00312 æ50bbf6d416fbf0edb061aff9ba2fbc

315

Optimizing Defect Levels and Losses from Gage Errors

finał test gage is installed. If the gage error is normally distributed with a standard deviation of 20, then it becomes obvious that several of the reject units will still be sent on to the customer. In addition, several good units will be thrown away as rejects. Utilizing models generated in this paper, it can be shown that the probability of sending a reject on to the customer is 0.01024 and the probability of throwing away a good unit is 0.01624.

A guard band is one means of reducing the defect level of products reaching the customers. Specifically, a guard band is a limit set by the manufacturer on a finał test gage that is tighter than the specification limit established by the customer. The gage loss in terms of good units that are incorrectly rejected should also be determined when adding a guard band. Additional gages will also reduce the defect level to the customer. We will develop models for determining the defect levels and the losses obtained by adding guard bands and additional gages. We will also discuss the complexity of solving these generał mathematical models for optimal operating conditions. A linear model approach is utilized to approximate the morę complex models, allowing an optimal solution to be generated much morę easily. An example is provided of this approach.

Basic Models of Defect Levels and Gage Losses

If the product has a distribution f(x) and the gage error follows a distribution g(x), then the probability that a unit xj, that is beyond the upper specification limit, being passed by the gage as a good unit is

(2)

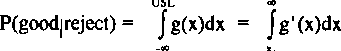

P(good)reject) = j g(x)dx

FigurÄ™ 1 shows this relationship.

An assumption that will be madÄ™ throughout this research is that the gage errors are normally distributed. With this assumption, an important equality for the risk of having the gage accept the defective unit is

USL

Xj

where g(x) ~ N(xj,ag) and g'(x) ~ N(USL,crg)

(3)

Wyszukiwarka

Podobne podstrony:

00314 ?f49248905805fa4cf0d5be042fd4c1 317 Optimizing Defect Levels and Losses from Gage Errors Figu

00316 ?09c0d2f3a2243d1d46b1f997b3d3cf 319 Optimizing Defect Levels and Losses from Gage Errors Figu

00318 Fc61831291a35229ea5e67ab507c8cf 321 Optimizing Defect Levels and Losses from Gage Errors Guar

00320 ?5cd1011755558fd005661a9b3cd8ed 323 Optimizing Defect Levels and Losses from Gage Errors Defe

00322 ?b73d4dcbb3956a7a53bceacac34fb9 Optimizing Defect Levels and Losses from Gage Errors 325 Figu

00324 ?4f0003b2ed2810dd76bb30abe464e6 327 Optimizing Defect Levels and Losses from Gage Errors goal

00326 A9b69718dd18cd338e0f0700b7c79c2 329 Optimizing Defect Levels and Losses from Gage Errors + f(

00328 ?80eb3e1366a39705d7b77d62f12780 331 Optimizing Defect Levels and Losses from Gage Errors ao P

00330 r8ad54f747f0f287dd69fb4ed228e35 333 Optimizing Defect Levels and Losses from Gage Errors The

00332 ?133d2464eb28601d2d991683b45647 335 Optimizing Defect Levels and Losses from Gage Errors on t

00334 ?b2793f238bc36b5f1c29c11f214359 Optimizing Defect Levels and Losses from Gage Errors 337 Resp

00336 ?e7e8dcfe0a23e46d4a41cf7d1feb53 Optimizing Defect Levels and Losses from Gage Errors 339 zao

00338 ?79650d4af41fcdcb3a1354afe938a8 Optimizing Defect Levels and Losses from Gage Errors 341 di =

00340 Vbfa1728c6ca8c65c355df31b8a4ed5 343 Optimizing Defect Levels and Losses from Gage Errors Grub

00310 Ad65eb5323f68600e39f63d1a31de2f 16Optimizing Defect Levels and Losses from Gage Errors Daniel

TROUBLE-SHOOTING AND DIAGNOSES -Preliminary Checks- (Prior to Road Testing) FLUID LEAKAGE If the gov

12ANALYSIS, TESTING JPRS-UMS-92-003 16 March 1992 UDC (548.5+537.311 ):621.315.5 [Abstract] InSb foi

69 The influence of anthropopressure.. elevational drop in lowland areas resulted in a rise in water

Performance & speed Load pages faster by allowing Jetpack to optimize your images and serve your

więcej podobnych podstron