Władysław DYBCZYŃSKI

Bialystok University of Technology

Application of Light Emitting Diodes for local lighting

Abstract. The paper presents possibilities of illumination of work areas with white Light Emitting Diodes (LED). The work task area is illuminated

with a local lighting fitting and with a general lighting system (producing illumination 300 lx) as well. Geometry of the lighting system has been

discussed: illuminated work area, visual task area and position of the lighting fitting. Computer simulation of lighting systems based on different types

of LEDs and analyses of results of lighting of a reference work area have been carried out. Technical parameters such as average illumination on

the visual task area and its neighbourhood, illumination uniformity and coefficient of utilisation have been determined.

Streszczenie. Przedstawiono możliwości oświetlenia miejsc pracy za pomocą diod elektroluminescencyjnych, emitujących światło białe. Oprócz

oświetlenia miejscowego powierzchnia pracy wzrokowej jest oświetlona światłem ogólnym z natężeniem oświetlenia wynoszącym 300 lx. Omówiono

geometrię związaną z technologią oświetlenia: wymiary powierzchni roboczej, powierzchni pracy wzrokowej i usytuowanie oprawy oświetlenia

miejscowego. Drogą symulacji komputerowej przeprowadzono analizę możliwości oświetlenia powierzchni odniesieniowej za pomocą diod LED

różnego rodzaju. Wyznaczono: średnie natężenie oświetlenia, równomierność natężenia oświetlenia oraz sprawność oświetlenia. (Zastosowanie

diod elektroluminescencyjnych do oświetlenia miejscowego).

Keywords: local lighting, light emitting diodes.

Słowa kluczowe: oświetlenie miejscowe, diody świecące.

Introduction

It is expected, that the development of Light Emitting

Diodes (LEDs), will be followed by new applications. For the

time being, power of LEDs is small and their cost

comparatively high so their use for lighting big areas with

high illumination levels would not be reasonable.

Nevertheless there are some specific areas in which their

application can be justifiable.

In the paper a possibility of illumination of a desk using a

lighting fitting with white LED diodes with rotationally-

symmetrical light distribution has been analysed. Such

diodes are offered by different manufacturers. Technical

data of such diodes greatly differ from those of conventional

light sources. Basic catalogue data for some selected

diodes are shown in Table 1.

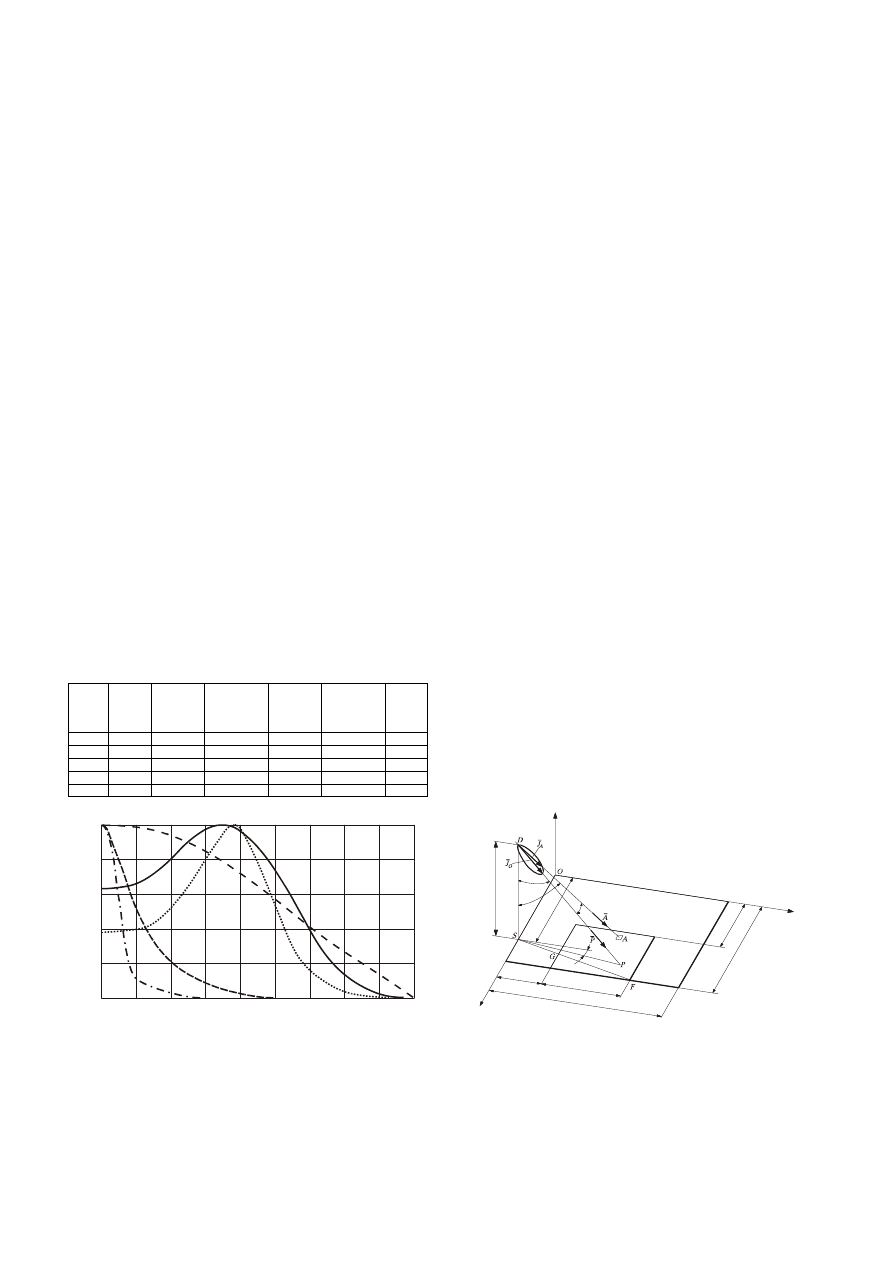

Table 1. Technical data of Light Emitting Diodes

No. Pow-

er

[W]

Lum.

flux

[lm]

Lum.

effic-

iency

[lm/W]

Colour

temp.

[K]

Light

distr.

Plot

no.

on

fig.1

1 1 20 20 3

300

Limited 1

2 1,1 21,7 19,7 6

000 Limited 2

3 1,3 17,1 13,2 5

500 Narrow 3

4 1 12 12 6

000

Narrow 4

5 3 66 22 5

600

Cosine 5

Fig. 1. Light distribution curves of selected LED diodes

On Figure 1 light distribution curves of selected diodes

are shown. Diodes No. 1 and 2 are designed for lighting of

flat surfaces illuminated from the normal direction with

uniform illumination. The size of illuminated area depends

on the distance between the light source and the illuminated

surface and is determined by the angle 2 x 38° (plot l) i 2 x

40° (plot 2). Plots No. 3 and 4 are light distributions of

elements equipped with lenses. These narrow-beam diodes

are designed for directional lighting and are applied in

torches, in bike headlights, in visual signalling devices and

in local lighting fittings.

The most popular are LEDs with cosine (Lambert) light

distribution (plot 5). They have the highest luminous

efficiency and they find many applications. They can be

applied also for local lighting but a useful light output ratio of

a fitting with such diodes (coefficient of utilisation) will be

small. It will also depend on a position of the fitting with

respect to the illuminated area.

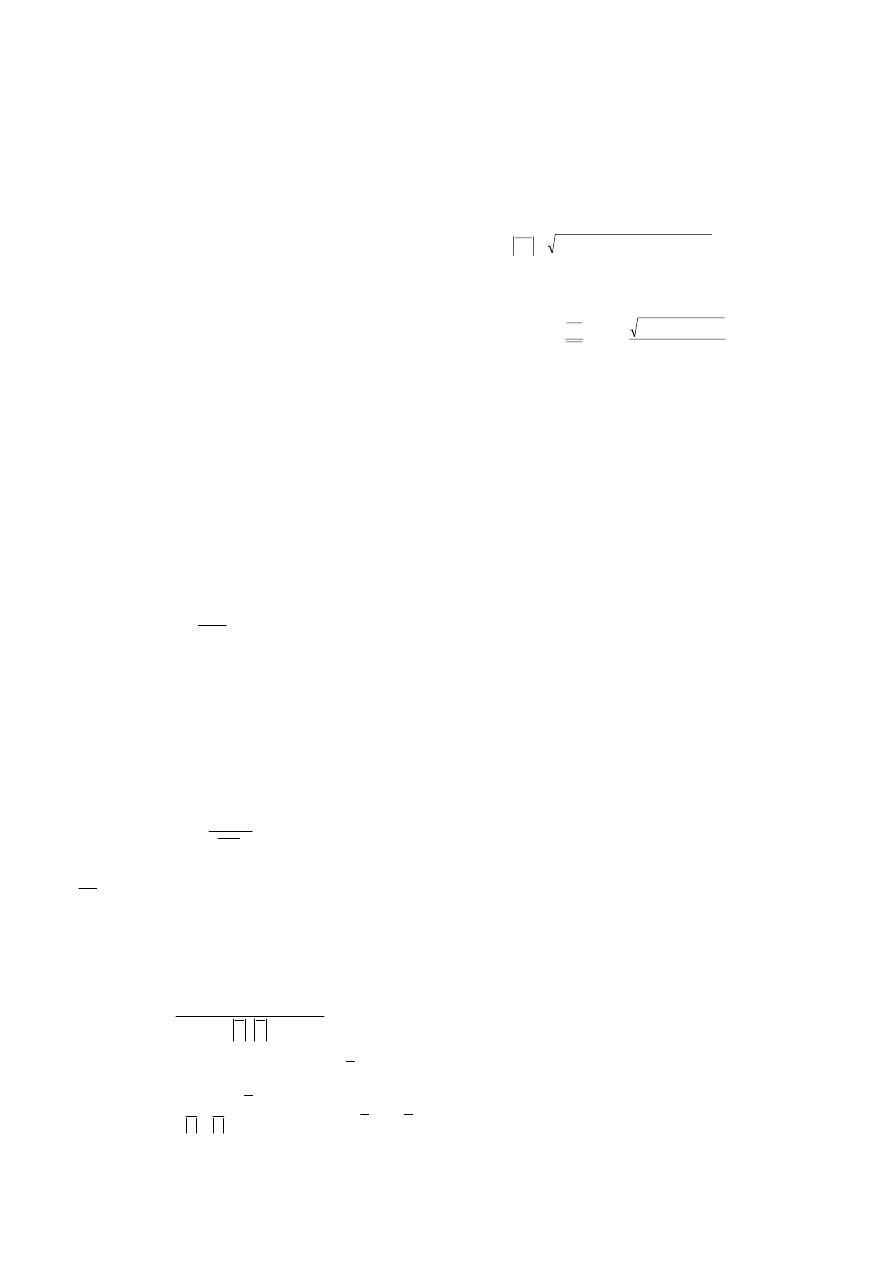

Geometry of the Work Place

The work place taken as a base for following

discussions is a top of a desk with dimensions 600 x 900

mm. The work task area situated on the desk top has the

size of an A3 paper (ca. 300 x 420 mm). The work task area

is adjacent to the longer side of the desk and is situated

symmetrically - its transverse axis of symmetry and the

transverse axis of symmetry of the desk are the same (see

Fig. 2). The work place is illuminated by general lighting

fittings with illumination equal to 300 lx. The assumed

uniformity is 100%.

d

e

b

c

f

h

a

y

x

z

α

γ

β

ε

0

10

20

30

40

50

60

70

80

90

1,0

0,8

0,6

0,4

0,2

0

o

o

o

o

o

1

2

3

4

5

o

Fig. 2. Geometry of the desk lighting

The task field is additionally illuminated by a local

lighting fitting. The luminous central point of the lighting

(point D) is situated above the left edge of the desk, on the

height h. The projection of the central point of the fitting on

the desk surface (point S) is situated at a distance f from the

opposite, longer edge of the desk.

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

11

The symmetry axis of the surface of intensity distribution

of the LED located in the local lighting fitting, intersects the

desk surface at the point P. Usually there are several diodes

in one fitting. All points P should be situated in such a way,

that illumination on the visual task area is equal to 200 lx

multiplied by the depreciation

factor (k = 1,3). As a result of

general and local lighting,

illumination on the area will reach

the value of 560 lx, which will conform the standard [1].

According to the requirement of the standard, uniformity of

the illumination on the visual task area should not be less

than 0,7 and in the direct environment of the area – not less

than 0,5.

If the total flux of the a.m. lighting fitting is directed to the

visual task area, the coefficient of utilisation would be at its

maximum. In reality, this can not be reached. A part of

luminous flux will always be directed outside the area, and

even outside the desk.

The above mentioned requirements, together with the

coefficient of utilisation, form a basis for analyses of

application of LEDs for local lighting.

Direction of the LEds Light Beam

Calculations of illumination obtained by the way of local

lighting are carried out with the point by point method, which

means that dispersed light is not taken into account. The

visual task area and its direct surrounding (the desk top) is

divided into equal elementary fields, each of them being a

square or a similar geometrical figure. In the present

analysis, the longer side (d) of the visual task area is divided

into m

x

= 26 elements, which means that the distance

between calculation points will be Δx = 16,15 mm.

The number of calculation points alongside y axis can be

calculated from the formula

(1)

19

9

,

0

=

⎟

⎠

⎞

⎜

⎝

⎛

+

⋅

−

=

x

y

m

d

e

b

INT

m

thus the distance between calculation points will be Δy =

15,79 mm.

The area of the desk has been divided into 56 parts

alongside axis x, and into 38 parts alongside axis y, which

gives as a result 2128 elementary fields, including 494 fields

on the visual task area.

Point A, which is situated in the centre of each

elementary field, is illuminated with the luminous intensity

vector I

A

, which produces illumination E.

(2)

2

)

(

cos

AD

I

E

A

γ

=

where: I

A

– luminous intensity vector directed at the point A,

AD – distance between the diode lighting centre and the

point A,

γ

– luminous ray incidence angle.

The value of the vector I

A

can be determined from LED

light distribution f(

ε

) and the angle

ε

. The angle can be

calculated from the formula:

(3)

A

P

P

A

P

A

P

A

z

z

y

y

x

x

⋅

⋅

+

⋅

+

⋅

=

ε

cos

where: A

x

, A

y

, A

z

– components of the vector A , determining

the direction of the light intensity vector I

A

, P

x

, P

y

, P

z

–

components of the vector P , determining the direction of

the axis vector I

0

,

P

A ,

– modules of vectors A and P .

The diode light distribution is usually presented in a

table form, so values of I

A

(4)

)

(

ε

f

I

I

o

A

⋅

=

are determined with parabolic interpolation.

When co-ordinates of points A and D are known, the

distance between them can be calculated from the formula:

(5)

2

2

2

)

(

)

(

D

D

A

D

A

z

y

y

x

x

AD

+

−

+

−

=

.

The angle of incidence

γ

applied in formula (2) is

calculated from the trigonometric formula

(6)

h

y

y

x

DS

AS

S

A

A

2

2

)

(

arctan

arctan

−

+

=

=

γ

.

Usually a visual task area must be illuminated with a

few, and sometimes with a few dozens LEDs, so

illumination value at the selected point A is a sum of

individual illumination values produced by each source.

(7)

∑

=

=

n

i

A

E

E

1

where: n – number of LED diodes.

Results of calculations based on earlier presented light

distribution curves are shown in Table 2.

In case of diodes with wide light distribution (No 1, 2 and

5) only one position of point P, close to the centre of the

visual task area, has been assumed. Shifting the position of

the point P has practically no effect on the calculation

results. But in case of narrow beam diodes it was necessary

to distribute points P for particular light sources in such a

way, that the required illumination level (E = 560 lx) and

uniformity of illumination (

δ

= 70%) could be obtained.

It should be noted, that diodes No 1 and 2, if situated

over the visual task area with their axis perpendicular to it,

illuminate the area with high uniformity. However, if they are

situated askew, they illuminate a side part of the desk with

bigger illumination, than that on the visual task area.

Maximum value on the surrounding area equals to 1191 lx

and 1769 lx respectively. Luminous flux falling on the visual

task area equals to 5,1% and 4,3% of the total flux emitted

by the light sources. Therefore such LED diodes cannot be

applied for local lighting.

Cosine (Lambert) light distribution (LED No 5) is also too

wide. A change of position of points P only slightly changes

results of the calculations. Maximum value of illumination on

the area surrounding the visual task area is 821 lx, and the

coefficient of utilisation

η

= 7,4%. It is also too small to

recommend such light sources for local lighting.

Light distribution of diodes No 3 is characterised with

following useful angles:

δ

0,5

= 21° and

δ

0,1

= 56°. Situating

points P in the way shown in Table 2, only five diodes were

necessary to obtain required lighting parameters (E,

δ

). The

obtained coefficient of utilisation was

η

= 38,4%. By

changes of positions of points P, higher average illumination

can be obtained, but with poorer uniformity. Changes of

average illumination (E) and the coefficient of utilisation (

η

)

as a function of lighting uniformity (

δ

) are shown on Figure

3. As it was expected, increased uniformity is followed by a

decrease of illumination and of the coefficient of utilisation.

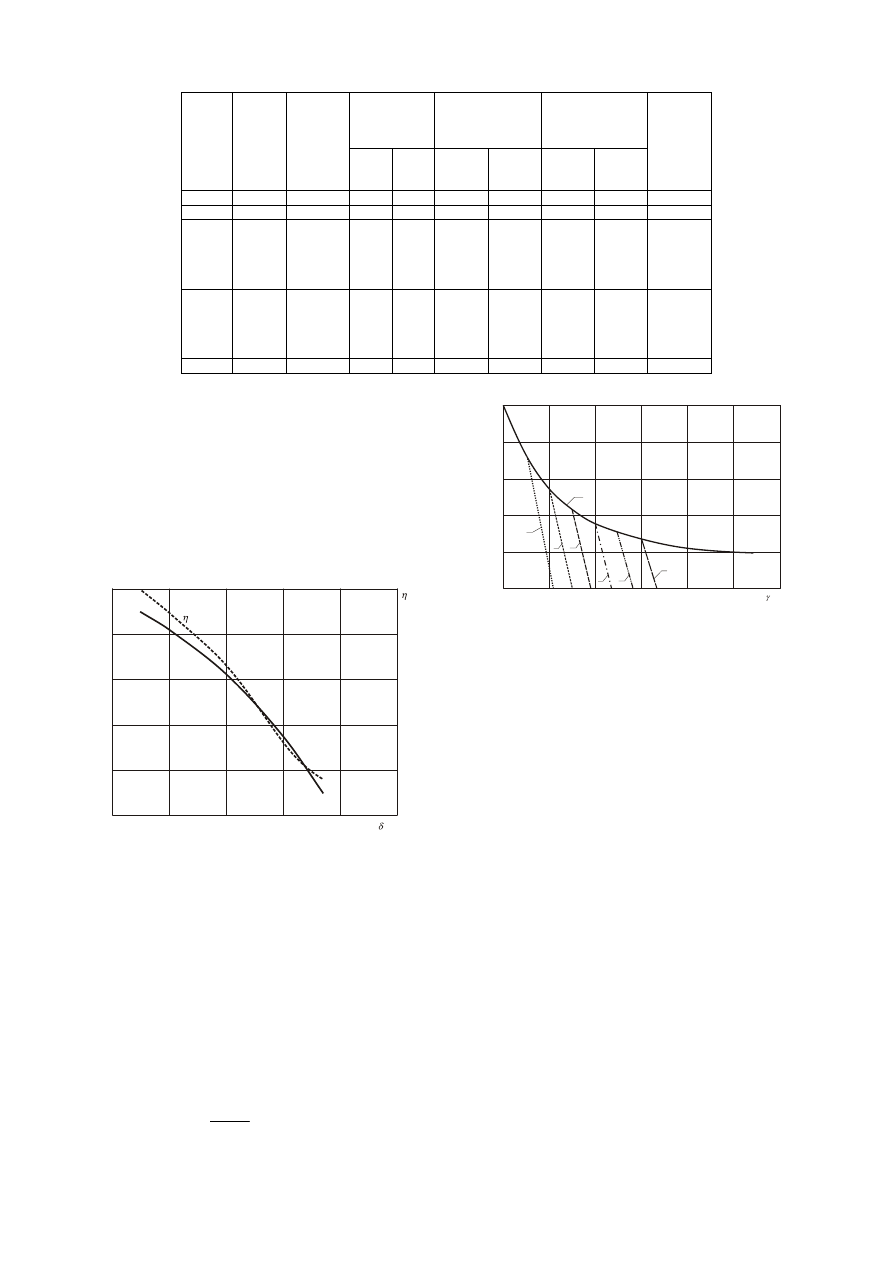

Table 2. Positions of calculation points P and results of lighting calculations

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

12

Position of

calculation

points P

[mm]

Average

illuminance

[lx]

Illuminance

uniformity

Light

distri-

bution

no.

No. of

diodes

n

Total

luminous

flux

[lm]

x

P

y

P

Visual

task

area

Rem.

part of

desk

Visual

task

area

Rem.

part of

desk

Coeffi-

cient of

utiliza-

tion

η

u

1 32 640

450

450

560,5

629,8

77,8%

60,4%

5,1%

2 35 760

450

460

559,2

739,5

77,2%

51,9%

4,3%

3 5 85,5

480

560

480

560

520

420

420

480

480

450

560,3 358,5 75,8% 83,7% 38,4%

4 5 60

320

570

320

570

530

350

350

340

560

450

591,1 332,9 74,5% 90,1% 61,1%

5 7 462

450

450

572,0

519,3

76,4%

67,5%

7,4%

Diodes No 4 have a still narrower light beam (

δ

0,5

= 11°;

δ

0,1

= 21°). Required lighting parameters can be obtained

using five such diodes. The coefficient of utilisation in this

case is

η

= 61,1%, in spite of lesser luminous efficiency

(compared with other LEDs).

In case of narrow beam diodes, better lighting uniformity

can be obtained by increasing number of diodes. On the

other hand, the coefficient of utilisation can be increased by

diminishing lighting flux radiated outside the useful angle.

Therefore a LED diode with an improved light distribution

should be elaborated.

500

520

540

560

580

lx

600

65%

70%

75%

80%

85%

E

E

30%

35%

40%

Fig. 3. Plots of average illumination (E) and the coefficient of

utilisation (

η

) as a function of lighting uniformity (

δ

)

A new structure of intensity distribution of a LED diode

If we assume, that the axis of the surface of intensity

distribution is directed to a corner of the visual task area

(point F on fig. 2), it would be possible to determine such a

curve of intensity distribution, which leads to constant

illumination on the segment FG.

If the surface of intensity distribution has a rotational

symmetry, illumination in a direction perpendicular to the

segment FG will change according to cosine function. With

the geometry described above, angle of incidence of the

luminous intensity vector at the point F is

γ

= 54°. Therefore

the curve of intensity distribution as a function of the angle

γ

can be determined using the formula:

(8)

γ

3

2

cos

h

E

I

=

0

0,2

0,4

0,6

0,8

1,0

0

10

20

30

40

50

60

J

o

o

o

o

o

o

o

1

2

3

4

5

6

7

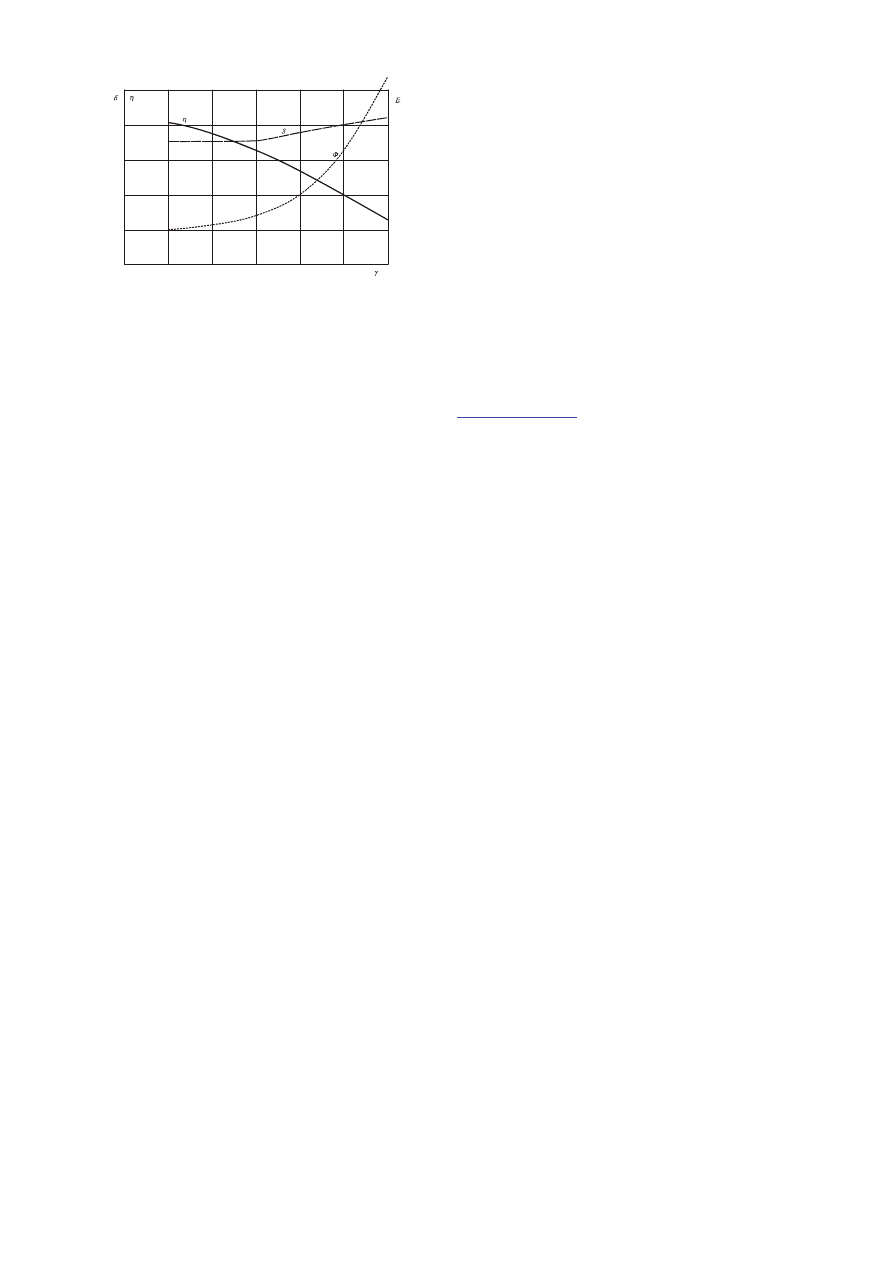

Fig. 4. Curves of intensity distribution of LED diodes

The curve of intensity distribution has been presented

on Figure 4 (plot 1). The useful angle of the diode can be

selected in such a way, that the segment from point F to

point G (Fig. 2) is illuminated. In the discussed example it

will be

γ

= 28°. Figure 4 presents a few curves of intensity

distribution with different useful angles. A fall of luminous

intensity outside the useful angle

γ

has been designed in

such a way, that the fall is ca. 0,1 per 1

°. Plot 2 results in

constant illumination on the segment from point F in the

direction to point G within the angle 5

°, plot 3 – within the

angle 10

° and so on up to the plot 7 which gives constant

illumination within the angle 30

°.

Results of simulation of illumination of the visual task

area with such diodes are presented on Figure 5. The

smaller is the angle (

γ

), the smaller is luminous flux (

Φ

)

necessary to produce required illumination on the area. It is

a result of higher coefficient of utilisation – with smaller light

distribution angles (

γ

), bigger part of the flux falls on the

visual task area. In case of diodes with light distribution

angles smaller than 15°, it is necessary to apply a few

diodes (four) to obtain illumination uniformity equal to 0.7.

The highest coefficient of utilisation is obtained for a fitting

with four narrow beam diodes (light distribution angle

γ

= 5°

and useful angle δ

0,5

= 14°). Luminous flux equal to 40 lm

will be enough to illuminate an A3 sheet with illumination

equal to 560 lx (including 300 lx from general lighting) with

uniformity not less than 0.7. But LEDs light distribution

should conform to the plot 2 (Fig. 4) and LED axes of

symmetry should be aimed at defined points P on the work

area.

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

13

0

0,2

0,4

0,6

0,8

1,0

0

5

10

15

20

40

20

25

30

60

80

100

120

o

o

o

o

o

o

o

[lx]

Fig. 5. Changes of luminous flux (

Φ

), useful coefficient of utilisation

(η) and uniformity of illumination (δ) in relation to the light

distribution angle (

γ

) of LED diodes

Remarks and conclusions

LED diodes with a Lambert light distribution can be

applied for illumination of visual task areas, but their

coefficient of utilisation is very small – equals to 7,4%, while

20% of the flux falls on the surrounding area (desk top) and

more than 72% - outside the desk.

Application of LED diodes with specific light distribution

may lead to even better coefficient of utilisation. Simulated

calculations for diodes with light distribution presented by

plot No 2 (on Fig. 4) show, that 81,9% of the total flux of the

lighting fitting falls on the visual task area and 12,8% on its

surrounding (totally above 94%).

The above reasoning leads to the conclusion, that it is

advisable to elaborate a specific local lighting fitting for LED

diodes with cosine light distribution, which uses an optic

system. Such a system (dioptic and/or catoptric) should

provide the required light distribution designed according to

requirements of work stands illumination.

The work was conducted at Bialystok University of Technology

within the statutory task S/WE/2/03

REFERENCES

[1] Polish Standard PN-EN 12464: 2004-1. Light and lighting.

Illumination of work places. Part 1. Work places in interiors

___________________

Author: prof. D.Sc. Władysław Dybczyński, Bialystok University of

Technology, ul. Wiejska 45D, 15-351 Białystok, Poland, E-mail:

PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 83 NR 5/2007

14

Wyszukiwarka

Podobne podstrony:

Light Emitting Diodes

Applications of polyphase filters for bandpass sigma delta analog to digital conversion

94 1363 1372 On the Application of Hot Work Tool Steels for Mandrel Bars

Applications of polyphase filters for bandpass sigma delta analog to digital conversion

Application of LEDs in road lighting

Smarzewska, Sylwia; Ciesielski, Witold Application of a Graphene Oxide–Carbon Paste Electrode for t

Global Requirements for Medical Applications of Chitin and its Derivatives

Munster Application of an acoustic enhancement system for outdoor venues

Light quality impovement for white electroluminescent diodes

Application of SPME for determination of organic vapours in

Application of binary immobilized Candida rugosa lipase for

Application of Data Mining based Malicious Code Detection Techniques for Detecting new Spyware

Principles of Sigma Delta Conversion for Analog to Digital Converters

2 Application of Distributed Loads

2004 Applications of RT to translation

więcej podobnych podstron