PLEASE SCROLL DOWN FOR ARTICLE

This article was downloaded by:

[British Museum]

On:

22 August 2008

Access details:

Access Details: [subscription number 788671141]

Publisher

Routledge

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

World Archaeology

Publication details, including instructions for authors and subscription information:

http://www.informaworld.com/smpp/title~content=t713699333

Creating traditions and shaping technologies: understanding the earliest metal

objects and metal production in Western Europe

Ben Roberts

a

a

British Museum, London

Online Publication Date: 01 September 2008

To cite this Article

Roberts, Ben(2008)'Creating traditions and shaping technologies: understanding the earliest metal objects and

metal production in Western Europe',World Archaeology,40:3,354 — 372

To link to this Article: DOI:

10.1080/00438240802261390

URL:

http://dx.doi.org/10.1080/00438240802261390

Full terms and conditions of use:

http://www.informaworld.com/terms-and-conditions-of-access.pdf

This article may be used for research, teaching and private study purposes. Any substantial or

systematic reproduction, re-distribution, re-selling, loan or sub-licensing, systematic supply or

distribution in any form to anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representation that the contents

will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses

should be independently verified with primary sources. The publisher shall not be liable for any loss,

actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly

or indirectly in connection with or arising out of the use of this material.

Creating traditions and shaping

technologies: understanding the earliest

metal objects and metal production in

Western Europe

Ben Roberts

Abstract

The earliest metallurgy in Western Europe tends to be investigated through comparing the

exploitation of different ore sources and the presence of specific production techniques. However,

this approach does not address why the earliest metal occurred in the form that it did and how this

relates to the dynamics of the prehistoric communities involved. Exploring the processes through

which the earliest metallurgical traditions are created involves examining the broader spatial and

temporal patterning in the available choices and identifiable actions that influence the production,

circulation and deposition of metal objects. It can be shown that, despite common origins, metal

reflects the distinctive, variable and changing standards of the communities during the later fourth

and third millennia

BC

.

Keywords

Metallurgical traditions; Western Europe; cultural transmission; networks of expertise; consump-

tion.

Introduction

When seeking to describe spatially and/or temporally coherent similarities in early metal

objects or production practices, there is a wealth of possible labels that can be employed in

modern scholarship. An assemblage could be described as part of a typological series (e.g.

Harbison 1969a), a metallurgical group (e.g. Krause 2003) or province (e.g. Chernykh

1992), an industrial phase (e.g. Strahm 1994), a metalwork period (e.g. Needham 1996) or

it can be subsumed within an archaeological culture (e.g. Vaquer 1998). While these are

World Archaeology

Vol. 40(3): 354–372

Tradition

ª 2008 Taylor & Francis ISSN 0043-8243 print/1470-1375 online

DOI: 10.1080/00438240802261390

Downloaded By: [British Museum] At: 12:42 22 August 2008

definable entities to varying degrees and therefore serve a purpose in constructing an

interpretation, none provides an intellectual framework with which to address why early

metal occurred in the form that it did and how this relates to the prehistoric communities

involved.

The term ‘tradition’ used to feature very prominently in this literature but does so no

longer (unless reference is being made to the history of the discipline or an ethnographic

case study). The reasons for this are unclear, though for many scholars tradition has

evidently been superseded and is not considered relevant. In this paper I argue that this is a

mistake as the conceptualizing of the presence and nature of early metal in terms of

creating and reproducing traditions can provide valuable insights. The creation of a

tradition involves the transmission of information such as ideas, techniques and practices

through social learning from person to person (see Dobres and Robb 2000; Eerkens and

Lipo 2007; O’Brien 2008). Understanding the nature of this information, the mechanisms

of the processes involved and the observable consequences is fundamental to interpreting

early metal objects and production. Furthermore, traditions do not have to be constant

homogeneous blocs, in the manner of archaeological or metallurgical cultures, groups

and phases. As has long been recognized by historians (e.g. Hobsbawm and Ranger

1983), anthropologists (e.g. Friedman 1992; Hughes and Trautmann 1995) and latterly

by archaeologists (e.g. Holtorf 2000–7), traditions are heterogeneous, complex and

changeable.

For research into early metal to exploit the rich explanatory potential bound up in

the idea of traditions, there needs to be a replicable methodology, otherwise such an

endeavour risks becoming an intellectual platitude. Underlying the approach needs to

be the idea that objects and technologies embody certain social and symbolic practices

and ideas in a specific cultural context. This requires going beyond looking at the

physical and chemical conditions of production or the final properties of the object to

examine and compare the available choices and subsequent decisions that influenced

the creation, use and deposition of metal, thereby creating the earliest metallurgical

traditions. The knowledge, skills and tools that would be required to perform each

identifiable transformation need to be assessed to analyse how variation and change

could have been enacted within these traditions. As it is in the context of the

communities responsible that the early development of metal objects and metal

production can be understood, insights can be gained from analysing the roles of metal

in the broader socio-economic and ideological dynamics underlying prehistoric

communities.

This paper explores how the earliest metallurgical traditions were established

throughout Western Europe, defined as Spain, Portugal, France, Belgium, Holland,

Britain and Ireland, during the fourth and third millennia

BC

. While it concentrates on

copper and gold as the consistently earliest metals throughout this region, it also considers

the evidence for arsenical copper, lead and silver. It outlines an approach towards

analysing metallurgical traditions that centres on establishing and comparing aspects of

cultural transmission and reproduction within a systemic framework. It then looks at how

the earliest transmission of metal objects and metal production practices occurred and

therefore what was involved in the creation of the distinct metallurgical traditions that

emerged.

Creating traditions and shaping technologies

355

Downloaded By: [British Museum] At: 12:42 22 August 2008

Approaching metallurgical transmission and metallurgical traditions

If objects and technologies embody certain social and symbolic traditions in specific

cultural contexts, then their transmission through time and space will involve more than

logistical or technological considerations (e.g. Gosselain 1992a; Helms 1988, 1993; Schiffer

2001). Acquiring the knowledge and expertise to make unfamiliar materials and objects in

pre-literate societies involves gaining access to the blend of verbal and non-verbal

instruction that provides the foundations for the uninitiated or apprenticed to perform

(e.g. Gosselain 1998; Keller and Keller 1996). The details of the selection and preparation

of the correct raw materials, the assembling of the equipment and fuel, the nature and

timing of the actions during the transformation, and the design and execution of the final

object must be mastered (see Keller 2001; Kingery 2001) within the framework of the

social and religious beliefs and symbolism bound into the process. The process of

incorporating and reproducing new materials and objects into the existing traditions of a

community is influenced by how they are perceived, which is naturally influenced by the

nature of their arrival and the ideas surrounding them (Helms 1988; Sofaer-Derevenski

and Stig-Sørensen 2002, in press). It is therefore not only the transmission of metal objects

and information relating to metal production that underlie the creation of metallurgical

traditions but also the reception by communities and their decisions regarding possible

incorporation and reproduction within existing practices.

To analyse the transmission of the earliest metal objects and metal production practices

in Western Europe, it is necessary to look at how metallurgical transmission could and

could not have been achieved and therefore what metallurgical traditions needed to

become established. In particular, it is important to ask: 1) could existing circumstances

and technologies have led to independent discoveries of metallurgy? 2) could sufficient

metallurgical inspirations have derived from contact with a metal object or knowledge of

potential ores and the involvement of fire? 3) did the process require gaining expertise from

experienced individuals? These possibilities can be examined from the perspective of: the

recognition, availability and extraction of the metal sources; the smelting of ores and

melting of the native metals; the casting and manipulation of metal objects; and the

recycling and re-melting of metal. This enables a re-evaluation of the evidence for the

earliest metal and the construction of probable scenarios regarding the creation of distinct

metallurgical traditions.

In order to explore the nature of metallurgical traditions, a systemic approach that

encompasses each aspect of early metal creation, use and deposition to reveal a biography

that is general rather than specific is required (cf. Ehrhardt 2005; Hosler 1995; Lechtman

1977; Ottaway 2001; Needham 2004). This would entail: the selection of an ore or ore

source; the ore extraction, processing and distribution; the smelting, melting and alloying;

the casting, manipulation and design of objects; the potential object uses; the circulation of

the objects; the extent of object recycling/re-melting; and the nature of object deposition

(Ottaway and Roberts 2008). Rather than connections through linear sequences, it is the

dynamic nature of the interrelationships that needs to be explored (cf. Kingery 1993;

Knappett 2005). The actions taken and not taken, the knowledge, skills and tools needed

to perform the transformation and the consequences of decisions can be assessed. The

purpose is to obtain insights into the broader spatial and temporal patterning in the

356

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

choices and actions underpinning the changes and continuities in cultural transmission

reflected in metallurgical traditions and to analyse these in the context of the socio-

economic and ideological dynamics that underlay these prehistoric societies.

The absence of living informants or written records means that the prehistoric

archaeologist is always going to be unable to reconstruct or explain everything relating to

a metallurgical tradition. Though even ethno-archaeologists struggle to obtain informa-

tion they desire regarding a certain production practice and how it is understood within a

society (e.g. David and Kramer 2001; Lemmonier 1992), the challenges are not really

comparable. Archaeologists will never be able to observe metal production or deposition

being performed in its social setting while painstaking experimental reconstructions based

on archaeological, archaeometallurgical and even (ethno) historical data will never be as

immediately illuminating as actual observation. Scholars of early metallurgical traditions

not only have to analyse and interpret very fragmentary data but also have to negotiate

different spatial and temporal scales. While the perennial criticism of the relative or total

absence of the social and symbolic in their research (e.g. Budd and Taylor 1995; Rowlands

1971) when compared to ethnographic and anthropological research (e.g. Bisson et al.

2000; Herbert 1984) is an important point, it should not lead to the uncritical application

of analogies. Though potentially interesting, it would simply be replacing a past that feels

primitive yet familiar with one that feels unfamiliar, yet is also not a verifiable reflection of

past realities (cf. Shennan 1999; Stig-Sørensen 1996).

Analysing metallurgical transmission and metallurgical traditions

The relatively abundant presence of colourful outcrops of copper ores throughout Iberia,

south-east France, Wales and southern Ireland would seem to imply that the earliest

prospecting would have presented few challenges. However, the presence of other brightly

coloured mineral sources and the diversity of the copper ore colours could have been a

source of confusion for inexperienced prospectors. While it is highly likely that prehistoric

communities would have observed copper ores during the pre-metallurgy period, they

would also have observed many other mineral sources. As there is no evidence of copper

ores or native copper being exploited during the pre-metallurgical period as occurred in

south-east Europe and the Near East (see Schoop 1995; Thornton 2002), there is no sense

that a distinction of copper-bearing minerals had been made or of their having any

identifiable significance until being recognized for their metallurgical properties. If

consideration is given to the differing requirements for smelting oxidic and sulphidic

copper ores (see Ottaway and Roberts 2008), then it is not simply copper ores that have to

be identified but those copper ores that can be smelted employing existing practices. Due

to the variation in regional geologies, environments and in the accessibility of copper ores,

the discovery of new sources requires flexible prospecting techniques as well as flexible

expectations.

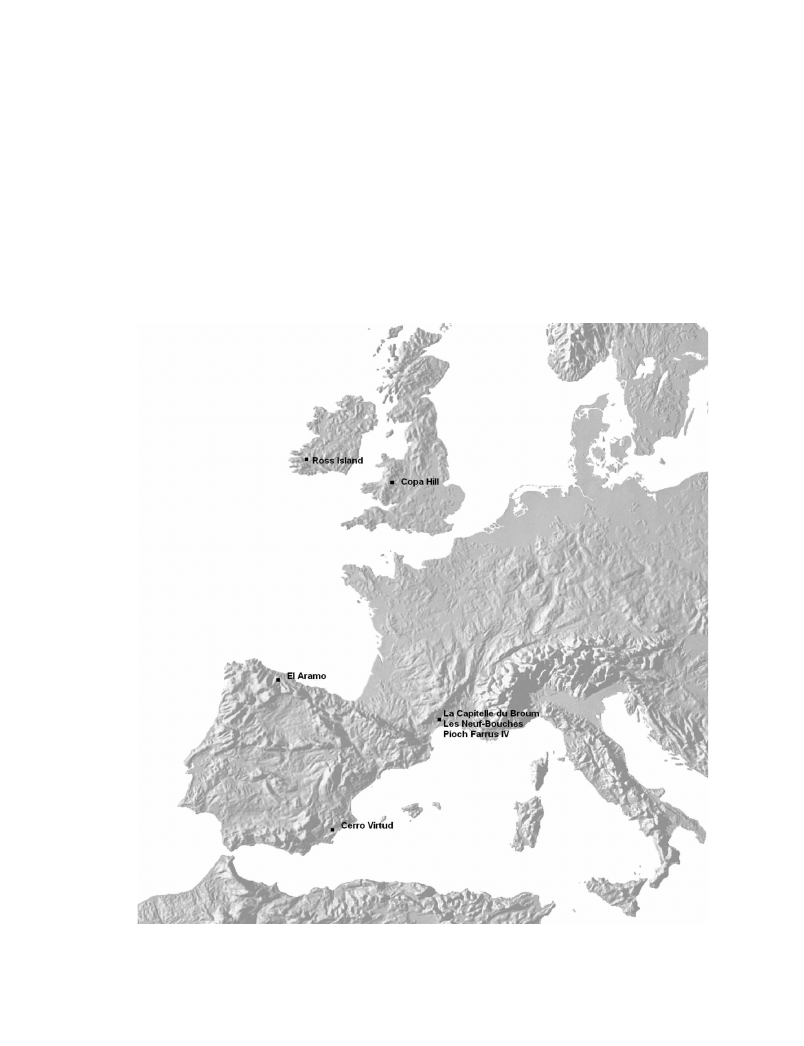

When compared to later mining techniques (e.g. Craddock 1995), the evidence for

surface and sub-surface extraction of copper ores in Western Europe at sites in Cabrie`res,

south-east France from c. 3100

BC

(Bouquet et al. 2006), Ross Island, south-west Ireland

from c. 2400

BC

(O’Brien 2004), El Aramo, northern Spain from c. 2500

BC

(Blas-Cortina

Creating traditions and shaping technologies

357

Downloaded By: [British Museum] At: 12:42 22 August 2008

2005) and Copa Hill, central Wales from c. 2100/2000 cal.

BC

(Timberlake 2002, 2003)

appears, with the possible exception of El Aramo, relatively simple and straightforward

(Fig. 1). The presence of earlier and more extensive underground mines, such as the

variscite mines at Can Tintorer, northern Spain (Bosch 2005) dating to the late fifth

millennium

BC

or the flint mines at Cissbury or Grimes Graves in southern England dating

to the fourth millennium

BC

(Barber et al. 1999), implies that copper extraction

represented an adaptation of earlier practices. However, this does not mean that anyone

seeking to extract copper ore innately possessed the necessary expertise to do so. It simply

implies an established knowledge of where to strike the rock, the ability to perform fire-

setting or organize a mining expedition. Furthermore, if the desired ore sources were

Figure 1

Copper production sites mentioned in the text.

358

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

present and recognized in a region, then access to the ore and the labour to perform the

activities would have been required. Ore extraction is an endeavour that would have

required the active participation of a small group or community even during the extraction

of surface ore deposits. As well as being involved in the extraction, their involvement

would be needed in the processing and movement of ore, which, to people used to the

grinding and carrying of foodstuffs, would have been familiar activities.

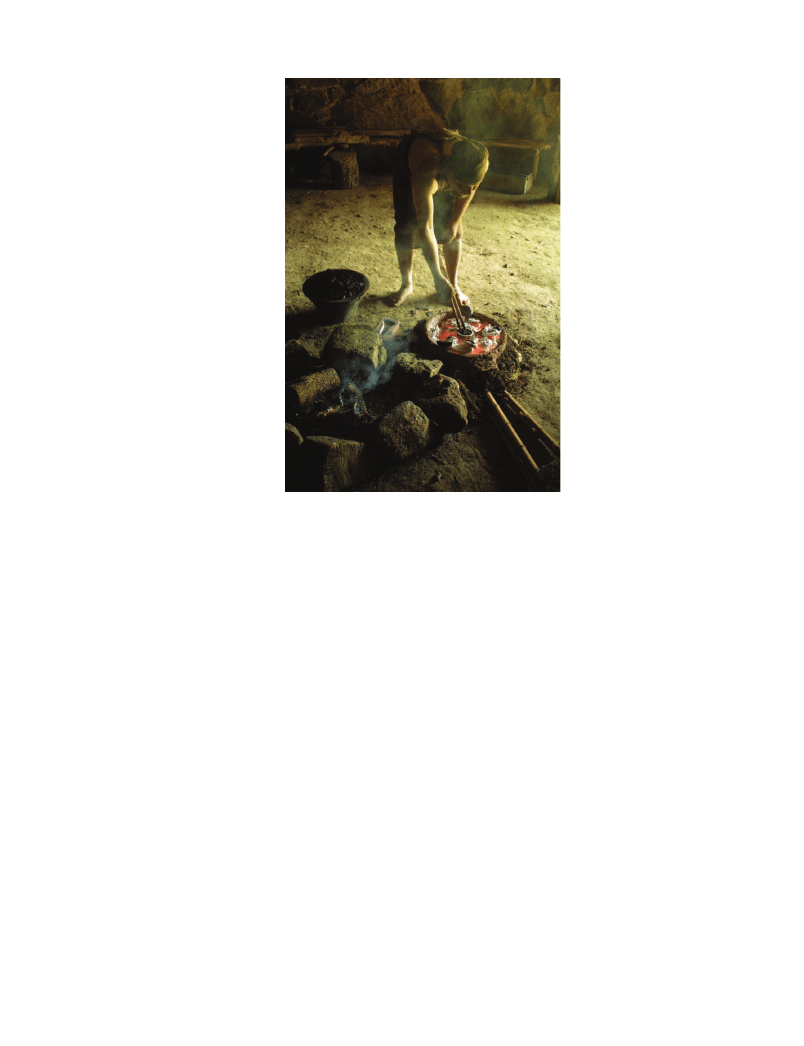

Whether a transfer of existing pyrotechnological capabilities during the pre-

metallurgical period to the smelting of metal can be envisaged depends on the

characteristics of the processes involved. The extensive presence of ceramics throughout

Western Europe before metallurgy provides the most promising evidence though there are

no known ceramic firing sites. It is therefore probable that pottery in this region, as

elsewhere during this time, was fired in an open bonfire, which would render the process

virtually invisible archaeologically (see Orton et al. 1997: 127–30). It is therefore the

experimental reconstructions of ceramic open bonfire firings that provide the clearest

indications of the pyrotechnological abilities (e.g. Gosselain 1992b; Livingstone-Smith

2001; McDonnell 2001). Characteristics of this open firing technique are a lack of control,

rapid changes in temperature, an oxidizing atmosphere and a duration varying from

several minutes to several hours. Though temperatures of c. 10008C can occasionally be

reached, this is only for a very short duration and cannot be maintained before dropping

back to 600–8008C or lower. This failure to sustain a sufficient temperature – comparable

to experimental reconstructions of smelting of ores based on evidence and/or probable

conditions in south-east Spain (Rovira-Llorens and Guttierez 2005), south-east France

(Bourgarit et al. 2003), Wales (Timberlake 2007) and south-west Ireland (O’Brien 2004)

(Plate 1) – the oxidizing rather than reducing atmosphere and the lack of control over both

make it unlikely that copper smelting using a ceramic open firing method could have

occurred.

Furthermore, it is unlikely that charcoal was used in the firing of ceramics or that its

recognition and use occurred before metallurgy. Wood, peat and dung would have been

available and perfectly sufficient in the production of pottery and other activities involving

heat and fire and there does not appear to have been any pyrotechnological reason for

charcoal to be employed. For metallurgy, the use of charcoal is particularly important, not

simply due to its ability to create high temperatures using relatively small quantities in a

small space, but due to it being a source of highly reducing carbon monoxide gas (see

Craddock 2001; Horne 1982). This makes it ideal for smelting copper ores and its absence

renders the smelting process far less effective if not completely impossible. If any transfer

of pyrotechnological knowledge from ceramics to metallurgy did occur, it could not have

been straightforward or simple. If independent experimentation led to the successful

smelting of copper ores then there would have to have been significant alterations to the

existing practices as well as the independent motivation to attempt such experimentation

in the first place. Neither does it appear that copper smelting could have been consistently

achieved with only a partial knowledge of the process involved – such as the ability to

identify ores or the need for high temperatures. As modern experiments have shown,

smelting needed to be carried out within a fairly narrow margin of error or else the entire

process would fail. Though lead could be smelted at lower temperatures, there is no

evidence that it preceded the smelting of copper in Western Europe. Similarly, there is no

Creating traditions and shaping technologies

359

Downloaded By: [British Museum] At: 12:42 22 August 2008

evidence for gold objects preceding copper despite gold melting being a more

straightforward process, albeit at a comparable temperature to copper smelting. For

smelting technology to spread, the expertise would have to be learnt in one place and

applied elsewhere (Roberts in press). This could therefore apparently occur only through

the movement of either groups or individuals possessing the smelting skills into Western

Europe.

This challenges the idea of independent origins of metallurgy in south-east Spain (e.g.

Renfrew 1967, 1973; Ruı´z Taboada and Montero-Ruı´z 1999) which stands in contrast to

other regions of Western Europe where discussion concentrates upon transmission from

neighbouring regions where there is earlier evidence of metal objects or metal production.

The reason for this lies in the argument that the radiocarbon dates for copper

metallurgy in south-east Spain are apparently so much earlier than for its neighbouring

regions, thus indicating indigenous development. A fragment of copper oxide smelting slag

at Cerro Virtud, south-east Spain, dating to the early fifth millennium

BC

has been

heralded as the evidence for independently invented metallurgy (Montero-Ruı´z and Ruı´z

Taboada 1996; Ruı´z Taboada and Montero-Ruı´z 1999). However, it is more than a

millennium older than any other secure evidence of smelting or anything metallurgical in

the region (cf. Montero-Ruı´z 1994, 2005), it was excavated under rescue conditions from a

site disturbed by mining and it is dated by stratigraphic layer, rather than by associated

organic material, material culture or features. The subsequent earliest dates for metal

Plate 1

Experimental copper smelting in south-west England (photo: Neil Burridge).

360

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

objects and metal production throughout Iberia tend to be from unreliable contexts or, if

potential remains of copper smelting, have not been properly analysed. It is most probable

oxidic copper ore smelting occurred earliest in southern Iberia during the late fourth

millennium

BC

and before being practised in central and northern Iberia during the early–

mid-third millennium

BC

(Bartelheim 2007; Delibes de Castro and Montero-Ruı´z 1999;

Ferna´ndez-Manzano and Martı´nez 2003; Montero-Ruı´z 2005; Rovira-Llorens 2002).

Rather than evidence of an independent discovery of metallurgy in south-east Spain, the

technology and the revised dating indicate that copper objects and production practices

were the consequence of interactions with earlier metal-producing communities in the

central and western Mediterranean (Lo Schiavo et al. 2005; Bourgarit 2007; Pearce 2007;

Roberts in press).

To the north of the Iberian peninsula, the earliest copper smelting is on sulphidic rather

than oxidic ores, thus requiring a slightly different technique, and dates to the beginning of

the third millennium

BC

at sites such as La Capitelle-du-Broum at Cabrie`res, south-east

France (Ambert et al. 2005) and probably to the mid-third millennium

BC

at Ross Island,

south-west Ireland (O’Brien 2004). While there is no direct evidence for gold melting, it

seems probable that gold was contemporary with copper throughout much of Western

Europe, though the frequent lack of secure datable contexts means that there are few

radiocarbon dates (e.g. Elue`re 1982; Eogan 1994; Pingel 1992). Where they do exist, as in

southern Britain, there are copper and gold objects dating to the mid–late third

millennium cal.

BC

radiocarbon dates in Bell Beaker burial sites such as Barrow Hills,

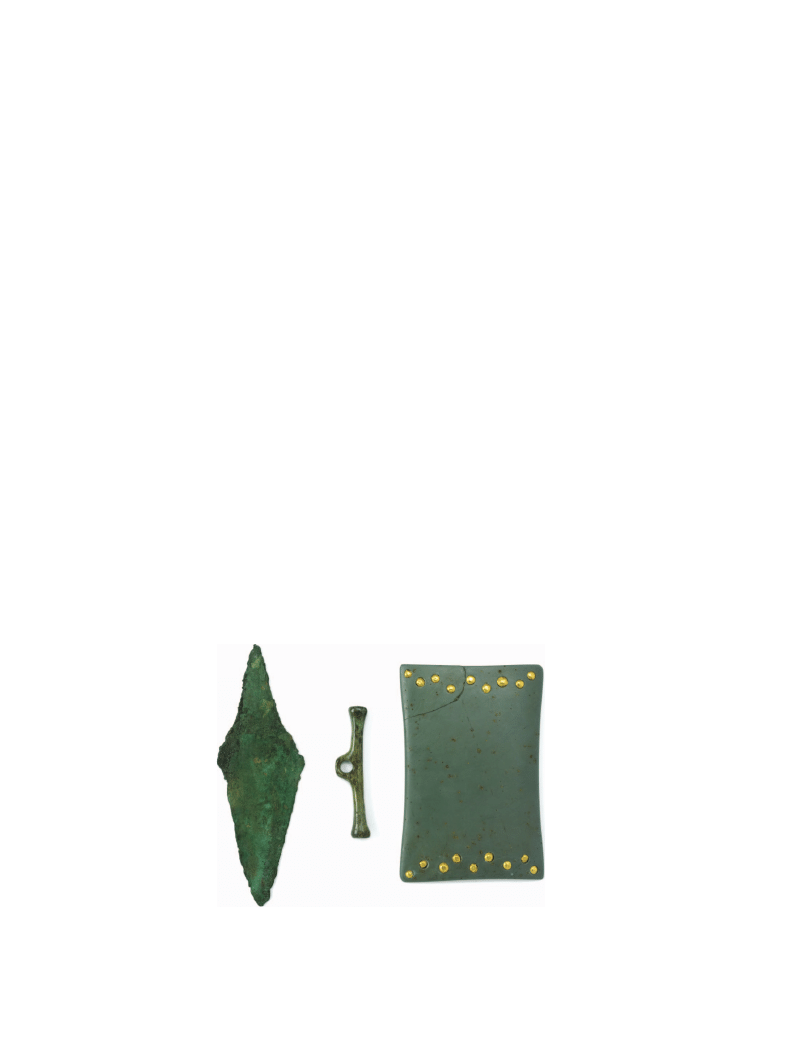

Shrewton, Barnack (Plate 2), Chilbolton and Amesbury (Needham 1996; Fitzpatrick

2002). The lower smelting temperature of lead and the abundance of its ores relative to

copper ores and gold imply that it could have been the earliest smelted metal, as appears to

have occurred in the Near East (Mu¨ller-Karpe 1990; Schoop 1995: 23). The sporadic

presence of lead objects throughout Western Europe tends to receive less attention, despite

the dating of copper and lead objects at Roquemengarde, south-east France, to mid–late

Plate 2

Bell Beaker burial assemblage at Barnack, eastern England featuring a stone wristguard

inlaid with gold, a bone toggle and a copper tanged dagger.

Creating traditions and shaping technologies

361

Downloaded By: [British Museum] At: 12:42 22 August 2008

fourth millennium

BC

(Guilaine 1991). There is no secure evidence that lead was among

the earliest metals being produced elsewhere though it remains a possibility (cf.

Timberlake 2003). While silver is present in Sardinia during the fourth millennium

BC

and contemporary with the earliest copper production (Lo Schiavo et al. 2005; Skeates

1994), it does not feature in Western Europe until the late third millennium

BC

(Primas

1995).

Despite the availability and potential, there is no evidence that the earliest copper, gold

or lead in Western Europe were alloyed. The ongoing debates concerning the intentional

alloying of arsenic copper are beginning to indicate the presence and awareness of this

distinct silver-coloured metal during the third millennium

BC

as well as a desire and ability

to reproduce it in specific objects, as evidenced by halberds in Ireland (Northover 1989) as

well as sheet-metal fragments and long awls in central Portugal (Mu¨ller et al. 2007). While

this relates to the arsenical content of the ores being exploited, it seems to go beyond mere

opportunism or random occurrence, though the issue remains unresolved for many

scholars (e.g. Rovira-Llorens and Delibes de Castro 2005). The application of heat to

create a liquid from a solid that could then be poured into a mould to form a new object

when cooled does not have real parallels in pre-metallurgical societies. However, where

metallographic analysis has been performed, as in Iberia and Ireland, casting appears to

have been present in the earliest objects and widespread (Northover 1989; Rovira-Llorens

and Go´mez-Ramos 2004). The realization that the metal can be cold-worked for a longer

time if heated in between shaping will not have escaped the notice of people who were used

to fire-hardening wood, heating flint and firing pottery. However, while these techniques

of cold-working and annealing are extensively utilized in Iberia, they are less well

represented in the later copper objects in Ireland.

These techniques created a range of possible forms that could be produced in the

new material that were exploited in certain metallurgical traditions but not others. In

metal-producing areas such as south-east Spain, the earliest copper repertoire is dominated

by awls but included flat axes, punches, knives, needles, fishhooks, daggers, beads, rings,

pins, beads, chisels and saws (Montero-Ruı´z 1994) together with gold laminae (Pingel

1992). By comparison, in south-east France, the vast majority of copper objects are

beads though daggers, awls and flat axes are present together with gold and lead beads

and gold laminae (Gutherz and Jallot 2005), while in Ireland the vast majority of early

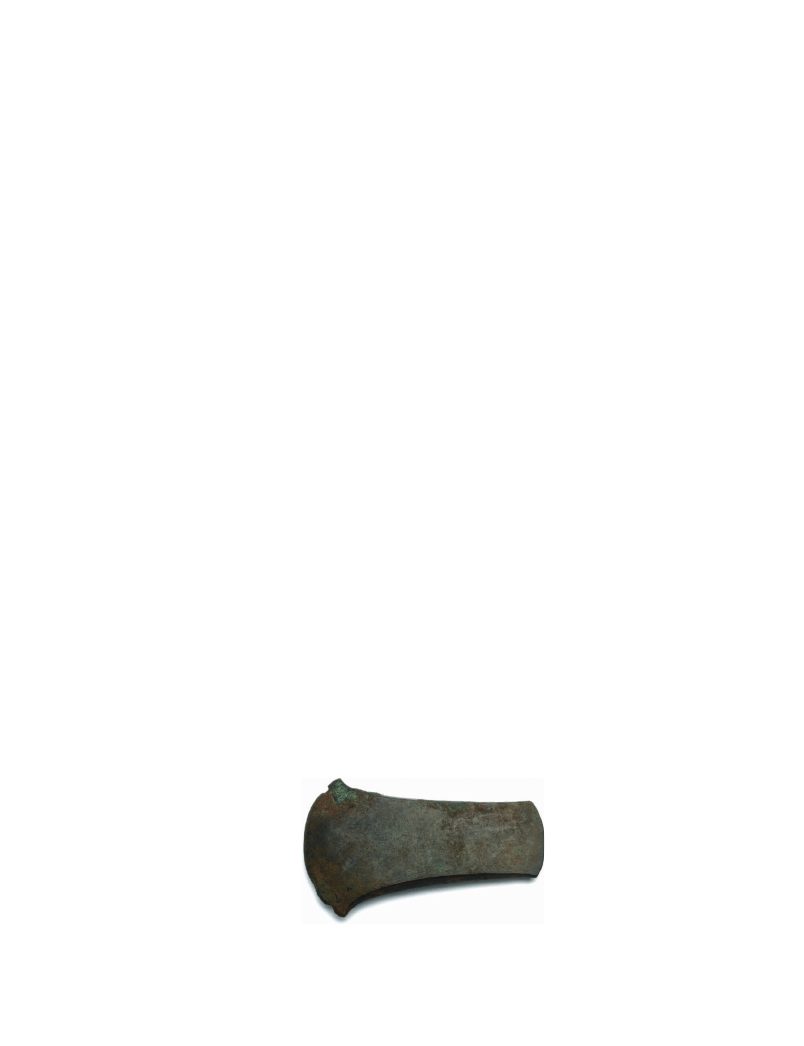

copper objects are flat axes (Plate 3) and occasionally halberds (Harbison 1969a, 1969b)

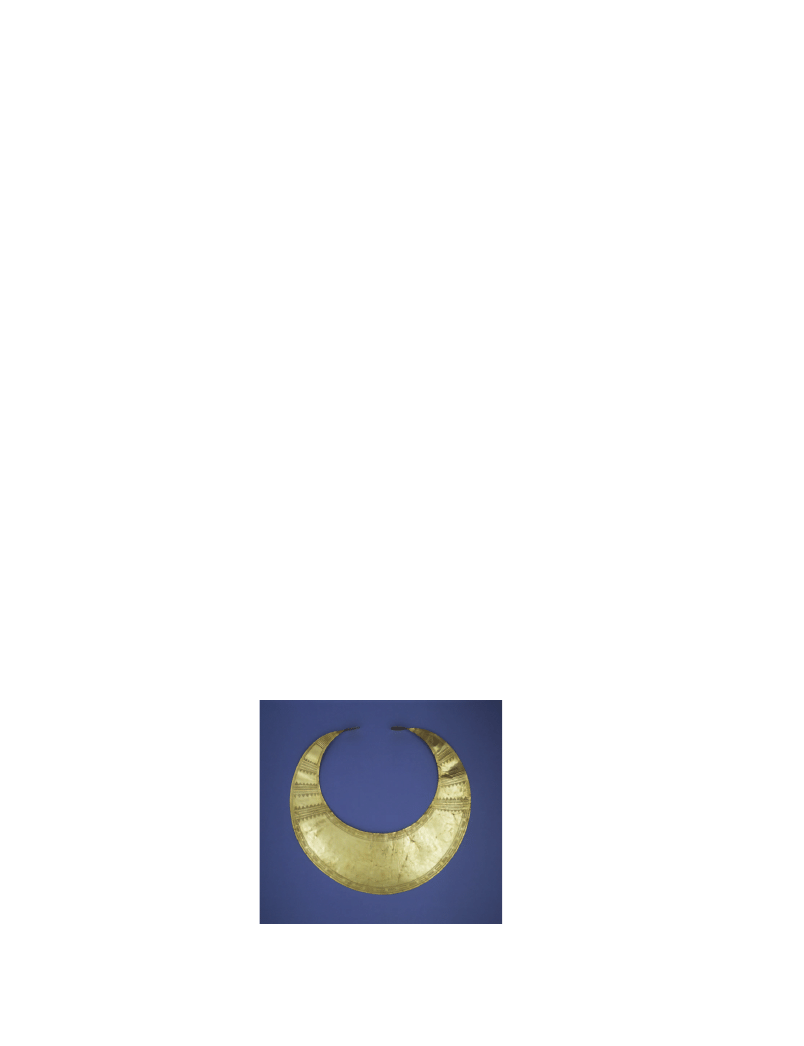

together with gold lunula, basket ornaments, plaques and

discs

(Eogan 1994)

Plate 3

Copper flat axe found at Gowran, south-east Ireland.

362

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

(Plate 4). Despite the possibility of specific object designs being reproduced in both

copper and gold, there is little evidence of this occurring beyond south-east France

where bead forms in lead, copper and gold are known (Barge 1982). Where exhaustive

typological research has been conducted on an early metal object types such as flat axes

and beads in south-central and south-east France (Barge 1982; Chardenoux and

Courtois 1979), flat axes and daggers in Ireland (Harbison 1969a, 1969b) and flat axes in

England and Scotland (Needham 1983; Schmidt and Burgess 1981), it has revealed

extensive morphological micro-variations based on distinctive general designs. It appears

that the replication of specific objects occurred far less frequently than the creation of

subtly new ones implying that only slight alterations on accepted norms occurred within

a metallurgical tradition. This means that, rather than reuse stone moulds or wooden

patterns for shaping clay and sand moulds, new moulds would have to be made or the

metal would have to be manipulated in a different way. The recycling, re-melting and

mixing of metal objects would have required creating temperatures comparable to those

needed for the smelting process together with the equipment and expertise to shape an

object. However, an individual possessing the expertise would be able to imitate and

innovate on existing or desired forms, potentially creating distinctive early metallurgical

traditions even when far from original metal-producing areas with ores and naturally

occurring metals. This can be seen in the presence of a distinctive ‘Bell Beaker’ metal

composition in northern France, eastern England and the Low Countries that are far

from any copper ores. Analysis of the compositional evidence has demonstrated that the

creation of ‘Bell Beaker’ metal objects involved the mixing of metals from at least two

sources, one of which is thought to be northern Spain, to create an object repertoire that

comprised primarily daggers, knives, halberds and flat axes (Needham 2002).

The life of metal objects after they are produced and before they are discarded or

deposited within a metallurgical tradition is the most elusive part of their existence.

Aspects such as where objects were taken, how they were used, how they changed

possession, the perceptions that surrounded them and whether they were recycled or re-

melted may well be more important to understanding a metallurgical tradition than

production or depositional practices. While the movement of metal objects from the

Plate 4

Gold lunula found near Mangerton, south-west Ireland.

Creating traditions and shaping technologies

363

Downloaded By: [British Museum] At: 12:42 22 August 2008

original ore source can be explored through careful trace element and lead isotope analysis,

this tends to demonstrate high concentrations close to production areas as well as specific

longer-distance connections over 150km, such as from south-west Ireland to western Britain

(O’Brien 2004), south-east to western France (Briard and Roussot-Laroque 2002; Roussot-

Laroque 2005) or eastern to western Portugal (Mu¨ller et al. 2007). The debates over what

practical activities objects were used for, which objects should be regarded as decorative,

whether a defined ingot form existed and if certain object forms, such as axes and knives,

should be classified as weapons or tools are hard to evaluate in the absence of wear trace

interpretation (cf. Roberts and Ottaway 2004). Instead, the use of metal objects in each

region has to be assumed from the modern correlate of its form and, where possible, the

alteration of physical properties such as hardness. There has been similarly little

experimental research, exploring their potentials and limitations, where the copper objects

have been employed to perform specific tasks. However, the current fragments of

information enable no convincing patterns to be discerned. While perspectives on early

metal are naturally distorted by prehistoric depositional and recycling practices (cf. Taylor

1999), the vast majority of the metal objects recovered were accidentally discovered during

the nineteenth to mid-twentieth century so that the quality of the contextual data tends to be

highly variable. However, it is possible to define where metal objects were placed with the

dead, as in southern Spain (Bartelheim 2007) and south-east France (Gutherz and Jallot

2005), and where they were not, as in Ireland (O’Brien 2004).

Discussion

The expertise to create a metallurgical tradition would have to have been gained through

an apprenticeship whereby certain aspects of metal production could be transferred from

one individual to another. This makes it probable that metallurgical skills were restricted

to certain people, whether intentionally or not. The inevitable or deliberate restriction of

such crucial knowledge, such as the correct raw materials, the smelting equipment or the

sequence and timing of actions and addition of substances, could have ensured that it

remained in the hands of a few select groups of metal producers, who passed on their craft

only to people of their choosing. If the ethnographic record is any guide, in virtually all

instances this means specific members of an extended family or tribe (e.g. Bisson et al.

2000), with songs, rituals and taboos reinforcing the restricted knowledge and expertise.

The requirement of a metallurgical apprenticeship and the absence of convincing evidence

for the independent discovery of metallurgy in southern Iberia meant that the crucial

production knowledge would have to have originated outside Western Europe. Only

through the movement of metallurgists, either returning to their original regions or settling

in new ones as may well have occurred at Amesbury, south-central England (Fitzpatrick

2002), could new metallurgical traditions have been created (Roberts in press). This would

have created extensive yet fragile networks of production expertise which would

undoubtedly have been fundamental in sustaining the production and circulation of the

new material.

However, it is important not to over-emphasize the primacy of metal production

techniques in this process. The desires of the communities supporting metal production as

364

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

metal consumers were arguably actually more important. For metal-orientated networks

of production expertise to exist, individuals and communities must have invested in the

acquisition of metal objects and metallurgical technology. It is perhaps even erroneous to

discuss individuals in certain aspects of the metallurgy, given the collective nature of so

many parts of the production processes, including the ore prospection, extraction,

processing and transport. Even the existence of part-time copper smelters or smiths, who

are more likely to have had distinctive individual roles owing to their specialist expertise,

required the commitment of the broader community to aid in the procurement of food and

shelter as well as production and acquisition of the objects. Furthermore, there is no

inherent reason why metal objects or metal production should be adopted by local

communities or introduced by non-local communities and therefore no reason why

metallurgical traditions should be created or reproduced.

It is important to emphasize that the early copper, gold and lead objects were not

necessarily superior to wood, bone, flint and ceramics for performing everyday tasks,

and that there were many obstacles and complications involved in metal-production

practices relative to those in existing materials. The distinctive colours, lustre,

malleability and ability to carry decorations and be recycled are attractive qualities

for adopting metal (cf. Keates 2002) but these do not provide compelling explanations

on their own. It seems probable that metal objects were transmitted in Western Europe

earlier and more rapidly than metal production, though this is hard to demonstrate in

the frequent absence of objects from secure contexts. However, the mid–late fourth

millennium

BC

radiocarbon dates for Roquemengarde, south-east France (Guilaine

1991) and Vignely, north-central France (Mille and Bouquet 2004) preceding metal

production lend credence to the possibilities implied by purely typological connections

(e.g. Guilaine 2003: 210–14). The initial contact with metal objects and their

incorporation, as for example bodily adornments in life and death, could have

stimulated further desire leading to connections to distant metal-producing centres being

established, before subsequent obtaining of metallurgical skills and establishing a

metallurgical tradition (Brodie 2001).

While this remains a scenario, it is perhaps too simplistic. Technological changes and

material innovations, such as the earliest appearance of metal, continue to provide the

framework through which social change and transformation in prehistory are constructed

(Sofaer-Derevenski and Stig-Sørensen in press). This leads to the privileging of a

phenomenon that, due to its relatively small scale and very gradual development, appears

to lack serious revolutionary credentials when placed in the broader worlds of the fourth

and third millennia

BC

(Bartelheim 2007). The shaping of early metal objects and

production practices into metallurgical traditions throughout Western Europe reflects,

rather than alters, specific community standards and desires, despite the many visual

possibilities afforded by the new material and new inter-connections generated by the

technology, implying that there were evidently boundaries that could not be transgressed.

Metallurgical traditions did not exist independently and were closely bound into other

larger and more pervasive socio-cultural networks and traditions whose spatial and

temporal variations are expressed through metal as well as other material culture (e.g.

Lechtman 1996; Sofaer 2006; Vander Linden 2006a). The role of early metal objects and

metal production practices in Western Europe therefore varied.

Creating traditions and shaping technologies

365

Downloaded By: [British Museum] At: 12:42 22 August 2008

In Ireland, metal appears to re-define existing traditions, with the extraction of the raw

material for producing copper flat axes at a specific place with a widespread distribution

and a virtual absence from burial contexts paralleling earlier practices with polished stone

axes (e.g. Cooney and Mandal 1998). It is possible to observe the replacement of polished

stone axes by copper flat axes throughout Ireland, demonstrated by the subsequent

decrease of polished stone axes during the mid-late third millennium

BC

, a process that is

especially acute in south-west Ireland where the Ross Island copper mine is located

(O’Brien 2004: 562). During the same period in southern England, metal was employed

together with other materials to adorn the dead in the distinctively new Bell Beaker burial

rites (Fitzpatrick 2002; Needham 1996, 2005; Vander Linden 2006a). The creation of gold,

copper and lead beads from the mid-fourth millennium

BC

in south-east France can be

traced to desire for ostentatious bodily adornment in the burial rite, which included a

diverse range of beads, pendulums and buttons in metal as well as animal bones, horns,

teeth, shells and stones (Barge 1982). The subsequent introduction of the standardized

metal repertoire of the Bell Beaker burial rite during the mid–late third millennium

BC

sees

the marked reduction in the diversity and quantity of metal objects (Ambert 2001; Vander

Linden 2006b). In contrast, the impact of the Bell Beaker burial rite in Iberia on existing

copper metallurgical traditions seems to be limited to the addition of several new forms,

such as Palmela points and tanged daggers, to the existing repertoire with no discernible

change in the underlying technology (Rovira-Llorens and Delibes de Castro 2005) while in

gold there is a shift from fine-beaten gold laminae decorated by repousse´ to various forms

of beads, sheets, tubes and diadems that are left undecorated (Perea 1991). While there

remains a certain validity to the old broad classification scheme for the earliest metal

objects and metallurgy throughout Western Europe of either ‘pre-Beaker’ or ‘Beaker’, the

heterogeneous nature of the metallurgical traditions reveals the many interrelationships

influencing local and regionally orientated community practices.

Conclusion

The dynamics underlying the creation and reproduction of early metallurgical traditions

were the transmission of ideas, objects and practices within and between individuals and

communities that can be traced at a variety of spatial and temporal scales. This process

of transmission does not produce perfect replications of metal objects and production

practices and does not take place in cultural isolation. The nature of the connections

involved in the transmission implies that the many small observable variations tended

not to be the consequence of imperfect copies or understandings of the production

techniques but rather were founded on choices available in terms of metal forms,

materials, hardness and decorations. The influence of existing material, technological

and social traditions can be seen in the subsequent selection of specific metallurgical

traits by individuals and communities that enabled the incorporation of the new

material.

British Museum, London

366

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

References

Ambert, P. 2001. La place de la me´tallurgie campaniforme dans la premie`re me´tallurgie franc¸aise:

e´tat de la question. In Bell Beakers Today: Pottery, People, Culture and Symbols in Prehistoric

Europe

(ed. F. Nicolis). Trento: Ufficio Beni Culturali, pp. 387–409.

Ambert, P., Bouquet, L., Guendon, J. L. and Mischka, D. 2005. La Capitelle du Broum (district

minier de Cabrie`res–Pe´ret, He´rault): e´tablissement industriel de l’aurore de la me´tallurgie franc¸aise

(3100–2400

BC

). In La Premie`re me´tallurgie en France et dans les pays limitrophes (eds P. Ambert and

J. Vaque). Me´moire de la Socie´te´ Pre´historique Franc¸aise 3783–96.

Barber, M., Field, D. and Topping, P. 1999. The Neolithic Flint Mines of England. Swindon: English

Heritage.

Barge, H. 1982. Les parures du Ne´olithique ancien au de´but de l’Age des Me´taux en Languedoc. Paris:

CNRS.

Bartelheim, M. 2007. Die Rolle der Metallurgie in vorgeschichtlichen Gesellschaften. Rahden: Verlag

Marie Leidorf.

Bisson, M., Childs, T., De Barros, P., Holl, A. and Vogel, J. 2000. Ancient African Metallurgy: The

Socio-cultural Context.

Lanham, MD: Altamira Press.

Blas-Cortina, M. 2005. Un te´moignage probant de l’exploitation pre´historique du cuivre dans le

nord de la Pe´ninsule Ibe´rique: le complexe minier d’El Aramo (Asturias). In La Premie`re me´tallurgie

en France et dans les pays limitrophes

(eds P. Ambert and J. Vaque). Me´moire de la Socie´te´

Pre´historique Franc¸aise 3783–96, pp. 195–206.

Bosch, J. 2005. Les techniques d’exploitation des plus anciennes mines d’Europe me´diterrane´enes:

l’example de Gava´, Barcelona. In La Premie`re me´tallurgie en France et dans les pays limitrophes (eds

P. Ambert and J. Vaque). Me´moire de la Socie´te´ Pre´historique Franc¸aise 3783–96, pp. 207–10.

Bouquet, L., Figueroa-Larre, V., Laroche, M., Guendon, J-L. and Ambert, P. 2006. Les Neuf-

Bouches (district minier de Cabrie`res–Pe´ret), la plus ancienne exploitation minie`re de cuivre de

France: travaux re´cents, consequences. Bulletin de la Socie´te´ Pre´historique Franc¸aise, 103(1): 143–59.

Bourgarit, D. 2007. Chalcolithic copper smelting. In Metals and Mines: Studies in Archaeometallurgy

(eds S. La Niece, D. Hook and P. Craddock). London: Archetype, pp. 3–14.

Bourgarit, D., Mille, B., Prange, M., Hauptmann A. and Ambert, P. 2003. Chalcolithic fahlore

smelting at Cabrie`res: reconstruction of smelting processes by archaeometallurgical finds. In

Archaeometallurgy in Europe.

Milan: Associazione Italiana di Metallurgia, pp. 431–40.

Briard, J. and Roussot-Larroque, J. 2002. Les debuts de la metallurgie dans la France Atlantique. In

The Beginnings of Metallurgy in the Old World

(eds M. Bartelheim, E. Pernicka and R. Krause).

Rahden: Verlag Marie Leidorf, pp. 135–60.

Brodie, N. 2001. Technological frontiers and the emergence of the Beaker culture. In Bell Beakers

Today: Pottery, People, Culture and Symbols in Prehistoric Europe

(ed. F. Nicoli). Trento: Ufficio

Beni Culturali, pp. 487–96.

Budd, P. and Taylor, T. 1995. The faerie smith meets the bronze industry: magic versus science in the

interpretation of prehistoric metal-making. World Archaeology, 27: 133–43.

Chardenoux, M-B. and Courtois, J. 1979. Les haches dans la France me´ridonale: Praehistorische

Bronzefunde.

Praehistorische Bronzefunde IX, 2. Munich: Beck.

Chernykh, E. N. 1992. Ancient Metallurgy in the USSR: The Early Metal Age. Cambridge:

Cambridge University Press.

Cooney, G. and Mandal, S. 1998. Irish Stone Axe Project I. Dublin: Wordwell.

Craddock, P. 1995. Early Mining and Metal Production. Edinburgh: Edinburgh University Press.

Creating traditions and shaping technologies

367

Downloaded By: [British Museum] At: 12:42 22 August 2008

Craddock, P. 2001. From hearth to furnace: evidences for the earliest metal smelting technologies in

the eastern Mediterranean. Palaeorient, 26: 151–65.

David, N. and Kramer, C. 2001. Ethnoarchaeology in Action. Cambridge: Cambridge University

Press.

Delibes de Castro, G. and Montero, I. 1999. Las Primeras Etapas Metalurgicas en la Peninsula

Ibe´rica,

II, Estudios Regionales. Madrid: Instituto Universitario Ortega y Gasset y Ministerio de

Educacion, Cultura y Deporte.

Dobres, M-A. and Robb, J. (eds) 2000. Agency in Archaeology. London: Routledge.

Eerkens, J. W. and Lipo, C. P. 2007. Cultural transmission theory and the archaeological record:

providing context to understanding variation and temporal changes in material culture. Journal of

Archaeological Research

, 15(3): 239–74.

Ehrhardt, K. L. 2005. European Metals in Native Hands: Rethinking the Dynamics of Technological

Change 1640–1683.

Tuscaloosa: University of Alabama Press.

Elue`re, C. 1982. Les Ors Pre´historiques. Picard: Paris.

Eogan, G. 1994. The Accomplished Art: Gold and Goldworking in Britain and Ireland during the

Bronze Age (c. 2300–650

BC

).

Oxford: Oxbow.

Ferna´ndez-Manzano, J. and Martı´nez, J. I. (eds) 2003. Mineros y Fundidores en el Inicio de la Edad

de los Metales: El Midi France´s y el Norte de la Penı´nsula Ibe´rica.

Leon: Editorial.

Fitzpatrick, A. P. 2002. The Amesbury archer: a well-furnished Early Bronze Age Burial in southern

England. Antiquity, 76: 629–30.

Friedman, J. 1992. The past in the future: history and the politics of identity. American

Anthropologist

, 94(4): 837–59.

Gosselain, O. P. 1992a. Technology and style: potters and pottery among Bafia of Cameroon. Man,

27(3): 559–86.

Gosselain, O. P. 1992b. Bonfire of the enquiries: pottery firing temperatures in archaeology: what

for? Journal of Archaeological Science, 19: 243–59.

Gosselain, O. P. 1998. Social and technical identity in a clay crystal ball. In The Archaeology of

Social Boundaries

(ed. M. Stark). Washington, DC: Smithsonian Institute Press, pp. 78–

106.

Guilaine, J. 1991. Roquemengarde et les de´buts de la me´tallurgie en France me´diterrane´enne. In

De´couverte du me´tal

(eds C. Elue`re and J. P. Mohen). Paris: Picard, pp. 279–94.

Guilaine, J. 2003. De la vague a` la tombe: Me´tamorphoses en Me´diterrane´e (8000–2000 avant J.C.).

Paris: Seuil.

Gutherz, X. and Jallot, L. 2005. Aˆge du cuivre et changements sociaux en Languedoc me´diterrane´en.

In La Premie`re me´tallurgie en France et dans les pays limitrophes (eds P. Ambert and J. Vaquer).

Me´moire de la Socie´te´ Pre´historique Franc¸aise 3783–96, pp. 83–96.

Harbison, P. 1969a. The Axes of the Early Bronze Age in Ireland. Bronzefunde VI, 2. Munich: Beck.

Harbison, P. 1969b. The Daggers and the Halberds of the Early Bronze Age in Ireland. Praehistorische

Bronzefunde VI, 1. Munich: Beck.

Helms, M. W. 1988. Ulysses’ Sail: An Ethnographic Odyssey of Power, Knowledge, and Geographical

Distance.

Princeton, NJ: Princeton University Press.

Helms, M. W. 1993. Craft and the Kingly Ideal: Art, Trade and Power. Austin: University of Texas

Press.

Herbert, E. W. 1984. Red Gold of Africa: Copper in Precolonial History and Culture. Madison:

University of Wisconsin Press.

368

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

Hobsbawm, E. and Ranger, T. (eds) 1983. The Invention of Tradition. Cambridge: Cambridge

University Press.

Holtorf, C. 2000–7. Monumental Past: The Life-histories of Megalithic Monuments in Mecklenburg-

Vorpommern (Germany).

University of Toronto, Centre for Instructional Technology Development.

Available from: http://hdl.handle.net/1807/245.

Horne, L. 1982. Fuel for the metal worker: the role of charcoal and charcoal production in ancient

metallurgy. Expedition, 25: 6–13.

Hosler, D. 1995. Sound, colour and meaning in the metallurgy of ancient west Mexico. World

Archaeology

, 27: 100–15.

Hughes, D. and Trautmann, T. (eds) 1995. Time: Histories and Ethnologies. Ann Arbor: University

of Michigan Press.

Keates, S. 2002. The flashing blade: copper, colour and luminosity in North Italian Copper Age

society. In Colouring the Past: The Significance of Colour in Archaeological Research (eds A. Jones

and G. MacGregor). Oxford: Berg, pp 109–25.

Keller, C. M. 2001. Thoughts and production: insights of a practitioner. In Anthropological

Perspectives on Technology

(ed. M. Schiffer). Albuquerque: University of New Mexico Press, pp. 33–

45.

Keller, C. M. and Keller, J. D. 1996. Cognition and Tool Use: The Blacksmith at Work. Cambridge:

Cambridge University Press.

Kingery, D. W. 1993. Technological systems and some implications with regard to continuity and

change. In History from Things (eds S. Lubar and D. W. Kingery). Washington, DC: Smithsonian

Institution Press, pp. 215–30.

Kingery, D. W. 2001. The design process as a critical component of the anthropology of technology.

In Anthropological Perspectives on Technology (ed. M. Schiffer). Albuquerque: University of New

Mexico Press, pp. 123–38.

Knappett, C. 2005. Thinking through Material Culture: An Interdisciplinary Perspective. Philadel-

phia: University of Pennsylvania Press.

Krause, R. 2003. Studien zur kupfer- und fru¨hbronzezeitlichen Metallurgie zwischen. Karpatenbecken

und Ostsee.

Leidorf: Rahden/Westf.

Lechtman, H. 1977. Style in technology: some early thoughts. In Material Culture: Styles,

Organization, and Dynamics of Technology

(eds H. Lechtman and R. Merrill). St. Paul, MN: West

Publishing, pp. 3–20.

Lechtman, H. 1996. Cloth and metal: the culture of technology. In Andean Art at Dumbarton Oaks

(ed. E. Boone). Washington, DC: Dumbarton Oaks Research Library and Collection,

pp. 33–43.

Lemmonier, P. 1992. Elements for an Anthropology of Technology. Ann Arbor: The Museum of

Anthropology, University of Michigan.

Livingstone-Smith, A. 2001. Bonfire II: the return of pottery firing temperatures. Journal of

Archaeological Science

, 28: 991–1003.

Lo Schiavo, F., Giumlia-Mair, A. and Valera, R. 2005. Archaeometallurgy in Sardinia: From the

Origin to the Beginning of Early Iron Age.

Montagnac: Monique Mergoil.

McDonnell, J. G. 2001. Pyrotechnology. In Handbook of Archaeological Sciences (eds D. Brothwell

and M. Pollard). London: Wiley, pp. 493–506.

Mille, B. and Bouquet, L. 2004. Le me´tal au 3e mille´naire avant notre e`re dans le Centre-Nord de la

France. In Le troisie`me mille´naire dans le nord de la France et en Belgique (eds M. Vander Linden and

L. Salanova). Anthropologica et Praehistorica, 115: 197–215.

Creating traditions and shaping technologies

369

Downloaded By: [British Museum] At: 12:42 22 August 2008

Montero Ruiz, I. 1994. El origen de la Metalurgia en el Sureste Peninsula. Almerı´a: Instituto de

Estudios Almerienses.

Montero Ruiz, I. 2005. Me´tallurgie ancienne dans la Pe´ninsule Ibe´rique. In La Premie`re me´tallurgie

en France et dans les pays limitrophes

(eds P. Ambert and J. Vaquer). Me´moire de la Socie´te´

Pre´historique Franc¸aise 3783–96, pp. 187–94.

Montero Ruı´z, I. and Ruı´z Taboada, A. 1996. Enterramiento colectivo y metalurgia en el

yacimiento neolı´tico del Cerro Virtud (Cuevas de Almanzora, Almerı´a). Trabajos de Prehistoria,

53(2): 55–75.

Mu¨ller, R., Goldenberg, G., Bartelheim, M., Kunst, M. and Pernicka, E. 2007. Zambujal and the

beginnings of metallurgy in southern Portugal. In Metals and Mines: Studies in Archaeometallurgy

(eds S. La Niece, D. Hook and P. Craddock). London: Archetype, pp. 15–26.

Mu¨ller-Karpe, M. 1990. Aspects of early metallurgy in Mesopotamia. In Archaeometry ’90 (eds

E. Pernicka, and G. A. Wagner). Basel: Birkhauser Verlag, pp. 105–16.

Needham, S. 1983. The Early Bronze Age axeheads of Central and Southern England. Doctoral

dissertation, University College, Cardiff.

Needham, S. 1996. Chronology and periodisation in the British Bronze Age. Acta Archaeologica, 67:

121–40.

Needham, S. 2002. Analytical implications for Beaker metallurgy in north-west Europe. In The

Beginnings of Metallurgy in the Old World

(eds M. Bartelheim, E. Pernicka and R. Krause). Rahden:

Verlag Marie Leidorf, pp. 99–133.

Needham, S. 2004. Migdale-Marnoch: sunburst of Scottish metallurgy. In The Neolithic and Early

Bronze Age of Scotland in their European Context

(eds I. Shepherd and G. Barclay). Edinburgh:

Royal Society of Antiquaries of Scotland, pp. 217–45.

Needham, S. 2005. Transforming Beaker Culture in north-west Europe: processes of fusion and

fission. Proceedings of the Prehistoric Society, 71: 171–218.

Northover, Peter 1989. Properties and use of arsenic-copper alloys. In Old World Archaeometallurgy

(eds A. Hauptmann, E. Pernicka and G. Wagner). Bochum: Deutsches Bergbau Museum, pp. 111–18.

O’Brien, M. 2008. Cultural Transmission and Archaeology: Issues and Case Studies. Washington, DC:

SAA Press.

O’Brien, W. 2004. Ross Island. Bronze Age Studies 5. Galway: National University of Ireland.

Orton, C., Tyers, P. and Vince, A. 1997. Pottery in Archaeology. Cambridge: Cambridge University Press.

Ottaway, B. S. 2001. Innovation, production and specialisation in early prehistoric copper

metallurgy. European Journal of Archaeology, 4(1): 87–112.

Ottaway, B. S. and Roberts, B. W. 2008. The emergence of metalworking. In Prehistoric Europe:

Theory and Practice

(ed. A. Jones). London: Blackwell, pp. 193–225.

Pearce, M. 2007. Bright Blades and Red Metal: Essays on North Italian Prehistoric Metalwork.

Specialist Studies on Italy 14. London: Accordia Research Institute.

Perea, A. 1991. Orfebrerı´a Prerromana: Arqueologia de Oro. Madrid: Caja de Madrid.

Pingel, V. 1992. Die vorgeschichtlichen Goldfunde der Iberischen Halbinsel: Eine archa¨eologische

Untersuchung zur Auswertung der Spektranalysen.

Berlin: de Gruyter.

Primas, M. 1995. Gold and silver during the 3rd mill cal

BC

. In Prehistoric Gold in Europe (eds

G. Morteani and J. P. Northover). Dordrecht: NATO ASI Series, pp. 77–93.

Renfrew, C. 1967. Colonialism and megalithismus. Antiquity, 41: 276–88.

Renfrew, C. 1973. Before Civilization: The Radiocarbon Revolution and Prehistoric Europe.

Cambridge: Cambridge University Press.

370

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

Roberts, B. W. In press. Migration, craft expertise and metallurgy: analysing the ‘spread’ of metal in

Europe. Archaeological Review from Cambridge, 23(2).

Roberts, B. W. and Ottaway, B. S. 2004. The use and significance of socketed axes during the Late

Bronze Age. European Journal of Archaeology, 6(2): 119–40.

Roussot-Larroque, J. 2005. Premiere metallurgie du Sud-Ouest Atlantique de la France. In La

Premie`re me´tallurgie en France et dans les pays limitrophes

(eds P. Ambert and J. Vaquer). Me´moire

de la Socie´te´ Pre´historique Franc¸aise 3783–96, pp. 159–74.

Rovira-Llorens, S. 2002. Metallurgy and society in prehistoric Spain. In Metals and Society

(eds B. S. Ottaway and E. C. Wager). Oxford: British Archaeological Reports International Series

1061, pp. 5–20.

Rovira-Llorens, S. and Delibes de Castro, G. 2005. Tecnologı´a metalu´rgia campaniforme en la

Peninsula Ibe´rica: coladas, moldeado y tratamientos postfundicio´n. In El Campaniforme en la

Penı´nsula Ibe´rica y su Contexto Europeo

(eds M. A. Rojo-Guerra, R. Garrido-Pena and I. Garcı´a

Martı´nez de Lagra´n). Valladolid: Junta de Castilla y Leon, pp. 495–521.

Rovira-Llorens, S. and Go´mez-Ramos, P. 2004. Las Primeras Etapas Metalurgicas en la Peninsula

Ibe´rica,

III, Estudios Metalogra´ficos. Madrid: Instituto Universitario Ortega y Gasset y Ministerio de

Educacion, Cultura y Deporte.

Rovira-Llorens, S. and Guttierez, A. 2005. Utilisation expe´rimentale d’un four primitive pour fonder

du minerai de cuivre. In La Premie`re me´tallurgie en France et dans les pays limitrophes

(eds P. Ambert and J. Vaquer). Me´moire de la Socie´te´ Pre´historique Franc¸aise 3783–96, pp. 241–6.

Rowlands, M. 1971. The archaeological interpretation of metalworking. World Archaeology, 3: 210–

23.

Ruı´z Taboada, A. and Montero-Ruı´z, I. 1999. The oldest metallurgy in Western Europe. Antiquity,

73: 897–903.

Schiffer, M. (ed.) 2001. Anthropological Perspectives on Technology. Albuquerque: University of New

Mexico Press.

Schmidt, P. K. and Burgess, C. B. 1981. The Axes of Scotland and Northern England. Praehistorische

Bronzefunde IX, 7.

Munich: Beck.

Schoop, U-D. 1995. Die Geburt des Hephaistos: Technologie und Kulturgeschichte neolithischer

Metallverwendung im Vorderen Orient.

Espelkamp: Marie Leidorf.

Shennan, S. 1999. Cost, benefit and value in the organization of early European copper production.

Antiquity

, 73: 352–63.

Skeates, R. 1994. Early metal use in the Central Mediterranean region. Accordia Research Papers, 4:

5–47.

Sofaer, J. 2006. Pots, houses and metal: technological relations at the Bronze Age tell at

Sza´zhalombatta, Hungary. Oxford Journal of Archaeology, 25(2): 127–47.

Sofaer-Derevenski, J. and Stig-Sørensen, M. L. 2002. Becoming cultural: society and the

incorporation of bronze. In Metals and Society (eds B. S. Ottaway and E. C. Wager). Oxford:

British Archaeological Reports International Series 1061, pp. 17–122.

Sofaer-Derevenski, J. and Stig-Sørensen, M. L. In press. Technological change as social change: the

introduction of metal in Europe. In Continuity–Discontinuity: Transition Periods in European

Prehistory

(eds M. Bartelheim and V. Heyd).

Stig-Sørensen, M. L. 1996. Women as/and metalworkers. In Women in Industry and Technology:

From Prehistory to the Present

(eds A. Devonshire and B. Wood). London: Museum of London, pp.

45–52.

Strahm, C. 1994. Die Anfa¨nge der Metallurgie in Mitteleuropa. Helvetia Archaeologica, 25: 2–39.

Creating traditions and shaping technologies

371

Downloaded By: [British Museum] At: 12:42 22 August 2008

Taylor, T. 1999. Envaluing metal: theorizing the Eneolithic ‘hiatus’. In Metals in Antiquity (eds

S. Young, M. Pollard, P. Budd and R. Ixer). Oxford: British Archaeological Reports International

Series 792, pp. 22–32.

Thornton, C. P. 2002. The domestication of metal: a reassessment of the early use of copper minerals

and metal in Anatolia and southeastern Europe. MPhil thesis, Cambridge University.

Timberlake, S. 2002. Ancient prospection for metals and modern prospection for ancient mines: the

evidence for Bronze Age Mining within the British Isles. In The Beginnings of Metallurgy in the Old

World

(eds M. Bartelheim, E. Pernicka and R. Krause). Rahden: Verlag Marie Leidorf, pp. 327–57.

Timberlake, S. 2003. Excavations on Copa Hill, Cwmystwyth (1986–1999): An Early Bronze Age

Copper Mine within the Uplands of Central Wales.

Oxford: British Archaeological Reports British

Series 348.

Timberlake, S. 2007. The use of experimental archaeology/archaeometallurgy for the understanding

and reconstruction of Early Bronze Age mining and smelting technologies. In Metals and Mines:

Studies in Archaeometallurgy

(eds S. La Niece, D. Hook and P. Craddock). London: Archetype,

pp. 27–35.

Vander Linden, M. 2006a. Le phe´nome`ne campaniforme dans l’Europe du 3e`me. mille´naire avant notre

e`re: synthe`se et nouvelles perspectives.

Oxford: British Archaeological Reports International Series

1470.

Vander Linden, M. 2006b. For whom the bell tolls: social hierarchy vs. social integration in the Bell

Beaker culture of southern France (3rd millennium

B

.

C

.). Cambridge Archaeological Journal, 16(3):

317–32.

Vaquer, J. 1998. La midi me´diterrane´en de la France. In Atlas du Ne´olithique 2B: Europe Occidentale

(ed. J. Guilaine). Lie`ge: University of Lie`ge, pp. 413–500.

Ben Roberts is the Curator of the British and European Bronze Age at the British

Museum. His research interests include Copper and Bronze Age Europe, archaeome-

tallurgy and archaeological theory. His article derives from his PhD thesis, on the origins

and early development of metal in Western Europe, at the University of Cambridge.

372

Ben Roberts

Downloaded By: [British Museum] At: 12:42 22 August 2008

Wyszukiwarka

Podobne podstrony:

Kwiek, Marek Universities and Knowledge Production in Central Europe (2012)

Production networks and consumer choice in the earliest metal of Western Europe

From Plato To Postmodernism Understanding The Essence Of Literature And The Role Of The Author (Deta

Understanding the Nature of Autism And A Edward R Ritvo

The Experiences of French and German Soldiers in World War I

18 Nepal and the Eastern Himalayas (Language and National Identity in Asia)

The Roles of Gender and Coping Styles in the Relationship Between Child Abuse and the SCL 90 R Subsc

Wellendorf, The Interplay of Pagan and Christian Traditions in Icelandic Settlement Myths

Migration and welfare state solidarity in Western Europe

explaining variation in the success of extreme right parties in western europe

The Witch Cult in Western Europe

Understanding the productives economy during the bronze age trought archeometallurgical and palaeo e

Prehistoric copper production in the Inn Valley (Austria) and the earliest copper in Central Europe

Palaikastro Shells and Bronze Age Purple Dye Production in the Mediterranean Basin

(Trading) Paul Counsel Towards An Understanding Of The Psychology Of Risk And Succes

Gronlie, Reading and Understanding The Miracles in Thorvalds thattr

Coping with Vision Loss Understanding the Psychological, Social, and Spiritual Effects by Cheri Colb

Cadmium and Other Metal Levels in Autopsy Samplesfrom a Cadmium Polluted Area and Non polluted Contr

Donald Hicks Understanding The G Spot And Female Sexuality

więcej podobnych podstron