An analysis of energy ef

ficiency in the production of oilseed crops

of the family Brassicaceae in Poland

Krzysztof J

ozef Jankowski

*

, Wojciech Stefan Budzy

nski, Łukasz Kijewski

Department of Agrotechnology, Agricultural Production Management and Agribusiness, University of Warmia and Mazury in Olsztyn, Oczapowskiego 8,

10-719 Olsztyn, Poland

a r t i c l e i n f o

Article history:

Received 21 July 2014

Received in revised form

30 December 2014

Accepted 3 January 2015

Available online 24 January 2015

Keywords:

Oilseed crops

Biomass yield

Energy balance

a b s t r a c t

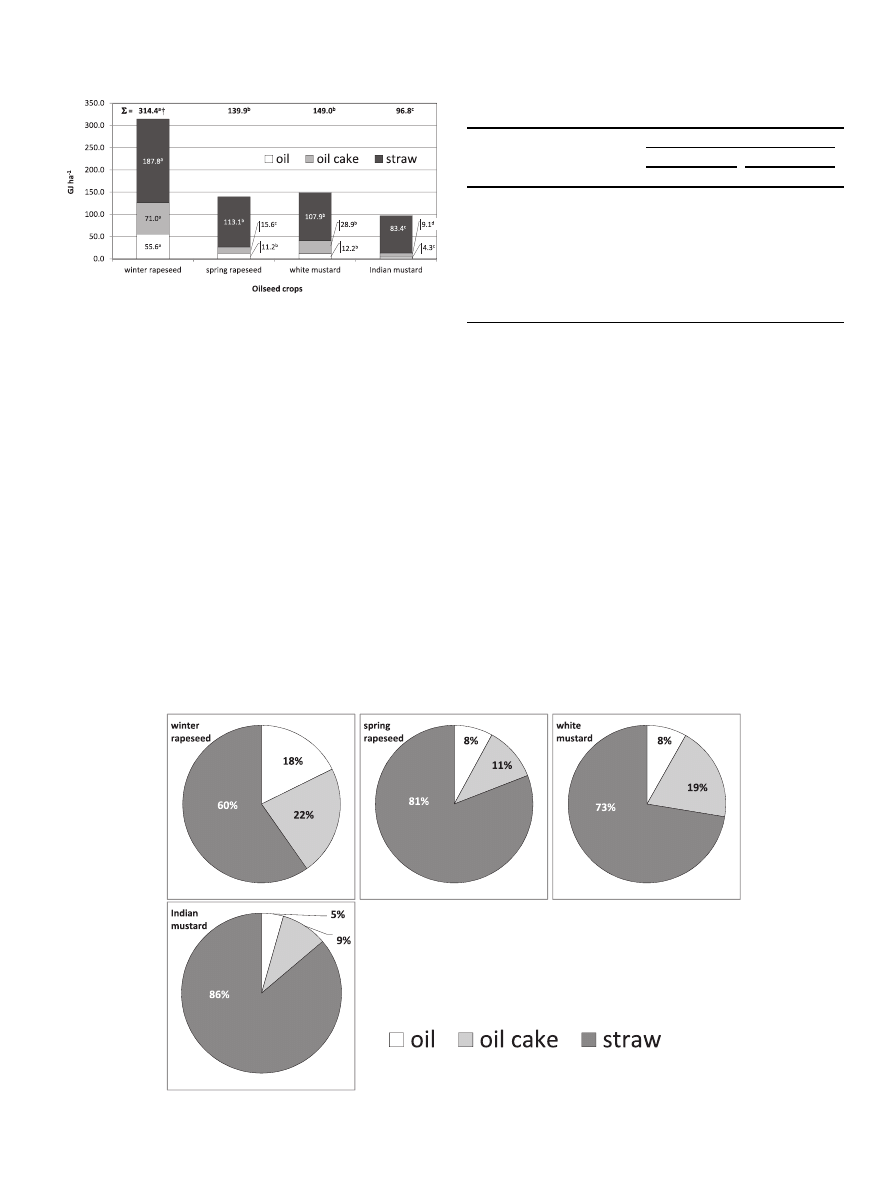

This paper discusses the results of a three-year study into energy ef

ficiency in the production of oilseed

crops of the family Brassicaceae in north-eastern Poland. The energy inputs per ha of winter rapeseed

were determined at 26.29 GJ, and were 1.8-fold higher (spring rapeseed, white mustard) to more than

2.3-fold higher (Indian mustard) in comparison with spring oilseed crops. The potential use of energy

accumulated in the biomass of winter rapeseed (314.4 GJ ha

1

) was as follows: 18%

e effective energy for

the petrochemical industry (oil), and 82%

e energy for the generation of heat and electricity (22% e oil

cake and 60%

e straw). The energy value of the biomass of spring oilseed crops was determined in the

range of 96.8

e149.0 GJ ha

1

. Signi

ficant differences in the utilization of biomass as a renewable source of

energy were noted between spring oilseed crops and winter rapeseed. The highest energy ef

ficiency ratio

of seed production was noted in winter rapeseed (4.92). The energy ef

ficiency ratio of seed production in

spring oilseed crops was 39% to 62

e75% lower as compared with winter rapeseed. The energy efficiency

ratio of oilseed crops increased (8.61

e11.96) when the energy potential of straw was taken into account.

© 2015 Elsevier Ltd. All rights reserved.

1. Introduction

Highly developed countries have been attempting to replace

liquid fuels derived from fossil fuels with liquid fuels derived from

biomass, which is renewable. To be energy ef

ficient and to justify

production, the ratio of energy output to energy input for biomass

must be 5 to 10 times or greater

. On the European market of

renewable energy sources, biofuels for transportation are produced

mainly from annual oilseed plants, mostly rapeseed and, to a lesser

extent, beetroots and cereals. Perennial herbaceous and woody

plants (miscanthus, switchgrass, giant reed, willows and poplars)

as well as plant waste are the main renewable sources of electricity

and heat

. The key oilseed crops in Europe are rapeseed

(above all winter cultivars), sun

flower and soybean

. In

2008

e2013, the predominant oilseed crops on the European mar-

ket (total European output was estimated at 51 million (MM) Mg)

were sun

flower (45%), rapeseed (44%), soybean (9%) as well as

linseed, mustard and seed cotton (2%)

. In some parts of Europe,

including Scandinavia and Eastern Europe, sun

flower and soybean

production is impossible or the resulting crops are very low. Sun-

flowers and soybeans have high temperature requirements that are

not met in the climate of the above regions, which have a short

growing season and relatively low average ambient temperature in

comparison with Western Europe. For this reason, winter rapeseed

is the main oilseed crop in Poland and other Eastern European

countries

. Rapeseed has an even higher share of the Polish

oilseed market. In 2010

e2013, the average was 99%, where winter

rapeseed accounted for 91

e98% of the total yield of oilseed crop

species in Poland (1.9

e2.6 MM Mg)

.

In Europe, the production of winter rapeseed is highly region-

alized due to variations in soil quality, agrarian structure, farming

traditions and length of the growing season. Winter rapeseed has

relatively low resistance to freezing, which is why winter rapeseed

production is relatively low in north-eastern Poland, Scandinavia,

Baltic countries and the northern regions of Russia

. In Poland,

the risk of frost damage to winter rapeseed is relatively high,

ranging from approximately 10% in southern Poland to 20% in

north-eastern Poland on the multi-year average. In selected Polish

regions, winter rapeseed is frost damaged once every

five years,

which necessitates the closure of plantations and the sowing of

spring oilseed crops

* Corresponding author.

E-mail address:

krzysztof.jankowski@uwm.edu.pl

(K.J. Jankowski).

Contents lists available at

Energy

j o u r n a l h o me p a g e :

w w w . e l s e v i e r . c o m/ l o ca t e / e n e r g y

http://dx.doi.org/10.1016/j.energy.2015.01.012

0360-5442/

© 2015 Elsevier Ltd. All rights reserved.

Oilseed crops of the family Brassicaceae

e rapeseed, white

mustard and Indian mustard

e are best adapted to the Polish

climate. Spring rapeseed synthesizes approximately 20

e30 g kg

1

DM (dry matter) less fat than winter rapeseed (440

e490 g kg

1

DM)

. Oil extracted from double-zero varieties of spring and

winter rapeseed is characterized by a similar composition of fatty

acids (approximately 56

e68% oleic acid, 18e22% linoleic acid and

10

e13% linolenic acid), which makes rapeseed oil suitable for a

variety of applications in food processing, petrochemicals and in-

dustry. The fat content of mustard seeds is also relatively high at

250

e300 g kg

1

DM (white mustard) to 340

e370 g kg

1

DM (In-

dian mustard)

. The predominant fatty acid in traditional

mustard varieties is erucic acid (35

e44%), which makes those

plants unsuitable for the production of edible oils

. Due to their

fatty acid composition and the presence of erucic acid, the majority

of spring oilseed plants are not suitable for the production of

edible oils, but they are valuable raw materials for the production

of biodiesel

. Miller and Kumar

demonstrated that

greenhouse gas emissions associated with the production of HDRD

(hydrogenation-derived renewable diesel) from camelina were

lower than from canola in western Canada due to lower agricul-

tural inputs and a higher yield of camelina (GHG (greenhouse gas)

emissions were determined in the range of 33

e94 gCO

2e

MJ

1

for

canola-based HDRD and 30

e82 gCO

2e

MJ

1

for camelina-based

HDRD). Unlike winter and spring rapeseed, mustard has rela-

tively low soil requirements and can be grown on poor soils that

are de

ficient in water for long periods of time. Mustard can be

cultivated on less fertile soils

This paper discusses the ef

ficiency of winter rapeseed, spring

rapeseed, white mustard and Indian mustard production, the

relevant energy inputs and the ef

ficiency of field farming opera-

tions involving production techniques characteristic of large-scale

commercial farms. It analyzes the energy output of biomass

(seeds, straw) from oilseed crops, and it determines oilseed plants'

potential that can be harnessed on the renewable energy market.

The study also attempts to verify a working hypothesis that the

lower energy value of spring oilseed crops could be compensated

by relatively lower energy inputs associated with their production

relative to winter rapeseed.

2. Materials and methods

2.1. Field experiment

The

field experiment was conducted in 2005e2008 at the

Agricultural Experiment Station in Ba

łcyny (N ¼ 53

35

0

49

00

;

E

¼ 19

51

0

20

00

) owned by the University of the Warmia and Mazury

in Olsztyn. The experimental

field had an area of 20 ha and the

experiment used a completely randomized design with three rep-

lications. The soil was a greybrown podsolic silty soil developed

from light loam. Spring barley was the forecrop.

The applied farming operations, mineral fertilization rates, rates

of crop protection agents and the months in which farming oper-

ations were performed (

) were adapted to the speci

fic re-

quirements of the analyzed oilseed plant species. After forecrop

harvest, the soil was skimmed and ploughed in August before

sowing winter rapeseed in August or ploughed in November for the

planting of spring oilseed crops in April. Fertilizer application rates

and composition were determined based on soil tests and carefully

measured to ensure optimum production because the energy rep-

resented by fertilizer is usually the major energy input. Phosphorus

was applied to soil as triple superphosphate, potassium

e as 60%

potash salt, and nitrogen

e as ammonium nitrate. Herbicides were

applied immediately after winter rapeseed sowing, at 1166 g ha

1

of metazachlor and 290.5 g ha

1

of quinmerac. In spring rapeseed

treatments, pre-emergent weed control involved the same active

ingredients, but at doses reduced to 999 g ha

1

of metazachlor and

249 g ha

1

of quinmerac. Haloxyfop-R was applied at 52 g ha

1

at

the 4

e6 leaves unfolded stage (BBCH 14e16 (Biologische Bunde-

sanstalt, Bundessortenamt und Chemische Industrie)) in winter

rapeseed. In white mustard and Indian mustard, herbicide treat-

ment consisted of 105 g ha

1

of clopyralid at the 4 leaves unfolded

stage (BBCH 14). In the

first year of the study, high pest levels

necessitated one chemical treatment in white mustard (10 g ha

1

of

the active ingredient

e a.i.), three treatments in Indian mustard

(58 g ha

1

a.i.), four treatments in winter rapeseed (351 g ha

1

a.i.)

and six treatments in spring rapeseed (416 g ha

1

a.i.). In the sec-

ond and third year of the study, pest infestation was high during the

period of high phenological sensitivity of spring oilseed plants. For

Table 1

Oilseed crop production process.

Farming operation

Month of operation and agricultural inputs

Winter rapeseed

Spring rapeseed

White mustard

Indian mustard

Skimming (5

e8 cm)

July

July

July

July

Pre-sowing ploughing (15

e18 cm)

August

e

e

e

Fall ploughing (18

e22 cm)

e

October

October

October

Sowing

cv. Californium

(90

August

cv. Hunter

(140

)

April

cv. Borowska

(130

April

cv. Ma

łopolska

April

Mineral fertilization

Pre-sowing

30/24/166

August

70/17/100

April

70/17/100

April

70/13/66

April

120

þ 80

March

þ April

30

May

30

May

e

Chemical crop protection

1456.5

þ 52.0

August

þ September

1248

April

105

May

105

May

Insecticides

330

e351

April, May

86

e416

April, May, June

10

e83

April, May, June

58

e82

April, May, June

200

May

e

e

e

Seed and straw harvest

July

August

August

August

a

Germinating seeds per 1 m

2

.

b

N/P/K kg ha

1

.

c

N kg ha

1

.

d

g ha

1

active ingredient (a.i.).

e

Variations resulting from differences in pest intensity in each year of the study.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

675

this reason, only one insecticide treatment (330 g ha

1

a.i.) was

applied in winter rapeseed, whereas spring oilseed plants required

four to six treatments (31

e412 g ha

1

a.i). The spread of pathogens

was controlled chemically only in winter rapeseed with 100 g ha

1

of dimoxystrobin and 100 g ha

1

of boscalid at the stage of

flow-

ering declining: majority of petals fallen (BBCH 66-67). Once-over

harvest of oilseed crops was carried out upon the achievement of

processing maturity.

2.2. Biomass processing experiment

The seed yield of oilseed plants from every treatment was

determined after threshing in terms of weight and adjusted to

standard moisture content (13%). The results were expressed in

terms of Mg ha

1

. The straw yield from every treatment was

determined after threshing in terms of weight, adjusted to dry

matter content and expressed in terms of Mg ha

1

. Seed samples

were cold pressed in a laboratory press with the estimated output

of 50 kg h

1

. The oil content of oil cake ranged from 95 to 106

(mustard) to 127

e129 g kg

1

DM (rapeseed). The oil cake yield of

oilseed plants was adjusted to dry matter content and expressed in

terms of Mg ha

1

.

2.3. Combustion experiment (energy output analysis)

The unit energy value (higher heating value, HHV) of biomass

from oilseed plants (seeds, oil, oil cake, straw) was determined by

adiabatic combustion in the IKA C 2000 calorimeter. The energy

value of seeds, oil, oil cake and straw was calculated as the product

of HHV (higher heating value) (MJ kg

1

DM) and biomass yield

(Mg ha

1

DM).

2.4. Work load experiment (energy inputs analysis)

The energy inputs in the production of oilseed plants were

determined by process analysis based on direct measurements of

Diesel oil consumption, labor and effective

field capacity of farming

machines and equipment (

). Process analysis examines

successive operations in crop production. This method is used to

evaluate the type and accumulation of energy inputs. The analysis

begins with energy inputs that are directly involved in the pro-

duction of a given crop, followed by energy inputs associated with

raw materials, semi-

finished goods and energy carriers required in

the production process

. The energy inputs for the production of

oilseed plants were divided into groups representing different

input categories (labor, energy carriers, farming machines and

equipment, materials) and farming operations (tillage, sowing,

fertilization, etc.). The energy inputs associated with the operation

of tractors and machines were calculated by multiplying the spe-

ci

fic consumption of a machine unit by the energy equivalent of

112 MJ kg

1

of mass

. Labor was evaluated based on the energy

equivalent of 40 MJ man-hour

1

. The energy value of 1 L of

Diesel oil was set at 48 MJ

. Each farming operation was started

with a full fuel tank that was re

filled at the end of the operation to

estimate fuel consumption. Energy inputs associated with pro-

duction materials were determined based on the energy indicators

proposed by W

ojcicki

: seeds of oilseed plants

e 24 MJ kg

1

,

nitrogen fertilizers

e 77 MJ kg

1

N, phosphorus fertilizers

e

15 MJ kg

1

P

2

O

5

, potassium fertilizers

e 10 MJ kg

1

K

2

O, crop

protection chemicals

e 300 MJ kg

1

of active ingredient.

The energy ef

ficiency of oilseed crop production was deter-

mined based on energy gain (Equation

), the unit energy con-

sumption ratio (Equation

) and the energy ef

ficiency ratio

(Equation

).

Energy gain

GJ ha

1

¼ Energy output

GJ ha

1

Energy input

GJ ha

1

(1)

Unit energy consumption ratio for 1 Mg DM of biomass

ðMJÞ

¼

Energy input MJ ha

1

Biomass yield Mg DM ha

1

(2)

Energy efficiency ratio

¼

Energy output GJ ha

1

Energy input GJ ha

1

(3)

Table 2

Technical parameters of agricultural machines, their performance and fuel consumption in the process of producing oilseed crops.

Farming operations

Engine power of

self-propelled

machine (kW)

Parameters of

accompanying

machine

Service life (h)

Weight (kg)

Performance of

self-propelled machine

and accompanying

machine (ha h

1

Fuel

consumption

(l h

1

)

Self-propelled

machine

Accompanying

machine

Self-propelled

machine

Accompanying

machine

Skimming (5

e8 cm)

136

7

12,000

2000

9285

2600

4.0

32.5

Pre-sowing ploughing

(15

e18 cm)

136

7

12,000

2000

9285

3360

2.6

53.9

Fall ploughing

(18

e22 cm)

136

7

12,000

2000

9285

3360

2.4

60,0

Sowing

202

4.0

12,000

1440

9500

5200

3.3

21.7

Mineral fertilization

59

20.0

9000

1200

6100

300

8.4

4.5

Chemical crop

protection

97

20.0

9000

1050

5200

1350

12.1

7.4

Seed harvesting

220

6.0

3000

e

13,300

e

2.4

e4.0

37.4

Straw harvesting

97

2.1

9000

1500

5200

2400

4.5

e6.0

9.2

Seed transportation

59

10

9000

6000

6100

3740

e

8.5

Straw transportation

59

8

9000

6000

6100

2800

e

8.5

Loading

55

2500

4800

e

4922

e

e

8.0

a

Tractor/harvester/loader.

b

Number of furrows.

c

Working width (m).

d

Carrying capacity (Mg).

e

Load capacity (kg).

f

Means of three years (2005

e2008).

g

Differences resulting from different biomass yields.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

676

2.5. Statistical analysis

The results of biomass yield (seeds, oil, oil cake and straw), unit

energy value of biomass (HHV) and energy value of biomass yield

(energy outputs) were processed by ANOVA in accordance with the

experimental method. Mean values from every treatment were

compared by Duncan's test (P

0.05). The results were processed

in the Statistica 10.1 PL application.

3. Results

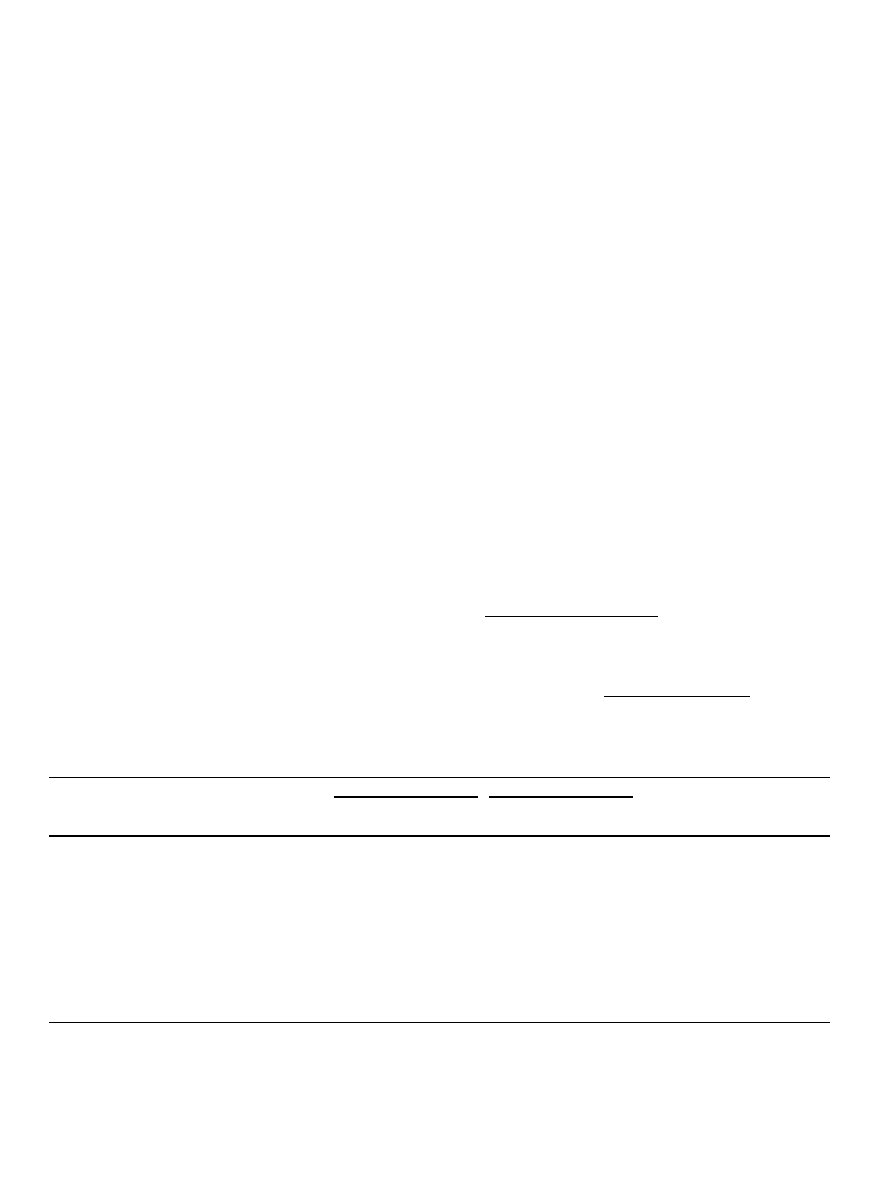

3.1. Energy inputs for the production of oilseed crops

The energy inputs associated with the production of 1 ha of

winter rapeseed were determined at 26.29 GJ. The most energy-

intensive

spring

oilseed

crops

were

spring

rapeseed

(14.77 GJ ha

1

) and white mustard (14.20 GJ ha

1

). Indian mustard

was characterized by the lowest energy input (11.24 GJ ha

1

)

The most energy-intensive process during the production of

oilseed crops was mineral fertilization that accounted for 61

e69%

(spring oilseed crops) to 79% (winter rapeseed) of total energy in-

puts (

). The remaining farming operations had the following

share of total energy inputs in the production of winter rapeseed:

seed and straw harvesting

e 9%, tillage e 6%, pest, weed and

pathogen control

e 4%, sowing e 2%. In less intensively farmed

spring oilseed crop species, fertilization had a smaller share of total

energy inputs, whereas harvesting (13

e15%), tillage (12e16%) and

sowing (4

e6%) proved to be more energy-intensive.

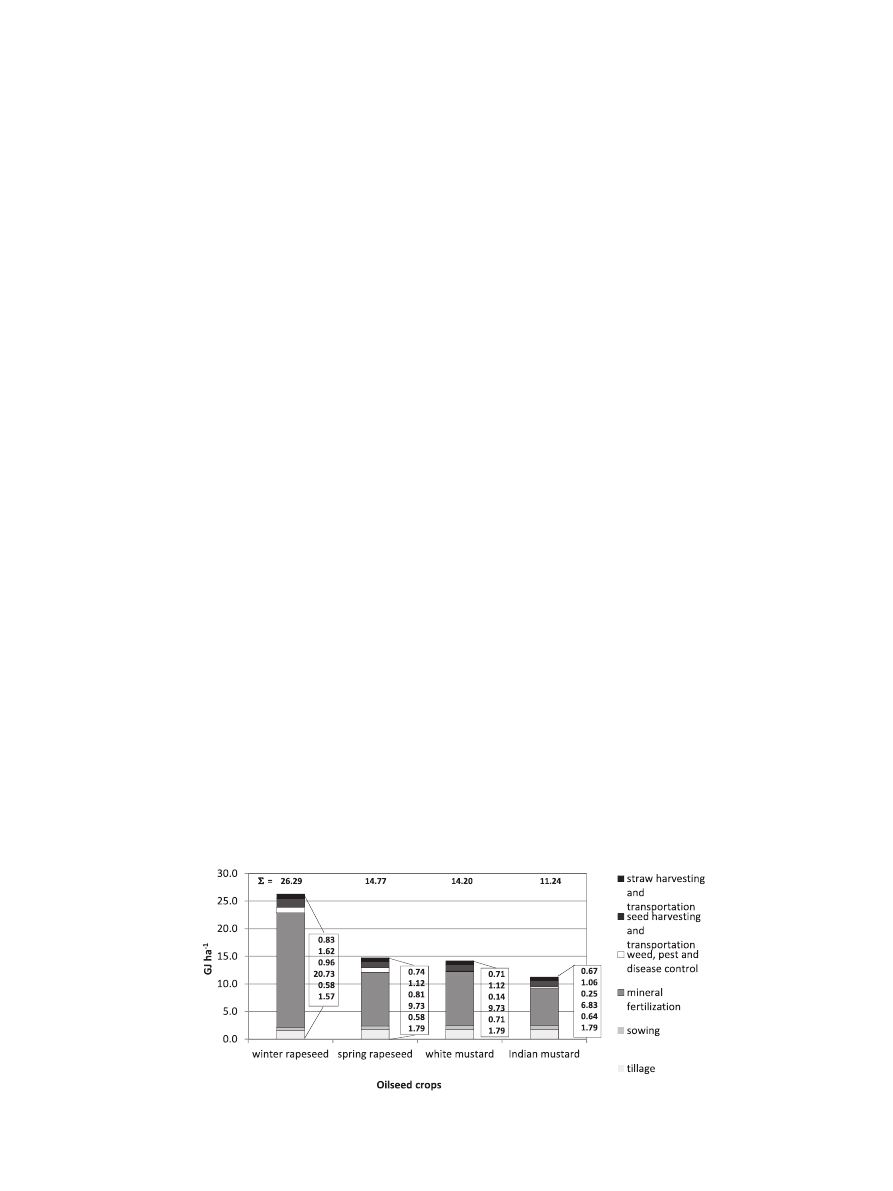

From

, materials accounted for most of the energy input at

61

e80% and fuel and labor together were 17e32%. The energy value

of consumed fuel was a relatively stable (from 3.5 to 4.0 GJ ha

1

)

component of the production process. Much greater variations

were observed in energy inputs associated with fertilization (from

6.6 to 20.5 GJ ha

1

). In winter rapeseed production, fertilization

accounted for 78% of total energy inputs (20.5 GJ ha

1

). The energy

equivalent for fertilization in the production of spring oilseed crops

ranged from 6.6 GJ ha

1

(Indian mustard) to 9.5 GJ ha

1

(spring

rapeseed and white mustard). In relative values, fertilizers

accounted for 59

e67% of total energy inputs associated with the

cultivation of the analyzed species (

3.2. Biomass yield of oilseed crops. Energy output

In the group of the analyzed oilseed plants, the highest seed

yield (5.36 Mg ha

1

) was reported for winter rapeseed (

),

followed by white mustard (37% of the winter rapeseed yield),

spring rapeseed (22%) and Indian mustard (12%). The oil cake yield

of winter rapeseed was determined at 3.27 Mg ha

1

DM. The oil

cake yield of spring oilseed crops was lower, and it was determined

at 56% of the rapeseed yield for white mustard and at 78

e86% for

spring rapeseed and Indian mustard. The highest straw yield

(10.09 Mg ha

1

DM) was noted in winter rapeseed, followed by

white mustard and spring rapeseed (57

e61% of winter rapeseed

straw yield). The lowest straw yield (4.39 Mg ha

1

DM) was re-

ported in Indian mustard. Winter rapeseed was also characterized

by the highest oil yield per ha (1.39 Mg). The oil yield of spring

oilseed crops was lower, accounting for 20% (spring rapeseed and

white mustard) and 7% (Indian mustard) of that reported in winter

rapeseed (

The energy value of 1 kg of winter rapeseed and spring rapeseed

was similar at 26.42

e27.17 MJ (

), and it was approximately

11% higher in comparison with white mustard and Indian mustard

seeds. The energy value of mustard straw was determined at

18.63

e19.00 MJ kg

1

DM, and the energy value of mustard oil

e at

43.50

e44.00 MJ kg

1

. The energy value of 1 kg of mustard straw

and oil was higher by 2% and 9%, respectively, in comparison with

rapeseed straw and oil. The energy value of mustard oil cake was

lower by 6% on average as compared with rapeseed oil cake

(

).

Winter rapeseed was characterized by the highest amount of

effective energy (accumulated in oil) for the production of liquid

transportation fuels (55.6 GJ ha

1

) (

). The energy value of the

oil yield of spring oilseed crops accounted for 8% (Indian mustard)

to 20

e22% (spring rapeseed and white mustard) of that noted in

winter rapeseed. In the three-year study, the average energy value

of the oil cake yield of winter rapeseed was estimated at

71.0 GJ ha

1

. In comparison with winter rapeseed, the energy

accumulated in the oil cake yield of spring oilseed plants was 59%

lower in white mustard, 78% lower in spring rapeseed and 87%

lower in Indian mustard.

The energy value of straw harvested from 1 ha of winter rape-

seed was 187.8 GJ. The energy accumulated in the straw yield of

spring oilseed crops accounted for 44

e60% of the energy value of

winter rapeseed straw. The highest amount of energy was accu-

mulated in the seeds and straw of winter rapeseed (314.4 GJ ha

1

).

The energy value of total biomass harvested from white mustard

was 53% lower, spring rapeseed

e 56% lower and Indian mustard e

69% lower in comparison with winter rapeseed (

).

The potential use of energy accumulated in the biomass of

winter rapeseed was as follows: 18%

e effective energy for the

petrochemical industry (oil), 82%

e energy for the generation of

heat and electricity (22%

e oil cake and 60% straw) (

). The

potential use of energy accumulated in the biomass of spring

Fig. 1. Estimated energy inputs in oilseed crop production by operations (average of three years).

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

677

oilseed crops was determined at 5

e8% for oil, 9e19% for oil cake,

and 73

e86% for straw (

3.3. Energy ef

ficiency ratio for the production of oilseed crops

The energy ef

ficiency analysis included two scenarios for man-

aging biomass-derived energy. In the

first variant (A), the energy

output of seed biomass was analyzed (straw was left in the

field to

decompose naturally). In the second variant (B), the amount of

energy accumulated in the entire biomass of oilseed crops (seeds

and straw) was determined (

The energy gain from the seeds of winter rapeseed (variant A)

was determined at 100.85 GJ ha

1

), and it was 3.7-fold and

8.1-fold higher than that of white mustard and spring rapeseed,

respectively. Indian mustard seeds were characterized by the

lowest energy gain (2.6% of the energy gain in winter rapeseed).

Winter rapeseed was the least-energy intensive crop (4835 MJ per

Mg of seeds). The amount of energy that had gone into the pro-

duction of 1 tonne of white mustard, spring rapeseed and Indian

mustard seeds was 1.5-fold, 3.2-fold and 3.7-fold higher, respec-

tively, in comparison with winter rapeseed. The highest energy

ef

ficiency ratio of seed biomass was noted in winter rapeseed

(4.92), followed by white mustard (2.99), spring rapeseed (1.87)

and Indian mustard (1.24) (

). Therefore, the working hy-

pothesis that the lower energy value of the seed yield of spring

oilseed crops could be compensated by relatively lower energy

inputs associated with their production relative to winter rapeseed

was not con

firmed.

The energy ef

ficiency ratio of biomass increased significantly to

reach 8.61

e10.49 (spring oilseed crops) or even 11.96 (winter

rapeseed) when the energy potential of both seeds and straw was

taken into account (

). The inclusion of straw in the energy

balance signi

ficantly improved the production efficiency of spring

oilseed plants relative to winter rapeseed. In the above approach,

the energy ef

ficiency ratio of winter rapeseed biomass (seeds and

straw) was higher by only 14

e39% in comparison with spring

oilseed crops (

4. Discussion and conclusions

4.1. Energy inputs

In European agricultural systems, the amount of energy

consumed during the production of 1 tonne of oilseed rape seeds is

estimated at 2.1

e4.5 GJ

. In this study, 4.8 GJ of energy was

required to deliver an average winter rapeseed yield of 1 Mg. In

central Italy (Tuscany), the energy input for the production of 1 Mg

seeds of winter rapeseed was estimated at 4.5. GJ (low-input sys-

tem) and 7.4 GJ (high-input system)

. In the climate and habitat

conditions of Great Britain, 3.7

e4.6 GJ of energy was consumed

during the production of 1 Mg seeds of oilseed rape

. In Turkish

farms with an area of

<5, 5e9.9 and >10 ha, energy consumption

for the needs of canola (Brassica napus) cultivation was estimated at

5.9 GJ Mg

1

seeds

. The energy demand per 1 tonne of canola

(B. napus) seeds in Iran reached 8.2 GJ

. In large-scale com-

mercial farms in North Dakota, Montana and Minnesota (USA), the

energy input requirement per ha of canola (B. napus) was estimated

Fig. 2. Structure of energy inputs in oilseed crop production by energy

fluxes (average of three years).

Table 3

Biomass yield of oilseed crops (average of three years).

Yield

Oilseed crops

Rapeseed

Mustard

Winter

Spring

White

Indian

Seeds (Mg ha

1

87% DM)

5.36

1.16

c

1.97

b

0.63

d

Oil (Mg ha

1

)

1.39

a

0.28

b

0.28

b

0.10

c

Oil cake (Mg ha

1

DM)

3.27

a

0.73

c

1.44

b

0.45

d

Straw (Mg ha

1

DM)

10.09

a

6.17

b

5.79

b

4.39

c

a

Means with the same letter are not signi

ficantly different at P 0.05 in Duncan's

test.

Table 4

Unit energy value of the biomass yield of oilseed crops (average of three years).

Unit energy value

Oilseed crops

Rapeseed

Mustard

Winter

Spring

White

Indian

Seeds (MJ kg

1

DM)

27.17

26.42

b

23.79

d

24.40

c

Oil (MJ kg

1

)

40.11

d

40.36

c

43.50

b

44.00

a

Oil cake (MJ kg

1

DM)

21.68

a

20.92

b

20.00

c

20.14

c

Straw (MJ kg

1

DM)

18.60

ab

18.31

b

18.63

ab

19.00

a

a

Means with the same letter are not signi

ficantly different at P 0.05 in Duncan's

test.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

678

at 9.5 GJ

. A study of a large-scale commercial farm with an area

of 2000 ha in north-eastern Poland revealed that the production of

1 Mg of winter rapeseed required 6.7 GJ (high-input system), 5.2 GJ

(medium-input system) and 4.5 GJ (low-input system) of energy

. Contrary results were reported by Cardone et al.

in Tus-

cany where energy consumption associated with the production of

1 Mg of winter rapeseed increased from 4.5 to 7.4 GJ after the

introduction of a less intensive production regime. In Poland, the

energy demand associated with the production of 1 ha of spring

oilseed crops of the family Brassicacea (spring rapeseed, white

mustard, Indian mustard, spring camelina, crambe) was 26

e41%

lower on average than that of winter rapeseed

. In this study, the

energy input of spring oilseed crops was lower by 44

e57% in

comparison with winter rapeseed.

An analysis of various types of energy inputs indicates that the

most energy-intensive components in winter rapeseed cultivation

are

fertilization

(59

e80%) and energy carriers (12e30%)

e26]

. In the production of spring oilseed crops, fertilizers

play a somewhat smaller role (58

e63%), whereas energy carriers

have a somewhat higher share (27

e32%) of total energy inputs,

compared with winter rapeseed

. A similar distribution of energy

inputs was observed in crop production technologies evaluated in

this study. The energy consumption in large-scale commercial

farms can be lowered only by increasing the effectiveness of min-

eral fertilizers. The introduction of advanced technological solu-

tions, including more effective machines that consume less fuel, is a

necessity, but it is unlikely to induce a signi

ficant reduction in the

energy requirements of crop production.

4.2. Energy outputs

In a Polish study evaluating Brassica oilseed crops

, the

highest amount of energy was accumulated in the biomass of

winter rapeseed. In large-scale commercial farms, the amount of

energy accumulated in the biomass yield of winter rapeseed (seeds

and straw) produced in a high-input system can reach 250 GJ ha

1

,

where 45% of the energy is accumulated in seeds and 55% in straw

. In comparison with winter rapeseed, the energy value of the

biomass of spring oilseed crops was lower by 31

e63%

.

Fig. 3. Energy value of the biomass yield of oilseed crops (average of three years).

y

means with the same letter are not signi

ficantly different at P 0.05 in Duncan's test.

Fig. 4. Structure of effective energy accumulated in the biomass of oilseed crops (average of three years).

Table 5

Energy analysis of the biomass of oilseed crops (average of three years).

Speci

fication

Oilseed crops

Rapeseed

Mustard

Winter

Spring

White

Indian

Energy inputs (GJ ha

1

)

A

25.73

14.27

13.71

10.77

B

26.29

14.77

14.20

11.24

Energy value of biomass yield

(energy outputs) (GJ ha

1

)

A

126.58

26.75

41.04

13.35

B

314.35

139.85

148.98

96.81

Energy gain (GJ ha

1

)

A

100.85

12.48

27.33

2.58

B

288.06

125.08

134.78

85.57

Energy consumption per unit of

production

e 1 Mg DM (MJ)

A 4835

15,319

7192

17,905

B

1786

2206

2023

2673

Energy ef

ficiency ratio

A

4.92

1.87

2.99

1.24

B

11.96

9.47

10.49

8.61

A

e seeds; B e seeds þ straw.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

679

Differences were also noted in the energy accumulation patterns of

spring oilseed plants and winter rapeseed. Approximately 60

e65%

of energy in the biomass of spring oilseed crops is accumulated in

straw

. In the current study, the energy value of seed and straw

biomass of winter rapeseed was estimated at 314.4 GJ ha

1

. The

amount of energy accumulated in the biomass of white mustard

was 165.4 GJ ha

1

lower, in the biomass of spring rapeseed

e

174.5 GJ ha

1

lower, and in the biomass of Indian mustard

e

217.6 GJ ha

1

lower (56

e69% lower in relative values) than in

winter rapeseed. The results of this study con

firmed that the

biomass of spring oilseed crops is a valuable source of energy for

the generation of heat and electricity (the energy accumulated in

straw accounted for 73

e86% of the total energy value of biomass).

4.3. Energy ef

ficiency ratio

A review of the literature points to signi

ficant variations in the

energy ef

ficiency ratio of winter rapeseed production, which is

signi

ficantly influenced by the efficiency of the applied production

technology. According to Venturi and Venturi

, the energy ef

fi-

ciency ratio of rapeseed in European farming systems ranges from

1.4 to 2.2. The discussed parameter was determined at 1.1

e1.7 in

traditional farms in Italy

. Unakitan et al.

estimated the

energy ef

ficiency of canola (B. napus) seed production at 4.7 in

Turkey. In Iran, the energy ef

ficiency of canola (B. napus) seed

production was estimated at 3.2

. In a high-input farm in

Poland, Jankowski

estimated the energy ef

ficiency ratio of

winter rapeseed at 3.6. In less intensive production systems the

value of the energy ef

ficiency ratio increased to 4.7 and 5.4. Bielski

et al.

analyzed the energy ef

ficiency of oilseed crops and the

conversion of oilseed plant biomass to biofuel to demonstrate that

EROEI (Energy Return On Energy Invested), an indicator presenting

the amount of energy acquired from a given type of fuel relative to

the energy input required for its production, can exceed 1 when the

energy ratio of biomass production in a farm equals 5. In our study,

the energy ratio of the highest-yielding species of Brassica oilseed

crops (winter rapeseed) was determined below the above

threshold (4.92), therefore its conversion to liquid fuel was not

justi

fied. The energy efficiency of white mustard, spring rapeseed

and Indian mustard seeds was lower by 39%, 62% and 75% in

comparison with winter rapeseed. The energy ef

ficiency of white

mustard, spring rapeseed and Indian mustard seeds was lower by

39%, 62% and 75% in comparison with winter rapeseed. The pro-

duction of Brassica oilseed crops for energy generation is justi

fied

when fat-free biomass components are also used and converted to

solid fuel (straw briquettes and a mixture of straw and oil cake)

In our study, the energy ef

ficiency ratio of winter rape seeds and

straw reached 11.96. When both biomass components were utilized

as sources of energy, the energy ef

ficiency of spring oilseed plants

was lower by only 12

e21% (white mustard, spring rapeseed) and

28% (Indian mustard) in comparison with winter rapeseed.

In this study, the potential energy output of the above-ground

biomass of spring cultivars of oilseed plants (rapeseed, white

mustard and Indian mustard) was compared with winter rapeseed,

the best energy crop in Europe. This Mediterranean species is

characterized by a high and repeatable yield in Western and Central

Europe. The freeze risk zone for winter rapeseed begins in eastern

Poland and covers Eastern European countries. Freeze-damaged

plantations have to be resown with spring oilseed crops. The

biomass yield of the highest yielding species of white mustard,

Indian mustard and spring rapeseed is 57% lower, and their energy

output is 3

e9-fold lower in comparison with winter rapeseed. It

should be noted that the use of the highest-yielding Brassica oilseed

crop (winter rapeseed) is justi

fied only when the entire biomass is

converted to liquid fuel (oil) and solid fuel (oil cake and/or straw).

Spring oilseed plants of the family Brassicaceae are characterized by

very low energy outputs in the process of conversion to liquid fuel,

and they do not pose a viable alternative to winter rapeseed.

However, the results of our study demonstrate that when the entire

above-ground biomass (seeds

þ straw) is used for the generation of

heat/electricity, the energy ratio increases to 8.6

e10.5, i.e. to a level

that is only 20% lower in comparison with winter rapeseed. In this

scenario, spring oilseed plants of the family Brassicaceae pose a

realistic alternative to winter rapeseed if the latter is frost damaged

in winter and early spring. In our study, white mustard was char-

acterized by a higher unit energy value (MJ Mg

1

DM biomass) and

a higher energy ef

ficiency ratio than spring rapeseed. This is an

important consideration since European breeders are making at-

tempts to improve white mustard by making it suitable for culti-

vation on lighter and drier soils where rapeseed cannot be grown.

Our results provide valuable information for breeders in Eastern

Europe, including the eastern parts of Poland, Ukraine, Belarus,

Russia, Latvia, Estonia and Finland, where the risk of frost damage

for winter rapeseed exceeds 20%. The acreage of oilseed crops of the

family Brassicaceae has been increasingly steadily in the above

regions.

Acknowledgments

The results presented in this paper were obtained as part of a

comprehensive study

financed by the Polish Ministry of Science

and Higher Education (grant No. N310 031 32/167). We would like

to thank Dr Andrzej Kosecki and Andrzej Kerner, Eng. from the

Agricultural Experiment Station in Ba

łcyny for assistance in deter-

mining energy inputs and the ef

ficiency of farming operations in

production

fields. We are also grateful to the Reviewers for their

valuable comments on the manuscript.

References

[1]

Roszkowski A. Energy and agriculture (energy crisis

_zynieria Rol 2008;4(102):25e35 [In Polish]

[2]

e85

[3]

e C, Mantineo M, D'Agosta GM. Agronomic,

[4]

Zegada-Lizarazu W, Monti A. Energy crops in rotation. A review. Biomass

Bioenergy 2011;35:12

[5]

Stolarski MJ, Szczukowski S, Tworkowski J, Krzy

e6

[6]

[7] FAOSTAT. Faostat agriculture data. 2014. Available from:

[17.09.14].

[8]

nski W. Energy potential of oilseed crops. Probl Ekol

.

[9] Statistical yearbook of agriculture. 2013. Available from:

pl/cps/rde/xbcr/gus/rs_rocznik_rolnictwa_2013.pdf

[09.04.14].

[10]

Egesel C €

ıman F. Changes in yield and seed quality traits in

rapeseed genotypes by sulphur fertilization. Eur Food Res Technol 2009;229:

505

e13

.

[11]

e6

.

[12]

Nowak-Polakowska H, Czaplicki S, Ta

nska M, Jankowski K. Chemical compo-

.

[13]

acterization. Biomass Bioenergy 2003;25:623

[14]

.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

680

[15]

[16]

Ciubota-Rosie C, Macoveanu M, Fern

andez CM, Ramos MJ, Perez A, Moreno A.

Sinapis alba seed as a prospective biodiesel source. Biomass Bioenergy

2013;51:83

.

[17]

e37

.

[18]

Banasiak J. Agricultural technology. PWN; 2003 [In Polish]

[19]

[20]

ojcicki Z. Equipment, materials and energy inputs in growth-oriented

farms. IBMER; 2000 [In Polish]

[21]

e40

.

[22]

Unakitan G, Hurma H, Yilmaz F. An analysis of energy use ef

production in Turkey. Energy 2010;35:3623

[23]

fiee S, Jafari A, Mohammadi A. Energy flow modeling

and sensitivity analysis of inputs for canola production in Iran. J Clean Prod

2011;19:1464

e70

.

[24]

e44

.

[25]

Disseratations and Monographs [In Polish]

[26]

[27]

nski W. The energy efficiency of oil seed crops

production and their biomass conversion into liquid fuels. Przem Chem

2014;93(12):2270

e3

.

K.J. Jankowski et al. / Energy 81 (2015) 674

e681

681

Document Outline

- An analysis of energy efficiency in the production of oilseed crops of the family Brassicaceae in Poland

Wyszukiwarka

Podobne podstrony:

An analysis of the energy efficiency of winter rapeseed biomass under

Can we accelerate the improvement of energy efficiency in aircraft systems 2010 Energy Conversion an

Orszulak Dudkowska, Katarzyna Food Expenses in the Rhythm of Daily Life An Analysis of Household Ac

Piotr Siuda Prosumption in the Pop Industry An Analysis of Polish Entertainment Companies

Terrorists as Enemy Combatants An Analysis of How the United States Applies the Law of Armed Conflic

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

An analysis of the European low Nieznany

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

A Philosophy for all an analysis of the Tao

an analysis of the legal high mephedrone bioorg med chem lett 20 4135 4139 2010

With Microscope and Tweezers An Analysis of the Internet Virus of November 1988

Price An Analysis of the Strategy and Tactics of Alexious I Komnenos

An Analysis of U S Army Fratricide Incidents during the Global War on Terror (11 September 2001 to 3

2012 vol 07 Geopolitics and energy security in the Caspian region

Prospect theory an analysis of decision under risk

An Analysis of Euro Area Sovereign CDS and their Relation with Government Bonds

Rueda Electromagnetic Zero Point Field as Active Energy Source in the Intergalactic Medium (1999)

więcej podobnych podstron