Journal of Cereal Science 33 (2001) 223–229

doi:10.1006/jcrs.2000.0362, available online at http://www.idealibrary.com on

Analysis of Headspace Compounds of

Distillers Grains using SPME in Conjunction

with GC/MS and TGA

Sumana Biswas and Charlie Staff

University of Louisville Food Processing Program, Speed Research Administration, KY 40292, U.S.A.

Received 20 September 2000

ABSTRACT

Chemical composition of headspace compounds of distillers grains was investigated using solid phase

microextraction (SPME) along with GC/MS and TGA. Dryer feed (DF) and distillers dried grains

(DDG) from a local distillery were utilised for this study. A SUPELCO 75

m Carboxen/PDMS

SPME fibre was found suitable for extraction of analytes from grains. Samples were placed in small

vials (40 mL from SUPELCO) filled to one-third of their capacity. SPME was exposed to the

headspace for 1 to 2 h. The fibre was then thermally desorbed in GC injection port for separation

and identification. The gas chromatogram showed as many as 64 compounds eluting out of the

column, the number being greater in DF as compared to DDG. Thermogravimetric analysis (TGA)

was performed on the grains to study the oxidative stability of the compounds. SPME fiber was

inserted directly into TGA purge gas outlet to study the compounds being evolved. Three weight

loss transitions were observed in the TGA curve of DF and DDG. The components from the three

transitions were captured by SPME and analysed by GC/MS for identification. TGA helped in

determining the degradation stages of grains thereby indicating the temperature limits in drying

grains. Di

fference between the heated and unheated DF and DDG have been discussed in detail.

2001 Academic Press

Keywords: distillers grains, SPME, GC/MS, TGA, grain drying.

to analyse oil, protein and moisture content of

INTRODUCTION

cereal grains. Cereal grains have been subjected

Distillers grains—a co-product when cereal grains,

to pressure digestion for mineral analysis by atomic

predominantly corn, are used in the production

absorption spectroscopy.

Fluorescence micro-

of fuel or beverage ethanol, have long been re-

has been reported to detect niacin, aromatic

cognised as a potential animal feed ingredient,

amines and phytin in mature cereal grains. How-

particularly for dairy and beef cattle. They contain

ever, no systematic study has been reported so

a highly desirable combination of by-pass protein,

far about this nutritionally rich co-product called

digestible fibre and fat. Research is being con-

‘distillers grains’. To ensure that the highest quality

ducted worldwide to e

ffectively utilise this nu-

distillers grains are provided to customers, it is

tritionally rich co-product from the distilleries for

necessary that there be proper investigation re-

human consumption.

There are many factors

garding its chemical composition. Besides nutrients

that contribute to the quality of distillers dried

like protein, minerals and fat, the presence of

grains (DDG) including initial grain quality, pro-

trace compounds cannot be overlooked which are

cess conditions and drying technology.

critical in producing proper taste and aroma of

Technology has been developed to study and

food and feed products. These trace quantities of

analyse di

fferent aspects of cereal grains. Near

compounds are also responsible for the ‘o

ff’ flavour

infrared reflectance spectroscopy

has been applied

or taste often detected in food. Therefore it is

0733–5210/01/020223

+07 $35.00/0

2001 Academic Press

S. Biswas and C. Staff

224

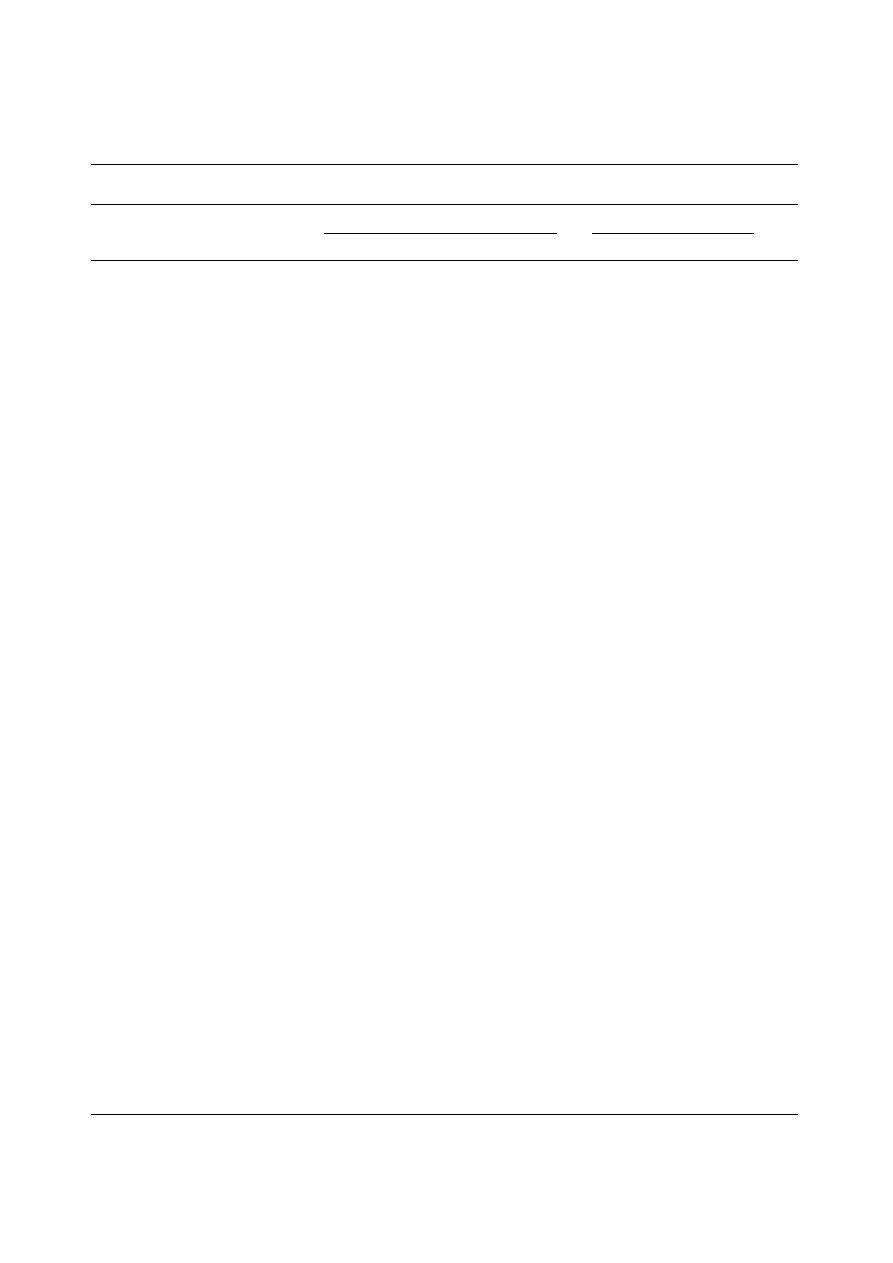

Table I

SPME-GC/MS results of DF and DDG

Dryer feed

DDG

Compound

R.T.

b

Unheated

Heated

Unheated

Heated

Ethanol

2·23

Present

Present

Present

Present

2-methyl propanal

3·31

Present

Present

Present

Present

2,3-butanedione

3·9

Present

Present

Present

Present

Formic acid

4·46

Present

Present

Present

Present

Acetic acid

5·05

Present

Present

Present

Present

Pentanal

5·83

Present

Present

Present

Present

Dimethyl disulphide

6·72

Present

Present

Present

Present

Propanoic acid

6·87

Present

Present

Present

1-pentanol

7·46

Present

Present

Propylene glycol

7·9

Present

Present

Present

Present

Hexanal

7·96

Present

Present

Present

Present

Methyl pyrazine

8·42

Present

Present

Present

2,3-butanediol

8·64

Present

Present

Present

Present

1,2-dimethylbenzene

9·17

Present

Furfural

9·27

Present

Present

Present

Present

2-hexenal

9·4

Present

Present

3-methyl butanoic acid

9·68

Present

Tetrahydrothiophene

9·68

Present

2-furanmethanol

9·8

Present

Present

Present

Present

5-methylhexanone

9·91

Present

Present

Present

Present

Heptanal

10·07

Present

Present

Present

Present

2,6-dimethylpyrazine

10·21

Present

Present

Present

Present

2,6-dimethylphenol

10·41

Present

3-methylthio propanal

10·7

Present

Present

Present

1,2-furanylethanone

10·77

Present

Present

Present

Present

2-pentylfuran

11·41

Present

Present

Present

Present

2-heptenal

11·5

Present

Present

Present

Present

1-octene-3-one/3-ol

a

11·62

Present

Present

Present

Present

Benzaldehyde

11·79

Present

Present

Present

Present

2-hydroxypropanoic acid

11·86

Present

Present

Present

2-furancarboxaldehyde

11·93

Present

Ethyl acetate

12·05

Present

Present

Present

Present

Hexanoic acid

12·35

Present

Present

Present

Present

2,4-heptadienal

12·71

Present

Present

3-ethyl2-methylhexadiene

12·96

Present

Undecane

13·04

Present

Present

Present

Present

Benzeneacetaldehyde

13·44

Present

Glycerin

13·68

Present

Present

Present

Present

Nonanal

13·97

Present

Present

Present

Present

Heptanoic acid

14·04

Present

Triacontane

14·3

Present

Present

Dodecane

14·8

Present

Present

Present

Phenylethyl alcohol

14·95

Present

Present

Present

Present

Octanoic acid ethylester

15·21

Present

Present

Present

Present

Octanoic acid

15·65

Present

Present

Present

Present

Decanal

15·72

Present

Present

Ethyl hydrogen succinate

16·11

Present

Present

Benzoic acid

16·19

Present

Present

Present

Present

Tridecane

16·43

Present

Present

Present

Present

2-decenal

16·94

Present

Present

Nonanoic acid

17·18

Present

Present

Present

Present

2,3-dihydro benzofuran

17·35

Present

Present

Phenylpropanedioicacid

17·57

Present

Tetradecane

17·97

Present

Present

Present

Present

1,3-methoxy phenyl ethanol

18·19

Present

Present

Decanoic acid ethyl ester

18·34

Present

Present

Present

Present

continued

Distillers grains headspace compounds

225

Table I

SPME-GC/MS results of DF and DDG—continued

Dryer feed

DDG

Compound

R.T.

b

Unheated

Heated

Unheated

Heated

n-decanoic acid

18·65

Present

Present

Propanoic acid,2-methyl heptyl ester

18·97

Present

Present

Octanoic acid,3-methylbutyl ester

19·12

Present

Present

Pentadecane

19·43

Present

Present

2,5-cyclohexadiene-1,4-dione2,6-bis

20·34

Present

Present

Eicosane

21·01

Present

Present

Phenol bis-1,1-dimethylethyl

21·38

Present

Present

Dodecanoic acidethyl ester

21·44

Present

Present

Nonacosane

22·86

Present

Present

2,4-di-t-butyl6-nitrophenol

24·76

Present

Pentadecanoic acid ethyl ester

21·4

Present

Present

Tetradecanoicacid ethyl ester

25·956

Present

Present

Hexadecanoic acid ethyl ester

33·57

Present

Present

a

1-octene-3-ol in unheated grains.

b

Retention time.

essential to develop a procedure for assay of these

Equipment Specifications

minor but important constituents. The objective

SPME

of the present study is to determine the composition

For SPME extraction, SUPELCO 75

m Car-

of the compounds present in the headspace of

boxen/PDMS (polydimethylsiloxane) was used.

distillers grains (dryer feed (DF) & distillers dried

grains (DDG)), using a simple, fast and inexpensive

method which would benefit the cereal food in-

GC/MS Conditions

dustry in their quality control operations. SPME

The extractives were analysed using a Hewlett-

(solid phase microextraction)

unit consists of a

Packard (Palo Alto, U.S.A.) gas chromatograph

fused silica fiber coated with a polymeric material.

5890 equipped with a 5970 mass selective detector,

The coated fiber is attached to a stainless steel

and a HP G1034C MS chemstation. The column

plunger inside a protective needle. It requires no

used was a 30 m SPB-624 SUPELCO, 0·25 mm

solvent or complicated apparatus. It can con-

id and 1·4

m film thickness. An SPME injection

centrate volatiles and non-volatiles in both liquid

sleeve (0·75 mm id for Hewlett-Packard) was in-

and gaseous samples for analysis by GC/MS or

serted into the GC injection port. The carrier gas

HPLC. Use of SPME has been extended to food

was helium maintained at 32 psi. The splitless

flavour

injection port was heated at 220

°C. Temperature

and countless other applications. The grains were

ramping was adjusted from 40

°C to 250 °C at the

also subjected to TGA to study their oxidative

rate of 10

°C/min. All mass spectra were acquired

stability at high temperature.

in the electron impact (EI) mode at 70 eV. The

electron multiplier was set at 1490 V. Compound

identification was done using NIST 98 library.

MATERIALS AND METHOD

Materials

TGA Conditions

Thermogravimetric analysis was performed using

Dryer feed (DF) and distillers dried grains (DDG)

were obtained from a local distillery that pre-

Hi-Res. TGA 2950, TA Instruments. The tem-

perature range of the instrument was from ambient

dominantly uses corn as a feed stock. DF is the

concentrated mixture (after distillation of alcohol)

to 1000

°C. Balance sensitivity and accuracy were

0·1

g and ±0·1% respectively. Air was used as

that enters the final stage of grain drying. DDG

is the final product of the drying process. The

purge gas in the experiments. Purge gas flow rates

in the furnace and balance were 60 mL/min and

moisture contents of DF and DDG are 31% and

11·6% respectively.

40 mL/min respectively. Temperature ramping

S. Biswas and C. Staff

226

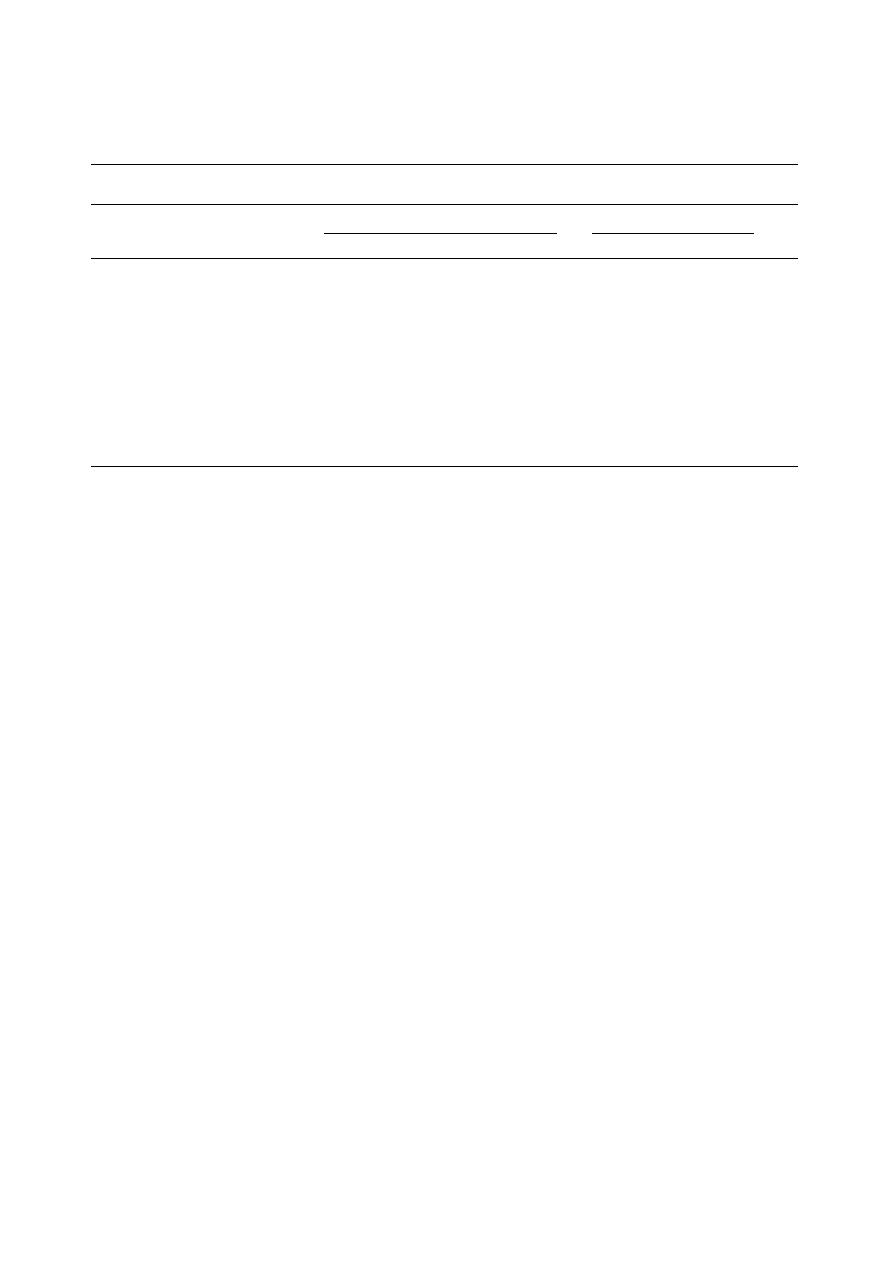

Table II

TGA-SPME-GC/MS results of DF and DDG

60–70

°C

250–300

°C

510–550

°C

Compounds

DF

DDG

DF

DDG

DF

DDG

2-propenal

Present

Present

Present

Acetone

Present

Present

2,3-butanedione

Present

Present

Cyclobutylamine

Formic acid

Present

Present

Present

Present

Present

Present

Acetic acid

Present

Present

Present

Present

Present

Present

Pyridine

Present

Present

Pentanal

Present

Present

Hexanal

Present

Present

Present

Dimethyl disulphide

Present

2-propanoic acid

Present

Present

Furfural

Present

Present

Present

Present

Present

Present

3-methyl butanoic acid

Present

2-furanmethanol

Present

Present

Present

Present

2-propanone,1-acetyloxy,

Present

Present

Heptanal

Present

Present

2,6-dimethylpyrazine

Present

2-cyclopentene-1,4-dione

Present

Present

Present

Present

2-pentyl furan

Present

Present

Present

Heptenal

Present

Present

Dimethyl trisulfide

Present

Present

Benzaldehyde

Present

Present

Present

Present

2-furanone

Present

Present

5-methylfurancarboxaldehyde

Present

Present

Present

Present

Octanal

Present

Present

Present

2,5-furandione,3-methylene

Present

Present

Benzofuran

Present

Present

Hexanoic acid

Present

Benzonitrile

Present

Present

Butyl benzene

Present

Present

Present

Present

Phenol

Present

Present

Acetophenone

Present

Present

Nonanal

Present

Present

Present

Present

2-methoxy phenol

Present

Pentyl benzene

Present

Present

Dodecane

Present

Present

Hexyl benzene

Decadienal

Present

Present

Phthallic anhydride

Present

6-undecylamine

Present

Present

Present

Present

Furaltadone

Present

Present

Present

Present

Present

Present

Decanamine

Present

Present

Present

Present

Present

Present

was set from ambient to 800

°C at the rate of

order to facilitate analyte concentration in the

10

°C/min.

headspace. Two vials each of DF and DDG were

prepared and left to equilibrate overnight at room

temperature. After equilibration, one vial each of

Sample Preparation and Analysis

DF and DDG were exposed to heat at 60

°C for

40 min. SPME analysis was performed on both

DF and DDG were finely ground in a cyclone

the 60

°C and room temperature vials on each DF

sample mill (Udy Corp., 1 mm screen), and placed

and DDG sample, by piercing the needle into the

in screw-capped vials (40 mL) fitted with rubber

vial septum and coated fibre exposed for sample

septa. The vials were filled to one-third of their

capacity (

≈3·20 g) and then shaken vigorously in

adsorption. The heated vials were subjected to

Distillers grains headspace compounds

227

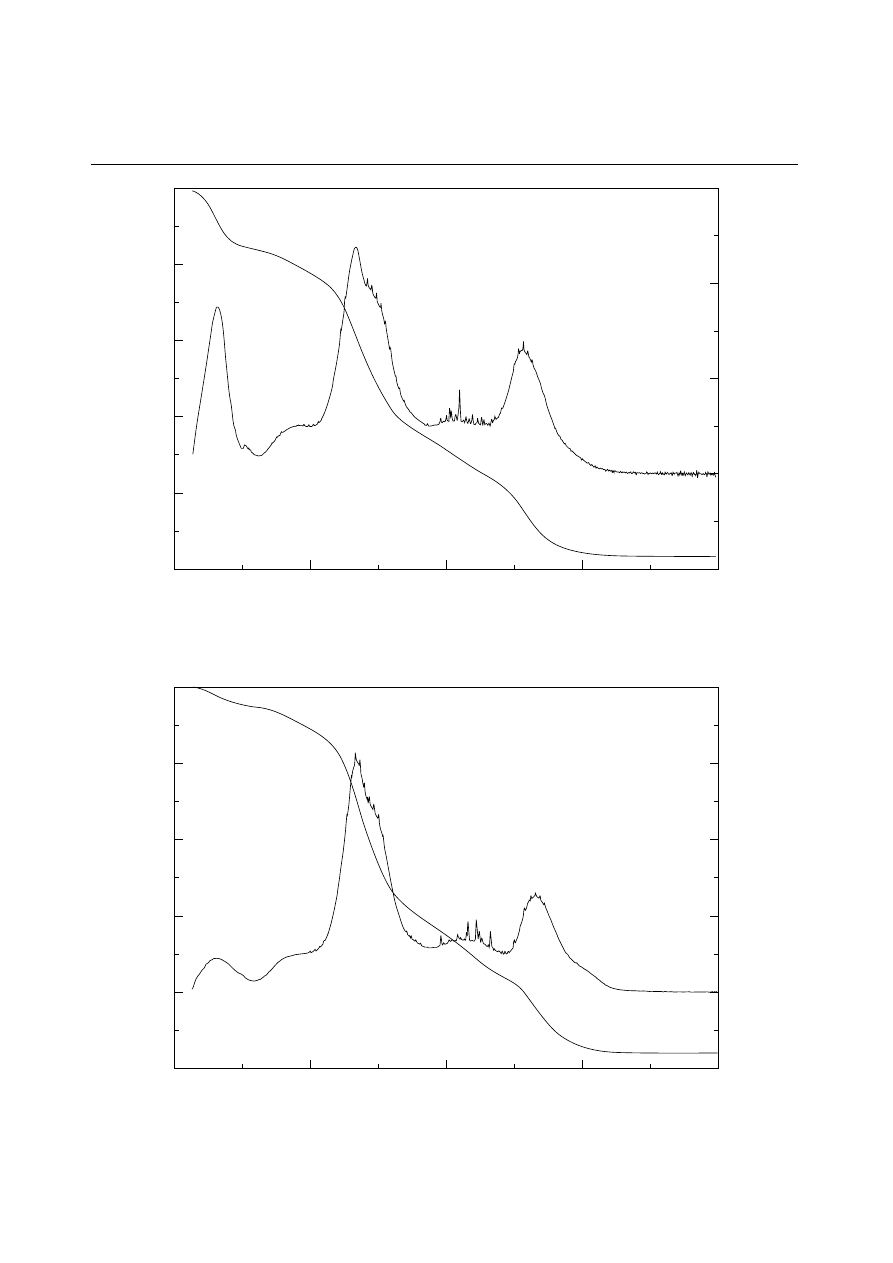

0

800

100

Temperature (

°C)

1

W

eight (%)

20

40

60

80

200

400

600

2

3

Derivative weight

Thermal degradation

curve

–2

6

0

2

4

Deriv

. weight (%/min)

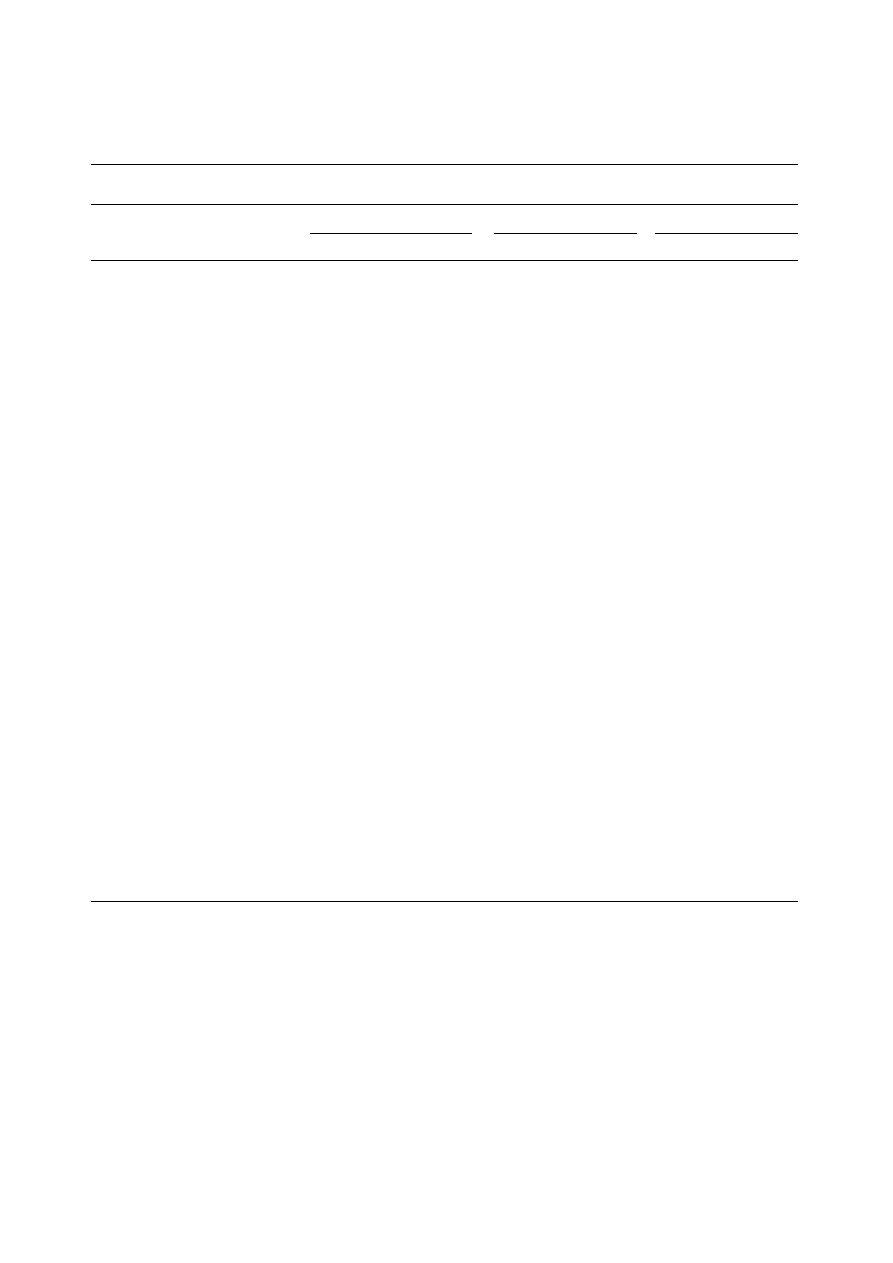

Figure 1

TGA curve of DF.

0

800

100

Temperature (

°C)

1

W

eight (%)

20

40

60

80

200

400

600

2

3

Derivative weight

Thermal degradation

curve

–2

8

0

2

4

Deriv

. weight (%/min)

6

Figure 2

TGA curve of DDG.

S. Biswas and C. Staff

228

SPME extraction for 1 h and the unheated vials-

Difference between Unheated and Heated

(room temperature) for 2 h. The SPME fibre con-

Grains

taining the volatiles was injected and thermally

A larger number of constituents were observed in

desorbed in GC injection port maintained at

the heated (60

°C) grain samples as compared to

220

°C. SPME was held in the port for 10–15 s

the unheated ones. The low molecular weight

and retracted. Desorption of the SPME for 45–60 s

compound profile was somewhat similar in both

was tried but it did not show any di

fference in the

the heated and unheated ones, but it was in the

overall compound profile in the chromatogram.

higher retention time region, that showed marked

To test the reproducibility of the procedure and

di

fference. Heated samples showed the presence

confirm the retention times, about 10–15 replicates

of esters of higher fatty acids as dodecanoic, tetra-

were analysed.

decanoic and hexadecanoic acid. This increase in

In TGA analysis, the grains were subjected to

number of components in the heated samples was

an air-purged environment during the experiment.

reasonable due to increased mass transfer of larger

They were heated from ambient to 800

°C, heating

molecules in the headspace during heating.

rate being 10

°C/min. SPME fibre was used to

adsorb the gases evolved from the distillers grains

at the TGA outlet and then the fiber was injected

Difference between DF and DDG

in GC injection port for analysis by GC/MS. This

Mass chromatograms of DF show slightly in-

process was followed at each weight loss transition

creased number of components than for DDG. As

of DF and DDG.

explained earlier, DF is the wet concentrated dryer

feed before the final drying process and DDG is

the final dried product. So it can be inferred that

some of the volatiles are driven o

ff from DDG

during drying. A number of higher alkanes like

RESULTS AND DISCUSSION

undecane, dodecane, pentadecane, eicosane etc.

are observed in both DF and DDG which could

GC/MS results showed the presence of as many

be coming from natural gas used in direct fired

as 62 compounds in the distillers grains. These

plant dryers. The aldehydes detected could be the

included the volatile compounds as well as the

result of fatty acid breakdown of the corn oil from

semi-volatile ones. SPME extracted volatile com-

the original grain. Ethyl acetate and glycerin was

pounds like ethanol, formic and acetic acid to

found in the samples. 2,6-dimethyl and methyl

aldehydes such as pentanal, hexanal, heptanal,

pyrazine was detected which are fairly common

furfural and several unsaturated aldehydes as hep-

chemicals found in grain and feed that has been

tenal and decenal from the grain headspace (Table

heated to toasted levels. Lactic or 2-hydroxy pro-

I). Acetic acid was detected in significantly high

panoic acid was seen in GC that could have

amount in all the grain samples. A major source

come from Lactobacillus bacterial growth during

of this chemical could be microbial contamination

fermentation.

during yeast fermentation. These compounds were

identified by library search (NIST 98). SPME has

earlier been used for measurement of hexanal and

Thermogravimetric analysis of grains

pentanal in cooked turkey.

Volatile fatty acids

like formic, acetic, propanoic and lactic acid were

Thermogravimetric analysis or TGA was per-

formed on distillers grains to study their oxidative

detected. Long chain fatty acids were found in the

heated samples. Rosenberg et al.

has reported

stability and volatile compounds evolved during

heating. The GC/MS results of TGA outlet gases

detection of these fatty acids from headspace vol-

atiles of di

fferent varieties of cheese using SPME.

are given in Table II. Three TGA weight loss

transition stages were observed in the TGA curve

Dowd et al.

analysed the stillage from ethanol

distillation of yeast fermented hydrolysed corn

of both DF and DDG (Figs 1 & 2). The degradation

pattern of DF and DDG were similar except for

starch by GC/MS and HPLC. They reported the

presence of volatile low-molecular-weight com-

their first transitions, where DF shows a larger

transition change than DDG. This is due to the

pounds like lactic acid, glycerol, ethanol and some

fatty acids which were also detected in the DDG

higher moisture content of DF. The first transition

at 60–70

°C, gives off mostly moisture along with a

headspace in the present study.

Distillers grains headspace compounds

229

Dried Grains with Solubles from Soft White Winter

few volatile compounds. Use of TGA to determine

Wheat. Cereal Chemistry 64 (1987) 139–143.

moisture content of grains has been reported

2. Wu, Y.V., Youngs, V.L., Warner, K. and Bookwalter,

The second transition temperature range

G.N. Evaluation of Spaghetti Supplemented with Corn

(250–300

°C) shows compounds similar to those

Distillers’ Dried Grains. Cereal Chemistry 64 (1987) 434–

seen earlier in this work in the headspace of heated

436.

3. Bookwalter, G.N., Warner, K., Wall, J.S., Wu, Y.V. and

DF and DDG. Some amino and nitro compounds

Kwolek, W.F. Corn Distillers’ Grains and other By-

are seen which could have resulted from the break-

products of Alcohol Production in Blended Foods. II.

down of proteins/amino-acids of the grains. But

Sensory, Stability and Processing Studies. Cereal Chemistry

it is the third and last TGA transition (510–550

°C)

61 (1984) 509–513.

that shows maximum number of degradation prod-

4. Williams, P.C. Application of Near Infrared Reflectance

ucts. Compounds like butyl benzene, furanone,

Spectroscopy to Analysis of Cereal Grains and Oilseeds.

Cereal Chemistry 52 (1975) 561–576.

pyran and some diones and dienals are observed

5. Lorenz, K., MacFarland, G. and Maga, J. Research Note

which formed from breakdown of proteins, car-

on Pressure Digestion of Cereal Grains and Flours for

bohydrates and possible reaction between them in

Mineral Analysis by Atomic Absorption Spectroscopy.

the course of oxidation.

Cereal Chemistry 54 (1977) 281–286.

6. Fulcher, R.G., O’Brien, T.P. and Wong, S.I. Micro-

CONCLUSION

chemical Detection of Niacin, Aromatic Amine, and

Phytin Reserves in Cereal Bran. Cereal Chemistry 58 (1981)

From the above study it can be concluded that

130–135.

SPME in conjunction with GC/MS and TGA

7. Technology licensed exclusively to SUPELCO.

8. Pelusio, F., Nilsson, T., Tino, R., Larsen, B. and Montna-

provides a quick and convenient way to determine

rell, L. Headspace SPME Analysis of Volatile Organic

the volatiles and semi-volatiles from distillers grains

Sulfur Compounds in Black and White Tru

ffle Aroma.

headspace. The minor constituents discussed

Journal of Agriculture and Food Chemistry 43 (1995) 2138–

earlier are usually present in complex mixtures

2143.

which otherwise pose great di

fficulty during sep-

9. Ng, L., Hupe, M., Harnois, J. and Moccia, D. Char-

aration. SPME could also separate the long chain

acterisation of Commercial Vodkas by SPME-GC/MS.

Journal of the Science Food and Agriculture 70 (1996) 380–388.

fatty acids, which would have been a multiple

10. Potter, D. and Pawliszyn, J. Rapid Determination of

step procedure if analysed by the conventional

Polyaromatic Hydrocarbons and Polychlorinated Bi-

methods.

phenyls in Water using SPME and GC/MS. Journal of

TGA revealed many important aspects of drying

Environmental Science and Technology 28 (1994) 298–305.

temperatures of distillers grains. It is clear from

11. Cizkova, H., Voldrich, M. and Dobias, J. Determination

the study that heating and drying the grains above

of Residual Acetaldehyde in Polyethyleneterephthalate

250–300

°C would result in degradation. The com-

bottles on SPME. Czech. Journal of Food Science 36 (1998)

401–405.

bined use of TGA analysis and SPME-GC/MS

12. Frerot, B., Malosse, C. and Cain, A.SPME, A New Tool

provides a rapid means for determining the tem-

in Pheromone Identification in Lipidoptera. Journal of

perature degradation limits of cereal grains and

High Resolution Chromatography 20 (1997) 340–342.

their processed products. It also provides an in-

13. Brunton, N.P., Cronin, D.A., Monahan, F.J. and Durcan,

dication of oxidative reactions as well as identifies

R.A Comparison of Solid phase Microextraction (SPME)

volatile compounds evolved during drying.

Fibres for Measurement of Hexanal and Pentanal in

Cooked Turkey. Food Chemistry 68 (2000) 339–345.

14. Chin, H., Bernard, R. and Rosenberg, M.SPME for

Acknowledgement

Cheese Volatile Compound Analysis. Journal of Food Science

61 (1996) 1118–1123.

The authors wish to thank Distillers Grains Technology

15. Dowd, M.K., Reilly, P.J. and Trahanovsky, W.S.Low-

Council (DGTC) for financial support of this project.

molecular-weight Organic Composition of Ethanol Still-

age from Corn. Cereal Chemistry 70 (1993) 204–209.

REFERENCES

16. Neher, M.B., Pheil, R.W. and Watson, C.A. Therm-

oanalytical Study of Moisture in Grain. Cereal Chemistry

1. Rasco, B.A., Downey, S.E. and Dong, F.M. Consumer

Acceptability of Baked Goods Containing Distillers’

50 (1973) 617–628.

Document Outline

Wyszukiwarka

Podobne podstrony:

Analysis of total propionic acid in feed using headspace sol

Analysis of volatile organic compounds using gas

Analysis of soil fertility and its anomalies using an objective model

SEISMIC ANALYSIS OF THE SHEAR WALL DOMINANT BUILDING USING CONTINUOUS-DISCRETE APPROACH

Analysis of Reinforced Concrete Structures Using ANSYS Nonlinear Concrete Model

Comparative study based on exergy analysis of solar air heater collector using thermal energy storag

Solid Phase Microextraction Analyses of Flavor Compounds in

Analysis of soil fertility and its anomalies using an objective model

Rapid analysis of malathion in blood using head space solid

Malware Detection using Statistical Analysis of Byte Level File Content

Optimization of Intake System and Filter of an Automobile Using CFD Analysis

Analysis of shear wall structures of variable thickness using continuous connection method

Parallel analysis of polymorphic viral code using automated deduction system

Rapid analysis of amphetamines in blood using head space sol

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

A Contrastive Analysis of Engli Nieznany (3)

więcej podobnych podstron