©2001 Sigma-Aldrich Co.

SUPELCO

Supelco, Supelco Park, Bellefonte, PA, 16823 USA

T401042

CFD

Improved Performance of SPME

Fibers and Applications

Ray Mindrup, Robert E. Shirey

01-0061

©2001 Sigma-Aldrich Co.

SUPELCO

713-1344

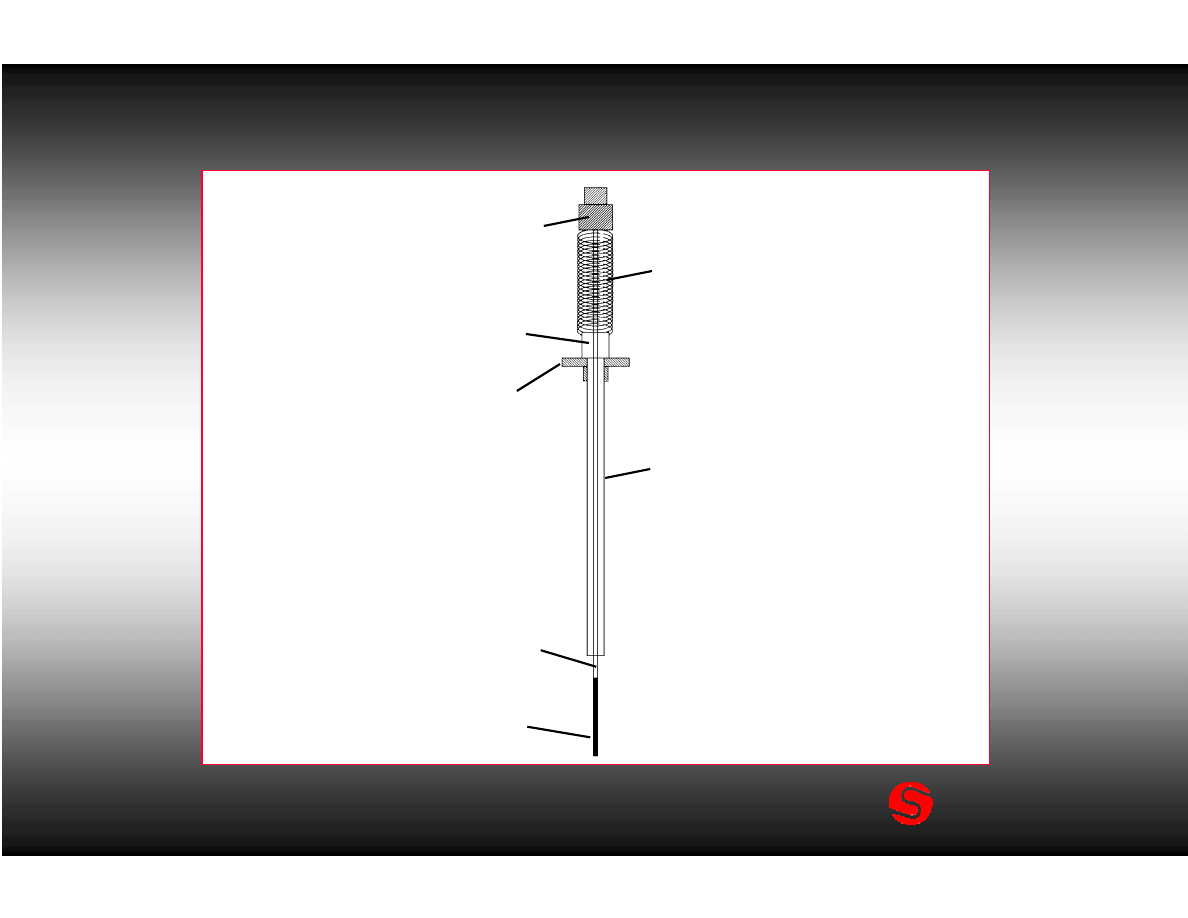

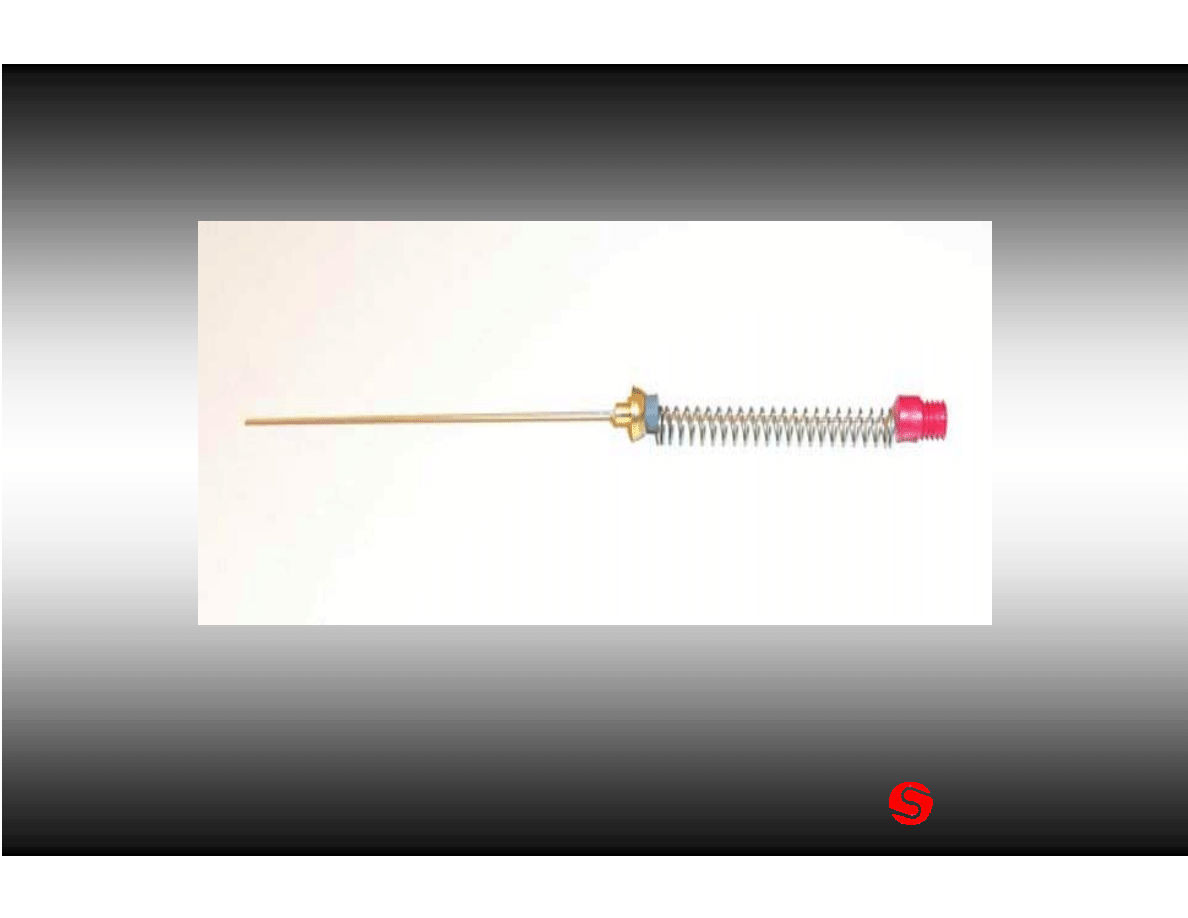

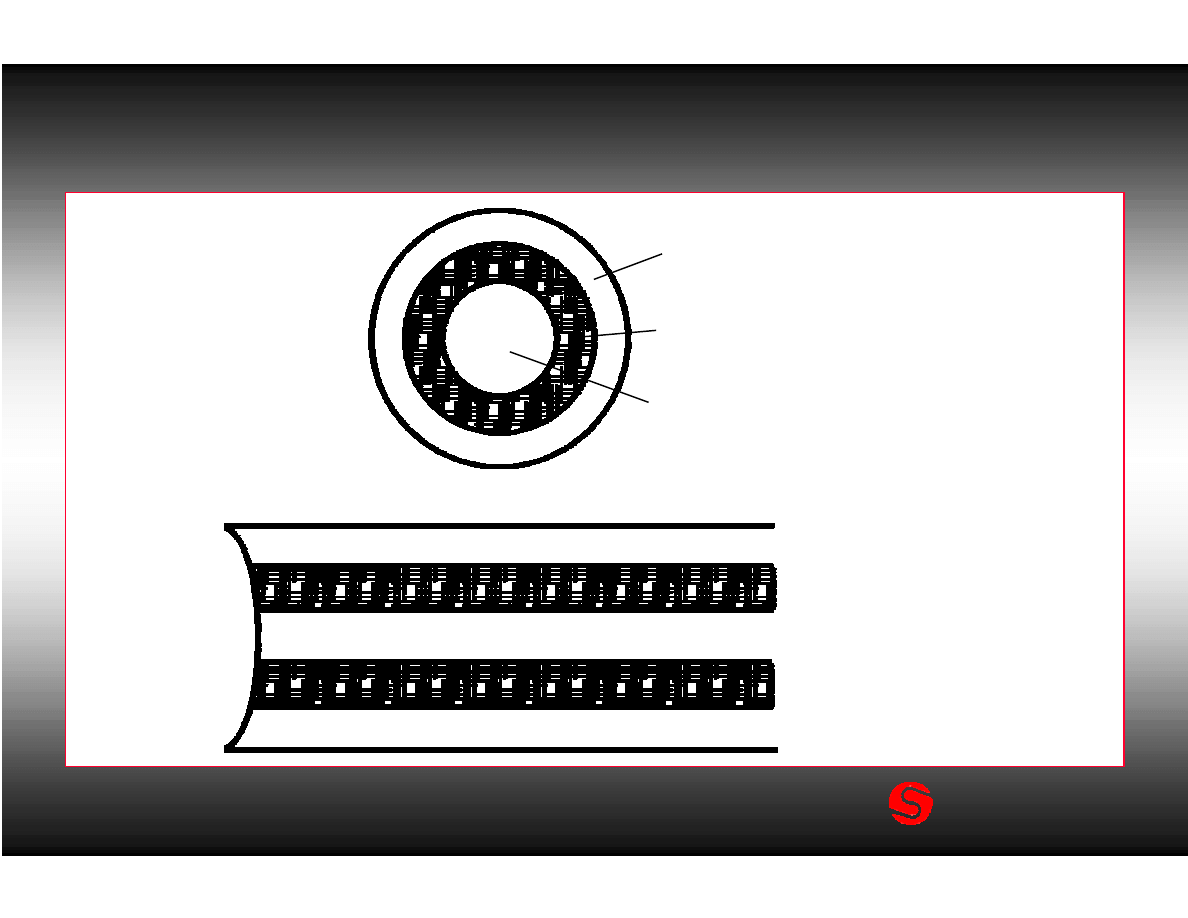

SPME Fiber Assembly Detail (Manual)

01-0062

Color-Coded Screw Hub

Tensioning Spring

Sealing Septum

Ferrule

Septum-Piercing Needle

Fiber-Attachment Needle

Coated SPME

Fused Silica Fiber

©2001 Sigma-Aldrich Co.

SUPELCO

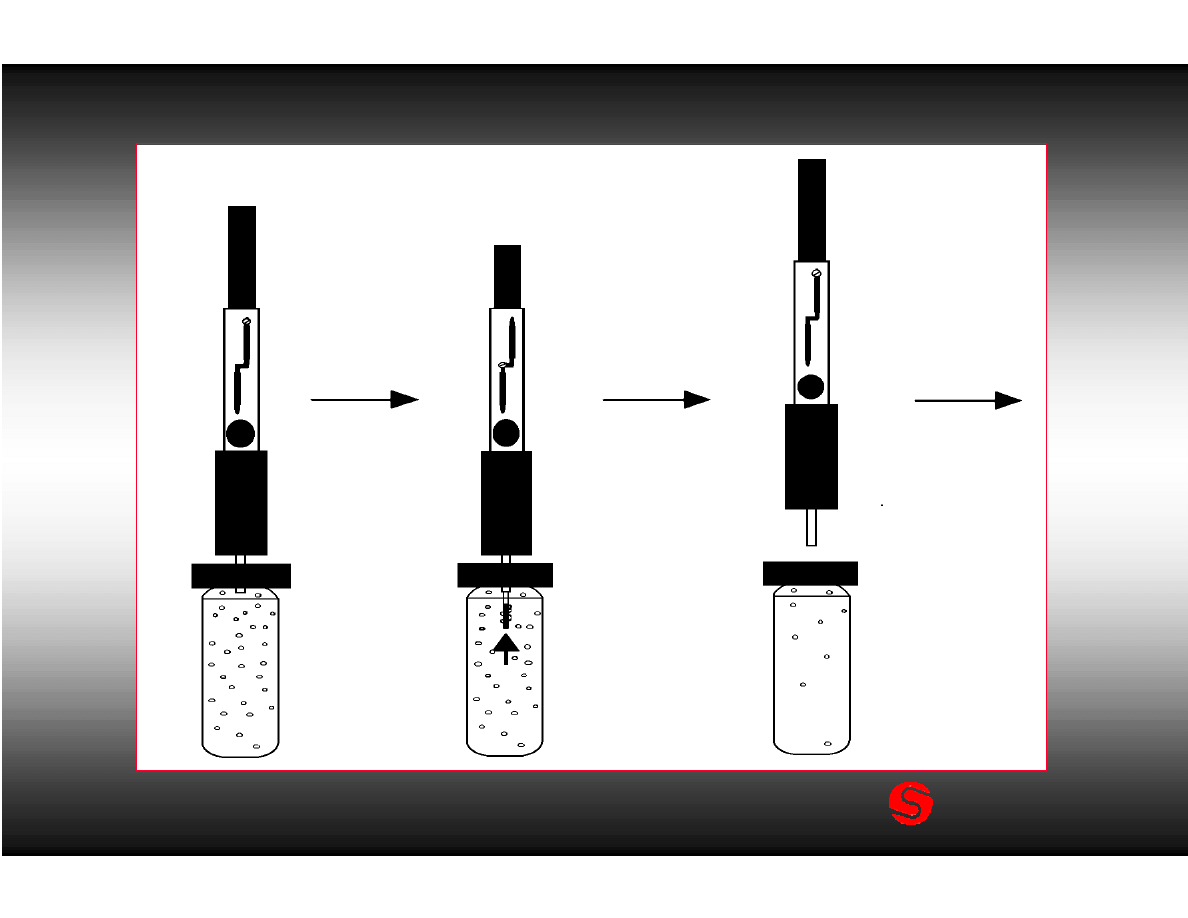

Pierce

Sample Septum

Retract

Fiber/Remove

Expose

Fiber/Extract

Extraction Procedure for SPME

01-0063

©2001 Sigma-Aldrich Co.

SUPELCO

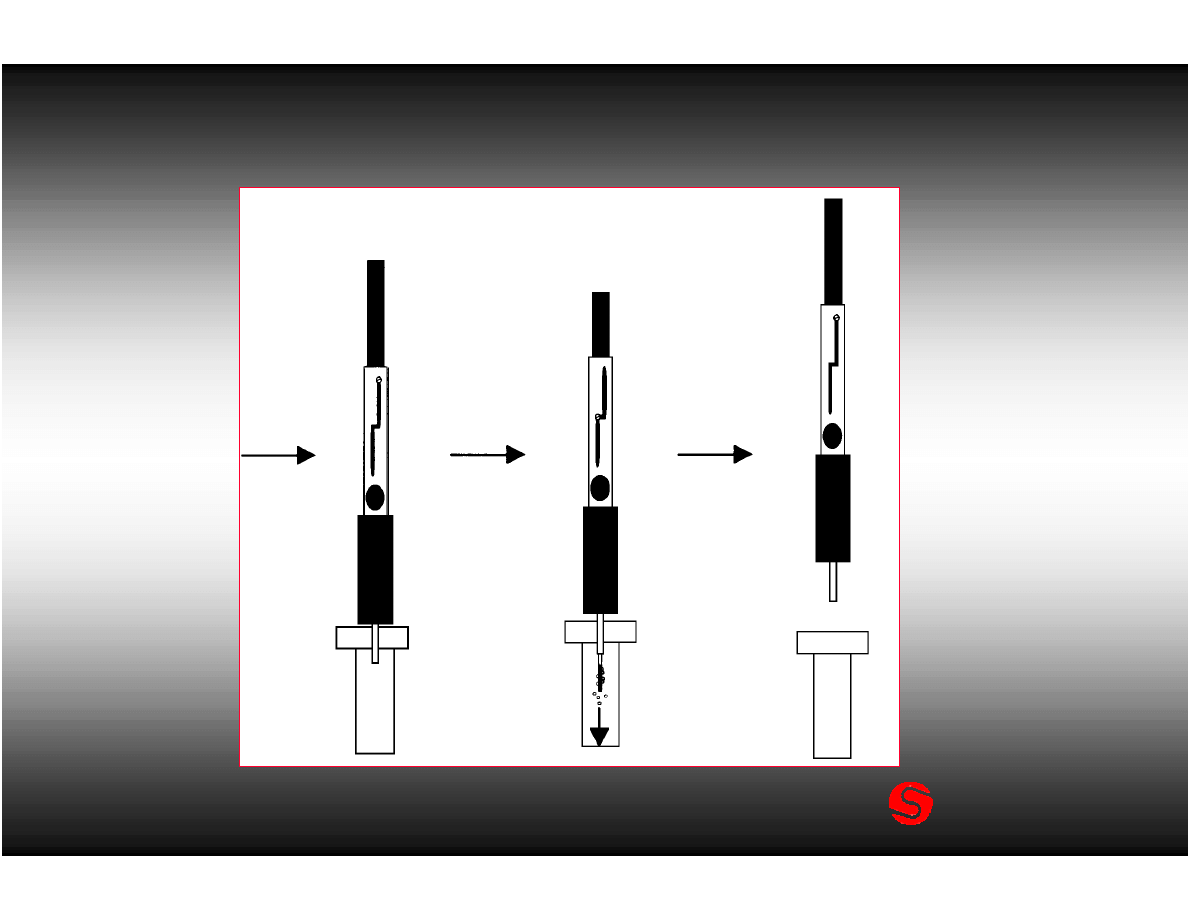

Desorption Procedure for SPME

Pierce GC

Inlet Septum

Expose

Fiber/Desorb

Retract

Fiber/Remove

01-0064

©2001 Sigma-Aldrich Co.

SUPELCO

01-0065

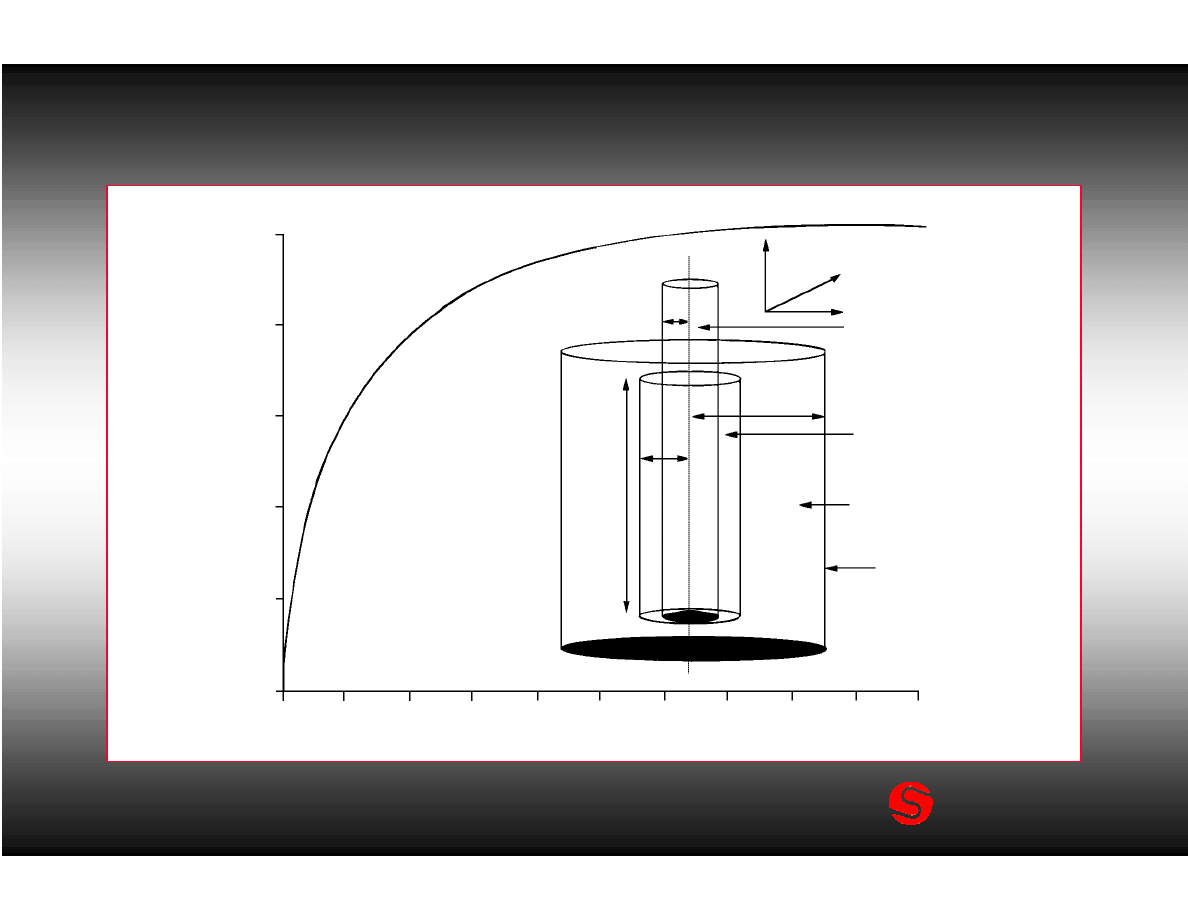

Adsorption Mechanism for SPME

794-0836

Analyte

Adsorbed

Silica Rod

Liquid Polymer

Aqueous

Solution

Vial

Selection of Analytical Column

©2001 Sigma-Aldrich Co.

SUPELCO

Concentration of analyte in stationary phase compared to

concentration of analyte in solution:

K = n

s

/V

1

C

2

°

K = Distribution constant

n

s

= Moles of analyte in stationary phase

V

1

= Volume of stationary phase

C

2

° = Final analyte concentration in water

Distribution Constant

01-0066

©2001 Sigma-Aldrich Co.

SUPELCO

01-0067

©2001 Sigma-Aldrich Co.

SUPELCO

01-0068

Evaluation of Crimped Design

48 injection

1st injection =

78082

48th injection = 84001

Average = 78675

4.8% RSD

100µm PDMS

50psig inlet pressure using Varian 8200 Autosampler,

30 sec extraction, 4ppm benzene in 25% NaCl water

©2001 Sigma-Aldrich Co.

SUPELCO

Available SPME Fibers, by Polarity

Nonpolar Fibers

Polydimethylsiloxane (PDMS): 100µm, 30µm, 7µm

Polar Fibers

85µm Polyacrylate

65µm Carbowax

®

-divinylbenzene StableFlex ™ (CW-DVB)

50µm CW-templated resin (CW-TPR) (HPLC only – crimped)

Bi-Polar Fibers

65µm PDMS-DVB StableFlex

75µm Carboxen™-PDMS StableFlex

55/30µm DVB-Carboxen-PDMS StableFlex

60µm PDMS-DVB (HPLC only – crimped)

01-0069

©2001 Sigma-Aldrich Co.

SUPELCO

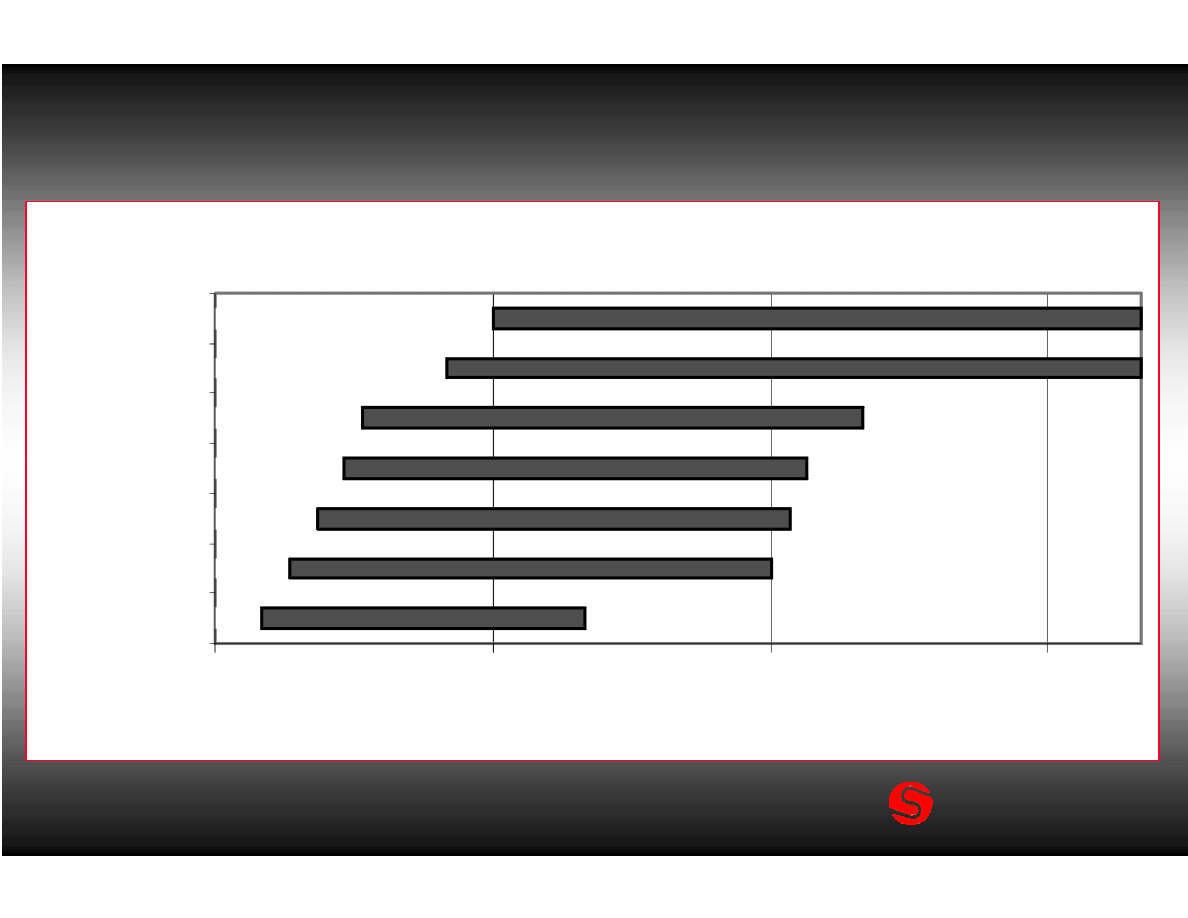

SPME Fibers, by Adsorption Strength

01-0070

TPR

7µm PDMS

30µm PDMS

100µm PDMS

DVB

DVB-Carboxen

Carboxen

Analyte Molecular Weight Range

0

150

300

450

©2001 Sigma-Aldrich Co.

SUPELCO

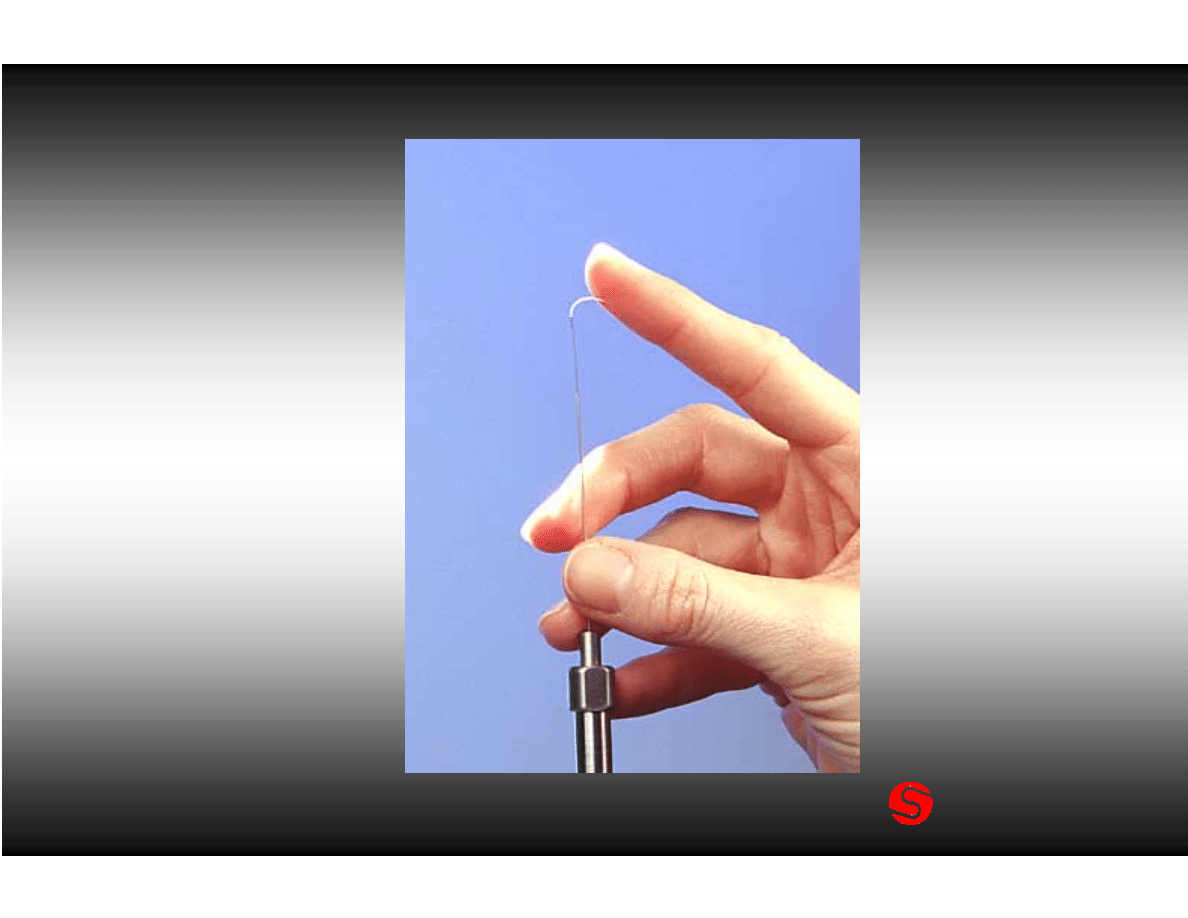

StableFlex

Fiber

01-0071

©2001 Sigma-Aldrich Co.

SUPELCO

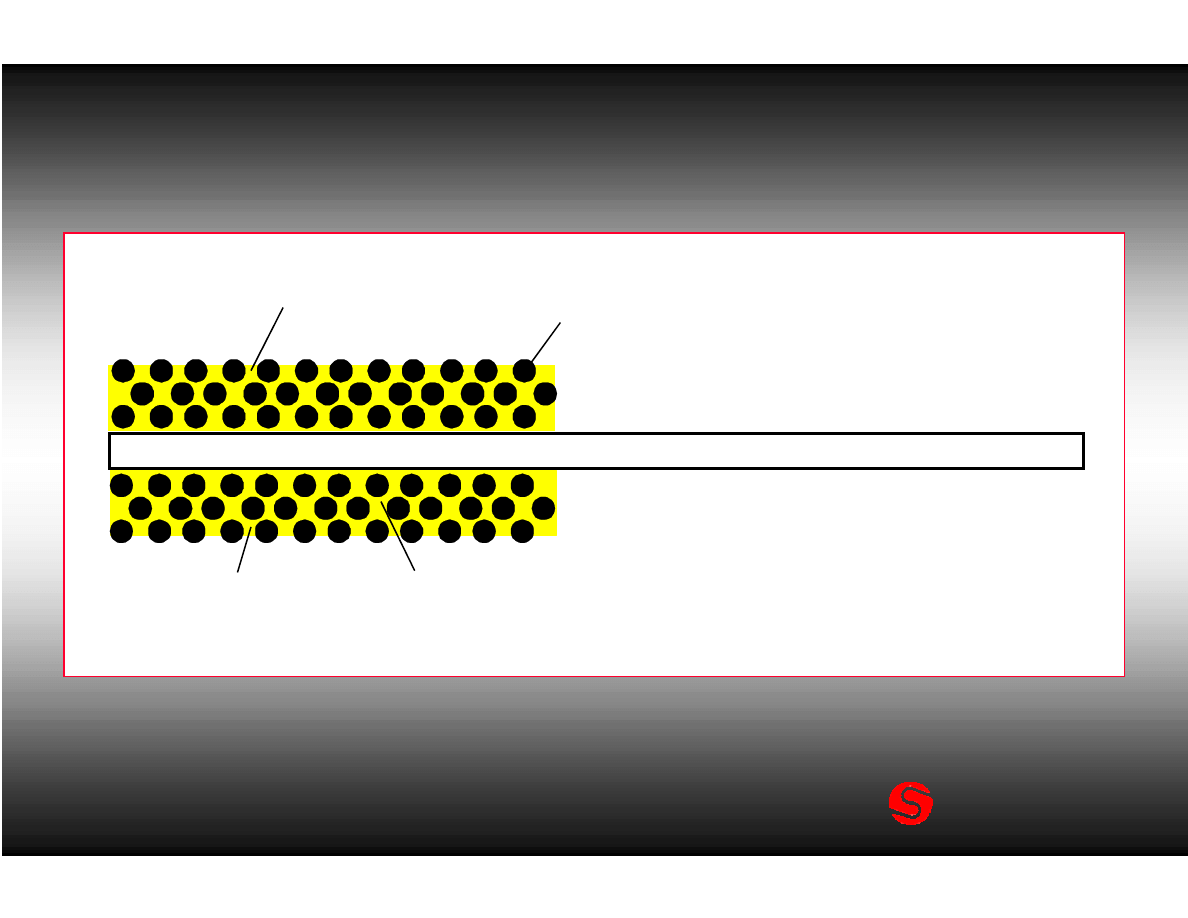

Carboxen/PDMS Fiber

PDMS phase

Carboxen

TM

particles (2-10µm)

Analytes can migrate between

layers-increased capacity

Fused Silica Rod

01-0072

©2001 Sigma-Aldrich Co.

SUPELCO

1. Acetone

2. 2-Butanone

3. 3-Methylpentane

4. Pentanal

5. Dimethyldisulfide

6. Hexanal

IS 4-Methyl-2-pentanone (int. std.)

01-0073

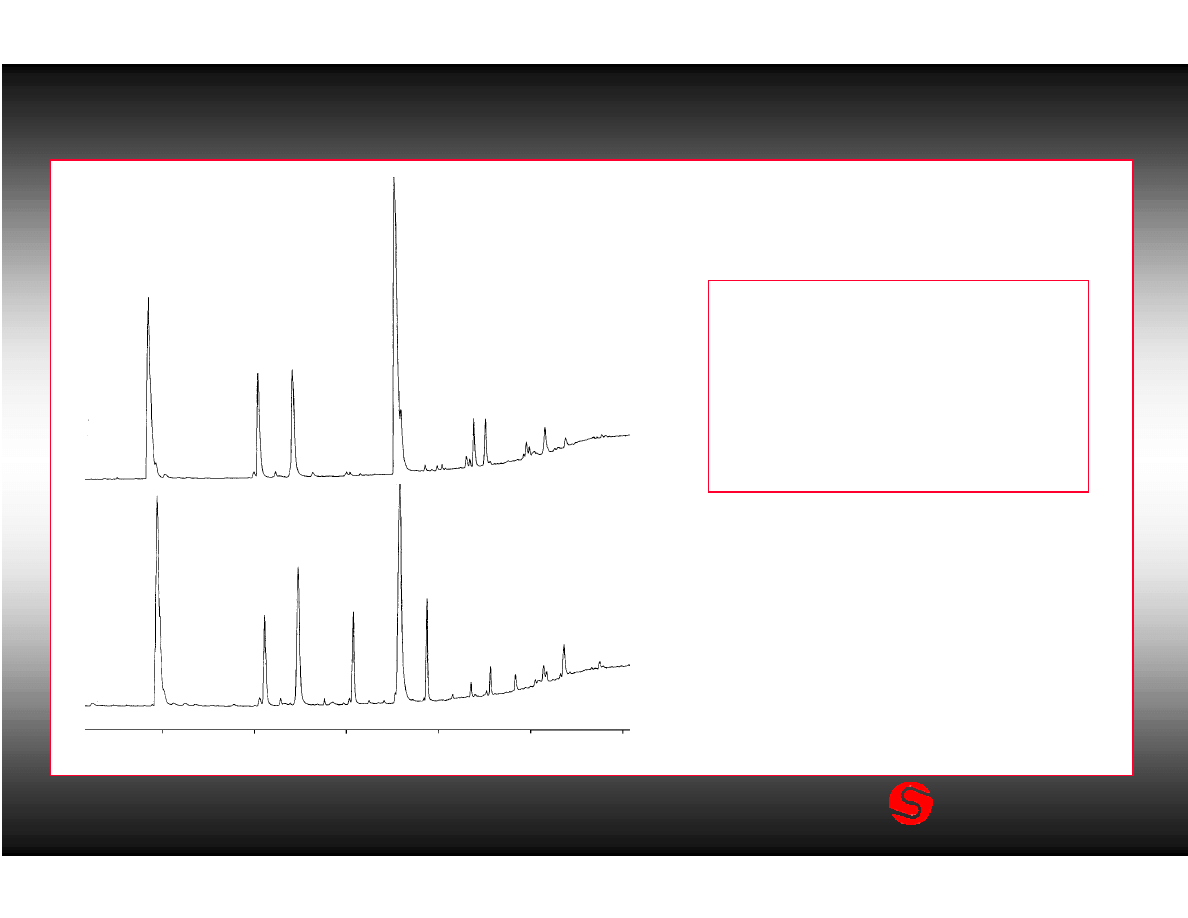

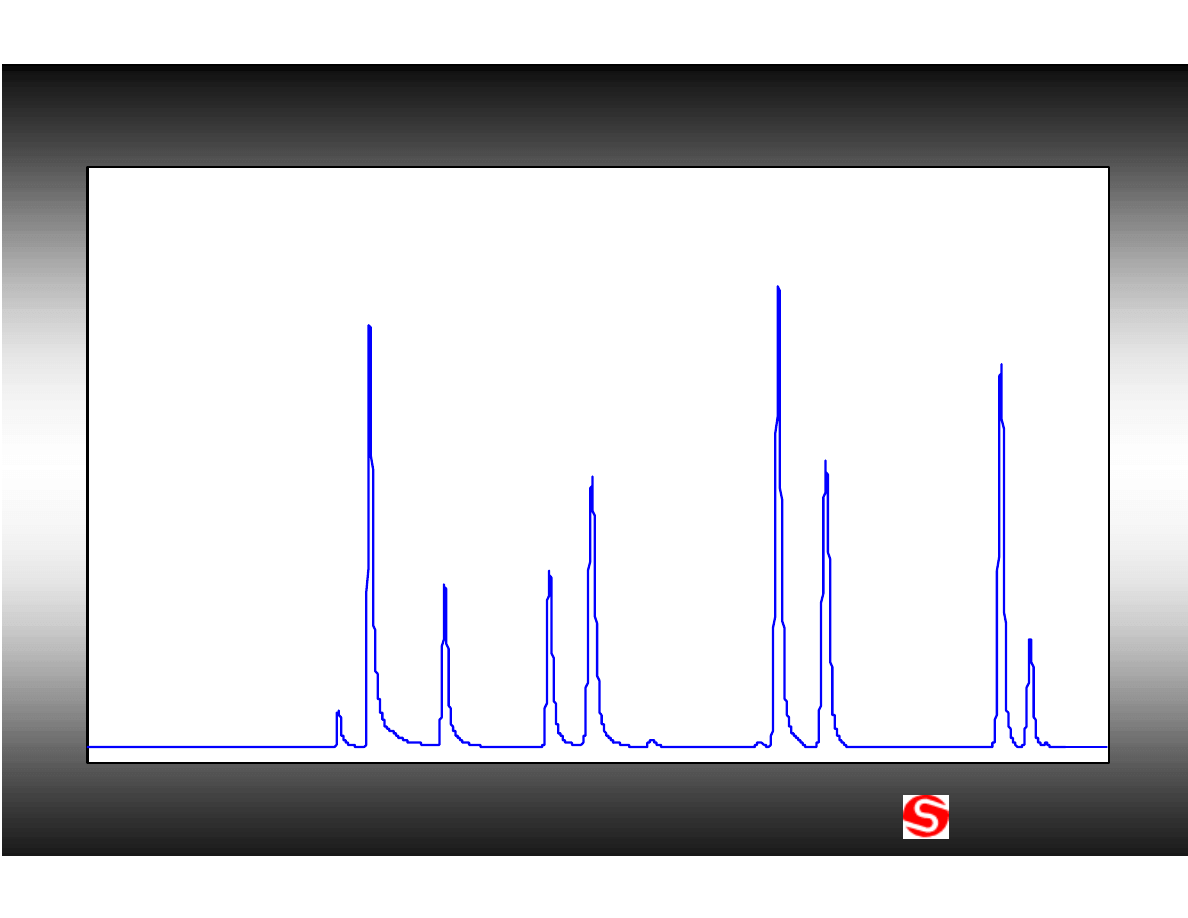

Milk Sample Off-Flavors by SPME-GC/MS

Chromatogram provided by Ray Marsili, Dean

Foods Technical Center, Rockford, IL, USA.

G00507, 508

Prior to Exposure to Sunlight

After 1-Hour Exposure to Sunlight

1

3

IS

2

4

6

10

15

20

Min

25

30

35

5

©2001 Sigma-Aldrich Co.

SUPELCO

Sample: 3g of 2% milk + 10µL internal standard solution

(20µg/mL 4-methyl-2-pentanone) (9mL GC vial)

SPME Fiber: PDMS/Carboxen™, 75µm film

Extraction: headspace, 15 min with constant stirring at 45°C

Desorption: 5 min, 250°C

Column: Supel-Q™ PLOT, 30m x 0.32mm ID

Oven: 70°C (2 min) to 140°C at 6°C/min (2 min hold)

then to 220°C at 6°C/min (5 min hold)

Carrier: helium, 35cm/sec

Inj.: splitless (closed 2 min)

Det.: GC/MS ion trap, m/z = 33-300

01-0074

Conditions for Analysis of Milk Off-Flavors

©2001 Sigma-Aldrich Co.

SUPELCO

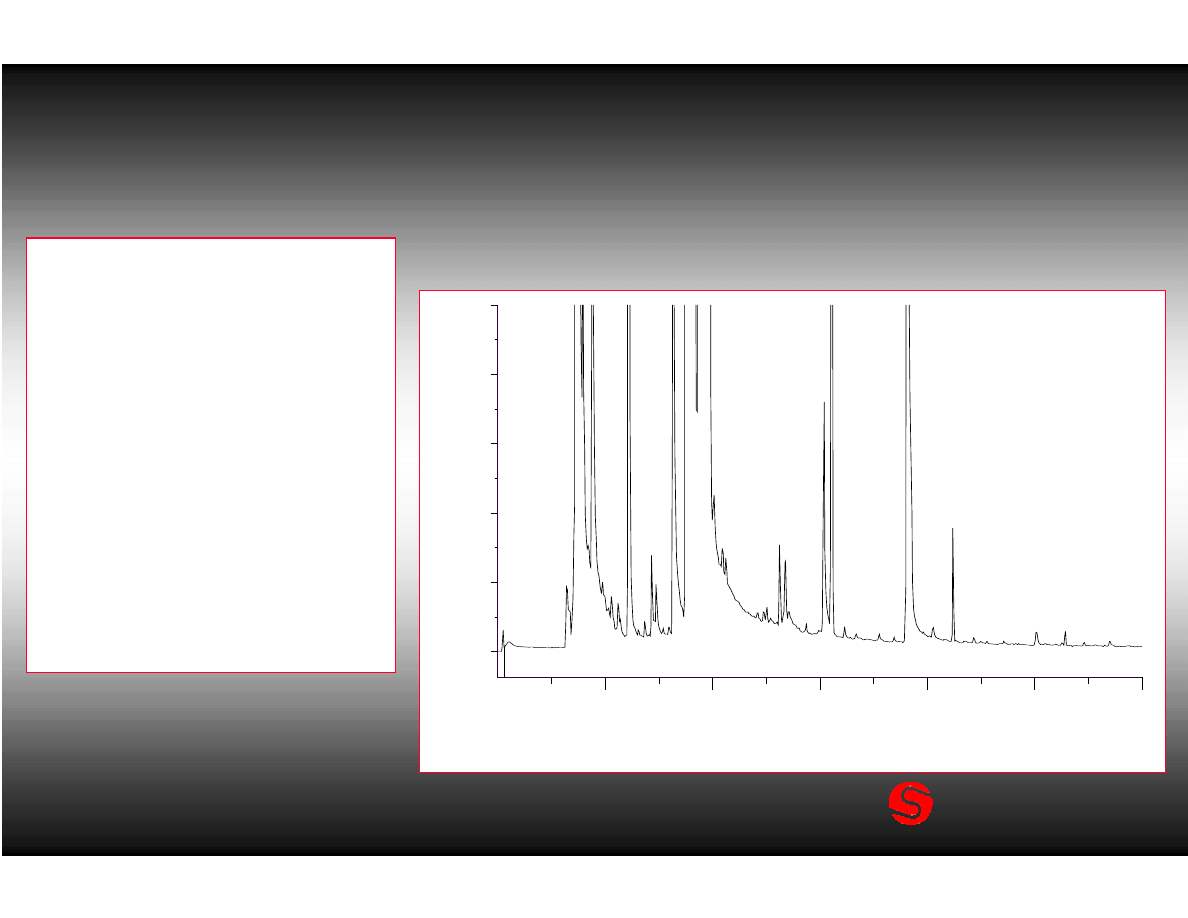

2

4

6

8

10

12

0

4E+4

8E+4

1E+5

2E+5

2E+5

Minutes

1,2

3

4

F

5

6

7

8

9

10

11

12

13

14

15

F

16 17

18

19

20

21

F

Sample:

3ml. saliva solution

w/thioglycollate medium

Fiber:

75µm Carboxen-PDMS

Extraction: headspace,

15 min. @ 22°C, stirred

Desorption: 1 min., 250°C

Column:

30m x 0.25mm x 0.25µm,

Supelcowax 10

Oven:

50-200°C, 10°C/min hold

5 min. @ 200°C

Carrier:

Helium @ 30cm/sec.

Injection:

250°C, 0.75mm ID

inlet liner, splitless

Detector:

GC-MS ion trap

Compounds in Salivary Headspace

by Dynamic HS-SPME

01-0075

©2001 Sigma-Aldrich Co.

SUPELCO

Peak No.

Compounds

Ret. Time (min)

ID

a

2

Methyl Mercaptan

1.55

rt,ms

3

Dimethyl Sulfide

1.63

rt,ms

4

Acetone

1.82

rt,ms

5

Butanone

b

2.15

rt,ms

6

Z-1-(methylthio)-1-propane*

2.77

T,ms

7

E-1-(methylthio)-1-propane*

2.97

T,ms

8

S-methyl ethanethioate

3.28

T,ms

9

Dimethyl disulfide

3.55

rt,ms

10

Limonene

b

4.97

rt,ms

11

Amyl alcohol

b

5.02

rt,ms

12

S-methyl pentanethioate*

5.25

T,ms

13

S-Methyl 3-methyl butanethioate*

5.35

T,ms

14

Thiocyanic acid methyl ester*

6.08

T,ms

15

2,5-dimethyl pyrazine

b

6.68

rt,ms

16

5-methyl-6-hepten-2-one

b

6.88

T,ms

17

4-hydroxy-4-methyl-2-pentanone

b

7.25

T,ms

18

Dimethyl trisulfide

7.65

rt,ms

19

Alkyl Benzene

b

8.12

T,ms

20

Acetic acid

8.58

rt,ms

21

Dimethyl sulfoxide*

10.02

rt,ms

22

Methyl(methylthio)methyl disulfide

11.14

T,ms

23

Benzyl alcohol

b

13.85

rt,ms

24

Phenol

15.32

rt,ms

25

Indole

23.32

rt,ms

a

Identification was by GC retention times (rt) and mass spectrometry (ms) of

authentic compounds.

Tentative (T) identification by mass spectrometry only when authentic compound

was not available.

b

Probable exogenous sources.

* Not previously identified in saliva.

01-0076

©2001 Sigma-Aldrich Co.

SUPELCO

Dual-Coated SPME Fiber

DVB (60µm)

Carboxen™-1006 (25µm)

Fused silica core (110µm)

Fused silica core

Carboxen-1006 (25µm)

Carboxen-1006 (25µm)

DVB

(60µm)

DVB (60µm)

Front View

Side View

01-0077

©2001 Sigma-Aldrich Co.

SUPELCO

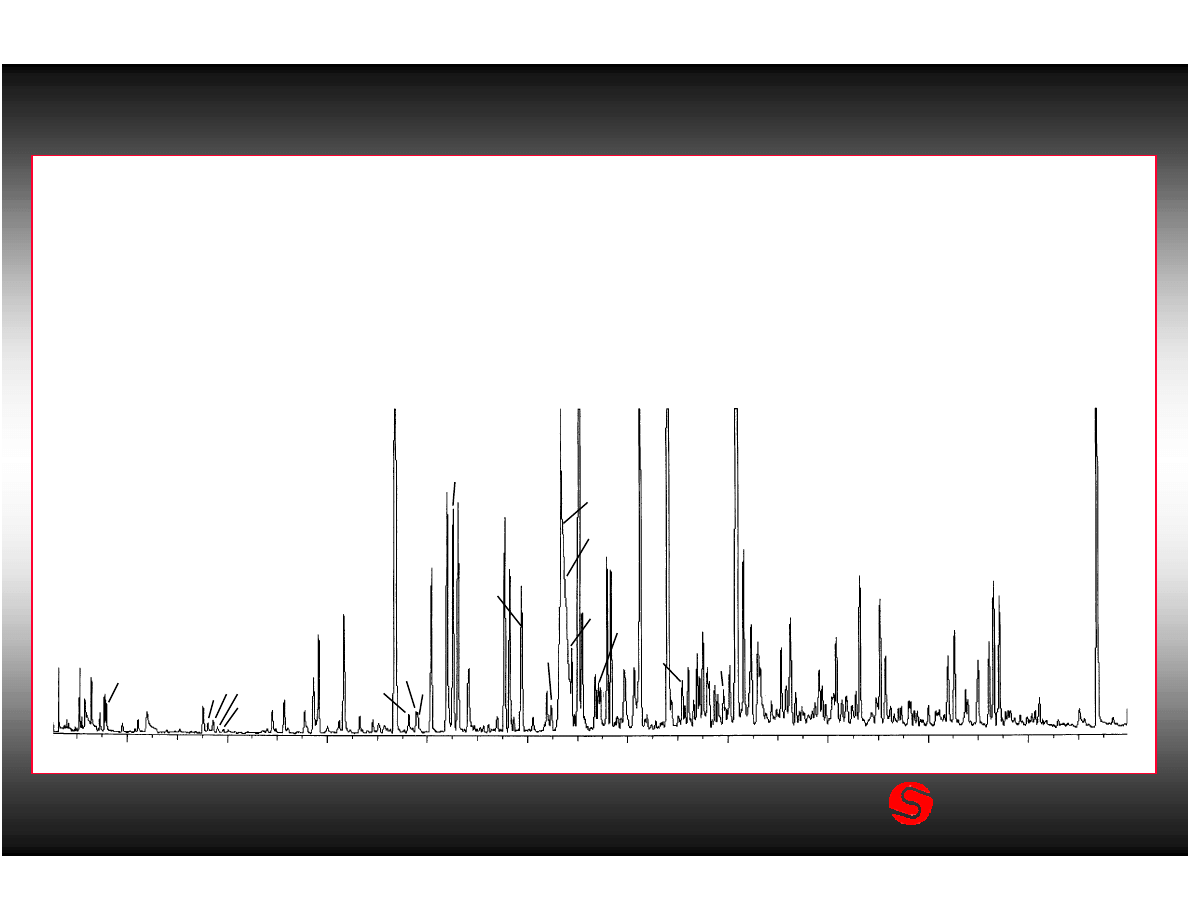

Regular Coffee Grounds by SPME

01-0078

Sample: 5g coffee grounds in 40mL vial

SPME Fiber: DVB/Carboxen™/PDMS (StableFlex™ Fiber)

Extraction: headspace, 30 min at 65°C

Desorption: 270°C for 5 min

Column: SUPELCOWAX™ 10, 30m x 0.25mm x 0.25µm film

Oven: 40°C (5 min) to 230°C at 4°C/min

Inj.: splitless/split, closed 0.5 min, 270°C, with 0.75mm liner

Det.: ion trap mass spectrometer, m/z = 30-350 at 0.6 sec/scan

Selected ions used for quantitation.

1

3 4

5

2

6

7 8 9 10

11 12

13

14

15

16

17

18

20

21

22

24

25

26

27

28

29

19

23

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44 45

46

47

48

49

50

51

52

53

54

55

56

57

4

8

12

Min

16

28

20

24

36

32

40

©2001 Sigma-Aldrich Co.

SUPELCO

1. 2-Methyl furan

2. 2-Butanone

3. 2-Pentanone

4. 3-Methyl butanal

5. 2,5-Dimethylfuran

6. 2-Acetyloxy-2-propanone

7. 2-Ethyl hexanol

8. Dimethyldisulfide

9. Phenol

10. Hexanal

11. 2-Methyl thiophene

12. n-Methyl pyrrole

13. 4-Methylphenol

14. 2-Ethyl pyrrole

15. Pyridine

16. Pyrazine

17. Methyl pyrazine

18. 4-Methyl thiazole

19. 3-Hydroxy butanone

01-0079

39. Furfural formate

40. 2-Furonyl ethanone

41. Methyl benzoylformate

42. Furanmethanol acetate

43. 5-Methyl-2-furancarboxaldehyde

44. Furanmethanol proprionate

45. Furfanyl furan

46. Pyridine methanol

47. 2-Methyl-5-propenylpyrazine

48. Furanmethanol

49. 3-Ethyl-4-methyl-2,5-furandione

50. Pyrazinecarboxamide

51. 2-Ethyl-3-hydroxy-4H pyran-4-one

52. 1-(2-Furanylmethyl)-pyrrole

53. 2-Methoxyphenol

54. 1-(1H-pyrrole-2-yl)-ethanone

55. 4-Ethyl-2-methoxy phenol

56. 3-Phenylpropenal or 2-Methylbenzofuran

57. 3,5-Dimethylbenzoic acid

Components in Coffee

20. Dimethyl phenol (isomer)

21. 1,2-Ethanediol, monoacetate

22. 2,5-Dimethylpyrazine

23. 2,3-Dimethylpyrazine

24. 2-Ethylpyrazine

25. 2,6-Dimethylpyrazine

26. 2-Ethyl-6-methylpyrazine

27. 2-Ethyl-5-methylpyrazine

28. Trimethylpyrazine

29. 2-Ethyl-3-methylpyrazine

30. 2,6-Diethylpyrazine

31. 2-Ethenylpyrazine

32. 2-Ethyl-3,5-dimethylpyrazine

33. Glycerol

34. 2,3-Diethylpyrazine

35. 2-Ethyl-3,6-dimethylpyrazine

36. 2-Furancarboxaldehyde

37. 2-Isopropenylpyrazine

38. 3,5-Diethyl-2-methylpyrazine

©2001 Sigma-Aldrich Co.

SUPELCO

©1 999 Sigma-A ldrich Co.

SUPELCO

Log Plot of Acenapthene/Heptane Responses

-1

-0.5

0

0.5

1

1.5

2

Carboxen

DVB-CAR

PDMS-DVB

01-0080

©2001 Sigma-Aldrich Co.

SUPELCO

©1 999 Sigma-A ldrich Co.

SUPELCO

Analytes in Test Mixture

1

1. Dimethylamine 40 ppm

2. Acetone

50 ppm

3. n-Propanol 50 ppm

4. MTBE

1 ppm

5. Benzene

0.2 ppm

6. Triethylamine 2 ppm

7. Toluene

0.1 ppm

1.

2.

3.

4.

5.

6.

7.

01-0081

©2001 Sigma-Aldrich Co.

SUPELCO

©1 999 Sigm a-Aldr ic h Co.

SUPELCO

Conditions for Analysis of Test Mix

Extraction Conditions

Sample:

0.8µl of test mix spiked in 0.8mL of

water containing 25% NaCl and 0.1M

`

phosphate buffer, pH 11 in 2mLvial.

Fiber:

65µm PDMS-DVB StableFlex

Extraction:

Headspace (amibient) for 2 min with

Varian 8200 autosampler with

agitation

Desorption:

250°C for 2min

Chromatographic Conditions

Column:

SPB-1 Sulfur 30m x 0.32mm x 4.0µm

Oven:

50°C(0.5min) to 150°C@20°C/min.

Injector:

Splitless/split, 250°C, 0.75mmID liner

Detector:

FID, 280°C

01-0082

©2001 Sigma-Aldrich Co.

SUPELCO

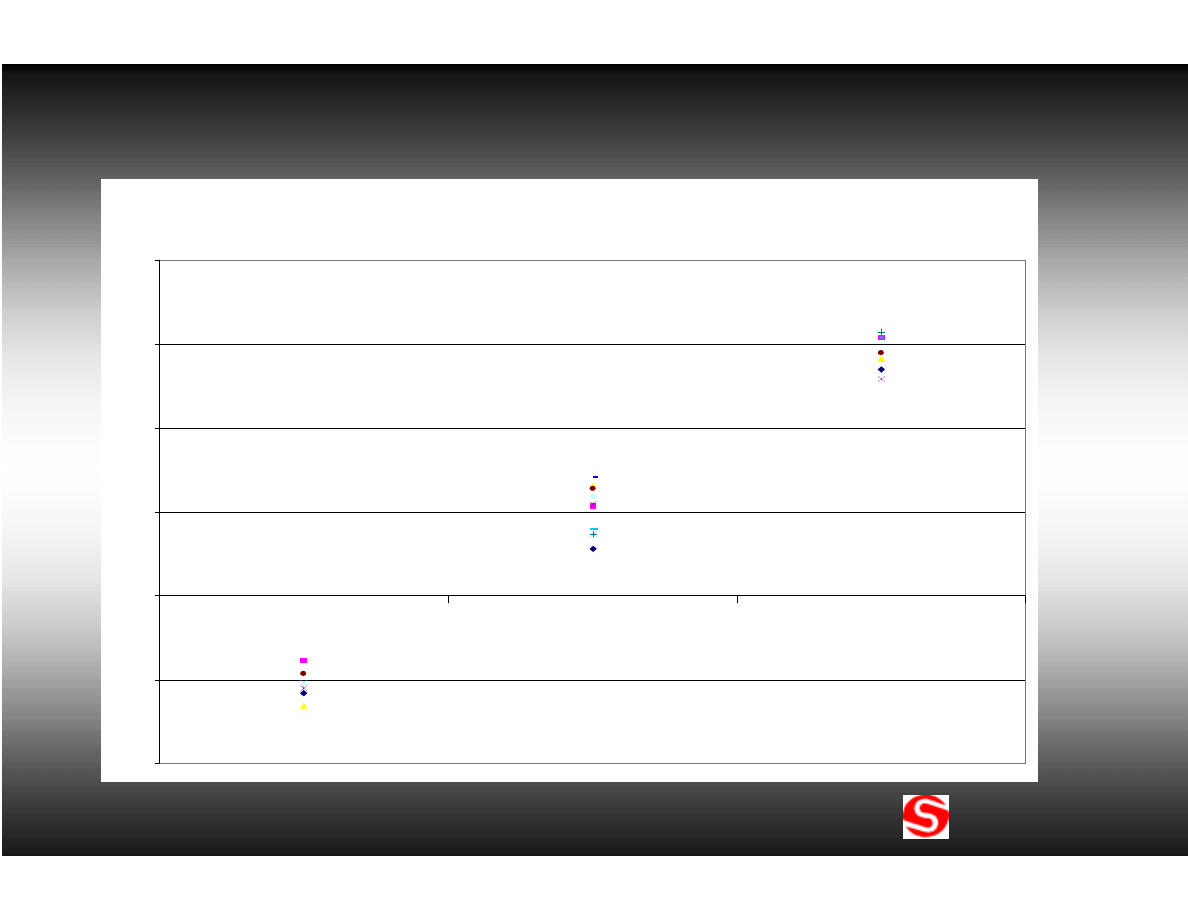

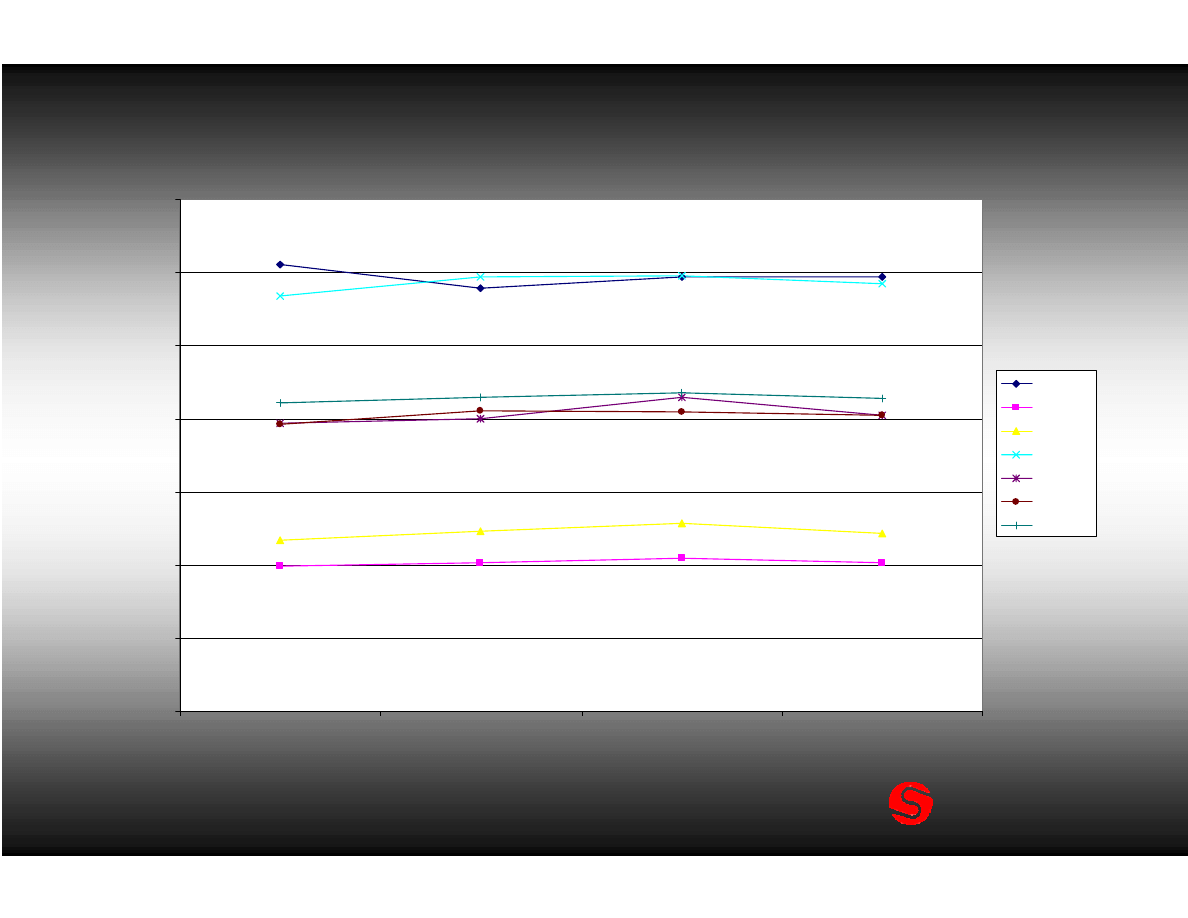

Precision for DVB/PDMS fiber

0

5000

10000

15000

20000

25000

30000

35000

a

1 to 95

b

97-191

c

193-250

d

All 250

Number of injections

D

e

te

c

tor r

e

spons

e

DMA

Acetone

Propanol

MTBE

Benzene

TEA

Toluene

01-0083

©2001 Sigma-Aldrich Co.

SUPELCO

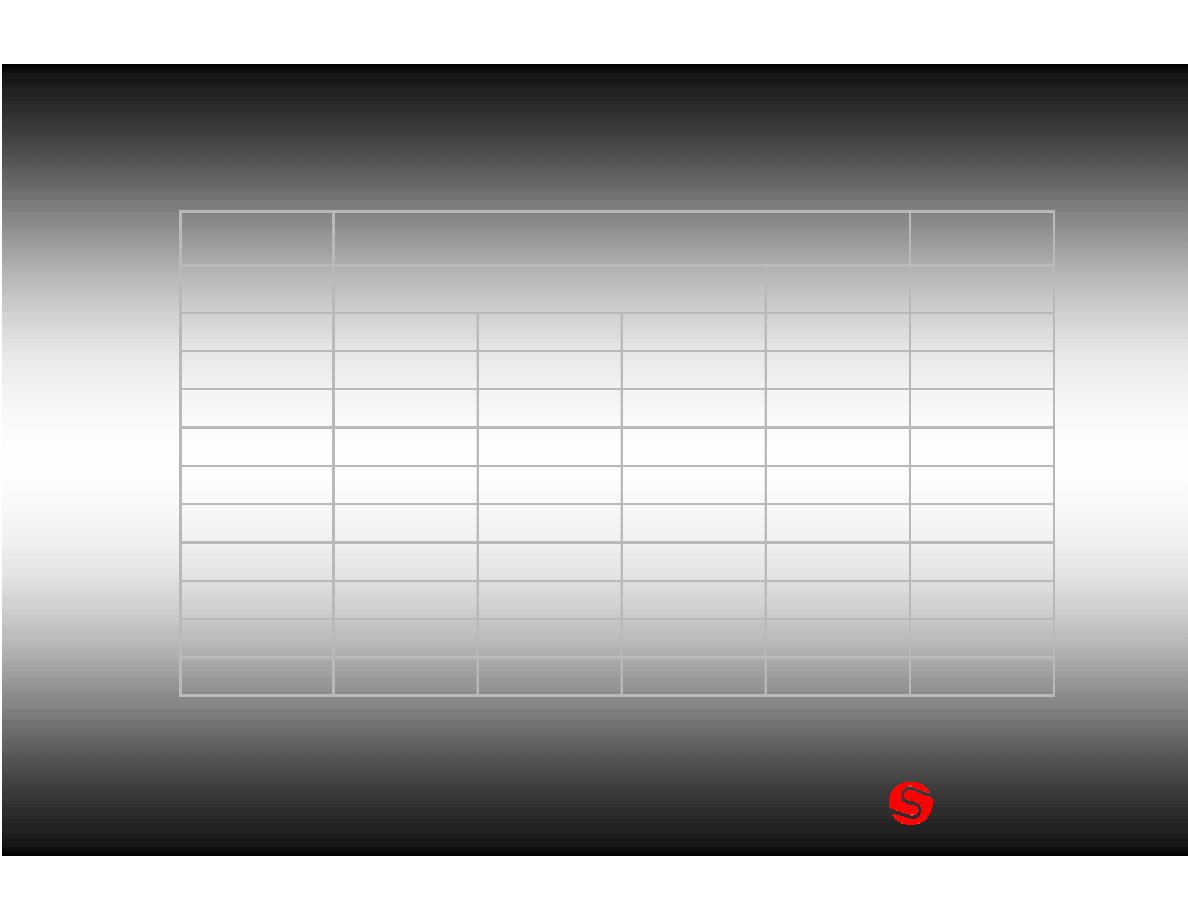

Precision Measurement -

DVB/PDMS Fiber

1 to 95

97-191

193-250

All 250

% RSD

a

b

c

d

DMA

30535

28926

29719

29701

8.4

Acetone

9943

10161

10433

10132

4.3

Propanol

11661

12322

12817

12190

5.5

MTBE

28355

29729

29773

29224

5.9

Benzene

19658

20012

21439

20214

5.2

TEA

19649

20553

20491

20199

8.8

Toluene

21041

21434

21738

21363

4.3

01-0084

©2001 Sigma-Aldrich Co.

SUPELCO

Where are we going in Fiber development?

Minimize the variability in Carboxen coatings

by:

a. controlling the porosity

b. optimize the conditioning process

Development of new fiber coatings

01-0085

Wyszukiwarka

Podobne podstrony:

Improved Characterization of Nitromethane, Nitromethane Mixtures, and Shaped Charge Jet

improvment of chain saw and changes of symptoms in the operators

Augmentation Improves Thermal Performance of Air Cooled Heat

Method of gravity distortion and time displacement United States Application US20060073976

improvment of chain saw and changes of symptoms in the operators

Performance Parameters of Explosives Equilibrium and Non Equilibrium Reactions

social networks and the performance of individualns and groups

Biological performance of uncoated and octacalcium phosphate

Application of SPME for determination of organic vapours in

Contents of SPME Applications

Design and Performance of the OpenBSD Statefull Packet Filter Slides

Susan B A Somers Willett The Cultural Politics of Slam Poetry, Race, Identity, and the Performance

A dynamic model for solid oxide fuel cell system and analyzing of its performance for direct current

Approaches to improving the quality of dried fruit and vegetables

Lewkowski, Jarosław Synthesis, Chemistry and Applications of 5 Hydroxymethyl furfural And Its Deriv

Improving the Performance of Two stroke Motorcycle with

Sailing Yacht Performance The Effects of Heel Angle and Leeway Angle on Resistance

Improved biological performance of Ti implants due to surfac

An Assessment of the Spatial Performance of Virtual Home Theatre Algorithms by Subjective and Object

więcej podobnych podstron