8495020580

J MELSOFT MR Configurator2 New project : Project View File Machinę Analyzer(Z)

ID8HII.I O. i|fflfe|g>

• Project

O X

ł X

Parameter Safety Positioning-data Monitor Diagnosis Test Modę Adjustment Tools Window Help

sg »fcSJfaitg tn

*

0 Q New project

System Setting 5“ Unit Conversion B 0a,Axisl:MR-J4-B (-RJ) Standard [li Parameter

Servo Assistant

Test Run

1 2 3

1. System Check

Checks the system configuration and wiring.

System Con

Check the system configuration.

\S* System Configuration

I/O Monitor

Check the input wiring.

| 1/*11/O Monitor

Check the output wiring.

Iz* DO Forced Output

< Return

Next >

Parameter Setting

|

JOG Modę |

Alarm Occurrence Data |

Machinę Diagnosis |

Alarm Display |

Positioning Modę |

Tuning |

One-touch Tuning |

Test Modę Informatory^ Machinę Anaiyzer X |

<1 > ^r

•(■]Axisl v 4-]]Read §aVerify ^jjcontinuous Write ^Parameter Monitor YFilter Vib. Supp. Ctrl.

Basic setting

Write

Update Project

• [¥| Axisl

STĘPI Gain adjustment modę selection(PA08 ATU)

0 Auto tuning modę 1 Auto. est. of Id. inertia moment ratio -> STEP3 Response level setting

O Auto tuning modę 2 STEP2 Load inertia moment ratio setting -> STEP3 Response level setting

O 2 gain adj. modę 1 (Interpolation) Auto. est. of Id. inertia moment ratio -> STEP3 Response level setting/Model loop gain setting

O 2 gain adj. modę 2 STEP2 Load inertia moment ratio setting -> STEP3 Response level setting/Model loop gain setting

O Manuał modę STEP2 Load inertia moment ratio setting -> STEP3 Gain parameter setting

STEP2 Load inertia moment ratio setting Load inertia moment ratio (PB06 GD2)

STEP 3 Response level setting

Auto tuning response i (1-W) (PA09 RSP)

OFilter auto.

O

times (0,00-300,00)

STEP3 Gain parameter setting Model loop gain (PB07 PG1)

Position loop gain (PB08 PG2)

Speed loop gain (PB09 VG2)

Speed integral comp. (PB 10 VIC)

Overshoot amount

1,5

5,0

23

250,0 Z

rad/s (1,0-2000 rad/s (1,0-2000 rad/s (20-65535 ms (0,1-1000,0)

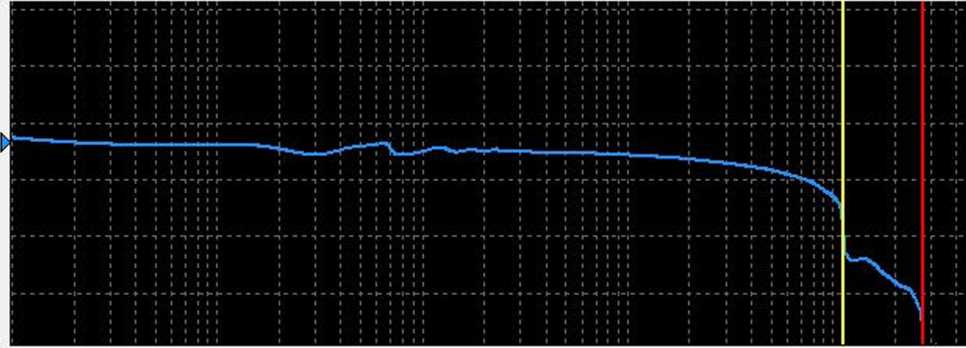

Adjustment result = (■) Axis 1 v 4-jRead 0Open p|SaveAs Acquisition time 10.06.2017 11:32:20

Adjustment result ||

Friction estimation Yibration estimation Total move distance

Adjustment resu Jsettling

Oversho

Machinę charact

Load ine

Motor speed

Accel./decel. time constant

Move distance (Encoder pulse unit)

|

3000 jfj |

r/min |

Repeat pattern |

|

(1-6900) | ||

|

1 ^ |

ms |

Dwell time |

|

(0-50000) | ||

|

43943040 |

pulse |

Operation count |

Fwd. rot. (CCW)->Rev. rot. (CW)

cnine Anaiyzer

Setting Display Resn. pt.

Detailed Setting ||lnitialization |

0 Stimulus condition

|

Direction |

Horizontal axis _________________________1 |

|

Torque cmd. |

50 % |

|

Permissible stro |

10 rotations |

0 Axis

Target axis Axisl;

Friction trouble prediction

The friction trouble prediction function cannot be used in connecting servo amplifier.

Set the detailed pa

Tuning ofovershoc Friction estimation

a Parameter

-20

(0,1-50,0)

999

times

• p^Open Import P|SaveAs |^Save Image ^History Management |q Parameter Display | Select History 1 Previous (J)Next | |g^Overwrite IjSaeen Copy Scalę Optimization J^Gray Display |łf Cursor

I ► Start |

100

30

30

| 40

20

0

10,0

4,5kHz

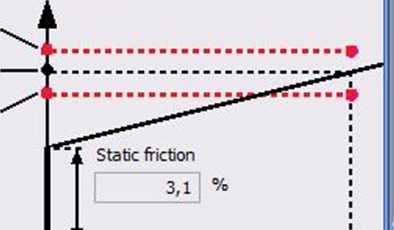

The coulomb friction (induding gravity factor, etc.) and viscous friction coeffióent of a bali screw or a are estimated after operating an arbitrary operation pattern.

Friction torgue

Upper threshold Estimation value Lower threshold

Rated speed

r/min

4,1

%

%

%

|

-f- 1 1 |

Static friction |

j |

L |

Rated speed | ||

|

Alarm... o3 □ |

■ |

— |

% |

3000 | ||

r/min

330

130

'o' 0

41

"O

<11

i ■m

-330

-540

iii

Ready

[Station 00] MR-J4-B (-RJ) Standard Servo amplifier connection: USB

NUM

Wyszukiwarka

Podobne podstrony:

New ProjectatosO - ATOS Professional V8 File Edit View Acquisrtion Construct Inspection-

OuickTime Player 7 File Edit View Window Help E3 0 <S> V * <D ^ ■«» 56% New Project- P New

Bfigs19 FirstDialog - Microsoft Developer Studio File Edit View insert Project Build Jools Window He

file New Project & Open Project... Ctrl+N Ctrl+O Add Project... Remove Project O Save Project

file New Project & Open Project... Ctrl+N Ctrl+O Add Project... Remove Project O Save Project

nic mini m Dev-C++ 4.9.9*2 File Edit Searrh Vtew Project i New Open Project, or file.,. .Ctfl+O

12fg0004 Microsoft Visual Basic - Projectl [design] File Edit View insert Bun lools Ądd-lns Help Dft

12fg0005 Microsoft Visual Basic - Projectl [design]File Edit View insert FUin Jools Ądd-lns

12fg0016 Microsoft Visual Basic - Projectl [design] File Edit View insert FUin Jools Ądd-lns Help

12fg0028 _Microsoft Visual Basic - Project! [design] File Edit View insert Bun lools Ądd-lns Help Ad

select target O X [New ProjectSelect a Target Select the platform and configurattons you wlsh to dep

wgc2 iMicrosoft Project - WyposażenieMieszkaniaWStanieSurowym File Edit View Insert Format lools Pro

x3 razy X2 M FluidSIM-P File Edit Execute Library Insert Didactics Project View Options Window ?

E EnvisioneerTrial Version - [Projectl - Model] File Edit View Insert Tools Settings Window

więcej podobnych podstron