313

313

313

I

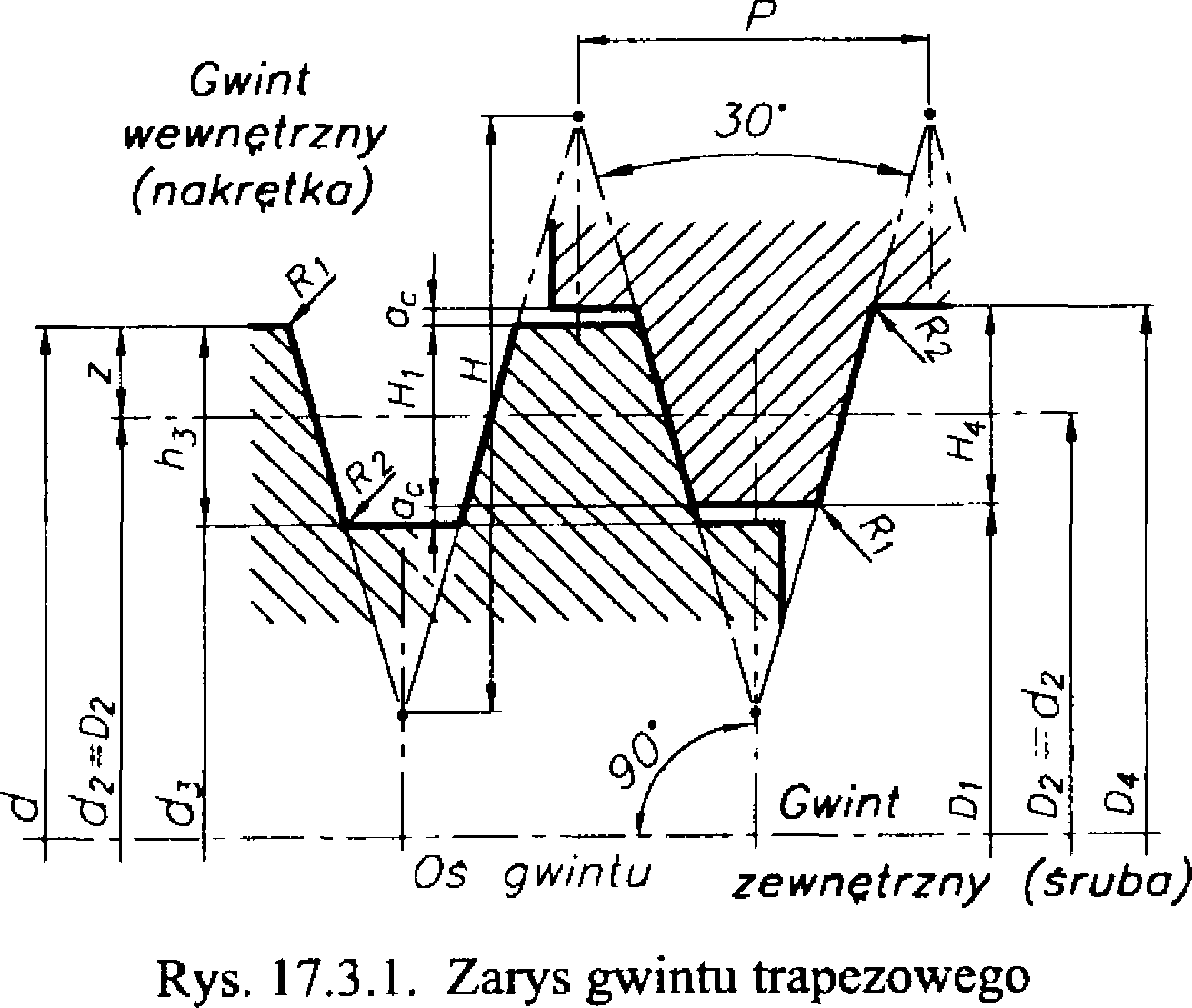

17.3. ZARYSY GWINTÓW

1. GWINTY TRAPEZOWE METRYCZNE ISO

PN-ISO 2904+A: 1996; PN-ISO 2902:1996

Tabl. 17.3.1. Wymiary nominalne

zarysu gwintu, mm

PN-ISO 2904+A: 1996

Tabl. 17.3.2. Wymiary gwintów, mm

|

PN-ISO 2901:1995 |

P |

Oc |

£ i II |

7/, |

D 1X Ima1 |

P 2max |

|

H= 1,866P |

1,5 |

0,15 |

0,90 |

0,75 |

0,08 |

0,15 |

|

Hj=0,5P |

2 |

0,25 |

1,25 |

1,0 |

0,13 |

0,25 |

|

hi=H4 =Hj + ar=0,5P + ac |

3 |

0,25 |

1,75 |

1,5 |

0,13 |

0,25 |

|

z=0,25P=H1/2 |

4 |

0,25 |

2,25 |

2,0 |

0,13 |

0,25 |

|

5 |

0,25 |

2,75 |

2,5 |

0,13 |

0,25 | |

|

dj=d-2hj = d-2(0,5P+ac) |

6 |

0,5 |

3,5 |

3,0 |

0,25 |

0,5 |

|

d2=D2 =d-2z=d-0,5P |

7 |

0,5 |

4,0 |

3,5 |

0,25 |

0,5 |

|

Df ~d-2Hj~d-P |

8 |

0,5 |

4,5 |

4,0 |

0,25 |

0,5 |

|

D4 ~d+2oc |

9 |

0,5 |

5,0 |

4,5 |

0,25 |

0,5 |

|

Klm<,x=°-5ac |

10 |

0,5 |

5,5 |

5,0 |

0,25 |

0,5 |

|

R2max =°c |

12 |

0,5 |

6,5 |

6,0 |

0,25 |

0,5 |

|

14 |

1,0 |

8,0 |

7,0 |

0,5 |

1,0 | |

|

16 |

1,0 |

9,0 |

8,0 |

0,5 |

1,0 | |

|

18 |

1,0 |

10 |

9,0 |

0,5 |

KO | |

|

20 * 4 1 |

1,0 |

11 |

10 |

0,5 |

1,0 |

PN-ISO 2904+A: 1996; PN-ISO 2902:1996

|

d szc 1 |

_1 |

P |

d2=D2 |

d4 |

d, |

Di |

|

8 |

1,5 |

7,25 |

8,3 |

6,2 |

6,5 | |

|

9 |

1,5 |

8,25 |

9,5 |

7,2 |

7,5 | |

|

2 |

8,00 |

9,5 |

6,5 |

7,0 | ||

|

10 |

1,5 |

9,25 |

10,3 |

8,2 |

8,5 | |

|

2 |

9,00 |

10,5 |

7,5 |

8,0 | ||

|

11 |

2 |

10,0 |

11,5 |

8,5 |

9,0 | |

|

3 |

9,50 |

11,5 |

7,5 |

8,0 | ||

|

12 |

2 |

11,0 |

12,5 |

9,5 |

10 | |

|

3 |

10,5 |

12,5 |

8,5 |

9,0 | ||

|

14 |

2 |

13,0 |

14,5 |

11,5 |

12 | |

|

3 |

12,5 |

14,5 |

10,5 |

11 | ||

|

16 |

2 |

15,0 |

16,5 |

13,5 |

14 | |

|

4 |

14,0 |

16,5 |

11,5 |

12 | ||

|

18 |

2 |

17,0 |

18,5 |

15,5 |

16 | |

|

4 |

16,0 |

18,5 |

13,5 |

14 | ||

|

20 |

2 |

19,0 |

20,5 |

17,5 |

18 | |

|

4 |

18,0 |

20,5 |

15,5 |

16 | ||

|

22 |

3 |

20,5 |

22,5 |

18,5 |

19 | |

|

5 |

19,5 |

22,5 |

16,5 |

17 | ||

|

8 |

18,0 |

23,0 |

13,0 |

14 | ||

|

24 |

3 |

22,5 |

24,5 |

20,5 |

21 | |

|

5 |

21,5 |

24,5 |

18,5 |

19 | ||

|

8 |

20,0 |

25,0 |

15,0 |

16 | ||

|

26 |

3 |

24,5 |

26,5 |

22,5 |

23 | |

|

5 |

23,5 |

26,5 |

20,5 |

21 | ||

|

8 |

22,0 |

27,0 |

17,0 |

18 | ||

|

28 |

3 |

26,5 |

28,5 |

24,5 |

25 | |

|

5 |

25,5 |

28,5 |

22,5 |

23 | ||

|

8 |

24,0 |

29,0 |

19,0 |

20 | ||

|

30 |

3 |

28,5 |

30,5 |

26,5 |

27 | |

|

6 |

27,0 |

31,0 |

23,0 |

24 | ||

|

10 |

25,0 |

31,0 |

19,0 |

20 |

|

d szereg1 1 2 |

P |

d2-D2 |

d4 |

ds |

Dx | |

|

32 |

3 |

30,5 |

32,5 |

28,5 |

29 | |

|

6 |

29,0 |

33,0 |

25,0 |

26 | ||

|

10 |

27,0 |

33,0 |

21,0 |

22 | ||

|

34 |

3 |

32,5 |

34,4 |

30,5 |

31 | |

|

6 |

31,0 |

35,0 |

27,0 |

28 | ||

|

10 |

29,0 |

35,0 |

23,0 |

24 | ||

|

36 |

3 |

34,5 |

36,5 |

32,5 |

33 | |

|

6 |

33,0 |

37,0 |

29,0 |

30 | ||

|

10 |

31,0 |

37,0 |

25,0 |

26 | ||

|

38 |

3 |

36,5 |

38,5 |

34,5 |

35 | |

|

7 |

34,5 |

39,0 |

30,0 |

31 | ||

|

10 |

33,0 |

39,0 |

27,0 |

28 | ||

|

40 |

3 |

38,5 |

40,5 |

36,5 |

37 | |

|

7 |

36,5 |

41,0 |

32,0 |

33 | ||

|

10 |

35,0 |

41,0 |

29,0 |

30 | ||

|

42 |

3 |

40,5 |

42,5 |

38,5 |

39 | |

|

7 |

38,5 |

43,0 |

34,0 |

35 | ||

|

10 |

37,0 |

43,0 |

31,0 |

32 | ||

|

44 |

3 |

42,5 |

44,5 |

40,5 |

41 | |

|

7 |

40,5 |

45,0 |

36,0 |

37 | ||

|

12 |

38,0 |

45,0 |

31,0 |

32 | ||

|

46 |

3 |

44,5 |

46,5 |

42,5 |

43 | |

|

8 |

42,0 |

47,0 |

37,0 |

38 | ||

|

12 |

40,0 |

47,0 |

33,0 |

34 | ||

|

~~3 |

46,5 |

48,5 |

44,5 |

45 | ||

|

8 |

44,0 |

49,0 |

39,0 |

40 | ||

|

12 |

42,0 |

49,0 |

35,0 |

36 | ||

|

50 |

3 |

48,5 |

50,5 |

46,5 |

47 | |

|

8 |

46,0 |

51,0 |

41,0 |

42 | ||

|

12 |

44,0 |

51,0 |

37,0 |

38 | ||

|

52 |

3 |

50,5 |

52,5 |

48,5 |

49 | |

|

8 |

48,0 |

53,0 |

43,0 |

44 | ||

|

12 |

46,0 |

53,0 |

39,0 |

40 | ||

|

d szereg1 1 2 |

P |

d2=D2 |

04 |

d-$ | ||

|

55 |

3 |

53,5 |

55,5 |

51,5 |

52 | |

|

9 |

50,5 |

56,0 |

45,0 |

46 | ||

|

14 |

48,0 |

57,0 |

39,0 |

41 | ||

|

60 |

3 |

58,5 |

60,5 |

56,5 |

57 | |

|

9 |

55,5 |

61,0 |

50,0 |

51 | ||

|

14 |

53,0 |

62,0 |

44,0 |

46 | ||

|

65 |

4 |

63,0 |

65,5 |

60,5 |

61 | |

|

10 |

60,0 |

66,0 |

54,0 |

55 | ||

|

16 |

57,0 |

67,0 |

47,0 |

49 | ||

|

70 |

4 |

68,0 |

70,5 |

65,6 |

66 | |

|

10 |

65,0 |

71,0 |

59,0 |

60 | ||

|

16 |

62,0 |

72,0 |

52,0 |

54 | ||

|

75 |

4 |

73,0 |

75,5 |

70,5 |

71 | |

|

10 |

70,0 |

76,0 |

64,0 |

65 | ||

|

16 |

67,0 |

77,0 |

57,0 |

59 | ||

|

80 |

'1■ 1 — 1 |

4 |

78,0 |

80,5 |

75,5 |

76 |

|

10 |

75,0 |

81,0 |

69,0 |

70 | ||

|

16 |

72,0 |

82,0 |

62,0 |

64 | ||

|

85 |

4 |

83,0 |

85,5 |

80,5 |

81 | |

|

12 |

79,0 |

86,0 |

72,0 |

73 | ||

|

18 |

76,0 |

87,0 |

65,0 |

67 | ||

|

90 |

4 |

88,0 |

90,5 |

85,5 |

86 | |

|

12 |

84,0 |

91,0 |

77,0 |

78 | ||

|

18 |

81,0 |

92,0 |

70,0 |

72 | ||

|

95 |

4 |

93,0 |

95,5 |

90,5 |

91 | |

|

12 |

89,0 |

96,0 |

82,0 |

83 | ||

|

18 |

86,0 |

97,0 |

75,0 |

77 | ||

|

100 |

4 |

98,0 |

100,5 |

95,5 |

96 | |

|

12 |

94,0 |

101,0 |

87,0 |

88 | ||

|

20 |

90,0 |

102,0 |

78,0 |

80 | ||

|

* » V |

* i # | |||||

Zalecane pola tolerancji dla gwintów o normalnej długości skręcenia:

- dla gwintów wewnętrznych - 6H;

- dla gwintów zewnętrznych o klasie dokładności:

- dokładnej - 6e, 6g;

- śrcdniodokładnej - 7g;

- zgrubnej - 8g.

Szereg średnic 1 jest uprzywilejowany.

PRZYKŁAD OZNACZENIA

- pary gwintowej (gwint trapezowy o średnicy znamionowej d = 40 mm, jednokrotny o podziałce P= 3 mm, prawy): Tr40x3-6H/7g

- gwintu 7r40x3 wewnętrznego z polem tolerancji 6H\ Tr40x3-6H

- gwintu 7?4013 zewnętrznego z polem tolerancji Ig: Tr40x3~ 7g

- pary gwintowej (gwint trapezowy o średnicy znamionowej d = 40

mm, dwukrotny o skoku ~ 6 mm i podziałce P = 3 mm, lewy (LH)): Tr40x6(P3)LH-6H/7g

Wyszukiwarka

Podobne podstrony:

IMG00333 33317.3. ZARYSY GWINTÓW 1. GWINTY TRAPEZOWE METRYCZNE ISO PN-ISO 2904+A: 1996; PN-ISO 2902:

37355 Str333 333 17.3. ZARYSY GWINTÓW 1. GWINTY TRAPEZOWE METRYCZNE ISO PN-ISO 2904+A:1996; PN-ISO

2.5. ZARYSY GWINTÓW 2.5.1. GWINTY TRAPEZOWE NIESYMETRYCZNE 2.5.2. GWINTY TRAPEZOWETabl. 2.5.1. Wymia

kurmaz156 1562.5. ZARYSY GWINTÓW 2.5.1. GWINTY TRAPEZOWE NIESYMETRYCZNE 2.5.2. GWINTY TRAPEZOWE Tabl

2.5. ZARYSY GWINTÓW 2.5.2. GWINTY TRAPEZOWE2.5.1. GWINTY TRAPEZOWE NIESYMETRYCZNE Tabl. 2.5.1. Wymia

Save0019 Linia równoległa do osi gwintu (do osi rury) Zarysy gwintów znormalizowanych: a) gwint metr

tablice0006 - 4 Str. Tablica 3.3. Gwinty trapezowe symetryczne wg PN-74/M-02017. 4

gwinty05 c) Rys. 10.25. Zarysy najczęściej stosowanych gwintów znormalizowanych: a) gwint metryczny

gwintownik m6 GWINTY METRYCZNE ISO. GWINTOWNIKI DO GWINTÓW ZWYKŁYCH (M). Krótkie pojedyncze oraz w k

new 20 (2) 42 2. Charakterystyka gwintów znormalizowanych Tablica 2.9. Gwinty trapezowe niesymetrycz

więcej podobnych podstron