Thin-layer modelling of the convective, microwave,

microwave-convective and microwave-vacuum

drying of lactose powder

W.A.M. McMinn

*

Food Process Engineering Research Group, School of Chemical Engineering, QueenÕs University Belfast,

David Keir Building, Stranmillis Road, Belfast BT9 5AG, UK

Received 5 August 2004; accepted 11 November 2004

Available online 22 December 2004

Abstract

Lactose-water samples were dried under selected convective, microwave, microwave-convective and microwave-vacuum condi-

tions in an experimental system (2.45 GHz, 90W). Irrespective of the drying technique, a typical drying profile, with a constant dry-

ing rate stage followed by two falling rate periods, was exhibited. The magnitude of the drying rate, however, was dependent on the

convective air temperature and velocity, and system pressure. The experimental moisture loss data were fitted to selected semi-

theoretical and empirical thin-layer drying equations. The mathematical models were compared according to three statistical param-

eters, i.e. reduced chi-square, root mean square error and residual sum of squares. The drying characteristics were satisfactorily

described by the Page, Logarithmic, Chavez-Mendez et al. and Midilli et al. models, with the latter providing the best representation

of the experimental data.

2004 Elsevier Ltd. All rights reserved.

Keywords: Convective; Drying; Lactose; Powder; Thin-layer models; Microwave; Vacuum

1. Introduction

Quantitative understanding of drying operations is of

great practical and economic importance. An under-

standing of the fundamental mechanisms, and knowl-

edge of the moisture and temperature distributions

within the product, is crucial for process design, quality

control, product handling and energy savings. A number

of complex theoretical models to describe the heat and

mass transfer phenomena during drying are available.

However, both design and process engineers involved

in industrial drying operations clearly need simple, but

accurate, analytical tools, in order to conduct design

analysis and relevant calculations. Availability of such

correlations and models, verified by experimental data,

will enable engineers and operators to provide optimum

solutions to aspects of drying operations such as energy

use, operating conditions, process control, without

undertaking experimental trials on the system (

). In particular, thin-layer equations contribute to

the understanding of the heat and mass transfer phe-

nomena, and computer simulations, for designing new

processes and improving existing commercial operations

(

Kardum, Sander, & Skansi, 2001

).

Thin-layer drying models can be categorised as theo-

retical, semi-theoretical and empirical (

Models within the latter two categories consider only

external resistance to moisture transfer (

) and neglect the effect of a

variation in sample temperature on the drying process

(

0260-8774/$ - see front matter

2004 Elsevier Ltd. All rights reserved.

doi:10.1016/j.jfoodeng.2004.11.025

*

Tel.: +44 28 9027 4065; fax: +44 28 9038 1753.

E-mail address:

www.elsevier.com/locate/jfoodeng

Journal of Food Engineering 72 (2006) 113–123

Semi-theoretical models offer a compromise between

theory and ease of use. The models are generally derived

by simplifying general series solutions of FickÕs second

law and are only valid within the drying conditions for

which they have been developed (

). However, they require short time, as compared

with theoretical thin-layer equations, and do not require

assumptions regarding sample geometry, mass diffusiv-

ity and conductivity. Such models include the

Two-Term (

Sharaf-Eldeen, Blaisdell, & Hamdy, 1980

Approximation of Diffusion (

and

Midilli, Kucuk, and Yapar (2002)

equations.

Empirical models, which derive a direct relationship

between moisture content and drying time, neglect the

fundamentals of the drying process and have parameters

with no physical meaning (

Among them, the

and

Mendez, Salgado-Cervantes, Garcia-Galindo, De La

Cruz-Medina, and Garcia-Alvarado (1995)

have found

application in literature.

Although thin-layer equations have been widely used

to describe experimental convective drying data, appli-

cation to microwave-assisted drying operations is more

limited.

assessed the ability of the Lewis and Page equa-

tions to characterise the experimental drying curves for

microwave-assisted convective air drying of carrots,

and reported that only the Page model adequately de-

scribed the data.

Kiranoudis, Tsami, and Maroulis

represented the microwave-vacuum drying kinet-

ics of fruits using an one-parameter empirical mass

transfer model of exponential form, and further indi-

cated that the magnitude of the drying constant was

dependent on the vacuum pressure and microwave

power of the system.

modelled the microwave-vacuum drying kinetics

of model fruit gels using the Lewis Ôthin-layerÕ drying

equation, and further proposed an empirical correlation

to estimate the drying rate constant as a function of the

absolute pressure and microwave power of the system.

reported that the microwave dry-

ing kinetics of a pharmaceutical product was adequately

described by the Lewis and Page models, with the latter

providing a better correlation with the experimental

data.

approximated the tran-

sient behaviour of normalised moisture during the

microwave heating of cement powder by an exponential

evolution with a time constant.

Previous work by

, and

involved extensive experimental examination

of the convective, microwave, and combined micro-

wave-convective and microwave-vacuum drying behav-

iour of lactose powder. Using the acquired data, the

aim of this work is to assess the ability of selected

thin-layer based drying models to quantify the moisture

removal behaviour.

2. Materials and methods

2.1. Equipment

The atmospheric microwave drying system used in

this work is a standard microwave oven (Brother, Hi-

speed cooker, Model No. MF 3200 d13) of variable

power output settings (650, 500, 250, 90 and 30 W)

and a rated capacity of 650W at 2.45 GHz. The equip-

ment was modified to facilitate microwave-convective

processing. A precisely dimensioned duct, fitted with a

fan and a heater, was attached to the side of the oven.

The air velocity (0–1.0 ± 0.05 m s

1

) and temperature

(20–100 ± 5

C) are controlled by means of analogue

controllers. The system was also modified to allow for

microwave-vacuum drying. A glass dessicator was posi-

tioned inside the microwave cavity, to which a vacuum

pump was attached. The vacuum level is controlled

(0–101 kPa (absolute)) by means of an actuator valve

and released using a vent valve. Further details on the

equipment are outlined in

and

Nomenclature

a, b, c, g, h, L

1

, L

2

, n constants

k, k

1

, k

2

drying rate constants (min

1

)

MR

moisture ratio

MR

exp,i

experimental moisture ratio

MR

pre,i

predicted moisture ratio

N

number of experimental data points

n

p

number of parameters in model

R

residual error

R

c

maximum drying rate (kg m

2

s

1

)

RMSE root mean square error

RSS

residual sum of squares

t

time (min)

t

total

total drying time (min)

X

moisture content at time t (kg kg

1

, dry solid)

X

e

equilibrium moisture content (kg kg

1

, dry

solid)

X

0

initial moisture content (kg kg

1

, dry solid)

v

2

reduced chi-square

114

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

2.2. Experimental method

The drying characteristics of lactose powder during

convective, microwave (90W), microwave-convective

and microwave-vacuum processing were examined.

Before each experimental run, the microwave oven was

preheated at full power (650W) for 5 min using a

500 ml water load (

) and the con-

vective system allowed to stabilise, at the selected condi-

tion, for 10min. A water load (approximately 75 g) was

placed in the microwave cavity to provide a heating load

sufficient to protect the magnetron from overheating,

especially during the latter stages of drying. For each

experiment, a water-wetted lactose sample of 1.0kg

kg

1

db (dry basis, water) was prepared, and placed in

a glass dish in the oven. At 5-min intervals throughout

the drying process (until material had attained at least

95% moisture loss) the sample was removed, weighed,

and then agitated for 15 ± 1 s. This procedure was

adopted to investigate the effect of product and process-

ing characteristics on the drying behaviour, as summa-

rized in

. Each experiment was performed in

triplicate. Further information on the experimental

procedures is detailed in

and

2.3. Data analysis

The experimental moisture content data were non-

dimensionlized using the equation:

MR

¼

X

X

e

X

0

X

e

ð1Þ

where MR is the moisture ratio; X

0

is the initial moisture

content (kg kg

1

, dry solid); X

e

is the equilibrium mois-

ture content (kg kg

1

, dry solid), and X is the moisture

content at time t (kg kg

1

, dry solid).

For the analysis it was assumed that the equilibrium

moisture content, X

e

, was equal to zero.

Selected thin-layer drying models, detailed in

were fitted to the drying curves (MR versus time), and

the equation parameters determined using non-linear

least squares regression analysis.

Three criteria were adopted to evaluate the goodness

of fit of each model, the reduced chi-square (v

2

), root

mean square error (RMSE) and residual sum of squares

(RSS). These parameters were calculated using (

v

2

¼

P

N

i

¼1

ðMR

exp;i

MR

pred;i

Þ

2

N

n

p

ð2Þ

Table 1

Summary of experiments

Experimental

parameter

Dry mass

· 10

3

(kg)

Surface area

· 10

3

(m

2

)

Depth

· 10

3

(m)

Microwave

power (W)

Air velocity

(m/s)

Air temperature

(

C)

Pressure

(kPa)

Convective

Air temperature

20

20

6.36

6

–

0.7

40

101

60

Microwave

Bed depth/surface area

106.36

3

206.36

6

306.36

9

90 –

–

10

1

100

6.36

30

25

15.4

3

100

57.3

3

Microwave–convective

Air velocity/temperature

0.4

20

0.7

20

20

6.36

6

90

0.7

40

101

0.7

60

Bed depth/surface area

106.36

3

40

206.36

6

40

25

15.4

3

90

0.7

40

101

100

57.3

3

40

Microwave-vacuum

Pressure

30

206.36

6

90 –

–

50

80

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

115

RMSE

¼

1

N

X

N

i

¼1

ðMR

exp;i

MR

pred;i

Þ

2

"

#

0:5

ð3Þ

RSS

¼

X

N

i

¼1

ðMR

exp;i

MR

pred;i

Þ

2

ð4Þ

where MR

exp,i

is the experimental moisture ratio;

MR

pred,i

is the predicted moisture ratio; N is the number

of experimental data points, and n

p

is the number of

parameters in model.

The lower the calculated values of reduced chi-square

and root mean square error, the better the ability of the

model to represent the experimental data. The reduced

chi-square accounts for the number of constants in the

model, with the magnitude of this parameter giving a

measure of the reliability of the model to describe the

experimental data, irrespective of the number of param-

eters (

). These statistical parame-

ters have been widely used as the primary criterion to

select the best equation to account for variation in the

drying curves of dried samples (

;

). The residual sum of

squares value is an important parameter in the non-

linear regression process, with the fitting procedure

being designed to achieve the minimum RSS (

3. Results and discussion

3.1. Drying characteristics

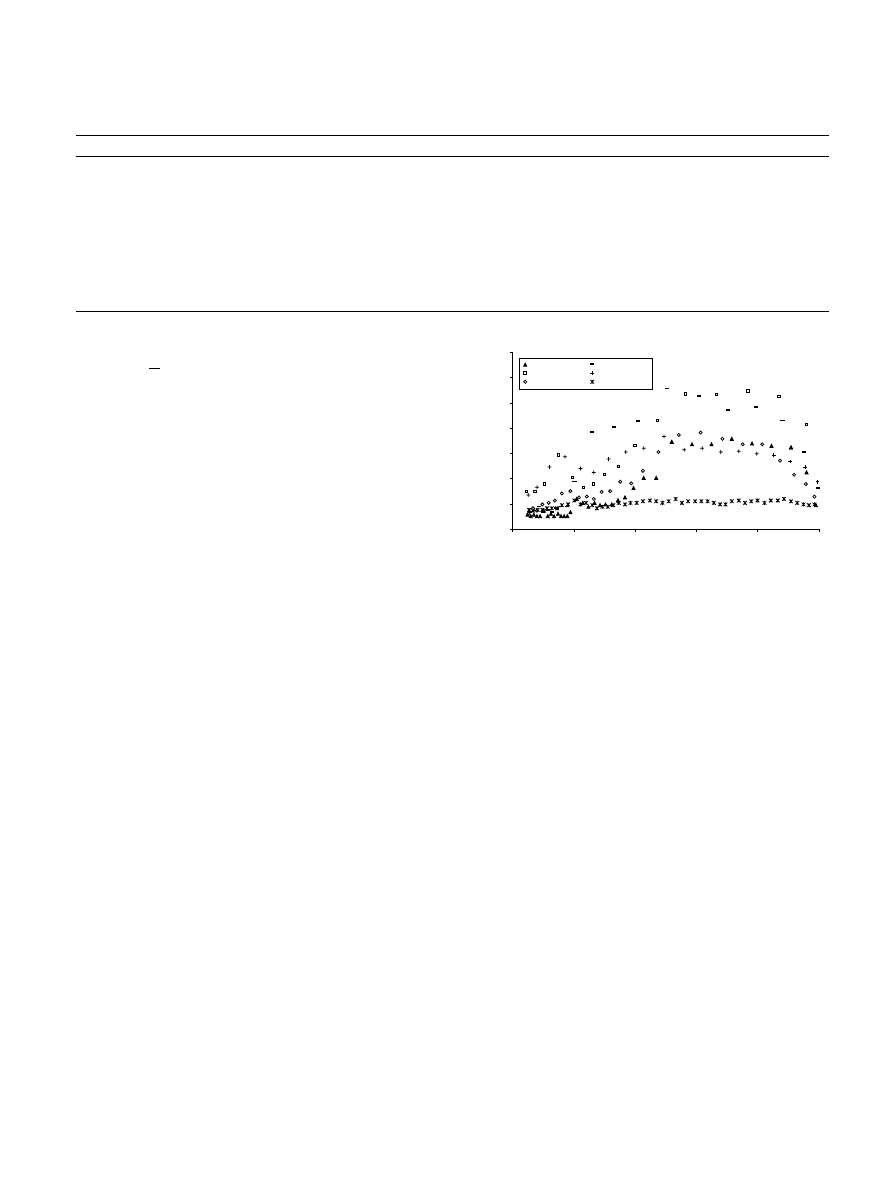

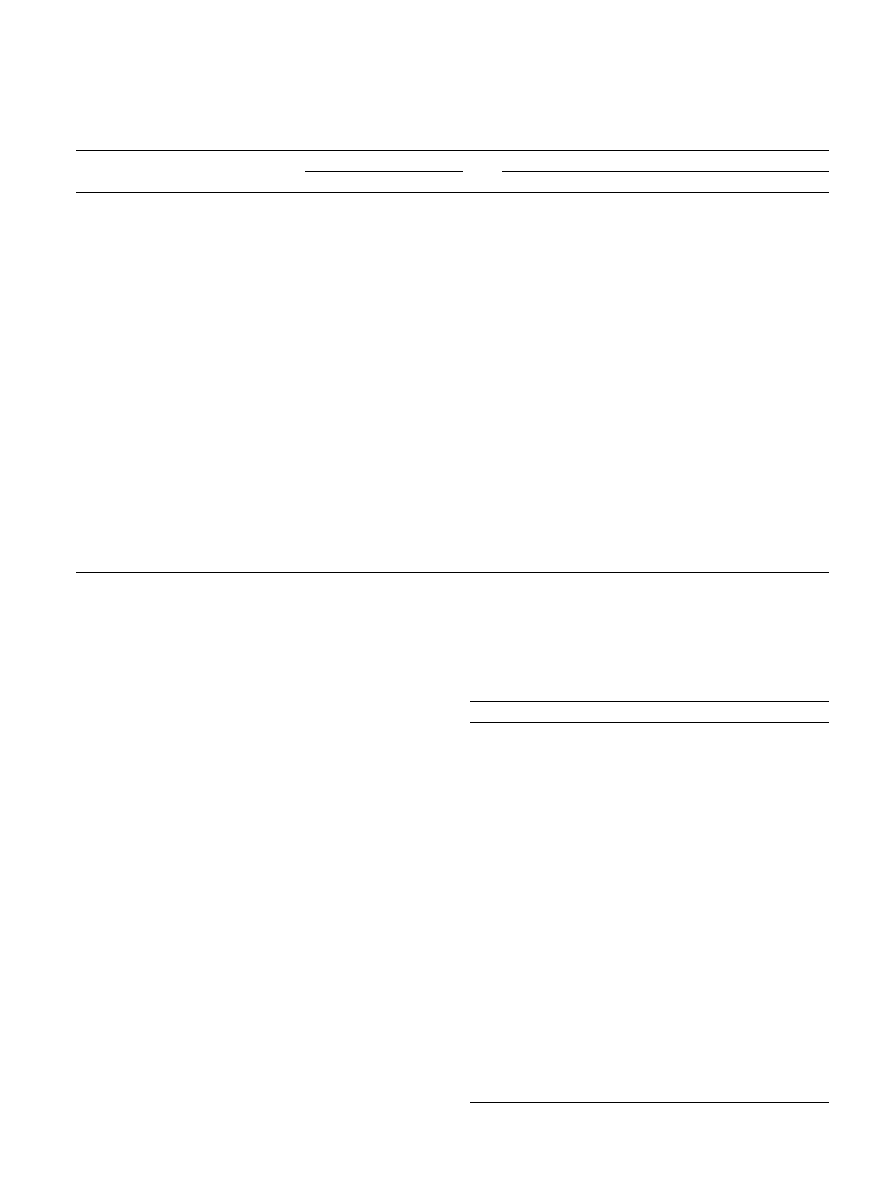

Representative drying rate curves for lactose-water

samples dried under convective (C) (20and 60

C air),

microwave (Mw), microwave-convective (Mw-C) (20

and

60

C

air)

and

microwave-vacuum

(Mw-V)

(80kPa) conditions are shown in

. In general, four

distinct periods are identifiable, namely a warming-up,

constant rate and two falling rate periods. Irrespective

of the drying technique, a critical moisture content of

0.54 kg kg

1

db (dry basis) is observed, with samples

dried using convective, microwave and microwave-

convective processing exhibiting a secondary moisture

content of 0.36 kg kg

1

db. This is reduced to 0.14 kg

kg

1

db during microwave-vacuum (80kPa) operation.

The observed decrease may be attributed to the corre-

sponding reduction in solvent boiling point, and the

Ô

pullingÕ effect of the vacuum, which draws the solvent

out of the material pores. The magnitude of the maxi-

mum drying rate, drying rate constants and drying time

are, however, specific to the method of moisture re-

moval.

provides a summary of the maximum

drying rate (R

c

) and total drying time (t

total

) for all con-

vective, microwave, microwave-convective and micro-

wave-vacuum conditions examined. It should be noted,

however, that during microwave-vacuum processing at

less than 80kPa, material loss occurred at low moisture

contents, so kinetic data is available for the initial stages

only.

Ambient temperature (20

C) convective drying

exhibits the slowest drying rate, with the reduction in

rate between the constant and falling stages being rela-

tively indistinguishable. As expected, the drying rate

can be enhanced, and hence drying time lowered, by

increasing the air temperature; an increase in constant

drying rate of approximately 150%, from 0.26 to

Table 2

Thin-layer models fitted to experimental data

Model

Mathematical expression

Lewis (

)

MR = exp(

kt)

Page (

MR = exp(

kt

n

)

Henderson and Pabis (

MR = a exp(

kt)

Modified Henderson and Pabis (

)

MR = a exp(

kt) + bexp(gt) + cexp(ht)

Logarithmic (

)

MR = a exp(

kt) + c

Two-Term (

MR = a exp(

k

1

t) + bexp(

k

2

t)

Wang and Singh (

MR = 1 + at + bt

2

Approximation of Diffusion (

MR = a exp(

kt) + (1a)exp(kbt)

Chavez-Mendez et al. (Chavez-Mendez et al., 1995)

MR

¼ ½1 ð1 L

2

ÞL

1

t

ð1=ð1L

2

ÞÞ

Midilli (

)

MR = a exp(

kt

n

) + bt

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0.0

0.2

0.4

0.6

0.8

1.0

Moisture Content (kgkg

-1

, dry basis)

Drying Rate (x10

-3

kgm

-2

s

-1

)

Mw

Mw-V (80kPa)

Mw-C (60°C)

C (60°C)

Mw-C (20°C)

C (20°C)

Fig. 1. Drying characteristics of water wetted lactose dried under

selected processing conditions [Mw—microwave; Mw-C—microwave-

convective; Mw-V—microwave-vacuum].

116

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

0.66

· 10

3

kg m

2

s

1

, is achieved by elevating the air

temperature from 20to 60

C.

The use of microwave-only drying provides a slight

elevation in the maximum drying rate, as compared with

high temperature convective processing (0.66

· 10

3

kg m

2

s

1

for convective at 60

C and 0.70 · 10

3

kg m

2

s

1

for microwave). With the subsequent

introduction of air over the sample surface, i.e. micro-

wave-convective drying, the microwave drying rate is in-

creased. Again this can be further elevated by increasing

the air temperature (60

C). Air temperature, however,

has a less significant affect during microwave-convective

operation than convective-only. In the former process, a

reduction in drying time of approximately 17%, from 90

to 75 min, is achieved by increasing the air temperature

from 40to 60

C. However, in convective drying, the

drying time is decreased by approximately 32%, with

the same temperature elevation. Thus, increasing air

temperature during microwave-convective drying is less

energy efficient than during convective drying. During

microwave-convective operation, the velocity of the air

also has a relatively limited impact on the drying behav-

iour. Drying times of 140and 120min were observed

with the use of 0.4 and 0.7 m s

1

air, respectively.

Microwave-vacuum drying is found to provide drying

times comparable with those observed during high tem-

perature microwave-convective processing. The maxi-

mum drying rate increases significantly as the system

pressure decreases from 101 to 30 kPa; lowering of sys-

tem pressure is accompanied by a decrease in water

evaporation temperature. Consequently, a reduction in

system pressure from 101 to 80 kPa offers a reduction

in drying time of more than 38%, from 170to 105 min.

The drying characteristics are also observed to be

dependent on the bed dimensions, with an increase in

depth and decrease in surface area, in general, providing

enhanced drying rates. The extent of the rate elevation

is, however, dictated by the sample geometry and pro-

cessing technique (microwave, microwave-convective).

A more detailed characterisation of the drying behav-

iour of lactose-water samples subjected to convective,

microwave and combined microwave-convective and

microwave-vacuum drying is presented in

and

3.2. Model application

Thin-layer models have found wide application due

to their ease of use and lack of required data, such as

phenomenological and coupling coefficients, as in com-

plex theoretical models. Many correlations are avail-

able in the literature, with those included in this study

(

) being selected as they represent some of the

more commonly adopted. Although other models were

Table 3

Comparison of maximum drying rate (R

c

) and drying time (t

total

) for convective, microwave-convective and microwave-vacuum drying of lactose

powder

Dry mass

· 10

3

(kg)

Surface area

· 10

3

(m

2

)

Depth

· 10

3

(m)

Microwave

power (W)

Air temperature

(

C)

Air velocity

(m s

1

)

Pressure

(kPa)

R

c

(

·10

3

kg m

2

s

1

)

t

total

(min)

Convective

20

101

0.26

270

20

6.36

6

–

40

0.7

101

0.46

140

60

101

0.66

95

Microwave

106.36

3

0

.18

190

206.36

6

0

.70

175

30

6.36

9

90

–

–

101

0.72

210

100

6.36

30

0.88

370

25

15.4

3

0.38

175

100

57.3

3

0.19

185

Microwave-convective

20

0.4

101

0.68

140

20

6.36

6

90

20

0.7

101

0.80

120

40

0.7

101

0.97

90

60

0.7

101

1.12

75

106.36

3

0

.54

60

25

15.4

3

40

0.7

101

0.62

55

100

57.3

3

0.38

80

Microwave-vacuum

90–

–

30

1.36

–

206.36

6

90

–

–

50

1.17

–

90

–

–

80

0.98

105

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

117

Table 4

Estimated values of coefficients and statistical analysis for the thin-layer models: lactose dried under convective (C) (0.7 m s

1

/60

C), microwave

(Mw), microwave-convective (Mw-C) (0.7 m s

1

/60

C) and microwave-vacuum (Mw-V) (80kPa) conditions

Model

Constants

C

Mw

Mw-C

Mw-V

Lewis

k

1.72

· 10

2

1.06

· 10

2

2.82

· 10

2

2.55

· 10

2

v

2

6.74

· 10

3

1.26

· 10

3

1.70

· 10

3

3.46

· 10

3

RMSE

0.080

0.035

0.040

0.057

RSS

0.128

0.044

0.027

0.073

Page

k

1.78

· 10

3

8.57

· 10

3

1.19

· 10

2

4.98

· 10

3

n

1.58

1.13

1.24

1.44

v

2

5.75

· 10

4

5.62

· 10

4

3.58

· 10

4

5.86

· 10

4

RMSE

0.023

0.023

0.018

0.023

RSS

0.010

0.019

0.005

0.012

Henderson and Pabis

a

1.11

1.07

1.06

1.11

k

1.95

· 10

2

1.62

· 10

2

3.01

· 10

2

2.84

· 10

2

v

2

5.00

· 10

3

4.74

· 10

4

1.20

· 10

3

1.47

· 10

3

RMSE

0.067

0.021

0.032

0.037

RSS

0.090

0.016

0.018

0.029

Modified Henderson and Pabis

a

3.68

· 10

1

3.56

· 10

1

3.55

· 10

1

3.70

· 10

1

b

3.68

· 10

1

3.56

· 10

1

3.55

· 10

1

3.70

· 10

1

c

3.68

· 10

1

3.56

· 10

1

3.55

· 10

1

3.70

· 10

1

g

1.96

· 10

2

1.62

· 10

2

3.01

· 10

2

2.85

· 10

2

h

1.94

· 10

2

1.62

· 10

2

3.01

· 10

2

2.85

· 10

2

k

1.94

· 10

2

1.62

· 10

2

3.01

· 10

2

2.84

· 10

2

v

2

6.45

· 10

3

5.37

· 10

4

1.64

· 10

3

1.84

· 10

3

RMSE

0.067

0.021

0.033

0.037

RSS

0.090

0.016

0.018

0.030

Logarithmic

a

4.49

1.07

1.21

1.24

k

2.69

· 10

3

1.59

· 10

2

2.13

· 10

2

2.09

· 10

2

c

3.46

5.99 · 10

3

1.82 · 10

1

1.66 · 10

1

v

2

4.23

· 10

3

4.86

· 10

4

3.45

· 10

4

1.93

· 10

3

RMSE

0.060

0.021

0.017

0.041

RSS

0.072

0.016

0.005

0.037

Two-Term

a

5.52

· 10

1

5.43

· 10

1

5.32

· 10

1

5.55

· 10

1

k

1

1.94

· 10

2

1.62

· 10

2

3.01

· 10

2

2.85

· 10

2

b

5.52

· 10

1

5.35

· 10

1

5.32

· 10

1

5.55

· 10

1

k

2

1.95

· 10

2

1.62

· 10

2

3.01

· 10

2

2.84

· 10

2

v

2

5.63

· 10

3

5.19

· 10

4

1.39

· 10

3

1.64

· 10

3

RMSE

0.067

0.021

0.033

0.037

RSS

0.090

0.016

0.018

0.030

Wang and Singh

a

1.11 · 10

2

1.18 · 10

2

2.14 · 10

2

1.99 · 10

2

b

6.20

· 10

6

3.81

· 10

5

1.19

· 10

4

1.06

· 10

4

v

2

2.97

· 10

4

9.33

· 10

3

3.43

· 10

2

1.39

· 10

3

RMSE

0.016

0.094

0.140

0.036

RSS

0.005

0.317

0.333

0.028

Approximate Diffusion

a

2.78

1.58

1.00

3.53

b

2.77

· 10

3

1.18

· 10

2

2.82

· 10

2

1.18

· 10

2

k

6.89 · 10

1

6.60

· 10

1

1.00

· 10

2

6.95

· 10

1

v

2

3.25

· 10

4

1.04

· 10

3

1.94

· 10

3

3.20

· 10

3

RMSE

0.017

0.030

0.040

0.053

RSS

0.006

0.028

0.027

0.061

Chevez-Mendez et al.

L

1

1.11

· 10

2

1.38

· 10

2

2.23

· 10

2

1.95

· 10

2

L

2

6.51

· 10

2

8.59

· 10

1

6.15

· 10

1

5.43

· 10

1

v

2

2.26

· 10

4

9.57

· 10

4

4.01

· 10

4

1.95

· 10

3

RMSE

0.014

0.029

0.019

0.042

RSS

0.004

0.027

0.006

0.039

Midilli et al.

a

9.95

· 10

1

1.04

1.01

9.94

· 10

1

k

2.62

· 10

3

9.52

· 10

3

1.64

· 10

2

2.74

· 10

3

n

1.37

1.13

1.12

1.644

b

2.36 · 10

3

1.79

· 10

4

7.47 · 10

4

9.39

· 10

4

v

2

2.12

· 10

2

5.03

· 10

4

2.95

· 10

4

4.28

· 10

4

RMSE

0.130

0.021

0.015

0.019

RSS

0.339

0.013

0.004

0.008

118

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

initially considered, following preliminary examination

these were excluded: the modified-Page equation (

), were an exponent ÔnÕ is

also added to the constant ÔkÕ, merely giving a constant

of differing magnitude; the two-term exponential model

(

) in which the constant ÔaÕ

approximates to 1 on application to the experimental

data and thus, simplifies to the form of the Henderson

and Pabis model, and the Verma et al. model (

Bucklin, Endan, & Wratten, 1985

) which takes the form

of the Approximation of Diffusion model, with parame-

ters Ôk * bÕ being lumped together to give a new constant

ÔgÕ

.

The experimental moisture content results (0.1–

1.0kg kg

1

, db) were non-dimensionalised using Eq.

. The dimensionless data were then regressed against

time, according to the form of the various thin-layer cor-

relations (

), using the least squares curve fitting

method. This defined the drying behaviour in terms of

the drying constant(s) (k, k

1

, k

2

) and constant(s) (a, b,

c, g, h, L

1

, L

2

, n), as appropriate to the specific equation.

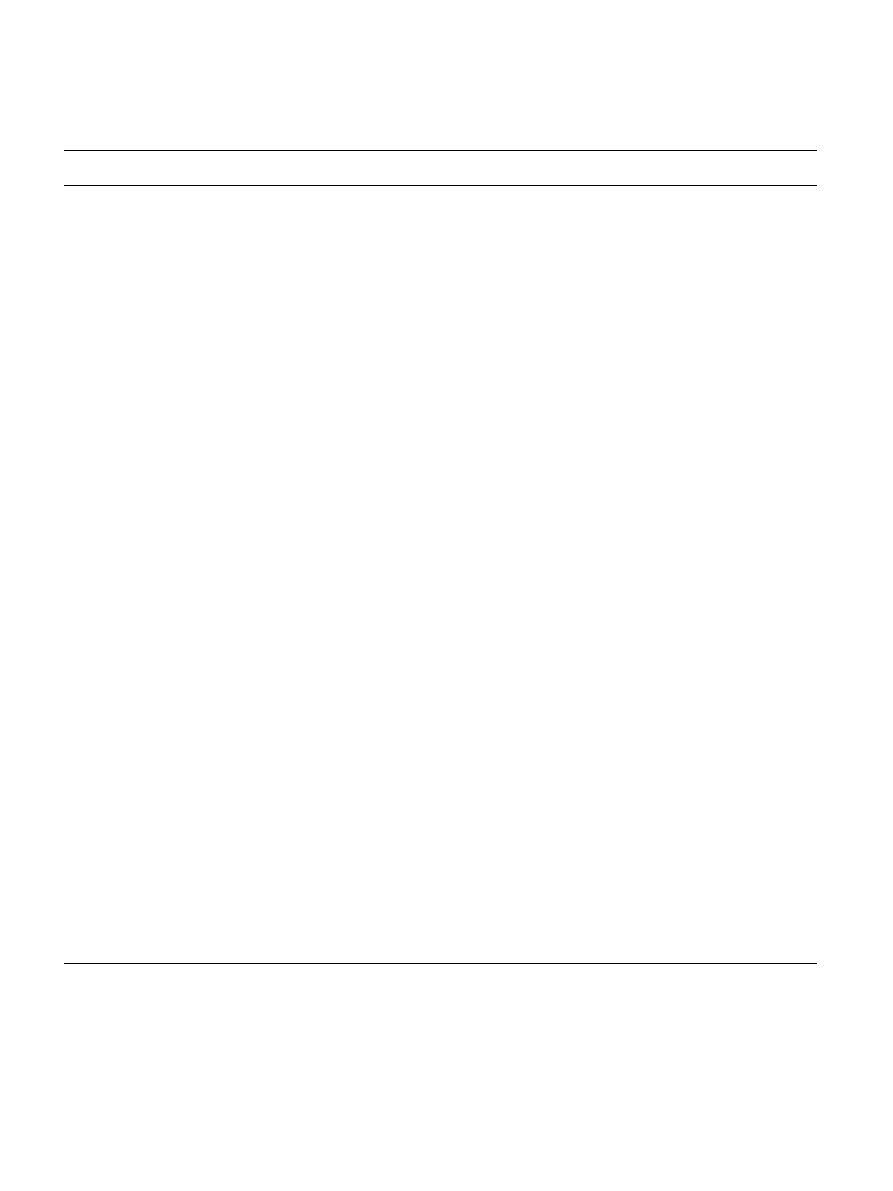

details the parameter values for 10drying mod-

els, with the corresponding reduced chi-square (v

2

), root

mean square error (RMSE) and residual sum of squares

(RSS) values, for representative drying techniques (

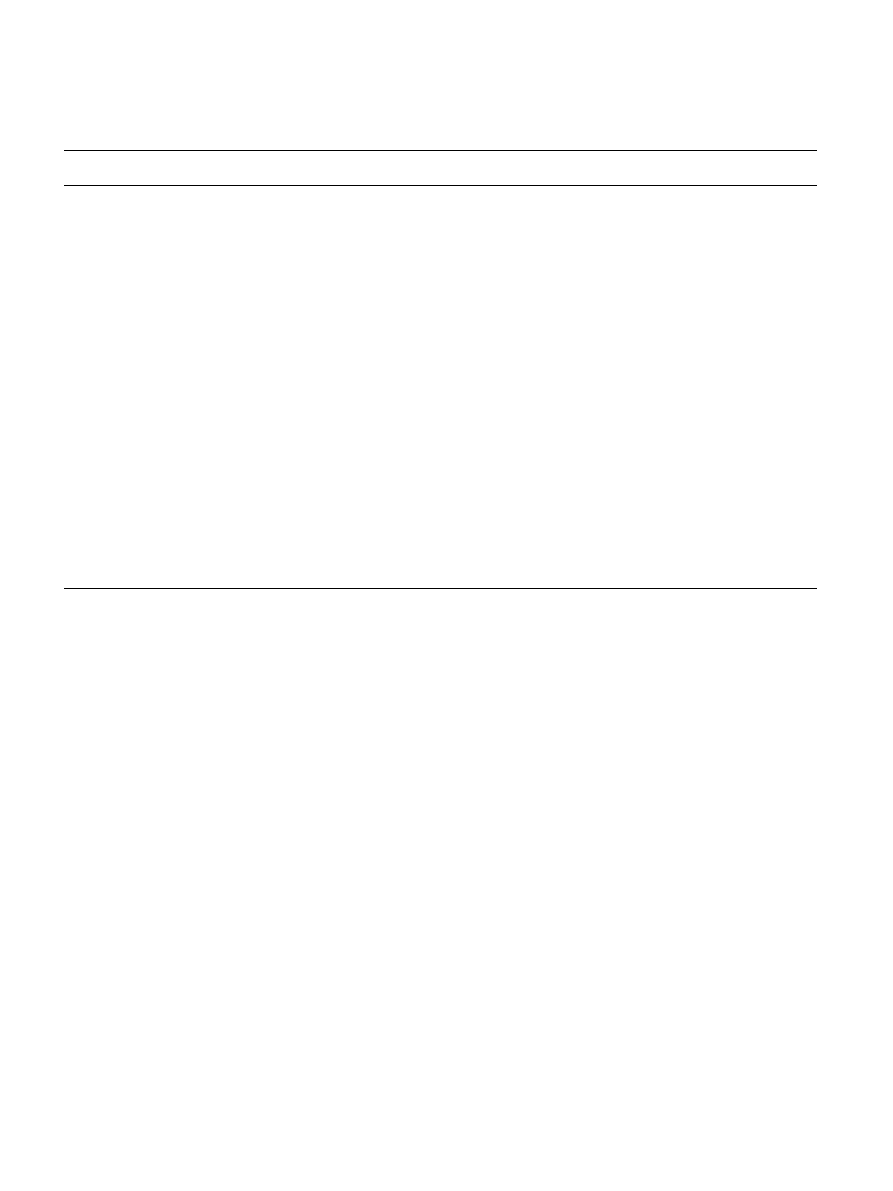

). The aforementioned statistical criteria, for all the

experimental conditions (

), are plotted against

the number of parameters in the model in

and

, respectively. The v

2

values are in the range

9.05

· 10

6

–3.43

· 10

2

, and RSME and RSS values

vary between 0.003 and 0.140, and 0.0001 and 0.544,

respectively.

Two comparison techniques are adopted in order to

determine the most appropriate equations for descrip-

tion of the experimental data. The first method consid-

ers the range and average values of the error

parameters (v

2

, RSME and RSS). This indicates that

the Page, Logarithmic, Chavez-Mendez et al. and

Midilli et al. models provide a good representation of

the experimental results. Although the four aforemen-

tioned models all demonstrate good agreement with

the data, the Midilli et al. equation can, in general, be

considered the most suitable, followed by the Page mod-

el. The RSME values for the Midilli et al. and Page

equations are of lowest magnitude, varying between

0.003 and 0.138 (average 0.025), and 0.008 and 0.130

(average 0.024), respectively, according to the different

experimental conditions, with corresponding average

v

2

values of 26.27

· 10

4

and 13.59

· 10

4

. The RSS val-

ues for the Midilli et al. and Page models range between

0.0001 and 0.324, and 0.0004 and 0.286, respectively.

Both of these models are semi-theoretical in form, with

the latter having the advantage of only requiring the

estimation of two parameters. The Chavez-Mendez

et al. and Logarithmic models are empirical, however,

the similarity of the latter expression to the analytical

solution of the drying problem favours its acceptance

(

). The second comparative

technique examines the frequency with which each equa-

tion best fits the experimental data. The results of the

analysis confirm that the Midilli et al. equation is the

most appropriate equation, with this providing the most

accurate predictions for more than 50% of the data sets.

0.000

0.005

0.010

0.015

0.020

0.025

0.030

0.035

0

1

2

3

4

5

6

Number of Parameters

χ

2

Page

Logarithmic

Chavez-Mendez et al.

Midilli et al.

Other Models

Fig. 2. Comparison of reduced chi-square (v

2

) values for the thin-layer

models.

0

0.025

0.05

0.075

0.1

0.125

0.15

0

1

2

3

4

5

6

Number of Parameters

RMSE

Page

Logarithmic

Chavez-Mendez et al.

Midilli et al.

Other Models

Fig. 3. Comparison of root mean square error (RMSE) values for the

thin-layer models.

0

0.1

0.2

0.3

0.4

0.5

0.6

0

1

2

3

4

5

6

Number of Parameters

RSS

Page

Logarithmic

Chavez-Mendez et al.

Midilli et al.

Other Models

Fig. 4. Comparison of residual sum of squares (RSS) values for the

thin-layer models.

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

119

The results of the statistical analysis and estimated val-

ues of coefficients for the mathematical models which

adequately represent the experimental values, for all

operating conditions considered, are shown in

. The least suitable model is the Lewis equation, with

RSME values in the range 0.035–0.119, and an average

value of 0.056.

Examination of the drying constant (k) in the Midilli

et al. model (most suitable correlation) indicates that the

relative magnitude of the parameter accurately reflects

the drying behaviour. The higher k values for the micro-

wave-assisted techniques, as compared with those for

convective-only processing, verifies the elevated mois-

ture removal rates (

and

). The increase

in the drying constant with increasing air temperature

during both convective and microwave-convective pro-

cessing indicates an enhancement of drying potential

(

). In contrast, the relative insensitivity of the

drying behaviour to a variation in air velocity during

microwave-convective drying is revealed by the similar-

ity of the k and b values with 0.4 and 0.7 m s

1

air. For

vacuum processing, as expected, the k value is shown to

increase as the system pressure is reduced from 101 kPa

to 30kPa (

). The variation in drying characteris-

tics with bed geometry is also confirmed by a change in k

value with both sample surface area and depth (

Similar trends with respect to variation in the drying

constant (k) of the Page and Logarithmic models with

Table 5

Estimated values of coefficients and statistical analysis for selected thin-layer models: lactose dried under convective (C) and microwave-convective

(Mw-C) conditions

Model

Constants

C

Mw-C

20

C

40

C

20

C/0.4 ms

1

20

C/0.7 m s

1

40

C/0.7 m s

1

Page

k

4.89

· 10

4

1.31

· 10

3

6.79

· 10

3

6.19

· 10

3

7.52

· 10

3

n

1.51

1.51

1.22

1.29

1.31

v

2

7.61

· 10

4

1.22

· 10

3

1.04

· 10

4

1.39

· 10

4

2.12

· 10

4

RMSE

0.027

0.034

0.009

0.011

0.014

RSS

0.038

0.032

0.003

0.003

0.004

Logarithmic

a

6.38

1.77

· 10

1

1.16

1.25

1.29

k

6.64

· 10

4

4.35

· 10

4

1.43

· 10

2

1.52

· 10

2

1.71

· 10

2

c

5.37

1.67 · 10

1

1.16 · 10

1

1.96

· 10

1

2.51 · 10

1

v

2

4.48

· 10

5

8.72

· 10

5

2.80

· 10

4

3.35

· 10

4

4.06

· 10

4

RMSE

0.006

0.009

0.016

0.017

0.018

RSS

0.002

0.002

0.007

0.066

0.007

Chavez-Mendez et al.

L

1

3.96

· 10

3

7.52

· 10

3

1.38

· 10

2

1.55

· 10

2

1.83

· 10

2

L

2

3.48

· 10

2

1.00

· 10

2

6.69

· 10

1

5.59

· 10

1

5.18

· 10

1

v

2

7.19

· 10

5

3.97

· 10

5

3.31

· 10

4

3.99

· 10

4

4.63

· 10

4

RMSE

0.008

0.006

0.018

0.019

0.020

RSS

0.004

0.001

0.009

0.008

0.008

Midilli et al.

a

1.00

9.99

· 10

1

1.01

1.01

1.01

k

9.58

· 10

4

1.97

· 10

3

6.36

· 10

3

6.08

· 10

3

8.29

· 10

3

n

1.24

1.13

1.25

1.31

1.28

b

1.45 · 10

3

4.44 · 10

3

1.80

· 10

4

1.79

· 10

4

5.07 · 10

5

v

2

9.05

· 10

6

7.41

· 10

5

1.35

· 10

4

2.08

· 10

4

2.27

· 10

4

RMSE

0.003

0.008

0.011

0.013

0.013

RSS

0.0004

0.002

0.003

0.004

0.003

Table 6

Estimated values of coefficients and statistical analysis for selected

thin-layer models: effect of pressure during microwave-vacuum (Mw-

V) drying

Model

Constants

30kPa

50kPa

Page

k

2.79

· 10

3

5.12

· 10

3

n

1.701.52

v

2

8.58

· 10

5

7.88

· 10

5

RMSE

0.008

0.008

RSS

0.0004

0.0004

Logarithmic

a

4.34

· 10

1

1.23

k

4.59

· 10

4

1.70

· 10

3

c

4.23 · 10

1

1.12 · 10

1

v

2

2.09

· 10

3

6.88

· 10

4

RMSE

0.035

0.019

RSS

0.008

0.003

Chavez-Mendez et al.

L

1

1.49

· 10

2

1.66

· 10

2

L

2

8.15 · 10

1

4.83 · 10

1

v

2

9.20

· 10

4

5.92

· 10

4

RMSE

0.026

0.021

RSS

0.005

0.003

Midilli et al.

a

1.05

1.03

k

3.47

· 10

4

3.46 · 10

5

n

1.00

1.00

b

2.04 · 10

2

2.05 · 10

2

v

2

1.72

· 10

3

7.60

· 10

4

RMSE

0.027

0.018

RSS

0.005

0.002

120

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

air temperature, air velocity and pressure can also be

identified.

Thin-layer models are clearly of significant practical

value to engineers for the preliminary evaluation of po-

tential microwave drying operations. The correlations

are mathematically simple with the characteristic

parameters, namely drying constant, providing a com-

bined, but sufficiently informative, measure of the trans-

port properties (moisture diffusivity, thermal diffusivity,

heat transfer coefficient and mass transfer coefficient). In

addition, their ease of application provides a standard-

ized process description, independent of the controlling

Table 7

Estimated values of coefficients and statistical analysis for selected thin-layer models: effect of bed dimensions (surface area; depth) during microwave

(Mw) and microwave-convective (Mw-C) drying

Model

Constants

6.36

· 10

3

m

2

;

3

· 10

3

m

6.36

· 10

3

m

2

;

6

· 10

3

m

6.36

· 10

3

m

2

;

9

· 10

3

m

6.36

· 10

3

m

2

;

30

· 10

3

m

15.4

· 10

3

m

2

;

3

· 10

3

m

57.3

· 10

3

m

2

;

3

· 10

3

m

Microwave

Page

k

7.25

· 10

3

8.56

· 10

3

1.31

· 10

3

2.05

· 10

4

1.04

· 10

2

5.49

· 10

4

n

1.09

1.13

1.47

1.59

1.07

1.62

v

2

8.06

· 10

4

5.62

· 10

4

3.19

· 10

4

3.11

· 10

4

2.36

· 10

4

1.99

· 10

4

RMSE

0.028

0.023

0.017

0.017

0.015

0.017

RSS

0.030

0.019

0.013

0.023

0.008

0.007

Logarithmic

a

1.25

1.06

1.35

3.94

1.05

3.17

k

6.96

· 10

3

1.65

· 10

2

8.09

· 10

3

8.73

· 10

4

1.36

· 10

2

2.21

· 10

3

c

2.74 · 10

1

9.73

· 10

3

2.67 · 10

1

2.89

2.87 · 10

2

2.12

v

2

1.18

· 10

4

5.07

· 10

4

1.52

· 10

3

6.35

· 10

4

1.84

· 10

4

5.88

· 10

4

RMSE

0.010

0.022

0.038

0.025

0.013

0.023

RSS

0.004

0.017

0.061

0.046

0.006

0.021

Chavez-Mendez et al.

L

1

9.23

· 10

3

1.38

· 10

2

7.99

· 10

3

2.91

· 10

3

1.30

· 10

2

5.94

· 10

3

L

2

7.12

· 10

1

8.62

· 10

1

4.20

· 10

1

1.56

· 10

2

8.78

· 10

1

7.16

· 10

2

v

2

3.69

· 10

4

7.88

· 10

4

1.70

· 10

3

5.13

· 10

4

2.36

· 10

4

6.49

· 10

4

RMSE

0.019

0.027

0.040

0.022

0.015

0.025

RSS

0.014

0.027

0.070

0.037

0.008

0.023

Midilli et al.

a

1.01

1.03

9.99

· 10

1

1.01

1.03

9.97

· 10

1

k

1.71

· 10

2

7.16

· 10

3

7.77

· 10

4

4.06

· 10

4

1.43

· 10

2

7.21

· 10

4

n

8.05

· 10

1

1.21

1.62

1.409.93

· 10

1

1.51

b

1.47 · 10

3

5.08

· 10

4

4.33

· 10

4

5.31 · 10

4

1.55 · 10

4

5.85 · 10

4

v

2

1.98

· 10

5

6.93

· 10

4

2.87

· 10

4

1.33

· 10

4

1.75

· 10

4

4.17

· 10

5

RMSE

0.004

0.025

0.016

0.011

0.012

0.006

RSS

0.0007

0.022

0.011

0.009

0.006

0.001

Microwave-convective

Page

k

1.69

· 10

2

1.01

· 10

2

–

–

1.51

· 10

2

1.09

· 10

3

n

1.19

1.30–

–

1.29

1.66

v

2

7.17

· 10

4

2.81

· 10

4

–

–

5.25

· 10

4

1.91

· 10

2

RMSE

0.025

0.016

–

–

0.022

0.130

RSS

0.008

0.004

0.008

0.286

Logarithmic

a

1.37

1.32

–

–

1.41

5.24

k

1.87

· 10

2

1.98

· 10

2

–

–

2.19

· 10

2

2.08

· 10

3

c

3.87 · 10

1

2.88 · 10

1

–

–

4.07 · 10

1

4.21

v

2

5.91

· 10

5

4.01

· 10

4

–

–

4.20

· 10

5

2.37

· 10

2

RMSE

0.007

0.018

–

–

0.006

0.140

RSS

0.001

0.005

0.0004

0.332

Chavez-Mendez et al.

L

1

2.54

· 10

2

2.24

· 10

2

–

–

2.85

· 10

2

1.03

· 10

2

L

2

5.49

· 10

2

5.15

· 10

1

–

–

4.63

· 10

1

9.99

· 10

2

v

2

1.82

· 10

2

4.18

· 10

4

–

–

1.03

· 10

4

2.01

· 10

2

RMSE

0.012

0.019

–

–

0.009

0.133

RSS

0.002

0.005

0.001

0.301

Midilli et al.

a

9.99

· 10

1

1.01

–

–

1.01

9.97

· 10

1

k

3.08

· 10

2

1.13

· 10

2

–

–

2.62

· 10

2

1.96

· 10

3

n

8.93

· 10

1

1.26

–

–

1.02

1.39

b

4.18 · 10

3

3.23 · 10

3

–

–

3.48 · 10

3

2.51 · 10

3

v

2

1.59

· 10

5

2.73

· 10

4

–

–

4.73

· 10

4

2.49

· 10

2

RMSE

0.003

0.014

–

–

0.006

0.138

RSS

0.0001

0.003

0.0004

0.324

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

121

mechanism (this differs for microwave and convective

drying techniques).

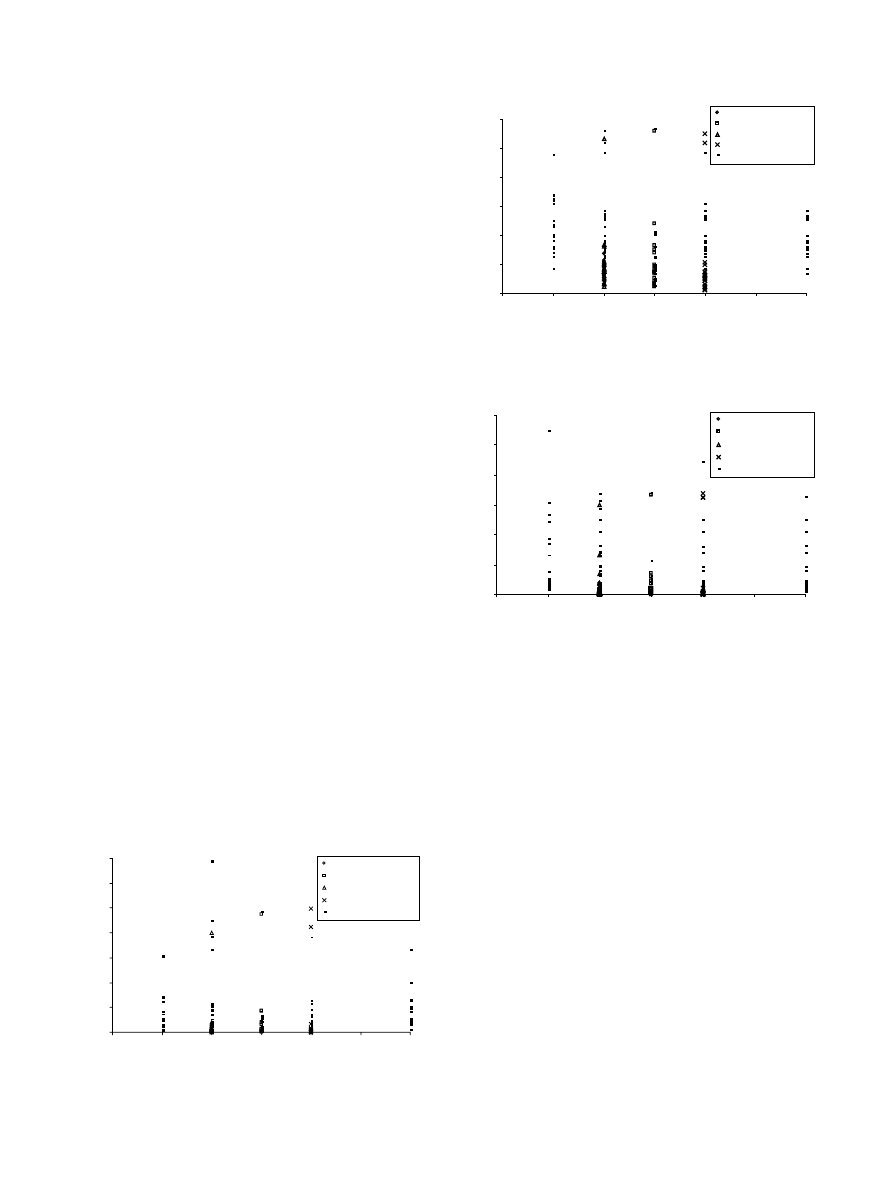

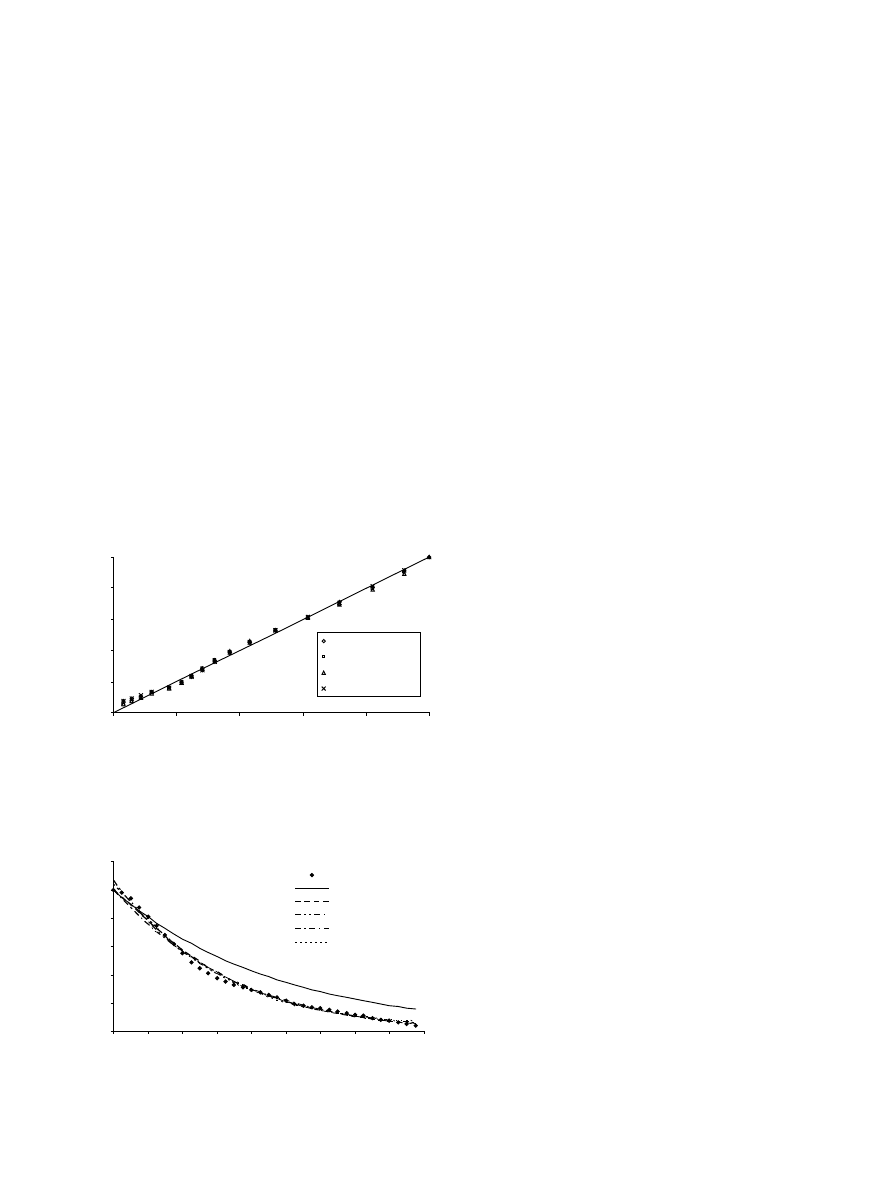

To validate the suitability of the models, the

experimental and predicted drying characteristics were

compared. The measured and calculated data for exem-

plary sets of processing conditions, namely microwave-

convective (Mw-C) (0.7 m s

1

/60

C) and microwave

(Mw), are presented in

, respectively. The

experimental data are closely correlated with the com-

puted data for the Page, Logarithmic, Chavez-Mendez

et al. and Midilli et al. models. This confirms the suit-

ability of the models to represent the experimental re-

sults. The observed deviation between the experimental

results and the moisture ratio values calculated using

the Lewis model (

) verifies its inability to represent

the drying behaviour.

and

found the Page equation to give a good approximation

of the drying kinetics in microwave-convective and

microwave systems, respectively, with

reporting the Midilli et al. equation as

the best model for describing the convective drying

curves of eggplants. Although the Lewis equation was

successfully adopted by

for the

microwave-vacuum drying of model fruits gels,

reported it to be inadequate to rep-

resent the microwave-assisted convective air drying

curves of carrots.

4. Conclusions

On the basis of this work the following conclusions

can be drawn.

• The generalized convective, microwave, microwave-

convective and microwave-vacuum drying profiles

consisted of an initial pre-heating phase, a constant

drying rate stage and two falling rate periods.

• Sample drying rate was dependent on system pressure

and presence/absence of external heating/cooling

sources.

• Of the 10thin-layer drying correlations considered,

the semi-theoretical Midilli et al. model provided

the best representation of the lactose powder drying

kinetics.

References

Abdelghani-Idrissi, M. A. (2001). Experimental investigations of

occupied volume effect on the microwave heating and drying

kinetics of cement powder in mono-mode cavity. Applied Thermal

Engineering, 21, 955–965.

Chavez-Mendez, C., Salgado-Cervantes, M. A., Garcia-Galindo, H.

S., De La Cruz-Medina, J., & Garcia-Alvarado, M. A. (1995).

Modelling of drying curves for some foodstuffs using kinetic

equation of high order. Drying Technology, 13, 2113–2122.

Dincer, I. (1998). Moisture loss from wood products during drying—

Part II: Surface moisture content distributions. Energy Source,

20(1), 77–83.

Drouzas, A. E., Tsami, E., & Saravacos, G. D. (1999). Microwave/

vacuum drying of model fruit gels. Journal of Food Engineering, 39,

117–122.

Ertekin, C., & Yaldiz, O. (2004). Drying of eggplant and selection of a

suitable thin layer drying model. Journal of Food Engineering,

63(3), 349–359.

Fortes, M., & Okos, M. R. (1980). In A. S. Mujumdar (Ed.), Drying

theories: their bases and limitations as applied to foods and grains.

Advances in Drying (vol. 1, pp. 119–153). New York: Hemisphere

Publishing.

Henderson, S. M., & Pabis, S. (1961). Grain drying theory I:

temperature effect on drying coefficient. Journal of Agriculture

Research Engineering, 6, 169–174.

Karathanos, V. T. (1999). Determination of water content of dried

fruits by drying kinetics. Journal of Food Engineering, 39, 337–344.

Kardum, J. P., Sander, A., & Skansi, D. (2001). Comparison of

convective, vacuum, and microwave drying chlorpropamide. Dry-

ing Technology, 19(1), 167–183.

Kiranoudis, C. T., Tsami, E., & Maroulis, Z. B. (1997). Microwave

vacuum drying kinetics of some fruits. Drying Technology, 15(10),

2421–2440.

0

0.2

0.4

0.6

0.8

1

0

0.2

0.4

0.6

0.8

1

Experimental Moisture Ratio

Predicted Moisture Ratio

Page

Logarithmic

Chavez-Mendez et al.

Midilli et al.

Fig. 5. Experimental and predicted drying curves for water wetted

lactose samples dried under microwave-convective (Mw-C) conditions

(0.7 m s

1

/60

C).

0

0.2

0.4

0.6

0.8

1

1.2

0

20

40

60

80

100

120

140

160

180

Time (min)

Moisture Ratio

Experimental

Lewis

Page

Logarithmic

Chavez-Mendez et al.

Midilli et al.

Fig. 6. Experimental and predicted drying curves for water wetted

lactose samples dried under microwave (Mw) conditions.

122

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

Lewis, W. K. (1921). The rate of drying of solid materials. Journal of

Industrial Engineering., 13, 427–443.

Lu, L., Tang, J., & Ran, X. (1999). Temperature and moisture changes

during microwave drying of sliced food. Drying Technology, 17(3),

413–432.

McLoughlin, C. M., McMinn, W. A. M., & Magee, T. R. A. (2003a).

Microwave drying of multi-component powder systems. Drying

Technology, 21(2), 293–309.

McLoughlin, C. M., McMinn, W. A. M., & Magee, T. R. A. (2003b).

Microwave-vacuum drying of pharmaceutical powders. Drying

Technology, 134(1–2), 40–51.

McMinn, W. A. M., McLoughlin, C. M., & Magee, T. R. A., (in

press). Microwave-convective drying characteristics of pharmaceu-

tical powders. Powder Technology.

Midilli, A., Kucuk, H., & Yapar, Z. (2002). A new model for single-

layer drying. Drying Technology, 20, 1503–1513.

Ozdemir, M., & Devres, Y. O. (1999). The thin layer drying

characteristics of hazelnuts during roasting. Journal of Food

Engineering, 42, 225–233.

Page, G., (1949). Factors influencing the maximum rates of air drying

shelled corn in thin layers. MSc Thesis, Purdue University, Indiana,

USA.

Panchariya, P. C., Popovic, D., & Sharma, A. L. (2002). Thin-layer

modelling of black tea drying process. Journal of Food Engineering,

52, 349–357.

Parti, M. (1990). A theoretical model for thin-layer grain drying.

Drying Technology, 8, 101–122.

Parti, M. (1993). Selection of mathematical models for drying grain in

thin-layers. Journal of Agricultural Engineering Research, 54,

339–352.

Prabhanjan, D. G., Ramaswamy, H. S., & Raghavan, G. S. V. (1995).

Microwave-assisted convective air drying of thin layer carrots.

Journal of Food Engineering, 25, 283–293.

Sarsavadia, P. N., Sawhney, R. L., Pangavhane, D. R., & Singh, S. P.

(1999). Drying behaviour of brined onion slices. Journal of Food

Engineering, 40, 219–226.

Sharaf-Eldeen, Y. I., Blaisdell, J. L., & Hamdy, M. Y. (1980). A model

for air corn drying. Transactions of American Society of Agricul-

tural Engineers, 23, 1261–1265.

Sun, D. W., & Byrne, C. (1998). Selection of EMC/ERH isotherm

equations for rapeseed. Journal of Agricultural Engineering

Research, 69, 307–315.

Togrul, I. T., & Pehlivan, D. (2003). Modelling of drying kinetics of

single apricot. Journal of Food Engineering, 58, 23–32.

Verma, L. R., Bucklin, R. A., Endan, J. B., & Wratten, F. T. (1985).

Effects of drying air parameters on rice drying models. Transaction

of American Society of Agricultural Engineers, 28, 296–301.

Wang, C. Y., & Singh, R. P., (1978). A single layer drying equation for

rough rice. ASAE Paper No: 78-3001. St. Joseph, MI: ASAE.

White, G. M., Bridges, T. C., Loewer, O. J., & Ross, I. J., (1973). Seed

coat damage in thin layer drying of soybeans as effected by drying

conditions. ASAE Paper No: 78-3052. St. Joseph, MI: ASAE.

Yaldiz, O., & Ertekin, C. (2001). Thin layer solar drying of some

vegetables. Drying Technology, 19, 583–597.

W.A.M. McMinn / Journal of Food Engineering 72 (2006) 113–123

123

Document Outline

Wyszukiwarka

Podobne podstrony:

Microwave vacuum drying of model fruit gels (Drouzas, Tsami, Saravacos)

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

Mapping of temperature distribution in pharmaceutical microwave vacuum drying

Microwave vacuum drying of porous media experimental study and qualitative considerations of interna

Microwave vacuum drying of marine sediment determination of moisture content, metals and total carbo

Effective Moisture Diffusivity of Plain Yogurt Undergoing Microwave Vacuum Drying

Improving Grape Quality Using Microwave Vacuum Drying Associated with Temperature Control (Clary)

Improving Grape Quality Using Microwave Vacuum Drying Associated with Temperature Control (Clary)

Modelling of dehydration rehydration of orange slices in combined microwaveair drying

Drying kinetics and rehydration characteristics of microwave vacuum and convective hot air dried mus

Energy Consumption and Colour Characteristics of Nettle Leaves during Microwave, Vacuum and Convecti

The thin layer drying characteristics of hazelnuts during roasting

Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum microwav

Convective air drying characteristics of thin layer carrots

Microwave Convective and Microw Nieznany

więcej podobnych podstron