Recent Patents on Biotechnology 2010, 4, 23-29

23

1872-2083/10 $100.00+.00

© 2010 Bentham Science Publishers Ltd.

Secretory Production of Recombinant Proteins in Escherichia coli

Sung Ho Yoon

1

, Seong Keun Kim

1

and Jihyun F. Kim

1,2

*

1

Industrial Biotechnology and Bioenergy Research Center, Korea Research Institute of Bioscience and Biotechnology

(KRIBB), 111 Gwahangno, Yuseong, Daejeon 305-806, Republic of Korea,

2

Functional Genomics Program, School of

Science, University of Science and Technology, Yuseong, Daejeon 305-333, Republic of Korea

Received: July 31, 2009; Accepted: September 8, 2009; Revised: September 25, 2009

Abstract: Extracellular production of heterologous proteins using the Escherichia coli cell factory offers several

advantages over intracellular production and mammalian culture. Properly folded proteins can be rapidly accumulated in

the culture media, and downstream processes for isolation and purification can be much simplified. Efforts to enhance the

secretory production of target proteins can be largely classified as selection and modification of the signal peptide,

coexpression of proteins to assist translocation and folding, improvement of periplasmic release, and protection of target

proteins from degradation and contamination. Here, we review recent patents on the secretory production of recombinant

proteins in E. coli.

Keywords: Secretion, excretion, periplasm, extracellular production, signal peptide, recombinant protein, Escherichia coli.

INTRODUCTION

Inarguably,

Escherichia coli has been the most widely

used organism for mass-production of recombinant proteins

of pharmaceutical and industrial importance. Despite the

lack of post-translational modification and the existence of

endotoxin, this remarkable microorganism has numerous

desirable characteristics as a production host such as fast cell

growth, easy manipulation, straightforward high cell density

cultivation, and capacity to hold over 50% of foreign protein

in total protein expression [1].

Secretory production of recombinant proteins in E. coli

has been particularly useful for production of pharmaceutical

proteins [2,3]. Compared to cytoplasmic production,

targeting a protein of interest to the periplasmic space or the

culture medium enables downstream processing much easier

at a reduced process cost. Isolation and purification of the

over-expressed products can be much simplified due to

reduced contamination of various cellular components and

circumvention of proteolytic degradation by intracellular

proteases. Correct folding of eukaryotic proteins containing

multiple disulfide bonds is more likely to happen in the

oxidative environment of the periplasm. Secretory process

allows removal of the amino-terminal signal sequence,

which leads to the appearance of mature proteins as naturally

occurring sequences contain no N-terminal methionine

residue. In addition, laboratory and industrial strains of E.

coli normally do not secrete much extracellular proteins [4],

which further facilitates already simple purification steps.

E.

coli has various systems (Type I through V) for

transporting proteins from the cytosol into the periplasm or

the extracellular milieu [5]. In the type I mechanism, an ATP

binding cassette (ABC) transporter recognizes a C-

*Address correspondence to this author at the KRIBB, 111 Gwahangno,

Yuseong-gu, Daejeon 305-806, Republic of Korea; Tel: +82-42-860-4412;

Fax: +82-42-879-8595; E-mail: jfk@kribb.re.kr

terminal signal peptide, in most cases E. coli

–haemolysin

(HlyA), connected to a target protein, and transports it

directly from the cytoplasm to the medium. As the secreted

protein doesn’t experience a periplasmic intermediate, it

contains a signal sequence which should be cleaved off later

to result in the intact native protein. The type II secretion

system transports proteins in two steps, periplasmic

translocation and extracellular transport. Transport from the

cytoplasm to the periplasm is mediated by the Sec-dependent

pathway or the twin-arginine translocation (Tat) pathway. In

the Sec-dependent pathway, the cytosolic chaperone SecB or

the ribonucleoprotein signal recognition particle (SRP) binds

an unfolded preprotein harboring an N-terminal signal

peptide and moves them to inner membrane-bound SecA [6].

By contrast, the Tat system recognizes a folded preprotein by

TatBC complex. When the preprotein traverses the inner

membrane through SecYEG or TatA channel, the signal

peptide is removed by a signal peptidase. Extracellular

release of the periplasmic protein is carried out by a

concerted action of 12-16 proteins constituting a secreton.

Attempts to improve the secretion productivity have been

made on every step of the secretion process [2,3]. Trans-

portation of cytosolic recombinant proteins to the cyto-

plasmic membrane can be enhanced by proper selection and

modification of the signal peptide. In a next step where the

precursor protein is transported across the cytoplasmic

membrane to the periplasm, proteins constituting the

transport machinery can be co-expressed with a target

protein. Finally, the periplasmic protein can be secreted to

the culture medium by osmotic shock or periplasmic lea-

kage. E. coli host cells have been engineered to be a more

efficient cell factory for secretory production of foreign

proteins. For example, it can be made devoid of host-specific

proteases or genes controlling the regulation of proteases.

Despite remarkable progress in utilizing the E. coli cell

factory for secretory production of recombinant proteins, the

challenges of industrial production are still daunting. Target

24 Recent Patents on Biotechnology 2010, Vol. 4, No. 1

Yoon et al.

protein production is limited by insufficient capacity of the

transport machinery. Especially, secretory production into

the periplasm is physically limited by periplasmic volume

and normally results in increased cellular burden and

reduced cell growth. Also, foreign proteins can be degraded

by host proteases. High rate of target translation may lead to

accumulation inside the cell as an inclusion body.

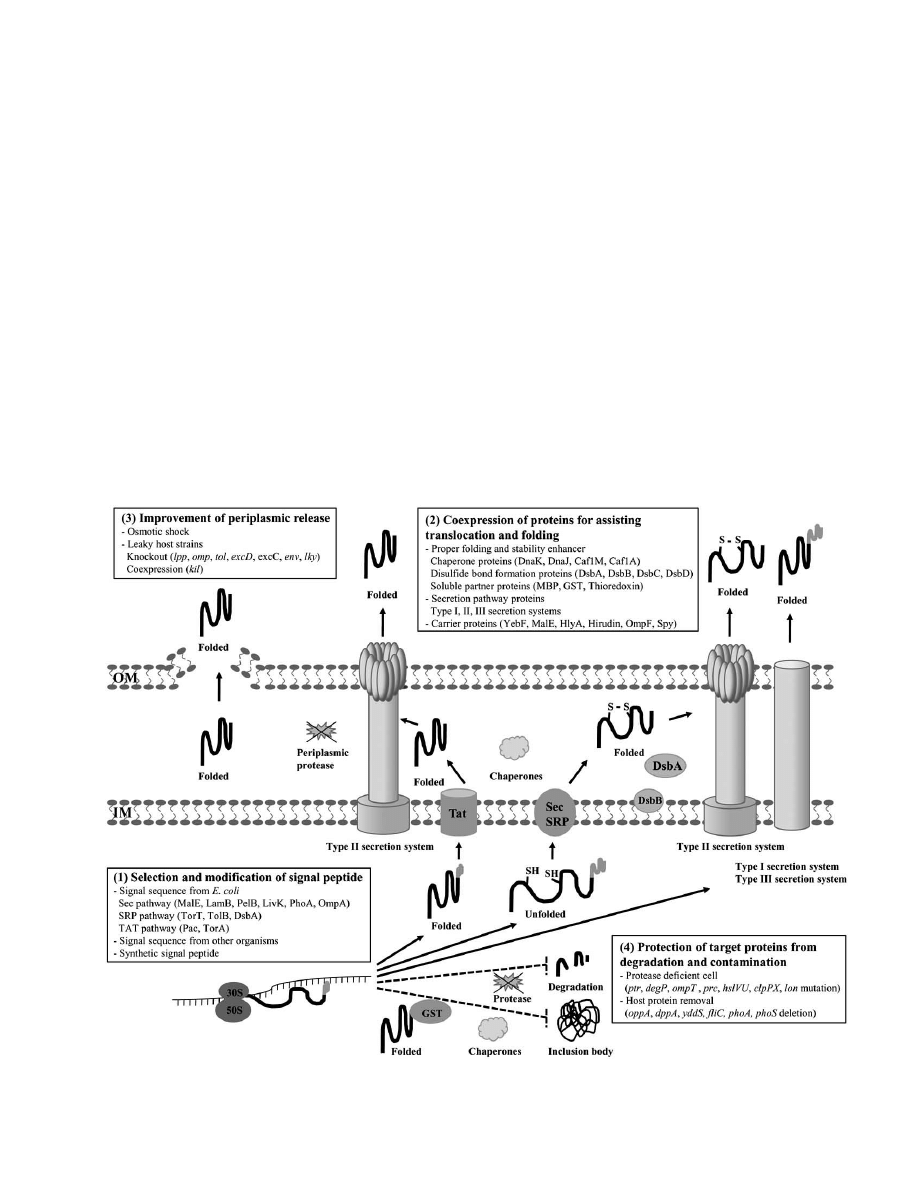

In this review, we summarize various attempts to inc-

rease secretory production of recombinant proteins and

applications recently patented (Fig. (1)).

1. SELECTION AND MODIFICATION OF THE

SIGNAL PEPTIDE

Selection of a signal peptide is the primary choice for

efficient secretion of a recombinant protein. The majority of

the signal peptides developed are for secretory production

through the Sec-dependent system. In E. coli, signal

sequences typically consist of a positively charged n-region,

a nonpolar hydrophobic h-region, and a neutral polar c-

region which has a cleavage site for the signal peptidase [2].

By pattern match or sequence homology searches with

known ones, for example BLAST searches into public seq-

uence databases such as GenBank, Swiss-Prot or a sequen-

ced genome, signal sequences can be readily identified.

Also, machine learning approaches such as a neural net-work

or hidden Markov model can be used for the computational

prediction of signal peptides and the cleavage site [7].

In general, eukaryotic signal peptides do not function

efficiently in a prokaryotic host and has been applied for

prokaryotic expression with limited success [8]. A number of

signal peptides from bacterial proteins have been linked to

recombinant proteins. A full-length immunoglobulin G (IgG)

antibody having a complex structure was secreted to the

culture media by being attached to signal sequences from

bacterial proteins which are translocated via various secre-

tion pathways – the Sec pathway (maltose-binding protein

subunit, MalE; maltoporin, LamB; pectate lyase subunit,

PelB; leucine binding protein subunit LivK; alkaline phos-

phatase subunit, PhoA; outer membrane protein, OmpA), the

SRP pathway (periplasmic sensory protein, TorT; subunit of

the Tol-Pal cell envelope complex, TolB; disulfide

oxidoreductase, DsbA), and the Tat pathway (penicillin

acylase, Pac; subunit of trimethylamine N-oxide reductase I,

TorA) [9]. Heterologous signal sequences can come from

pullulanases (derived from Klebsiella, Thermoanaero-

bacter, and Thermotoga), penicillinase (Staphylococcus,

Fig. (1). Strategies for enhancing the secretory production in Escherichia coli

Secretory Production in E. coli

Recent Patents on Biotechnology 2010, Vol. 4, No. 1 25

Klebsiella, and Bacillus), cyclomaltodextrin glucano-

transferase (Klebsiellla oxytoca), or PelB (Erwinia and Xan-

thomonas). Also, the signal sequence of the bacteriophage

M13 major coat protein can be used for antibody production

[10] and that of the Bacillus endoxylanase for human granu-

locyte colony stimulating factor (hG-CSF) [11]. US020080-

193974A1 [12] claimed a variety of signal sequences for a

mutant phosphate binding protein (Pdb), disulfide

oxidoreductase (DsbA), protein disulfide isomerase (DsbC),

Bce, CupA2, CupB2, CupC2, NikA, FlgI, a tetratricopeptide

repeat family protein (ORF5550), a toluene tolerance protein

(Ttg2C), and a methyl accepting chemotaxis protein (ORF-

8124). Until now, only a limited number of bacterial signal

peptides such as those of OmpA, LamB, PelB, PhoA, and

thermostable enterotoxin II (STII) have been widely used in

recombinant E. coli.

The signal sequence has been artificially modified and

optimized. It is reported that the positive charge of the N-

terminal region and the hydrophobicity of the central

hydrophobic region are important for secretion efficiency

[13,14]. Bacterial signal sequences such as STII have been

modified [15,16]. A novel synthetic signal peptide can be

designed based on a rule-based approach. EP00000-

1290197B1 [17] describes synthetic features of a signal

peptide – (i) two or more positively charged amino acids

close to the N terminus, (ii) a region of between 7 and 16

consecutive hydrophobic amino acid residues, (iii) one or

more amino acids which may act as an alpha helix disrupter,

and (iv) at the C-terminus, the sequence Z-X-Z, wherein Z is

an amino acid having a small side chain and X is any amino

acid. Various modifications to the native signal peptide have

been made, too. OmpA signal sequence was modified to

ensure production of the nerve growth factor without N-

terminal methionine [18]. Basic amino acid-rich polypeptide

was added after the signal peptide [19]. A secretional

enhancer consisting of hydrophilic amino acids was linked to

the basic n-region alone or the basic n-region and the

hydrophobic h-region [20]. To ensure that the signal is

appropriately expressed and cleaved from the expressed

protein, alanine-phenylalanine-alanine was added just before

the cleavage site [21]. Along with the synthetic approach,

experimental methods to screen for a new signal peptide

have been developed [22].

2. COEXPRESSION OF PROTEINS FOR ASSISTING

TRANSLOCATION AND FOLDING

Coexpression of helper proteins with target proteins has

been exploited for a proper folding and translocation through

the cytosolic membrane. They come in separate expression

vectors or are fused with the target protein.

2.1. Coexpression of Proteins that Enhance a Proper

Folding and Solubility

Expression of many heterologous proteins in E. coli often

leads to intracellular aggregates due to their incorrect folding

[23]. Although inclusion body formation allows target pro-

teins to be highly resistant to proteolysis and to be expressed

in large quantity, it should be followed by a sophisticated

downstream processing such as isolation, renaturation, and

refolding to obtain functionally active proteins [24].

Two types of proteins, molecular chaperones and enzy-

mes involved in disulfide bond formation, have been

coexpressed for assisting in correct folding of the recom-

binant proteins. Coexpression of DnaK and DnaJ chaperones

remarkably increased the amount of granulocyte colony

stimulating factor (G-CSF) produced [25]. To increase

periplasmic folding and extracellular secretion of human

Interleukin-1 (hIL-1) or human granulocyte-macrophage

colony-stimulating factor (hGM-CSF), periplasmic cha-

perone (Caf1M) and usher protein (Caf1A) from Yersinia

pestis were coexpressed [26]. To translocate overexpressed

chaperones into the periplasm, an OmpA signal sequence

was fused to DnaJ, the N-terminal fragment of DnaJ, or a

small heat shock protein [27]. Genes encoding inclusion

body-associated proteins, IbpA and IbpB, were deleted from

the E. coli host to reduce inclusion body formation and to

enhance secretory production [28]. Conversely, those genes

were amplified to produce a target protein as an inclusion

body.

Most mammalian proteins contain multiple disulfide

bonds that require correct oxidation and pairing between the

two partner cysteines for their folding. Disulfide bond

formation in the cytoplasm is catalyzed by an oxidized form

of thioredoxins (TrxA and TrxC) and glutaredoxins [29,30].

However, in the cytosol of E. coli, these enzymes are mostly

in a reduced form by the action of thioredoxin reductase

(encoded by trxB),

-glutamylcysteine synthetase (gshA),

glutathione synthetase (gshB), and glutathione oxidore-

ductase (gor). US000007410788B2 [31] describes a method

for changing the reductive cytoplasm into a more oxidative

environment by introducing a null mutation to trxB, gshA,

gshB and/or gor. In order to increase the reducing capacity of

the cytoplasm enough to support the cell growth, the mutant

strain was further engineered to have a mutated form of

AhpC, subunit of alkyl hydroperoxidase. As for increasing

disulfide bond formation in the periplasm, E. coli disulfide

isomerases (DsbC or DsbG) [32] or human disulfide iso-

merase [33] have been coexpressed. Also, plasmids con-

taining cell envelope proteins involved in disulfide bond

formation (DsbA, DsbB, DsbC, and DsbD) have been

constructed [34, 35]. The periplasmic protein folding can be

improved simply by adding L-arginine [36] or a reducing

thiol reagent such as reduced glutathione [27].

Solubility of an insoluble polypeptide can be increased

by expressing a highly soluble partner such as maltose-

binding protein, glutathione S-transferase (GST), or thiore-

doxin [37]. Probability of protein solubility was calculated

based on the amino residues constituting the protein, and

aggregate-prone human interleukin-3 (hIL-3) was expressed

substantially in the soluble form when fused with NusA,

GrpE, YjgD-YjgD, or BFR [38]. Fusion expression systems

have been devised using the omega leader sequence of

tobacco mosaic virus [39], a lysyl tRNA synthetase [40], and

a domain of p26, SicA, or alpha crystalline type proteins

[41].

A method for monitoring folding and solubility of target

proteins in the periplasm has been devised using a reporter

gene. EP000001407052B1 [42] reported an on-line method

based on the promoter of the major periplasmic protease

DegP fused to the luciferase gene. WO002008089132A2

26 Recent Patents on Biotechnology 2010, Vol. 4, No. 1

Yoon et al.

[43] describes TEM-I -lactamase secreted through the SRP

dependent pathway. The N-terminal signal sequence from

proteins which can be recognized by the SRP dependent

pathway (e.g. DsbA, TotT, SfmC, TolB, YraI, CcmH, FocC,

NikA, and FlgI) was fused to the target protein sequence,

where -lactamase was attached as a reporter. These

monitoring methods would be useful in screening of protein

variants that fold correctly in the periplasm.

2.2. Coexpression of Proteins Involved in the Secretion

Pathways

If translocation into the periplasm is a rate-determining

step, coexpression of proteins involved in membrane

transport can be considered. The type II secretion pathway is

mostly used for industrial secretory production. As for Sec-

dependent secretion, SecY and/or SecE of E. coli were

overexpressed for enhancing the secretory production of

interleukin 6 (IL-6) [44]. In US5824502A [45], various

plasmids containing one or two sec genes (secB, secD/F,

secG and secE/Y) and the human growth hormone (hGH)

gene were constructed and transformed into various E. coli

strains. The accumulation of hGH in the periplasm varied

depending on the selection of the sec gene and the host

strain, and was affected by the expression level of sec.

Secretion pathways other than type II secretion can be

used for the production of heterologous proteins, too.

Although transport via the Tat pathway is less efficient and

slower than the Sec pathway, it has an outstanding feature of

transporting fully-folded cytosolic proteins through the

cytosolic membrane [46]. The Tat pathway can be used for

secreting proteins which fold slowly or incorrectly in the

periplasm and are often degraded before being getting

secreted into the medium. Weiner and coworkers reported a

paper and applied a patent on proteins which are involved in

the Tat pathway of E. coli and are encoded by the mttABC

operon [47,48]. Later, the mttA gene was found to be two

genes and the operon was renamed as tatABCD [49]. A

functional Tat pathway was also identified in Gram-positive

Bacillus subtilis, and expression of Bacillus tat genes was

required for the secretion of a Bacillus protein in E. coli [50].

Secretory production of the lipase or the protease of

Pseudomonas fluorescens in E. coli was accomplished by

expressing an ABC transporter gene cluster from P.

fluorescens [51]. E. coli harboring the type III secretion gene

(hrp) cluster of Erwinia chryanthemi was constructed for

expression of foreign proteins [52]. The strain also can be

used to screen effector proteins of the type III pathway

which are potential virulence factors of bacterial pathogens.

On the other hand, the oligopeptide permease (opp)

operon or the dipeptide permease (dpp) operon has been

disrupted to reduce the peptide uptake rate, ending up with

increased peptide secretion [53].

2.3. Coexpression of Carrier Proteins

Proteins directing the secretion of target proteins to the

periplasm or culture media can be used. Fusion system was

disclosed for the YebF putative lipoprotein [54], MalE [55],

and HlyA [56]. US000007202059B2 [57] discloses an

expression vector consisting of sequences for, in order,

hirudin, arginine, and the target protein. Hirudin drives the

target protein into the media and the fusion protein is cleaved

off at the arginine site by digestion with trypsin. The

secretion capacity can be further improved by adding a

signal peptide.

With the observation of a large accumulation of outer

membrane porin (OmpF) in culture media during high cell

density cultivation of E. coli BL21(DE3) [58], OmpF was

fused with the N-terminal region of

-endorphin [59].

Recently, an expression system in which OmpF is co-

expressed, but not fused to the target protein, was developed

and used for the production of epithelial cell growth factor

(EGF) and human leptin in a pure form [60]. Spy, a small

periplasmic protein having no cysteine residue can be used

as a carrier protein [61]. Oftentimes, the carrier protein

enables an affinity purification of the fusion protein.

3. IMPROVEMENT OF PERIPLASMIC RELEASE

Proteins accumulated in the periplasm can be made

secreted into the culture media through various strategies [3].

An apparatus and a method for subjecting cells to osmotic

shock were devised [62]. Leaky strains which are defective

in the outer membrane were constructed by introducing a

mutation in the coding region or in the promoter of the outer

membrane lipoprotein gene (lpp) [63]. Using various

mutants of omp, tol, excD, excC, lpp, env, and lky, full-

length antibodies were released to the culture media [64].

Along with a knock-out strategy, a membrane opening

system can be made by expression of the bacteriocin release

protein gene (kil). High expression of the kil gene causes cell

lysis, and thus, regulating the expression level and the

induction time is important. In the production of strepto-

kinase which is derived from Streptococcus equisimilis and

used in the treatment of heart diseases, bacteriocin release

protein (BRP) was induced to form permeable zones in the

cell envelope [65]. The kil gene was fused with a stationary

phase promoter and the target

-glucanase was released into

the surrounding media [66]. However, in general, those

leaky strains do not provide robustness enough for high-

density cultivation.

4. PROTECTION OF TARGET PROTEINS FROM

DEGRADATION AND CONTAMINATION

Preventing target proteins from degradation and conta-

mination can make the purification process much easier.

Protease-deficient cells are particularly suitable for the

production of proteolytically sensitive proteins. Georgiou et

al. [67] constructed many hosts deficient in ptr coding for

protease III, degP (periplasmic serine protease, HtrA), ompT

(outer membrane protease), and/or prc (periplasmic protease)

combined with the rpoH (heat shock sigma factor) mutation,

which resulted in a significantly increased yield in the

production of proteolytically sensitive peptides. Multiple

deletion mutations in the HslVU protease genes (hslVU) and

major ATP-dependent proteases genes of E. coli (clpPX and

lon) were constructed [68]. Gene and putative genes

encoding aminoamidases that cleave N-terminal amino acid

residues from some recombinant proteins such as human

growth hormone were all eliminated from the chromosome

[69]. To compensate for the growth and stability of the cells,

Secretory Production in E. coli

Recent Patents on Biotechnology 2010, Vol. 4, No. 1 27

the spr gene whose product suppresses cell growth exhibited

by prc mutants was further mutated [70].

To enhance the degree of purity of the produced proteins,

host proteins to be secreted to the culture media (OppA,

DppA, YddS, FliC, PhoA, and PhoS) were identified and the

coding genes were deleted from the host chromosome [71].

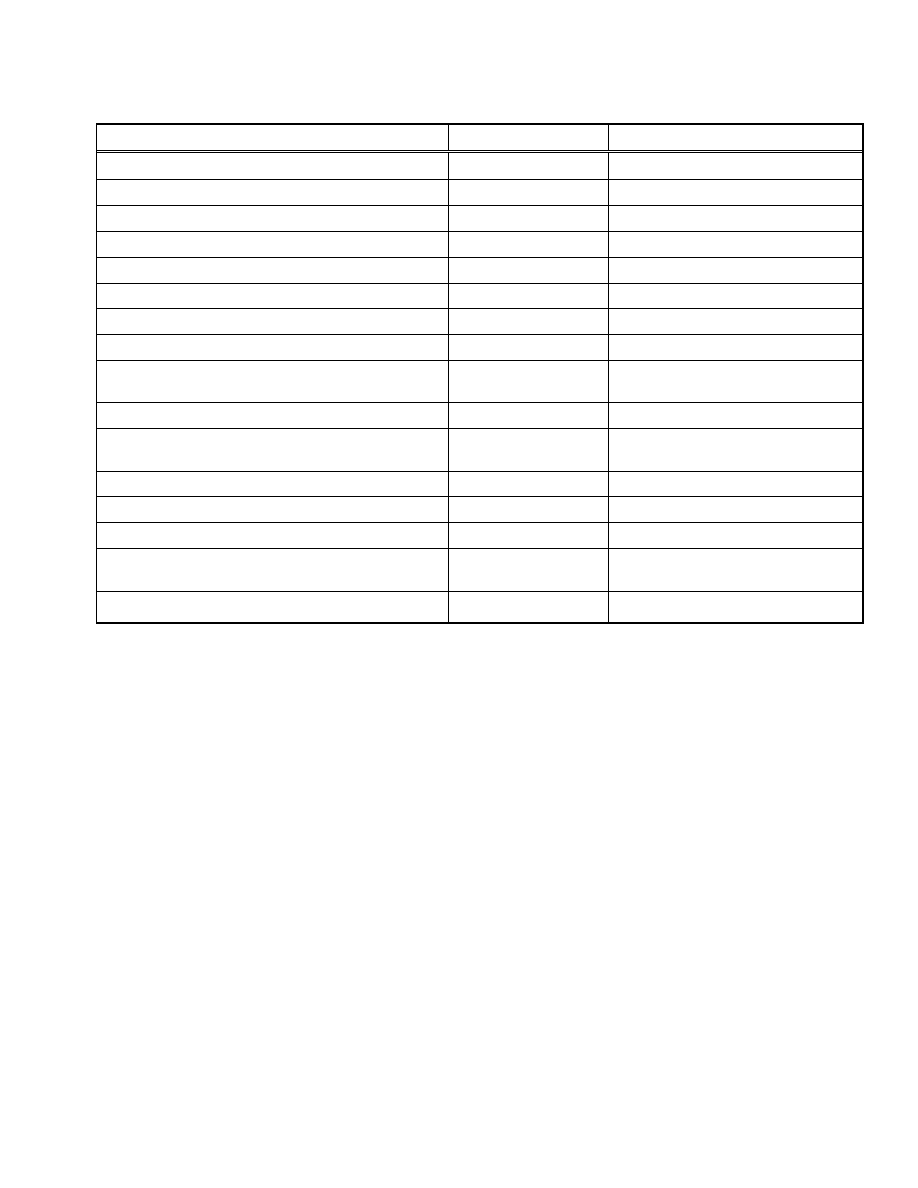

5. CURRENT & FUTURE DEVELOPMENTS

Past decades have witnessed remarkable advances in

understanding the membrane transport mechanism and

secretory production of foreign proteins using E. coli. A

number of aforementioned patents are now available in com-

mercially marketed systems (Table 1). However, industrial

application has been fraught with technical challenges. An

optimum signal peptide should be found by trial and error

because secretion efficiency largely depends on the

combination of the signal peptide, the target protein, and the

host strain, which is hard to predict. Coexpression of the

helper proteins can cause a severe metabolic burden to the

host cell and reduce the capacity to hold target proteins. In

addition, current understanding of function and regulation of

heat shock proteins is far from complete due to their comple-

xity. There remains to be issues regarding coordinated

activities of chaperones and proteases that supervise protein

folding and degradation, regulation of rpoH primarily at the

translational level, and possibility of the existence of another

protease [72]. Genetic mutations are normally accompanied

by growth defects, making such host strains of little

commercial value.

Traditional biotechnology based on the case-by-case

approach is turning into “systems biotechnology” which can

develop an efficient industrial process based on compu-

tational modeling and simulation that utilize high-throughput

omics data [73]. This transition is being accelerated by rapid

development of genome engineering tools [74] and synthetic

genomics. Recently, the genome sequence of BL21(DE3),

the most popular E. coli strain as an industrial host, along

with those of two BL21(DE3) derivatives and REL606

another B strain used in a long-term evolution experiment

have been determined and their omics based systems study

has begun [75-77]. Such advances will make it possible to

have the E. coli bioengine customized to secrete correctly

folded recombinant proteins into the culture medium in high

yield.

ACKNOWLEDGEMENTS

We thank Soon-Kyeong Kwon and Choong Hoon Lee for

critical reading of the manuscript. This work was financially

supported by the KRIBB Research Initiative Program and

the 21C Frontier Microbial Genomics and Applications

Center Program, Ministry of Science and Technology,

Republic of Korea.

Table 1.

Examples of Commercialized Protein Secretion Systems

Feature Company

Product

Sec, SRP, TAT pathway signal sequence

AthenaES

®

The

ACES

TM

Signal Sequence Kit

Sec pathway signal sequence (PelB)

Progen

pOPE 101 vector

Sec pathway signal sequence (PelB, OmpT)

Novagen

®

pET-12, 20, 22, 25, 26, 27 vectors

Sec pathway signal sequence (OmpA)

IBA

pASK-IBA2, 4, 6, 12, 14, 16, 32, 44 vectors

Sec pathway signal sequence (OmpA)

SIGMA

pFLAG-ATS

TM

, pFLAG-CTS

TM

vector

Leader peptide from the bacteriophage fd gene III protein (gIII)

Invitrogen

pBAD/gIII vector

Coexpression of chaperone proteins

TAKARA BIO INC.

Chaperone Plasmid Set

Enhanced cytoplasmic disulfide formation (trxB, gor mutant strain)

Novagen

®

Orgami

TM

, Orgami B series

Enhanced cytoplasmic disulfide formation (trxB, gor, ahpC mutant

and DsbC expression strain)

NEW ENGLAND BioLabs

®

INC.

SHuffle

TM

strains

Enhanced disulfide formation fusion (DsbA, DsbC)

Novagen

®

pET-39, 40 vectors

Soluble protein fusion (MBP)

NEW ENGLAND BioLabs

®

INC.

pMAL

TM

Protein Fusion and Purification System

Soluble protein fusion (Trx, GST, NusA)

Novagen

®

pET-32, 41, 42, 43.1 vectors

Soluble protein fusion (GST)

GE Healthcare

pGEX vectors

Carrier protein fusion (YebF)

AthenaES

®

The

ACES

TM

YebF Protein Export Kit

Carrier protein fusion (MBP fused with M13 pIII leader sequence)

NEW ENGLAND BioLabs

®

INC.

pMal-pIII vector

Enhanced secretion (Modified outer membrane strain)

Wacker Chemie AG

The WACKER secretion system

28 Recent Patents on Biotechnology 2010, Vol. 4, No. 1

Yoon et al.

CONFLICT OF INTEREST

The authors have no conflict of interest to declare.

REFERENCES

[1]

Choi JH, Keum KC, Lee SY. Production of recombinant proteins

by high cell density culture of Escherichia coli. Chem Eng Sci

2006; 61: 876-885.

[2]

Choi JH, Lee SY. Secretory and extracellular production of

recombinant proteins using Escherichia coli. Appl Microbiol

Biotechnol 2004; 64: 625-635.

[3]

Mergulhao FJ, Summers DK, Monteiro GA. Recombinant protein

secretion in Escherichia coli. Biotechnol Adv 2005; 23: 177-202.

[4]

Francetic O, Belin D, Badaut C, Pugsley AP. Expression of the

endogenous type II secretion pathway in Escherichia coli leads to

chitinase secretion. EMBO J 2000; 19: 6697-6703.

[5]

Thanassi DG, Hultgren SJ. Multiple pathways allow protein

secretion across the bacterial outer membrane. Curr Opin Cell Biol

2000; 12: 420-430.

[6]

van der Does C, Nouwen N, Driessen AJM. The SEC translocase.

Protein Secretion Pathways in Bacteria. In: Oudega B, Ed. Springer

USA 2003; 23-50.

[7]

Bendtsen JD, Nielsen H, Von Heijne G, Brunak S. Improved

prediction of signal peptides: SignalP 3.0. J Mol Biol 2004;

340:783-795.

[8]

Gray, J., Buechler, J., Veeramallu, U.K.: US20067094579B2

(2006).

[9]

Ostendorp, R., Popp, A., Fischer, M.: WO2009021548A1 (2009).

[10]

Humphreys, D.P.: EP1402036B1 (2004).

[11]

Lee, S.Y., Jeong, K.J.: US20067070989B2 (2006).

[12]

Coleman, R.J., Retallack, D., Schneider, J.C., Ramseier, T.M.,

Hershberger, C.D., Lee, S., Resnick, S.M.: US20080193974A1

(2008).

[13]

Andersson H, Von Heijne G. A 30-residue-long "export initiation

domain" adjacent to the signal sequence is critical for protein

translocation across the inner membrane of Escherichia coli. Proc

Natl Acad Sci USA 1991; 88: 9751-9754.

[14]

Hikita C, Mizushima S. Effects of total hydrophobicity and length

of the hydrophobic domain of a signal peptide on in vitro

translocation efficiency. J Biol Chem 1992; 267: 4882-4888.

[15]

Kwon, S.C., Jung, S.Y., Choi, K.D., Kim, C.S., Bae, S.M., Lee,

G.S.: US20067052867B2 (2006).

[16]

Kwon, S.C., Jung, S.Y., Shin, H., Choi, J.D., Choi, K.D., Lee, G.S.:

US20036605697B1 (2003).

[17]

Chen, T.-H.T., Schmidt, B.: EP1290197B1 (2003).

[18]

Meng, S.-Y., Morris, C.F., Tsai, L.B.: US5470719A (1995).

[19]

Inouye, S.: US20070287171A1 (2007).

[20]

Lee, S.J., Kim, Y.O., Nam, B.H.: US20090011995A1 (2009).

[21] Leonhartsberger, S., Candussio, A., Schmid, G.:

US20080076157A1 (2008).

[22]

Cannon, J.P., Haire, R.N., Litman, G.W.: US20067112434B2

(2006).

[23]

Kane JF, Hartley DL. Formation of recombinant protein inclusion

bodies in Escherichia coli. Trends Biotechnol 1988; 6: 95-101.

[24]

Chung BH, Choi YJ, Yoon SH, Lee SY, Lee YI. Process

development for production of recombinant human insulin-like

growth factor-I in Escherichia coli. J Ind Microbiol Biotechnol

2000; 24: 94-99.

[25]

Perez-Perez J, Martinez-Caja C, Barbero JL, Gutierrez J.

DNAK/DNAJ supplementation improves the periplasmic produc-

tion of human granulocyte-colony stimulating factor in Escherichia

coli. Biochem Biophys Res Commun 1995; 210: 524-529.

[26]

Korpela, T., Macintyreayane, S., Zavialov, A., Battchikova, N.,

Petrovskaya, L., Zav'yalov, V., Korobko, G.P.: US20056919198B1

(2005).

[27]

Ambrosius, D., Rudolph, R., Schaeffner, J., Schwarz, E.:

US026455279B1 (2002).

[28]

Lee, S.Y., Han, M.J., Park, S.J.: US20077291325B2 (2007).

[29]

Rietsch A, Beckwith J. The genetics of disulfide bond metabolism.

Annu Rev Genet 1998; 32: 163-184.

[30]

Stewart EJ, Aslund F, Beckwith J. Disulfide bond formation in the

Escherichia coli cytoplasm: an in vivo role reversal for the

thioredoxins. EMBO J 1998; 17: 5543-5550.

[31]

Beckwith, J., Aslund, F., Bessette, P.H., Georgiou, G., Ritz, D.,

Lim, J.E.-A.: US20087410788B2 (2008).

[32]

Georgiou, G., Oiu, J., Bessette, P., Swartz, J.: US006083715A

(2000).

[33]

Udaka, S., Sato, S., Kudo, T., Oka, S., Higashikuni, N., Kondo, M.:

EP1270730A1 (2003).

[34]

Joly, J.C., Swartz, J.R.: EP786009B1 (1997).

[35]

Kurokawa, Y., Yanagi, H., Yura, T.: US20046673569B1 (2004).

[36]

Ambrosius, D., Rudolph, R., Schaeffner, J., Schwarz, E.:

US016309861B1 (2001).

[37]

Kapust RB, Waugh DS. Escherichia coli maltose-binding protein is

uncommonly effective at promoting the solubility of polypeptides

to which it is fused. Protein Sci 1999; 8: 1668-1674.

[38]

Harrison, R.G., Davis, G.D.: US5989868A (1999).

[39]

Hua, Z., Zhang, H.: US20067056732B2 (2006).

[40]

Choi, S.I., Seong, B.L.: US20056852512B2 (2005).

[41]

Sanders, M.C.: US20056861403B2 (2005).

[42]

Horn, U., Strittmatter, W., Riesenberg, U.: EP1407052B1 (2004).

[43]

Delisa, M.P., Mansell, T.J., Fisher, A.C.: WO2008089132A2

(2008).

[44]

Perez-Perez J, Marquez G, Barbero JL, Gutierrez J. Increasing the

efficiency of protein export in Escherichia coli. Biotechnology

1994; 12: 178-180.

[45]

Honjo, M., Naito, N., Uchida, H.: US5824502A (1998).

[46]

Bruser T. The twin-arginine translocation system and its capability

for protein secretion in biotechnological protein production. Appl

Microbiol Biotechnol 2007; 76: 35-45.

[47]

Weiner JH, Bilous PT, Shaw GM, et al. A novel and ubiquitous

system for membrane targeting and secretion of cofactor-

containing proteins. Cell 1998; 93: 93-101.

[48]

Weiner, J.H., Turner, R.J.: EP1068339B1 (2001).

[49]

Sargent F, Bogsch EG, Stanley NR, et al. Overlapping functions of

components of a bacterial Sec-independent protein export pathway.

EMBO J 1998; 17: 3640-3650.

[50]

Bron, S., Jongbloed, J.D.H., Muller, J., Van Dijl, J.M.:

US20080166757A1 (2008).

[51]

Rhee, J.S., Pan, J.G., Ahn, J.H.: US016329172B1 (2001).

[52]

Bauer, D.W., Beer, S.V., Bogdanove, A.J., Collmer, A., Ham, J.H.:

US036596509B1 (2003).

[53]

Diaz-torres, M.R.: US20036642027B2 (2003).

[54]

Weiner, J.H., Zhang, G.: WO2006017929A1 (2006).

[55]

Lubitz, W., Resch, S.: US20036596510B1 (2003).

[56]

De Lorenzo, P.V., Fernandez Herrero, L.A.: US20080280346A1

(2008).

[57]

Habermann, P., Ertl, J.: US20077202059B2 (2007).

[58]

Jeong KJ, Lee SY. Excretion of human beta-endorphin into culture

medium by using outer membrane protein F as a fusion partner in

recombinant Escherichia coli. Appl Environ Microbiol 2002;

68:4979-4985.

[59]

Lee, S.Y., Jeong, K.J.: US20097491528B2 (2009).

[60]

Lee, S.Y., Choi, J.H.: US20080206814A1 (2008).

[61] Schloesser, T., Dassler, T., Pfeiffer-Schwiesow, K.:

US20080166764A1 (2008).

[62]

Patkar, A.Y., Sen, S., Chappell, M.L.: US20080182295A1 (2008).

[63]

Dassler, T., Wich, G., Schmid, G.: US20080254511A1 (2008).

[64]

Wich, G., Dassler, T.: US20080206818A1 (2008).

[65]

Kuppusamy, M., Srinivas, V.K., Lahiri, S., Ella, K., Khatri, G.S.:

US20067105327B1 (2006).

[66]

Miksch, G., Flaschel, E., Breves, R., Maurer, K.-H., Kleist, S.:

US20040005695A1 (2004).

[67]

Georgiou, G., Baneyx, F.: US5508192A (1996).

[68]

Georgiou, G., Baneyx, F.: EP866132A2 (1996).

[69]

Joly, J.C.: US6921659B2 (2005).

[70]

Chen, C.Y.-C.: US6828121B2 (2004).

[71]

Leonhartsberger, S., Wich, G.: US20080064062A1 (2008).

[72] Bross

CA.

Escherichia coli and Salmonella typhimurium cellular

and molecular biology. In: Neidhardt FC, Ed. ASM Press: USA

1996; 1382-1399.

[73]

Lee SY, Lee DY, Kim TY. Systems biotechnology for strain

improvement. Trends Biotechnol 2005; 23: 349-358.

Secretory Production in E. coli

Recent Patents on Biotechnology 2010, Vol. 4, No. 1 29

[74]

Blattner, F.R., Posfai, G., Herring, C.D., Plunkett III, G., Glasner,

J.D.: US20060270043A1 (2006).

[75]

Yoon SH, Jeong H, Kwon SK, Kim JF. Genomics, biological

features, and biotechnological applications of Escherichia coli B:

“Is B for better?!” Systems biology and biotechnology of E. coli.

In: Lee SY, Ed.: Springer: USA 2009; 1-17.

[76]

Jeong H, Barbe V, Lee CH, et al. Genome sequences of

Escherichia coli B strains REL606 and BL21(DE3). J Mol Biol

2009; 394: (in press) doi:101016/j.jmb.2009.09.052.

[77]

Yoon SH, Han MJ, Jeong H, et al. Comparative multi-omics

systems analysis of closely related Escherichia coli strains.

submitted.

Wyszukiwarka

Podobne podstrony:

Production of recombinant proteins in E coli

Solube expression of recombinant proteins in the cytoplasma of E coli

Method for enhancing solubility of the expressed recombinant protein in E coli

(gardening) Production of Therapeutic Proteins in Plants

Tuning different expression parametres to achive solube recombinant proteins in E coli

Expression of correctly folded proteins in E coli

Making recombinant proteins in animals

Refolding of recombinant protein

Rapid and efficient purification and refolding of a (His) tagged recombinant protein produced in E c

Advanced genetic strategies for recombinant protein expression in E coli

Producing proteins in transgenic plants and animals

Strategies to maximize heterologous protein expression in E coli

Formation of active inclusion bodies in E coli

Molecular chaperones involved in heterologous protein expression in E coli

Strategies for optimizing heterologous protein expression in E coli

An analysis of energy efficiency in the production of oilseed crops

Wiktorek Smagur, Aneta i inni Green Way of Biomedicine – How to Force Plants to Produce New Importa

LIST OF COLORANTS ALLOWED IN COSMETIC PRODUCTS

Production of benzaldehyde, a case study in a possible industrial application of phase transfer cata

więcej podobnych podstron