A review on recent approaches in the field of hot dip zinc galvanizing process

S.M.A. Shibli, B.N. Meena, R. Remya

PII:

S0257-8972(14)01198-0

DOI:

doi:

10.1016/j.surfcoat.2014.12.054

Reference:

SCT 19991

To appear in:

Surface & Coatings Technology

Received date:

7 November 2014

Accepted date:

22 December 2014

Please cite this article as: S.M.A. Shibli, B.N. Meena, R. Remya, A review on recent

approaches in the field of hot dip zinc galvanizing process, Surface & Coatings Technology

(2014), doi:

10.1016/j.surfcoat.2014.12.054

This is a PDF file of an unedited manuscript that has been accepted for publication.

As a service to our customers we are providing this early version of the manuscript.

The manuscript will undergo copyediting, typesetting, and review of the resulting proof

before it is published in its final form. Please note that during the production process

errors may be discovered which could affect the content, and all legal disclaimers that

apply to the journal pertain.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

1

A review on recent approaches in the field of hot dip zinc

galvanizing process

S.M.A. Shibli*, B.N. Meena, R. Remya

Department of Chemistry, University of Kerala, Kariavattom Campus

Thiruvananthapuram, Kerala-695 581, India

Abstract

The recent developments in the field of hot dip zinc coating are reviewed with special

reference to different industrial applications. The improvements in physical and chemical

structural composition due to pre and post modification process are discussed. The present

review has the focus mainly on the readership of young researchers engaged in this field.

Very recent developments on the hot dip galvanization processes are highlighted. Their

industrial competencies with aluminium dipping are also briefly discussed. The scopes for

immediate future developments are also highlighted then and there.

Key words: Hot dip galvanization, Intermetallics, Metal/metal oxide incorporation,

Galvannealed coating, Aluminide coating.

----------------------------------------------------------------------------------------------------------

*Author for all correspondence: smashibli@yahoo.com

Phone: + 91 85470 67230 (mob), +91 471 2308682 (off), +91 471 2167 230 (Res)

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

2

1. Introduction

Steel of different forms, is an integral part of building and construction industry due

to its high strength and durability. Although many new and advanced materials have been

developed for engineering applications, steel is still considered to be the main construction

material for automobiles, appliances and industrial machinery [1]. Steel undergoes corrosion

when exposed to different environments. There are different methods to prevent corrosion

such as cathodic protection, anodic protection, addition of inhibitors, protective coatings and

metallic coatings. Zinc coatings are extensively used for the protection of steel. In such cases,

the more active zinc metal corrodes preferentially than the steel substrate by a cathodic

reaction that prevents steel from undergoing anodic corrosion reaction. Different types of

zinc coatings include: hot dip galvanizing (batch or continuous), electroplating, metalizing

(zinc spraying), mechanical plating and zinc rich paint. Among them, the hot dip

galvanization process, offers a unique combination of superior properties such as high

strength, formability, light weight, corrosion resistance, low cost and recyclability. In a

conventional hot dip galvanizing process, a steel article is cleaned, fluxed and then immersed

in a molten zinc bath at a temperature of about 450 °C [2]. Hot dip galvanized steels have

been extensively used in industrial fields such as automobiles, electrical home appliances or

construction due to their excellent corrosion resistance characteristics [3]. This technique has

been adopted as a well proven feasible process since 1800 soon after the exploration of iron

and zinc. The exploration of the process was attempted in 1742 when a French Chemist

Melouin presented a paper on hot dip galvanizing, and the process received commercial

momentum with patents mainly in the 1830‟s. The reason for the extensive use of hot dip

galvanization is the two-fold protective nature of the coating. As a barrier coating, it provides

a tough, metallurgically bonded zinc coating that completely covers the steel surface and

protects steel from corrosion. Additionally, the sacrificial action of zinc protects the steel

even when damage or a minor discontinuity occurs on its surface.

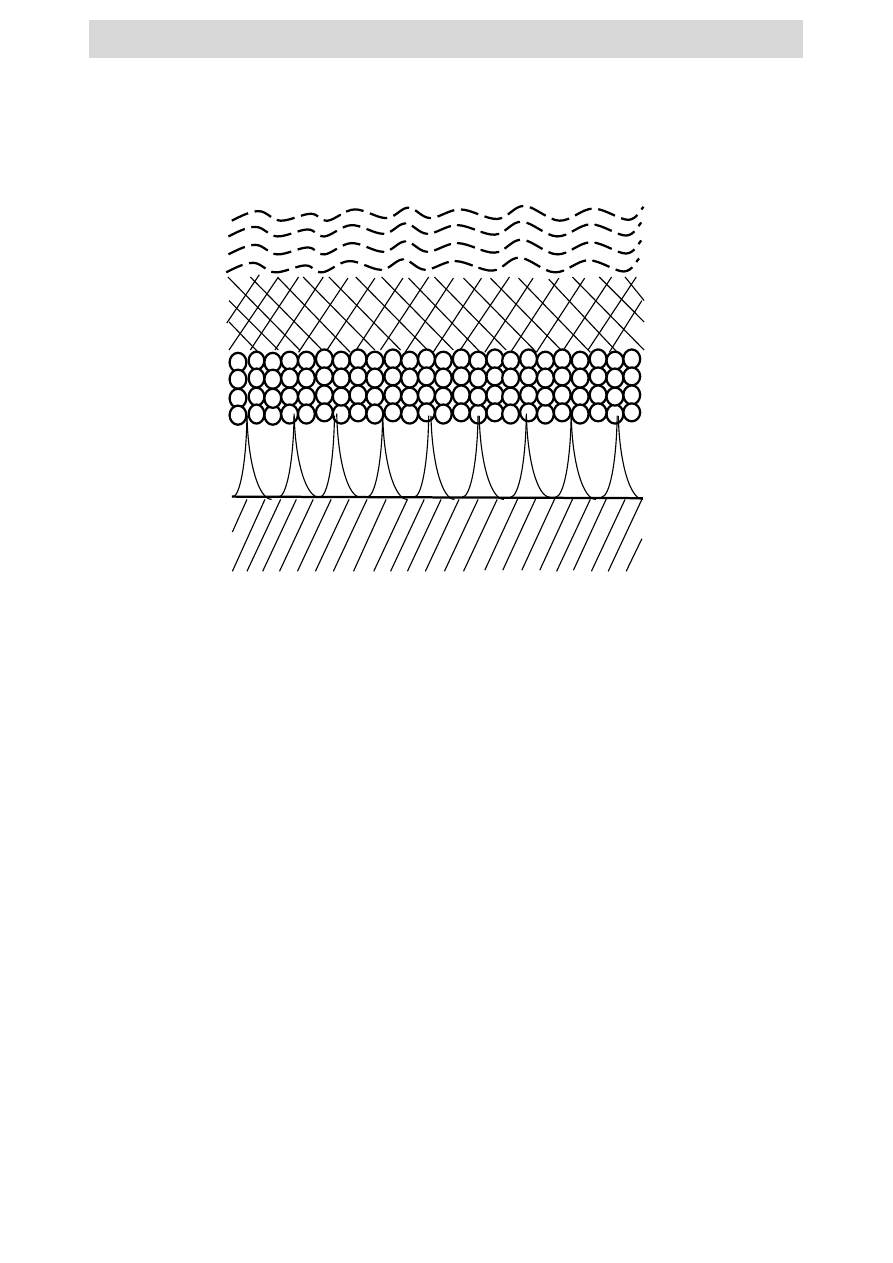

A hot dip galvanized coating consists of a heterogeneous assembly of different phases

which are formed due to metallurgical reactions between iron and zinc when a ferrite

substrate is immersed into molten zinc [4]. After solidification, the coating consists of an

outer layer of 100 % zinc (η-eta layer) and inner layers called alloy layers consisting of

intermetallic phases of iron and zinc such as zeta (ζ) layer (94 % Zn – 6 % Fe), delta (δ) layer

(90 % Zn – 10 % Fe) and gamma (Г) layer (75 % Zn – 25 % Fe) [5-7] (Fig. 1). These

intermetallic layers are relatively harder than the underlying steel and provide exceptional

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

3

protection against coating damage. The characteristics of the intermetallic phases of hot dip

zinc coatings are compared in Table1 [8-11].

2. The process

2.1. Selection of substrate

The composition of a steel substrate has great influence on the hot dipping process

and the performance of the resultant hot dip zinc coating. The change in the composition of

the substrate not only influences the rate of attack of steel by molten zinc but also changes the

mode of attack at a given galvanizing temperature [12]. The compositional variation of the

steel used for hot dip zinc coating is an important factor that determines the zinc drainage,

coating morphology and protection capacity of the coating. The chemical composition of the

steel substrate also influences the metallurgical properties of the hot dip zinc coatings. The

presence of Si, P, C and Mn in the steel substrate can influence the Fe-Zn solidification

mechanism depending on their concentration. The presence of critical amount of silicon and

phosphorus in the steel substrate is necessary to control the coating weight and the presence

of carbon & phosphorus accelerates the growth of the alloy layer, thereby improving the

adherence of the coating [13,14]. There are mainly two groups of steels that are used for hot

dip galvanization namely low carbon, non-killed steel with low silicon and reactive steel with

high silicon content.

2.2. Preparation of the base surface

Surface preparation is an important step in hot dip galvanization because zinc does

not metallurgically react with steel surface when it is not completely clean. The effective

cleaning of steel substrate can be achieved by a variety of processes. Surface preparation

typically consists of degreasing, pickling and fluxing. Oils, greases and other saponificable

compounds present in the steel substrates are removed through degreasing. Alkaline solutions

are normally used for this purpose since they are less expensive than vapour degreases using

costly organic solvents. Yuttanant et al. [15] and R. Sa-nguanmo et al. [2] used to degrease

the low carbon cold rolled steel substrate using 10 % NaOH solution at 60 °C for 10 minute

prior to hot dip galvanization. The steel substrate could also be degreased using 5 % NaOH

solution at 50 °C to ensure that the substrate is free from foreign materials [16].

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

4

Normally steel substrate contains oxides of iron, even after the removal of greasy

substances and that are to be removed by pickling. The warm/hot acid solutions such as HCl

and H

2

SO

4

are commonly used for the pickling process as both provide same pickling effect.

But most of the researchers prefer HCl as pickling agent due to its use at low temperature,

with less volume. Moreover, it is easy to inhibit and the steel substrate doesn‟t require any

caustic treatment [17]. Shibli et al. have reported about the usage of 8 % HCl as a pickling

agent for steel substrate [16]. It should be noted that steel coupons could also be pretreated by

pickling in 14 % HCl at room temperature for 20 min [15, 2]. Stieglitz et al. have reported the

use of a pickling solution of HCl and H

3

PO

4

to ensure a stable coating [18].

Fluxing is required to dissolve any oxide films formed on the steel surface after

pickling. It should be ensured that a clear metal surface contacts the molten zinc during the

galvanization process. The fluxing treatment provides good adherence of liquid zinc on the

steel substrate and facilitates adequate metallurgical interaction between zinc and steel. It also

suppresses in-situ oxidation of the steel surface by atmospheric oxidation. Fluxing solutions

consist of alkali and alkaline earth metal chlorides or fluorides with zinc chloride. The

conventional fluxing solution consists of a mixture of zinc chloride (ZnCl

2

) and ammonium

chloride (NH

4

Cl) in 1:3 mole ratio [19]. The presence of ammonium chloride in the flux

promotes drying of the flux on the steel substrate before its entry into the molten zinc bath

and zinc chloride protects the steel from corrosion or surface oxidation prior to its entry into

the molten zinc bath. The flux coated steel substrate is dried at a temperature of about 120 °C

since the flux decomposes at about 150 °C. A salt mixture containing zinc, ammonium,

sodium, potassium, cobalt and lead chloride has been formulated based on the decomposition

temperature of individual chloride salts for Zn – 5 wt. % Al alloy coating on wire surface

[20]. Yuttanant et al. have reported that a fluxing solution that contains NiCl

2

could affect the

growth morphology of zeta phase and reduce its growth rate, resulting in the reduction of the

overall thickness of the coating [15]. The use of NiCl

2

in a fluxing solution serves as a simple

and effective method for preventing excessive growth of galvanized coatings. Balloy et al.

have reported the use of vegetable oil like linseed oil as fluxing agent rather than

conventional industrial chloride flux [21]. The use of a mineral oil with an acid function such

as HCl has also been reported as a fluxing agent during hot dip galvanization. However the

usage of vegetable or mineral oils is yet to be proved commercially. There is no scope for

commercialization of such processes as conventional fluxing does not involve with much

cost. Similar is the case regarding the proposal by Balloy et al. who has proposed a process

called “single bath” in order to merge the steps of pickling & fluxing. In this case the same

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

5

bath has HCl at the bottom to accelerate the pickling of steel while the mineral oil at the top

is used as flux [21]. Such complicated processes have limited scope of reaching industry as

many more recent developments have been emerged for this purpose.

2.3. Hot dip galvanization

During hot dip galvanization, the steel substrate is completely immersed in a bath

consisting of a minimum of 98 % pure molten zinc. The bath chemistry is specified by the

ASTM in specification B6. The bath temperature is maintained at about 450 °C. The zinc

metal then reacts with the iron on the steel surface to form a zinc/iron intermetallic alloy. The

articles are withdrawn slowly from the galvanizing bath and the excess zinc is removed by

draining, vibrating or centrifuging. The articles are cooled in air immediately after

withdrawal from the bath. The characteristics of the resultant hot dip zinc coatings depend on

the following parameters.

2.3.1. Bath temperature

Conventionally the hot dip bath is maintained at around 440-460 °C. However, most

of the significant chemical reactions between iron-zinc alloy coatings and the molten zinc

occur at 480 °C. Below 480 °C, a compact Zn-Fe alloy is formed at the surface of the steel

with the alloying action eventually ceasing up and above this critical temperature,

fragmentation of the alloy layer is happened that stimulates zinc to penetrate into the metal

resulting in the formation of very large amount of dross. The bath temperature can be

controlled to tune the nature and thickness of the intermittent layers to suit the purpose of the

specific application.

2.3.2. Dipping time

The alloying reactions proceed after about 20 seconds of immersion of the substrate

into the molten zinc bath. Conventionally 4-5 minutes duration is maintained for optimum

alloying reactions. In certain cases where heavy articles are to be galvanized, they are kept

immersed for longer durations to enhance zinc penetration as well as the overall coating

thickness. The dipping duration can be controlled to tune the nature and thickness of the

intermittent layers and also the extent of coverage.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

6

2.3.3. Withdrawal speed

The steel substrate is taken out of the bath when the reaction between iron and zinc

completed. The thickness of hot dip galvanized coatings depends on withdrawal speed.

Conventionally an optimum withdrawal rate of 1.5m per minute is maintained for the

formation of a bright shiny zinc coating. If the withdrawal speed is too slow, a uniform

unalloyed zinc layer is formed while in the case of faster withdrawal speed, an uneven

coating is formed. Hence, the withdrawal speed should be controlled to tune the nature,

thickness and the surface finishing of the coating.

2.3.4. Bath composition

The extent of effective life of hot dip zinc coating not only depends on the coating

composition but also on the metallurgical characteristics of the coating. It is necessary to

increase the quality and thus the service life of the coating by making improvements in the

galvanizing techniques. Several additives are incorporated into molten zinc bath in order to

improve the performance of hot dip zinc coatings. The presence of elements such as

aluminium, magnesium, and nickel plays an important role in improving the galvanic

performance of hot dip zinc coatings. Aluminium is one of the commonly used additives in

molten zinc bath. Aluminium has the ability to reduce the rate of oxidation of molten zinc

and to reduce the spangle size thereby improves the uniformity of the coating. The effect of

aluminium on the bath has also been extensively studied for improving the corrosion

resistance [22,23]. During hot dip galvanization, the presence of aluminium in the molten

zinc bath suppresses the growth of Fe-Zn intermetallic layer and reduces iron loss into the

bath through the formation of Fe

2

Al

5

and FeAl

3

intermetallic layers. It has been reported that

the presence of Al (0.15 – 0.2 wt. %) in molten zinc bath can prevent the growth of Fe-Zn

intermetallic layer at the steel coating interface [24]. Liberski et al. has reported that hot dip

zinc coating containing 5 wt. % Al could possess excellent corrosion resistance than

conventional zinc coatings [25]. The most commonly used industrial hot dip zinc coatings

with aluminium as additive are the galvanized iron (Zn – 0.2 wt. % Al), galvalume (55 wt. %

Al, 43.5 wt. % Zn, 1.5 wt. % Si) and galfan (Zn – 5 wt. % Al) [26]. The addition of lead and

antimony in small concentrations (0.004 – 0.200 %) could significantly improve the

uniformity and adherence of the coating [27]. Pistofidis et al. have found that the addition of

bismuth into the galvanizing bath could yield excellent adhesion and corrosion resistance

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

7

[28]. However the compositional modification using elements such as lead and antimony is

seemed to have no scope for receiving any commercial attention.

3. Evaluation of coating composition

The important properties that concern the use of zinc coatings are primarily corrosion

and formability and other properties involved are weldability & paintability. The progress of

corrosion in different types of galvanized coatings can be investigated by using

Electrochemical Impedance Spectroscopic (EIS) technique. V. Barranco et al. have compared

the corrosion rate of hot dip galvanized coatings especially pure zinc, Zn – 5 wt. % Al and Zn

– 10 wt. % Fe in 3 % NaCl, based on EIS measurements. The EIS results revealed that

corrosion of the pure zinc & Zn – 5 wt. % Al coatings progresses in an almost uniform way

while the corrosion rate of the Zn – 10 wt. % Fe coating experiences a decrease after 10 days

of exposure [29]. J.H. Hong et al. have reported that the Mossbauer properties can be used for

the phase formation and transformation studies as a function of the process parameters. The

Mossbauer spectra of different Fe-Zn intermetallic phases are different from each other.

According to them, the gamma and gamma-1 phases are composed of four sub spectra, while

the delta and zeta phases reveal three and one sub spectrum respectively [30]. H. Liu et al.

have studied the influence of H

2

and water vapour content on selective oxidation during

continuous hot dip galvanization by thermo-calc and Wagner model. As per the model, the

nature of oxidation process (internal/external) can be changed by altering H

2

content in the

annealing atmosphere. A study based on thermodynamic characteristics of the process has

revealed that simple oxides such as MnO

2

, Cr

2

O

3

etc produced by selective oxidation may be

reduced by effective Al in Zn liquid [31]. Thus, in-situ and post evaluation of the coating

characteristics could yield significant information to alter the composition of the bath and the

coating.

4. The phase reaction and formation of intermetallics

Dutta et al. have reported about the formation of MgZn

2

on the top surface and

described about the morphology and properties of Zn-Mg & Zn-Mg-Al coatings [32]. They

also discussed about the Mg gradient in the coating. Liu et al. have studied the relationship

between the annealing atmosphere and microstructure of Zn-Al coated dual phase steel. They

discussed about the coexistence of Fe-Al intermetallic compounds and needle like Fe-Zn

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

8

compound as the result of reduction in aluminothermic reaction during hot-dip zinc process

[33]. Song et al. have found that zinc coating on dual phase steel consists of a zinc layer and

columnar

–FeZn

13

particles on the top of a thin inhibition layer next to steel substrate. These

inhibition layers consist of lenticular –Fe

2

Al

5-x

Zn

x

particles [34]. Yang et al. have studied the

influence of strip entry temperature on the formation of interfacial layer during hot dip

galvanization of hardened steel. He has illustrated that the size of

-phase was increased with

strip entry temperature and was formed at the base steel surface when temperature was 480

°C. According to Yang et al. the Fe-Al intermetallic layer was fully formed at strip entry

temperature ranging from 440-480 °C [35].

Cheng et al. reported the formation of a new quaternary phase in the interdentritic

area of a laser treated Zn-Al-Mg-Si coating [36]. Yang et al. studied the growth of

2

intermetallic compounds on hot dipped Zn-Ti coating. The

2

particles generated in the η

layer prevents the generation of compact

layer in Zn – 0.05 % Ti coating. According to

them, higher Ti content increases the number of precipitated particles [37]. Peng et al.

reported that a typical shiny, feathery and dull spangle can be obtained by batch hot dip

galvanizing in Zn – 0.05 Al – 0.20 Sb bath. A large number of precipitated

-Sb

3

Zn

4

particles

get distributed randomly on the shiny spangle surface. Both

-Sb

3

Zn

4

particles and the

dentritic segregation of Sb result in spacing of feathery spangles on the surface [38]. The bath

parameters including the elemental and other additives such composites should be controlled

to tune the nature and thickness of the intermittent layers to suit the purpose of the specific

application of the coating.

5. Metal and metal oxide addition in molten zinc bath

Mg and Mg-Al additions in the galvanizing bath are a proven technique to regulate

the intermittent reactions improving the coating morphology and properties of low carbon

steel. The hardness of Zn-Mg & Zn-Mg-Al coatings is normally higher than that of pure zinc

coating, a favorable character for scratch resistance. The Zn - 0.5 wt. % Mg – 0.25 wt. % Al

coating has more corrosion resistance than pure zinc & Zn-Mg coatings [32]. Duchoslav et al.

have studied the initial progress of atmospheric corrosion of tenancy alloyed Zn-Mg-Al

coatings in aqueous NaCl environment. They have also reported that two fundamental

processes are involved in the initial corrosion attack. This results in dissolution of the surface

layer consisting of MgO and preferential anodic dissolution of both binary and ternary

eutectic phases constituting the coating [39]. Kondratiuk et al. have reported about the

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

9

formation of a ZnO layer on Zn-Ni coating during heat treatment. The electroplated uniphase

intermetallic Zn-Ni coatings are highly suitable for hot sheet metal forming applications

owing to their good thermal stability compared to hot dip zinc coatings [40]. The presence of

Mg in zinc coatings causes a remarkable improvement in the corrosion resistance of painted

systems. Hausbrand et al. have studied the corrosion of painted MgZn

2

with a defect, under

constant conditions of high humidity and an electrolyte covered defect [41]. They discussed

about the galvanic coupling among the defects and also about the galvanic coupling between

defect and intact interface. According to them, no cathodic delamination is possible due to an

unfavorable potential gradient between the defect and the intact interface in the case of

MgZn

2

. An anodic delamination is possible through the migration of ions at the metal oxide

interface [41]. LeBozec et al. have compared the corrosion performance of Zn-Mg-Al

coatings with conventional zinc coatings such as hot dip galvanized, electrogalvanized,

Galvannealed and galfan coatings. The performance of ZnMgAl coatings is depending on the

testing conditions and the configuration of the samples and these coatings provide a major

improvement during neutral salt spray analysis [42].

High performance hot dip zinc coatings can be developed by the incorporation of

individual and mixed metal oxides such as nano TiO

2

, CeO

2

-TiO

2

and Al

2

O

3

-ZrO

2

into the

hot dip zinc coating [43-45]. The incorporation of Al

2

O

3

-ZrO

2

mixed oxide composite into

galvanizing bath yields aluminium rich zinc coatings with high sliding and wear resistance.

The interior layers of the coatings are also known to possess high stability against corrosion.

The incorporation of nano TiO

2

in the hot dip zinc coating has been known to facilitate

phosphating and also good paintability. The hot dip galvanized coatings with high corrosion

resistance, effective barrier protection, good antifouling characteristics and improved surface

quality can be achieved by CeO

2

-TiO

2

incorporation. These composites not only yield

individual characteristics to the coating but also give a new range of reaction modification

during the process.

6. Annealing of hot dip zinc coatings

The annealing of hot dip galvanized coatings (galvannealed) leads to the formation of

Fe-Zn intermetallic phases. Galvannealed coatings differ from pure zinc coatings that they

consist of a layered structure of different Fe-Zn intermetallic phases and have superior

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

10

resistance to corrosion, improved paintability and better weldability than pure zinc coatings

[46]. Chakraborty et al. have studied the root cause of hitherto unknown and uncommon

defect that has been encountered in the coating of an industrial galvannealed HIF steel. The

root cause of the defect lies in the presence of some pickling resistant sticky iron oxide on the

surface of the hot rolled sheet, which exists even after cold rolling. According to them, the

subsequent galvannealing operation has no effect on Fe-Zn reaction at the spots covered by

the oxide layer and it causes defects in the final product [47]. H. Y. Ha et al. examined the

dissolution process of a galvannealed coating layer on a dual phase steel and the variation in

the corrosion rate during the stripping process. According to them, the corrosion rate gets

accelerated when the outermost

phase is completely dissolved and the galvanic couple of

the δ-Г substrate is exposed to the 1M NaCl + 0.01M H

2

SO

4

. However uniform and thick

layer of

phase is required for enhanced corrosion prevention [48]. Kim et al. have evaluated

the mechanical properties of galvannealed steel sheets used for automotive exposed panel and

the failure phenomenon of its coating layer using finite element method. They have reported

that the failure of the coating layer occurs when tensile deformation mode is activated at the

coating layer and equivalent local plastic strain becomes more than 0.28 [49].

Okamoto et al. have studied the compression deformability of

and

Fe-Zn

intermetallics to mitigate detachment of brittle intermetallic coating of galvannealed steels.

The

phase is the most deformable followed by the

phase, while the

1

,

1k

and

1P

phases

are all highly brittle based on compression tests of micrometer sized single phase specimens

[50]. Manna & Dutta have reported that the charge transfer resistivity of galvannealed

coatings with different intermediate layers is better than similar galvanized coatings and also

reported that the galvanized and galvannealed coatings with prior metal flash coatings show

better mechanical performance compared to the coatings obtained without prior metal flash

coating [51]. Choi et al. have studied the effect of pre-electroplating with prior to reduction of

annealing on the surface quality and resultant corrosion characteristics of galvannealed high

strength DP steel. The degree of Fe-Zn alloying can be significantly improved due to the

formation of a homogeneous interfacial Fe

2

Al

5

layer at the coating/substrate interface during

the galvanizing process, resulting in an increase in the thickness of the coating layer. These

changes arise due to the suppression of the segregation and selective oxidation of small

amount of alloying elements during reduction in the annealing process prior to the

galvanization [52]. Thus, apart from the bath reactions which are mainly controlled by the

composition and the dipping conditions, some superficial reactions can be tuned by

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

11

secondary parameters such as energy and strain during the annealing process. Such controlled

and post treated coatings only find extensive industrial applications.

7. Recent developments in hot dip galvanization of high strength steel

The performance of automotive designs requires high strength materials with good

formability, fatigue resistance and toughness [53]. The use of advanced high strength steels in

automotive industry has saved weight and enables economy of fuel. The protection of high

strength steel against corrosion by hot dip galvanization became an important issue in recent

years because it is an integral part of automotive industry. The developments in hot dip

galvanized high strength steels have been reported extensively. Some of the recent catches

are discussed in this review. The high strength steels undergo recrystallization annealing prior

to hot dip galvanization. The annealing in the reducing atmosphere causes segregation and

selective oxidation of alloying elements, making the steel surface unsuitable for

galvanization. The wetting nature of zinc is decreased by the presence of external oxides of

elements such as Al, Si and Mn on the surface of steel [54]. Frenznick et al. have reported

about the influence of Si, Mn oxides and their surface coverage on wetting kinetics of zinc

coatings. According to them, the Cassie equation along with Avrami growth law was a good

approximation for the wetting kinetics and the growth mechanism of reaction layer. They

found the reactive wetting dynamics depends not only on the overall oxide coverage but also

on the size of the oxide islands [55]. H. Liu et al. (2012) have reported about the surface

selective oxidation of alloying elements and mechanical property degradation of the hot dip

galvanized high strength dual phase steel by comparing three dual phase steels such as Mn-Si

steel, Cr steel and Cr-Mo steel. According to them, the surface segregation and the selective

oxidation are greatly influenced by the dew point of annealing atmosphere and the steel

composition [56]. Blumenau et al. have studied the effect of pre oxidation on improving the

reactive wetting of high manganese alloyed steel during hot dip galvanization. It becomes

clear that the pre oxidation offers several advantages regarding technical feasibility [57].

8. Competency with aluminium dipping

8.1. The advantages of aluminium hot dipping

Aluminium and aluminium alloy coatings are used in automobile and construction

industries as an alternative for zinc coating in order to reduce weight, provide better

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

12

mechanical properties and yield high temperature oxidation resistance compared to hot dip

zinc coating. The corrosion resistant characteristics of aluminized steel are due to the

formation of a stable thin film of aluminium oxide. Hot dip aluminizing is a diffusion coating

formation process used to deposit high temperature oxidation and corrosion resistant coatings

on stainless steels and low alloy steels [58-60]. The dipping of steel in molten aluminium

causes interdiffusion of the aluminium and iron leads to the formation of different

intermetallics [61]. The coating on hot dipped aluminide steel is composed of an aluminium

top coat and a thick (10-100

m) brittle Fe-Al intermetallic layer. The Fe-Al intermetallic

layer comprises an outer FeAl

3

layer (often called Fe

4

Al

13

[61]) and an inner Fe

2

Al

5

layer

[62]. The Fe

2

Al

5

layer determines the development of coating phases and the final coating

properties [63]. Hot dipped aluminide mild steels have been widely used in boilers and

exhaust pipes in high temperature environments, due to the formation of fine, dense Al

2

O

3

with good oxidation resistance on the surface of steel [64]. In order to improve the lifetime of

hot dipped aluminide steel in high temperature conditions, it is essential to create a diffusion

barrier between the steel substrate and the aluminide coating.

8.2. Influence of alloying elements in the formation of intermetallic layers vs aluminium

Cheng & Wang have studied the effect of silicon addition in the Al bath on the

oxidation behaviour of hot dipped aluminide mild steel [65]. Aluminide steel with high Si

having poor isothermal oxidation resistance is attributed to its thin aluminide layer and

formation of a large number of phase transformation induced voids. Aluminide steel with a

thick Fe

2

Al

5

layer in the low Si content aluminide layer has low cyclic oxidation resistance

because the low fracture toughness of Fe

2

Al

5

phase enhances crack formation in the

aluminide layer [65]. Windmann et al. have reported about the transformation of brittle Al-Si

coatings into more ductile phase of type Al-Fe during austenitization and have studied the

phase formation as a function of coating thickness and Si content [66]. The presence of

silicon influences the diffusivity of Al & Fe in the Al-Fe rich intermetallics and promotes the

formation of Si rich intermetallics of type Al

8

Fe

2

Si, Al

13

Fe

4

and Al

5

Fe

2

. The transformation

of Al rich intermetallic phases of type Al

5

Fe

2

& Al

13

Fe

4

into iron rich phase of type AlFe can

be enhanced by higher Si content (10 mass%) and by decreasing the coating thickness [66].

Cheng et al. have reported about the factors affecting the thickness and morphology of

the Al-Si coated CLAM steel. Fingerlike intermetallic layers are formed under optimum

conditions of 1073 K, 3 minute and Al – 5.8 at. % Si. The existence of certain amount of Si in

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

13

the molten Al bath suppresses the growth of Fe

2

Al

5

, builds up the thickness of FeAl

3

slightly

that causes reduction in the thickness of intermetallic layer [67]. Later Danzo et al. have

reported the microstructural and crystallographic features of steel during hot dipping with Al-

Si bath followed by diffusion annealing treatment (900-1200 °C for 1 hour). Columnar grain

shape can be achieved during diffusion annealing and the intermetallic layers formed during

hot dipping can be vanished, as they serve as an Al source for columnar grain growth [68].

Takata et al. have also studied the morphology and growth of Fe-Al intermetallic

layers formed on pure Fe sheets dipped in Al – 8.2 Mg – 4.8 Si alloy melt at 750 °C. The

intermetallic layer exhibits a dual layer structure which consists of a continuous

-FeAl

3

and

a large η-Fe

2

Al

5

phase layers. The presence of Si and Mg prevents the diffusion of Fe into Al

melt and thereby the growth of η phase layer and promotes the growth of

phase layer. The

phase acts as the diffusion barrier in Al-Si-Mg aluminide coating [69]. Cheng et al. have

found that a thin intermetallic layer composed of (Fe-Ni)

2

Al

9

, NiAl

3

and Ni

2

Al

3

and a thick

intermetallic layer composed of FeAl

3

and Fe

2

Al

5

are formed in the aluminide/nickel duplex

coating on mild steel. In such case, nickel pre-plating has no effect on the growth rates of

FeAl

3

& Fe

2

Al

5

as it only slows down the initial growth rate for FeAl

3

and Fe

2

Al

5

which can

be attributed to the presence of Ni

2

Al

3

, NiAl

3

and (Fe, Ni)

2

Al

9

in the intermetallic layers

before the formation of FeAl

3

& Fe

2

Al

5

. As the immersion time is increased, nickel pre-

plating layer is fully consumed due to its dissolution into the Al bath resulting in intermetallic

layers contained only outer minor FeAl

3

and inner major Fe

2

Al

5

. Among all the phases

formed, Fe

2

Al

5

had the fastest growth rate [62].

8.3. Corrosion resistant and oxidation resistant characteristics of aluminide coating vs

aluminium

Frutos et al. have reported the oxidation behaviour of hot dipped AISI 316 LVM

stainless steel in molten Al - 31at. % Si bath. At 900 °C, the rapid transformation of less

protective aluminas into the protective

–Al

2

O

3

enhances the oxidation resistance of the

aluminized material compared with uncoated one. Below 900 °C, the chromia layer is more

protective than the scale consisting of less protective aluminas. As a result the coating had no

beneficial effect on the oxidation resistance of stainless steel [70]. Lemmens et al. have

compared the electrochemical behavior of hot dipped DC06 European grade steel in Al & Al-

Si bath. According to them the crates do not corrode while the outer Al layer can dissolve

sacrificially to protect all underlying layers and the steel substrate in chloride environments

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

14

[61]. According to Cheng et al., Ni-Al alloys possess better corrosion resistance than Fe-Al

alloy in chloride containing atmospheres. Therefore, Ni-aluminide coating has been widely

used to improve the hot corrosion resistance of the substrate material [62]. Shi et al. have

studied the effect of dipping temperature and heat treatment on the aluminide coatings

characteristics. The thickness of the intermetallic layer increases with increasing dipping

temperature. The transformation of multiphase structures of aluminizing layer into a single

phase (Fe

3

Al) through heat treatment favors improvement on chemical stability, toughness,

corrosion and wear resistance of T91 steel [71]. Ni et al. have studied the corrosion resistant

characteristics of aluminium coating with and without annealing against molten carbonate

using electrochemical impedance spectroscopy. These annealed coatings generally exhibit

better corrosion resistance than Al-Fe intermetallic coating formed in-situ during the

corrosion process. The main cause for the degradation of aluminide coatings is not only due

to the corrosion of the coating in contact with molten carbonate but also due to the aluminium

depletion through the interdiffusion of aluminium and the substrate [72].

9. Conclusions

The role of composition of the substrate, the bath as well as the process parameters

including annealing conditions significantly tune the structural characteristics and

applicability of the coatings. Since the hot dipping process is an alloying reaction, the process

conditions significantly extent/suppress/delaying the targeted reaction. Thus the process

parameters of the whole processes including pretreatment, dipping and curing/annealing have

a greater role than the role of the composition of the bath or other solutions involved in the

process. The significance of presence of optimum amount of silicon and phosphorus in the

steel substrate has been found to be crucial during the hot dipping process. Apart from the

bath composition, the pretreatment and the dipping conditions alter the resultant coating to a

great extent. Tuning of intermetallics and multiphase interdentrices can fulfill the formation

of targeted characteristics of the hot dip coatings. Control of other in-situ physicochemical

reactions such as control of segregation, selective oxidation of doping elements and

suppression of selective intermetallic reactions are considered to be crucial during the hot

dipping process.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

15

Acknowledgement

The authors thank the Head of the Department of Chemistry, University of Kerala for

extending support to carry out the research work.

References

[1] A. Amadeh, B. Pahlevani, S. Heshmati-Manesh, Corros. Sci. 44 (2002) 2321.

[2] R. Sa-nguanmoo, E. Nisaratanaporn, Y. Boonyongmaneerat, Corros. Sci. 53 (2011)

122.

[3] S. Maeda, Prog. Org. Coat. 28 (1996) 227.

[4] G. Reumont, J.B. Vogt, A. Iost, J. Foet, Surf. Coat. Technol. 139 (2000) 265.

[5] P.R. Sere, J.D. Culcai, C.I. Elsner, A.R.D. Sarli, Rev. Metal. Madrid. 33 (1997) 376.

[6] C.S. Lin, M. Meshi, Metall. Mater. Trans. B. 25B (1994) 721.

[7] S. Felin Jr, V. Barranco, Acta Mater. 51 (2003) 5413.

[8] P. Rajak, U. Tewary, S. Das, B. Bhattacharya, N. Chakraborti, Comput. Mater. Sci. 50

(2011) 2502.

[9] C.H.E. Belin, R.C.H. Belin, J. Solid State Chem. 151 (2000) 85.

[10] W.H. Zhu, H.M. Jin, P. Wu, H.L. Liu, Phys. Rev. B 70 (2004) 165419.

[11] A.S. Koster, J.C. Schoone, Acta Crystallogr. B 37 (1981) 1905.

[12] D. Horstmann, „The influence of impurities in iron on attack by molten zinc‟, 4

th

Int.

Galv. Conf. Milan (1956).

[13] C.E. Jordan, A.R. Marder, J. Mater. Sci. 32 (1997) 5603.

[14] M.S. Kozdras, P. Niessen, Mater. Sci. Technol. 6 (1990) 681.

[15] Y. Boonyongmaneerat, K. Saengkiettiyut, P. Rattanawaleedirojn, C. Angkaprasert, J.

Wanichsampan, S. Saenapitak, J. Iron Steel Res. Int. 17(8) (2011) 74.

[16] S.M.A. Shibli, R. Manu, Surf. Coat. Technol. 197 (2005) 103.

[17] T.H. Cook, Met. Finish. 89 (6) (1991) 107.

[18] U. Stieglitz, M.W.D. Schulz, H. Kulker, V. Brucken, Metalloberflaeche 56 (2002) 11.

[19] R.P. Krepski, Met. Finish. 87 (10) (1989) 37.

[20] M. Manna, Surf. Coat. Technol. 205 (2011) 3716.

[21] D. Balloy, J.Y. Dauphin, J.C. Tissier, Surf. Coat. Technol. 202 (2007) 479.

[22] L. Allegra, J.C. Zoccola, Mater. Performance 22 (1983) 5.

[23] S.M.A. Shibli, A.C. Jayalekshmi, R. Remya, Surf. Coat. Technol. 201 (2007) 7560.

[24] S. Maeda, Prog. Org. Coat. 28 (1996) 227.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

16

[25] P. Liberski, K. Henryk, P. Podolski, A. Gierek, Ochrona przed Korozja, 47 (2004) 264.

[26] A. R. Marder, Prog. Mater. Sci. 45 (2000) 191.

[27] P.R. Sere, J.D. Culcasi, C.I. Elsner, A.R. Di Sarli, Surf. Coat. Technol. 122 (1999) 143.

[28] N. Pistofidis, G. Yourlias, S. Konidaris, E. Pavilidou, A. Stergiou, G. Stergioudis,

Mater. Lett. 61 (2007) 994.

[29] V. Barranco, S. Feliu Jr., S. Feliu, Corros. Sci. 46 (2004) 2203.

[30] J.H. Hong, S.J. Oh, S.J. Kwon, Intermetallics 11 (2003) 207.

[31] H. Liu, Y. He, L. Li, Appl. Surf. Sci. 256 (2009) 1399.

[32] M. Dutta, A.K. Halder, S.B. Singh, Surf. Coat. Technol. 205 (2010) 2578.

[33] H. Liu, F. Li, W. Shi, R. Liu, L. Li, Surf. Coat. Technol. 205 (2011) 3535.

[34] G.M. Song, T. Vystavel, N. van der Pers, J.Th.M. De Hosson, W.G. Sloof, Acta

Mater. 60 (2012) 2973.

[35] H. Yang, S. Zhang, J. Li, X. Liu, H. Wang, Surf. Coat. Technol. 240 (2014) 269.

[36] Z. Chen, C.T. Peng, Q. Liu, R. Smith, D. Nolan, J. Alloys Compd. 589 (2014) 226.

[37] Y. Gui, Q. Xu, Y. Guo, J. Iron Steel Res. Int. 21(3) (2014) 396.

[38] S. Peng, J. Lu, C. Che, G. Kong, Q. Xu, Appl. Surf. Sci. 256 (2010) 5015.

[39] J. Duchoslav, M. Arndt, R. Steinberger, T. Keppert, G. Luckeneder, K.H. Stellnberger,

J. Hagler, C.K. Riener, G. Angeli, D. Stifter, Corros. Sci. 83 (2014) 327.

[40] J. Kondratiuk, P. Kuhn, E. Labrenz, C. Bischoff, Surf. Coat. Technol. 205 (2011) 4141.

[41] R. Hausbrand, M. Stratmann, M. Rohwerder, Corros. Sci. 51 (2009) 2107.

[42] N. LeBozec, D. Thierry, A. Peltola, L. Luxem, G. Luckeneder, G. Marchiaro, M.

Rohwerder, Mater. Corros. 64 (2013) 969.

[43] S.M.A. Shibli, F. Chacko, C. Divya, Corros. Sci. 52 (2010) 518.

[44] S.M.A. Shibli, F. Chacko, Appl. Surf. Sci. 257 (2011) 3111.

[45] S.M.A. Shibli, F. Chacko, Surf. Coat. Technol. 205 (2011) 2931.

[46] C. Xhoffer, H. Dillen, B.C. Cooman, J. Appl. Electrochem. 29 (1999) 209.

[47] A. Chakraborty , M. Dutta , R. Pais , R.K. Ray, Surf. Coat. Technol. 204 (2010) 3481.

[48] H.Y. Ha, S.J. Park, J.Y. Kang, H.D. Kim, M.B. Moon, Corros. Sci. 53 (2011) 2430.

[49] S.I. Kim, J.U. Her, Y.C. Jang, Y. Lee, Trans. Nonferrous Met. Soc. China 21 (2011)

s111.

[50] N.L. Okamoto, D. Kashioka, M. Inomoto, H. Inui, H. Takebayashi, S. Yamaguchid

Scripta Mater. 69 (2013) 307.

[51] M. Manna, M. Dutta, Surf. Coat. Technol. 251 (2014) 29.

[52] Y.I. Choi, E.S. Shin, K. Kuroda, M. Okido, C.J. Park, Corros. Sci. 58 (2012) 152.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

17

[53] J. Sun, H. Yu, Mat. Sci. Eng. A 586 (2013) 100.

[54] H.J. Grabke, V. Leroy, H. Viefhaus, ISIJ Int. 35 (1995) 95.

[55] S. Frenznick, S. Swaminathan, M. Stratmann, M. Rohwerder, J. Mater. Sci. 45 (2010)

2106.

[56] H. Liu, F. Li, W. Shi, S. Swaminathan, Y. He, M. Rohwerder, L. Li, Surf. Coat.Technol.

206 (2012) 3428.

[57] M. Blumenau, M. Norden, F. Friedel, K. Peters, Surf. Coat. Technol. 206 (2011) 559.

[58] C.J. Wang, S.M. Chen, Surf. Coat. Technol. 201 (2006) 3862.

[59] C.C. Tsaur, J.C. Rock, Y.Y. Chang, Mater. Chem. Phys. 91 (2005) 330.

[60] C.J. Wang, C.C. Li, Surf. Coat. Technol. 177–178 (2003) 37.

[61] B. Lemmens, Y.G. Garcia, B. Corlud, J.D. Strycker, I.D. Graeve, K. Verbeken,

Surf. Coat. Technol. (2014) Article in Press, DOI: 10.1016/j.surfcoat.2014.06.064.

[62] W.J. Cheng, C.J. Wang, Mater. Charact. 69 (2012) 63.

[63] M. Dutta, S.B. Singh, Scripta Mater. 60 (2009) 643.

[64] W.J. Cheng, C.J. Wang, Surf. Coat. Technol. 204 (2009) 824.

[65] W.J. Cheng, C.J. Wang, Appl. Surf. Sci. 274 (2013) 258.

[66] M. Windmann, A. Röttger, W. Theisen, Surf. Coat. Technol. 246 (2014) 17.

[67] X. Chen

, Q. Huang, Z. Yan, Y. Song, S. Liu, Z. Jiang, J. Nucl. Mater. 442 (2013) S597.

[68] I.I. Danzo, Y. Houbaert, K. Verbeken, Surf. Coat. Technol. 251 (2014) 15.

[69] N. Takata, M. Nishimoto, S. Kobayashi, M. Takeyama, Intermetallics 54 (2014) 136.

[70] E. Frutos, P. Adeva, J.L. González-Carrasco, P. Pérez, Surf. Coat. Technol. 236 (2013)

188.

[71] Z. Shi, J. Cao, F. Han, J. Nucl. Mater. 447 (2014) 77.

[72] C.S. Ni, L.Y. Lu, C.L. Zeng, Y. Niu, J. Power Sources 261 (2014) 162.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

18

Table 1: Characteristics of Fe-Zn intermetallic phases of hot dip zinc coatings [8-11]

η phase

ζ phase

δ phase

Г1 phase

Г phase

Stoichiometry

Zn

FeZn13

FeZn10

Fe5Zn21

Fe3Zn10

Wt % of iron

0

5-6

7-11.5

17-19.5

23.5-28

Crystal structure

HCP

Monoclinic Hexagonal

FCC

BCC

Atoms/unit cell

6

28

555

408

52

Source: Comput. Mater. Sci., Vol. 50, 2011, pp. 2502 (Elsevier)

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

19

eta

zeta

delta

gamma

steel

Fig. 1. The intermetallic layers present in a typical / conventional hot dip galvanized

coating.

ACCEPTED MANUSCRIPT

ACCEPTED MANUSCRIPT

20

Highlights

highlighted.

iscussed.

Wyszukiwarka

Podobne podstrony:

więcej podobnych podstron