Development of a Polymeric Patch Impregnated with Naproxen

as a Model of Transdermal Sustained Release System

ANNA ARGEM´ı,

1

JEFFREY L. ELLIS,

2

JAVIER SAURINA,

1

DAVID L. TOMASKO

2

1

Department of Analytical Chemistry, University of Barcelona, Mart´ı i Franqu`es 1-11, 08028 Barcelona, Spain

2

William G. Lowrie, Department of Chemical and Biomolecular Engineering, The Ohio State University, Columbus, Ohio 43210

Received 29 April 2010; revised 6 July 2010; accepted 24 August 2010

Published online 16 September 2010 in Wiley Online Library (wileyonlinelibrary.com). DOI 10.1002/jps.22346

ABSTRACT: This paper describes the preparation and characterization of transdermal patches

impregnated with naproxen. A mixture of ethylene vinyl acetate and Eudragit

R

E100 (80:20,

w/w) is used as a polymeric matrix to obtain a thin membrane to be impregnated. Drug impreg-

nation is carried out under pressurized

CO

2

as a processing medium according to a two-step

procedure. The patch is first soaked at 1000 psi and 22

◦

C for 2 h, and then foamed as a result of

the rapid release of

CO

2

pressure in order to increase the porosity of the surface. Subsequently,

the naproxen solution is placed in contact with the membrane and then soaked in

CO

2

at 450

psi and 37

◦

C for 2.5 h to enhance the mass transfer of drug into the polymer matrix. The char-

acterization of the resulting samples by liquid chromatography, microscopy, and calorimetry

provides information on naproxen content and distribution. Patches synthesized in this way are

loaded with about 1% naproxen. The drug release and diffusion process through a membrane

have been studied chromatographically using a Franz diffusion cell. Results have shown that

a sustained delivery for more than 24 h is obtained. © 2010 Wiley-Liss, Inc. and the American

Pharmacists Association J Pharm Sci 100:992–1000, 2011

Keywords:

controlled delivery; transdermal drug delivery; processing; in vitro models; poly-

meric drug carrier; supercritical fluids

INTRODUCTION

An important pharmaceutical research field is fo-

cused on the development of new pharmaceutical

forms with improved bioavailability and stable dosage

by using clean technologies.

1–4

Processes carried out

under dense (pressurized) or supercritical carbon

dioxide result in an attractive alternative to those

involving traditional solvents, especially to overcome

the problems associated with toxicity and resid-

ual impurities.

5

Recent technological applications of

pressurized and supercritical fluids comprise extrac-

tion of natural products; removal of contaminants,

6,7

protein, and peptide fractionation

8

; and prepara-

tive supercritical fluid chromatography.

9,10

However,

apart from such type of industrial applications,

the potentiality of

CO

2

as a processing medium

in pharmaceutical particle engineering cannot be

Correspondence to: Anna Argem´ı (Telephone:

+34-934-034-445;

Fax:

+34-934-021-233; E-mail: annaargemi@ub.edu)

Journal of Pharmaceutical Sciences, Vol. 100, 992–1000 (2011)

© 2010 Wiley-Liss, Inc. and the American Pharmacists Association

underestimated

11,12

and following three main work-

ing topics are being investigated: (a) the preparation

of active compound powders with improved or mod-

ified therapeutic action, (b) the production of poly-

mers to be used as a matrix for drug impregnation,

and (c) the preparation of drug delivery systems with

enhanced bioavailability or sustained release char-

acteristics. Hence, multiple pharmaceutical applica-

tions have been reported including the preparation of

patches, sponges,

13

and catheters

14

with potential use

in tissue engineering and drug delivery.

Advantages gained from the use of supercritical

or dense

CO

2

include the excellent uniformity in the

distribution of the solute into the matrix, the reduc-

tion of process steps, and the simplicity of solvent

removal. As nonporous polymeric matrices exposed

to these fluids swell, the solute penetration through

the matrix is thus enhanced. In addition, the drug

entrapment can be carried out in a quick and easy

one-step procedure. As an example, Kazarian and

Martirosyan

15

described the impregnation of ibupro-

fen in polyvinylpyrrolidone (PVP), resulting in the

992

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

NAPROXEN-POLYMERIC PATCH FOR TRANSDERMAL SUSTAINED RELEASE SYSTEM

993

formation of a molecular dispersion of drug into the

matrix.

Although a wide variety of polymers have been

used in the past 40 years as drug carriers, recent

trends rely on water-soluble matrices such as PVP

or its copolymer with vinylacetate (PVP-VA 64).

16

Other polymers such as cellulose derivatives [e.g.,

ethylcellulose (EC), methylcellulose]

17,18

ethylene

vinyl acetate (EVA),

19,20

and pH-dependent polymers

such as Eudragit

R

E100 (Evonik Degussa, Essen,

Germany), (polymethacrylate copolymer)

18

are being

increasingly used.

This study is focused on the preparation and char-

acterization of a transdermal patch as a model sys-

tem of sustained released using pressurized

CO

2

as

a processing medium. Naproxen is the drug chosen

here for this development. Naproxen is a member of

the 2-arylpropionic acid family of nonsteroidal anti-

inflammatory drugs commonly used for the reduction

of mild-to-moderate pain, fever, inflammation, and

stiffness.

21

The US Food and Drug Administration

approved the use of naproxen sodium as an over the

counter drug in 1994. Analytical techniques, includ-

ing differential scanning calorimetry (DSC), confocal

fluorescence microscopy, and high-performance liq-

uid chromatography (HPLC), have been utilized for a

more rigorous characterization of naproxen samples.

MATERIALS AND METHODS

Materials

Sodium

hydrogenphosphate,

sodium

dihydro-

genphosphate,

formic

acid,

rhodamine

(5,6-

carboxytetramethylrhodamine),

and

naproxen

(99%) were purchased from Sigma–Aldrich (St.

Louis, Missouri). Methanol and methylene chloride

(HPLC grade, Merck, Darmstadt, Germany) were

used as solvents. Carbon dioxide (

CO

2

, 99.99 mol%

purity) was supplied by Praxair (Columbus, Ohio).

Polymers used were EC 20 cps from Keyser & Mackay

(Brussels, Belgium), PVP-VA 64 (molecular weight

=

45,000–70,000 g mol

−1

) from BASF (Ludwigshafen,

Germany), Eudragit

R

E100 (acrylic polymer, molecu-

lar weight

= 150,000 g mol

−1

) from Evonik Degussa

(Essen, Germany), and EVA (70 wt% of vinyl acetate)

from Sigma. Ultrapure water (Millipore, Milford,

Massachusetts) was used for the preparation of

aqueous solutions.

Analytical Instrumentation

The chromatographic system consists of an HPLC Ag-

ilent 1100 Series instrument equipped with a G1311A

quaternary pump, a G1379A degasser, a G1329B

standard autosampler (1200 Series), a G1315B diode-

array detector furnished with a 13-mL flow-cell,

a G1321A fluorescence detector, and an Agilent

Chem Station for data acquisition and analysis (Rev.

A 10.12), all of them from Agilent Technologies

(Waldbronn, Germany). The analytical column was a

reverse phase C

18

(Synergi Hydro-RP, Phenomenex,

150

× 4.6 mm

2

d.i., 4 µm particle size). Naproxen was

eluted isocratically with 10 mM of formic acid/formate

aqueous solution (pH 3.2)

+ MeOH (20/80, v/v) as a

mobile phase. The flow rate was maintained at 1 mL

× min

−1

and the injection volume was 20 µL. Ultra-

violet (UV) spectrophotometric detection was carried

out at 270 nm. Fluorescence detection was carried out

at 270 and 357 nm as excitation and emission wave-

lengths, respectively. A magnetic stirrer IKA

R

RCT

basic (Staufen, Germany) was used for controlling the

release conditions.

Standard solutions for calibration were prepared in

methanol in the concentration range from 5.2

× 10

−7

to 3.9

× 10

−5

M. For UV spectrophotometric detection,

a good linearity in the studied range was found with a

regression coefficient r

2

= 0.9989. Detection limit es-

timated for a signal-to-noise ratio of three was 1.8

×

10

−7

M. Repeatability expressed as relative standard

deviation (RSD in %) for the peak area was calcu-

lated from eight replicates at a concentration of 2.5

× 10

−6

M and was 2.1%. For fluorescence detection,

the linearity was found with a regression coefficient

r

2

= 0.9988. Detection limit was 1.1 × 10

−7

M and

repeatability was 1.5%. The chromatographic method

was used in both the determination of the impreg-

nation percentage and in the monitoring of the drug

release.

A differential scanning calorimeter (DSC-822e/400,

Mettler Toledo, Greifensee, Switzerland) was used to

determine melting and glass transition temperatures.

Thermograms were obtained at a heating rate of 10

◦

C

× min

−1

from 30

◦

C to 250

◦

C under a N

2

purge of

50 mL

× min

−1

.

A confocal microscope Leica TCS SPII (Leica Mi-

crosystems, Wetzlar, Germany) operating in both re-

flectance and fluorescence modes was used. Excita-

tion was at 351 and 364 nm using UV lasers and

reflectance, and emission intensities were recorded

in the range of 400—800 nm. The objective used

was a 10

× 0.3 N.A. HCPL FLUOTAR lens (Leica

Microsystems). Images were processed using the

ImageJ (NIH Image; www.rsb.info.nih.gov/ij) and

Photoshop 7.0 software (Adobe Corp., San Jose,

California). Transversal sections were taken every

2.4 µm.

Preparation of Working Solutions and Naproxen

Impregnated Patches

The working solution of rhodamine for preliminary

impregnation studies consisted of 1.5 mg dissolved in

100 mL of sodium phosphate buffer solution (PBS)

DOI 10.1002/jps

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

994

ARGEM´I ET AL.

at pH 6.2. Naproxen working solution consisted of

100 mg in 25 mL of PBS at pH 7.4.

Patch Synthesis.

Ten grams of EVA and 2.5 g of Eudragit

R

E100

were treated with 30 mL of CH

2

Cl

2

. The mixture

was left in an ultrasonic water bath (Unisonics ul-

trasonic cleaner FXP8) for 90 min (until polymers

were completely dissolved). This water bath sonica-

tor has an ultrasonic power of 50 W and provides a

frequency of 40 kHz. The resulting solution was cast

on a microporous Teflon film placed on a glass plate.

The Teflon film was used as a release agent because

polymer sticks on the glass. A thin layer of polymer

solution was obtained with the aid of an adjustable

thin film applicator (GARDCO, Paul N. Gardner Co.,

Pompano Beach, Florida). The solvent was allowed

to evaporate, first at ambient conditions, and then in

the vacuum oven (P

= 30 mmHg) at room temper-

ature overnight. The thin polymer layer was peeled

off and thickness was measured using an electronic

gauge Mitutoyo (Model 543-252B, Mitutoyo America

Corp., Aurora, Illinois) with an accuracy of

±0.5 µm.

Membranes with a thickness ranging from 231.5 to

242.4 µm were obtained. Finally, patches were cut in

square shape (4

× 4 cm

2

size, approx.) and were stored

at ambient conditions until further use.

Patch Impregnation Using

CO2

.

The procedure for impregnation of patches with

naproxen consisted of two steps as follows:

(1) Patch foaming process: First, the synthesized

patches (see patch synthesis section) were

treated with pressurized

CO

2

to induce the for-

mation of pores in the material. The polymeric

patch (placed on a piece of Teflon film) was lo-

cated inside a stainless steel high-pressure ves-

sel (Pressure Products Industries, Inc., Warmin-

ster, Pennsylvania). Another piece of Teflon film

and a piece of stainless steel were placed on

top of the patch. The system was pressurized

to 1000 psi and held at constant pressure for

2 h with an ISCO Syringe pump 500D (ISCO,

Lincoln, Nebraska). The temperature was main-

tained at 22

◦

C. The foaming process was initi-

ated with a rapid

CO

2

depressurization in 4 s

and the porous patch obtained was ready to be

impregnated with the drug.

(2) Impregnation process: 1000 µL of solution of

model (rhodamine, 1.5 mg in 100 mL PBS at pH

6.2) and active drug (naproxen, 0.1 g in 25 mL

PBS at pH 7.4) were dipped onto the porous ma-

trix surface of the patch. The high-pressure ves-

sel was then sealed airtight and heated with

a Peltier system up to the desired experimen-

tal temperature. A minimum of 15 min was

allowed to ensure thermal equilibrium. Then,

the 500D syringe pump was used to pressurize

the vessel with

CO

2

until the working pressure

was reached. The temperature and pressure

were held constant during this period. The sys-

tem was then depressurized over nearly 30 min

by slowly opening the purge valve. Finally, the

patch was dried at room temperature for 8 days

at least and stored in a sealed plastic bag until

future characterizations. The experimental pro-

cessing window for impregnation was explored

by experimental design. For this purpose, a full

factorial design with three factors (temperature,

pressure, and time) at two levels was utilized,

which corresponded to eight experiments.

Characterization Studies

Determination of the Percentage Impregnation.

The amount of naproxen entrapped in the polymeric

matrix was determined by HPLC. For this purpose,

about 30–40 mg of sample were dissolved in 10 mL of

CH

2

Cl

2

by ultrasonication for 1 h. Subsequently, the

solvent was evaporated under nitrogen current and

the dry residue was redissolved in 25 mL of methanol.

Twenty microliter of the resulting solution, previously

filtered through a 0.45 µm pore-size membrane, was

injected into the chromatograph.

Drug Release Studies.

The study of naproxen diffusion from the patches was

carried out using a Franz glass cell with 3.14 cm

2

of

diffusion area and a receptor chamber of 12 mL vol-

ume. Naproxen is soluble in the receptor medium at

a concentration of 5.2 mg mL

−1

. A sample amount of

25–60 mg was distributed on a synthetic Nylon mem-

brane of 0.45 µm pore size (Whatman Int., Maidstone,

Kent, UK) and placed in the donor chamber. Imme-

diately after that, the top of the cell cap was covered

with Parafilm

R

(Chicago, Illinois) to minimize evap-

oration during the test. The receptor chamber was

filled with 100 mM of PBS at pH 7.4 and the tem-

perature was kept at 32

± 0.5

◦

C. The solution in the

receptor chamber was stirred with the aid of a cylin-

drical magnetic stir bar at a constant rate of 70 rpm.

Aliquots of 300 µL withdrawn at preselected times of

1, 2, 4, 6, 8, and 24 h were analyzed by HPLC and,

immediately after, equal volumes of fresh temperate

PBS solution were added to the receptor chamber.

Sink conditions were well ensured by correcting any

volume losses, when necessary. At the end of the pro-

cess, the drug content remaining in the patch was

determined as indicated previously in section of the

percentage impregnation determination. Kinetic re-

leases were performed in triplicate.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

DOI 10.1002/jps

NAPROXEN-POLYMERIC PATCH FOR TRANSDERMAL SUSTAINED RELEASE SYSTEM

995

RESULTS AND DISCUSSION

Polymer Selection

The patch flexibility is recognized as an important

characteristic to be investigated. Flexibility strongly

depends on the composition of polymers utilized in

the patch synthesis. Here, various polymer mixtures

were assayed in order to optimize material to be used

as a matrix to develop the transdermal patch. These

preliminary studies were carried out in a hydraulic

press at different temperatures.

A mixture of ethyl cellulose and Eudragit

R

E100

was first considered. EC 20 cps, an ethyl ether of cellu-

lose, is widely used as a film coating. It is a semicrys-

talline polymer with a glass transition temperature

of approximately 130

◦

C and a melting point of about

180

◦

C. Eudragit

R

E100 is soluble in acidic solutions

up to pH 5, then suitable for releasing naproxen at the

skin pH. These two polymers were treated under var-

ious experimental conditions of pressure and temper-

ature. When the working temperature was lower than

the melting temperature of ethyl cellulose, the poly-

mers did not melt, even working at higher pressures.

Melting at higher temperatures caused EC degrada-

tion. Thus, in any case, the characteristics of the final

products were found satisfactory.

PVP-VA 64 is used as a binder pharmaceutical

tablets; it simply passes through the body when taken

orally. PVP-VA 64 was here used as an adhesive pro-

viding successful adhesion, although the stiffness of

the produced material was too rigid.

As a consequence of this rigidity and EC decomposi-

tion, we chose other polymers that could provide suit-

able properties. Finally, a combination of EVA (70%

acetate content) together with Eudragit

R

E100 was

found to be a good candidate. EVA was selected as

a flexible polymeric component and Eudragit

R

E100

resulted in a suitable drug carrier. EVA is mainly

used in the materials field because of its properties

as an elastomer with a high flexibility and softness,

yet it can be processed like other thermoplastics. The

percentage of each polymer in the mixture was opti-

mized. The patch became more rigid when increasing

the Eudragit

R

E100 percentage due to the pres-

ence of higher methacrylate amounts. The compo-

sition finally chosen was 20% of Eudragit

R

/80% of

EVA (w/w).

Patch Impregnation Studies

Raw patches were obtained as thin membranes of

Eudragit

R

/EVA polymer mixtures according to pro-

cedure detailed in patch synthesis section. The patch

impregnation with model compounds was first stud-

ied using rhodamine to check visually the charac-

teristics of the resulting materials. The influence of

the foaming process as a preliminary treatment of

polymeric membranes was here investigated. Apart

from inducing the formation of pores on the matrix

surface, this stage allows the control of the final mor-

phology to be exploited in applications such as biolog-

ical scaffolds and drug delivery systems.

22

The foam-

ing process was developed for 2 h at 1000 psi and the

resulting membranes were treated with the dye in a

second process developed at 450 psi and 22

◦

C for 2 h.

Such process proved that unaltered membranes were

not a suitable support for impregnation. In contrast,

membranes pretreated with dense CO

2

were modified

superficially. As a result, a successful distribution of

rhodamine on the surface of the activated matrix was

obtained.

Conditions established from rhodamine assays

were adapted to the elaboration of naproxen patches.

The membrane treatment relied on the two-step pro-

cedure consisting of the foaming surface preactivation

followed by the drug impregnation. In this case, how-

ever, experimental impregnation conditions of the sec-

ond step were studied, being pressure, temperature,

and time (P, T, and t) as the variables to be considered.

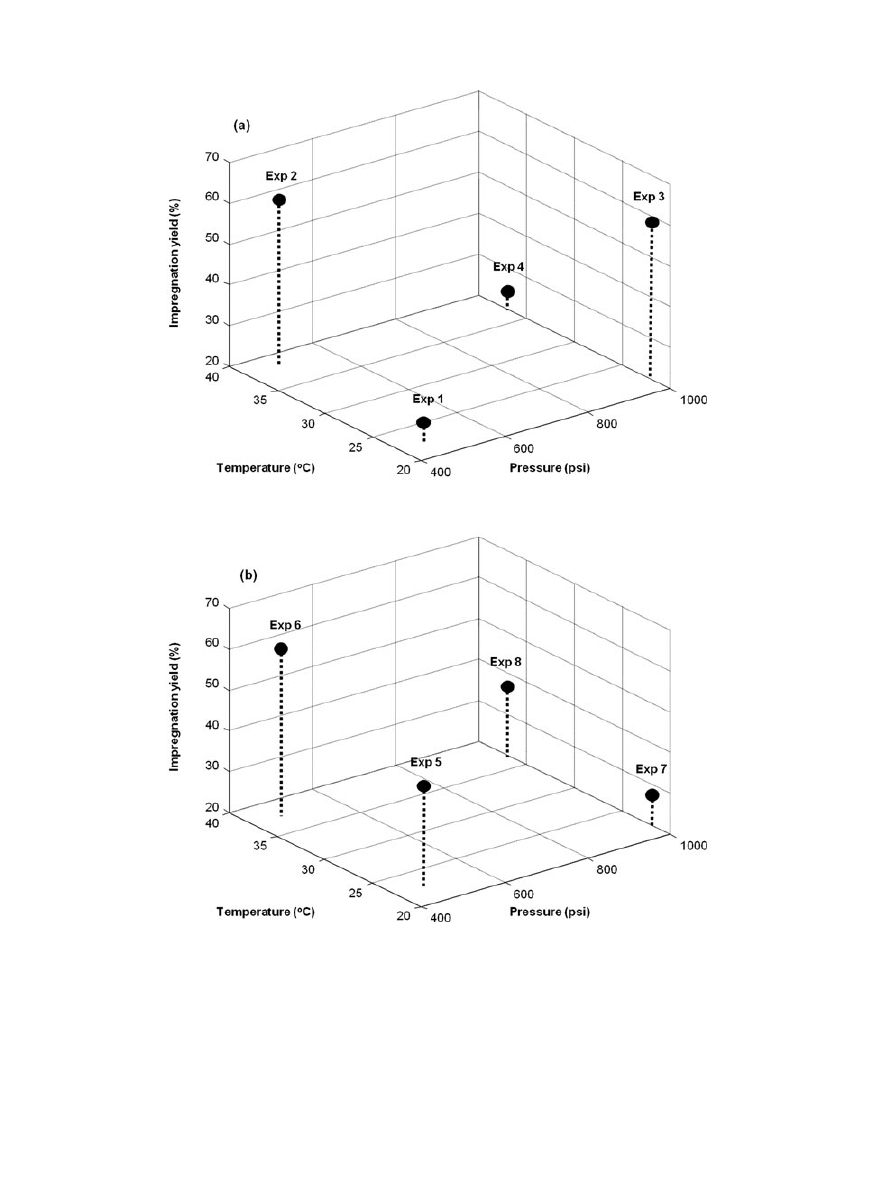

The highest impregnation yields corresponded to the

experiments 2 and 6 in Figure 1, which were per-

formed at low pressure and high temperature. Among

them, conditions of experiment 2 were more efficient

as the process time was shorter.

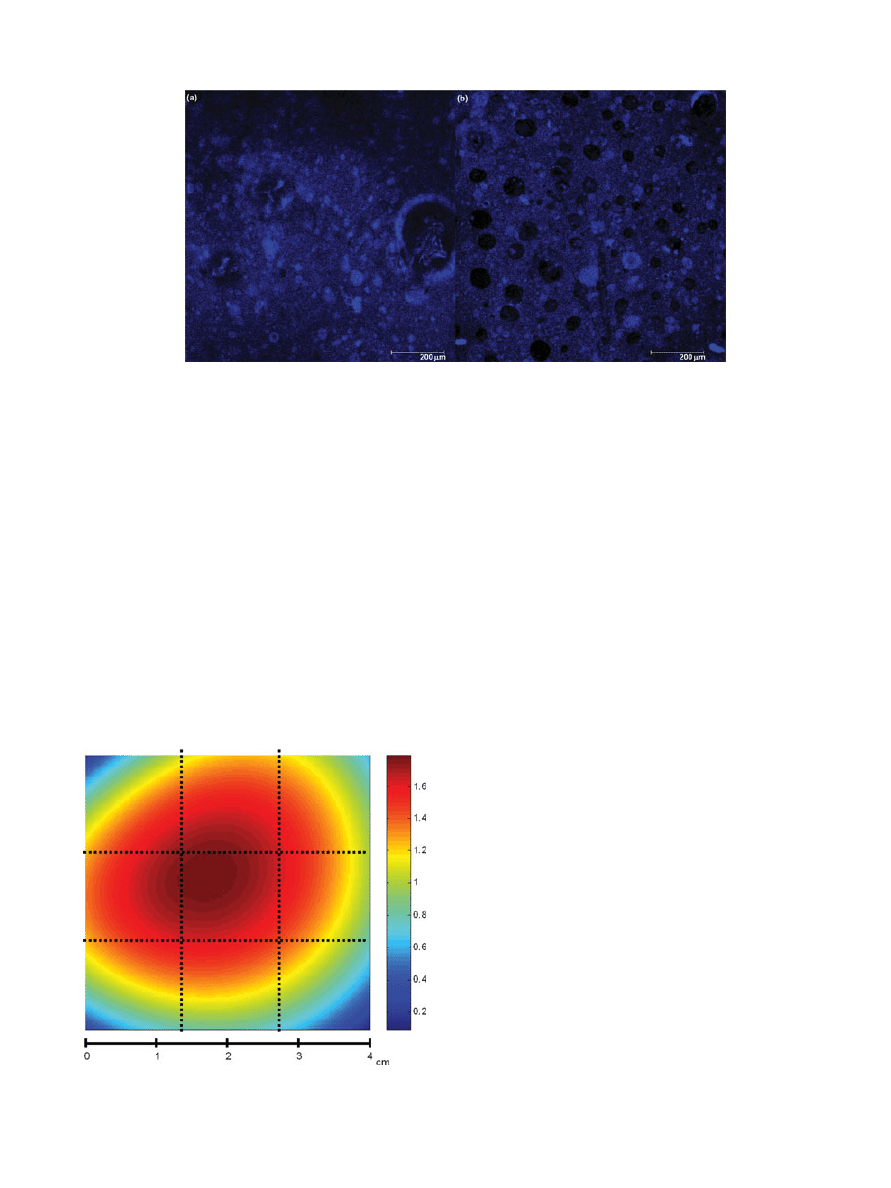

Confocal fluorescence microscopy was used to eval-

uate the morphology of a small section (1

× 1 mm

2

)

of the polymeric material after being in contact with

CO

2

. Different transversal sections of the sample

were studied to investigate the drug penetration in

the matrix. As an example, two pictures of sam-

ples obtained in experiments 3 and 5 are shown in

Figure 2. Porous cavities, which could also be observed

in Figure 2b, were generated during foaming process

and could be filled with the drug improving the im-

pregnation process. The pictures also showed the mi-

croscopic distribution of the drug and the heterogene-

ity of the samples. In addition, it was found that the

impregnation occurred not only superficially but also

in the depth.

Confocal fluorescence microscopy is a very useful

technique for surface profiling. In the pharmaceutical

industry, it was recommended to follow the manufac-

turing process of thin film pharmaceutical forms as

well as to control the quality and uniformity of the

drug distribution.

The homogeneity of naproxen contents was stud-

ied in more detail from a sample prepared at P

=

1000 psi, T

= 37

◦

C, and t

= 2.5 h. This was a sep-

arated sample, not included in the experimental de-

sign. The patch of 4

× 4 cm

2

was cut in nine equal

square pieces, which were analyzed chromatographi-

cally as described in the characterization studies sec-

tion. Naproxen contents in each piece (1.3

× 1.3 cm

2

,

approx.) were determined and an estimation of

DOI 10.1002/jps

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

996

ARGEM´I ET AL.

Figure 1.

Impregnation yields from the two-level three-variable experimental design. (a)

Processing time

= 2.5 h; (b) Processing time = 6 h.

macroscopic drug distribution is shown in Figure 3.

As 1000 µL aliquot of sample solution was poured in

the center of the patch, this area reasonably contained

a higher amount of naproxen. It was confirmed that

the drug impregnation in the center corresponded to

1.8% (w/w), whereas percentages were lower at the

corners (from 0.1% to 0.6%, approx.). Sections around

the central square piece contained intermediate drug

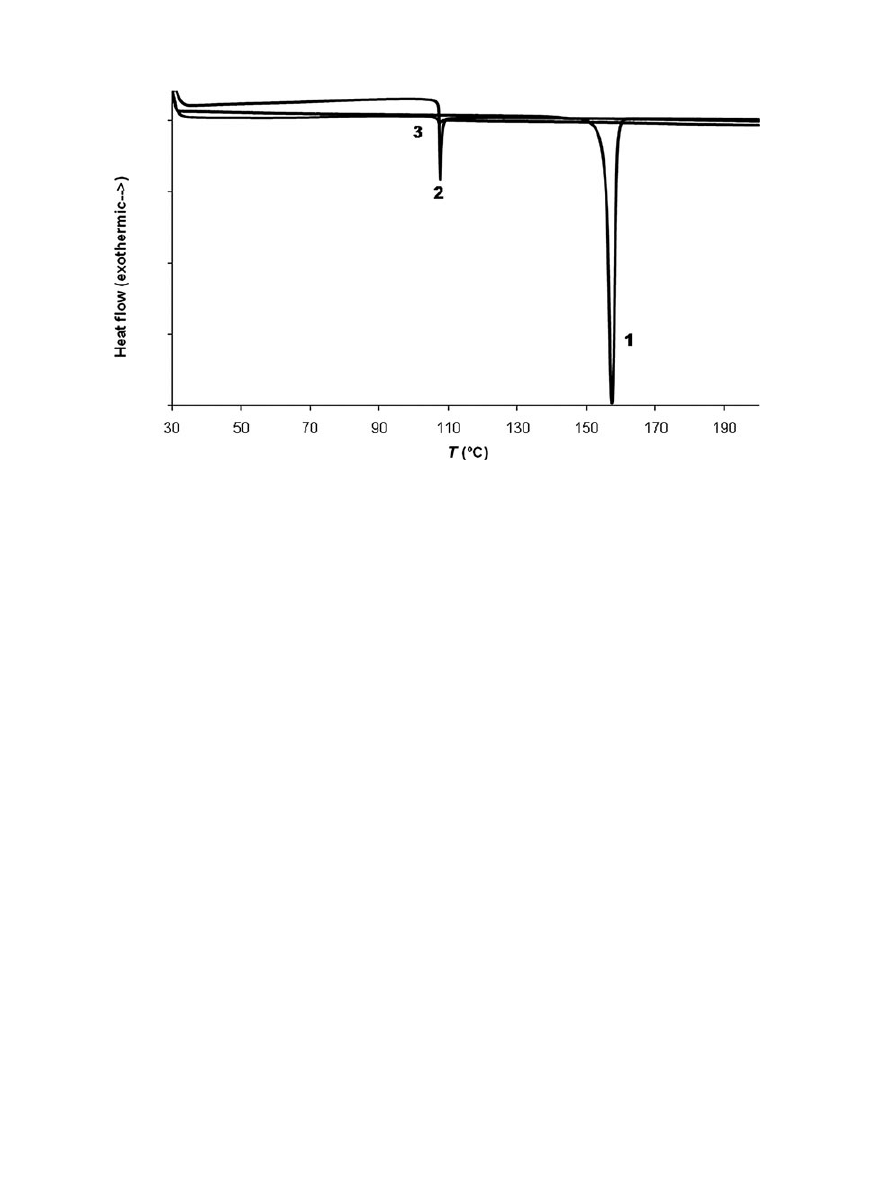

percentages (0.9%–1.4%, approx.).Differential scan-

ning calorimetry was used to study the thermal

properties of the

CO

2

-treated samples. Thermo-

grams of raw drug, unloaded polymeric patch, and

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

DOI 10.1002/jps

NAPROXEN-POLYMERIC PATCH FOR TRANSDERMAL SUSTAINED RELEASE SYSTEM

997

Figure 2.

Pictures obtained from fluorescence confocal microscopy in two dimensions. Pictures

of samples 3a and 5b measured at a certain depth. Scale bars shown.

drug–polymer impregnated patch (sample from ex-

periment 3) are compared in Figure 4. An endother-

mic peak corresponding to the melting temperature

of crystalline naproxen was clearly observed (T

m

=

154

◦

C). The peaks observed at 107

◦

C in both the un-

loaded polymeric patch and the drug–polymer im-

pregnated patch corresponded to the EVA melting

(typically occurring from 80

◦

C to 115

◦

C, depending on

the acetate content). Regarding Eudragit

R

, this is an

amorphous polymer with a glass transition tempera-

ture of 52

◦

C.

23

However, in these studies, no evidence

of glass transition was detected. As described else-

where, naproxen could decrease the T

g

of Eudragit

R

,

acting as a nonconventional plasticizer. This suggests

the existence of molecular interactions between the

polymer and the drug.

24

Figure 3.

Estimation of naproxen distribution in a 4

×

4 cm

2

patch.

Drug Release Monitoring

Preliminary studies of naproxen drug diffusion

through membranes were carried out with raw drug

in order to evaluate the influence of some experi-

mental conditions on the process. Various PBSs were

utilized as the receptor medium of the Franz diffu-

sion cell. In particular, 100 and 10 mM of PBS were

assayed; each one adjusted at pH 6.8 and 7.4. It

was concluded that naproxen diffused more rapidly

when the buffer concentration was 100 mM. This

fact was attributed to the higher buffering capac-

ity of the concentrated PBS. The pH of the PBS re-

ceptor solution affected the solubility and apparent

permeability as the analyte is a weakly ionizable

compound.

25

As a result, the diffusion/dissolution pro-

cess was faster at pH 7.4 than at pH 6.8. These re-

sults are in accordance with previous studies, which

measured naproxen permeability through synthetic

membranes.

26

Apart from chemical variables, the de-

sign characteristics of two kinds of Franz diffusion

cells were compared. One cell was designed with a

porous plate as a membrane support and the other

was constructed without a plate. It was evidenced that

the plate resulted in a physical obstacle, influencing

the diffusion process and the drug dissolution. As a

result, further evaluation of diffusion from patches

was carried out using a 100 mM PBS (at pH 7.4) and

working with a Franz cell without a plate to avoid any

physical hindrance.

Raw naproxen dissolution tested in the receptor

medium shown a fast permeation rate (t

1/2

= 1.7 h).

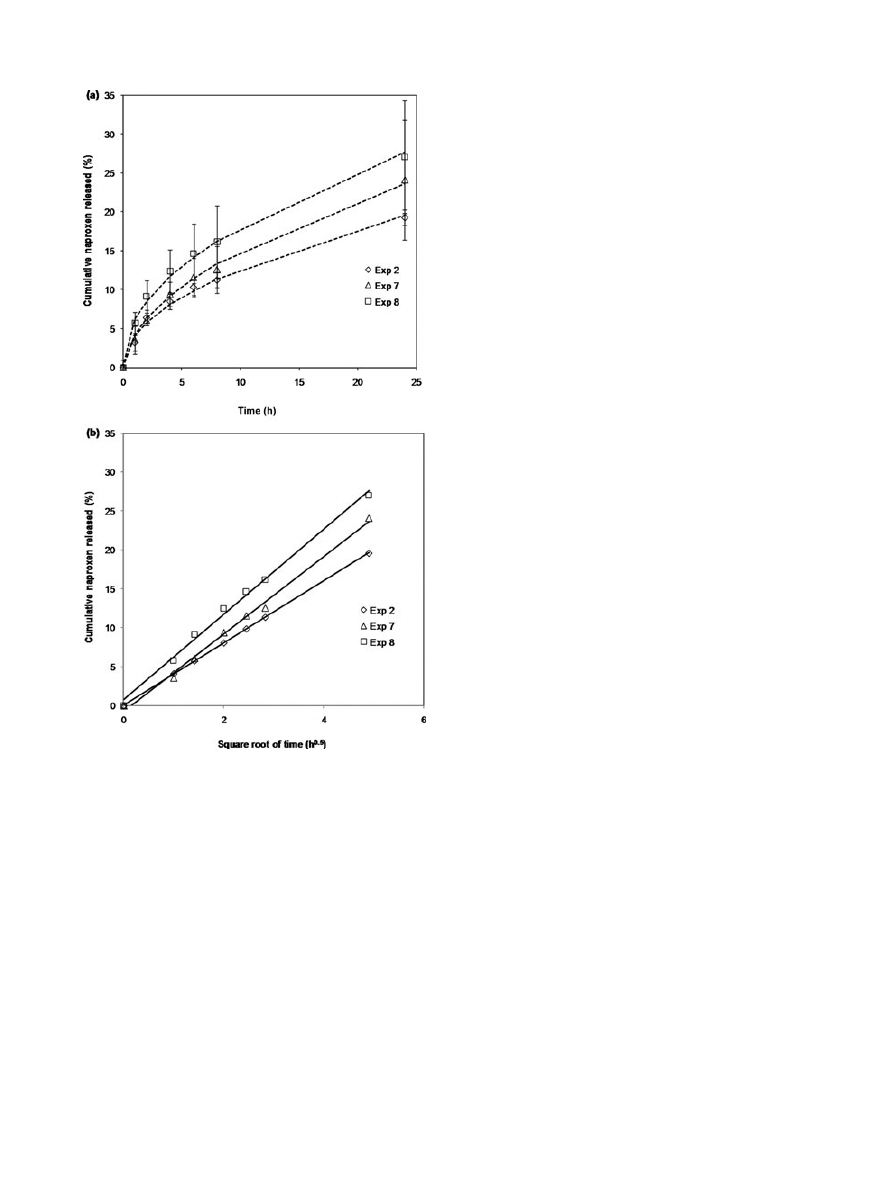

Studies of naproxen diffusion from the patch through

a nylon membrane were performed for 24 h. Figure 5

depicts the concentration profiles of the analyte

expressed in cumulative naproxen released (w/w, in

percentage) as a function of time. Drug delivery ki-

netics of all samples under study showed an initial

faster drug release step in which about a 10% of drug

DOI 10.1002/jps

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

998

ARGEM´I ET AL.

Figure 4.

Result from differential scanning calorimetry (DSC) analysis. (1) Raw naproxen,

(2) unloaded patch, and (3) impregnated patch.

release in the first 6 h was obtained. After this pe-

riod, a more prolonged release process was observed.

For all samples belonging to the experimental design,

the percentage of naproxen release over 24 h ranged

from 15% to 25%. In addition, a more sustained drug

delivery from the patches was attained in comparison

with the kinetics of the raw naproxen dissolution, ob-

taining t

1/2

> 24 h (Fig. 5a). No lag times were found

in the concentration delivery profiles. This fact was a

proof that the delivery was controlled by the pristine

formulation, hence the polymeric matrix. Moreover,

there are no diffusion limitations due to the mem-

brane. The release profile followed the well-known

Higuchi model

27

for simple diffusion processes. Suc-

cessful correlation with the experimental data was

achieved. Figure 5b plots the cumulative released

amount in function of the square root of time. The de-

livery rates determined for all samples were from 3.8

to 5.5 wt%h

0.5

. The relationship between delivery and

the square root of time was associated with a mecha-

nism controlled by the polymeric matrix. In this way,

the longitudinal diffusion resistance was increased

with residence time through the outer zone of the

matrix (where a reduction of drug has happened) and

the border of water–matrix layer. Naproxen concen-

tration in the donor chamber was gradually decreased

and as a consequence the drug delivery. This trend ex-

plained the two different behaviors of the cumulative

naproxen profiles: release stage and sustained deliv-

ery to the skin.

The respective rates of release were determined

from the slopes of the regression lines in the Higuchi

plots, being higher for experiments 7 and 8 (5.0 and

5.5 wt%h

0.5

, respectively) than for experiment 2 (4.0

wt%h

0.5

). Experiments 7 and 8 corresponded to lower

impregnation yields and experiment 2 to a higher im-

pregnation yield. In conclusion, lower impregnation

of naproxen facilitated its diffusion and release.

CONCLUSIONS

The novelty in this work consisted in the preparation

of a naproxen transdermal patch by using pressurized

CO

2

. The device presented here seemed to be a promis-

ing alternative approach to conventional formula-

tions. Although various procedures were assayed

for the preparation of the membranes, including

melting processes in a press, the most successful

strategy relied on dissolution/evaporation of poly-

mers. It has been evidenced that the patch pretreat-

ment with dense

CO

2

creates a higher porous mate-

rial, which was further impregnated with naproxen.

After that, the membrane was efficiently loaded with

the drug at 450 psi and 37

◦

C for 2.5 h. Significant

advantages were gained from the use of dense

CO

2

as

a processing agent because it is a not toxic gas and is

easily removable by depressurization. Characteriza-

tion in vitro assays proved excellent results, such as

the naproxen delivery for a prolonged period of time,

at least 24 h. Future perspectives should be focused

on the processing of the patch, optimizing impregna-

tion working parameters and paying attention in new

materials. Furthermore, drug capacity loading should

be appropriately studied and if possible, improved.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

DOI 10.1002/jps

NAPROXEN-POLYMERIC PATCH FOR TRANSDERMAL SUSTAINED RELEASE SYSTEM

999

Figure 5.

In vitro naproxen release kinetics in the Franz

diffusion cell in a phosphate buffer solution (PBS) at pH 7.4

at 32

± 0.5

◦

C by a circulating-water jacket while stirring at

70 rpm. Error bars represent the standard deviation based

on measurements in triplicate. (a) exp. 2, exp. 7, and exp. 8

(dashed lines correspond to Higuchi model correlation), (b)

Higuchi plots of exp. 2 (y

= 3.97 t

0.5

+ 0.13, R

2

= 0.992), exp.

7 (y

= 4.98 t

0.5

− 0.78, R

2

= 0.995), and exp. 8 (y = 5.49 t

0.5

+ 0.72, R

2

= 0.995).

ACKNOWLEDGMENTS

This paper has been supported by the Departa-

ment d’Educaci´o i Universitats de la Generalitat

de Catalunya i del Fons Social Europeu. A. Argem´ı

also gratefully acknowledges the financial support re-

ceived for a research grant BE2008 for a sojourn.

REFERENCES

1. Gorle BSK, Smirnova I, Arlt W. 2010. Adsorptive crystalliza-

tion of benzoic acid in aerogels from supercritical solutions. J

Supercrit Fluids 52(3):249–257.

2. Okamoto H, Sakakura Y, Shiraki K, Oka K, Nishida S, Todo

H, Iida K, Danjo K. 2005. Stability of chitosan-pDNA complex

powder prepared by supercritical carbon dioxide process. Int J

Pharm 290(1-2):73–81.

3. Sauceau M, Rodier E, Fages J. 2008. Preparation of inclusion

complex of piroxicam with cyclodextrin by using supercritical

carbon dioxide. J Supercrit Fluids 47(2):326–332.

4. T ¨

urk M, Hils P, Helfgen B, Schaber K, Martin HJ, Wahl

MA. 2002. Micronization of pharmaceutical substances by the

rapid expansion of supercritical solutions (RESS): A promising

method to improve bioavailability of poorly soluble pharma-

ceutical agents. J Supercrit Fluids 22(1):75–84.

5. Elvira C, Fanovich A, Fernandez M, Fraile J, San Roman J,

Domingo C. 2004. Evaluation of drug delivery characteris-

tics of microspheres of PMMA-PCL-cholesterol obtained by

supercritical-CO

2

impregnation and by dissolution–evapora-

tion techniques. J Controlled Release 99(2):231–240.

6. Marr R, Gamse T. 2000. Use of supercritical fluids for different

processes including new developments—a review. Chem Eng

Process 39(1):19–28.

7. Kawashima A, Watanabe S, Iwakiri R, Honda K. 2009. Re-

moval of dioxins and dioxin-like PCBs from fish oil by coun-

tercurrent supercritical CO

2

extraction and activated carbon

treatment. Chemosphere 75(6):788–794.

8. Winters MA, Frankel DZ, Debenedetti PG, Carey J, Devaney

M, Przybycien TM.

1999. Protein purification with vapor-

phase carbon dioxide. Biotechnol Bioeng 62(3):247–258.

9. Perrut M.

1994. Advances in supercritical-fluid chromato-

graphic processes. J Chromatogr A 658:292–313.

10. Majewski W, Valery E, Ludemann-Hombourger O. 2005. Prin-

ciple and Applications of Supercritical Fluid Chromatography.

J Liq Chromatogr Related Technol 28(7):1233–1252.

11. Jung J, Perrut M.

2001. Particle design using supercriti-

cal fluids: Literature and patent survey. J Supercrit Fluids

20(3):179–219.

12. Knez Z. 2004. High pressure process technology—Quo vadis?

Chem Eng Res Des 82(A12):1541–1548.

13. Lopez-Periago AM, Vega A, Subra P, Argemi A, Saurina J,

Garcia-Gonzalez CA, Domingo C.

2008. Supercritical CO

2

processing of polymers for the production of materials with

applications in tissue engineering and drug delivery. J Mater

Sci 43(6):1939–1947.

14. Greiner RW. 1991. Impregnation of catheters with pharma-

ceutical agents - by immersing in pharmaceutical agent satd.

soln., contacting at supercritical pressure and temp European

Patent Application

15. Kazarian SG, Martirosyan GG.

2002. Spectroscopy of

polymer–drug formulations processed with supercritical flu-

ids: In situ ATR-IR and Raman study of impregnation of

ibuprofen into PVP. Int J Pharm 232(1-2):81–90.

16. Weuts I, Kempen D, Decorte A, Verreck G, Peeters J, Brewster

M, Van Den Mooter G. 2005. Physical stability of the amor-

phous state of loperamide and two fragment molecules in solid

dispersions with the polymers PVP-K30 and PVP-VA64. Eur

J Pharm Sci 25(2-3):313–320.

17. Duarte ARC, Costa MS, Simplicio AL, Cardoso MM, Duarte

CMM. 2006. Preparation of controlled release microspheres

using supercritical fluid technology for delivery of anti-

inflammatory drugs. Int J Pharm 308(1-2):168–174.

18. Rowe RC, Sheskey PJ, Weller PJ. 2003. Handbook of pharma-

ceutical excipients; 4th ed. London: Pharmaceutical Press.

DOI 10.1002/jps

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

1000

ARGEM´I ET AL.

19. Devallencourt C, Marais S, Saiter JM, Labbe M, Metayer M.

2002. Study of transport of small molecules through ethylene-

co-vinyl acetate copolymers films. Part A: Water molecules.

Polym Test 21(3):253–262.

20. Marais S, Saiter JM, Davallencourt C, Nguyen QT, Metayer M.

2002. Study of transport of small molecules through ethylene-

co-vinyl acetate copolymers films. Part B: CO

2

and O-2 gases.

Polym Test 21(4):425–431.

21. Huskisson EC, Woolf DL, Balme HW, Scott J, Franklyn S.

1976. 4 New anti-inflammatory drugs—responses and varia-

tions. Br Med J 1(6017):1048–1049.

22. Jacobs MA, Kemmere MF, Keurentjes JTF. 2004. Foam pro-

cessing of poly (ethylene-co-vinyl acetate) rubber using super-

critical carbon dioxide. Polymer 45(22):7539–7547.

23. Verreck G, Decorte A, Li HB, Tomasko D, Arien A, Peeters

J, Rombaut P, Van Den Mooter G, Brewster ME.

2006.

The effect of pressurized carbon dioxide as a plasticizer and

foaming agent on the hot melt extrusion process and extru-

date properties of pharmaceutical polymers. J Supercrit Fluids

38(3):383–391.

24. Alvarez-Roman R, Ganem-Quintanar A, Quintanar-Guerrero

D. Proceedings—28th International Symposium on Controlled

Release of Bioactive Materials and 4th Consumer & Diver-

sified Products Conference, San Diego, CA, 2001, pp 1426–

1427.

25. Brain KR, Walters KA, Watkinson AC.

2002. Methods for

studying percutaneous absorption. Dermatological and Trans-

dermal Formulations 119:197–269.

26. Farinha A, Toscano C, Campos R, Bica A, Hadgraft J. 2003.

Permeation of naproxen from saturated solutions and commer-

cial formulations through synthetic membranes. Drug Dev Ind

Pharm 29(4):489–494.

27. Higuchi WI. 1962. Analysis of data on medicament release

from ointments. J Pharm Sci 51(8):802–804.

JOURNAL OF PHARMACEUTICAL SCIENCES, VOL. 100, NO. 3, MARCH 2011

DOI 10.1002/jps

Wyszukiwarka

Podobne podstrony:

jps 21681

jps 21579

jps 22023

jps 22081

jps 22139

Viofor JPS jest aparatem do magnetostymulacji, FIZJOTERAPIA

jps 21484

jps 21792

jps 21755

jps 22267

jps, kryminologia

jps 22075

jps 21904

jps 21667

jps 21681

jps 21828

jps 22219

jps 21704

jps 21947

więcej podobnych podstron