Thermo Top

Tele Thermo Top

from serial no. 300 000 onward

Thermo Top T

Tele Thermo Top T

from serial no. 300 000 onward

Auxiliary Heater

Type BW 50 (Petrol)

Type DW 50 (Diesel)

Operating Instructions must be read before

attempting to start up the heater.

8/2000

Water Heater

Installation instructions

Table of contents

Page

Installation instructions

1

Legal Provisions

1

Installation Location

2

Installation example

Thermo Top

4

Fuel Installation

5

Combustion Air Supply

5

Insert Plate

6

Exhaust Gas Pipe

6

Electrical Connections

7

wiring diagram

9

Initial Operation

10

Troubleshooting

11

Versions

12

Technical Data

13

Webasto Service Phone Line

14

Thermo Top

I

Installation instructions

Legal Provisions for Installation

For testing the heater in accordance with articles 19, 20 or

21 of the StVZO the following regulations are primarily to

be observed (art. 22a StVZO):

NOTE:

These provisions are binding within the scope of the

StVZO and should also be observed in countries

where no special regulations are in effect!

Within the scope of the StVZO (German Road Licensing

Regulations) “General Design Certifications” have been

granted by the Federal Office for Motor Traffic for the

Thermo Top water heaters with the following design ap-

proval numbers:

~

S 238 for the

Thermo Top - Patrol heating device,

type

BW

50

~

S 239 for the

Thermo Top - Diesel heating device,

type

DW

50

The installation of the heaters must be performed in ac-

cordance with these Installation Instructions. The installa-

tion must be checked

a) upon the homologation of the vehicles in accordance

with § 20 StVZO

b) upon any individual test in accordance with

§ 21 StVZO, or

c) upon any examination in accordance with § 19 StVZO

by a registered expert or examiner for motor traffic, an

expert for automotive vehicles, or any other authorised

official, in accordance with paragraph 4 of

Appendix VIIIb to the StVZO

and in the case of item c) the proper installation must be

certified on the approval certificate contained on the de-

sign certification stating the following:

- vehicle manufacturer

- vehicle type and

- vehicle identification number

The effectiveness of the design certification (homologa-

tion) is dependent on this certificate. The approval certifica-

tion is to be kept in the vehicle.

The year of the initial operation must be durably marked

on the type plate of the heater by the installer by removing

the years that do not apply.

Extracting the combustion air from the interior of the

vehicle is not permissible.

The exhaust pipe must be so mounted that its discharge

opening points downward, sideways or, in the case of rout-

ing the exhaust pipes on the underside of the bottom of the

vehicle, their discharge opening must be positioned near

the lateral or rear edge of the driver’s cab or vehicle.

Exhaust pipes must be routed in such a way that exhaust

gases cannot penetrate the interior of the vehicle. The

function of any parts of the vehicle essential for its oper-

ation must not be impaired.

The openings of the combustion air inlet and exhaust gas

outlet must be so designed that a spherical object of 16

mm diameter cannot be introduced.

Electric lines, switchgear and controlgear of the heater

must be so arranged in the vehicle that their proper func-

tion cannot be impaired under normal operating conditions.

For the routing of fuel lines and the installation of addi-

tional fuel tanks articles 45 and 46 of the StVZO are to be

adhered to. The most important excerpts therefrom are as

follows:

Fuel lines are to be designed in such a way that they re-

main unaffected by torsional stresses in the vehicle, en-

gine movement and the like. They must be protected

against mechanical damage. Fuel-carrying parts are to be

protected against excessive heat and are to be arranged

such that any dripping or evaporating fuel can neither col-

lect nor be ignited by hot components or electrical equip-

ment.

The heater must not be installed in passengers areas.

The operating state of the heater at any given time - i.e. at

least an indication as to whether it is “on” or “off” - must be

easily recognizable.

The installation of components that are not of an approved

type will lead to the invalidation of the General Design Cer-

tification of the heater and thus the General Operating Per-

mission of the vehicle. The same applies to improperly per-

formed repairs or those where other than genuine replace-

ment parts were used.

Use of the Water Heater

The Webasto

Thermo Top water heater in conjunction

with the vehicle heating system is used for

- heating the driver’s cab,

- defrosting the vehicle’s windows as well as

- preheating water-cooled engines.

The water heater operates independently of the vehicle en-

gine and is connected to the cooling system, the fuel sys-

tem and the electrical system of the vehicle.

Thermo Top

1

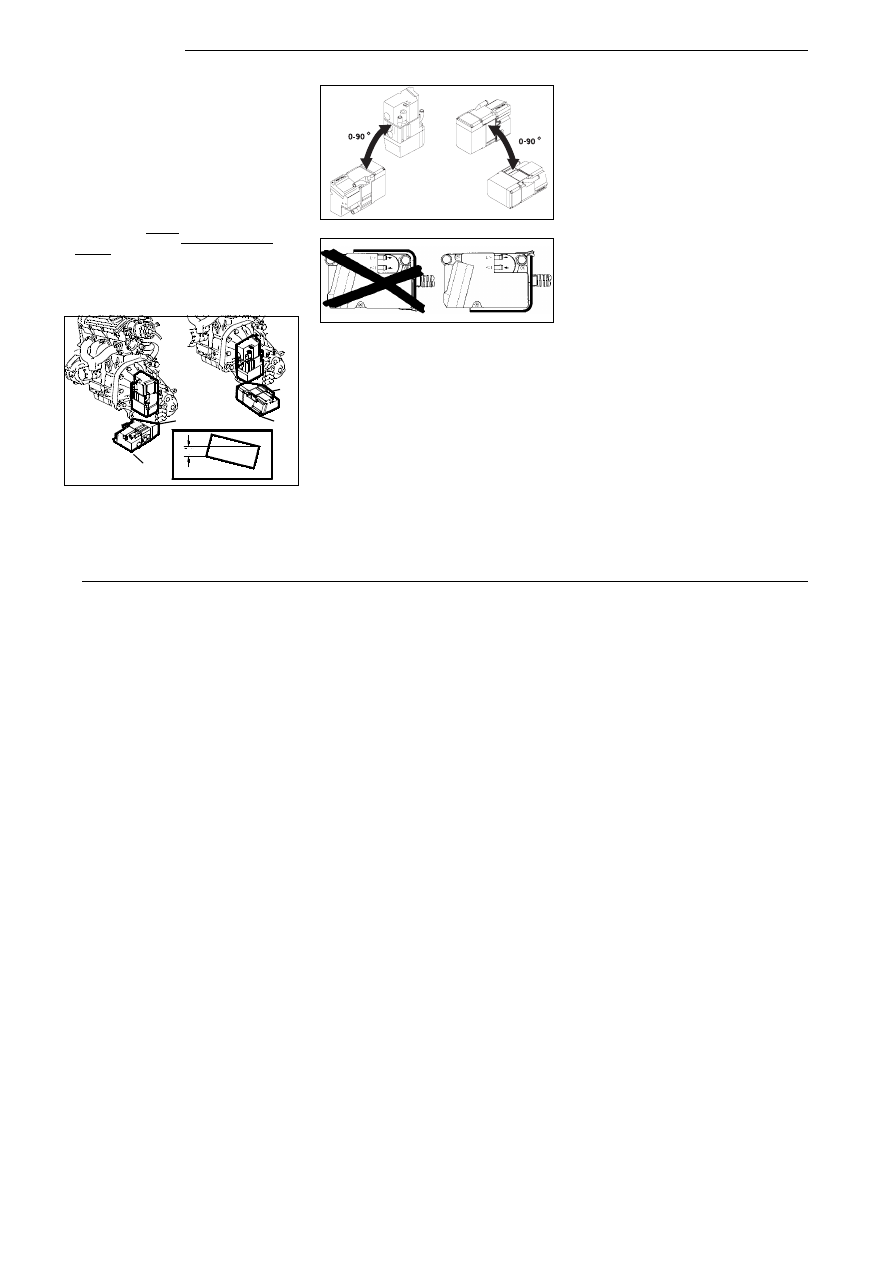

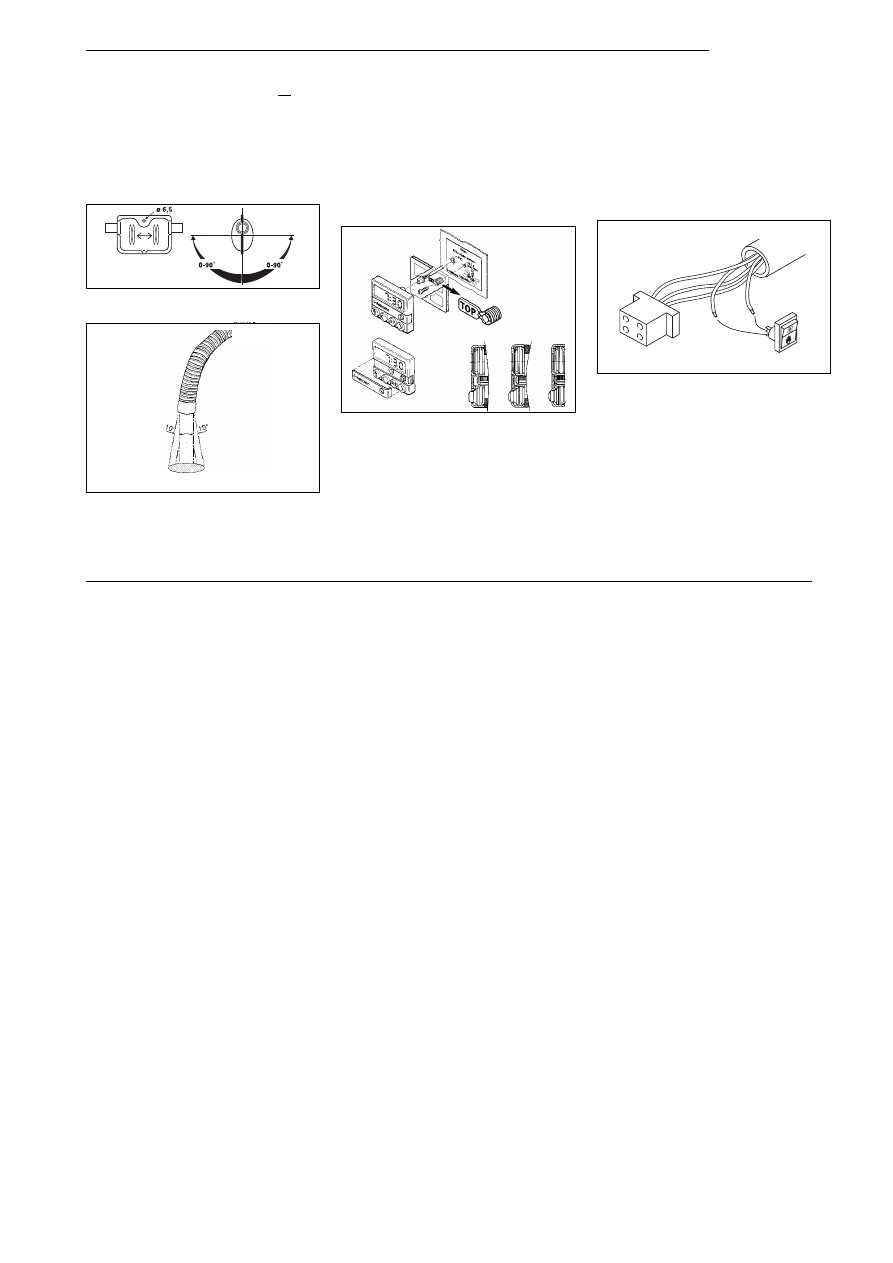

Installation Location

Preferably, the heater should be installed in the engine

compartment, the splash-water protected areas of the front

fenders or at the splashboard.

If the heater cannot be installed in the aforementioned loca-

tions it may also be installed:

- in upright position in front of the gearbox (partly

covered, see Fig. 1) provided the fuel supply system is

not located in front of the engine, any auxiliary equip-

ment or the gearbox.

-

in inclined position in front of the gearbox (see illus-

tration) provided point “A” is located below the lower

edge of the gearbox and at least 25 mm above

point “B”. This ensures that the heater can slide

underneath the gearbox in the case of an accident.

- in accordance with vehicle-specific Webasto installation

instructions which are to be presented to the officially

registered expert when the installation is being in-

spected.

The heater should be installed at a level as low as possible

so as to ensure automatic venting of heater and circulating

pump. This is of special importance since the circulating

pump is not of the self-priming type.

Note:

The heater must not be installed on the support plate in a

hanging position.

CAUTION:

The heater must not be installed in the following places:

- in the immediate vicinity of or above hot parts

- in the direct splash water area of the wheels

- in front of the engine block or the engine units

- in engine compartments which are open at the bottom,

below the wheel center (i.e. in each permissible mount-

ing position the bottom of the heater must be located

above the wheel center).

Caution:

The openings of the water connecting branches must not,

in any installation position, point in downward direction.

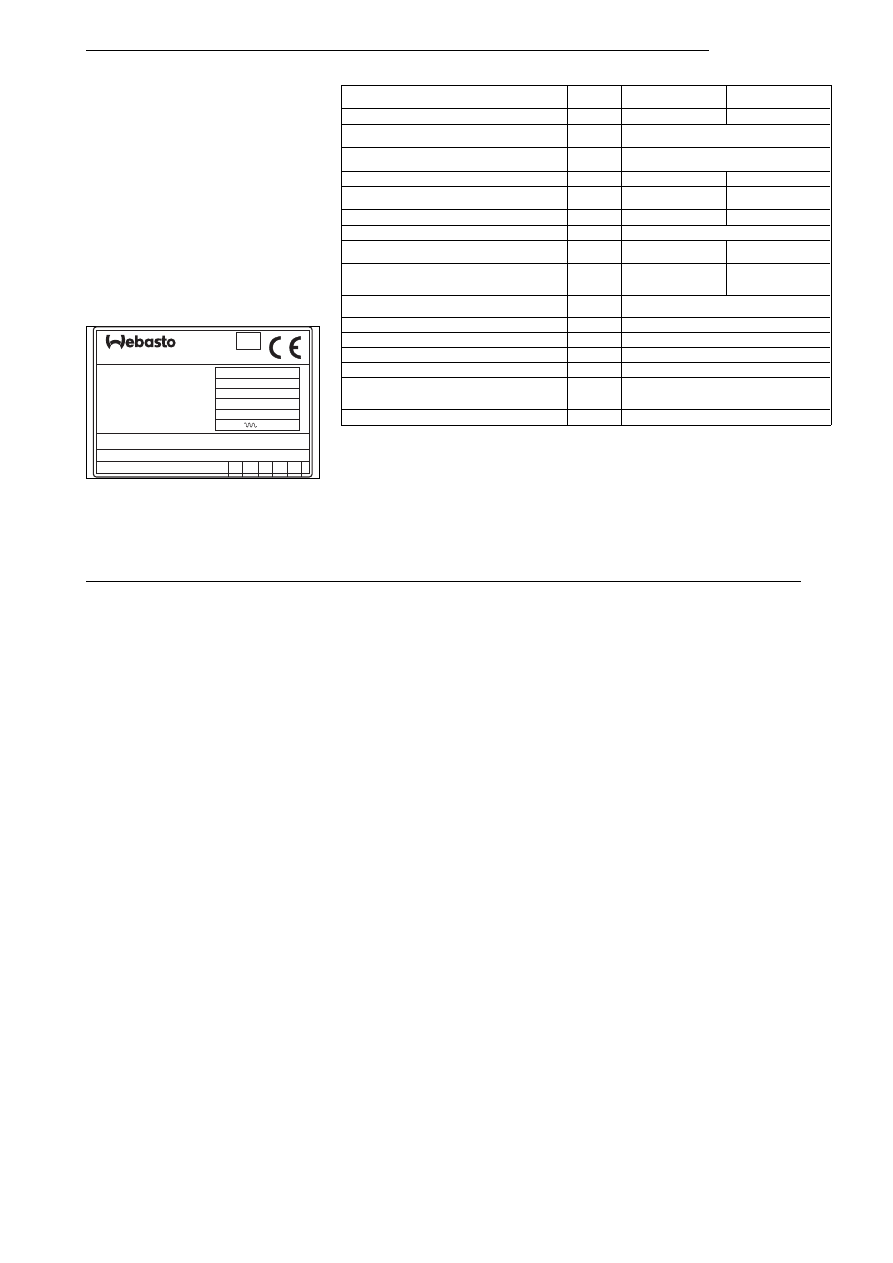

Nameplate

The type plate must be located at a place where it is pro-

tected against damage and must be easily accessible

once the heater has been installed (or a nameplate dupli-

cate is to be used).

The year not applicable is to be removed from the type

plate.

A

B

A

B

A

B

min 25

Fig. 1:

Installation location in front of the gearbox

Fig. 2:

Mounting position

Fig. 3:

Mounting position

Thermo Top

2

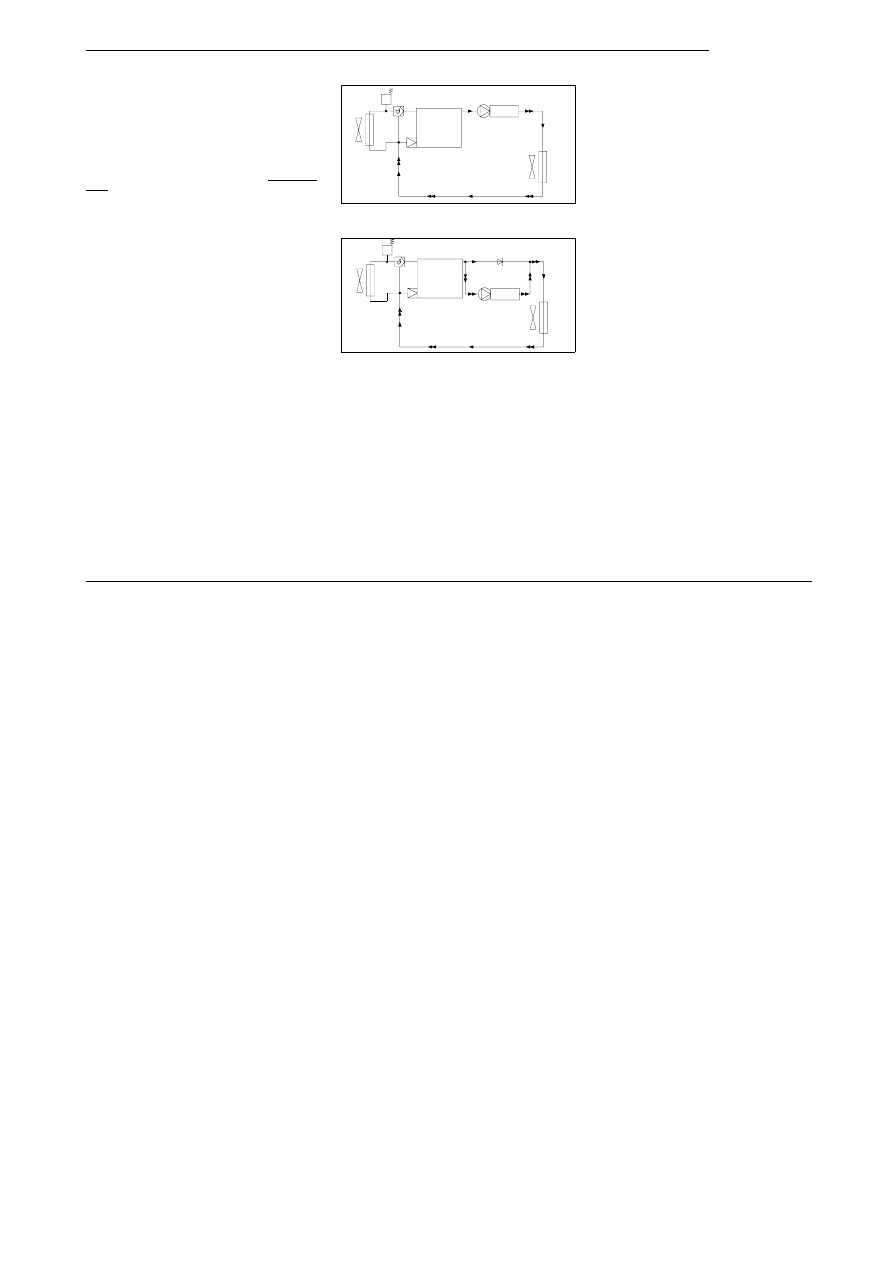

Connection to the Vehicle Cooling System

The heater is to be connected to the vehicle cooling sys-

tem in accordance with Figs. 4, 5 and 6. The coolant sys-

tem capacity must be at least 4 liters.

As a rule, the water hoses (pipes) supplied by Webasto

are to be used. If not, the hoses must at least conform to

DIN standard 73411. The hoses are to be laid

without any

kinks and - for proper venting - should be pitched upward,

if possible. Hose connections must be secured against slip-

ping off by means of hose clamps.

NOTE:

The hose clamps at the heater must be mounted between

the flared neck of the pipe and the heater.

The hose clamps must be tightened to a torque of 2,0 +

0,5 Nm.

Before the heater is operated for the first time or after cool-

ant has been replaced it must be ensured that the cooling

system is properly vented. Heater and piping should be so

installed as to ensure static venting.

Insufficient venting can result in a failure during heating

operation due to overheating.

Legend for Fig. 4 and 5:

1 Expansion

tank

2 Thermostat

3 Engine

4 Check

valve

5 Heater

6 Heat exchanger

7 Radiator

1

3

5

6

2

7

Fig. 4:

Integration into engine/cooling water circuit

“Inline-Integration”

1

3

4

5

6

2

7

Fig. 5:

Integration with check valve

Thermo Top

3

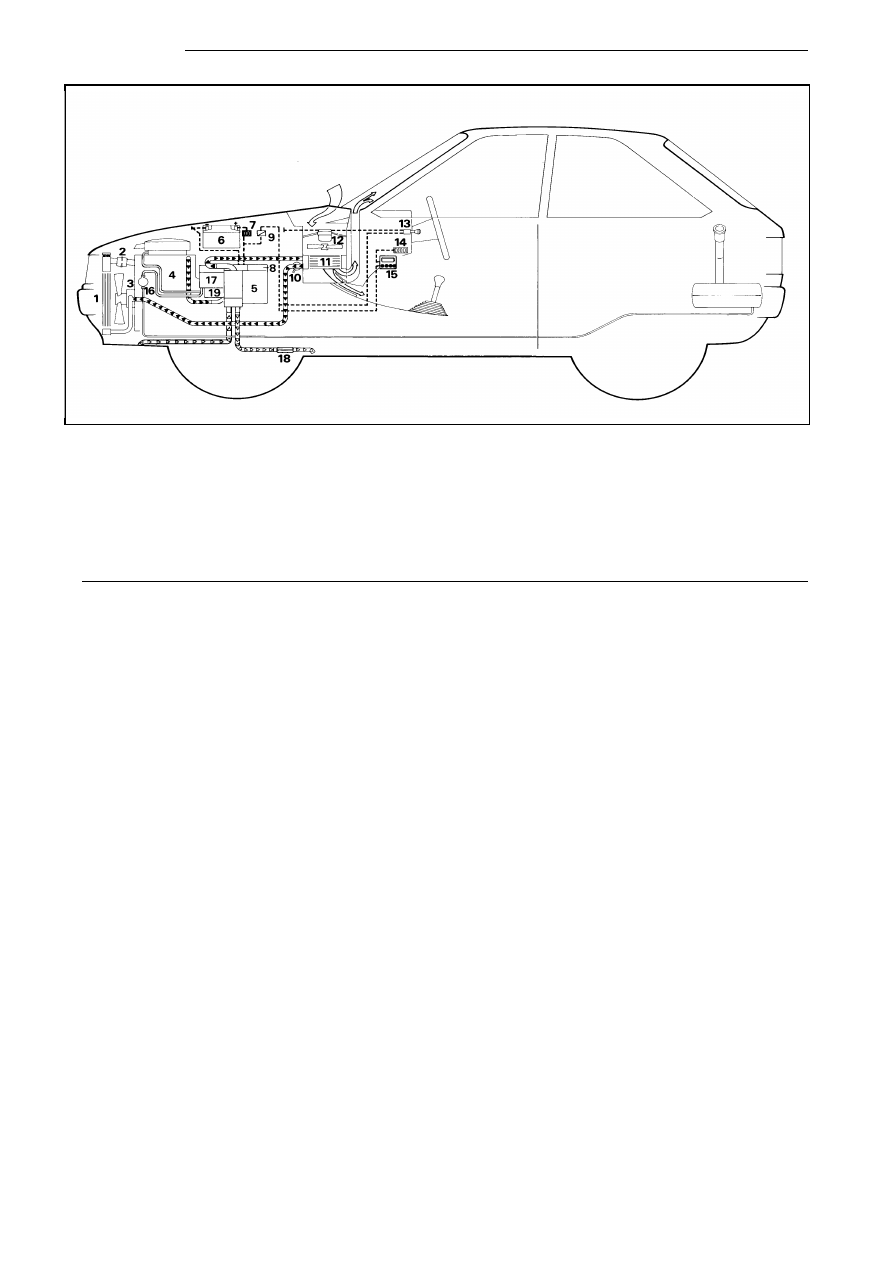

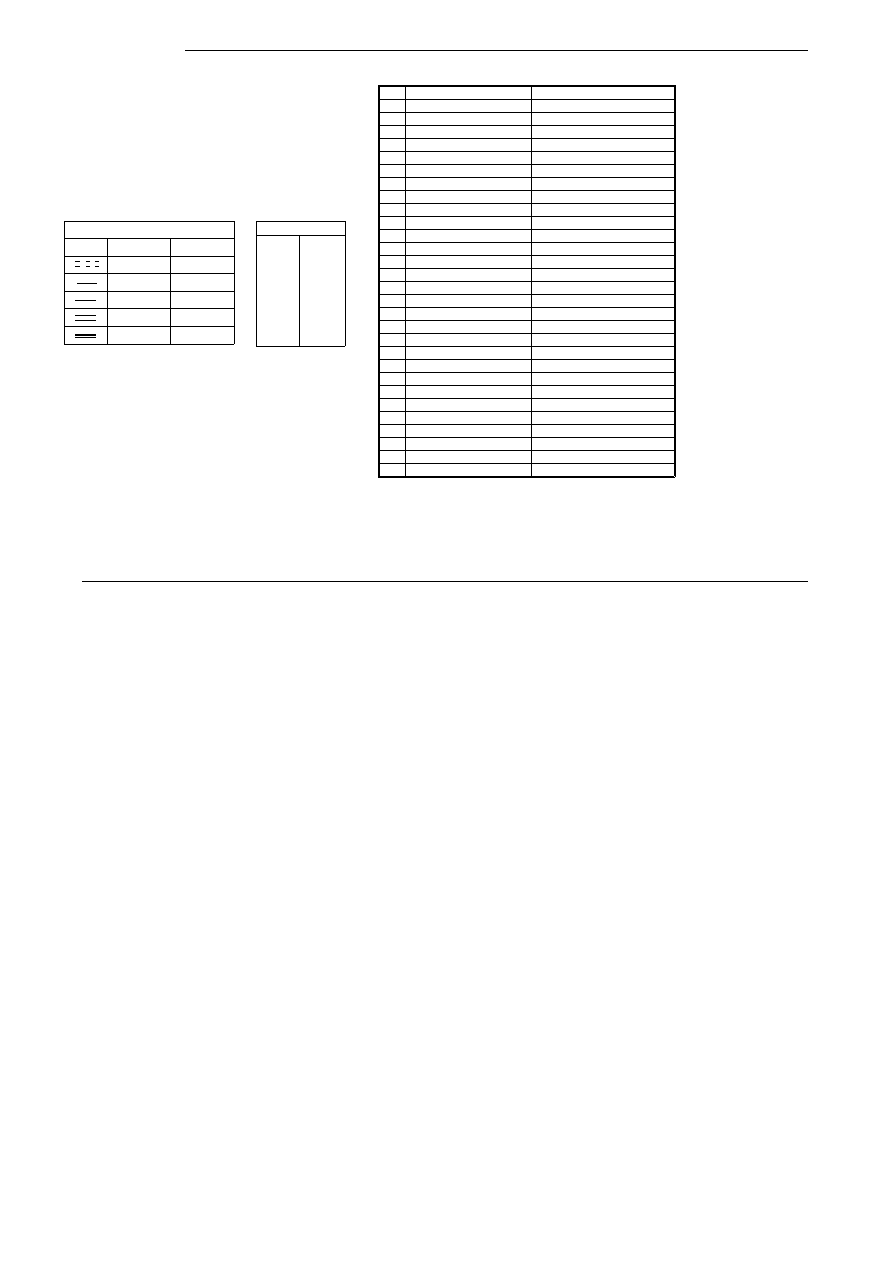

Fig. 6:

Installation example of heater

Thermo Top in a passenger car

1

Radiator

2

Cooling water thermostat

3

Water pump (of car engine)

4

Standard equipment engine

5

Water heater

6

Battery

7

Fuse holder

8

Control unit (in heater)

9

Relay (for vehicle fan)

10

Regulating valve of vehicle heating

11

Heat exchanger, vehicle heating system

12

Vehicle heater fan

13

Vehicle heater fan switch

14

Fuse bank in the vehicle

15

Digital timer

16

Fuel pickup

17

Fuel pump (in heater)

18

Exhaust muffler, as required

19

Circulating pump (in heater)

Thermo Top

4

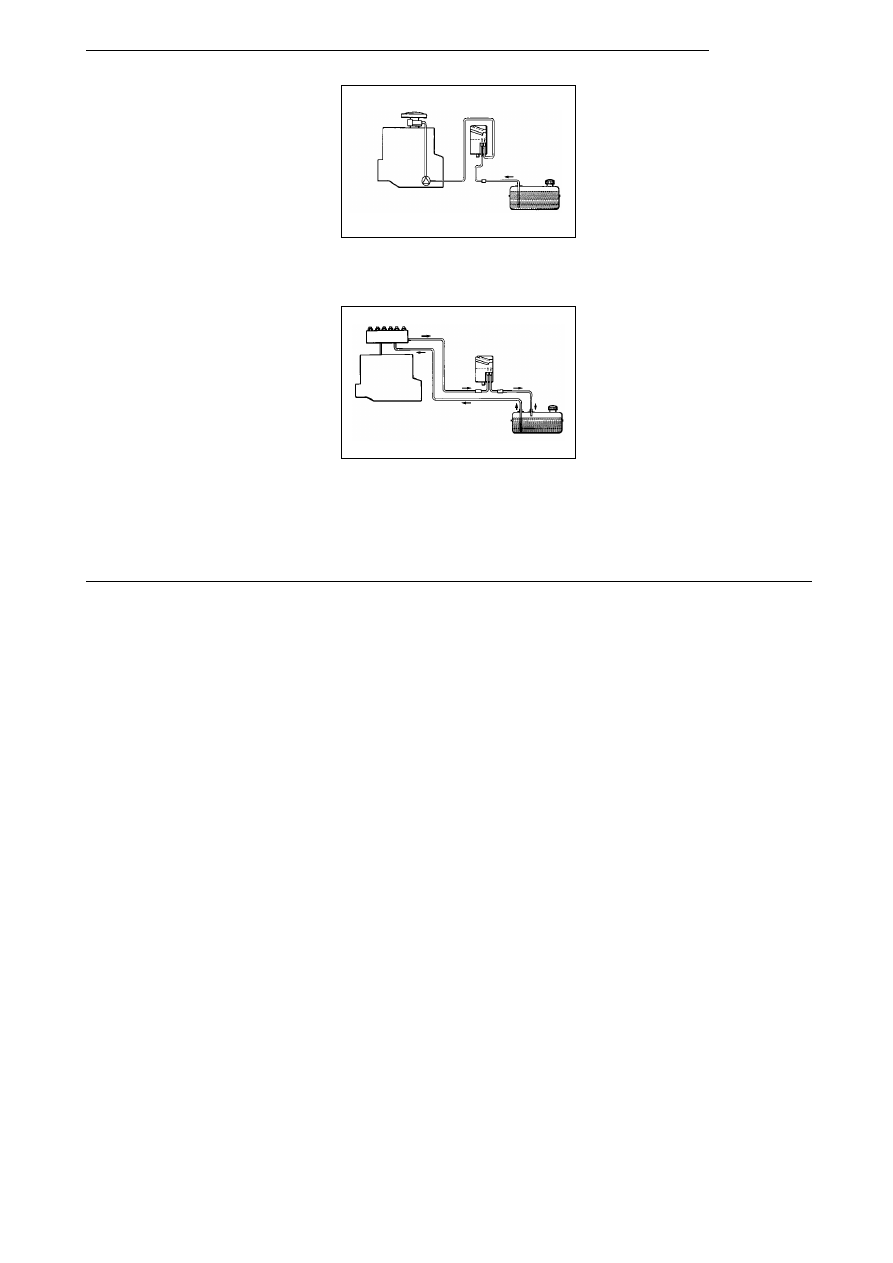

Fuel Installation

Fuel Supply

In the case of carburetor or injection engines equipped

with return line, the heater’s fuel supply circuit must be inte-

grated in the return line as shown in Fig. 8.

The direction arrows provided on the heater must be ob-

served.

In the case of carburettor engines without return line, the

fuel supply circuit of the heater must be integrated in the

flow line between vehicle fuel tank and pump as shown in

Fig. 7.

ANNOTATION

A fuel flow line can usually be identified by the in-line fuel

filter.

NOTE:

If the fuel system of the vehicle is equipped with a degass-

ing device, fuel extraction is to take place upstream of

same.

Fuel Lines

Only the special hoses supplied with the heater by We-

basto must be used as fuel lines between fuel connections

and heater. When using hoses, the joints are to be se-

cured using hose clamps. To prevent any sagging the fuel

line must be secured with clips.

Prior to cutting the fuel line open it must be clamped off or

a suitable vessel placed underneath the pipe.

Any fuel that may have leaked is to be removed from the

engine or heater prior to starting up the vehicle or heater

The fuel lines - not cut to length as yet - are to be con-

nected to the vehicle’s return line.

Keeping slack to a minimum, they are then to be routed

along any obstructing vehicle parts up to the fuel connec-

tions of the heater and the length thus obtained is to be

marked.

The fuel lines are to be cut off 35 cm longer than marked.

The excess length of the fuel lines of 35 cm is to be dis-

tributed evenly. The fuel lines are to be so fastened that

they will not be damaged by vehicle parts that may come

in contact with them.

The lines must be mounted in such a way that they are pro-

tected from mechanical damage (e.g. stones) and thermal

influence (e.g. exhaust pipe). If the fuel line is damaged

there is a danger of fire.

NOTE:

The hose clamps are to be tightened to a torque of 1.0 +

0.4 Nm.

Combustion Air Supply

Combustion air is to be drawn in from a location as cool as

possible and splash-proof via a combustion air line.

The combustion air line which is contained in the installa-

tion kit must not be extended.

It may be shortened to a min. of 500 mm.

The combustion air line may feature several bends (total of

270°, smallest bending radius 50 mm).

NOTE:

The combustion air line consists of an inside and outside

part.

Shorten combustion air line only at the end that is not pro-

vided with a fastening clip.

fuel pump

engine

carburator

Fig. 7:

Fuel Supply Circuit in the Single Line Sys-

tem (Carburetor Engine without Return Line)

“Inline Integration between Pump and Car-

buretor”

engine

injection system

flow pipe

return pipe

Fig. 8:

Fuel Supply Circuit in the Double Line Sys-

tem (Carburetor or Injection Motor with Re-

turn Pipe) “Inline Integration in Return Flow”

Thermo Top

5

Shorten combustion air line only at the end that is not pro-

vided with a fastening clip.

Prior to installing the heater make sure that the combus-

tion air intake connection has been mounted to the heater.

Under no circumstances must the combustion air be ex-

tracted from driver’s cabs or passenger compartments. If

the heater is installed in an enclosed housing a vent hole

of at least 3 cm

2

is required.

If the temperature in the installation housing exceeds the

permissible ambient temperature of the heater the vent

hole must be enlarged after consulting Webasto.

The combustion air intake opening must be so positioned

as to prevent any clogging due to contamination. It must

not point in the direction of travel.

When the heater is installed in the vicinity of the vehicle

tank in a common installation space, combustion air intake

must be from the outside of the vehicle and the exhaust

gas must be discharged to atmosphere. Appropriate cu-

touts must be splash-proof.

Support Plate

The support plate must be secured to the chassis or the in-

termediate support using at least 4 M6 screws.

It is mandatory that washers and spring lock washers be

used.

In the case of level chassis surfaces, the washers used

must be at least 22 mm in diameter.

No sheet-metal screws must be used to secure the heater

mounting plate (support plate).

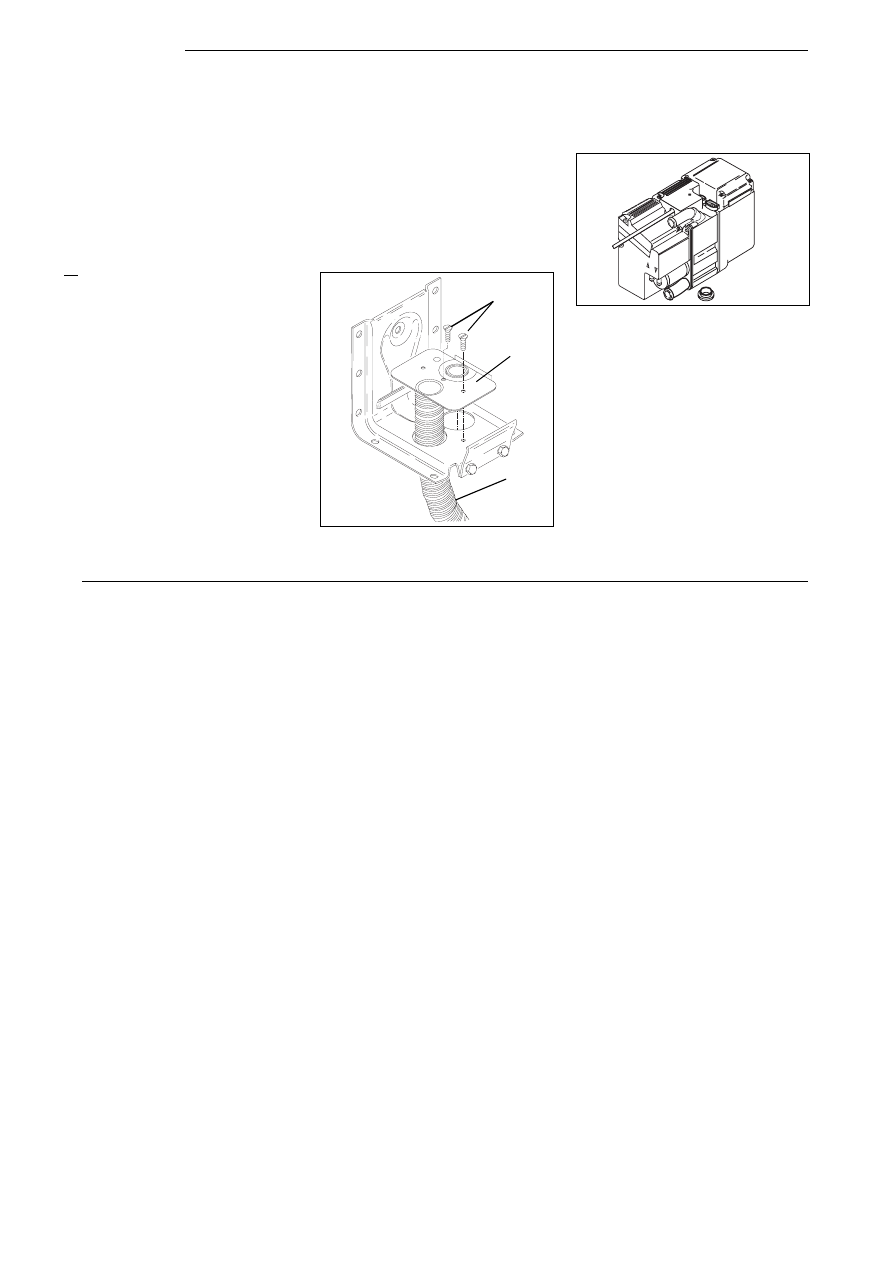

Insert Plate

The insert plate serves to connect exhaust gas and com-

bustion air lines.

The heater may be fastened to the mounting plate turned

by 180° provided the insert plate has also been turned ac-

cordingly.

The exhaust gas line is preassembled at the insert plate

whereas the combustion air line is to be attached by

means of a hose clamp during installation.

The insert plate is to be mounted to the bracket by means

of 2 M3 screws.

NOTE:

A coding is provided on the insert plate to ensure proper at-

tachment of exhaust gas and combustion air connections

of the heater relative to the insert plate.

Gasket at Exhaust Gas Outlet

Make sure that the gasket is fitted.

The gasket provided at the exhaust gas outlet of

the heater is to be replaced prior to each reinstal-

lation.

Exhaust Gas Pipe

The exhaust gas line (inside diameter 22 mm) is permitted

to have a length of up to 2 m and may feature several

bends (total of 270°, smallest bending radius 50 mm).

The exhaust gas line as a whole must not be shorter than

500 mm.

The exhaust muffler should preferably be installed near the

heater, but at least 200 mm away from the heater.

The exhaust silencer must not be mounted in the vicinity of

the combustion air intake opening.

M3 x 8 DIN695

Insert plate

Exhaust

gas pipe

CAUTION:

Do not use sheet-metal

screws for attaching in-

sert plate.

Fig. 9:

Insert plate

Mounting position

Fig. 10:

Exhaust Gas Seal

Thermo Top

6

The discharge opening of the exhaust pipe must

not point

in the direction of travel (see Fig. 12).

Rigid pipes made of unalloyed steel with a minimum wall

thickness of 1.0 mm or flexible tubes of alloyed steel are to

be used as exhaust pipes only.

NOTE:

Any collection of condensation water in the exhaust pipe

must be drained immediately; if required, it is permitted to

drill a condensation water drain hole

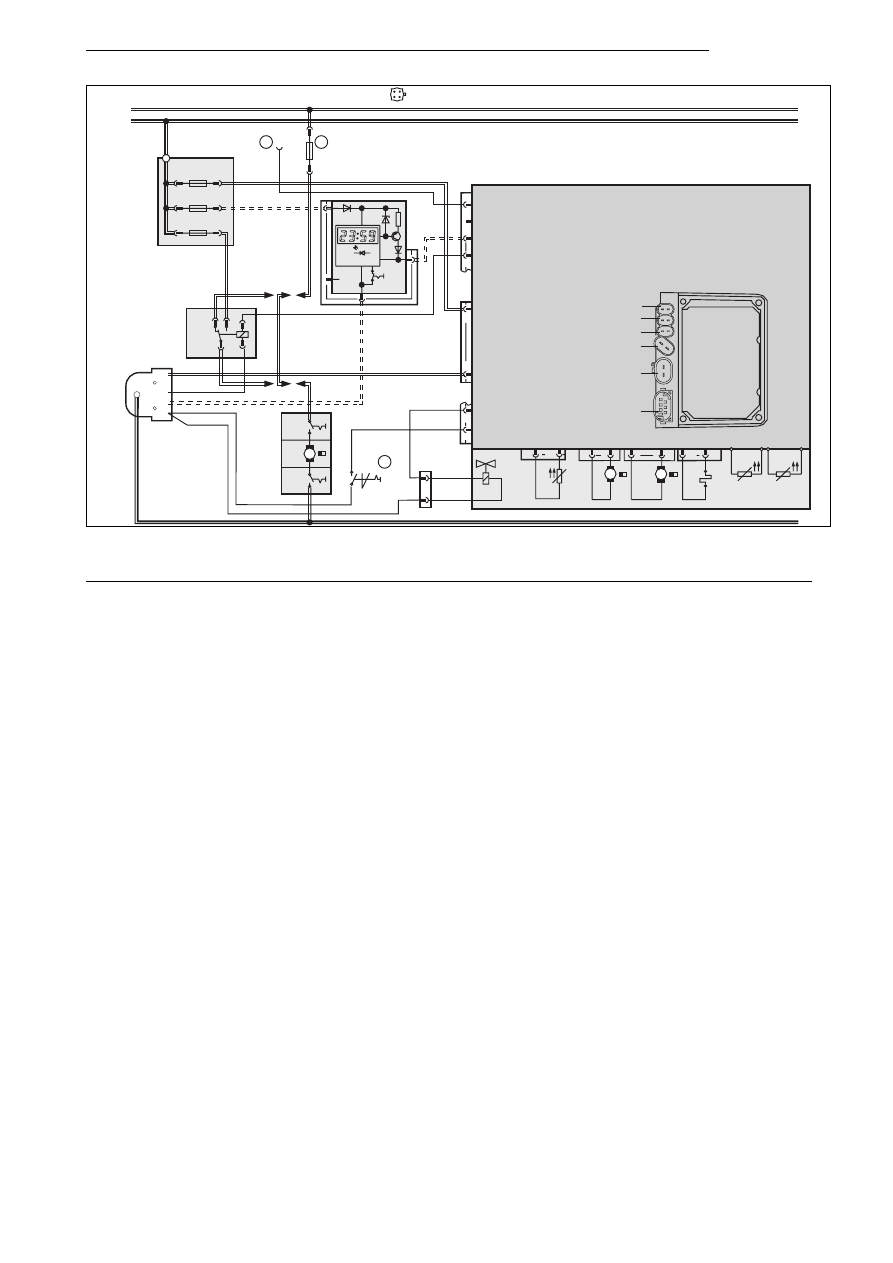

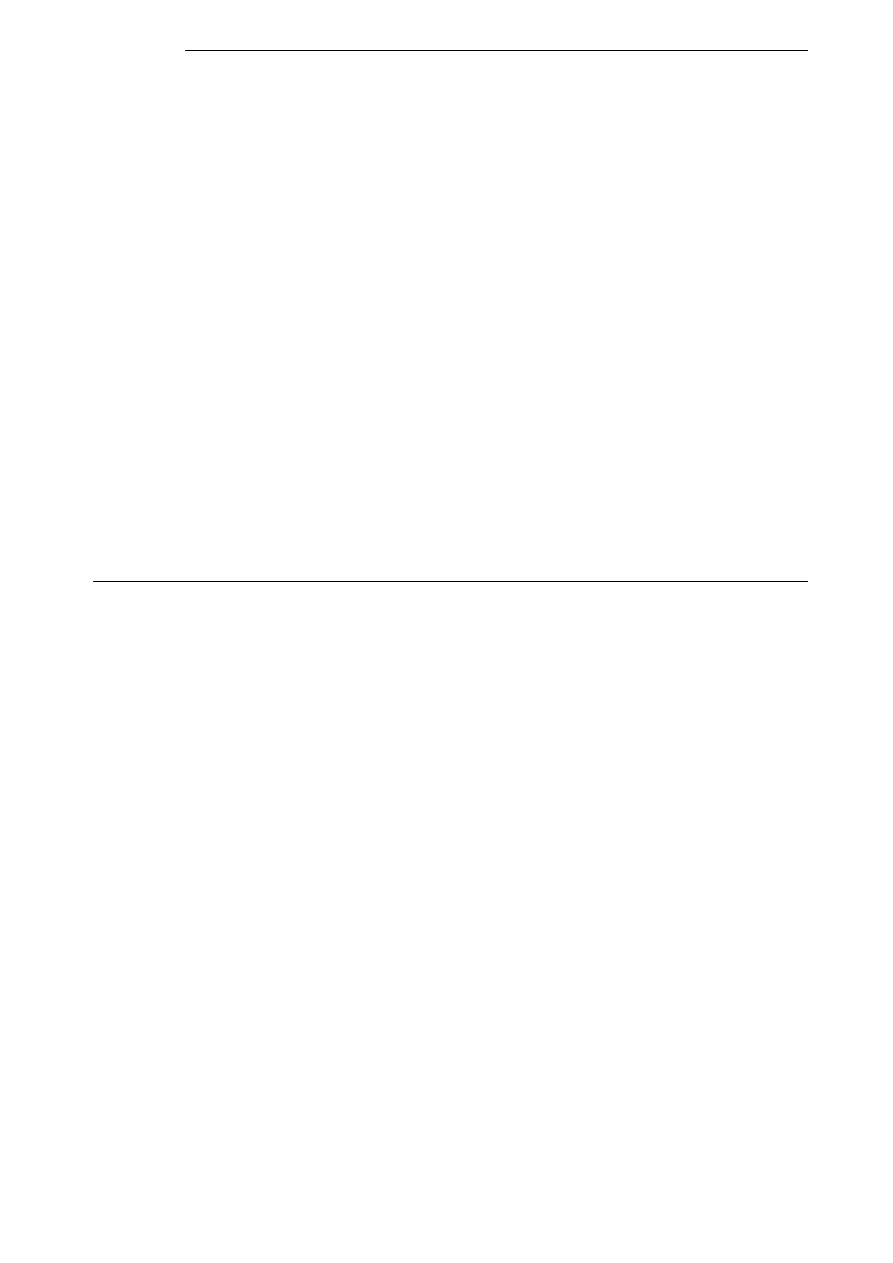

Electrical Connections

Control Unit/Heater Connection

The electrical connection of the heaters is to be performed

in accordance with Fig. 15.

Installation and Connection of Digital Timer

Installation of the digital timer is to be performed in accordance

with Fig. 13. A drilling template is part of the scope of delivery!

Connection of the digital timer is to be performed in accord-

ance with wiring diagram Fig. 15.

NOTE:

Do not press on the display panel during installation!

Vehicle Fan

The vehicle fan is activated via the vehicle fan relay fitted

to the fuse holder, see wiring diagram Fig. 15.

NOTE:

The connection terminal in the control unit (heater) is de-

signed for one fan relay (lmax = 0,5 A).

Connection of Summer/Winter Switch

NOTE:

It is not possible to connect a summer/winter switch when

a T70 is installed!

Connection of the summer/winter switch is to be performed

in accordance with Figs. 14 and 15.

NOTE:

The ends of the wires ’br’ and ’vi’ are inserted in the insula-

tion sleeving!

Installation of Telestart receiver T 70

The installation of the Telestart receiver and the aerial is to

be carried out in accordance with the T70 installation in-

structions.

’Teaching’ of Telestart transmitter

Following the installation of a Tele Thermo Top heater, the

transmitter must be allocated.

The Telestart transmitter must be "taught" in accordance

with the operating instructions.

Fig. 11:

Exhaust muffler

Direction of flow (not specified)

preferreed direction of discharge 90°

±

10°

Fig. 12:

Exhaust pipe discharge opening

Mounting position

Fig. 13:

Installation of Digital Timer

S5

br

plug

timer

vi

insulate

Fig. 14:

Connection of Summer/Winter Switch

Thermo Top

7

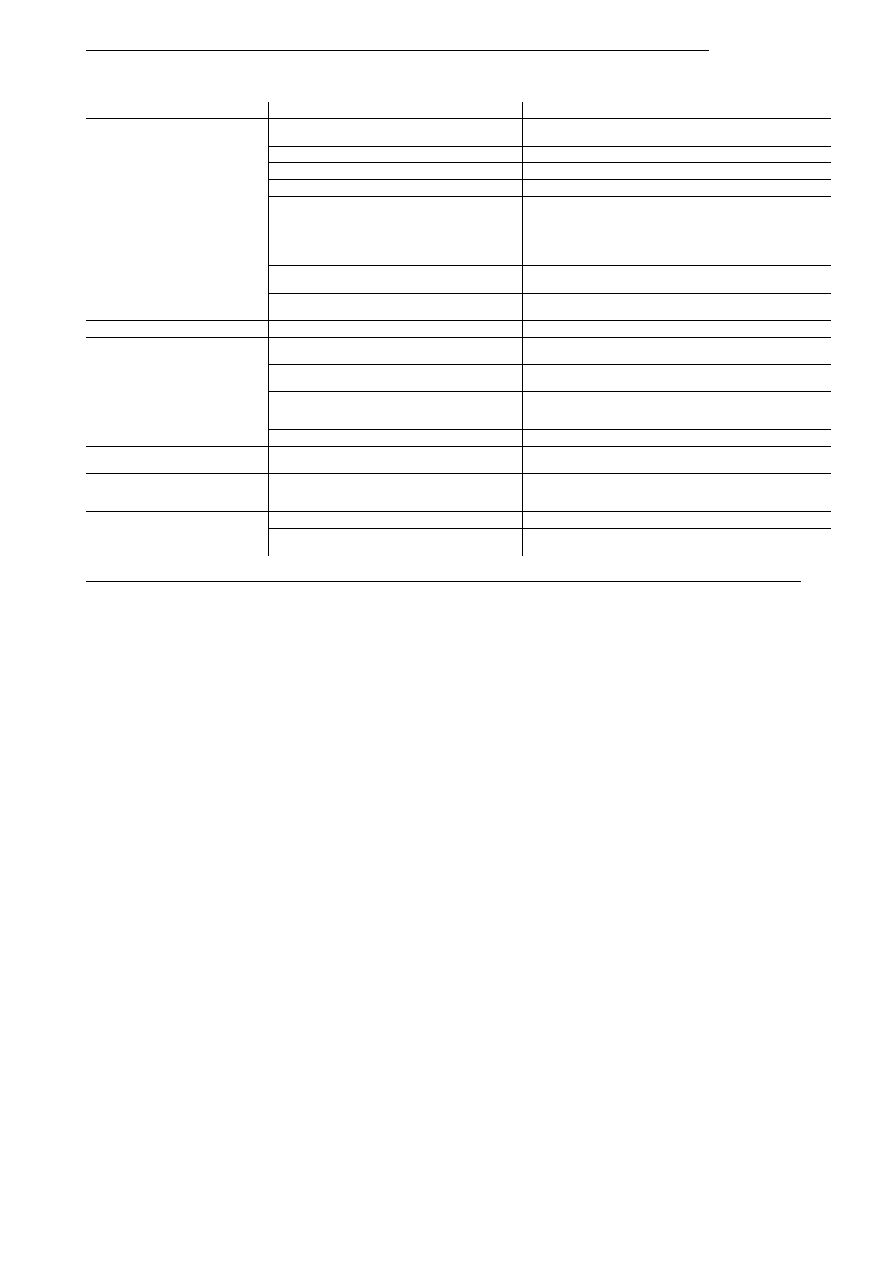

Pos. Designation

Remarks

A1

Heater

Thermo Top

A2

Electronic control unit

A3

Flat fuse holder

B1

Flame detector

B2

Temperature sensor

B3

Overheating thermostat

E

Glow plug

F1

Fuse 15 amp

blade-type acc. to SAE J 1284

F2

Fuse 1 amp

blade-type acc. to SAE J 1284

F3

Fuse 25 amp

blade-type acc. to SAE J 1284

H1

LED (in pos. P)

operation indicator

K3

Relay (in pos. A3)

vehicle fan

M1

Motor

combustion air fan

M2

Motor

circulating pump

M3

Motor

vehicle fan

P

Digital timer

for presetting operating times

S1

Switch for vehicle fan

S1 or S2 depending on vehicle

S2

Switch for vehicle fan

S1 or S2 depending on vehicle

S5

Switch

summer/winter switch

X9

Connector, 4-pole

X14

Connector, 6-pole

splash-water protected

X15

Connector, 2-pole

splash-water protected

X16

Connector, 2-pole

splash-water protected

X17

Connector, 2-pole

splash-water protected

X18

Connector, 2-pole

splash-water protected

X19

Connector, 2-pole

splash-water protected

X20

Connector, 2-pole

splash-water protected

X21

earth connection

Y2

Solenoid valve

Cable cross sections

< 7.5 m

7.5 - 15 m

0.5 mm

2

0.75 mm

2

0.75 mm

2

1.5 mm

2

1.5 mm

2

2.5 mm

2

2.5 mm

2

4.0 mm

2

4.0 mm

2

6.0 mm

2

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

blue

brown

yellow

green

grey

orange

red

black

violet

white

Legend for wiring diagrams:

➀

Diagnostic link

➁

Vehicle fan fuse installed in vehicle vorhanden

➂

Option

Thermo Top

8

M

M

M

-

+

(75) 15

30

rt

ge

OUT

sw

br

br

br

sw

Heiz

en

Lüften

bl

vi

+15

87a

86

85

87

30

31

I max. = 0,5 A

gn/ws

rt

rt

rt

br

br

4

3

2

1

2

1

6

5

2

1

2

1

1

1

2

2

ϑ

ϑ

ϑ

1

2

Y1

P

X9

X9

H1

B2

A1

X14

F1

F2

F3

K3

B3

M1

X17

X18

M2

X19

B1

A2

X14

X20

X21

X15

A3

1

3

2

S5

X16

E

M3

S2

S1

6

4

1

2

3

5

1

2

1

2

1

1

1

2

2

2

X14

X15

X16

X18

X19

A

B

C

X17

Fig. 15:

Automatic Control for

Thermo Top, Thermo Top T and Tele Thermo Top, 12V Digital Timer (Legend see page 8)

Thermo Top

9

Initial Operation

After the heater has been installed, the water circuit and

the fuel supply system are to be thoroughly bled. In so

doing the vehicle manufacturer’s instructions are to be ad-

hered to.

The fuel intermediate reservoir is to be filled by allowing

the engine to run for at least 2 minutes.

Perform a test run of the heater thereby checking all water

and fuel connections for leakage and secure attachment.

Should the heater fail during operation troubleshooting is

to be carried out.

Malfunctions

Shut-Down Due to Malfunctions of the Heater

If

no flame forms fuel is delivered for max. 170 seconds.

If

the flame goes out during operation fuel is delivered for

max. 85 seconds.

In the event of

overheating (tripping of safety thermostat),

fuel supply is immediately stopped.

In all cases (except of combustion air fan defects) an after-

run period of 120 seconds will follow if the system is shut

down on account of malfunctions.

CAUTION:

No indication occurs in the case of overheating.

Shut-Down Due to Undervoltage or Overvoltage

In the case of an undervoltage of 9,8

±

0.3 V (measured at

cable harness input) occurring over a period of 20 second-

s, the unit will be shut down and an after-run period of 120

seconds will follow.

In the case of an overvoltage of 15,5 + 0.5 V

(measured at the heater) occurring over a period of

more than 6 seconds, the unit will also be shut down

and an after-run period follows.

Interlock deactivation of the heater after a fault lock-

out situation

Fault lock-out deactivation is to be performed in accord-

ance with the operating instructions.

Thermo Top

10

Troubleshooting

Error Symptom

Possible cause

Remedy

Heater can’t be switched on

Heater is in the overheating lock-out mode

Remove 15A fuse

Determine cause

Summer/winter switch in summer position

Switch to correct position

Discharged battery

Charge

Defective fuse

Replace

Defective digital timer

Use testing device on heater and check if digital timer switches properly:

disconnect connector X14 from heater, connect testing device and switch

on digital timer. The indicator lamp must light up; if not, the timer is defective

and the power supply to the timer is disrupted.

Alternatively: Check if 12 V voltage is present across contact 1 (6-pole

connector).

Break in the power supply to the digital timer

Check if 12V voltage is present across the red and brown wires of the

connector of the digital timer. If necessary check fuse F2 and cables wires.

Break in the power supply to the heater

Disconnect connector X 15 from the heater and use the testing device to

check for presence of voltage.

Heater fails to ignite, fan motor is operating

Intermediate fuel reservoir empty

Allow vehicle engine to run for approx. 30 seconds

Heater operates for a few minutes only

Heater not seated properly in its support, exhaust gas is

aspirated

Loosen 2 M6 screws and position correctly

Fuel lines of heater not properly connected. Flow and return

pipes were interchanged.

Connect fuel lines in accordance with installation instructions

A non-return valve may have been installed in the fuel line

between heater and vehicle tank, or in the vehicle tank itself

(intermediate fuel reservoir is not ventilated).

Kinked coolant hose or system has not been bled completely

Check line routing, bleed cooling system (start engine)

Insufficient heat output

Heater control lever or vehicle fan out incorrectly set

Prior to operating the heater set heater control lever to "warm" and set fan

switch to a higher setting.

Vehicle fan fails to switch on when the thre-

shold temperature (>30° of coolant) is

reached

Defective fuse F3

Replace fuse

Blue smoke or soot in the exhaust gas,

heater is emitting smoke

Kinked or blocked suction or exhaust gas line

Check lines for unobstructed passage

Installation fault, heater is not properly seated in its support, or

gasket of exhaust gas pipe was not installed

Check installation

Thermo Top

11

Versions

Thermo Top

Petrol

type BW 50

Water heater for fuel “petrol” with

intermediate fuel reservoir.

Thermo Top

Diesel

type DW 50

Water heater for fuel “Diesel/fuel

oil EL” with intermediate fuel reser-

voir

The water heaters

Thermo Top

are designed to operate on 12

volts.

Thermo Top

12

Technical Data

Unless limit values are indicated, the technical data shown

in the Table on the right apply with the usual

±

10% toler-

ances for heaters at an ambient temperature of +20°C and

at rated voltage.

Fuel for

Thermo Top

(Petrol) type BW 50:

The type of fuel prescribed by the manufacturer of the ve-

hicle may be used.

Fuel for

Thermo Top

(Diesel/fuel oil EL) type DW 50:

The Diesel fuel recommended for use by the vehicle manu-

facturer is suitable as fuel for the heater.

Any negative effect caused by additives is not known.

Heater

Operation

Petrol

type BW 50

Diesel

type DW 50

Mark of confirmity

~S238

~S239

Type

Water heater with

vaporizing-type burner

Heat output

full load

part load

5,0 kW

2,5 kW

Fuel

Petrol

Diesel/EL fuel oil

Fuel consumption

full load

part load

0,67 l/h

0,33 l/h

0,59 l/h

0,29 l/h

Rated voltage

12 Volt

12 Volt

Operating voltage range

10 ... 14 Volt

Rated power consumption with circulation pump

(without vehicle fan)

full load

part load

44 W

27 W

44 W

27 W

Max. ambient temperature:

Heater:

-

operation

-

storage

-40°... + 60°C

-40°... +120°C

-40°... + 80°C

-40°... +120°C

Max. allow. working pressure

(heat transfer medium)

0,4 ... 2,0 bar

Heat exchanger capacity

0,15 l

Min. cooling system capacity

4,00 l

Flow rate of circulating pump at roughly 0,1 bar

500 l/h

CO

2

content in exhaust gas (perm. operating range)

9,5 ... 12,0 Vol .-%

Dimensions of heater

Length 240 mm

Width 103 mm

Height 168 mm

Weight

4.3 kg

HEIZGERÄT Typ

Wärmestrom

Spannung/El.Leistung

Brennstoff

zul. Betriebsüberdruck

Ident Nr. 908868

Inbetriebnahmejahr

Prüfzeichen

2 bar

S 236

Benzin

5 KW

12V/44W

BW 50

01

20

00

20

99

19

Ausf. 34 Fabr.Nr.

Thermosysteme GmbH

MADE IN

GERMANY

021279

e1

Fig. 16:

Type plate

Thermo Top

13

A

CND

J

ZA

AUS

NZ

FIN

NL

B

RA

GB

P

RCH

GR

PL

H

RF

USA

I

SLO

IS

SW

SK

L

TR

UA

N

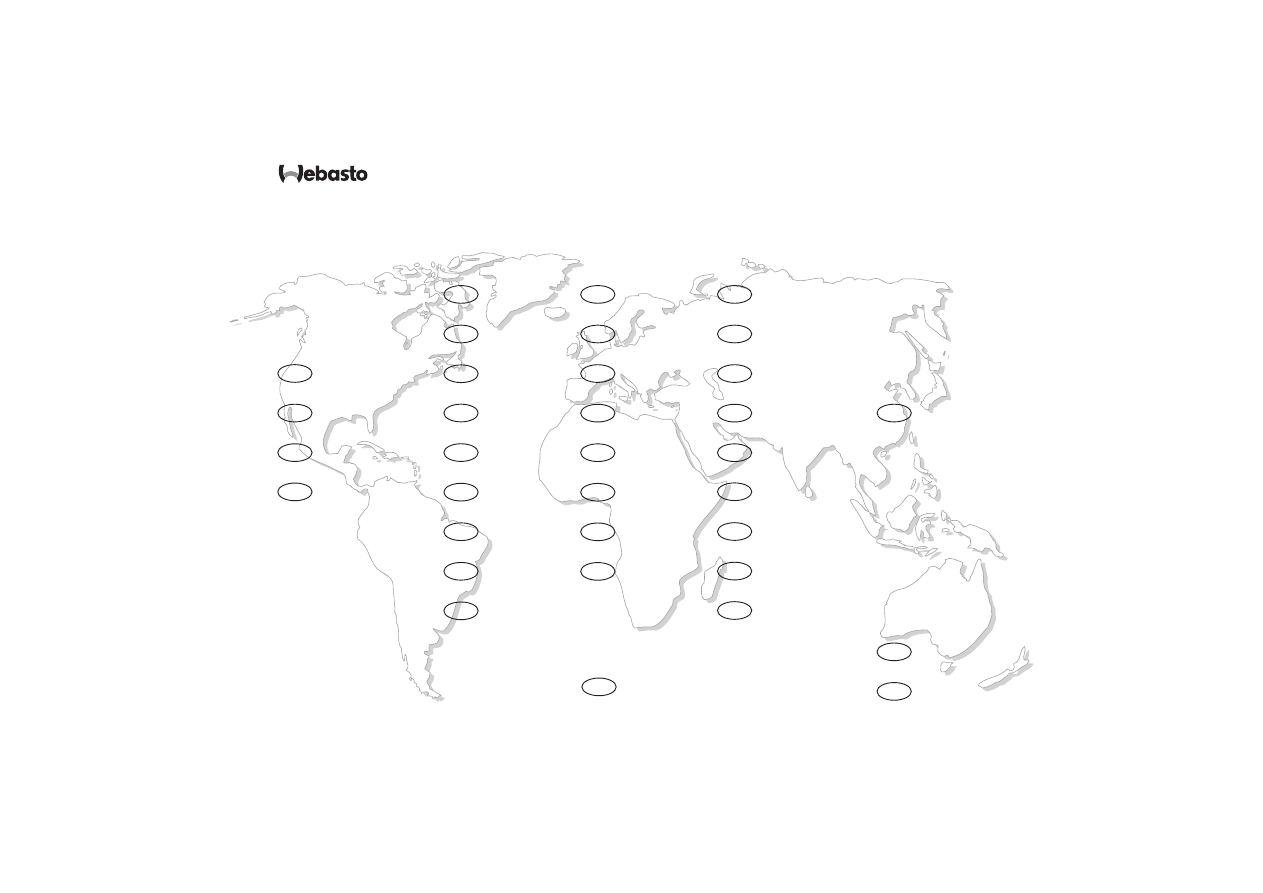

Service Phone Line

In case you encounter technical problems with your auxiliary heater -

Simply dial the

for your country as indicated below.

Webasto's Top Service for our customers

Webasto's world-wide Service Network will be glad to assist you!

Service Phone Number

Europe

America

Asia

Africa

Australia

Austria

Vienna

01-6043780

Belgium

Brussels

02-558 06 60

Switzerland

Allschwil

061-486 95 80

Czech Republic

Praha

02-464 468

Germany

Stockdorf

01805-932278

Denmark

Copenhagen

036-78 66 66

Spain

Sant Just Desvern

03-473 15 00

France

Maisons Alfort

01-45 18 35 35

Bulgarien

Sofia

02-9559536

Canada

Ontario

0905-335 41 34

Argentinia

Buenos Aires

01-746 96 00

Chile

Santiago de Chile

02-234 43 11

United States

48446 MI

0810-245 24 00

Japan

Tokyo

03-343 221 76

South Africa

Wetton

021-761 99 71

Australia

South Melbourne

03-699 83 22

New Zealand

Wellington

04-568 42 89

Finnland

Helsinki

0-968271

Great Britain

Doncaster Carr

01302-322232

Greece

Athen

01-252 09 96

Hungaria

Budapest

01-350 23 38

Italy

Milano

02-413 01 01

Iceland

Gardabae

354-567 2330

Luxembourg

Brussels

02-558 06 60

Norway

Oslo

022-709 000

Netherlands

Almere-Buiten

036-535 91 11

Portugal

Lisbon

01-363 99 50

Polen

Lomianki

4822-751 77 87

Russia

Moscow

095-917 18 10

Slovenia

Ljubljana

061-553 161

KoŠice

01-957 477 92

Sweden

Stockholm

08-923 00

Turkey

Istanbul

0212-623 21 35

Ukraine

Lwiw

0322-911 564

BG

CH

CR

D

DK

E

F

Slowakei

Document Outline

- Operating Instructions

- Table of contents

- Legal Provisions

- Use of the Water Heater

- Installation Location

- Nameplate

- Connection to the Vehicle Cooling System

- Installation example

- Fuel Installation

- Combustion Air Supply

- Support Plate

- Insert Plate

- Gasket at Exhaust Gas Outlet

- Exhaust Gas Pipe

- Electrical Connections

- Initial Operation

- Malfunctions

- Shut-Down Due to Undervoltage or Overvoltage

- Interlock deactivation of the heater after a fault lockout situation

- Troubleshooting

- Versions

- Technical Data

- Service Phone Line

Wyszukiwarka

Podobne podstrony:

Webasto - Thermo Top Z-C - opis, Webasto

MAN Ogrzewanie Webasto Thermo 230,300,350 obsługa i montaż(1)

MAN Ogrzewanie Webasto Thermo 230,300,350 obsługa i montaż(1)

Thermo Top ZC

Schemat Thermo Top V

MAN Ogrzewanie Webasto Thermo 230,300,350 obsługa i montaż(1)

Thermo Top Z C opis i schematy [EN]

Instrukcja Obsługi AIR TOP WEBASTO

01 Top 20 ports

01 Thermoregulation, Fever PLid Nieznany (2)

HD44780 ATTINY13 BOARD TOP MIRROR

Opisy top osnowa AGH syt i wykaz wys

Linear Technology Top Markings Nieznany

blokada samochodu, Top Silkscreen Overlay

pcb pdf, Top Paste Mask Print

egz top pyt 130206 odp

Instrukcja montażu Air Top 3500 ST

więcej podobnych podstron