5w induk

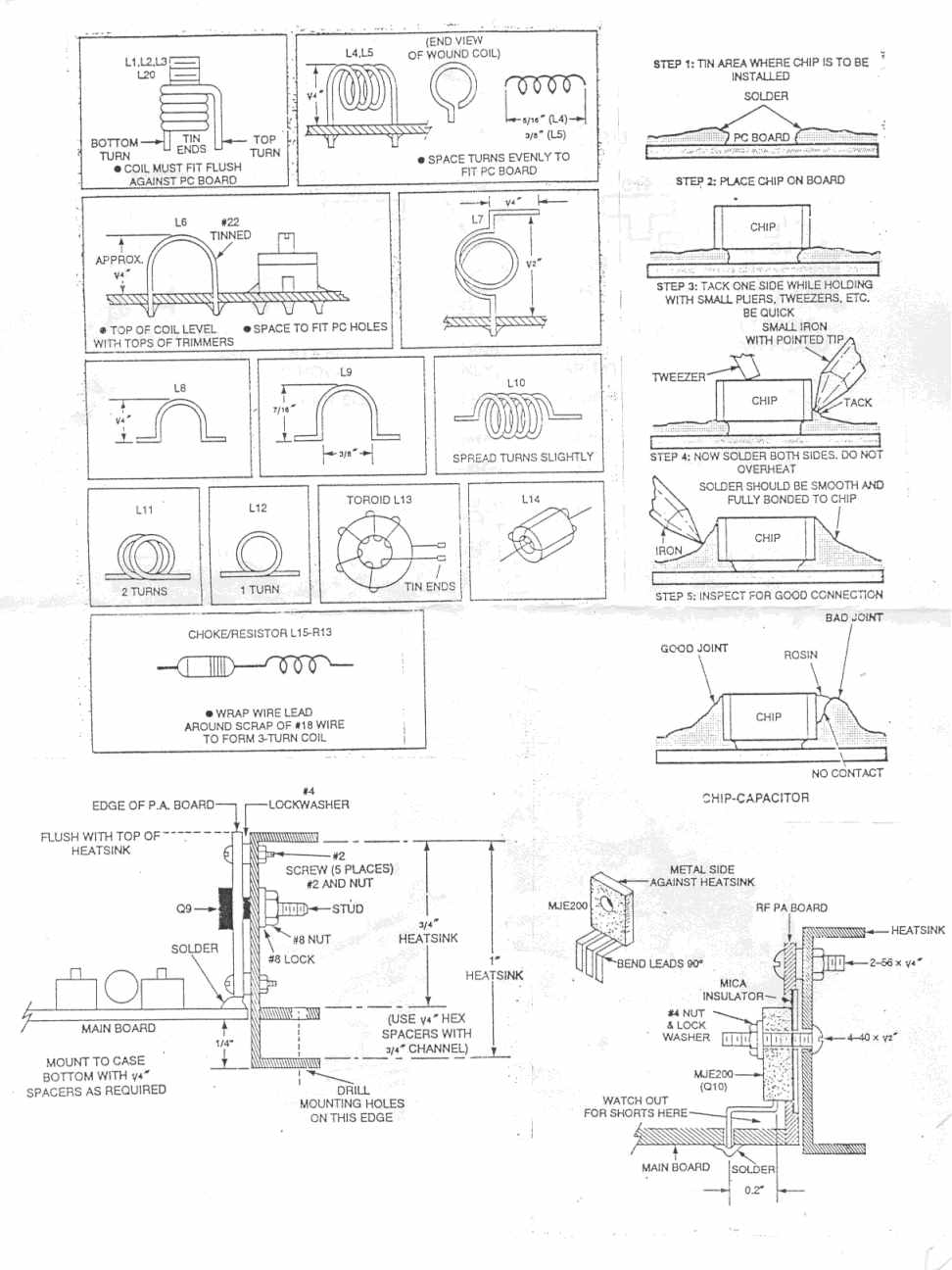

L1,L2.L3r=1 L2C t=)

L4.L5

T

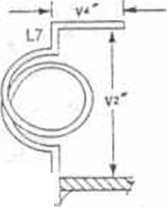

v<‘

(END VIEW OF WOUND COIL)

TIN

ENDS

BOTTOM TU RN

• COIL MUST FIT RUSH AGA1NST PC BOARO

TOP

TURN

(L4)-»-| 9/«" (L5)

SPACE TURNS EVENLY TO FIT PC BOARO

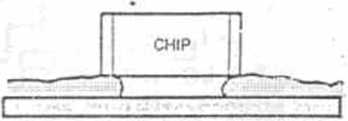

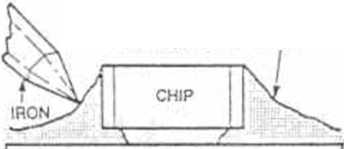

STEP 1: TIN AREA WHERE CHIP IS TO BE ’ INSTALLED

SOLD ER

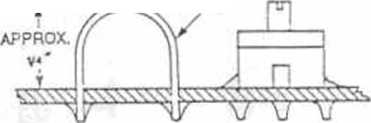

L6 #22 TINNED

• TOP OF COIL LEVEL • SPACE TO FIT PC HOLES

with tops of trimmers

jhSSSSS

STEP 2: PLACE CHIP ON BOARO

STEP 3: 7ACK CNE SIOE WHILE HOLDING WITH SMALL PUERS. TWEEZERS. ETC. BE OUICK SMALL IRON

no

SPREAD TURNS SLIGHTLY

• WRAP WIRE LEAD AROUND SCRAP OF #18 WIRE TO FORM 3-TURN COIL

*4

TWEEZER

CHIP

SOLDER SHOULD BE SMOOTH ANO FULLY 8CNDED TO CHIP

STEP 4: NO W SOLDER BO TH OYERHEAT

STEP 5: INSPECT FOR GOOO CCNNECTION

BAD JOINT

Wyszukiwarka

Podobne podstrony:

281 281 L1=6 L2=6.3 L3=7.2 L4=7.6 L5=5.7 L6=4.7 L7=4.3 Fig. 3A (left): ring drilling (vertical

10 a) Układ sieci TN-C d) Układ sieci TT Oznaczenia: L1; L2; L3 - przewody fazowe prądu przemiennego

> Glonass /JtSfa. Glonass-M ■ Glonass-KM L1 L2 L3 L1,

silnik asynchroniczny L1 L2 L3Schemat silnika asynchronicznego klatkowego 1 - silnik, 2 - uzwojenie

lista 3 5 ±ts: CC oo CU TT (*<pV* £5£ tB^ 3]y ~ htL r. £2. o* i tM^)v : %i ir^

L1 L2 13 Przy połączeniu rozruchowym gwizda - trójką. W trybie pracy należy zachować prawidłowość

* - *• ‘5 / i. /L1 .A ł L»2^2jPb ?£ ■ ** łfM * * • :••’ >vV 4pvfcj^

21 11 09 (5) STREFĄ PRZECZUUCY • okolica lędźwiowa L1-L2 • po ob

M 250 L1 L2 L3>[][][] FR 103 ■v S T I I> I> > ChS PT

L1 L2_ _ L3_4L L3 NPE N W_N_ i PE

21 11 09 (5) STREFĄ PRZECZUUCY • okolica lędźwiowa L1-L2 • po ob

L1 L2 L3 PE Roz. izolacyjny FR 304 do garażu 63A Roz. izolacyjny FR 304 63A do

dahlandera 1kierunek 1 »T3 J5 L1 L2 L3 4 6■Qi7

SNC00357 STANDARDOWE PROGRAMY ŁĄCZEŃ L1 L2 L3 lii 2 6 18 Rozłączniki gwiazda - trójkąt ...-29-.. *

więcej podobnych podstron