Funktionsgenerator KSS5.1 08.02.00 en

1 of 28

SOFTWARE

KR C...

Function Generator

System Tech (KSS) 5.1

2 of 28

Funktionsgenerator KSS5.1 08.02.00 en

e

Copyright

KUKA Roboter GmbH

This documentation or excerpts therefrom may not be reproduced or disclosed to third parties without the express permission of the publishers.

Other functions not described in this documentation may be operable in the controller. The user has no claim to these functions, however, in

the case of a replacement or service work.

We have checked the content of this documentation for conformity with the hardware and software described. Nevertheless, discrepancies

cannot be precluded, for which reason we are not able to guarantee total conformity. The information in this documentation is checked on a

regular basis, however, and necessary corrections will be incorporated in subsequent editions.

Subject to technical alterations without an effect on the function.

PD Interleaf

3 of 28

Funktionsgenerator KSS5.1 08.02.00 en

Contents

1

Characteristics, functional description

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

Characteristics

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2

Functional description

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1

Basic principle

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2

Function definition

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3

Correction direction

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4

The correction coordinate system TTS

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

Configuration

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Programming, parameterization

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1

Structure variables

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1

$TECH[i], $TECH_C[i], i=1,...,6

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2

$TECHIN[i], i = 1,...,6

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3

$TECHPAR[i, j], i=1,...,6 , j=1,...,10

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4

$TECHPAR_C[i, j], i = 1,...,6 , j=1,...,10

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5

$TECHVAL[i], i = 1,...,6

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.6

$TECHSYS

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.7

$TECHSYS_C

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.8

$TECHANGLE

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.9

$TECHANGLE_C

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.10

$TSYS

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.11

$DISTANCE

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2

Analog sensors

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1

Interface

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2

Parameterization

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3

Correction direction

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4

Changing technology mode, correction variable

19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3

Conveyor synchronization

20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4

Complex sensors

23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Application examples

25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1

Weaving

25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2

Analog sensor

26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3

Conveyor synchronization

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Generator

4 of 28

Funktionsgenerator KSS5.1 08.02.00 en

1

Characteristics, functional description

5 of 28

Funktionsgenerator KSS5.1 08.02.00 en

1

Characteristics, functional description

1.1

Characteristics

The function generator included in the KRC software is easy to use and allows the user to

implement the following functions:

G

Mechanical weaving

G

Thermal weaving

The function values can be used at KRC analog outputs to modulate the weld current

and the wire feed rate.

G

Analog sensors

G

Conveyor synchronization

G

Coupling of intelligent sensors (META, SCOUT, ...).

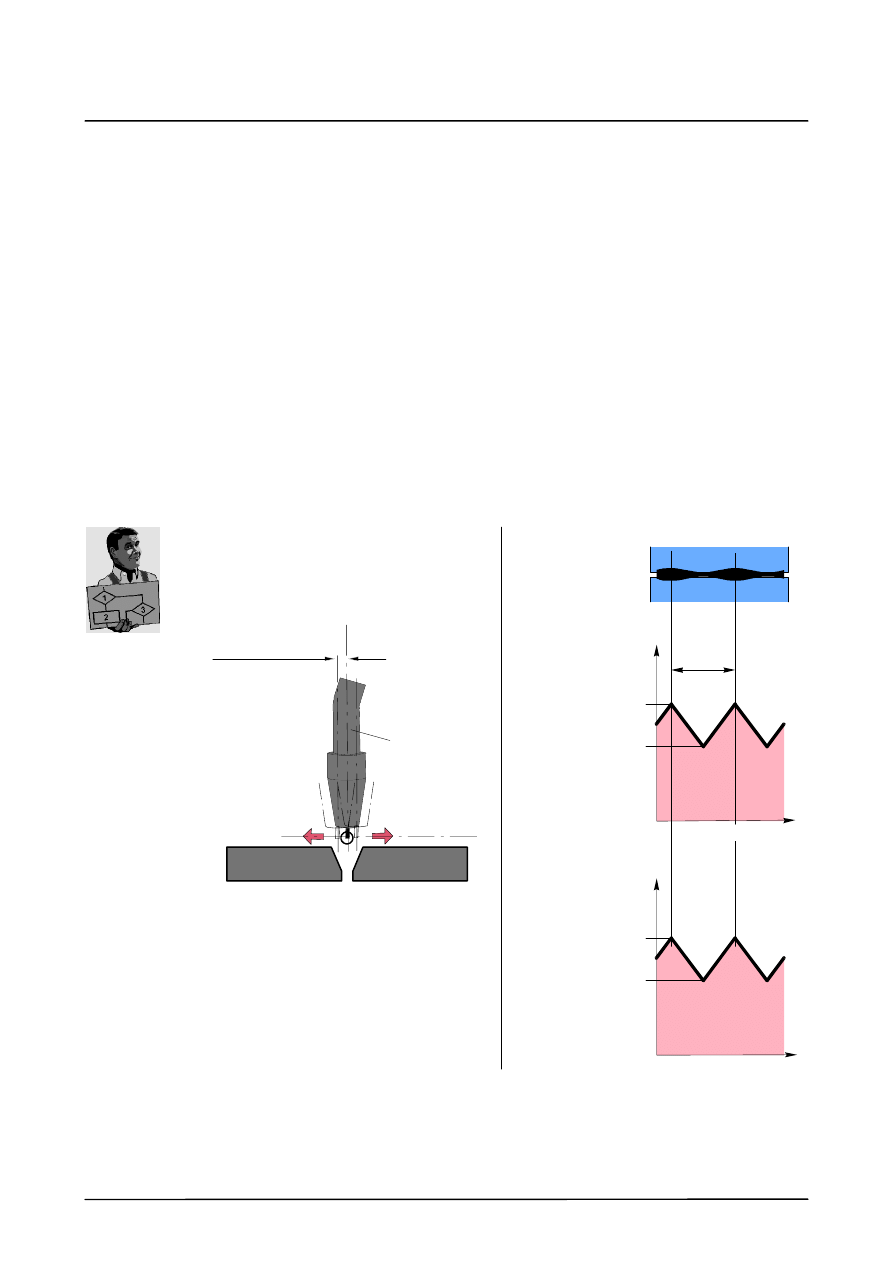

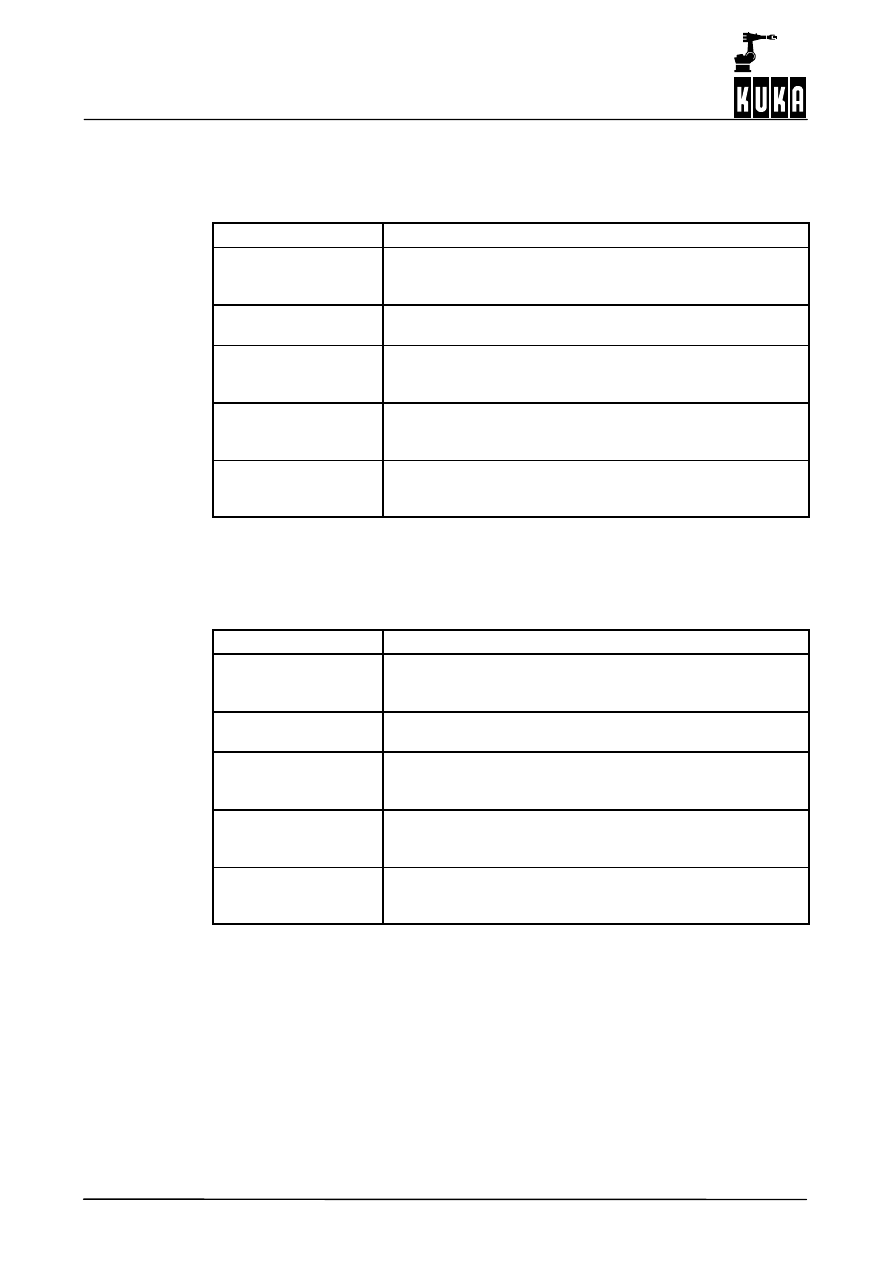

The following diagram illustrates mechanical and thermal weaving using the function

generator.

Weld direction

Weld direction

Max. feed

Min. feed

Wire feed

Length

(1 period)

Weld voltage

(volts)

Max. voltage

Min. voltage

Thermal weaving

Torch

Weave plane

Component

plane

Weave amplitude

Mechanical weaving

Taking the example of a weld

application

Function Generator

6 of 28

Funktionsgenerator KSS5.1 08.02.00 en

1.2

Functional description

1.2.1

Basic principle

The user defines a function which is evaluated accordingly by the system and processed

further. The input values of the function (distance, velocity, etc.), and also the further

processing of the results of the function (output to an analog channel, path correction, etc.),

can be selected and configured using variables.

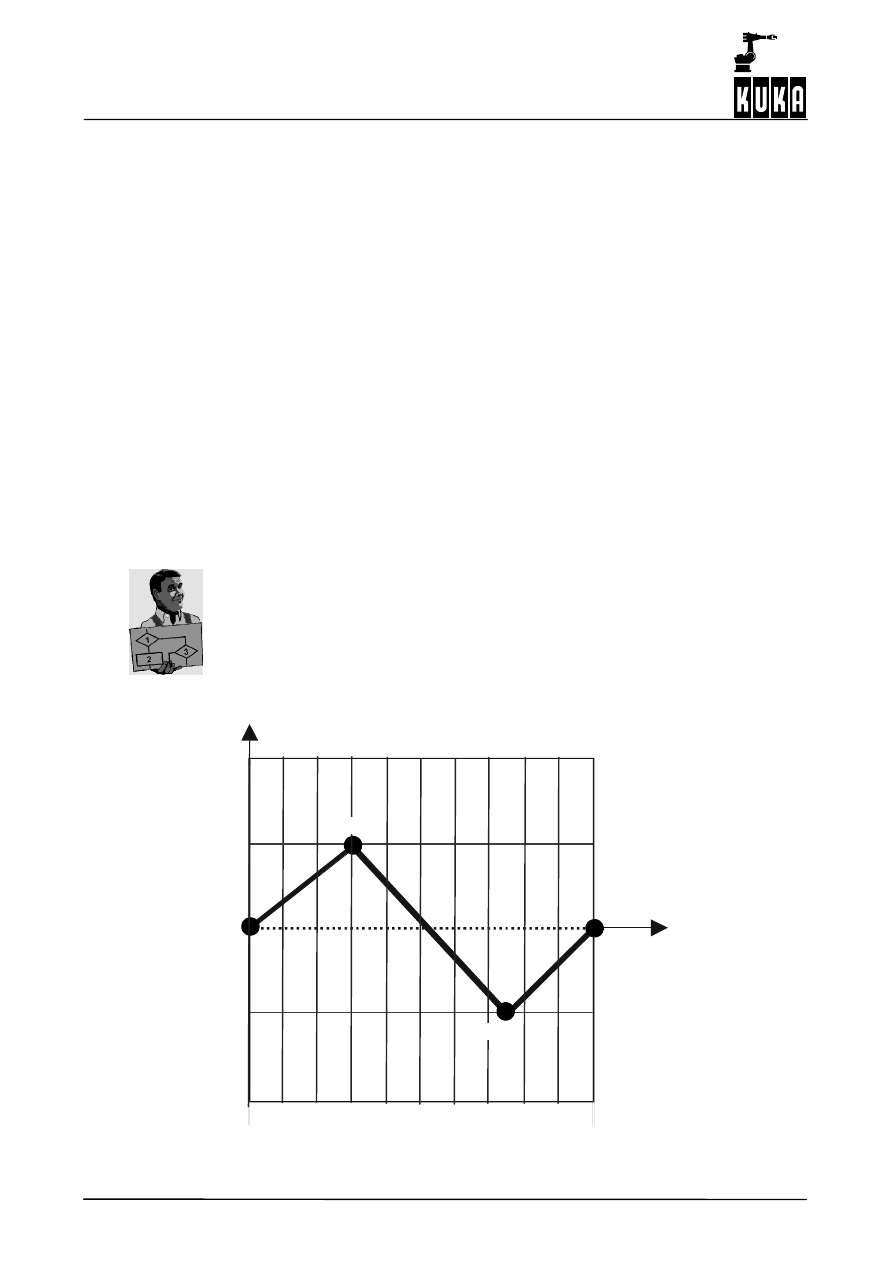

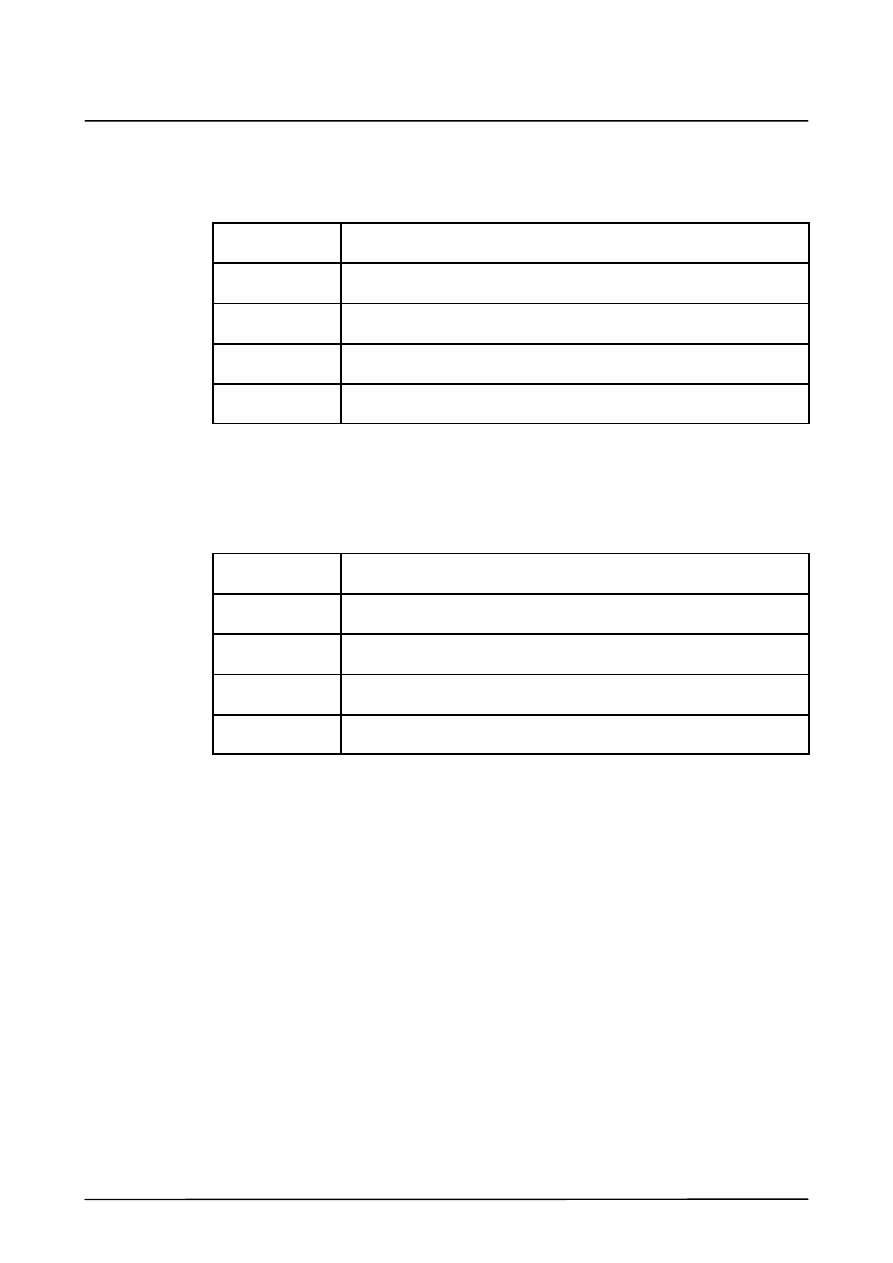

1.2.2

Function definition

G

The required function y(x) is defined in the interval [0,1] as a polygon.

G

The polygon is defined unambiguously by entering function control points.

G

A maximum of 50 control points (x,y) is permissible. They must be selected as follows:

--

x is a real number from the interval [0,1]

--

y is a real number from the interval [--1,1]

For control points 1 to max. 50, the following must be observed: x1 < x2 < ...<xN

The first and last control points must be situated on the edge of the

definition range (x1=0, xN=1).

Example

The control points

(0,0),

(0.3,0.5),

(0.75,--0.5) and

(1,0)

result in the function illustrated below:

(0,0)

(0,1)

(0,--1)

Y

X

(1,--1)

(0.3,0.5)

(0.75,--0.5)

(1,1)

(1,0)

1

Characteristics, functional description (continued)

7 of 28

Funktionsgenerator KSS5.1 08.02.00 en

1.2.3

Correction direction

The correction direction is defined using a user--defined correction coordinate system

(tool--based technological system, $TECHSYS):

WORLD, BASE, ROBROOT, TCP and TTS

The following definitions apply here:

The correction coordinate system can be rotated using the variable $TECHANGLE:

A:

Rotation about the Z axis of the tool--based technological system

in the mathematically positive direction.

B:

Rotation about the Y’ axis of the tool--based technological system

in the mathematically positive direction.

C:

Rotation about the X’’ axis of the tool--based technological system

in the mathematically positive direction.

The definition can be made unambiguous by selecting an axis of the correction coordinate

system by means of a “GEOREF” variable.

Corrections are only possible in Cartesian space and not in axis space. This means

that the function generator is only available for CP motions (LIN, CIRC).

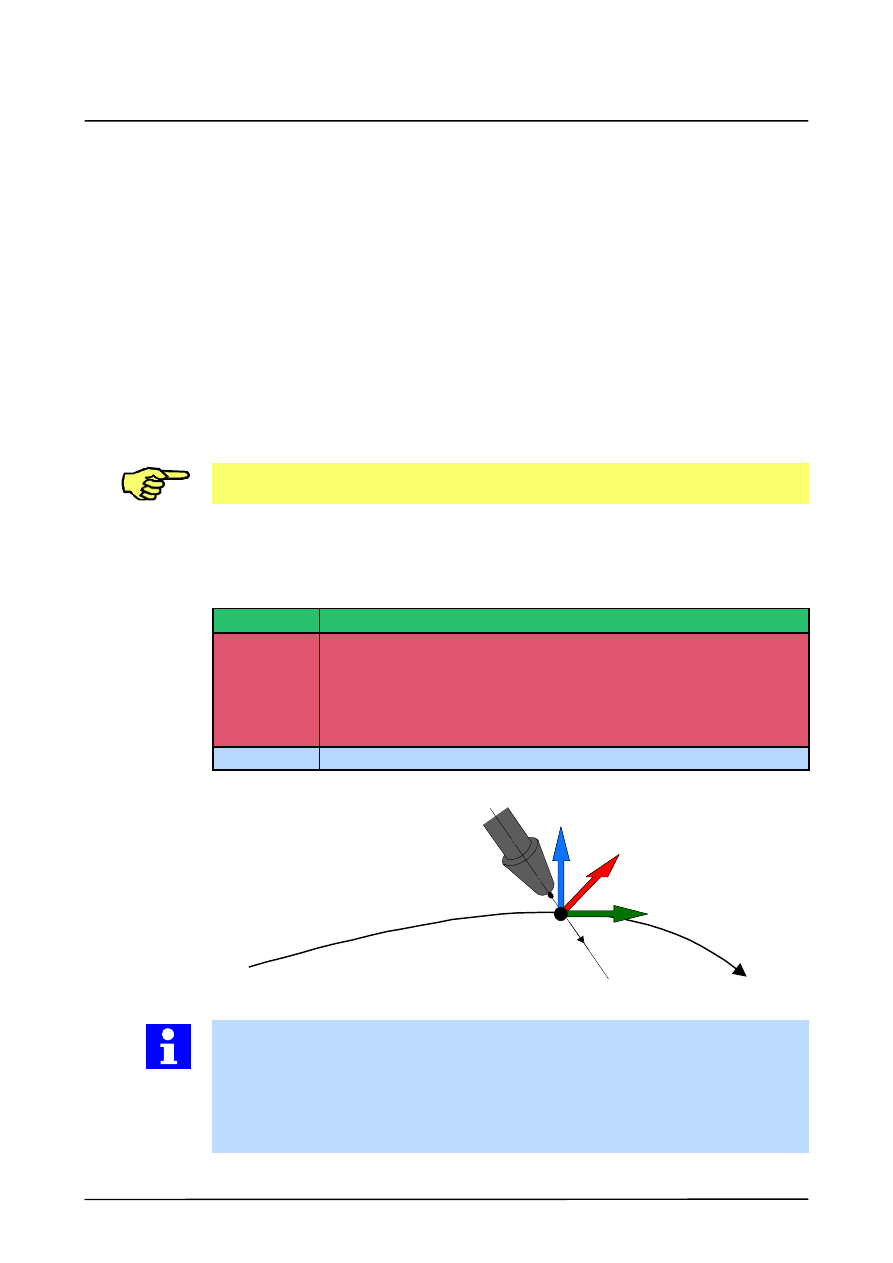

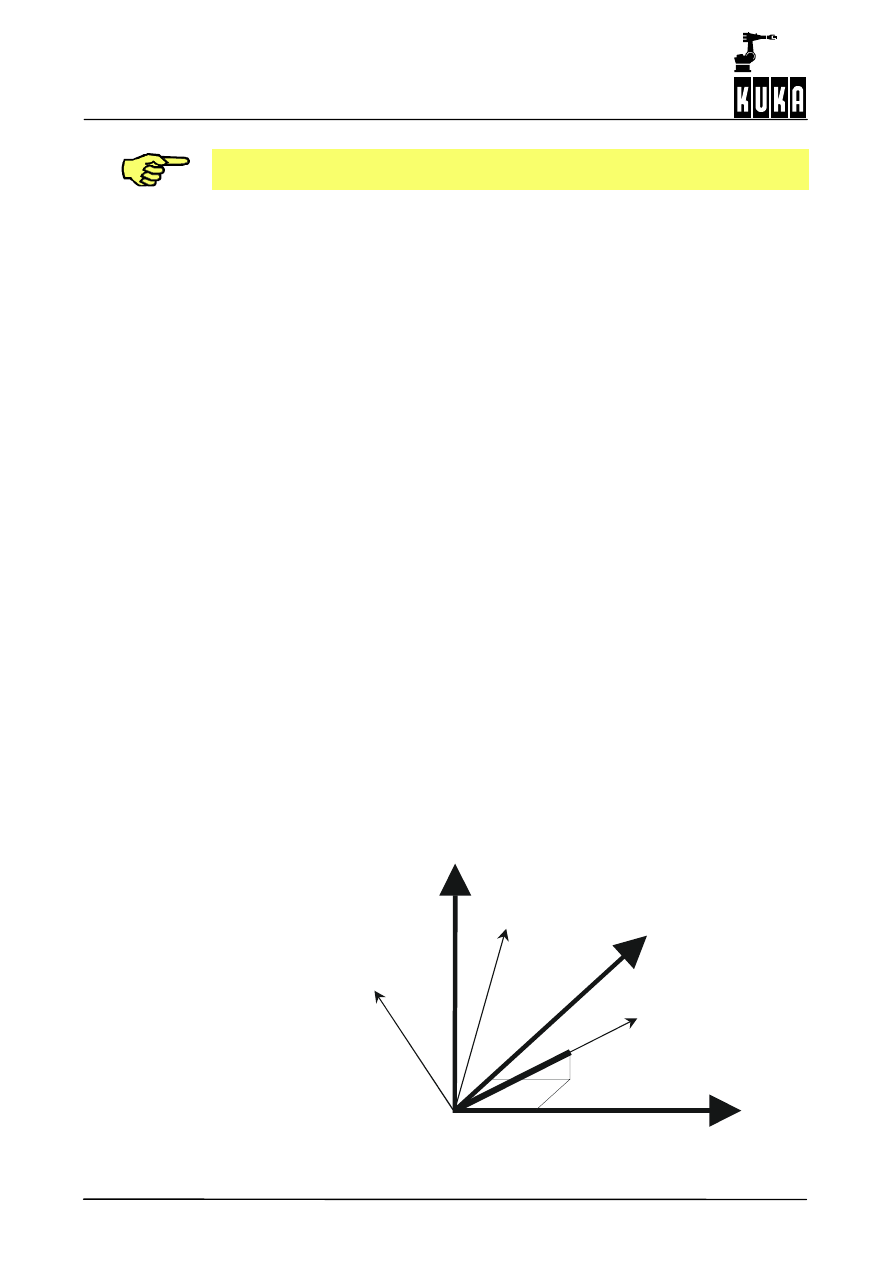

1.2.4

The correction coordinate system TTS

“TTS” stands for tool--based technological system. This tool--based moving frame is defined

as follows:

X axis

Unit vector in direction of path tangent.

Y axis

Unit vector in direction of vector product of path tangent and X axis of

tool coordinate system.

(Applying the right hand rule, the direction of the Y axis is that of the

middle finger if the thumb is pointing in the direction of the path tangent

and the index finger is pointing in the direction of the X axis of the tool

coordinate system.)

Z axis

Unit vector in direction of vector product of path tangent and Y axis.

Y axis (middle finger)

X axis (thumb)

Z axis

X

TOOL

axis

(index finger)

TTS

(tool--based technological system)

The correction coordinate system is calculated every time a CP motion is executed.

If the X axis of the tool coordinate system and the path tangent are parallel, the TTS cannot

be generated. The TTS is invalid in this case and results in the acknowledgement message

“TTS NOT EXISTING”

and dynamic braking when path correction is used.

In this case, a corresponding reorientation of the tool is required as well as reprogramming

of the motion.

Function Generator

8 of 28

Funktionsgenerator KSS5.1 08.02.00 en

1.3

Configuration

The maximum number of programmable function generators is selected in the robot--specific

machine data using the datum $TECH_MAX.

$TECH_MAX can be set to values between 3 and 6 with 3 being the default setting.

2

Programming, parameterization

9 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2

Programming, parameterization

The function generator can be programmed using advance run and main run system

variables. Advance run variables are copied into the main run variables internally in the

system at the start of a motion or when changing block to an approximate positioning block.

The function generator, which is only active for CP motions, only evaluates the main run

variables.

For this reason, when controlling the function generator using advance run variables, a CP

motion block must then be executed so that the data are transferred to the main run data.

A so--called zero block is also valid in this case.

2.1

Structure variables

2.1.1

$TECH[i], $TECH_C[i], i=1,...,6

These are structure variables for defining the function and programming the evaluation of

the function.

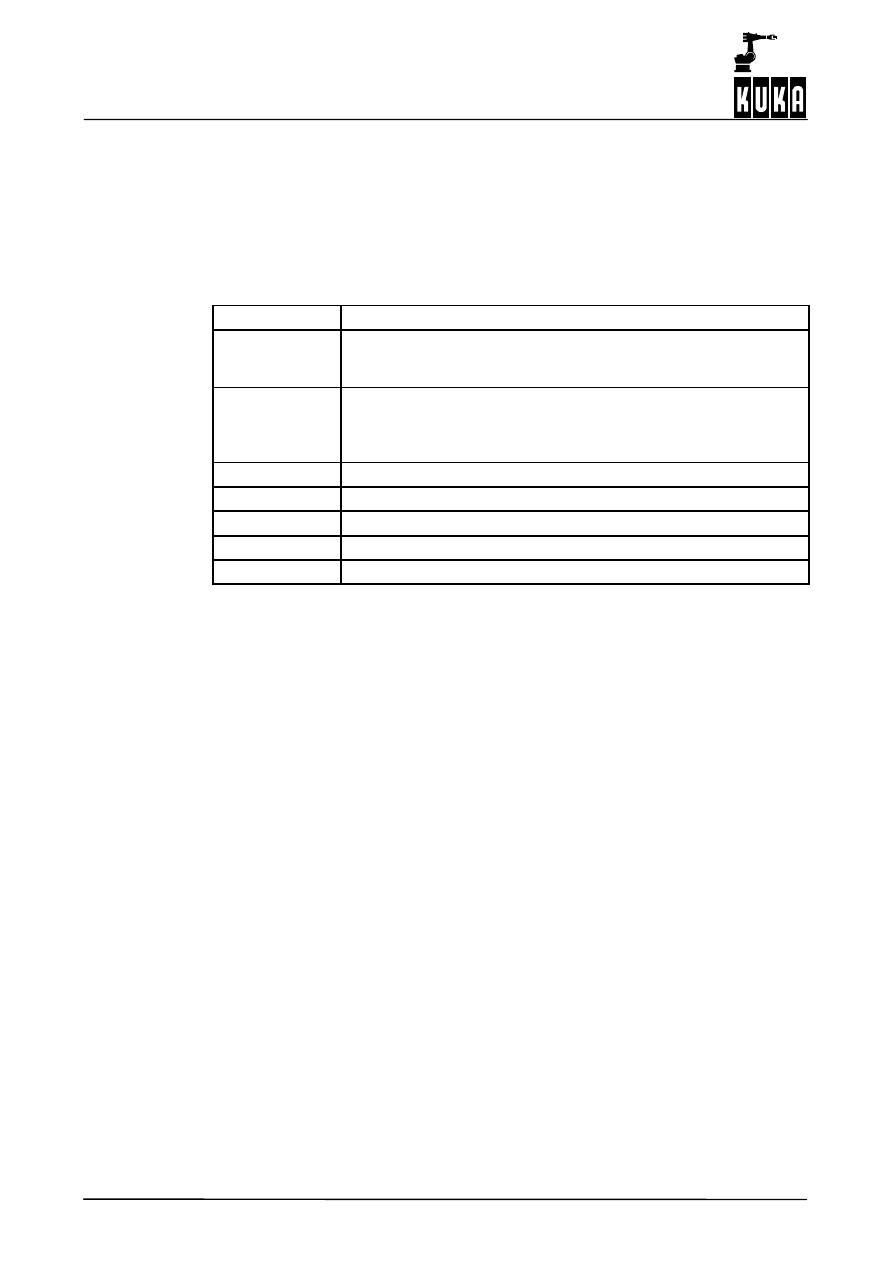

$TECH[i]. MODE

The parameter “MODE” defines the type of evaluation of the function in the advance run. The

parameter can be changed in the program and is block--specific.

MODE

Effect

#OFF

The function is not evaluated.

#SINGLE

The definition range of the function is run through just once

when the function is evaluated.

#CYCLE

Cyclical evaluation of the function.

$TECH_C[i]. MODE

The parameter “MODE” defines the type of evaluation of the function in the main run. The

parameter can be changed using Trigger, Interrupt or the variable modification function and

the changes take effect immediately.

MODE

Effect

#OFF

The function is not evaluated.

#SINGLE

The definition range of the function is run through just once

when the function is evaluated.

#CYCLE

Cyclical evaluation of the function.

Function Generator

10 of 28

Funktionsgenerator KSS5.1 08.02.00 en

$TECH[i].CLASS

The parameter “CLASS” can be used to define the technology class in the advance run. The

parameter can be changed in the program and is block--specific.

CLASS

Effect

#PATH

The input variable for the function generator is the system

variable $DISTANCE. The unit for the scaling and offset

variables is [mm].

#VEL

The input variable for the function generator is the path

velocity ($VEL_ACT).

#SENSOR

The input variable for the function generator is the system

variable $TECHIN[i], i=1..6. Depending on the input values, a

corresponding position correction is carried out.

#CONVEYOR

The input variable for the function generator is the system

variable $TECHIN[i], i=1..6. Depending on the input values, a

corresponding tracking motion is executed by the robot.

#DATALINK

The input variable for the function generator is a correction

frame that is set by the sensor task. Depending on the input

values, a corresponding correction is carried out by the robot.

$TECH_C[i].CLASS

The parameter “CLASS” can be used to define the technology class in the main run. The

parameter cannot be changed.

CLASS

Effect

#PATH

The input variable for the function generator is the system

variable $DISTANCE. The unit for the scaling and offset

variables is [mm].

#VEL

The input variable for the function generator is the path

velocity ($VEL_ACT).

#SENSOR

The input variable for the function generator is the system

variable $TECHIN[i], i=1..6. Depending on the input values, a

corresponding position correction is carried out.

#CONVEYOR

The input variable for the function generator is the system

variable $TECHIN[i], i=1..6. Depending on the input values, a

corresponding tracking motion is executed by the robot.

#DATALINK

The input variable for the function generator is a correction

frame that is set by the sensor task. Depending on the input

values, a corresponding correction is carried out by the robot.

2

Programming, parameterization (continued)

11 of 28

Funktionsgenerator KSS5.1 08.02.00 en

$TECH[i].FCTCTRL

This is a function control structure for setting the scaling and offset parameters in the

advance run. The parameter can be changed in the program and is block--specific.

FCTCTRL

element

Effect

OFFSET_IN

Real value which, depending on the parameter CLASS, can be used

to offset the zero point of the definition range of the function.

OFFSET_OUT

Real value which, depending on the parameter CLASS, can be used

to offset the zero point of the value range of the function.

SCALE_IN

Real value which can be used to scale the definition range of the

function with reference to the parameter CLASS.

SCALE_OUT

Real value which can be used to scale the value range of the

function with reference to the parameter CLASS.

$TECH_C[i].FCTCTRL

Function control structure for setting the scaling and offset parameters in the main run. The

parameter can be changed using Trigger, Interrupt or the variable modification function and

the changes take effect immediately.

FCTCTRL

element

Effect

OFFSET_IN

Real value which, depending on the parameter CLASS, can be used

to offset the zero point of the definition range of the function.

OFFSET_OUT

Real value which, depending on the parameter CLASS, can be used

to offset the zero point of the value range of the function.

SCALE_IN

Real value which can be used to scale the definition range of the

function with reference to the parameter CLASS.

SCALE_OUT

Real value which can be used to scale the value range of the

function with reference to the parameter CLASS.

Function Generator

12 of 28

Funktionsgenerator KSS5.1 08.02.00 en

GEOREF

GEOREF

If the technology class SBC is selected, the variable GEOREF is

irrelevant.

NONE

This result of the function evaluation is only available

as the system variable $TECHVAL. With the

technology class SENSOR, this parameter has the

effect that no function evaluation is carried out.

X

In addition to the system variable, the calculated value

is also included in the calculation of the TCP in the

direction of the X axis of the TTS programmed using

$TECHSYS and $TECHANGLE, or in the direction of

the X BASE axis in the case of technology class

CONVEYOR.

Y

In addition to the system variable, the calculated value

is also included in the calculation of the TCP in the

direction of the Y axis of the TTS programmed using

$TECHSYS and $TECHANGLE, or in the direction of

the Y BASE axis in the case of technology class

CONVEYOR.

Z

In addition to the system variable, the calculated value

is also included in the calculation of the TCP in the

direction of the Z axis of the TTS programmed using

$TECHSYS and $TECHANGLE, or in the direction of

the Z BASE axis in the case of technology class

CONVEYOR.

For technology classes SENSOR and CONVEYOR, the following

parameters can also be programmed for GEOREF:

A

Significance for technology class SENSOR:

Rotation about the Z axis of the tool--based

technological system in the mathematically positive

direction.

Significance for technology class CONVEYOR:

Tracking motion about the Z axis of the BASE

coordinate system in the mathematically positive

direction.

B

Significance for technology class SENSOR:

Rotation about the Y axis of the tool--based

technological system in the mathematically positive

direction.

Significance for technology class CONVEYOR:

Tracking motion about the Y axis of the BASE

coordinate system in the mathematically positive

direction.

C

Significance for technology class SENSOR:

Rotation about the X axis of the tool--based

technological system in the mathematically positive

direction.

Significance for technology class CONVEYOR:

Tracking motion about the X axis of the BASE

coordinate system in the mathematically positive

direction.

2

Programming, parameterization (continued)

13 of 28

Funktionsgenerator KSS5.1 08.02.00 en

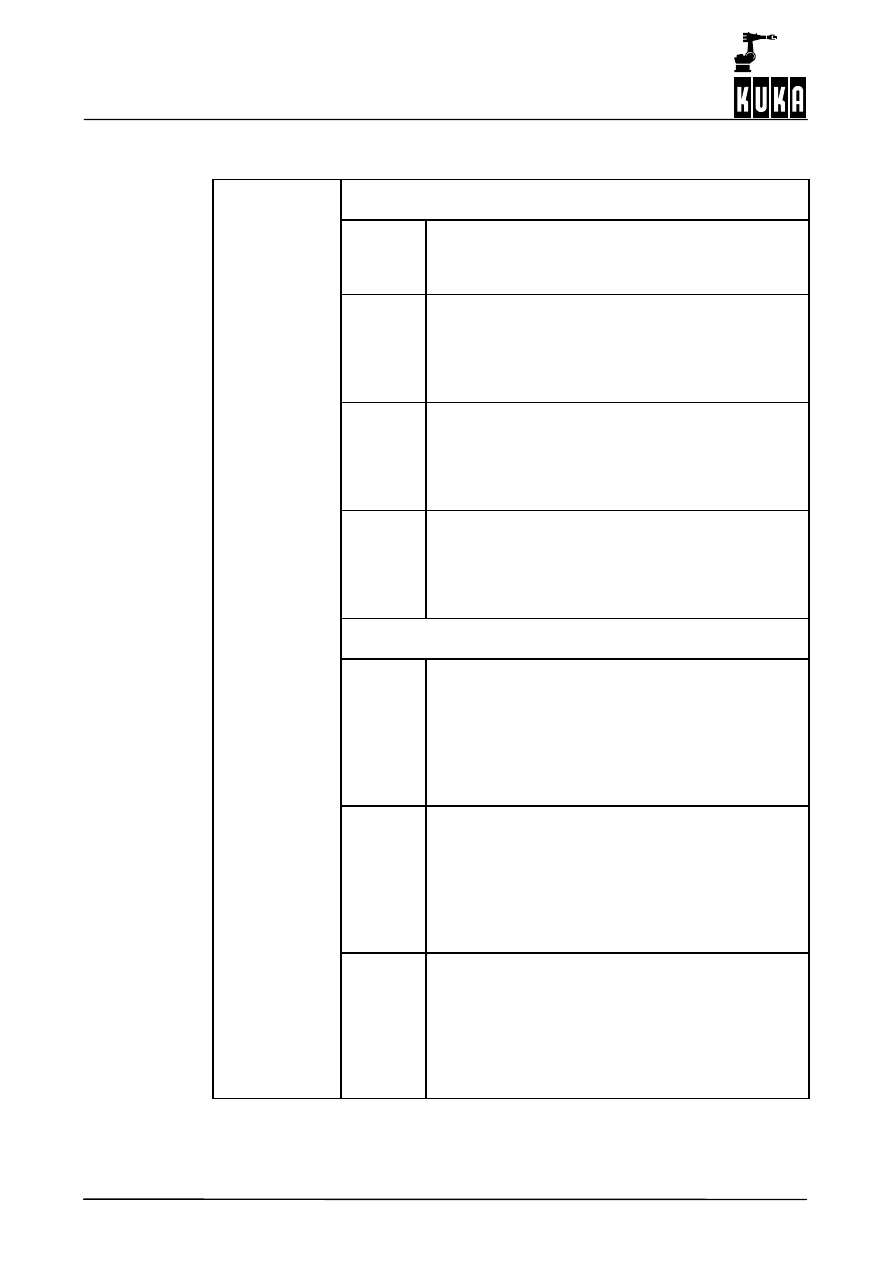

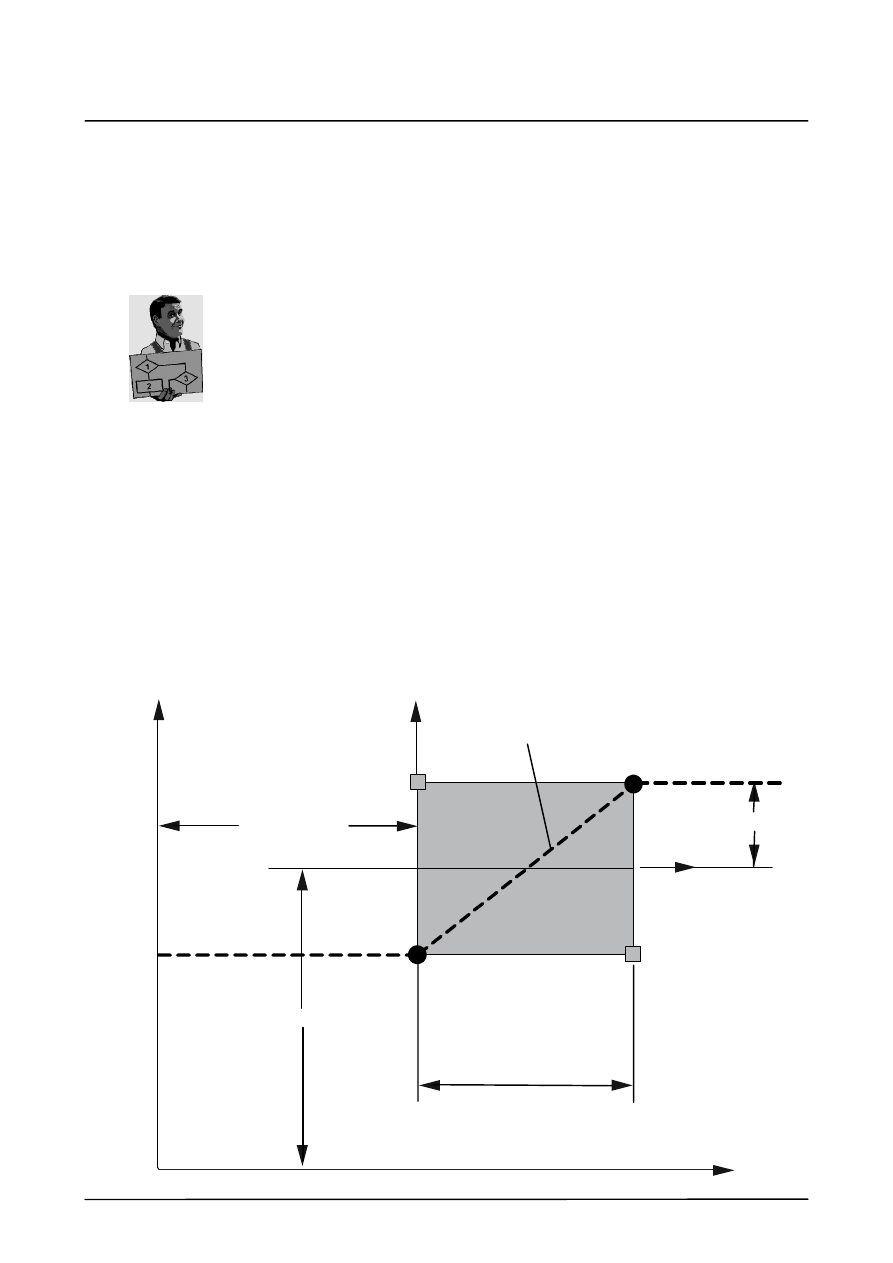

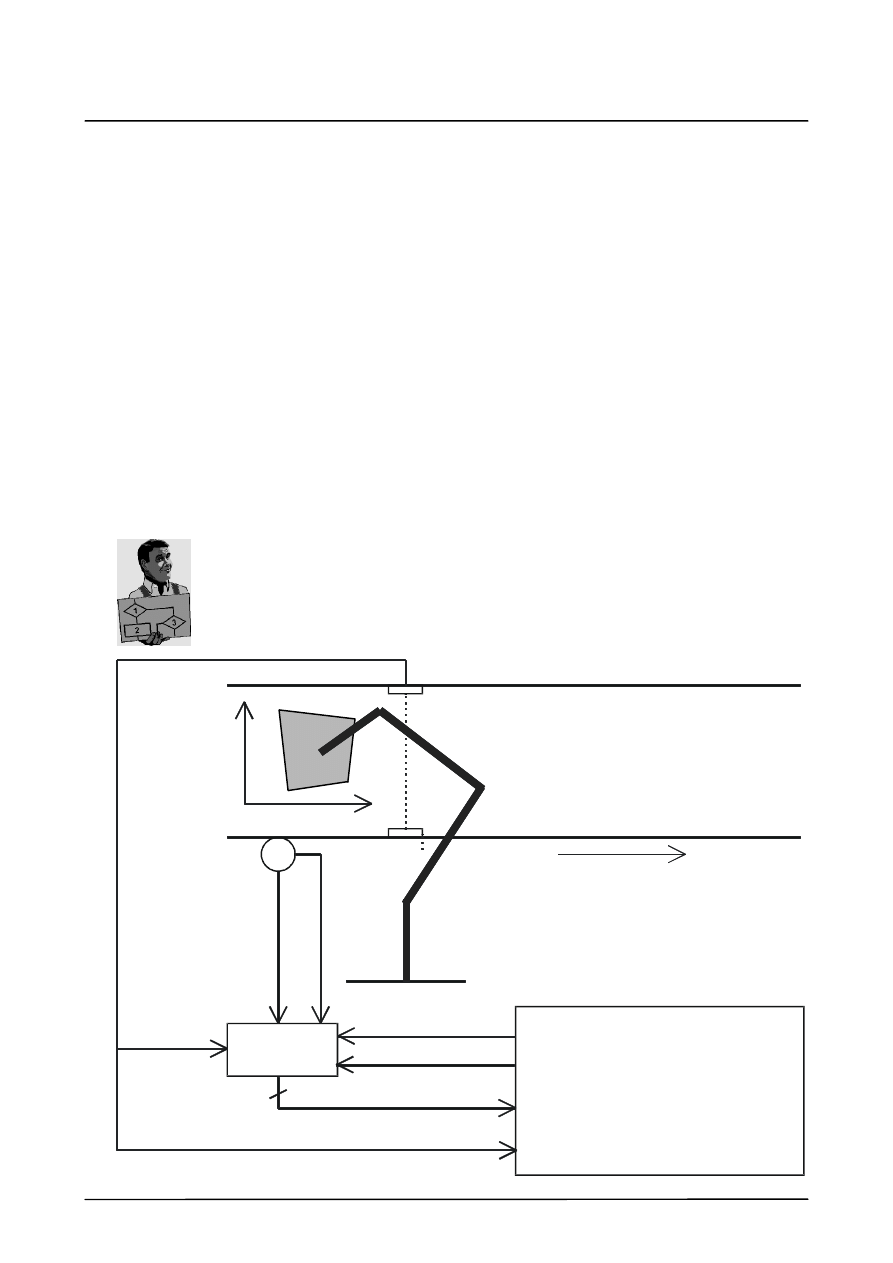

Example

$TECHVAL

(output variable)

OFFSET_IN

OFFSET_OUT

SCALE_IN

Technology mode

#CYCLE

e.g. length of arc

for #PATH

SCALE_OUT

(input variable)

$DISTANCE (CLASS = #PATH)

$VEL_ACT (CLASS = #VEL)

$TECHIN

(CLASS = #SENSOR,

CLASS = #CONVEYOR)

Correction frame

(CLASS = #DATALINK)

(0,--1)

(1,--1)

(0,0)

(1,0)

(0,1)

(1,1)

Y

X

Function Generator

14 of 28

Funktionsgenerator KSS5.1 08.02.00 en

$TECH[i].FCT

Defines the function in the advance run. It can be changed in the program and is

block--specific.

$TECH_C[i].FCT

Defines the function in the main run. It cannot be changed in the program.

FCT element

Effect

ORDER

Integer value specifying the degree of interpolation when the spline

is evaluated. The only degree of interpolation currently implemented

is 1.

CPNUM

Total number of valid control points in the following five control point

structures. The number of valid control points can be freely selected

between 2 and 50; no gaps are allowed between valid control

points.

CPS1

Control point list for control points 1 to 10

CPS2

Control point list for control points 11 to 20

CPS3

Control point list for control points 21 to 30

CPS4

Control point list for control points 31 to 40

CPS5

Control point list for control points 41 to 50

2.1.2

$TECHIN[i], i = 1,...,6

The system variable $TECHIN forms the interface between the cyclical analog and digital

inputs of the KR Cx and the function generator. The contents of this variable serve as the

input variable for the function generator.

The variable has the data type REAL and cannot be modified in the program.

2.1.3

$TECHPAR[i, j], i=1,...,6 , j=1,...,10

This is used for parameterization or output of the function generator (analog sensors,

conveyor tracking, etc.) in the advance run. Ten input parameters and ten output parameters

are available to each function generator (i). If a parameter is used to output function

generator states, the parameter value that is current in the interpolation cycle can be found

in the main run variable.

The data type is REAL. The variable can be modified in the program and is block--specific.

2.1.4

$TECHPAR_C[i, j], i = 1,...,6 , j=1,...,10

This is used for parameterization or output of the function generator (analog sensors,

conveyor tracking, etc.) in the main run. Ten input parameters and ten output parameters are

available to each function generator (i). If a parameter is used to output function generator

states, the parameter value that is current in the interpolation cycle can be found in the main

run variable.

The data type is REAL. The variable can be modified using Trigger, Interrupt or the variable

modification function. The changes take effect immediately.

2

Programming, parameterization (continued)

15 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2.1.5

$TECHVAL[i], i = 1,...,6

This is an output variable of the function generator. SCALE_OUT and OFFSET_OUT are

included in the calculations.

This variable has the data type REAL and cannot be modified during program execution.

2.1.6

$TECHSYS

Used for programming the TTS in the advance run. The coordinate systems #WORLD,

#BASE, #ROBROOT, #TCP and #TTS can be programmed. If GEOREF < > (is not equal

to) #NONE, then the calculated function values refer to the programmed coordinate system.

This variable can be modified in the program and is block--specific.

2.1.7

$TECHSYS_C

This variable is used for programming the TTS in the main run. The coordinate systems

#WORLD, #BASE, #ROBROOT, #TCP and #TTS can be programmed.

If GEOREF < > (is not equal to) #NONE, then the calculated function values refer to the

programmed coordinate system.

This variable can be modified using Trigger, Interrupt or the variable modification function

and the changes take effect immediately.

2.1.8

$TECHANGLE

Used for programming the rotation of the TTS in the advance run.

The rotation is specified in RPY angles.

This variable can be modified in the program and is block--specific.

2.1.9

$TECHANGLE_C

Used for programming the rotation of the TTS in the main run. The rotation is specified in

RPY angles.

The variable can be modified using Trigger, Interrupt or the variable modification function and

the changes take effect immediately.

2.1.10 $TSYS

For each interpolation cycle, this system variable contains the current TTS – insofar as there

is one available – with reference to the base coordinate system.

This variable is of type FRAME and cannot be modified.

2.1.11 $DISTANCE

This variable allows path--related function evaluation. During program execution, it

represents the current arc length of a Cartesian motion in millimeters.

$DISTANCE is set to zero at the start of an individual CP block or at the start of the CP motion

in a PTP/CP approximate positioning motion.

This variable is of type REAL and cannot be modified.

Function Generator

16 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2

Programming, parameterization (continued)

17 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2.2

Analog sensors

2.2.1

Interface

The system variables $TECHIN[i] (i = 1 .. 6) form the interface between the sensor inputs

and the function generator.

These variables are written to cyclically using the following statements and serve as the input

variable for the function generator.

Analog input:

SIGNAL CORRECTION $ANIN[1]

ANIN ON $TECHIN[2] = FACTOR * CORRECTION + OFFSET

Digital input:

Entry in “$MACHINE.DAT”

SIGNAL $DIGIN1 $IN[20] TO $IN[27]

DECL DIGINCODE $DIGIN1CODE=#UNSIGNED

DIGIN ON $TECHIN[3] = FACTOR * $DIGIN1 + OFFSET

2.2.2

Parameterization

Elements of the array variable $TECHPAR[i,j] are used for parameterization and for

outputting function generator states.

Technology class SENSOR ($TECH[i].CLASS = #SENSOR) causes the function generator

to use the variable $TECHIN[i] and thus the sensor signal as the input variable.

For function generator class #SENSOR, the function definition describes a controller

characteristic as illustrated in the following diagram.

Correction velocity

[mm/s] or [degrees/s]

OFFSET_IN

OFFSET_OUT

SCALE_IN

Technology mode

#CYCLE

$TECHIN

SCALE_OUT

(0,--1)

(1,--1)

(0,0)

(1,0)

(0,1)

(1,1)

Y

X

Controller characteristic

Function Generator

18 of 28

Funktionsgenerator KSS5.1 08.02.00 en

If the definition range “SCALE_IN” is exceeded, the corresponding limit value is

maintained.

For function generator class “#SENSOR”, the function generator calculates a correction

velocity (mm/s or degrees/s) from the input values. This correction velocity is used to

calculate a correction value (mm, degrees) which is added up in every interpolation cycle

(sensor correction, initial value 0.0).

With corresponding parameterization, the correction velocity is 0 (zero) and the sensor

correction value remains constant in the balanced state.

The correction velocity is smoothed before the correction value is calculated in order to avoid

abrupt corrections. This smoothing can be set using $TECHPAR[i,1].

If the filter $TECHPAR[i,1] is set to less than the duration of an interpolation cycle, the

unfiltered velocity value is used for calculating the correction.

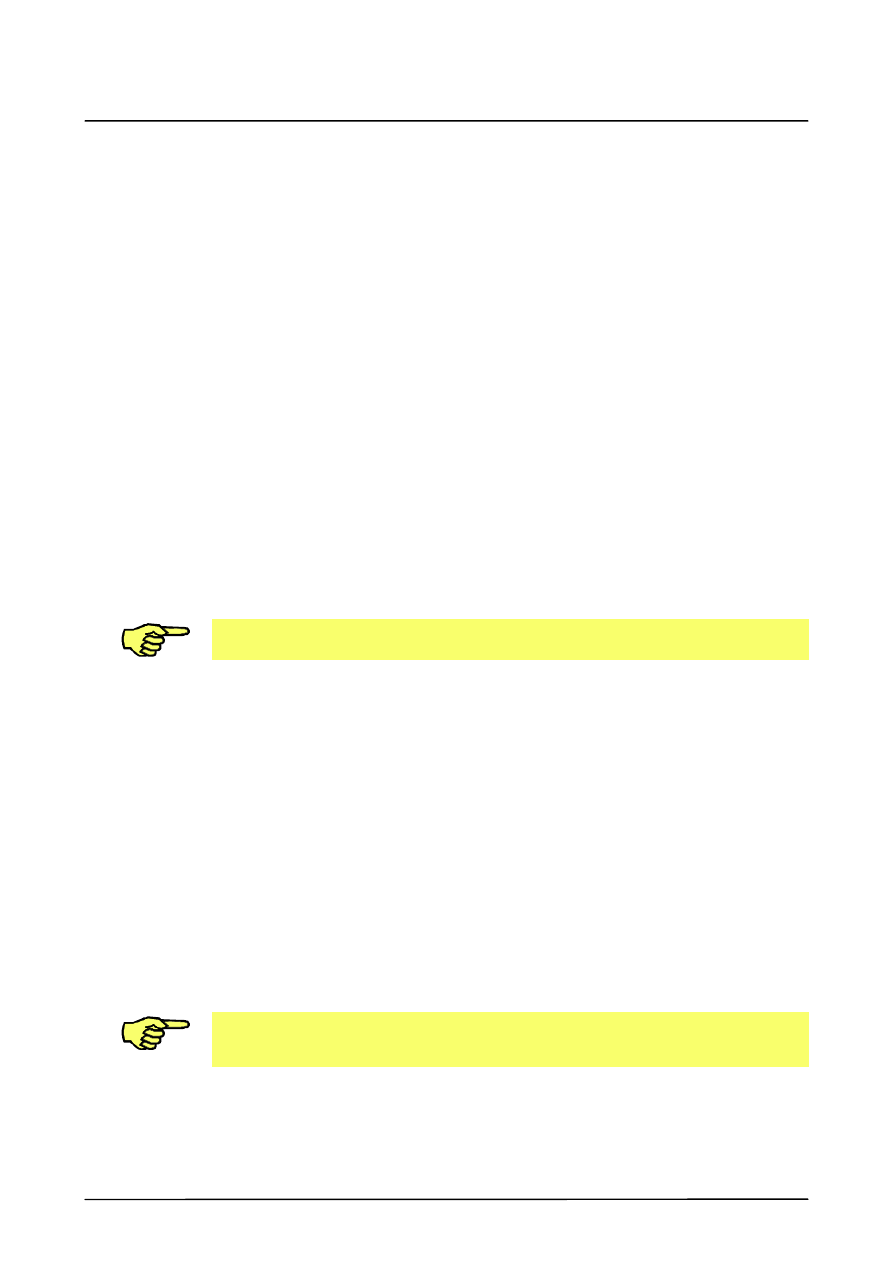

2.2.3

Correction direction

The correction direction is defined, as is usual for the function generator, by means of the

variables

$TECHSYS, $TECHANGLE and GEOREF.

Using the components

#A, #B, and #C

of the ENUM variable GEOREF, it is also possible to carry out an orientation correction to

the corresponding angles.

G

#A:

Rotation of the X axis of the tool about the Z axis of the tool--based technological

system in the mathematically positive direction.

G

#B:

Rotation of the X axis of the tool about the Y axis of the tool--based technological

system in the mathematically positive direction.

G

#C:

Rotation of the X axis of the tool about the X axis of the tool--based technological

system in the mathematically positive direction.

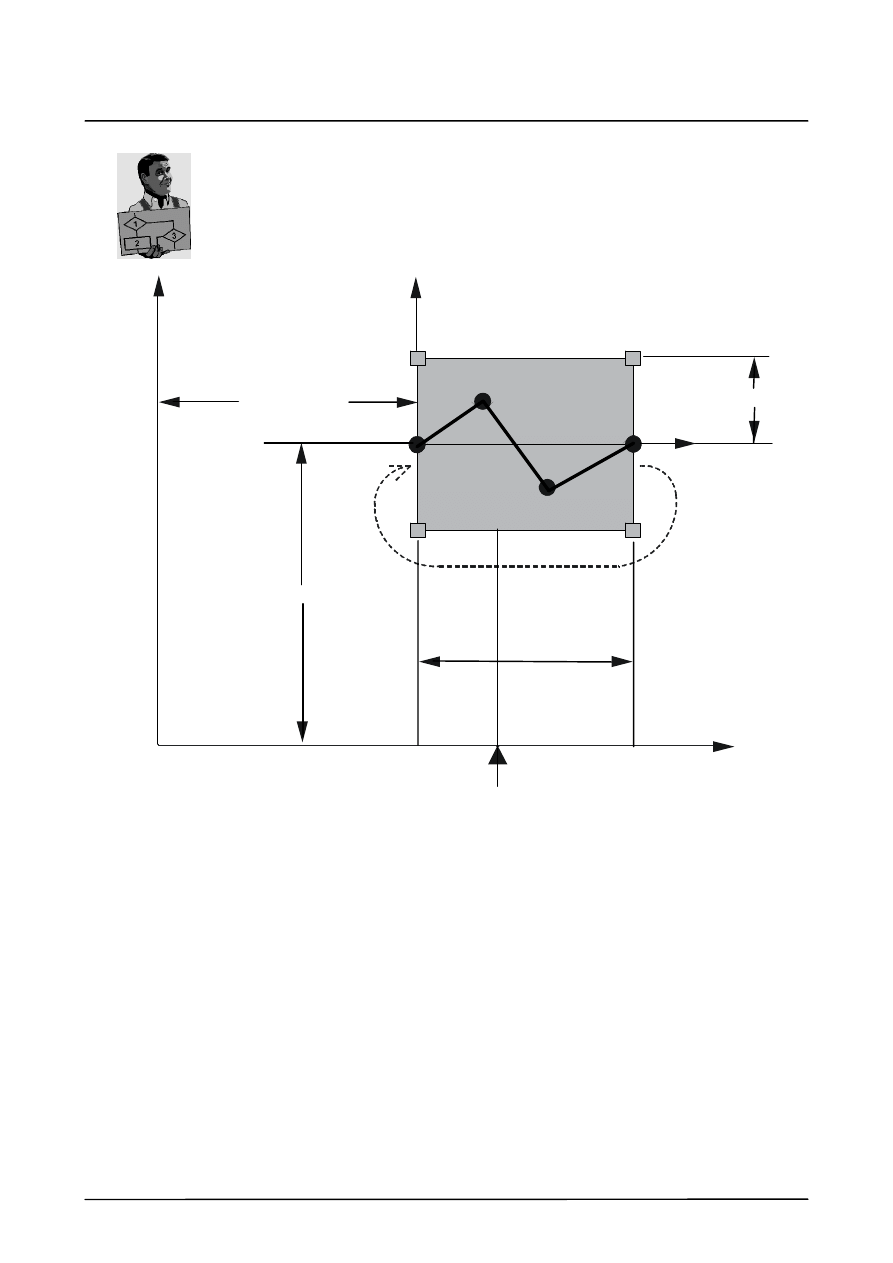

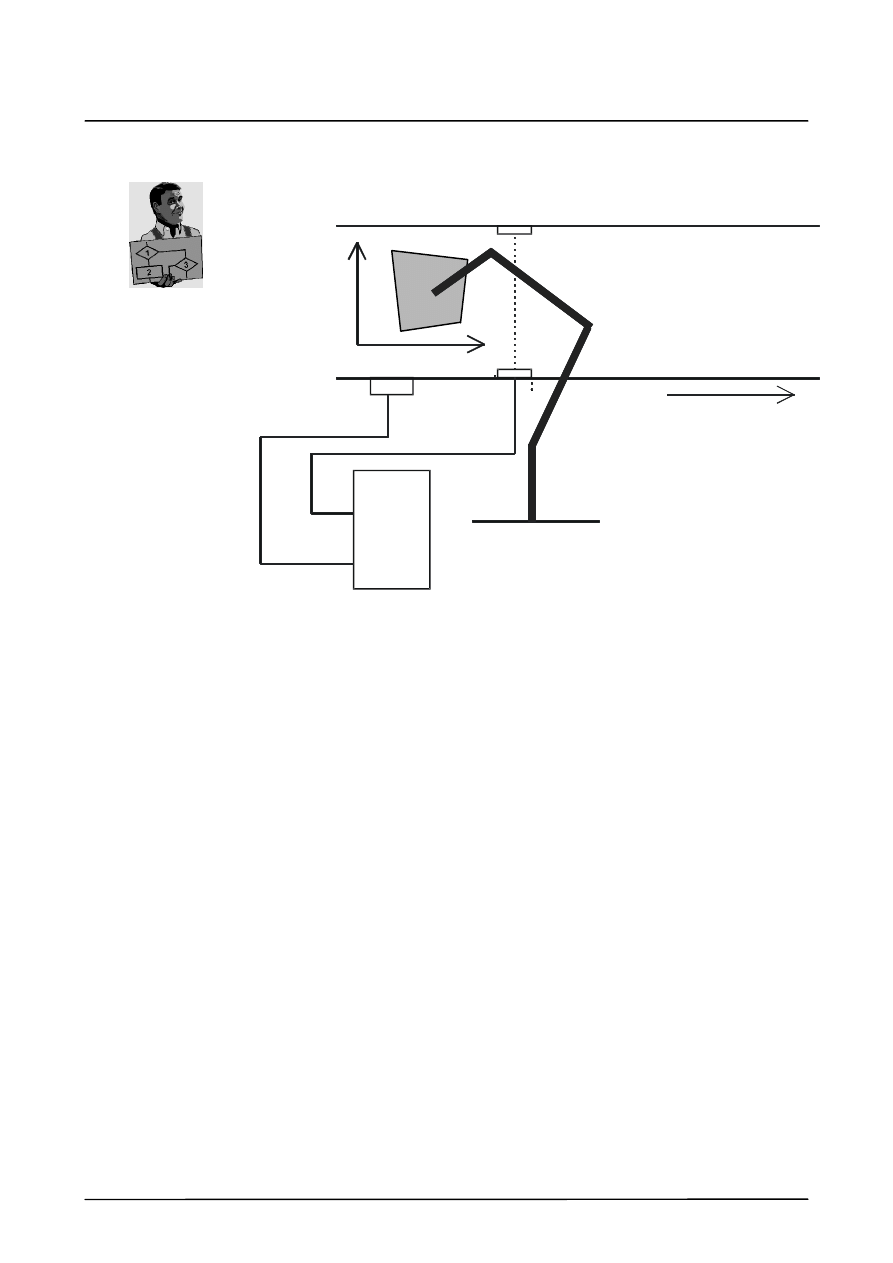

Since the tool--based technological system changes its position when following a contour,

the correction increase in the direction/orientation defined by GEOREF and calculated in the

interpolation cycle is converted to the corresponding BASE components (dx, dy, dz or da,

db, dc).

Z BASE

Y BASE

X BASE

GEOREF

ds

dz

dx

dy

X TSYS

Y TSYS

Z TSYS

ds = correction velocity * t_ipo

2

Programming, parameterization (continued)

19 of 28

Funktionsgenerator KSS5.1 08.02.00 en

The correction increase in the BASE components is added up (dX, dY, dZ or dA, dB, dC),

included in the calculation of the TCP and can be accessed by the user via the TECHPAR

variables.

TECHPAR_C[i, 3] : Correction value in X BASE (dX)

TECHPAR_C[i, 4] : Correction value in Y BASE (dY)

TECHPAR_C[i, 5] : Correction value in Z BASE (dZ)

TECHPAR_C[i, 6] : Correction value in A BASE (dA)

TECHPAR_C[i, 7] : Correction value in B BASE (dB)

TECHPAR_C[i, 8] : Correction value in C BASE (dC)

In the case of a TCP correction (GEOREF = #X, #Y or #Z), the value of the correction vector

in BASE (unit = mm) is written to the output variable of the function generator ($TECHVAL[i])

and can then be used, with the aid of two interrupt declarations, for monitoring the sensor

correction.

INTERRUPT DECL 1 WHEN $TECHVAL[1] > 20.0 DO UPPER_LIMIT()

INTERRUPT DECL 2 WHEN $TECHVAL[1] < --20.0 DO LOWER_LIMIT()

In the case of an orientation correction (GEOREF = #A, #B or #C), the value is calculated

using the correction angle in

BASE (dA, dB, dC)

and transferred to TECHVAL[i].

$TECHVAL[i] = SQRT(dA2 + dB2 + dC2)

All correction values that are made available to the user are interpolator command values

and are not filtered, i.e. there is no reference to actual values.

2.2.4

Changing technology mode, correction variable

Switching the technology mode from #CYCLE to #SINGLE has the effect that the input

variable $TECHIN[i] is no longer evaluated. The correction velocity is set to zero internally

in the system thus keeping the established sensor correction vector constant.

When an exact positioning point is reached, the correction variable is retained and is used

for the subsequent CP motion. This applies also for the transition to the following block when

a CP approximation contour is executed.

Block selection, program reset and interrupt commands followed by the RESUME statement

cause the start values of the motion block to be initialized and the correction value is lost.

The sensor offset is set to 0 in the function generator.

No sensor offset is permissible in the case of a PTP motion. If there is a correction value

present, the acknowledgement message

“DEVIATION IN THE START POINT”

is generated.

The instruction $TECH[i].MODE=#OFF triggers an advance run stop, deactivates the

functionality of the sensors, sets the sensor offset to 0 and continues the motion from the

current point in space.

Function Generator

20 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2.3

Conveyor synchronization

The system variables $TECHIN[i] (i = 1 .. 6) form the interface between the sensor inputs

and the conveyor functionality.

Data are written to these variables cyclically using the following statements:

Analog input:

SIGNAL CONVEYORVEL $ANIN[1]

ANIN ON $TECHIN[2] = FACTOR * CONVEYORVEL + OFFSET

Digital input:

Entry in “$MACHINE.DAT”

SIGNAL $DIGIN1 $IN[20] TO $IN[28]

DECL DIGINCODE $DIGIN1CODE=#UNSIGNED

DIGIN ON $TECHIN[3] = FACTOR * $DIGIN1 + OFFSET

Elements of the array variable $TECHPAR[i,j] are used for parameterization and for

outputting function generator states as described below.

Two conveyor modes are possible. The robot tracks the conveyor in the case of translational

or rotational motions of the part to be processed, e.g. with a conveyor belt or turntable.

The coordinate system in which tracking motions are possible is defined by means of the first

six TECHPAR variables of the next function generator.

If, for example, function generator 1 has been configured for the conveyor function,

$TECHPAR[2,1] to $TECHPAR[2,6] contain the tracking coordinate system (X, Y, Z, A, B,

C) with reference to $WORLD.

Function generator 2 should not be used for any other purpose in this case.

The TECH variable “GEOREF” defines the correction direction in this coordinate system.

The parameters

#X, #Y and #Z

define a translational correction in the corresponding direction.

For rotational tracking, the parameters

#A, #B and #C

of the “GEOREF” variable are used:

#A --> about Z, #B --> about Y, #C --> about X.

In the case of translational conveyor mode, it is of vital importance to ensure that the

tracking direction corresponds to the direction of motion of the conveyor belt.

In the case of rotational motions of the part, the correction axis must be located at the center

of rotation, for example:

GEOREF=#A

where the Z axis of the conveyor (Z Conv.) is the rotational axis and the direction of rotation

is mathematically positive.

2

Programming, parameterization (continued)

21 of 28

Funktionsgenerator KSS5.1 08.02.00 en

If the following is selected

GEOREF=#NONE

the tracking distance is calculated and is available to the user via the variable

$TECHVAL[i]

The robot does not carry out tracking, however.

The conveyor function is defined by means of the technology class

CONVEYOR ( $TECH[i].CLASS = #CONVEYOR)

and activated with technology mode “CYCLE”.

The parameter $TECHPAR[i,8] defines whether the variable $TECHIN[i] refers to a velocity

value or a distance.

$TECHPAR[i,8]=0 ----> $TECHIN[i] refers to a velocity

$TECHPAR[i,8]=1 ----> $TECHIN[i] refers to a distance

In the case of a conveyor synchronization with an “absolute” position sensing system,

$TECHPAR[i,8] must be set to 1.

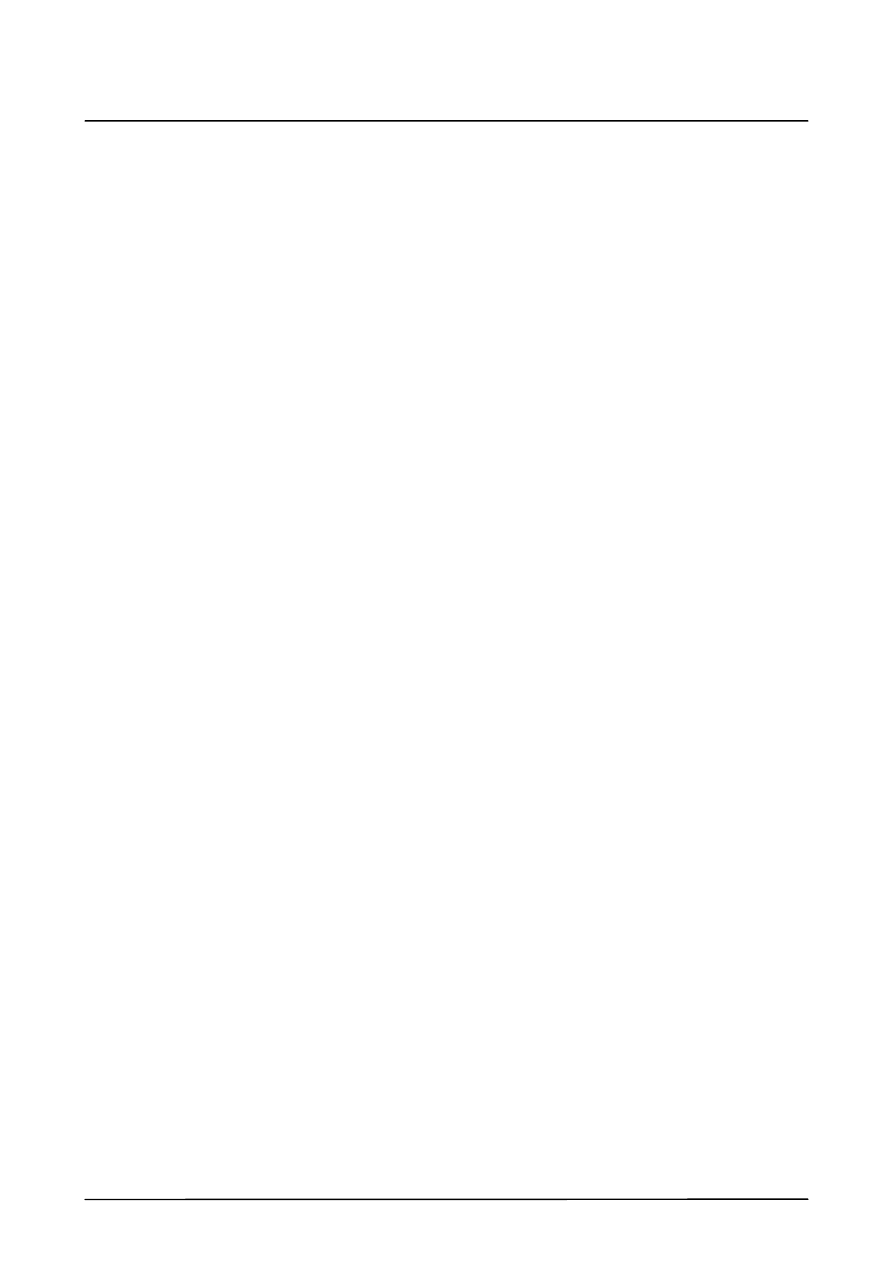

Example:

The synchronization switch enables the counting mode.

At the end of the tracking operation, a digital output in the KRC ensures that the counter

is set to 0 and that the enabling of the counting mode is withdrawn.

The 16--bit values are scaled to [mm] using the FACTOR in the

DIGIN statement.

KR C2

Direction of motion

Conveyor

Synchronization switch

Incremental

encoder

Pulse

Direction

of

rotation

Counter

Start counter

(enable)

16 bits

DIGIN ON

$TECHIN[i]=FACTOR*$DIGIN1+OFFSET

Start signal (digital input)

16 digital inputs

Z Conv.

P1

P2

P3

P4

Robot

Reset counter

(digital output)

Strobe (digital output)

X Conv.

Function Generator

22 of 28

Funktionsgenerator KSS5.1 08.02.00 en

If the parameter $TECHPAR[i,8] is set to 0, the tracking distance is calculated on the basis

of the conveyor velocity which is assigned cyclically to $TECHIN[i] by means of an ANIN or

DIGIN statement.

Make sure that $TECHIN[i] contains the conveyor velocity value in mm/s or degrees/s.

This is done by means of the factor in the ANIN/DIGIN statement.

The system variable $TECHVAL[i] contains the absolute tracking distance in mm or degrees.

This variable can be used to monitor the maximum permissible tracking distance, e.g.

INTERRUPT DECL 1 WHEN $TECHVAL[i] > 2000.0 DO STOP_TRACK()

The robot tracking motion is started by means of a synchronization signal which the conveyor

system sends to the robot controller when the part enters the robot’s processing area.

This synchronization input (user input) is transferred to the system via the variable

$TECHPAR[i,7]. The program interpreter is stopped by means of a

“WAIT FOR $TECHVAL[i]>0.05” statement

once the conveyor synchronization has been activated.

The conveyor functionality is activated as soon as the technology mode is switched to

CYCLE and the technology class CONVEYOR is selected.

Once the robot has detected the synchronization signal it leaves its starting position and

starts tracking and processing. For this kind of start from the rest position with the conveyor

already running (so--called “flying start”), special precautions (smoothing) must be taken in

order to ensure a “smooth”, but nonetheless sufficiently rapid, synchronization of the robot

motion with the conveyor motion.

The corresponding parameters are set using elements of $TECHPAR[i,j]:

G

“Distance gain” $TECHPAR[i,1] in [1/s],

G

“Velocity gain” $TECHPAR[i,2] in [1/s].

The following error between the conveyor and the robot caused by the smoothing and the

system run times can be compensated for by the user by means of

$TECHPAR[i,3] (rate time in s).

As the function generator (interpolator) is not called during pauses between motions, no

exact positioning motion should be programmed at any point in the tracking operation.

A programmed point can be reached exactly by setting the approximation radius to 0 (zero).

If it is necessary for there to be pauses between robot motions, this can be achieved by

setting the override to zero at the corresponding point in the program (TRIGGER in

approximation zero block).

The instruction $TECH[i].MODE=#OFF triggers an advance run stop, deactivates the

conveyor functionality, sets the tracking distance to 0 and continues the motion from the

current point in space.

2

Programming, parameterization (continued)

23 of 28

Funktionsgenerator KSS5.1 08.02.00 en

2.4

Complex sensors

Using an add--on controller task (sensor task), it is possible to couple an “intelligent” sensor

to the controller and correct the robot motion in Cartesian space ($TECH[i].CLASS =

#DATALINK).

Function Generator

24 of 28

Funktionsgenerator KSS5.1 08.02.00 en

3

Application examples

25 of 28

Funktionsgenerator KSS5.1 08.02.00 en

3

Application examples

3.1

Weaving

Example

DECL

TECH

WEAVE1, WEAVE2

; Declare variables of type TECH

WEAVE1.MODE

= #CYCLE

; Cartesian weaving is a cyclical

; function.

WEAVE1.FCTCTRL.SCALE_IN

= 2

; Wavelength of the weave oscillation is

; 2 mm.

WEAVE1.FCTCTRL.OFFSET_IN = 0

; Start of deflection is start of CP path.

WEAVE1.FCTCTRL.SCALE_OUT = 3

; Weave amplitude is 3 mm.

WEAVE1.FCTCTRL.OFFSET_OUT = 0

; Focus of the weave oscillation is

; on the path:

; If amplitude = 0, path is followed without

; weaving.

WEAVE1.CLASS = #PATH

; Argument of the weave pattern is the

; arc length, i.e. SCALE_IN the

; wavelength.

WEAVE1.FCTCTRL.GEOREF = #Y

; Direction of the weave deflection in the Y

; direction in the TTS

WEAVE1.FCT.ORDER = 1

; Create weave pattern from polygon using

; pairs of values in the function table.

TECHANGLE.C = 10

; Rotate TTS

; User--defined WEAVE1 is ready for assignment to the technology structure $TECH[1]

; Prepare FCTCTRL section of the structure WEAVE2 for structure

; assignment using TRIGGER command!

WEAVE2.MODE

= #CYCLE

; Cartesian weaving is a cyclical

; function.

WEAVE2.FCTCTRL.SCALE_IN

= 4

; Wavelength of the weave oscillation is

; 4 mm.

WEAVE2.FCTCTRL.OFFSET_IN = 0

; Start of deflection at start of CP path.

WEAVE2.FCTCTRL.SCALE_OUT = 3

; Weave amplitude is 3 mm.

WEAVE2.FCTCTRL.OFFSET_OUT = 0

; Focus of the weave oscillation is

; the path.

$TECH[1] = WEAVE1

; Weaving from next CP block onwards.

PTP X1

; PTP blocks always without weaving.

LIN L1

; Weaving with values of the structure

; WEAVE1.

$TECH[1].FCTCTRL.GEOREF = #Z

LIN L2 C_DIS

; Weaving in the Z direction, i.e. perpendicular

; to the plane of the panels to be welded,

; from the start of this block onwards.

TRIGGER WHEN DISTANCE=1 DELAY=0 DO

$TECH_C[1].FCTCTRL = WEAVE2.FCTCTRL

LIN L3 C_DIS

; From the center of the intermediate

; block of the approximate positioning,

; weaving with new wavelength 4 mm.

LIN L4

$TECH[1].MODE = #OFF

LIN L5

; This motion block without weaving

Function Generator

26 of 28

Funktionsgenerator KSS5.1 08.02.00 en

3.2

Analog sensor

Example

Using a distance sensor, a correction is to be made in the Z direction of the TTS.

Calibration is carried out using the offset variables. The maximum value for the correction

vector should be +/-- 20 mm.

The analog input delivers a voltage between --10 V and +10 V; this should be adjusted to

0 V.

FACTOR = 0.1

OFFSET = 1.0

; Sensor at analog input 2

SIGNAL CORRECTION $ANIN[2]

; Monitor sensor correction value

INTERRUPT DECL 1 WHEN $TECHVAL[1] > 20.0 DO UPPER_LIMIT()

INTERRUPT DECL 2 WHEN $TECHVAL[1] < -20.0 DO LOWER_LIMIT()

; Activate cyclical reading of the analog input and

; scaling of $TECHIN[1] to 0.0 - 2.0

ANIN ON $TECHIN[1] = FACTOR * CORRECTION + OFFSET

; Define correction direction

$TECHSYS = #TTS

$TECH[1].FCTCTRL.GEOREF = #Z

; Correction in Z direction

; Sensor correction using the function generator

$TECH[1].CLASS = #SENSOR

$TECH[1].FCTCTRL.SCALE_IN = 2.0

;

Definition of control parameters

$TECH[1].FCTCTRL.OFFSET_IN = 0.0 ;

”

$TECH[1].FCTCTRL.SCALE_OUT = 20.0;

”

$TECH[1].FCTCTRL.OFFSET_OUT = 0.0;

”

$TECH[1].FCT.ORDER = 1

;

”

$TECH[1].FCT.CPNUM = 3

;

”

$TECH[1].FCT.CPS1.X1 = 0.0

;

”

$TECH[1].FCT.CPS1.Y1 = -1.0

;

”

$TECH[1].FCT.CPS1.X2 = 0.5

;

”

$TECH[1].FCT.CPS1.Y2 = 0.0

;

”

$TECH[1].FCT.CPS1.X3 = 1.0

;

”

$TECH[1].FCT.CPS1.Y3 = 1.0

;

”

$TECHPAR[1,1] = 0.056

;

Smoothing constant in s

PTP BEFORE_PART

INTERRUPT ON 1

INTERRUPT ON 2

; Activate sensor correction

TECH[1].MODE = #CYCLE

LIN P1 C_DIS

LIN P2 C_DIS

LIN P3

; Deactivate sensor correction

TECH[1].MODE = #OFF

LIN_REL {X 0.0}

; Zero block for accepting advance run data

; in the main run data --> Deactivation of

; the function generator

; Deactivate cyclical analog input

ANIN OFF CORRECTION

3

Application examples (continued)

27 of 28

Funktionsgenerator KSS5.1 08.02.00 en

3.3

Conveyor synchronization

Example

Conveyor

Direction of motion

Robot

Velocity measuring system

KR C1

Z Conv.

P1

P2

P3

P4

Synchronization switch

X Conv.

Analog input

Digital

input

A workpiece on a conveyor belt is moved past a robot. The velocity measuring system

delivers a voltage of 10.0 V in the case of a maximum conveyor velocity of 0.08 m/s.

The voltage range of the analog input is 0 V to 10.0 V.

FACTOR = 80

OFFSET = 0.0

; Number of the user input to which the synchronization switch is attached

SYNCH_NO = 5

; Velocity measuring system at analog input 2

SIGNAL CONVEYORVEL $ANIN[2]

; Monitor tracking distance

INTERRUPT DECL 1 WHEN $TECHVAL[1] > 2000.0 DO STOP_TRACK()

; Define conveyor coordinate system relative to WORLD, Z axis points in

; direction of motion of the conveyor

$TECHPAR[2,1] = ...

; X Conv.

$TECHPAR[2,2] = ...

; Y Conv.

$TECHPAR[2,3] = ...

; Z Conv.

$TECHPAR[2,4] = ...

; A Conv.

$TECHPAR[2,5] = ...

; B Conv.

$TECHPAR[2,6] = ...

; C Conv.

; Activate cyclical reading of the analog input

ANIN ON $TECHIN[1] = FACTOR * CONVEYORVEL + OFFSET

Function Generator

28 of 28

Funktionsgenerator KSS5.1 08.02.00 en

; Conveyor synchronization using the function generator

$TECH[1].CLASS = #CONVEYOR

; Tracking direction is the Z axis of the conveyor coordinate system

$TECH[1].FCTCTRL.GEOREF = #Z

; Define control parameters

$TECHPAR[1,1] = 0.6

; “Distance gain” in 1/s

$TECHPAR[1,2] = 0.7

; “Velocity gain” in 1/s

$TECHPAR[1,3] = 0.084

; Rate time in s

$TECHPAR[1,7] = SYNCH_NO

; Synchronization input

$TECHPAR[1,8] = 0

; $TECHIN[i] corresponds to a

; velocity value

; (measuring sensor is a tachometer)

PTP WAIT_POS

INTERRUPT ON 1

; Activate conveyor synchronization

TECH[1].MODE = #CYCLE

LIN_REL {X 0.0}

; Zero block for accepting advance run data

; in the main run data --> Activation of

; conveyor functionality

; Wait for the synchronization signal

WAIT FOR $TECHVAL[1]>0.05

; Wait until the system has

; detected the synchronization signal

; --> $TECHVAL “grows”

; Process workpiece

LIN P1 C_DIS

LIN P2 C_DIS

LIN P3 C_DIS

LIN P4 C_DIS

LIN AWAY_FROM_BELT

; Deactivate robot tracking

TECH[1].MODE = #OFF

LIN_REL {X 0.0}

; Zero block for accepting advance run data

; in the main run data --> Deactivation of

; the function generator

; Deactivate cyclical analog input

ANIN OFF CONVEYORVEL

1

Index

Index -- i

Symbols

#CYCLE, 19

#SENSOR, 17, 18

#SINGLE, 19

$ANIN[1], 17, 20

$DIGIN1, 17

$DISTANCE, 15

$MACHINE.DAT, 17, 20

$TECH[i]. MODE, 9

$TECH[i].CLASS, 17

$TECH[i].CLASS , 10

$TECH[i].FCT, 14

$TECH[i].FCTCTRL , 11

$TECH[i].MODE, 19, 22

$TECH[i], $TECH_C[i], 9

$TECH_C[i]. MODE, 9

$TECH_C[i].CLASS , 10

$TECH_C[i].FCT, 14

$TECH_C[i].FCTCTRL, 11

$TECH_MAX, 8

$TECHANGLE, 7, 15

$TECHANGLE_C, 15

$TECHIN[i], 14, 17, 19, 20

$TECHPAR, 17, 20, 22

$TECHPAR[i, j], 14

$TECHPAR[i,1, 18

$TECHPAR[i,1], 18

$TECHPAR[i,j], 20

$TECHPAR_C[i, j], 14

$TECHSYS, 7, 15, 18

$TECHSYS_C, 15

$TECHVAL[i], 15, 19, 21

$TSYS, 15

A

Analog sensors, 17

B

BASE, 19

C

Configuration, 8

Control points, 6

Conveyor synchronization, 20

Correction coordinate system, 7

Correction coordinate system TTS, 7

Correction direction, 7

Correction value, 18

Correction velocity, 18

CYCLE, 21

D

DIGIN statement, 21

F

Function definition, 6

Functional description, 6

G

GEOREF, 7, 18, 20

M

Mechanical weaving, 5

O

OFFSET_OUT, 15

P

Parameterization, 9

Programming, 9

R

Reaching a programmed point, 22

RESUME, 19

S

SCALE_OUT, 15

Sensor correction value, 18

Sensor offset, 19

SIGNAL $DIGIN1, 17

SIGNAL CORRECTION, 17

Structure variables, 9

Index

Index -- ii

T

TCP correction, 19

TECHPAR variables, 20

TECHVAL[i], 19

Thermal weaving, 5

Tool--based technological system, 7

Tool--based technological system (TTS), 7, 15

TTS, 7

W

WAIT FOR $TECHVAL[i], 22

Document Outline

- Characteristics, functional description

- Programming, parameterization

- Application examples

Wyszukiwarka

Podobne podstrony:

MEDC17 Special Function Manual

MEDC17 Special Function Manual

XRC Interrupt function manual

PS4 Suscosoft S40 Function Block Reference Manual h1365g

L 3 Complex functions and Polynomials

3 ABAP 4 6 Basic Functions

PANsound manual

als manual RZ5IUSXZX237ENPGWFIN Nieznany

hplj 5p 6p service manual vhnlwmi5rxab6ao6bivsrdhllvztpnnomgxi2ma vhnlwmi5rxab6ao6bivsrdhllvztpnnomg

BSAVA Manual of Rabbit Surgery Dentistry and Imaging

Okidata Okipage 14e Parts Manual

Bmw 01 94 Business Mid Radio Owners Manual

Manual Acer TravelMate 2430 US EN

manual mechanika 2 2 id 279133 Nieznany

4 Steyr Operation and Maintenance Manual 8th edition Feb 08

Oberheim Prommer Service Manual

więcej podobnych podstron