38219 PICT0001 (15)

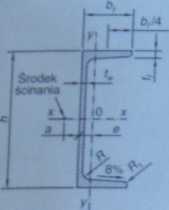

Tablica 1.20 CEOWNIKI ZWYKŁE C wg PN 8C/H-83403. OIN 1070 1 3000

|

Wyróżnik oznaczenia r |

Wymiary |

Otwory |

Pole przekroju |

Masa |

Obwód na 1 m długości | ||||||||

|

L |

h |

Ib' |

I <w |

R |

n< |

e |

• |

d |

w |

A |

m |

U | |

|

mm |

cm |

mm |

cm* |

kg/m |

trPfm | ||||||||

|

40 |

40 |

20 |

5.0 |

5.0 |

5.0 |

2.5 |

0.66 |

1.28 |

6 |

11 |

3.51 |

2.75 |

0.199 |

|

50 |

50 |

38 |

5.0 |

7.0 |

7.0 |

3,5 |

1,37 |

1.37 |

11 |

20 |

7.12 |

5,59 |

0.232 |

|

66 |

65 |

42 |

5.5 |

7,5 |

7.5 |

4.0 |

1.42 |

1.47 |

11 |

25 |

9.03 |

7.09 |

0.273 |

|

80 |

80 |

45 |

6.0 |

8.0 |

8.0 |

4.0 |

1.45 |

1.54 |

13 |

25 |

11.0 |

8,64 |

0.312 |

|

100 |

100 |

50 |

6.0 |

8.5 |

8.5 |

4.5 |

1.56 |

1.69 |

13 |

30 |

13.5 |

10,6 |

0.372 |

|

120 |

120 |

55 |

7.0 |

9.0 |

9.0 |

4.5 |

1.60 |

1.78 |

17 |

30 |

17.0 |

13.4 |

0.434 |

|

140 |

140 |

60 |

7.0 |

10.0 |

10.0 |

5.0 |

1.75 |

1.97 |

17 |

35 |

20.4 |

16.0 |

0.469 |

|

160 |

160 |

65 |

7,5 |

10.5 |

10.5 |

5,5 |

1.84 |

2.10 |

21 |

35 |

24.0 |

18.8 |

0.546 |

|

180 |

180 |

70 |

8.0 |

11.0 |

11.0 |

5.5 |

1.92 |

2.23 |

21 |

40 |

28,0 |

22.0 |

0.611 |

|

200 |

200 |

75 |

8.5 |

11.5 |

11.5 |

6.0 |

2,01 |

2.36 |

23 |

40 |

32,2 |

25.3 |

0,661 |

|

220 |

220 |

80 |

9.0 |

12.5 |

12.5 |

6.5 |

2.14 |

2.51 |

23 |

45 |

37.4 |

29.4 |

0.718 |

|

240 |

240 |

85 |

9.5 |

13,0 |

13.0 |

6.5 |

2.23 |

2.64 |

25 |

45 |

42.3 |

33.2 |

0.775 |

|

260 |

260 |

90 |

10.0 |

14,0 |

14.0 |

7,0 |

2,36 |

2,80 |

25 |

50 |

48.3 |

37,9 |

0.834 |

|

280 |

280 |

95 |

10.0 |

15,0 |

15.0 |

7.6 |

2.53 |

3,00 |

25 |

50 |

53.3 |

41.8 |

0,890 |

|

300 |

300 |

100 |

10,0 |

16,0 |

16.0 |

8.0 |

2,70 |

3.33 |

28 |

55 |

58,8 |

46.2 |

0,950 |

|

320 |

320 |

100 |

14.0 |

17.5 |

17.5 |

8.75 |

2,60 |

3,12 |

28 |

58 |

75.8 |

59.5 |

0.982 |

|

350 |

360 |

100 |

14.0 |

16,0 |

16.0 |

8.0 |

2.40 |

2.05 |

28 |

58 |

77,3 |

60.6 |

1.047 |

|

380 |

380 |

102 |

13,5 |

16.0 |

16.0 |

8.0 |

2.36 |

2,20 |

28 |

60 |

80.4 |

63.1 |

1,110 |

|

400 |

400 |

110 |

14.0 |

18.0 |

18.0 |

9.0 |

2.65 |

2.46 |

28 |

60 |

91.5 |

71.8 |

1.182 |

Momenty

bezwładności

364

606

925

1360

1010

2690

3600

4820

6280

8030

10670

12840

16760

20360

Wskaźniki

wytrzymałości

Promienie

bezwładności

Wycinkowy

moment

bezwładności

Moment bezwładności przy skręcaniu

Oielnoakifłna

cm*

W.

W.

cm3

cm

7.26

26.4

57.5 106 206

|

1.06 |

3.63 |

0.76 |

1.44 |

0.56 |

|

9.12 |

10.6 |

3.75 |

1.92 |

1.13 |

|

14.1 |

17.7 |

5.07 |

2.52 |

1.25 |

|

19.4 |

26.5 |

6.36 |

3.10 |

1.33 |

|

29.3 |

41.2 |

8.49 |

3.91 |

1.47 |

|

43.2 |

60.7 |

11.1 |

4.62 |

1.59 |

|

62.7 |

86.4 |

14.8 |

5.45 |

1.75 |

|

85.3 |

116 |

18.3 |

6£1 |

1.89 |

|

114 |

150 |

22.4 |

695 |

2.02 |

|

148 |

191 |

27.0 |

7.70 |

2.14 |

|

197 |

245 |

33,6 |

8.48 |

2.30 |

|

248 |

300 |

39,6 |

9.22 |

2.42 |

|

317 |

371 |

47.7 |

9.09 |

2.56 |

|

399 |

448 |

67.2 |

10.9 |

2.74 |

|

495 |

536 |

67.6 |

11.7 |

2.90 |

|

597 |

679 |

80.6 |

12.1 |

2.81 |

|

570 |

734 |

75.0 |

12.9 |

2.72 |

|

615 |

829 |

78.7 |

14.0 |

2.77 |

|

846 |

1020 |

102.0 |

14,9 |

3.04 |

cm"

cm4

IM

11.9

27.8

77.3

166

414

000 1800 3260 5670 0070 | ~14600 22100 33300 48600 60100 06100 114000 146000 221000

1 00 1.12 1.61 2.16 i 2,81 | 4.15 5.68 7.39 9.55 11,9 16.0

10.7

25.5

31.0 37.4

68.7 61.2

59.1

81.6

0.178

0.120

0.0940

0.0707

00511

6moma wyroby

Wyszukiwarka

Podobne podstrony:

skanuj0008 (252) Tablica 1.20 CEOWNIKI ZWYKŁE C wg PN-86/H-93403, DIN

ceowniki zwykle Tablica 1.20 CEOWNIKI ZWYKŁE C wg PN-86/H-93403, DIN

PICT0003 (15) Tablica 1.22 CEOWNIKI RÓWNOLEGŁOŚCIENNE UPE wg DIN

15833 PICT0007 (11) Tablica 1.25 KĄTOWNIKI NIERÓWNORAMIENNE L wg PN-EN 10056-12000 Tolerancje k

14479 PICT0005 (14) Tablica 1.24 KĄTOWNIKI RÓWNORAMIENNE L wg PN-EN 10056-1:2000 Tolerancje kształtu

PICT0004 (13) Tablica 1.23 CEOWNIKI ROWNOLEGŁOSCIENNE UAP «g katalogu producenta Arcelof

dwuteowniki zwykle * iib. (0max• Tablica 1.1« DWUTE0WNIK1 ZWYKŁE i • &

więcej podobnych podstron