Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

1

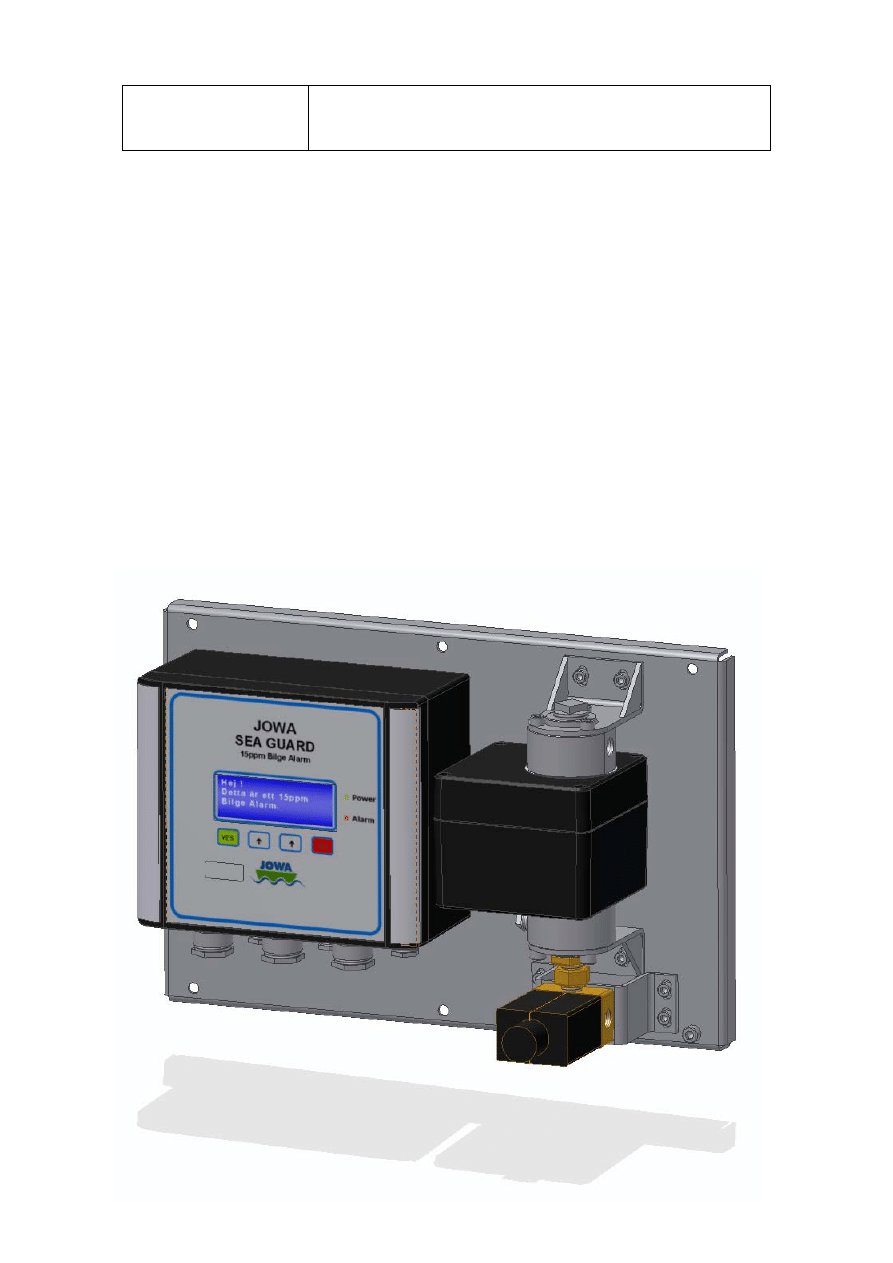

JOWA 15ppm Bilge Alarm

JOWA SEAGUARD

OPERATING INSTRUCTIONS AND

TECHNICAL MANUAL

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

2

Table of Contents

1.0

Introduction and general description .................................................. 4

1.1 General ............................................................................................................. 5

1.2

Guarantee and service...................................................................................... 5

1.3

Note on recycling. ............................................................................................ 5

2.0

Technical Specification......................................................................... 6

2 Specifications ................................................................................................ 7

2.1 Technical data JOWA SEAGUARD...................................................................... 7

3.0

Installation.............................................................................................. 8

3.1 Delivery ............................................................................................................ 8

3.2

Placement of the skid........................................................................................ 8

3.3 Pipe

Connections .............................................................................................. 8

3.4 Electric

Connections......................................................................................... 8

3.5

Adjusting the back pressure / flow in the sensor.............................................. 9

4.0

System Function Description. ............................................................ 10

4.1 Basic Functions .............................................................................................. 10

4.2 Alarms ............................................................................................................ 10

4.3 Logged

Data ................................................................................................... 10

4.3.1

Format of the log names ......................................................................... 11

4.3.2

Format of the logged data....................................................................... 11

4.3.3 Auto

flush ............................................................................................... 11

5.0

The Menu System ................................................................................ 12

5.1

General Overview of the Menu tree ............................................................... 12

5.2

Navigating the menus ..................................................................................... 13

5.3 Pages in the menu system.............................................................................. 13

5.3.1 Main Page.................................................................................................. 13

5.3.2 Service

Menu...................................................................................... 13

5.3.3 Clean sensor........................................................................................... 14

5.3.4. Signals .................................................................................................. 14

5.3.5 Simulation........................................................................................... 15

5.3.6 Password Protected................................................................................ 16

5.3.7 Settings Menu............................................................................................ 17

5.3.8 Valve/Alarm1/Alarm2........................................................................... 17

5.3.9 Auto flush .............................................................................................. 17

5.3.10

Log Menu .......................................................................................... 18

5.3.11 List log files........................................................................................ 18

5.3.12 Log

files.............................................................................................. 18

5.3.13

Print log on printer/RS232............................................................. 19

5.3.14 Alarm list ................................................................................................ 20

5.3.15 Information Menu................................................................................... 21

5.3.16 Control Unit........................................................................................ 21

5.3.17 Sensor Unit ......................................................................................... 21

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

3

5.3.18 JOWA info.............................................................................................. 21

6.0

Maintenance ......................................................................................... 22

7.0

Trouble Shooting ................................................................................. 23

8.0

Flow Diagram (P & I)............................................................................ 26

9.0

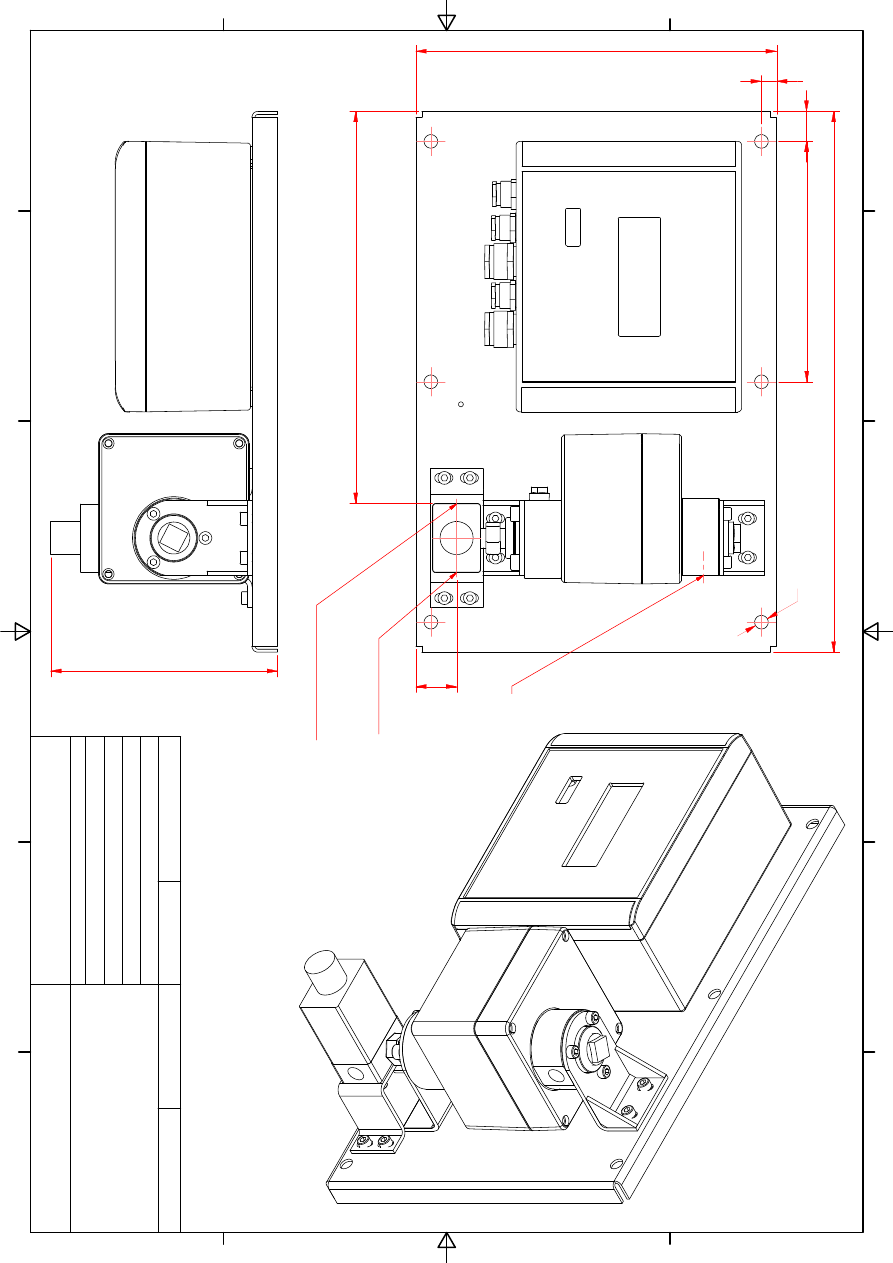

Mechanical Drawings .......................................................................... 27

10.0

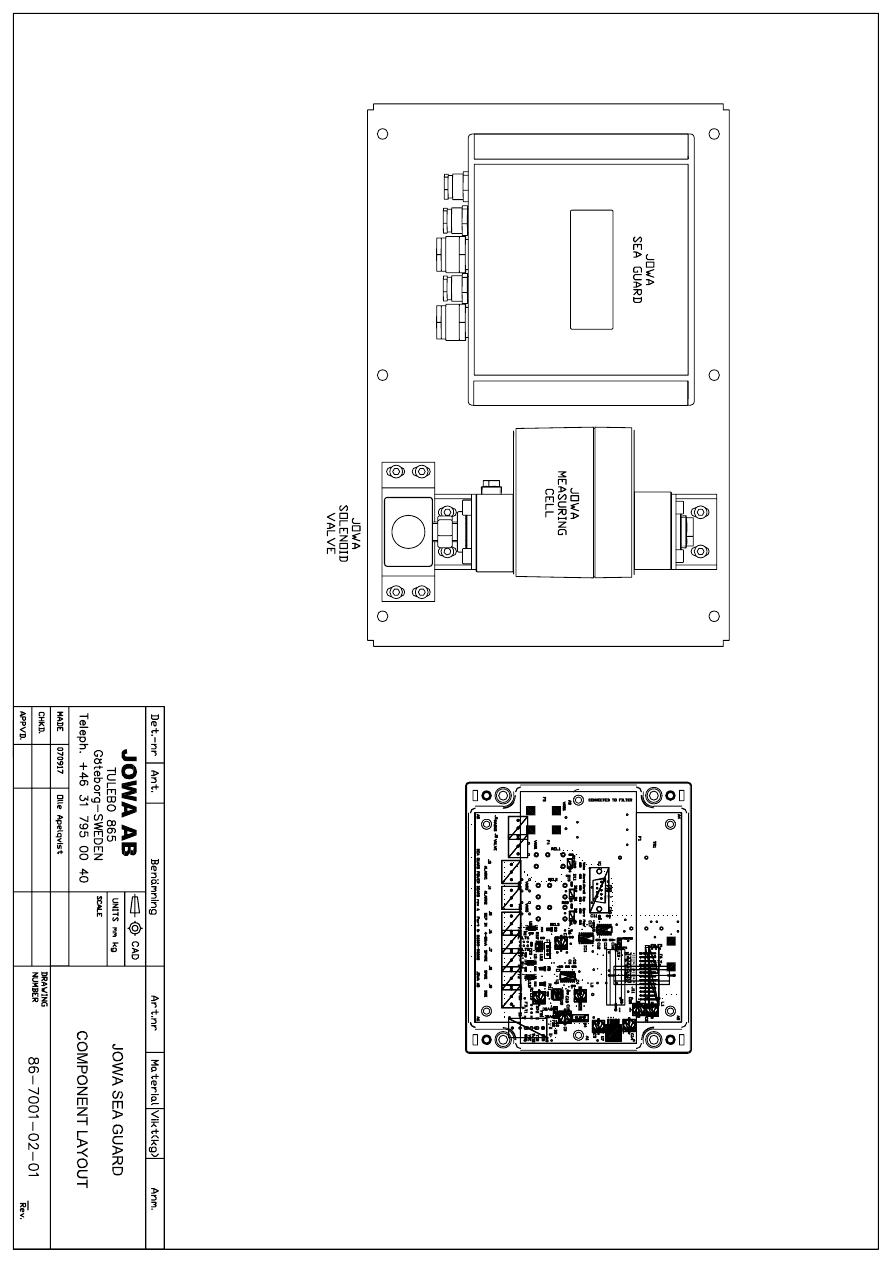

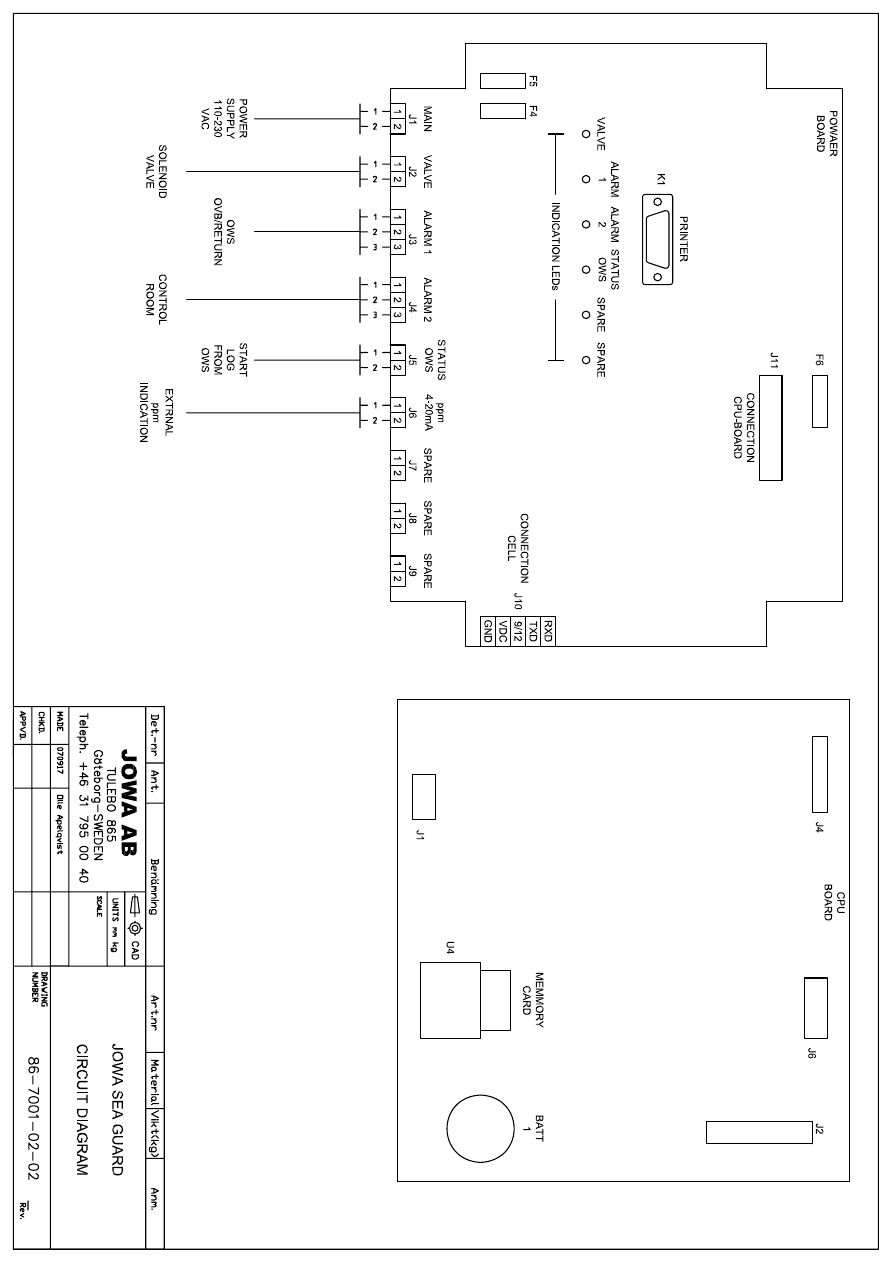

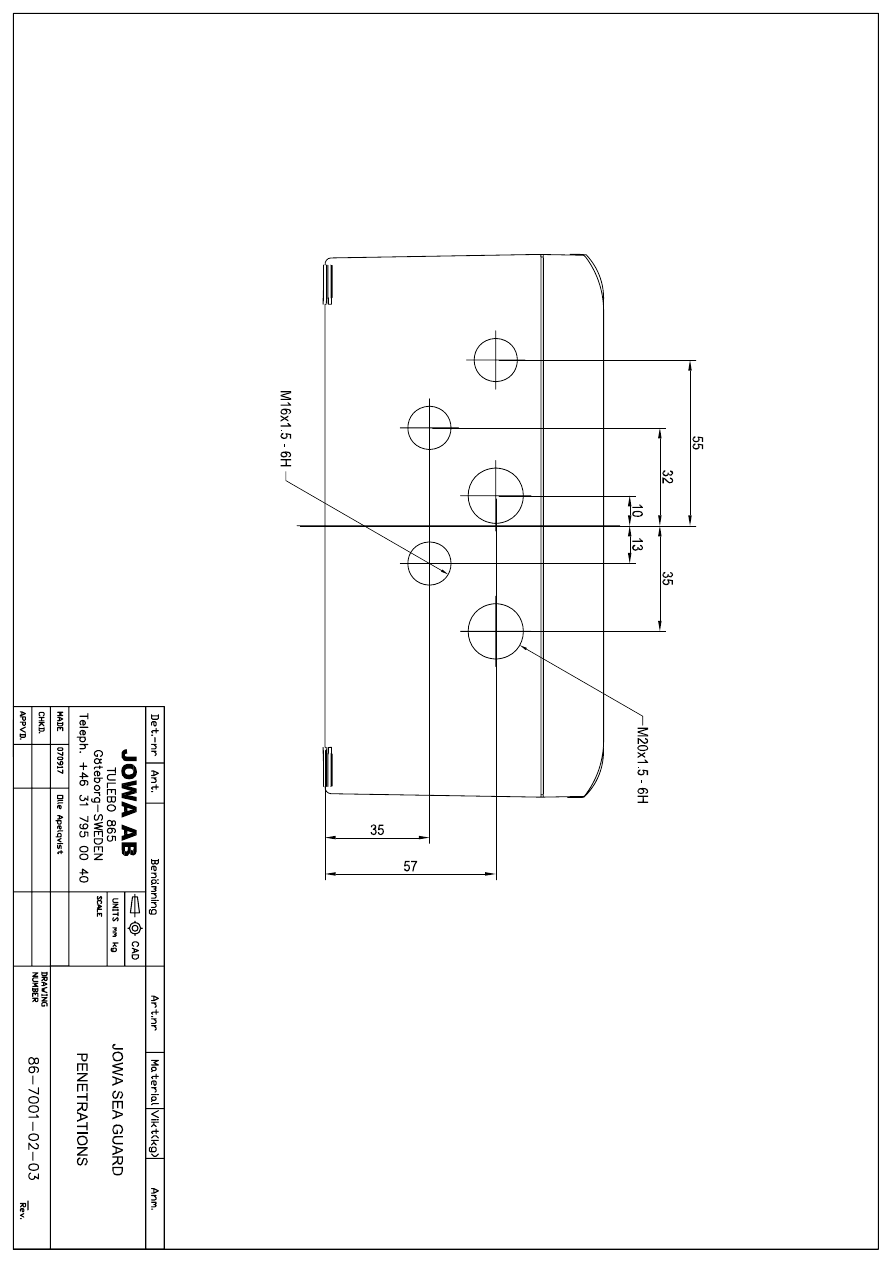

Electrical drawings.............................................................................. 28

11.0

Spare Parts List ................................................................................... 29

12.0

Approval Certificates........................................................................... 31

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

4

1.0 Introduction and general description

The JOWA SEAGUARD 15ppm Bilge alarm is designed to monitor the effluent

from a bilge water separator. The alarm is approved to IMO MEPC 107(49).

There are 2 alarm out signals which are triggered by the ppm oil content of the

separators effluent.

The JOWA SEAGUARD has a cleaning function, auto flush, designed to keep

the sensor as clean as possible. Auto flush occurs automatically.

The JOWA SEAGUARD log is controlled by a signal from the separator and is

saved on a removable SD card.

Before leaving our workshop each unit has to pass a quality-test, where

all functions are tested and checked.

All components are of the highest quality. Spare parts are easily available from

one of our offices or representatives worldwide.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

5

1.1 General

To obtain all the advantages from operating a JOWA SEAGUARD 15ppm Bilge

alarm ensure that all users have adequate education for the equipment, ensure

that the installation is correct and ensure that the JOWA SEAGUARD is

maintained and operated in accordance with the instructions in this manual. The

correct function of the equipment cannot be guaranteed if the user fails to follow

these instructions. We reserve the right to make changes to the JOWA

SEAGUARD, within the limits of applicable regulations, without previous notice.

Before installation and start-up read this manual carefully.

Supplier and manufacturer:

JOWA AB

Tulebovägen 104

S-428 34 Kållered , Göteborg

Sweden

Phone:

+46-31 726 54 00

Fax:

+46-31 795 45 40

Mail:

info@jowa.se

Homepage: www.jowa.se

1.2

Guarantee and service.

The JOWA SEAGUARD is covered by a guarantee period. Guarantee claims

can be made according to JOWA’s Guarantee claim procedure. The JOWA

SEAGUARD contains components with no user serviceable parts which are

sealed. Breaking the seals placed on these components automatically voids the

warranty. Contact JOWA for assistance.

Service should only be carried out by an authorised JOWA service engineer.

1.3

Note on recycling.

In the design and manufacture of the JOWA SEAGUARD all Efforts have been

made to use components that can be recycled. This product or the parts of it

must be disposed of in an environmentally sound manner. Use the local public

or private waste collection service

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

6

2.0 Technical

Specification

This chapter contains a quick reference table with the main technical

specifications for the JOWA SEAGUARD.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

7

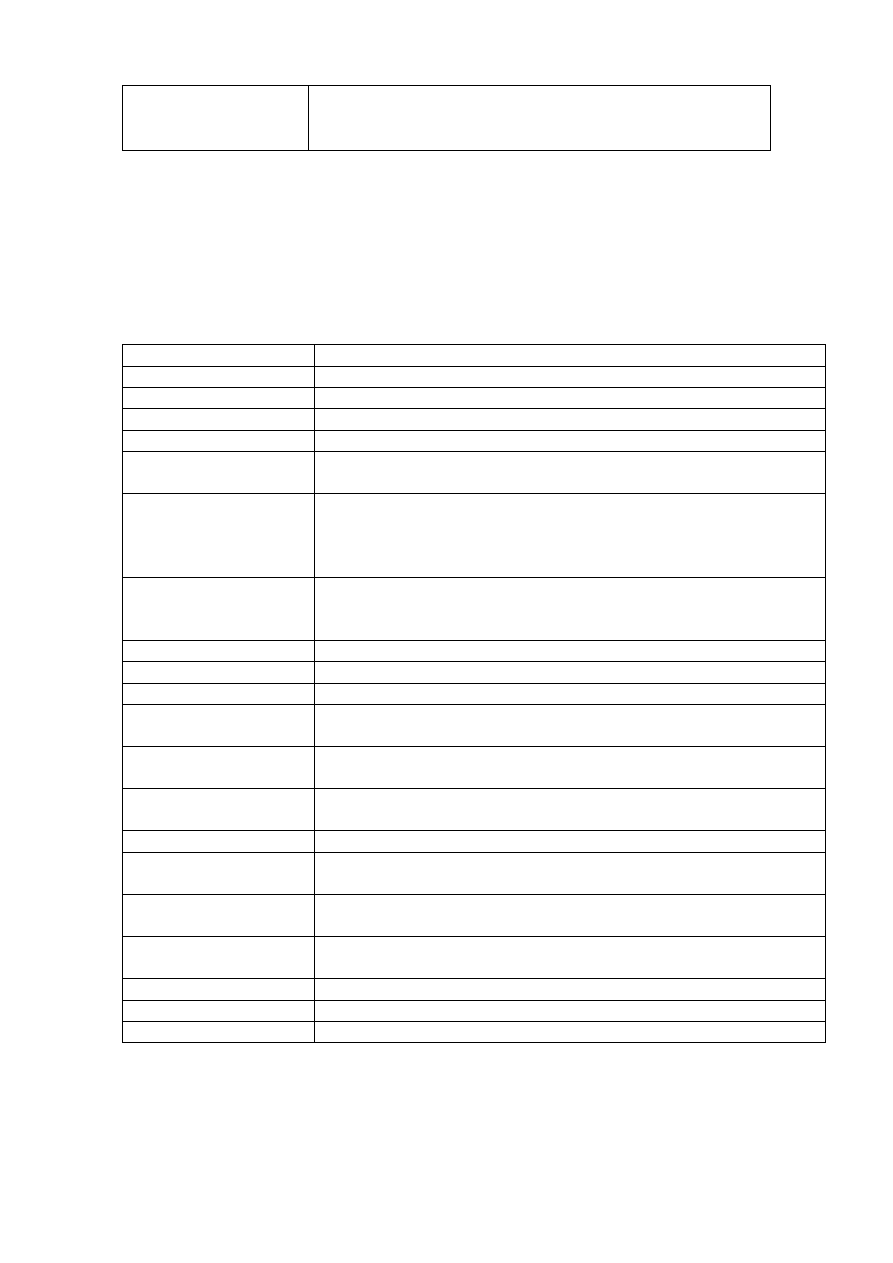

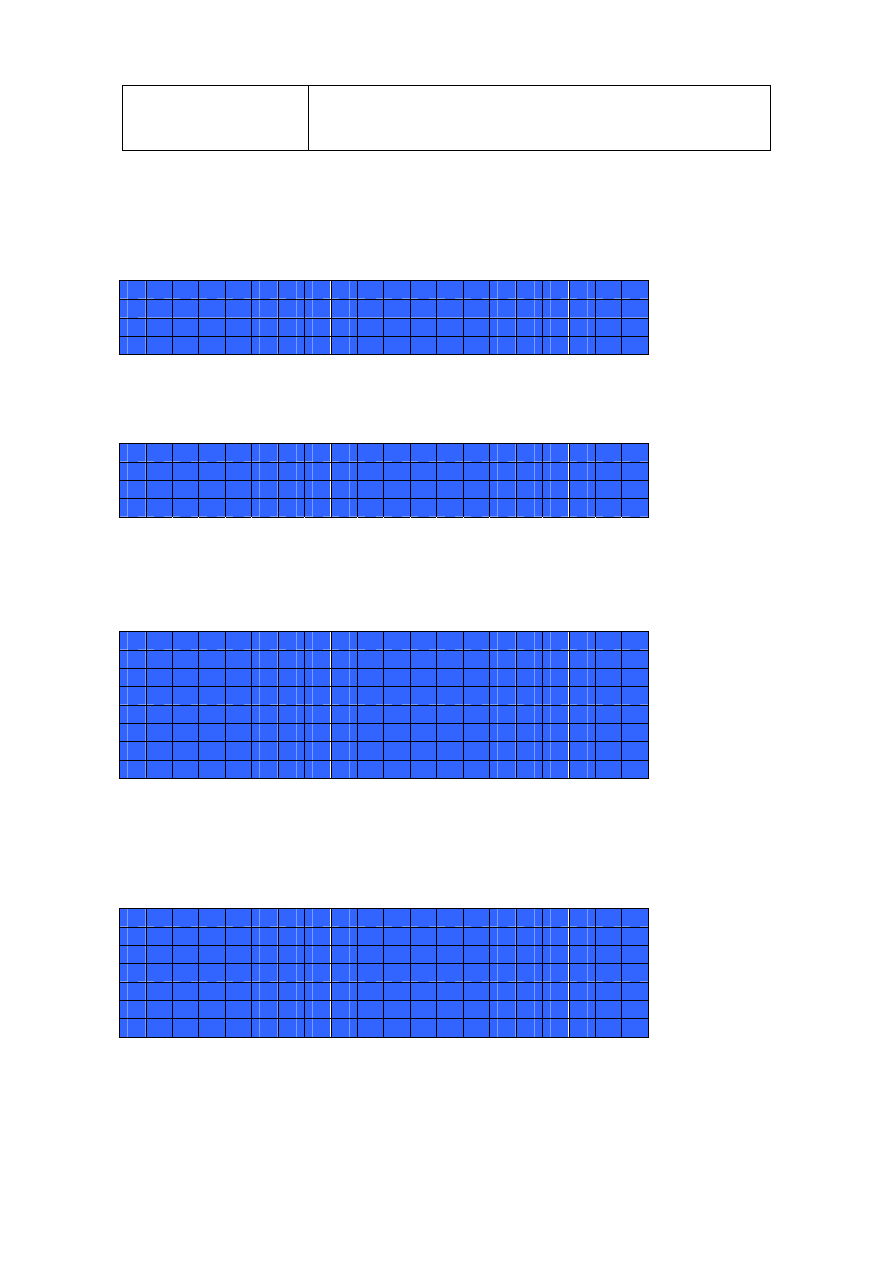

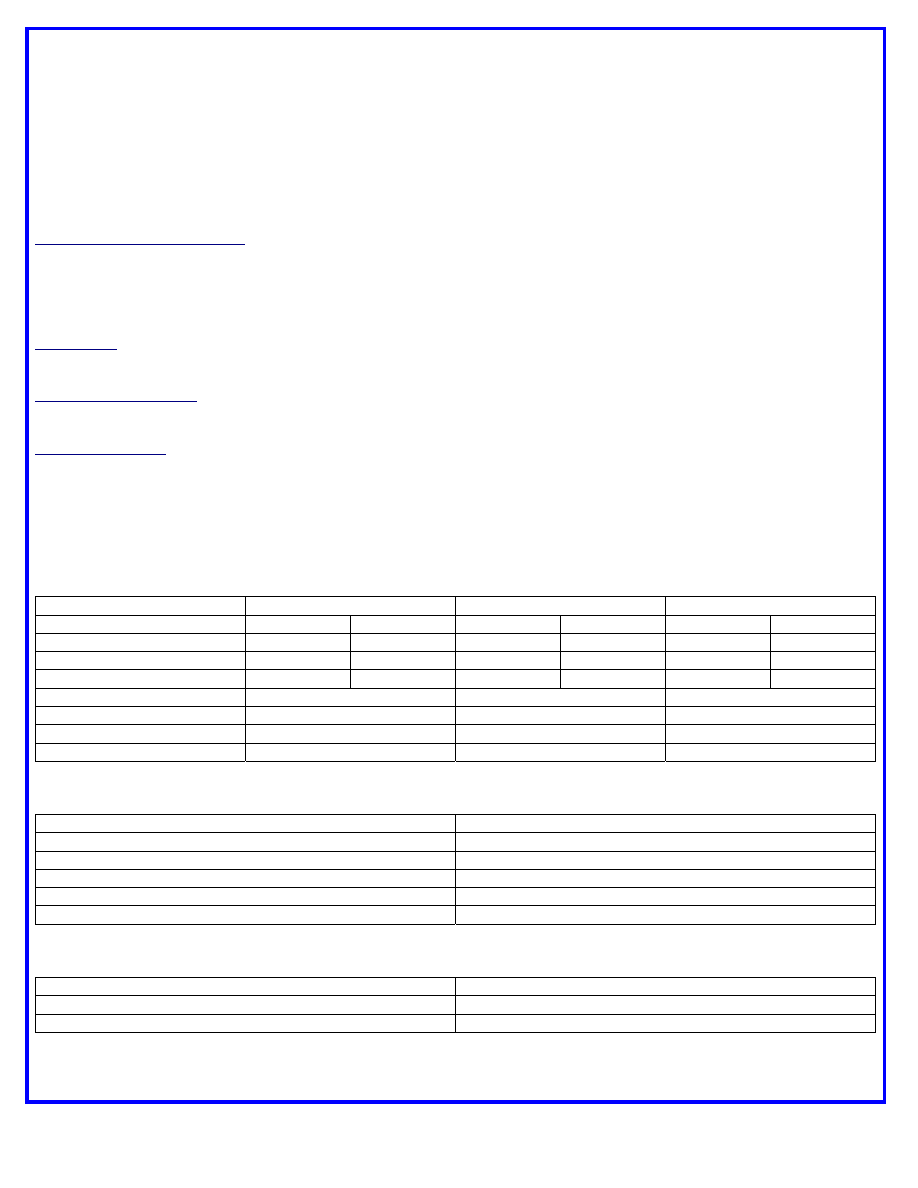

2 Specifications

2.1 Technical data JOWA SEAGUARD

Range:

0-30ppm, trend up to 40ppm

Approval/Accuracy:

According to IMO MEPC.107(49)

Display

20 x 4 characters LCD with Backlight

Power Supply:

115-230 VAC 50/60Hz Automatic voltage selection

Power Consumption: <15 VA

Alarm Points 1 + 2:

Adjustable between 0-15ppm

Factory setting 15ppm

Alarm 2 Operating

delay: (for

annunciation

purposes)

Adjustable between 0-540 seconds

Factory setting 0 seconds

Alarm 1 Operating

delay: (for control

purposes)

Adjustable between 0-10 seconds

Factory setting 0 seconds

System fault alarm:

Red LED light (flashing)

Alarm contact Rating: Potential free 1 pole change over contacts; 6A/250V

Alarm indication:

In LCD & Red LED light

Output signal:

0 – 20mA or 4 – 20mA for 0 – 40ppm, ext. load max 150 Ω

Sample water

pressure:

Nominal 2 bar

Sample Flow:

Nominal. 2l/min depending on pressure

Ambient temperature +1 to +60 degrees Celsius

Sample water

temperature:

+1 to +60 degrees Celsius

Roll:

Up to 45 degrees

Size:

360 x 240 x 150, LxWxD

Degree of protection: IP 65

Weight: 7,5

kg

Pipe connections:

R ¼” Female

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

8

3.0 Installation

This chapter contains step-by-step information detailing how the JOWA

SEAGUARD is installed.

3.1 Delivery

The JOWA SEAGUARD is delivered as a complete unit mounted on a base

plate

The unit has passed a work-shop tested before delivery.

3.2

Placement of the skid

The JOWA SEAGUARD should be placed on a plane vertical surface and

bolted using the pre drilled holes in the base plate. When installing the unit it is

important to leave a minimum of 500mm working space in front of the unit (see

mechanical drawings chapter).

3.3 Pipe

Connections

All pipe connection points are G ¼” female threads (see mechanical drawings

chapter). Piping layout from the separator to the JOWA SEAGUARD should

follow the schematic shown in the flow diagram chapter.

3.4 Electric

Connections

The electrical equipment of the JOWA SEAGUARD is ready for installation

when delivered. The power supply should be single phase 230 VAC 50/60Hz.

Other power supplies on request. See the electrical drawings for further

information.

Connect the main cable to terminal J1 1,2 in the main control box.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

9

3.5

Adjusting the back pressure / flow in the sensor

To adjust the back pressure/ flow in the sensor there is a small flow restrictor in

the sample outlet connection. The flow restrictor is only 11mm in Diameter/

4mm thick and the orifice is 1mm.

The flow restrictor is located behind the coupling that is mounted in the sample

outlet.

Standard delivery is 1mm, but if this is too small hole, it is very easy to drill a

bigger hole.

It is recommendable to drill only 1 millimetre each time and then test again to se

if the back pressure/ flow are ok.

When the Bilge alarm is delivered as a loose item, the flow restrictor is delivered

in a bag taped on to the bilge alarm.

This flow restrictor should always be mounted in the outlet hole before the

coupling is connected.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

10

4.0 System Function Description.

This chapter provides a detailed description of the unique functions of the

JOWA SEAGUARD. It is intended that the information in this chapter may be

used to help the operator optimise the JOWA SEAGUARD performance to his

or her specific bilge requirements.

4.1 Basic Functions

The main task of the JOWA SEAGUARD is to monitor the oil content of the

effluent from a bilge water separator and alarm if the oil content exceeds

15ppm. The JOWA SEAGUARD also logs specific events from the separator

and the JOWA SEAGUARD. These logs are useful in connection with

inspections.

4.2 Alarms

There are 2 alarm out signals which are triggered by the ppm oil content of the

separators effluent or by internal error codes. The first alarm triggers when the

effluent goes over the alarm’s set point. If the ppm oil content of the separators

effluent remains over this set point for a defined period the second alarm is

triggered. The alarm set points and time delays are adjustable.

4.3 Logged

Data

The JOWA SEAGUARD log is controlled by a signal from the separator and is

saved on a removable SD card . NOTE! The SD card is sealed against

unauthorised removal. The log updates every minute if there is no new events

occurring within the minute. The following data is logged:

• Date/GMT

time

• Start/stop of the log

• Auto flush start/stop

• High ppm alarm

• Alarm reset (under 15ppm)

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

11

4.3.1 Format of the log names

The logs are named following the following routine:

YY-MM-DD-HH:TT:SS

YY = year e.g. 06 for 2006

MM = month, 01-12

DD = day, 01-31

HH= hour, 00-24

TT= min, 00-60

SS= sec,00-60

4.3.2 Format of the logged data

PPM = actual PPM value at recorded time.

Lim = the ppm set point for alarm.

Sep = status for separator. (0 = inactive, 1 = active)

Val = position for 3-way valve.(0 = sample, 1 = clean water)

Al1 = condition for ALARM1

(0 = inactive, 1 = active)

Al2 = condition for Alarm2

(0 = inactive, 1 = active)

Sim = simulation mode ( 0 = inactive, 1 = active)

Err = Error code. (00 = no errors)

4.3.3 Auto

flush

Auto flush function cleans the sensor. During auto flush both alarms are

activated.

Auto flush occurs according to the following steps:

0

Both alarms are triggered at the same time.

1

2 seconds pause

2

Valve changes to clean water

3

Flushing for 20 seconds (adjustable)

4

Re-zero of the sensor (takes 13 sec)

5

Valve changes to sample water

6

2 seconds pause

7

Alarms released, ready

NOTE:

When auto flush is enabled, an auto flush procedure is performed when the

separator is started and when it is stopped. If the re-zero action fails at start up,

a second flush procedure is performed.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

12

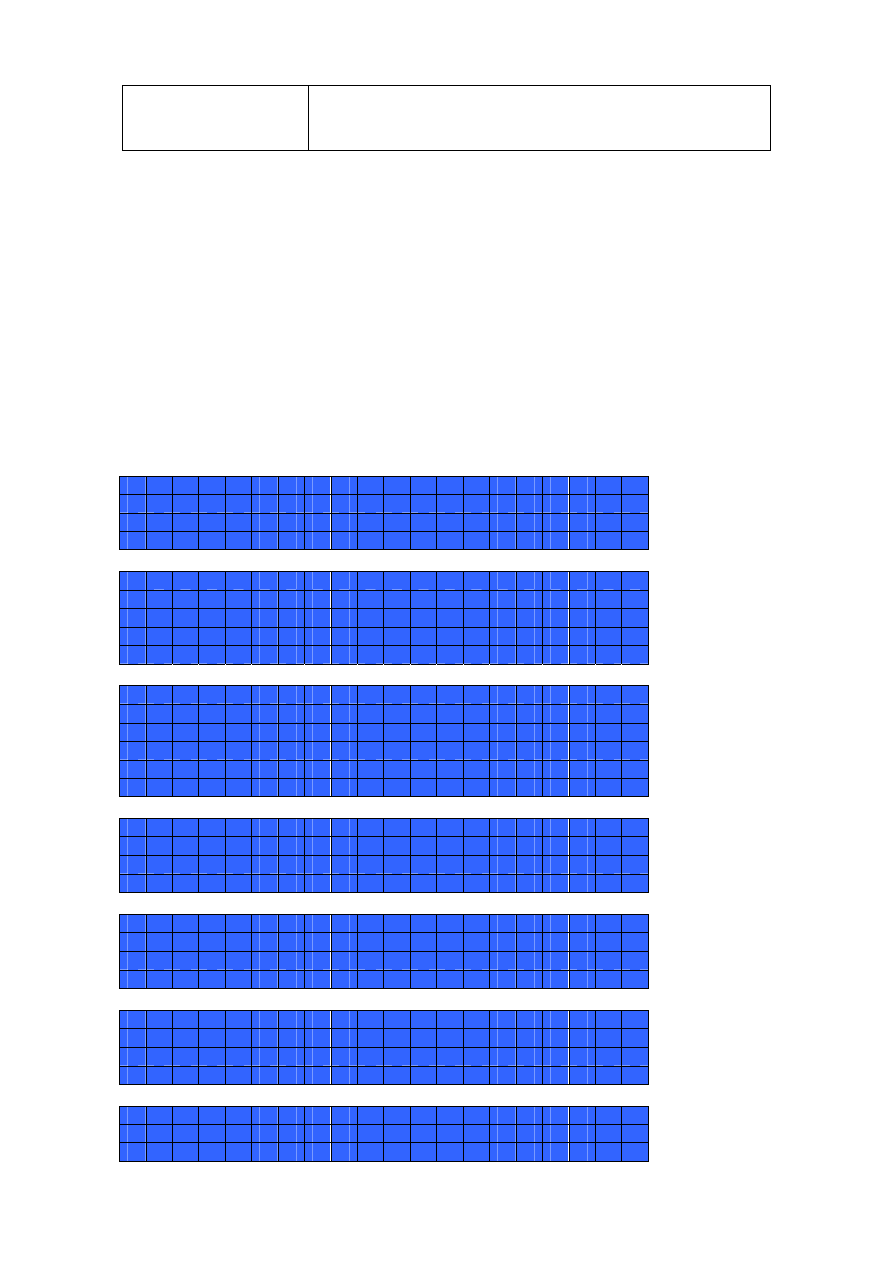

5.0 The Menu System

This chapter gives the operator detailed information on the JOWA SEAGUARD

menu system.

5.1

General Overview of the Menu tree

2 0 0 8 -

0 2 -

1 2

1 0 :

0 0 :

0 0

P P M :

1 0

S T A N D B Y

V a l

v e :

S A M P L E

A l

r m 1 :

O F F

A l

r m 2 :

O F F

↕

〉 S e r v i

c e

m e n u

S e t

t

i

n g s

m e n u

L o g

m e n u

I

n f

o r m a t

i

o n

m e n u

J O W A

I

n f

o

↕

S E R V I

C E

M E N U

〉 A l

a r m

l

i

s

t

C l

e a n

s

e n s

o r

S i

g n a l

s

S i

m u l

a t

i

o n

P a s

s

w o r d

p r o t

e c t

e d

↕

S E T T I

N G S

M E N U

〉 A l

a r m

o u t

p u t

s

C u r r e n t

o u t

p u T

A u t

o f

l

u s

h

↕

L O G

M E N U

〉 L i

s

t

l

o g

f

i

l

e s

P r i

n t

l

o g s

o n

R S 2 3 2

↕

I

N F O R M A T I

O N

M E N U

〉 C o n t r o l

u n i

t

S e n s

o r

u n i

t

↕

J O W A

A B

T u l

e b o v ä g e n

1 0 4

S E -

4 2 8

3 4

K å l

l

e r e d

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

13

G ö t

e b o r g ,

S W E D E N

+ 4 6

3 1

7 2 6

5 4

0 0

i

n f

o @ j

o w a .

s

e

w w w .

j

o w a .

s

e

5.2

Navigating the menus

Note!

It is only four lines at a time visible in the display. To scroll, use the arrow

UP or DOWN. This applies in all menus.

A alternative is confirmed by the Yes key and aborted by the no key. Values

are adjusted with the up/down keys.

5.3 Pages in the menu system

5.3.1 Main Page

2 0 0 8 -

0 2 -

1 2

1 0 :

0 0 :

0 0

P P M :

1 0

S T A N D B Y

V a l

v e :

S A M P L E

A l

r m 1 :

O F F

A l

r m 2 :

O F F

On the main page, the date, GMT (Greenwich Mean Time) is shown, actual

ppm, alarm status, 3-way valve position and log status. STANDBY= logging off.

RUN= logging on.

5.3.2 Service Menu

S E R V I

C E

M E N U

〉 A l

a r m

l

i

s

t

C l

e a n

s

e n s

o r

S i

g n a l

s

S i

m u l

a t

i

o n

P a s

s

w o r d

p r o t

e c t

e d

Alarm list is showing the presents alarms. Press Yes to enter the list.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

14

5.3.3 Clean sensor

S E R V I

C E

M E N U

A l

a r m

l

i

s

t

〉 C l

e a n

s

e n s

o r

S i

g n a l

s

S i

m u l

a t

i

o n

P a s

s

w o r d

p r o t

e c t

e d

Back-flushing of the cell according to the “auto flush” routine described earlier in

this manual. Cleaning finishes with a re-zero of the sensor and the result is

shown in the display.

5.3.4. Signals

I

N

&

O U T

S I

G N A L S

S e p

i

n :

P A S S I

V E

F l

o w

i

n :

P A S S I

V E

S p a r e

i

n :

P A S S I

V E

V a l

v e

o u t

:

P A S S I

V E

A l

a r m 1 :

o u t

:

P A S S I

V E

A l

a r m 2 :

o u t

:

P A S S I

V E

A l

a r m

l

e d :

P A S S I

V E

Sep in = separator run signal.

Flow in= spare.

Spare in = spare.

Valve out = solenoid valve

Alarm1 out = alarm 1

Alarm2 out = alarm 2

Alarm led= LED- alarm signal to display

Passive and active are the possible values for all signals.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

15

5.3.5 Simulation.

According to MEPC 107(49) § 4.2.5, onboard testing according to the

manufacturers instructions shall be permitted.

To facilitate this the JOWA 15ppm bilge alarm has a service menu called

simulation. A simulation run permits the user to imitate a ppm over the alarm set

point, (max alarm set point 15ppm).

This simulation run works by simulating the ppm ramping up from the real ppm

to a peak of 20ppm and down to the real ppm again.

-In this case “real ppm” refers to the ppm which is actually present.

Each ppm step in the simulation run takes 2 seconds. If, for example, the real

ppm is 10ppm when the simulation is started the alarm counts up from 10ppm

to 20ppm. If at the end of this simulation the real ppm is now 8ppm the count

down stops here

NOTE!

-If the real ppm value is higher than 15ppm then it is not possible to start a

simulation run

-During simulation the alarm continually monitors the real ppm in the

background. If at any time during a simulation run the real ppm goes higher

than 15ppm, there will be an alarm.

-All simulation runs are logged if the Sep in signal is active.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

16

To perform a simulation choose the “Simulation” from the Service menu and

press YES, now the below display will be presented.

P r e s

s

Y e s

t

o

s

t

a r t

t

h e

P P M

s

i

m u l

a t

i

o n

p r o c e d u r e .

P r e s

s

N o

t

o

c a n c e l

Start the separator and then press YES to start the simulation.

If the separator isn’t running there will be no log on the simulation.

S i

m u l

a t

i

o n

s

t

a r t

e d !

First “Simulation Started!” will appear for a few seconds.

2 0 0 8 -

0 2 -

1 2

1 0 :

0 0 :

0 0

P P M :

1 0

R U N .

.

.

V a l

v e :

S A M P L E

A l

r m 1 :

O F F

A l

r m 2 :

O F F

In this window the ppm is increasing from the ”real” ppm to 20ppm

And then back to the “real” ppm again. When the “simulated” ppm reach

The alarm limit the alarm will appear and the OBV will close. Then the

ppm will reach to 20, and then it will go back to “real” ppm again.

S i

m u l

a t

i

o n

d o n e !

After the Simulation this window will appear and the bilge alarm is

Going back to normal run. One log file is created on the simulation.

5.3.6 Password Protected

These menus are only available to authorised service engineers

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

17

5.3.7 Settings Menu

S E T T I

N G S

M E N U

〉 A l

a r m

o u t

p u t

s

C u r r e n t

o u t

p u t

A u t

o f

l

u s

h

To make changes in the main programmes parameters the user must navigate

to ‘settings’ where the user can change the settings for the alarms, valve, auto

flush and current out.

5.3.8 Valve/Alarm1/Alarm2

A L A R M

S E T T I

N G S

〉 P P M

l

i

m i

t

:

1 5

t

a l

a r m 1 :

0

[

S ]

t

a l

a r m 2 :

0

[

S ]

The different alarms have different delays and the ppm setting can be adjusted

between 0.0 and 15.0.

C U R R E N T

O U T P U T

M O D E

〉 [

]

0

t

o

2 0

m A

[

X ]

4

t

o

2 0

m A

The 4-20mA signal level can be adjusted where (0) 4 mA is equivalent to

0ppm, and 20 mA is equivalent to 30ppm.

5.3.9 Auto flush

A U T O F L U S H

S E T T I

N G S

〉 A u t o f l

u s

h :

O N

t

s

t

a r t

:

3 0

[

S ]

t

e n d :

3 0

[

S ]

000-540 [s]

Auto flush can be shut off or set under the settings menu. It is also possible to

set the length of time per auto flush, (t).

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

18

5.3.10 Log Menu

L O G

M E N U

〉 L i

s

t

l

o g

f

i

l

e s

P r i

n t

l

o g s

o n

R S 2 3 2

If choosing “print logs on RS232” all logs will be printed.

5.3.11 List log files.

E n t

e r

d a t

e :

-

2 0 0 8 -

0 3 -

3 1

-

By choosing “list log files” you are able to choose any log

At the memory card by date.

5.3.12 Log files

L O G

F I

L E S

〉 2 0 0 8 - 0 3 - 3 1

0 6 :

1 5 :

0 2

P r e v i

o u s

d a y

N e x t

d a y

When one specific log is chosen, press yes and then you will

Get to the window below. It is also possible to se log events next

day or previous day.

-

-

-

-

-

-

-

1

/

7 -

-

-

-

-

-

-

-

2 0 0 8 -

0 3 -

3 1

0 6 :

1 5 :

0 2

P P M = 0

L i

m = 1 5

E r r = 0 0

S = 1

V = 0

A 1 = 0

A 2 = 0

Every log is marked with start date and time, ppm, alarm and

valve position. Of (X/Y), X is log number of Y, total logs.

A log of format ’-----(X/Y)----------’ denotes a log without any

alarms, while ”====(X/Y)============” denotes a log with alarms.

PPM row shows the actual ppm value and the ppm alarm set point

and alarm. (Err=00 is normal) The bottom row shows the status for

alarm (A1) and (A2) valve position (V) (0=sample, 1=clean water).

separator status (S) (0 = inactive, 1 = active).

To get more options on the chosen log please press yes and

Then the below window will appear.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

19

5.3.13 Print log on printer/RS232

By choosing “print on printer” a special printer from Jowa is needed.

By choosing Print on RS232 it is possible to print the log to a pc.

Instruction of how to download log files into a PC, and items needed.

1a. A serial cable of 0-modem type, with two female 9 pin connectors. Connect

one end of the cable to RS232 connection at the Bilge alarm power board and

the other end to your PC’s serial COM port.

If your PC doesn’t have a serial com port it is possible to use a converter from

USB to RS232. Both, the 0-modem cable and the converter is possible to by

from JOWA.

2. A terminal program (it’s standard in all windows program)

Windows has one under Start-program-accessories-communication-hyper

terminal.

A

. A window pop up and says new connection, name it “Bilge alarm”, OK

B

. Next window, choose the com port where you have connected the cable, OK

C

. Properties for the COM port should be adjusted as follows:

Bits per second: 9600

Data bits:

8

Parity:

none

Stop bits:

1

Flow control:

none

D

. Within the terminal program, choose menu Transfer and “fetch text to file”

some computers has “capture text”.

E

. A new window pop up where to save, browse and choose desktop and a file

name e.g. bilge alarm.txt , save and start.

A C T I

O N

O N

L O G

〉 P r i

n t

o n

p r i

n t

e r

P r i

n t

o n

R S 2 3 2

A l

a r m

l

i

s

t

R e t

u r n

t

o

l

o g s

R e t

u r n

t

o

l

o g

m e n u

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

20

F

. At the Bilge alarm, go to the log menu and press YES, then choose “list log

files”. Now the display will show “Enter date” and you can choose the date that

you want by using YES, UP and DOWN arrow. After entering date, press YES.

Please choose the log that you want to print and press YES.

Choose print on RS232 and press YES.

H

. Go back to the hyper terminal menu transfer and stop “fetch text to file”

I

. To se the log file, open the created file at the desktop “bilge alarm.txt” by

double clicking on it and the log file will be visible.

J

. When closing HyperTerminal, Windows ask you if you want to save the

configured HyperTerminal, by clicking Yes the setup is saved until next time you

want to use it. You find it under Start-Program-Accessories-Communication-

HyperTerminal-Bilge alarm.

5.3.14 Alarm list

If an Error e.g.(Err=10) is presented in the log and to se what alarm it is please

press choose “Alarm list” and press YES. Now the error is presented.

A C T I

O N

O N

L O G

P r i

n t

o n

p r i

n t

e r

P r i

n t

o n

R S 2 3 2

〉 A l

a r m

l

i

s

t

R e t

u r n

t

o

l

o g s

R e t

u r n

t

o

l

o g

m e n u

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

21

5.3.15 Information Menu

I

N F O R M A T I

O N

M E N U

〉 C o n t r o l

u n i

t

S e n s

o r

u n i

t

Choose Control unit or Sensor unit and press YES

5.3.16 Control Unit

C O N T R O L

U N I

T

I

D :

B A C -

0 0 0 1

S W

v e r :

S G

1 .

1 .

1

H W

v e r :

S G

R e v

B

ID information for The Complete Bilge alarm, main circuit board, software and

hardware

versions

5.3.17 Sensor Unit

S E N S O R

U N I

T

I

D :

B A S :

0 0 0 1

S W

v e r :

0 1 .

0 1 .

0 0

H W

v e r :

F

0 2

C a l

i

:

0 8 0 3 1 8 1 2 0 0

T e m p :

2 0

S t

a t

u s

r e g 1 :

0 x 0 0

S t

a t

u s

r e g 2 :

0 x 0 0

ID information for sensor, circuit board, software and hardware versions. Sensor

calibration date and time, sensor temperature.

5.3.18 JOWA info

J O W A

A B

T u l

e b o v ä g e n

1 0 4

S E -

4 2 8

3 4

K å l

l

e r e d

G ö t

e b o r g ,

S W E D E N

+ 4 6

3 1

7 2 6

5 4

0 0

i

n f

o @ j

o w a .

s

e

w w w .

j

o w a .

s

e

Jowa Contact info.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

22

6.0 Maintenance

The JOWA SEAGUARD requires very little maintenance.

Weekly maintenance:

- Clean the sensor with the provided brush.

- Do an manual auto flush after the sensor is clean.

Go to the “service menu” and in that menu please choose “Clean Sensor”.

Now the fresh water is flushing the sensor and in the same time a clean

water calibration is done.

On every IOPP certificate renewal:

According to resolution MEPC.107(49) § 4.2.11

The accuracy of the 15 ppm Bilge Alarms should be checked at IOPP

Certificate renewal surveys according to the manufacturers instructions.

Alternatively the unit may be replaced by a calibrated 15 ppm Bilge Alarm.

The calibration certificate for the 15 ppm Bilge Alarm, certifying date of last

calibration check, should be retained onboard for inspection purposes.

The accuracy checks can only be done by the manufacturer or persons

authorized by the manufacturer.

On the JOWA 15PPM Bilge alarm it is only necessary to replace the sensor

unit.

With the sensor, a calibration certificate with the last calibrating date will follow.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

23

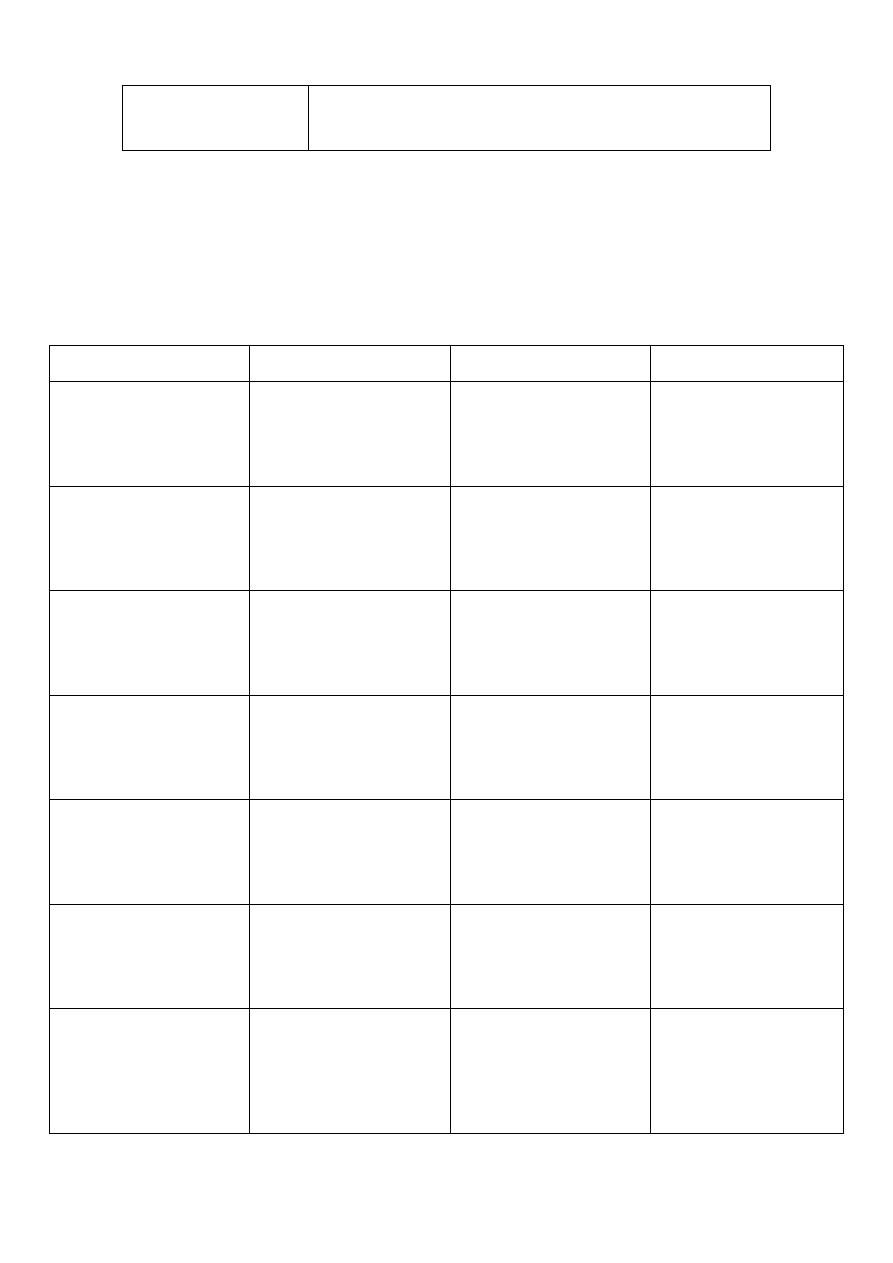

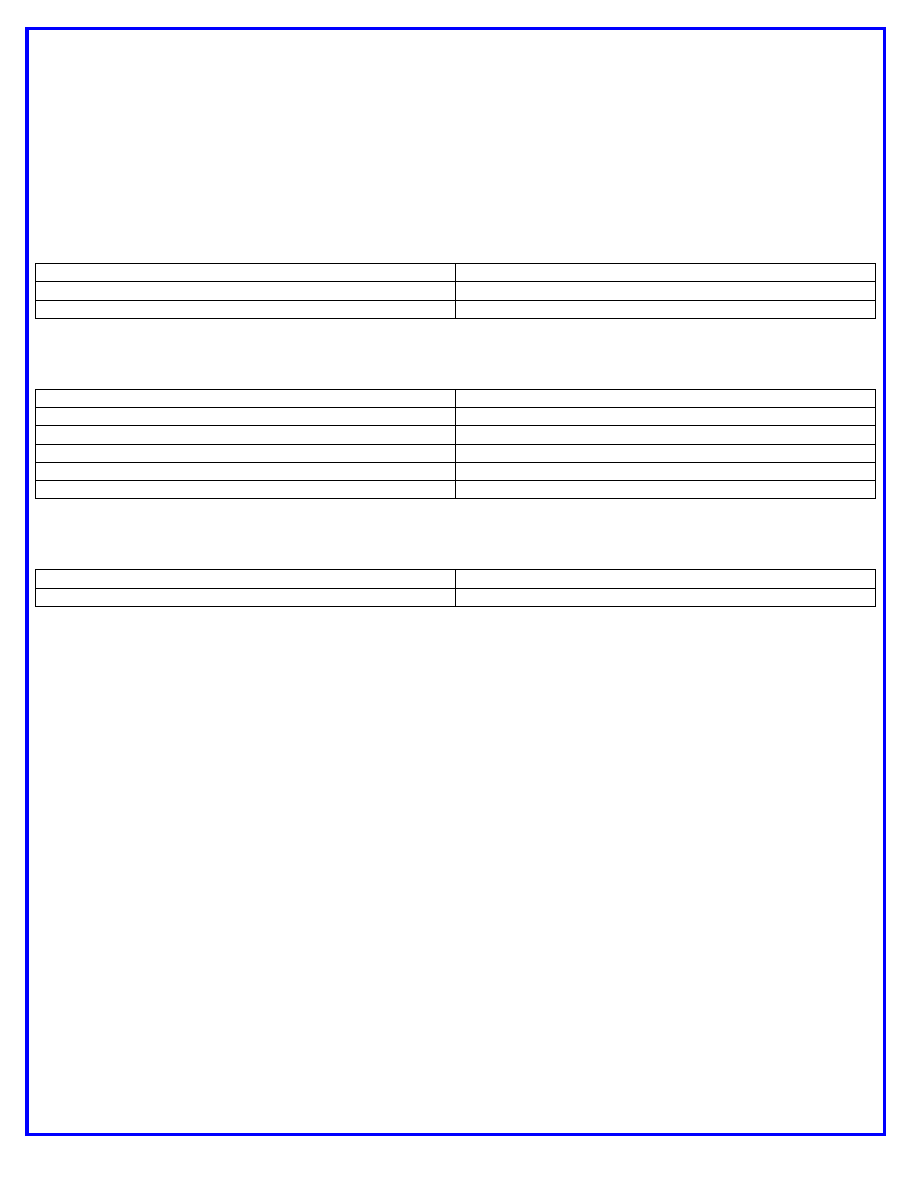

7.0 Trouble

Shooting

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

24

ALARM LIST

ALARM CODE

ERROR REPORTED: POSSIBLE

CAUSE:

ACTION:

ERR: 2

Clock failure

Hard ware failure.

Replace the CPU

card.

ERR: 4

Memory failure

1. Memory card loose.

2. Memory card

broken.

1. Check the memory

card. And restart the

system.

2. Change memory

card

ERR: 8

Sensor disconnected

1. Cable to the sensor

loose or broken.

2. Sensor broken.

1. Check the cable.

2. Replace the sensor

ERR: 10

Clean sensor

1. No FW. supply

2. Dirty sensor

3.Autoflush failed

1. Check FW. Supply

2. Clean sensor.

3. Clean sensor and

do another auto flush.

ERR: 20

Sensor temperature.

The temperature in the

sensor is out of range.

( +1-60 degrees

Celsius)

1. Check temperature

on the sample water.

2. Check ambient

temperature.

ERR: 80

Unspecified error.

Soft ware failure.

Restart the system.

(power off / power on)

PPM: O/R

Clean sensor

Outside PPM range

1. PPM out of

measuring area (o-

30ppm, trend up to

40ppm)

2. To dirty sample

water.

1. Clean sensor and

do a clean water

calibration.

2. Check the sample

water.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

25

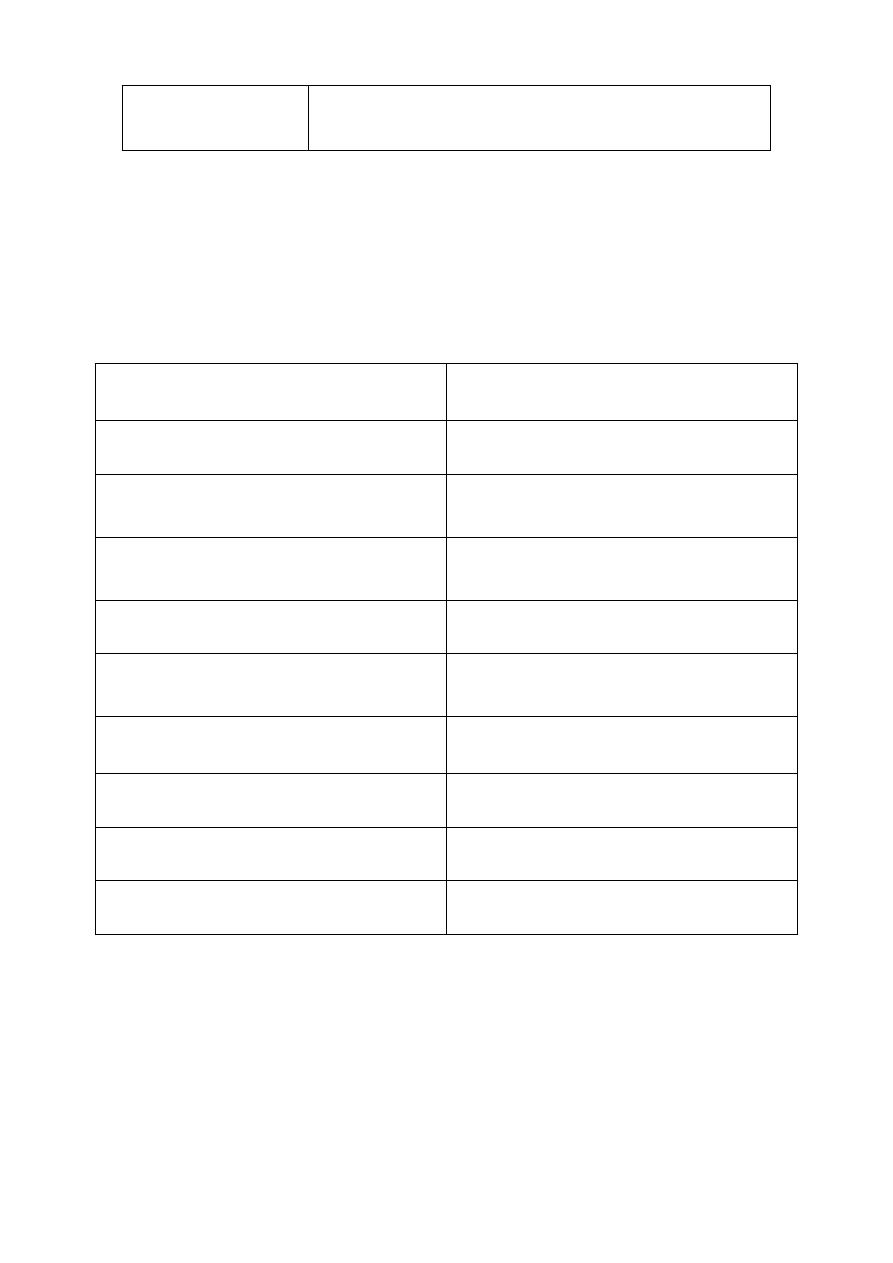

DISPLAY TEXT

INFO TEXT

EXPLANATION

A new clean attempt is started.

If the first auto clean is failed, a second

attempt will be started.

The power disconnected,

please wait

At start up or power failure this message

will appear.

A log operation was active when power

was disconnected.

If the running signal to the Bilge alarm is

on when the power is disconnected this

message will appear.

Printing

Please wait.

This text will pop up on the display when

a log is printed.

Opening a log for another Serial no.

If another memory card is installed in the

bilge alarm, it is possible to read the log

files.

Checksum error in log file.

File can not be opened.

This message can appear when the

memory card is manipulated.

Checksum error.

The following info could be incorrect.

This message can appear when the

memory card is manipulated.

The memory card is not for this unit.

Incorrect memory card.

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

26

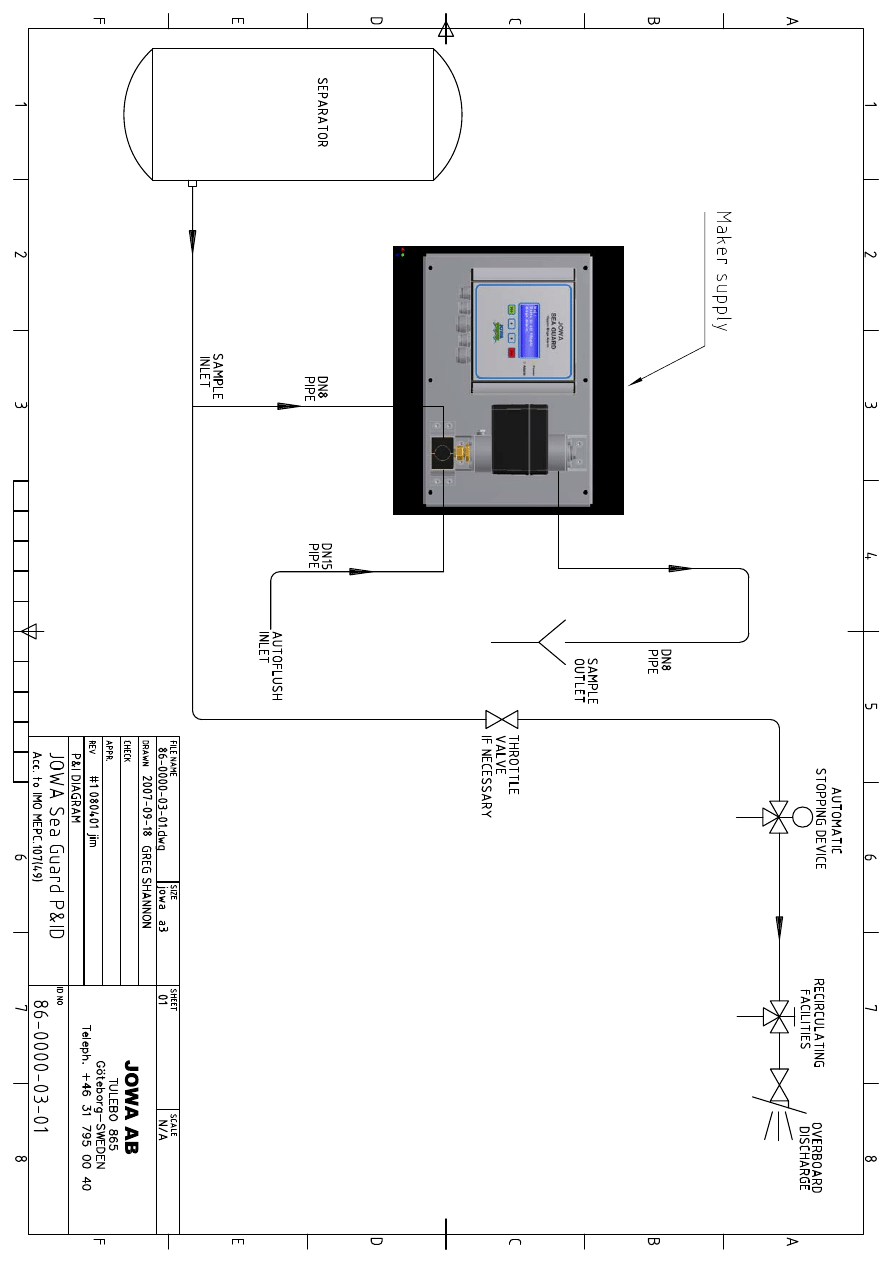

8.0 Flow Diagram (P & I)

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

27

9.0 Mechanical

Drawings

1

1

2

2

3

3

4

4

5

5

6

6

A

A

B

B

C

C

D

D

CHECK

RE

V

AP

PR

.

DRAWN

FI

LE

N

A

M

E

SI

ZE

ID

N

O

MODE

L I

D

SCA

LE

JO

W

A

AB

TU

L

E

B

O

86

5

Götebor

g

-SW

E

D

E

N

T

e

le

p

h

. +4

6

3

1

726

54

0

0

86

-0

000

-0

1-0

1 -

JOWA

S

eag

uar

d.i

am

A3

G

reg Sha

nnon

#2 080

401 ES

86

-000

0-

01

86-00

00

-0

1

200

7-06

-1

4

GA

Dr

aw

in

g

JOWA Sea G

uar

d

JO

WA

15

pp

m Bi

lg

e Al

ar

m

-0

1

151

T

O

T

A

L

WEI

G

T

H

A

PPROX 6

-7kg

360

240

10

20

n

9(x

6)

16

0

AU

TOF

LUS

H

INLE

T F

E

MA

LE

THREAD 1/

4"

SA

MPLE

IN

LET FEMALE

THR

E

AD 1/4"

SAMPLE

OU

TLET

FEM

A

LE

TH

REA

D

1/4"

27

26

1

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

28

10.0 Electrical drawings

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

29

11.0 Spare Parts List

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

30

DESCRIPTION. PART

NUMBER.

Sensor unit

86003-00001

Power board

86001-00030

CPU board

86001-00031

SD card

86001-00033

3-way valve 230V

86001-00022

Cleaning brush

83070-00002

Fuse 1A

94007-52010

Fuse 0.5A

19099-00050

Date:

Rev:

Sign:

2007-09-07

6. 080616

GS/jim

JOWA SEAGUARD

15ppm Bilge Alarm

K:\1-NYA K\1.2-JOWA PRODUKTER\JOWA 15PPM Bilge Alarm\Manual

31

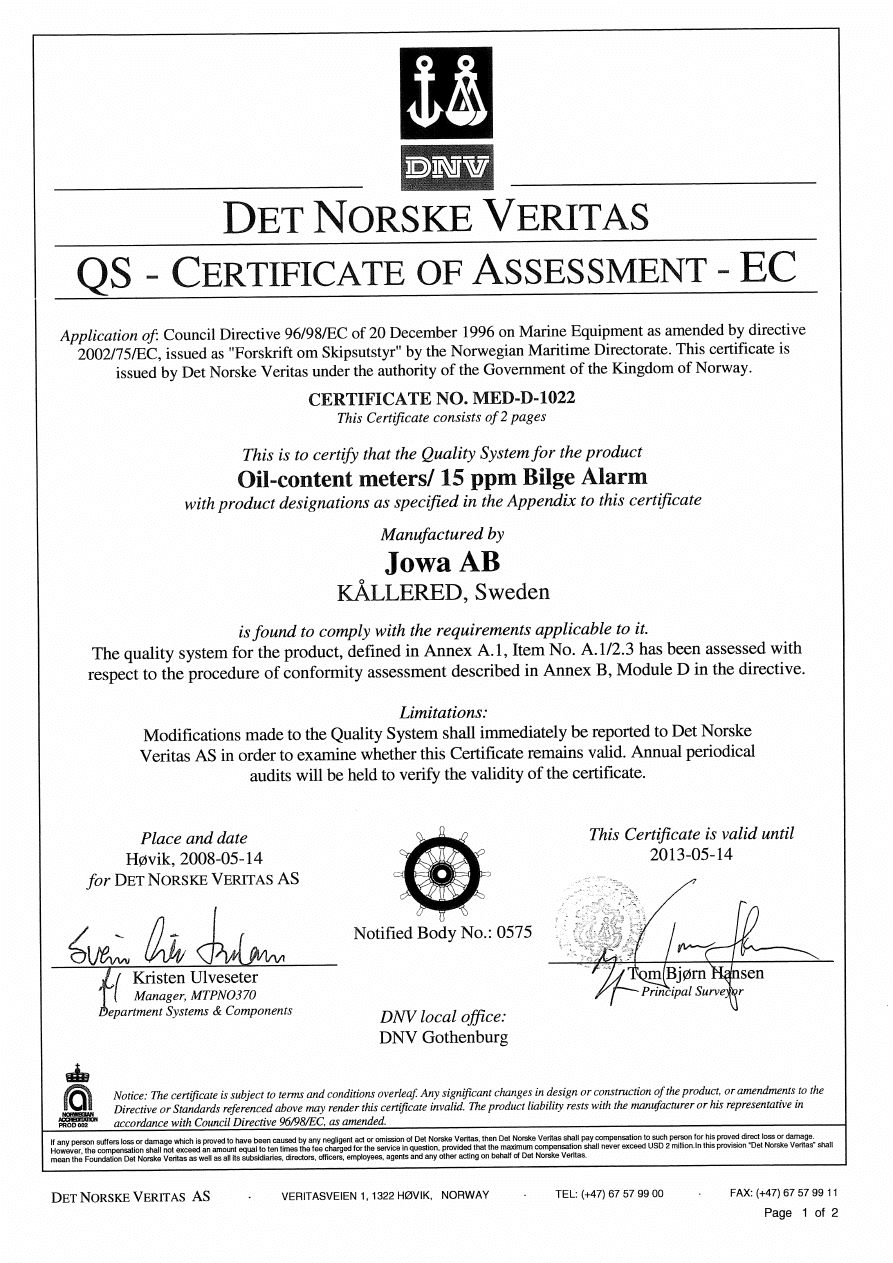

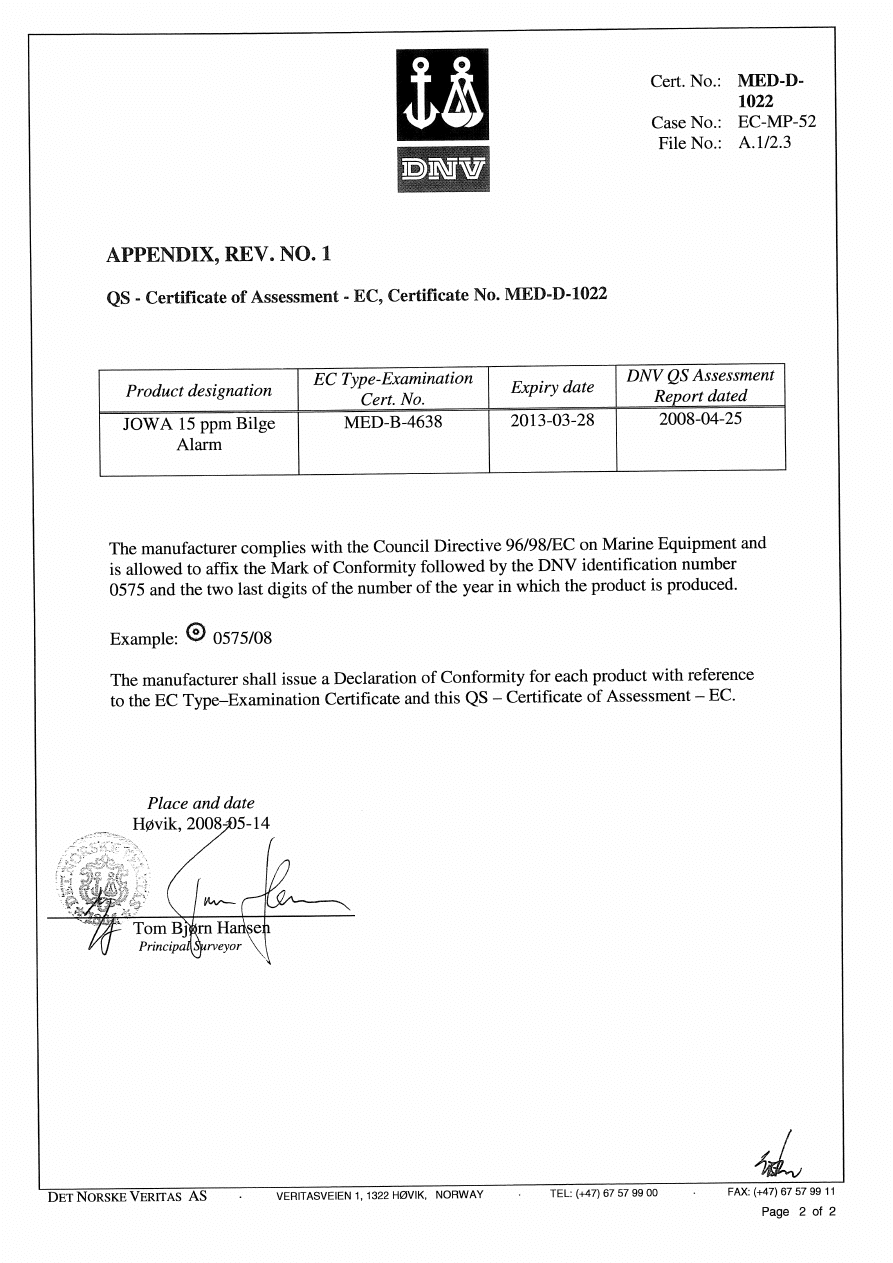

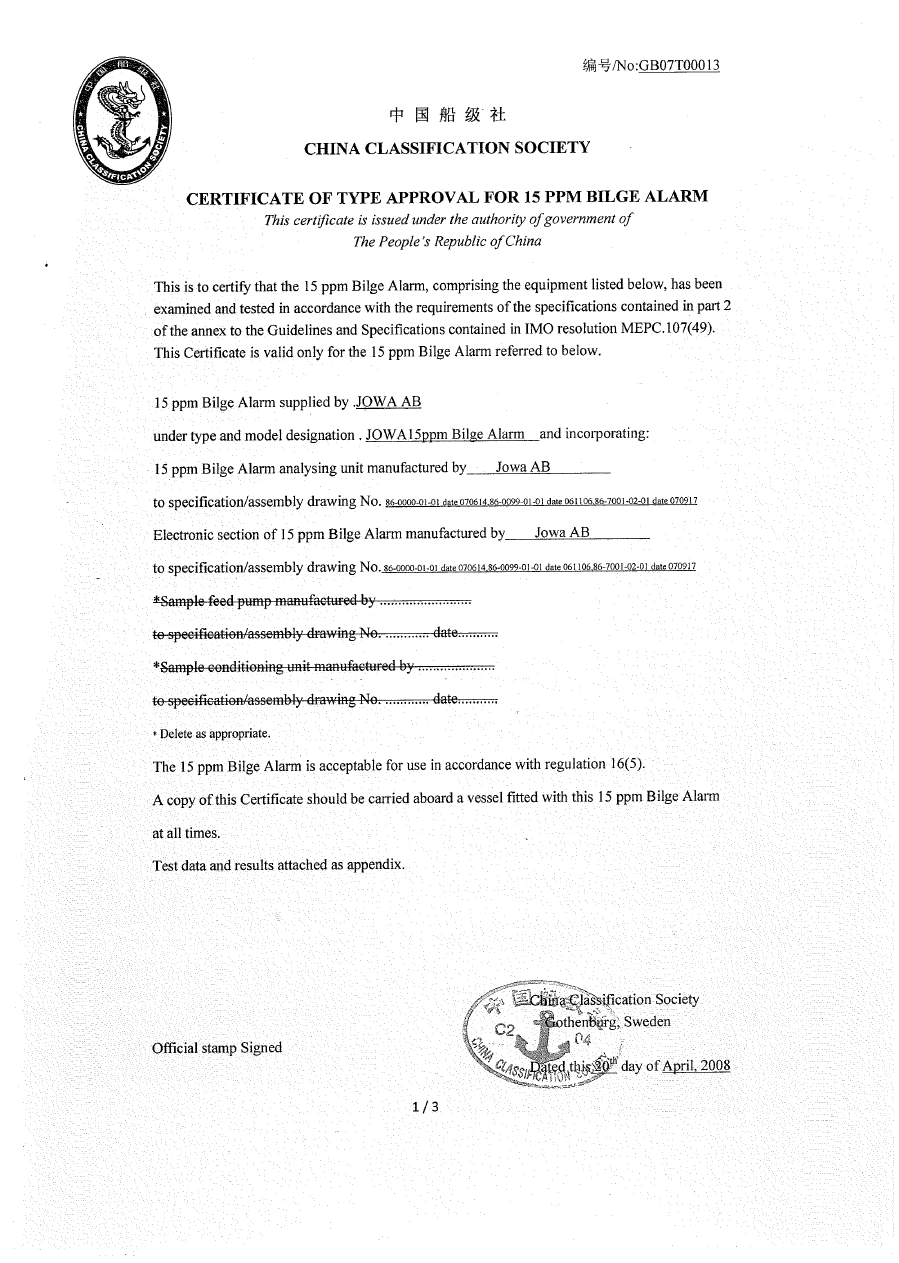

12.0 Approval Certificates

Coast Guard Approval Number: 162.050/9058/0 Expires: 30 January 2013

OIL POLLUTION PREVENTION EQUIPMENT

The following device has been tested in accordance with

IMO Resolution MEPC.107(49)

JOWA AB

Tulebo 865

S-428 34 Kallered

Gotheburg SWEDEN

JOWA Seaguard; 15 ppm Bilge Alarm

This is to certify that the equipment listed has been examined and tested in accordance with

the requirement of the specifications contained in annex 13 to the guidelines and

specifications contained in IMO resolution MEPC.107(49).

Equipment is manufactured by JOWA AB to specification/assembly drawing No. 86-0000-03-01

dated 9/18/2007, No. 86-0000-01-01 dated 6/14/2007 and No. 86-7001-02-01 through 86-7001-02-

03 dated 9/7/2007. The unit is not certified for use in Hazardous Locations.

A copy of this Certificate should be carried aboard a vessel fitted with this equipment at

all times. IMO Certificates of Type Approval do not expire and are valid for equipment

manufactured at any time during the period of validity of this Certificate. Test data and

results are attached in the appendix.

This certificate documents compliance with 46 CFR 162.050.

*** END ***

THIS IS TO CERTIFY THAT the above named manufacturer has submitted to the undersigned satisfactory evidence that the item specified herein complies

with the applicable laws and regulations as outlined on the reverse side of this Certificate, and approval is hereby given. This approval shall be in effect until the

expiration date hereon unless sooner canceled or suspended by proper authority.

GIVEN UNDER MY HAND THIS 30

th

DAY OF

JANUARY 2008, AT WASHINGTON D.C.

T.

E.

MEYERS

Chief,

Engineering

Division

U.S. Coast Guard Marine Safety Center

TERMS:

The approval of the item described on the face of the Certificate has been based upon the submittal of satisfactory

evidence that the item complies with the applicable provisions of the navigation and shipping laws and the applicable regulations

in Title 33 and/or Title 46 of the Code of Federal Regulations. The approval is subject to any conditions noted on this Certificate

and in the applicable laws and regulations governing the use of the item on vessels subject to Coast Guard inspection or on other

vessels and boats.

Consideration will be given to an extension of this approval provided application is made 3 months prior to the

expiration date of this Certificate.

The approval holder is responsible for making sure that the required inspections or tests of materials or devices covered

by this approval are carried out during production as prescribed in the applicable regulations.

The approval of the item covered by this certificate is valid only so long as the item is manufactured in conformance

with the details of the approved drawings, specifications, or other data referred to. No modification in the approved design,

construction, or materials is to be adopted until the modification has been presented for consideration by the Commandant and

confirmation received that the proposed alteration is acceptable.

NOTICE: Where a manufacturer of safety-at-sea equipment is offering for sale to the maritime industry, directly or indirectly,

equipment represented to be approved, which fails to conform with either the design details or material specifications, or both, as

approved by the Coast Guard, immediate action may be taken to invoke the various penalties and sanctions provided by law

including prosecution under 46 U.S.C. 3318, which provides:

"A person that knowingly manufactures, sells, offers for sale, or possesses with intent to sell, any equipment subject to

this part (Part B. of Subtitle II of Title 46 U.S.C.). and the equipment is so defective as to be insufficient to accomplish the purpose

for which it is intended, shall be fined not more than

$10,000

, imprisoned for not more than 5 years or both."

APPENDIX

United States Coast Guard Certificate of Approval

Coast Guard Approval Number: 162.050/9058/0

Expires: 30 January 2013

TEST DATA AND RESULTS OF TESTS CONDUCTED ON A 15 PPM BILGE

ALARM IN ACCORDANCE WITH THE GUIDELINES AND SPECIFICATIONS CONTAINED

IN IMO RESOLUTION MEPC.107(49)

15 ppm Bilge Alarm submitted by:

TEi-Testing Services, LLC - Plumbing Laboratory

3455 South 500 West

Salt Lake City, UT 84115-4234

USA

Test location:

TEi-Testing Services, LLC - Plumbing Laboratory

Method of sample analysis:

ISO 9377-2-2000(E)

Samples analyzed by:

Director, Tei-Testing Services-Analytical Laboratory

Environmental testing of the electrical and electronic sections of the 15 ppm Bilge Alarm has been carried out in accordance with the

guidelines and specifications contained in IMO resolution MEPC.107(49). The equipment functioned satisfactorily on completion of each

test specified on the environmental test protocol.

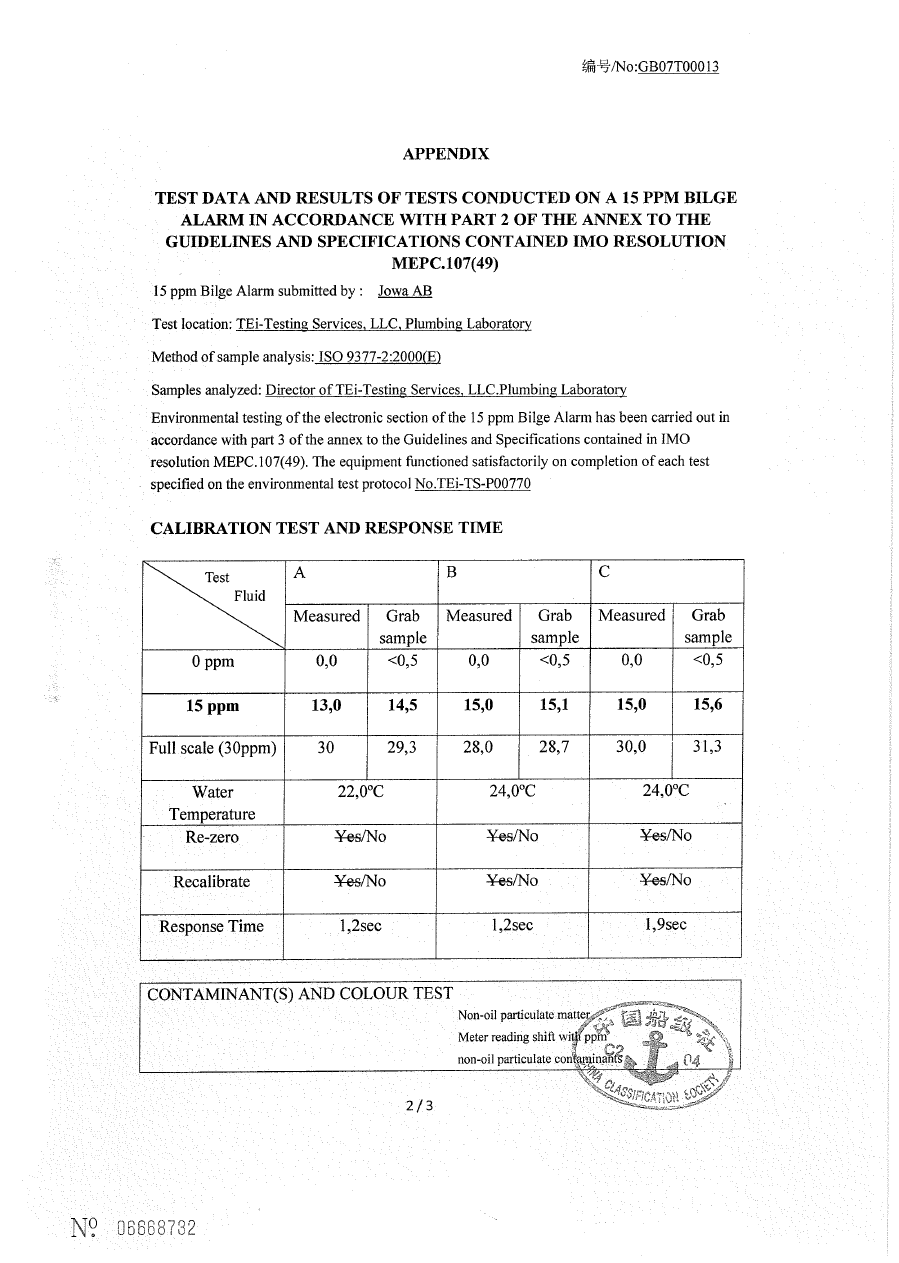

Calibration Test and Response Time Test

“A”

“B”

“C”

Measured

Grab

Measured Grab Measured Grab

0 ppm

0.0

< 0.5

0.0

< 0.5

0.0

< 0.5

15

ppm

13.0 14.5 15.0 15.1 15.0 15.6

Full

Scale

30.0 29.3 28.0 28.7 30.0 31.3

Water

Temperature 22.0°C 24.0°C 24.0°C

Re-zero

No No No

Recalibrate

No No No

Response Time (seconds)

1.2

1.2

1.9

Contamination and Color Test

Oil Content Meter Reading

Clean Water and Test Fluid “B” at 10 ppm

10.0 ppm

Very Salt Water and Test Fluid “B” at 10 ppm

9.0 ppm

Iron Oxide at 10 ppm

11.0 ppm

Iron Oxide at 50 ppm

11.0 ppm

Iron Oxide at 100 ppm

11.0 ppm

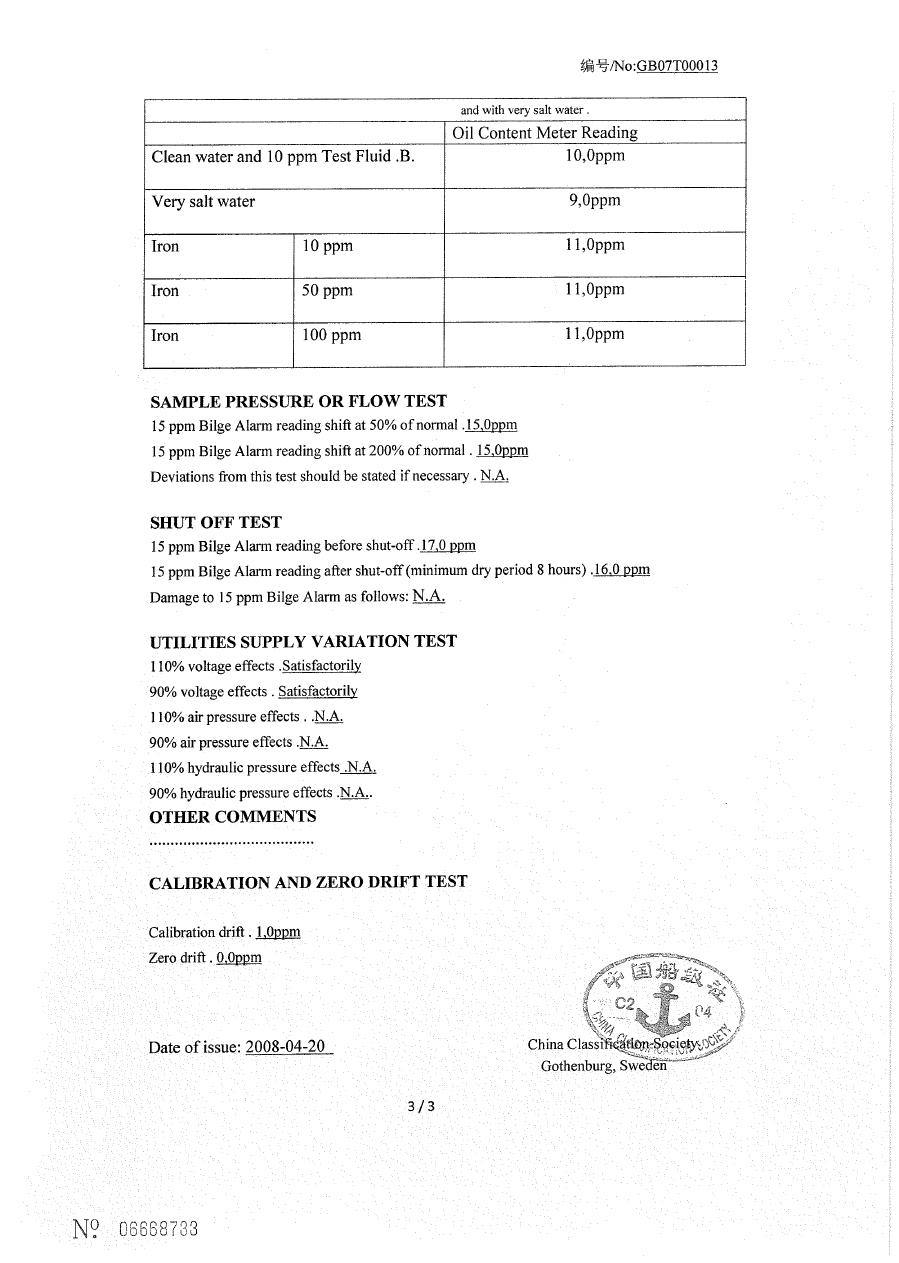

Sample Pressure or Flow Test

15 ppm Bilge Alarm reading shift at 50% of normal

0 ppm

15 ppm Bilge Alarm reading shift at 200% of normal

0 ppm

Deviations:

No deviations to the test method were made.

(1 of 2)

APPENDIX

United States Coast Guard Certificate of Approval

Coast Guard Approval Number: 162.050/9058/0

Expires: 30 January 2013

TEST DATA AND RESULTS OF TESTS CONDUCTED ON A 15 PPM BILGE

ALARM IN ACCORDANCE WITH THE GUIDELINES AND SPECIFICATIONS CONTAINED

IN IMO RESOLUTION MEPC.107(49)

Shut Off Test

15 ppm Bilge Alarm reading before shut off

17.0 ppm

15 ppm Bilge Alarm reading after shut off

16.0 ppm

Damage to 15 ppm Bilge Alarm:

No damage was caused by this test to the 15 ppm Bilge Alarm.

Utilities Supply Variation Test

110% Voltage Effects

There was no change in the Bilge Alarm reading.

90% Voltage Effects

There was no change in the Bilge Alarm reading.

110% Air Pressure Effects

Not Applicable

90% Air Pressure Effects

Not Applicable

110% Hydraulic Pressure Effects

Not Applicable

90% Hydraulic Pressure Effects

Not Applicable

Calibration and Zero Drift Test

Calibration Drift

1.0 ppm

Zero Drift

0.0 ppm

Diagram of test rig attached.

Diagram of sampling arrangement attached.

*** END ***

(2 of 2)

Document Outline

- flow.pdf

- Model

- Layout2

Wyszukiwarka

Podobne podstrony:

Jowa OWS 15ppm bilge alarm new

Jowa OWS 15ppm bilge alarm new 15

Jowa OWS 15ppm bilge alarm new

JOWA OWS Diagram

JOWA 3 SEP OWS Manual + deckmaRev Oil content meter 2

JOWA 3 SEP OWS Manual

JOWA 3 SEP OWS Manual + deckmaRev Oil content meter

JOWA 3 SEP OWS Pump Mono

JOWA 3 SEP OWS Pump Mono

Prezentacja KST 2007 new

new employee safety orientation 1201643571904060 5

jakość 1 new

Active new pl 200605

CHRYSLER NEW YORKER 1994

więcej podobnych podstron