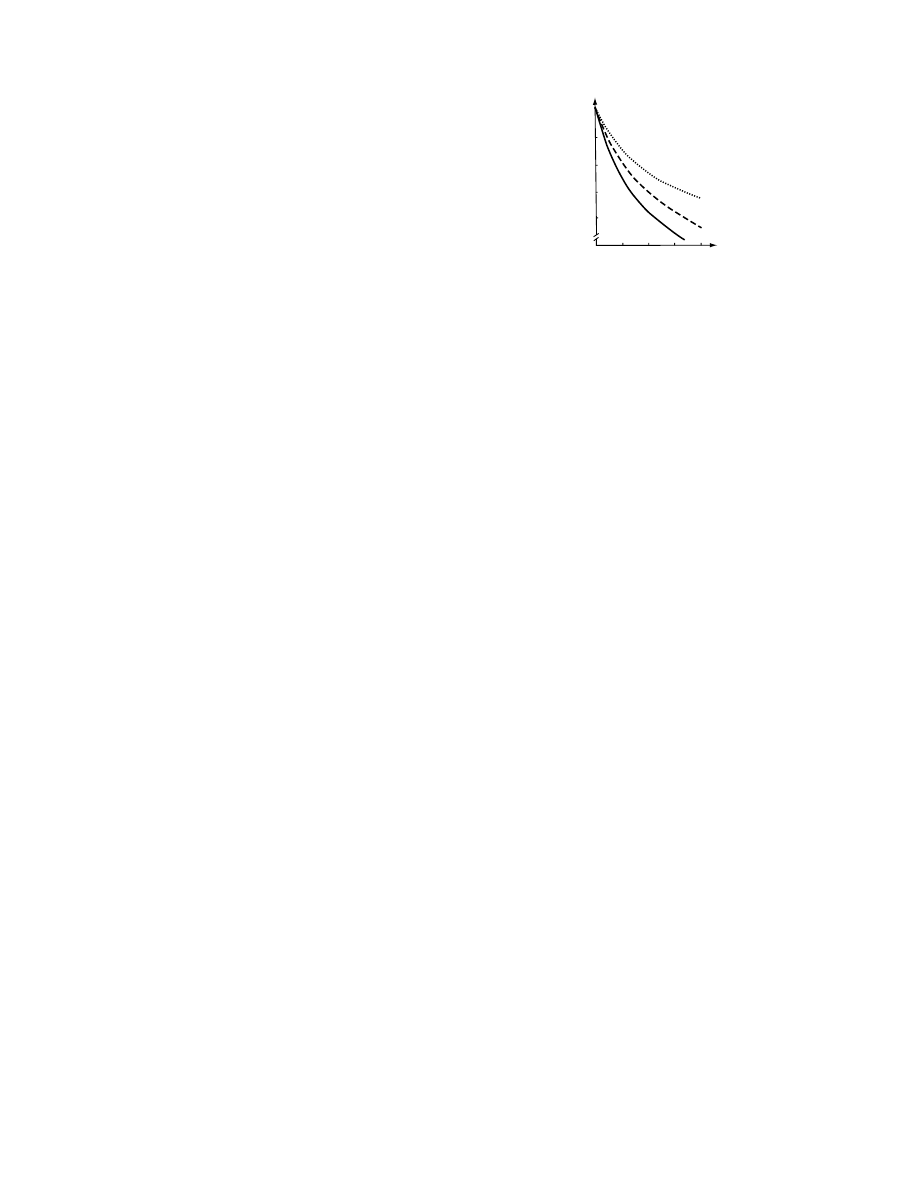

The rate of osmosis increases with increase of

concentration of the osmoactive substance (Figure

28.8) [23,66]. The weight loss of mango and papaya

is linearly dependent on sucrose concentration up to

60% [140]. Similar results were obtained for apple,

carrot, and pumpkin. At higher concentrations, a

lower rate is observed and the impregnation of fruits

with saccharose is high. Ponting [65] used 65–70%

sucrose solutions to dehydrate apples. Pinnavaia

et al. [101] recommend 70% starch syrup for osmode-

hydration of apples. Lenart and Cerkowniak used

glucose, saccharose, and starch syrup solutions to

dehydrate apples [141]. Rastogi et al. [23] recommend

40–708Bx sugar solution for osmotic dehydration

of bananas. A high rate of dehydration of carrot

and potato was obtained with 15% sodium chloride

solution [142,143].

Crystalline osmoactive substance is used at a

weight ratio of 1:1 to fruits [45,105]. For solutions,

investigations were done at weight ratios of 1:1 to 1:6

[87,144]. Osmotic dehydration of fruits and veget-

ables is recommended to be done at a weight ratio

of 1:4 to 1:5 of food to osmoactive solution [77,145].

Temperature has a substantial effect on the course

of osmotic dehydration. It not only affects the rate of

the process but also influences the chemical compos-

ition and properties of the product. Increased tempera-

ture increases the rate of chemical reactions and mass

transfer processes as well. Viscosity of hypertonic solu-

tion is lowered and the diffusion coefficient of water

increases with the increase of temperature [21,77].

Andreotti et al. [31] recognize a temperature of

438C as the optimal for osmotic dehydration of cher-

ries and pears in glucose or glucose–fructose syrup.

They recommended a temperature of 208C for os-

motic dehydration of apricots. Bananas were osmot-

ically dehydrated at 608C [146]; however, it was

shown that optimal temperature was dependent on

the concentration and pH of the osmotic solution

[105]. Pineapple was dehydrated at 42–478C [96] but

application of vacuum and temperature higher than

408C resulted in loss of volatiles [112]. Osmotic dehy-

dration of plums is done at 508C [147,148], kiwifruit

at 378C, and peas at 50–708C [124].

Kowalska et al. [149] recognize a temperature of

508C as the optimal for osmotic dehydration of straw-

berries and cherries in glucose, sucrose, and starch

syrup solution. They recommended osmosing fruits

at 30–508C. Nsonzi and Ramaswamy [21] osmotically

dehydrated blueberries at temperature 37–608C and

2

60

Relative weight, %

70

80

90

100

4

Time, h

6

8

FIGURE 28.8 The effect of sugar syrup concentration on

the course of osmotic dehydration of apples at 508C (708Bx;

------, 608Bx; ........., 508Bx). (Adapted from Farkas, D.F.

and Lazar, M.E., Food Technol., 23, 688, 1969.)

ß

2006 by Taylor & Francis Group, LLC.

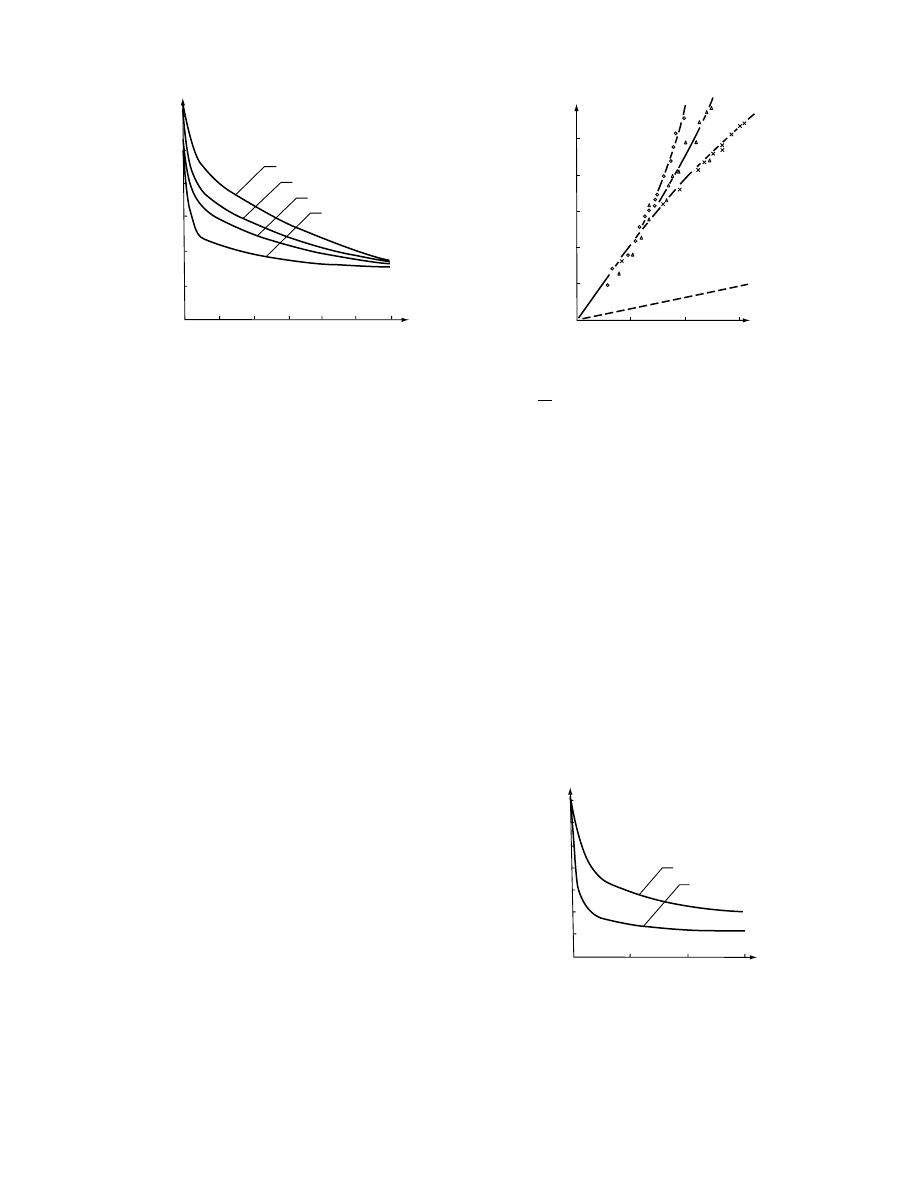

sucrose solution conc entration 47–70 8 Bx. Apples

were dehydrat ed at tempe ratur e 30–90 8 C [115] (Fig-

ure 28.9) . It has be en sho wn that the increa se of

tempe rature in the range of 30–80 8 C su bstantial ly

shorte ns the tim e of deh ydration [133]. How ever, in-

crease d tempe rature promot es penetra tion of

osmoact ive substa nce into the tissue [77] .

A HTS T proce ss was propo sed for osmotic de hy-

dration by Ma strocola et al. [118], Lerici et al. [78] ,

Levi et al. [150], and Da˛ browsk a an d Lena rt [151] .

The process is con ducted at 65–90 8 C at a tim e of

1–20 min. The de gree of dehydrat ion is equival ent to

that at 20 8C last ing for 2 h. The HTS T pro cess also

gives the effect of blanch ing, whi ch inact ivates en -

zymes and remove s part of the air from the inter cel-

lular sp ace. To obtain a high ratio between water loss

and soli ds gain (F igure 28.10) , a tempe ratur e between

20 8 C and 40 8 C is recomm ended [117, 152,153]. The

degree of dehyd ration is regula ted by the time of

osmosi s.

The cou rse of mass loss versus tim e is cu rvilinear .

The highest rates occur at the be ginning of the pr o-

cess [154]. Porosit y greatly increa ses during the first

period of osmot ic deh ydration . This impl ies that a

part of the air vo lume in the struc ture is replac ed by

the exter nal solution [155]. The most significan t

changes of water content , water loss, and soli ds ga in

take place during the first 30 min of dewat ering at

30 8 C. Rate of wat er loss is 5–10 times higher than the

rate of solids gain and depend s on the advan cement

of the dewateri ng pr ocess [156]. Accor ding to Lena rt

[157], opt imal tim e of apple de hydration is 5–6 h at

20 8 C, 3–4 h at 30 8 C, and 1–1.5 h at 40 8 C. A redu ction

of mass by 50% can be achieve d after 2.5–3 h of

osmosis at 5 08C.

It is well recognized tha t the charact eristics of the

material undergoing dehydration by osmosis

strongly affect the c ourse of the proc e ss. U nder

identical c onditions some materials l ose w ater faster

than others (Figure 28.11). The penetration of the

osm oactive sub s t ance dif fers m arkedly (

); he nce, properties of the product and its c on-

sumer acceptance are strongly affected by the i nitial

properties of the material, supposedly by its tissue

structure.

2

2

3

3

Time, h

4

4

5

6

1

1

1

Water content, g/gi·d·m

2

3

4

5

6

FIGURE 28.9 The effect of temperature on the course of

osmotic dehydration of apples in saccharose solution (1,

308C; 2, 508C; 3, 708C; 4, 908C). (From Lenart, A. and

Lewicki, P.P., in IDS ’89, Mujumdar, A.S. and Roques,

M., eds., Hemisphere Publ. Co., New York, 1990, p. 501.)

0.3

Water loss, g/gi·d·m

1

2

3

4

5

Solids gain, g/gi·d·m

0.6

0.9

FIGURE 28.10 Relationship between water loss and solids

gain in apples during osmotic dehydration in saccharose

solution (

, 208C;

; 308C; ++, 408C; . . . . . . ; diag-

onal). (From Lenart, A. and Lewicki, P.P., in Drying ’87,

Vol. 2 Mujumdar, A.S. ed., Hemisphere Publ. Co., New

York, 1987, p. 239.)

5

Time, h

Water content, g/gi·d·m

10

15

1

1

2

2

4

3

5

6

7

FIGURE 28.11 The effect of the kind of material on the

course of osmotic dehydration in saccharose solution at

208C. 1-apple, 2-carrot.

ß

2006 by Taylor & Francis Group, LLC.

Concluding the effect of procedures and process-

ing parameters on the rate and efficiency of osmotic

dehydration it can be stated that all of them are

equally important. The kind and concentration of

the osmoactive substance, the weight ratio of the

solution to food, the kind of osmosed material, its

size and shape, temperature and pressure, and the

pretreatment of the material prior to osmosis affect

strongly not only the course of the process but also,

first of all, influence the quality and organoleptic

attributes of the final product. To reach reques-

ted quality of the product the process of osmotic

dehydration must be individually designed.

28.3.4 O

SMOTIC

S

OLUTION

M

ANAGEMENT

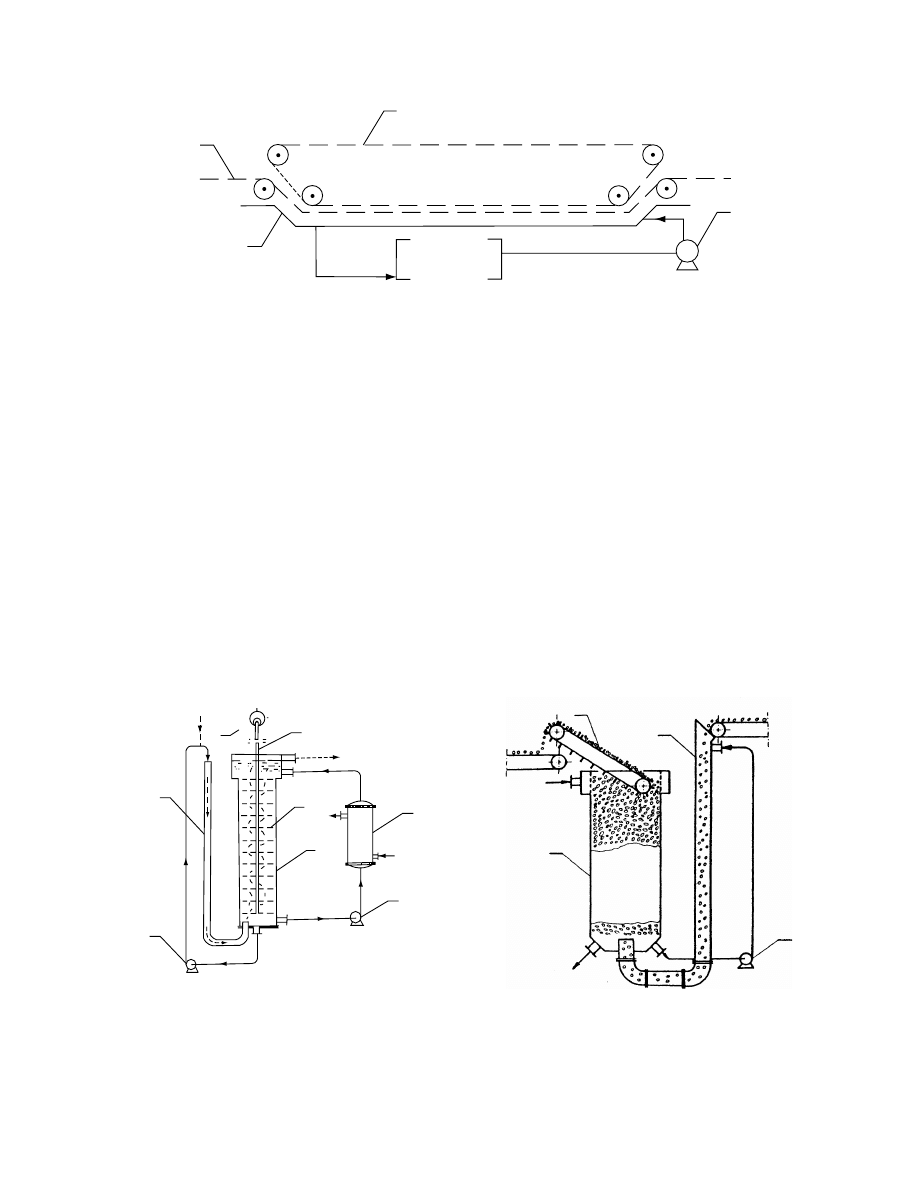

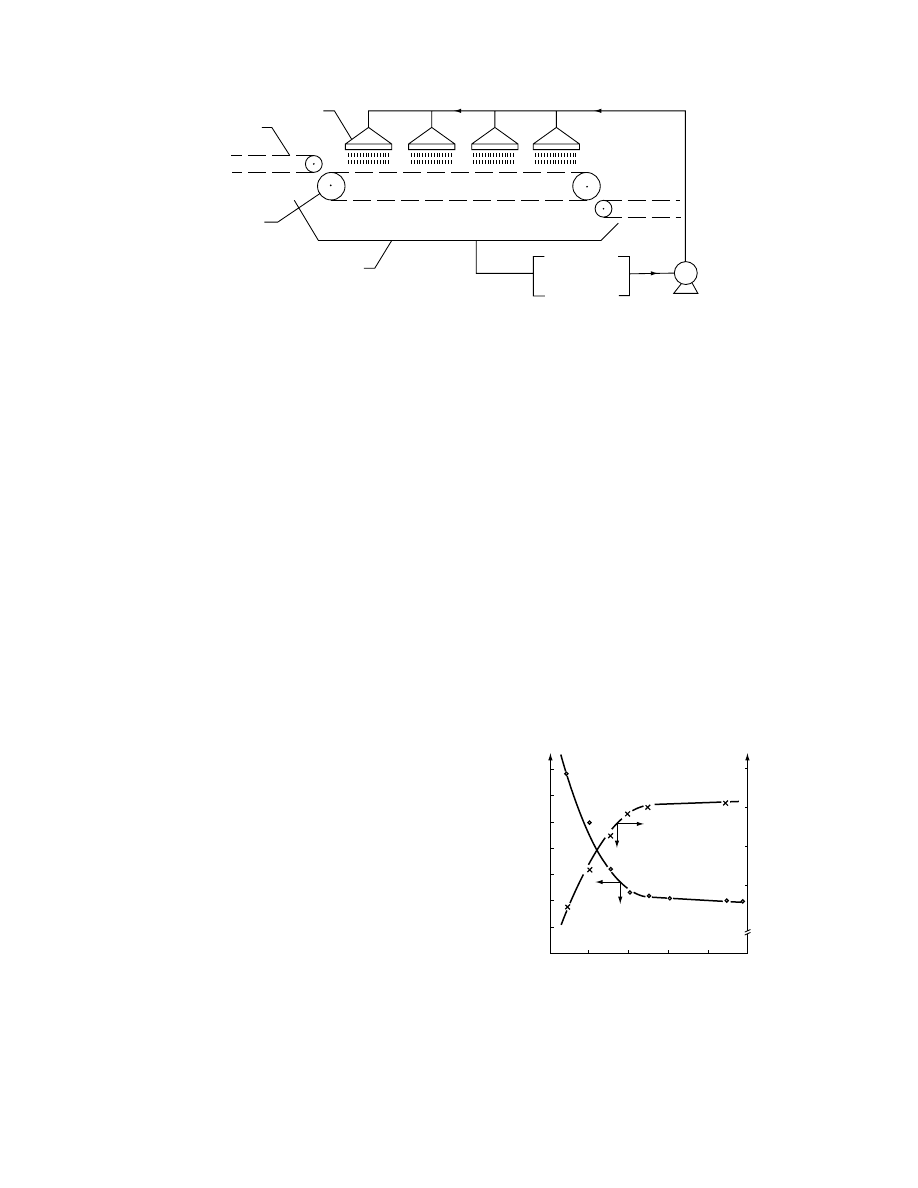

Water withdrawn from the material dilutes the hyper-

tonic solution. Hence, it is important to keep its

concentration constant, either by a continuous evapo-

ration of excess water [133,144] (Figure 28.13) or by

dissolution of osmoactive substance [144]. Both

methods make it possible to use the same hypertonic

solution several times.

Dilution of the hypertonic solution depends on

the ratio between solids and the solution. At high

ratio, i.e., 1:10, dilution is low and amounts to few

percent, whereas at high ratio such as 1:2 the increase

of volume of osmotic solution can be as large as

several percent [158].

Evaporation of excess water, membrane separation,

or dissolution of osmoactive substance can bring the

concentration of hypertonic solution to the required

value but the solution is not the same as that used in

the beginning of the process. Leaching of solubles from

fruits or vegetables [159,160] to the hypertonic solution

changes its physical, chemical, and sensory properties.

Moreover, debries of fruits and seeds are present in

the solution after its use. And finally, may be this is

the most important issue, the solution becomes a

good medium for microbial growth.

Concentration of substances leaching from the

processed material stabilizes after few uses depending

on the kind of osmosed material, and reaches the level

similar to that of the osmotically processed fruits or

vegetables.

Designing the process of the reuse of osmotic solution

the coarse filtration, pasteurization, and decolorization

0.3

Water loss, g/gi·d·m

1

2

3

4

5

Solids gain, g/gi·d·m

0.6

0.9

FIGURE 28.12 The effect of the kind of material on the

relationship between water loss and solids gain in osmotic

dehydration in saccharose solution at 208C (

, apple;

4—4, carrot; ------, diagonal).

2

1

3

4

5

7

6

FIGURE 28.13 Osmotic dehydration with reconcentration of hypertonic solution (1) feeding conveyor; (2) osmotic dehy-

drator; (3) redler conveyor; (4) heat exchanger; (5) scaraped surface evaporator; (6) thermocompressor; (7) driven wheel; flow

of hypertonic solution; ------, vapor; ), high pressure steam; ------, heating steam).

ß

2006 by Taylor & Francis Group, LLC.

must be taken into account. The sanitation of the solu-

tion is a priority in the recycling process.

Microbial contamination of the solution comes

from different sources but its water activity 0.90–

0.95 limits the growth of nonosmotolerant bacteria

and yeasts. Processing of fruits and vegetables results

in contamination of osmotic solution with moulds,

yeasts, and lactic bacteria. Reported microbial loads

of osmotic solution range from 10

2

to 10

5

cfu/ml after

long-time use [158]. Mild heat pasteurization is suffi-

cient to lower the microbial load of the solution to

value as low as 10

2

cfu/ml [161].

Heat treatment of sugar solutions containing

acids and proteins results in nonenzymatic browning.

The presence of 5-(hydroxymethyl)-2-furfuraldehyde

(HMF) was shown to be a good indicator of Maillard

reactions [158]. Decolorization of the solution can be

done with activated carbon, charcoal as filtration

coadjuvant and polyvinylpyrrolidone [132,160,161].

Filtered, pasteurized, and decolorized syrup can

be used few to several times depending on the pro-

cessed material and organization of the process. In

continuous processing more recycling can be done

in comparison to the process in which runs are not

done consequently. The possibility to reuse the os-

motic solution more than 20 times was reported

[158]. However, number of cycles is dependent on:

.

Kind of processed material

.

Type of reconcentration technology

.

Pasteurization parameters

.

Organization of the process

.

Individual adaptation to the given process

Osmotic solution, even after several uses must

be disposed. In the case of fruit processing, some

ways of further use of osmotic solution have been

proposed [158]:

.

Syrup for fruit canning

.

Pproduction of jams

.

Mixing with fruit juices

.

Production of fruity soft drinks

.

Production of natural flavorings

.

Bee feeding

Processing of vegetables, especially with sodium

chloride yields solution which further management

is not solved until today.

Spent solutions if not used in other processes must

be discharged as wastewater. High carbohydrate con-

tent and the presence of other organic materials cause

very high demand for oxygen. The biological oxygen

demand (BOD

5

) of the osmotic solution is high and

efficient wastewater treatment is needed. The presence

of salt in osmotic solution creates additional prob-

lems and probably the use of reverse osmosis is the

rational way of this spent-liquor treatment.

28.3.5 E

NERGY

A

SPECTS OF

O

SMOTIC

D

EHYDRATION

Osmotic dehydration is distinctive in that water is

removed from the product without undergoing the

phase change. It offers a considerable potential for

energy saving in comparison with convection drying.

Most publications consider energy consumption

in a drying process that is preceded by osmotic dehy-

dration [162] or analyze the process under laboratory

conditions [142,163,164].

Energy consumption in the osmotic dehydration

process arises from the following [165]:

.

Heating of the material and osmoactive solution

to the required temperature and making up a

heat loss

.

Solution mixing or pumping and recirculation,

depending on the variant applied

.

Dissolution of hypertonic substance in a diluted

solution

.

Evaporation of water in an appropriate eva-

porator

It is estimated that dissolution of osmoactive sub-

stance in a hypertonic solution needs some 1 kJ/kg of

water removed from the material. Hence, this process

affects energy consumption in osmotic dehydration

negligibly.

The amount of water removed during osmotic

dehydration is not large. Processing of 1 ton of fruits

or vegetables per h will give, at the most, 450 kg of

surplus solution (i.e., some 5.5 tons of water evapor-

ated per day). Hence, a single-effect evaporator with

vapor recompression will meet the needs.

Energy use in the evaporator consists of electric

energy for syrup circulation and heat for water evap-

oration. Electric energy use is estimated to be equal to

10 kJ/kg of evaporated water, and heat consumption

is some 1.8 MJ/kg of evaporated water.

The increase of temperature shortens the osmotic

process. The use of energy for syrup mixing or circu-

lation is estimated as 17.2, 10.0, and 4.3 kJ/kg of

water removed at temperatures 208C, 308C, and

408C, respectively. To keep the process running at a

desired temperature, a supply of heat is necessary.

Depending on the amount of water removed from

the material, the heat supply amounts to 180–240

kJ/kg at 308C and 380–500 kJ/kg of water removed

at 408C [166].

Energy consumption in osmotic dehydration of

fruits and vegetables under industrial conditions is

ß

2006 by Taylor & Francis Group, LLC.

estimat ed to be between 100 an d 2400 kJ/kg of wat er

remove d (Figur e 28.14), depending on the tempe ra-

ture of the process an d the way the surplus solution is

managed. It is wort hwhile to notice that con vection

drying needs some 5 MJ/kg of evap orated water,

which is at least twice as much as is needed in osmot ic

dehydrat ion.

28.4 EQUIPMENT FOR OSMOTIC

DEWATERING

Depending on the aim of osmotic process and desired

produc t charact eris tics the process can be de signed as

far as process ing parame ters are concerned. To im-

pleme nt the de signed proce ss a specia l equ ipment is

needed which must assure control of pro cessing

parame ters and effici ency and econo mics as wel l.

Choi ce of the equipment is based on the following

criteri a:

.

Type of process ing; periodi c or continuous

.

Resist ance of food to mechani cal damage

.

Shap e of food; whole or cut into pieces

.

Suscepta bility of food to oxidat ion in contact

with air

.

Relati ve mo vement of phases, soli d and liquid

.

Possibi lity to control pro cessing pa rameters

.

Invest ment and run ning co st

Accor ding to M arouze´ et al. [167] process es of

osmot ic deh ydration can be categor ized as foll ows:

.

Thos e in whi ch foo d is imm ersed in the osmot ic

solut ion

.

Thos e in whi ch solut ion is intr oduced onto the

food

.

Those in whi ch osmot ic substa nce in solid state

is con tacted with food

.

Those in whi ch reduced pr essure is used to fa-

cilitate mass trans fer

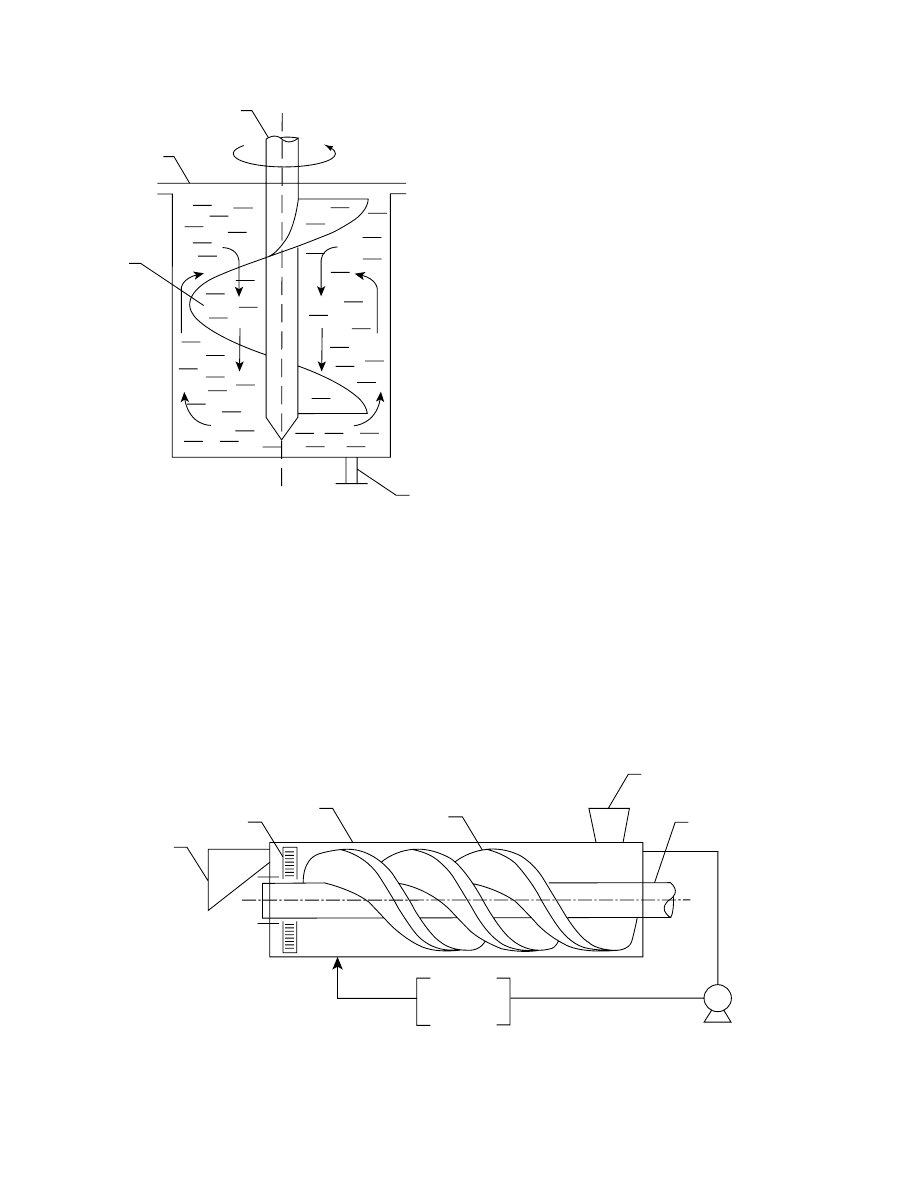

28.4.1 F

OOD

I

MMERSED IN

S

OLUTION

The sim plest way to contact foo d with osmo tic solu-

tion is to immerse a basket with food into solut ion.

The movem ent of solut ion is sli ght due to natural

convecti on. M ass trans fer is slow and most of pro -

cessing parame ters are not controlled. The method

can be used to soft frui ts.

Osm otic dewat ering can be facilitated by de -

creasing mass trans fer resistance . This can be

done eithe r by circul ation of solut ion or by slow

movem ent of food. Ci rculation of solut ion is done

by install ation of circul ation pump to a vessel in

which basket with food is immersed. Movement of

food in the solut ion is done by vibrat ion (Figur e

28.15) or by a conveyo r (

). The latter

solution is used in Poland in the process ing of app le

slices [168,169] .

Com binati on of solution circulatio n and mov e-

ment

of

food

particles

is

combined

in

such

equipment as vibrating plate mixer (

and percolated bed with slow displacement of food

(

) . In vibrated plate mixe r [133] , osmot ic

solution is circulating in two loops, one is a feed loop

by which food is fed into a mixer, and the second

loop maintains constant temperature of the solution.

Food moves from bottom of the mixer to its top

7.6

Energy consumption, MJ

1

20

⬚C

30

⬚C

40

⬚C

20

⬚C

30

⬚C

40

⬚C

4.0

2.0

7.6

2

FIGURE 28.14 Energy use in osmotic dehydration ex-

pressed per kilogram of removed water. Temperature of

the process and the degree of dewatering are the parameters

( , diluted hypertonic solution completed with osmoactive

substance; &, diluted hypertonic solution concentrated in

evaporator).

1

5

2

3

4

FIGURE 28.15 Osmotic dehydration with a vibrating bas-

ket (1, jacketed vessel; 2, basket; 3, shaft; 4, eccentric; 5,

spout). (From Lenart, A. and Lewicki, P.P., in IDS ’89,

Mujumdar, A.S. and Roques, M., eds., Hemisphere Publ.

Co., New York, 1990, p. 501. With permission.)

ß

2006 by Taylor & Francis Group, LLC.

through a series of perfor ated vibrat ing horizont al

plates mou nted on a v ertical axis. In a pe rcolated

bed, food is delivered at the bottom of the tank by a

hydrauli c feed an d forms a poro us be d. The bed

moves slowly to the top of the tank an d is extracted

by a redler or buck et co nveyor. Solutio n is fed a t

the top of the tank an d is circul ated through the

feed leg. In this equipment, a countercurrent movement

of food and solution occurs. A cocurrent movem en t of

food and solut ion as a percola ted bed was also

designe d for osmot ic process [167] .

M ovement of solut ion an d pa rticles can be

done by mechanical mixing. Mixing device can be

install ed vertical ly (

) or horizont ally

(

) . In the first design, a worm screw is

placed coaxially inside a vertical cylindrical tank. The

screw moves particles of food from top to the bottom

of the tank. Then the pieces rise toward the surface

under the buoyancy force. In the second technical

solution or design, the screw is mounted horizontally.

The food pieces together with the solution are moved

along the cylinder axle. Pieces of food are carried in

rotation toward the end of the cylinder where a de-

flector catches the pieces and directs them to the

outlet.

Designs of equipment with mechanical motion of

food pieces exert some force on processed material.

Hence some disintegration and deformation of food

can take place and increased pulp content in the

solution can be observed.

1

2

3

4

Reconstitution

system

FIGURE 28.16 Conveyor osmotic dehydration (1, perforated conveyor with osmosed material; 2, vessel with hypertonic

solution; 3, conveyor preventing apple slices from floating; 4, pump).

1

7

2

6

3

4

5

7

FIGURE 28.17 Osmotic dehydration with a vibrating plate

mixer (1, feed leg; 2, vessel; 3, vibrating mixer; 4, shaft; 5,

eccentric; 6, heat exchanger; 7, pump). (Adapted from

Pavasovec, V., Stefanovic, M., and Stefanovic. P., Drying

’86 Vol 2, Mujumdar, A.S., ed., Hemisphere Pub Co.,

New York, 1986, p. 761)

2

3

1

4

FIGURE 28.18 Osmotic dehydrator—a packed bed unit

(1, vessel; 2, redler conveyor; 3, feed leg; 4, pump). (Adapted

from Pavasovec, V., Stefanovic, M., and Stefanovic.

P., Drying ’86 Vol 2, Mujumdar, A.S., ed., Hemisphere

Pub Co., New York, 1986, p. 761)

ß

2006 by Taylor & Francis Group, LLC.

28.4.2 S

OLUTION

S

PRAYED ONTO THE

F

OOD

Reduct ion of solution and food ratio can be done by

applic ation of thin layer of hyp ertonic so lution to

food pieces . It is done by placi ng food pieces on

perfor ated conv eyor and sprayi ng con centrated solu-

tion on process ed mate rial (

). The de sign

is wel l suit ed to continuou s process ing but requir es

food pieces to be spread on the conveyo r in a single

layer. Hence, a large area of the conveyo r is needed to

process an y given quantity of foo d. This techni cal

solution of osmot ic de wateri ng was proposed by Le

Maguer [170] and Dall a Rosa et al. [161] .

28.4.3 S

OLID

O

SMOTIC

S

UBSTANCE

C

ONTACTED

WITH

F

OOD

The low est solut ion and food rati o is obtaine d when

solid osmo tic substa nce is co ntacted wi th food. Cry s-

tals of sugar or mixt ure of sugar and salt are mixed

with food pieces in appropri ate proporti on an d tum-

bled in slowly rotating cylind rical tank . The amoun t

of osmo tic substa nce used should be such that wate r

remove d from foo d pieces form s no solut ion in the

tank. W et but solid osmot ic sub stance is sep arated

from food on v ibrating screen. How ever, some cryst als

stick to the foo d surfa ce an d can creat e prob lems in

packaging or furt her process ing of osmo sed material.

28.4.4 E

QUIPMENT

W

ORKING UNDER

R

EDUCED

P

RESSURE

Static or pulsed- vacuum proc essing of immersed frui t

or vegeta ble pro ducts facilita tes os motic de waterin g.

Equipmen t used in this process c an be of any type

previously presented but requires hermetic design.

28.5 PRODUCT CHARACTERISTICS

Osmotic dehydration is a complex process of counter-

current mass transfer between the plant tissue and

hypertonic solution. This leads to dehydration of

the material and changes in its chemical composition

1

2

4

3

FIGURE 28.19 Osmotic dehydrator—a vertical mixer (1,

worm screw; 2, vessel; 3, shaft; 4, spout). (Adapted from

Marouze, A., Groux, F., Collignan, A., and River, M.,

J. Food Eng., 49,207,2001. With permission)

2

3

Regenerating

system

1

6

4

5

FIGURE 28.20 Osmotic dehydrator—a horizontal mixer (1, feed hopper; 2, vessel; 3, worm screw; 4, deflector; 5, discharge

hopper; 6, shaft). (From Lenart, A. and Lewicki, P.P., Zesz. Nauk. SGGW-AR, Technol. Roln.-Spo_zz., 14, 33, 1981. With

permission.)

ß

2006 by Taylor & Francis Group, LLC.

as well. Hence, it must be expected that the proper-

ties of the material dehydrated by osmosis will dif-

fer substantially from those dried by convection

[5,10,76,171].

The flux of osmoactive substance penetrating the

osmosed tissue changes its chemical composition. It

has been shown that the content of sucrose increases

in cell sap during osmotic dehydration [15,67,172],

and the sucrose flux is increased by the presence of

sodium chloride [70]. On the other hand, use of starch

syrup gives only a small influx of sugars to the mater-

ial [144]. Glucose seems more effective than sucrose in

the water loss and in the solids gain by fruits [102].

Sodium chloride penetrates tissue very effectively,

hence contacting of the material with this substance

leads to salting rather than to dewatering of the tis-

sue [73,80]. There is also a flux of native substances

leaving the tissue. Concentration of organic acids is

lowered and native sugars are replaced by sucrose

[67,117,173].

Penetration of an osmoactive substance, except

sodium chloride, is a surface process. Sugars pene-

trate to the depth of 2–3 mm whereas changes in

water content are observed up to the depth of 5 mm

(Figure 28.22) [109,174,175]. When sodium chloride

is used, it penetrates carrot tissue to a depth exceeding

12 mm.

Concentration of the cell sap and influx of

osmoactive substance lower the water activity in the

tissue to a value dependent on processing parameters.

The water-binding capacity of the tissue is also

affected by the osmotic process, although changes

are observed only in surface layers [176]. Osmotic

dehydration done for 0.5 h led to a sixfold decrease

of water-binding forces at the surface of apple in

comparison to the raw material [177]. Water removal

from the tissue by osmosis shows a much stronger

effect on water-binding forces than by the convection

drying done to the same final water content [178].

As it has been stated previously, osmotic dehydra-

tion cannot be treated as a food preservation process

per se. It is a pretreatment that removes a certain

amount of water from the material; to achieve shelf

stability, a further processing of the product is

needed. Hence, the interaction of osmotic dehydra-

tion with further processing is important for quality

assurance.

Use of osmotic dehydration practically eliminates

the need to use preservatives such as sulfur dioxide in

fruits. The process removes a substantial amount of

air from the tissue, thus blanching prior to osmotic

dehydration also can be omitted [166].

It has been shown that apples dried by osmosis

and then frozen compared favorably with the conven-

tional frozen fruits [144,179]. Osmotic dehydration

preceding freeze drying shortens the time of the pro-

cess and yields fruits superior to those not treated by

osmosis [15,79,97]. Osmotic dehydration followed by

Reconstitution

system

4

3

2

1

FIGURE 28.21 Spray osmotic dehydrator (1, spray nozzles; 2, feed conveyor; 3, perforated conveyor with material

undergoing osmotic dehydration; 4, collector for used hypertonic solution).

1

10

20

30

2

3

4

Distance, mm

Total sugars, %

0.6

0.7

0.8

0.9

1.0

Water content, g/g cell sap

FIGURE 28.22 The depth of osmotic substance penetration

and cell sap concentration in apple osmosed in 68.5%

saccharose solution at 408C for 4 h. (From Lenart, A. and

Lewicki,

P.P.,

Zesz.

Nauk.

SGGW-AR,

Technol.

Roln.-Spo_zz., 14, 33, 1981. With permission.)

ß

2006 by Taylor & Francis Group, LLC.

vacuum drying gives products that are very stable

upon storage [65].

Most research has been directed toward combin-

ing osmotic dehydration with convection drying

[75,88,180–183]. The approach is of special interest

due to the growing consumer demand for commod-

ities in the freshlike state. The IMF comply well with

consumer expectations [184–186].

Osmotic pretreatment before microwave-assisted

air drying increase the final overall quality of the

product [187]. Fruits and vegetables treated by osmo-

sis can be further dehydrated in a convection dryer to

lower the water activity to the level of 0.65–0.90. At

those water activities, water content in the material is

still high and the product presents such organoleptic

attributes as chewiness, softness, elasticity, and plas-

ticity [76,188–190]. The product has a natural color,

well-preserved flavor, and high retention of vitamins

[132]. Its shrinkage is much smaller when compared

with that observed in convection-dried products at

the same water activity.

REFERENCES

1. R.M. Spanswick, Symplasmic transport in tissues. In

Encyclopedia of Plant Physiology. Vol. 2. Transport in

Plants II, Part B. Tissues and Organs (U. Luttge and

M.G. Pitman, eds.), Springer Verlag, Berlin, 1976,

p. 35.

2. A. Nason and R.L. Dehaan, The Biological World,

John Wiley & Sons, New York, 1973.

3. A. Lauchli, Apoplasmic transport in tissues. In En-

cyclopedia of Plant Physiology. Vol. 2. Transport in

Plants II, Part B. Tissues and Organs (U. Luttge

and M.G. Pitman, eds.), Springer Verlag, Berlin,

1976, p. 3.

4. N.V. Parthasarathy, Sieve-element structure. In En-

cyclopedia of Plant Physiology, Vol. 2. Transport in

Plants I. Phloem Transport (M.H. Zimmermann and

J.A. Milburn, eds.), Springer Verlag, Berlin, 1975, p. 3.

5. H. Ziegler, Nature of transported substances. In En-

cyclopedia of Plant Physiology, Vol. 2. Transport in

Plants I. Phloem Transport (M.H. Zimmermann and

J.A. Milburn, eds.), Springer Verlag, Berlin, 1975,

p. 59.

6. J.A. Milburn, Pressure flow. In Encyclopedia of Plant

Physiology, Vol. 2. Transport in Plants I. Phloem

Transport (M.H. Zimmermann and J.A. Milburn,

eds.), Springer Verlag, Berlin, 1975, p. 328.

7. R.J. Poole, Transport in cells of storage tissue. In

Encyclopedia of Plant Physiology, Vol. 2. Transport in

Plants II. Part B. Tissues and Organs (U. Luttge and

M.G. Pitman, eds.), Springer Verlag, Berlin, 1976,

p. 227.

8. J.R. Philip, The osmotic cell, solute diffusibility and

the plant water economy, Plant Physiol., 33:264

(1958).

9. J.R. Philip, Propagation of turgor and other proper-

ties through cell aggregations, Plant Physiol., 33:271

(1958).

10. J.R. Philip, Osmosis and diffusion in tissue: half-times

and internal gradients, Plant Physiol., 33:275 (1958).

11. F.J. Molz and G.M. Hornberger, Water transport

through plant tissues in the presence of a diffusible

solute, Soil Sci. Soc. Am. Proc., 37:883 (1973).

12. F.J. Molz and E. Ikenberry, Water transport through

plant cell and cell walls: theoretical development, Soil

Sci. Soc. Am. Proc., 38:699 (1974).

13. F.J. Molz, Water transport through plant tissue: the

apoplasm and symplasm pathways, J. Theor. Biol.,

59:277 (1976).

14. F.J. Molz, D.V. Kerns, C.M. Peterson, and J.H. Dane,

A circuit analog model for studying qualitative water

relations of plant tissue, Plant Physiol., 64:712 (1979).

15. J. Hawkes and J.M. Flink, Osmotic concentration of

fruit slices prior to freeze dehydration, J. Food Proc.

Preserv., 2:265 (1978).

16. J. Conway, F. Castaigne, and X.V. Pickard, Mass

transfer considerations in the osmotic dehydration of

apples, Can. Inst. Food Sci. Technol., 16:1 (1983).

17. F. Kaymak-Ertekin and M. Sultanoglu, Modelling of

mass transfer during osmotic dehydration of apples.

J. Food Eng., 45:243 (2000).

18. N.K. Rastogi, M.N. Eshtiaghi, and D. Knorr, Accel-

erated mass transfer during osmotic dehydration of

high intensity electrical field pulse pretreated carrots,

J. Food Sci., 64:1020 (1999).

19. D. Salvatori, A. Andres, A. Chiralt, and P. Fito, Os-

motic dehydration progression in apple tissue. I. Spa-

tial distribution of solutes and moisture content,

J. Food Eng., 42:124 (1999).

20. S. Simal, J. Benedito, E.S. Sanchez, and C. Rosello, Use

of ultrasound to increase mass transport rates during

osmotic dehydration, J. Food Eng., 36:323 (1998).

21. F. Nsonzi and H.S. Ramaswamy, Osmotic dehydra-

tion kinetics of blueberries, Drying Technol., 16(3/5):

725 (1998).

22. K.N. Waliszewski, N.I. Texon, M.A. Salgado, and

M.A. Garcia, Mass transfer in banana chips during

osmotic dehydration, Drying Technol., 15(10): 2597

(1997).

23. N.K. Rastogi, K.S.M.S. Raghavarao, and K. Niran-

jan, Mass transfer during osmotic dehydration of ba-

nana: Fickian diffusion in cylindrical configuration,

J. Food Eng., 31:423 (1997).

24. Kwang Sup Youn and Yong Hee Choi, Mass transfer

characteristics during the osmotic dehydration process

of apples, J. Korean Soc. Food Sci. Nutr., 25:824

(1996) (FSTA 1997-11-J0048).

25. S. Simal, F. Bauza de Mirabo, E. Deya, and C. Rosello,

A simple model to predict mass transfers in de-

hydration by osmosis, Z. Lebensmit. Untersuch und

Forsch., 204(3): 210 (1997).

26. Kwang Sup Youn and Yong Hee Choi, Mass transfer

characteristics in the osmotic dehydration process of

carrot, Korean J. Food Sci. Technol., 27(3):387 (1995)

(FSTA 1996-12-J0076).

ß

2006 by Taylor & Francis Group, LLC.

27. N.K. Rastogi and K.S.M.S. Raghavarao, Kinetics of

osmotic dehydration of coconut, J. Food Process Eng.,

18(2):187 (1995).

28. E. Azuara, R. Cortes, H.S. Garcia, and C.I. Beristain,

Kinetic model for osmotic dehydration and its rela-

tionship with Fick’s second law, Int. J. Food Sci.

Technol., 27(4):409 (1992).

29. Z. Yao and M. Le Maguer, Possibility of using

pseudo-diffusion approach to model mass transfer in

osmotic dehydration, Trans. ASAE, 41:409 (1998).

30. R. Saurel, A.L. Raoult-Wack, R. Rios, and S. Guil-

bert, Mass transfer phenomena during osmotic dehy-

dration of apple. II. Frozen plant tissue, Int. J. Food

Sci. Technol., 29:543 (1994).

31. R. Andreotti, M. Tomasicchino, and L. Machiavell,

La disidratazione parziale della frutta per osmosi, Ind.

Conserve., 58:88 (1983).

32. M. Tomasicchino, R. Andreotti, and A. De Giorgi,

Desidratazione partiale della frutta per osmosi. II.

Ananas, fragole e susine, Ind. Conserve., 61:108 (1986).

33. D. Torreggiani, R. Giangiacomo, G. Bertolo, and E.

Abbo, Ricerche sulla disidratazione osmotica della

frutta. I. Idoneita varietale delle ciliege, Ind. Conserve.,

61:101 (1986).

34. M. Dalla Rosa, G. Pinnavaia, and C.R. Lerici, La

disidratazione della frutta mediante osmosi diretta.

II. Esperienze di laboratorio su alcumi generi di frutta,

Ind. Conserve., 57:3 (1982).

35. R. Giangiacomo, D. Torreggiani, and E. Abbo, Os-

motic dehydration of fruit. Part I. Sugars exchange

between fruit and extracting syrups, J. Food Process.

Preserv., 11:183 (1987).

36. D. Torreggiani, R. Giangiacomo, G. Bartolo, and E.

Abbo, Ricerche sulla disidratazione osmotica della

frutta. II. Idoneita varietale della albicocche, Ind. Con-

serve., 61:226 (1986).

37. T.R.A. Magee, A.A. Hassaballah, and W.R. Murphy,

Internal mass transfer during osmotic dehydration of

apple slices in sugar solutions, Ir. J. Food Sci. Tech-

nol., 7:147 (1983).

38. I. Beristain, E. Azuara, R. Cortes, and H.S. Garcia,

Mass transfer during osmotic dehydration of pine-

apple rings, Int. J. Food Sci. Technol., 25:576 (1990).

39. J. Toupin, M. Marcotte, and M. Le Maguer, Osmot-

ically-induced mass transfer in plant storage tissue.

A mathematical model. Part I, J. Food Eng., 10:13

(1989).

40. J. Toupin and M. Le Maguer, Osmotically-induced

mass transfer in plant storage tissue. A mathematical

model. Part II, J. Food Eng., 10:97 (1989).

41. M. Marcotte, C.J. Toupin, and M. Le Maguer, Mass