Combustion, Explosion, and Shock Waves, Vol. 37, No. 1, pp. 99–105, 2001

Approximate Method for Calculating the Impact Sensitivity

Indices of Solid Explosive Mixtures

UDC 662.215.4

A. V. Dubovik

1

Translated from Fizika Goreniya i Vzryva, Vol. 37, No. 1, pp. 112–119, January–February, 2001.

Original article submitted September 22, 1999.

An approximate method is proposed to calculate the impact sensitivity indices (critical

initiation pressure and critical charge thickness) for solid explosive mixtures (explo-

sive compositions and mixtures of an oxidizer with a fuel). The calculation is based

on some model concepts of the physicochemical and explosive properties of reactive

mixtures. Test calculations of the sensitivity indices were performed for mixtures of

HMX and TNT and mixtures of ammonium perchlorate with polymethylmethacrylate

(PMMA) and TNT, and the results are compared with data of laboratory experiments

on an impactor.

Calculations of the sensitivity indices of solid ex-

plosive mixtures (SEM) are required to substantiate

the previously proposed mechanisms of initiation of

explosive systems and to predict the sensitivity level

for new mixed compositions.

1. MIXTURES OF SOLID EXPLOSIVES

A rather simple method for calculating the sensi-

tivity indices of individual solid high explosives (HE)

was developed in [1]. This method gives sufficiently

accurate (

±6%) estimates of the critical initiation

pressure p

cr

and the critical charge thickness h

cr

for

HE tested for impact sensitivity by the critical stress

method [2]. For calculations, it is necessary to have

reliable information on a complex of physicochemi-

cal and explosive characteristics, including the den-

sity ρ, the specific heat c

p

, the melting point T

m

, the

piezoelectric coefficient of the melting point β, the

compression strength of the HE charge σ, the heat

of explosion Q, the activation energy of thermal de-

composition E, and the preexponent Z. According

to [1], it is assumed that the stiffness of the load-

ing system of the impact testing machine (impactor

and roller device) ensures a typical time of charge

collapse during which explosion occurs under critical

impact conditions, t

0

= 11.3 µsec. Calculation re-

1

Semenov Institute of Chemical Physics,

Russian Academy of Sciences, Moscow 117977.

duce to solution of the transcendental equation for

the parameter x = (T

m

− T

0

+ βp

m

)/T

0

:

A

x + 1

= B

− ln x,

A =

E

RT

0

,

B = ln

QZt

0

c

p

T

0

.

Here T

0

is the initial temperature,

R is the gas

constant, and p

m

= σ(1 + 2.4(p

cr

/σ

− 1)). The

quantity h

cr

is calculated from the formula h

cr

=

0.385R(p

cr

/σ

− 1), where R is the radius of the im-

pactor.

The method of [1] can be used to calculate the

sensitivity indices for SEM, which, as solid explosives,

explode under fast (brittle) fracture of the charge,

i.e., do not undergo marked viscoplastic or hyperelas-

tic deformation upon impact. Among such SEM are

primarily mechanical mixtures of solid explosives and

solid mixed compositions of the oxidizer–fuel type.

However, particular calculations of the sensitiv-

ity indices of SEM involve serious difficulties due to

the lack of necessary information on the physico-

chemical and explosive characteristics for the major-

ity of such mixtures. Some of these characteristics,

such as ρ, c

p

, and Q, can be calculated from well-

known formulas or simple additive relations using the

composition of the mixture. For the other character-

istics, there are no ready formulas or these charac-

teristics are meaningless in the case of mixtures (for

example, E, Z, and T

m

).

From the aforesaid it becomes obvious that even

approximate information on the physicochemical and

explosive characteristics of SEM can be obtained only

0010-5082/01/3701-0099 $25.00 c

2001

Plenum Publishing Corporation

99

100

Dubovik

using some model concepts on the behavior of mix-

tures upon impact.

It is not necessary that the

model of this or that characteristic of SEM be rather

plausible.

Before detailed theoretical studies, one

can restrict oneself to calculations using approximate

models for the sensitivity indices of SEM, whose re-

sults agree with available experimental data. Models

for the physicochemical and explosive characteristics

of SEM and calculations of sensitivity indices using

these models are considered below.

1.1. Strength of SEM Charges. Processing

of a great body of data on the impact strength of

solid HE obtained by the critical stress method [2]

gives a linear dependence of the quantity σ on the

modulus of bulk compression K = ρc

2

, where c is the

volume speed of sound in the HE material, which is

calculated from the structural formula of substances

by the Rao rule [3]:

σ [MPa] = a

0

+ aK.

(1)

Here a

0

=

−1.45 MPa and a = 0.007. The coeffi-

cient of correlation between the parameters is 0.93.

Because the value of the free term in Eq. (1) is com-

parable to the errors in experimental determination

σ and calculation K, we assume that σ = aK.

We estimate the strength of a mixed composi-

tion. The specific volume of an n-component mixture

is given by the additive relation

V =

X

α

i

V

i

(i = 1, 2, . . . , n),

(2)

where V

i

= 1/ρ

i

is the specific volume of the ith

component and α

i

is the mass content (

P α

i

= 1).

Here and below, the sign

P denotes summation over

all i from 1 to n. Differentiating (2) with respect

to the pressure p, which is considered equal over

the entire mixture, and taking into account that

V

2

i

(dp/dV

i

) =

−c

2

i

(c

i

is the volume speed of sound

in the ith component of the mixture), we obtain

K = V

. X

α

i

V

i

K

−1

i

.

(3)

Substituting V from Eq. (2) into Eq. (3) and assum-

ing that σ

i

= aK

i

, we obtain the following formula

for the strength of the mixture:

σ =

X

α

i

V

i

. X

α

i

V

i

σ

−1

i

= 1

. X

γ

i

σ

−1

i

.

(4)

Here γ

i

= α

i

V

i

/V is the volume content of the ith

component of the mixture.

In tests of impact sensitivity of HE using the

critical stress method [2] to determine the strength

of a charge, a thin layer of the tested material is

pressed under a rather high pressure (to 0.5 GPa).

But because of the poor compressibility of thin layers,

the strength of the HE charges produced is several

(from 10 and more) percent lower than the maximum

value calculated from (2). The decreased density of

the charges cannot be explained only by the presence

of air inclusions between the HE crystals. We assume

that the intercrystalline space is filled with fine par-

ticles — the products resulting from fracture of the

surface layers of the crystals during pressing. We as-

sume that the conglomerate of these dusty particles

is the (n + 1)th independent component of the SEM

charge and its volume content is Π = 1

−

P γ

i

> 0

and strength is σ

0

.

With allowance for the new component of the

mixture, (4) is written as

σ =

(1

− Π)

P α

i

V

i

/σ

i

P α

i

V

i

+

Π

σ

0

−1

.

(5)

The product σ

i

r

i

is called the mechanical stiff-

ness of crystals of size r

i

.

We assume that r

0

=

P α

i

r

i

is the typical size of gaps between the crystals,

and, by analogy with Eq. (3), we write the follow-

ing expression for the stiffness of the intercrystalline

medium:

(σ

0

r

0

)

−1

=

X

α

i

(σ

i

r

i

)

−1

.

(6)

Substituting (6) into (5), we obtain the final formula

for the strength of a SEM charge. In the case of a

binary (n = 2) mixture, it is written as

σ

σ

1

=

R

1

(1

− Π)(1 + R

2

(1 + b))

(7)

b =

Π(1

− α)R

1

R

3

R

4

(1

− Π)R

2

,

where R

1

= 1 + αρ

1

/(1

− α)ρ

2

, R

2

= αρ

1

σ

1

/(1

−

α)ρ

2

σ

2

, R

3

= 1 + αr

1

σ

1

/(1

− α)r

2

σ

2

, R

4

= 1 +

αr

2

/(1

− α)r

1

, σ

1

is the strength of the 1st com-

ponent, and α is the content of the 2nd component

of the mixture. From (7) it follows that σ

→ σ

1

as

α

→ 0 and σ → σ

2

as α

→ 1 for all Π. If the charge is

pressed to the maximum density (Π = 0), Eq. (7) be-

comes Eq. (4). A comparison of Eq. (7) and Eq. (4)

shows that in (7) the quantity b > 0 plays the role

of an adjusting parameter for the main formula (4).

Its role is minor if the particles of the mixture com-

ponents have approximately identical sizes (r

1

≈ r

2

),

but it increases markedly when r

1

r

2

or r

1

r

2

.

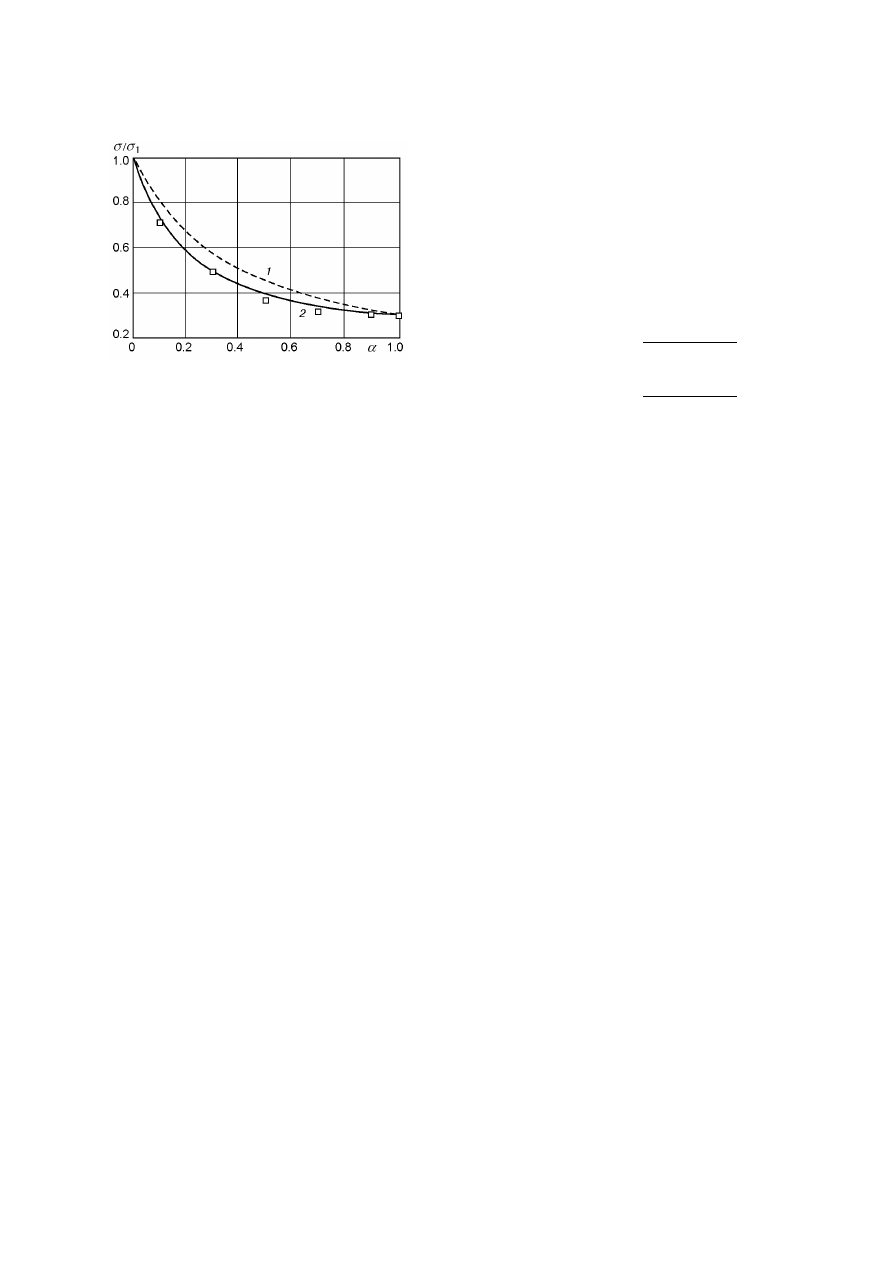

Figure 1 shows values of σ calculated from

Eq. (7) versus α for a mixture of HMX (here and

below indicated by subscript 1) and TNT (subscript

2) for r

1

= 4 µm, r

2

= 70 µm, ρ

1

= 1900 kg/m

3

,

ρ

2

= 1630 kg/m

3

, σ

1

= 130 MPa, and σ

2

= 40 MPa.

Points show the experimental data of [4].

Good

agreement between the theory and experiment is ob-

tained for Π = 0.1. Figure 1 also shows the depen-

dence σ(α) calculated from (4) for charges with ideal

continuity (Π = 0).

Calculating the Impact Sensitivity Indices of Solid Explosive Mixtures

101

Fig. 1. Ultimate strength of an HMX–TNT mixture

depending on the content of a TNT: curves 1 and 2 re-

fer to calculations on Eq. (4) and Eq. (7), respectively;

points refer to experimental data of [4].

1.2.

Chemical-Kinetic Characteristics of

SEM. The kinetic characteristics of HE imply data

from calorimetric studies of the specific (per unit

volume) heat-release rate, which, according to the

Arrhenius law, is determined by the activation en-

ergy E and the preexponent Z.

Considering that

the reactivities of the mixture components are simi-

lar, it is assumed with reasonable accuracy that the

rate of decomposition of the mixture is equal to the

rate of decomposition of each component, and, hence,

the kinetic characteristics of the components approx-

imately coincide and any pair of their values (E

i

, Z

i

)

can be chosen as a kinetic characteristic of SEM.

Difficulties arise when the mixture components

have different thermal stability. In this case, each

of the components decomposes with maximum heat-

release rate in a particular temperature range, and a

unique set of kinetic characteristics of SEM does not

exist. In practice, however, especially if one needs

only an averaged (over temperature) estimate of the

thermal stability of SEM, one uses some gross values

of the parameters E and Z, which are presumably

related to values of E

i

and Z

i

under a particular law.

Indeed, if the content of all components is much lower

than the content of the 1st component, the parame-

ters E and Z of the mixture are approximately char-

acterized by values of E

1

and Z

1

. A similar situation

is also observed when the mixture is dominated by

the 2nd component, etc.

Developing this model for the thermal decompo-

sition of SEM, we assume that as the composition of

the mixture changes gradually, there is a more or less

smooth transition from one mechanism of thermal de-

composition, typical of the predominance of the 1st

component in the mixture, to the mechanism of ther-

mal decomposition of the 2nd component, etc. In the

case of a binary mixture, one can use the following

formulas, in which the gross values of the activation

parameters for the thermal decomposition of the mix-

ture are related to the corresponding parameters of

the individual components:

E(α) = E

1

+ (E

2

− E

1

)/f

E

(α),

(8)

Z(α) = Z

1

+ (Z

2

− Z

1

)/f

Z

(α),

where

f

E

(α) = 1 + C

1

exp

C

2

(1

− α/α

th

)

α(1

− α)

,

f

Z

(α) = 1 + C

3

exp

C

4

(1

− α/α

th

)

α(1

− α)

.

It is easy to see that in the extreme cases α = 0

and α = 1, Eqs. (8) give the activation character-

istics of individual components. At the same time,

they adequately describe the thermal decomposition

of an explosive mixture if one properly choose the

parameters C

1

–C

4

, which describe the smoothness of

the transition from the first thermal-decomposition

mechanism to the second. The parameter α

th

is the

content of the 2nd component near which the indi-

cated transition occurs.

Equations (8) imply that none of the mixture

components is an inert material. In the extreme case,

it can be subjected to pyrolysis, whose mechanism is

also described by a set of some parameters (E and

Z). Unfortunately, there is no adequate method for

a priori estimation of the quantity α

th

. One can only

state that if the mixture components differ strongly

by thermal stability, then α

th

→ 0 or α

th

→ 1. If all

components make identical contributions to the total

rate of heat release due to thermal decomposition of

the mixture, then α

th

≈ 0.5.

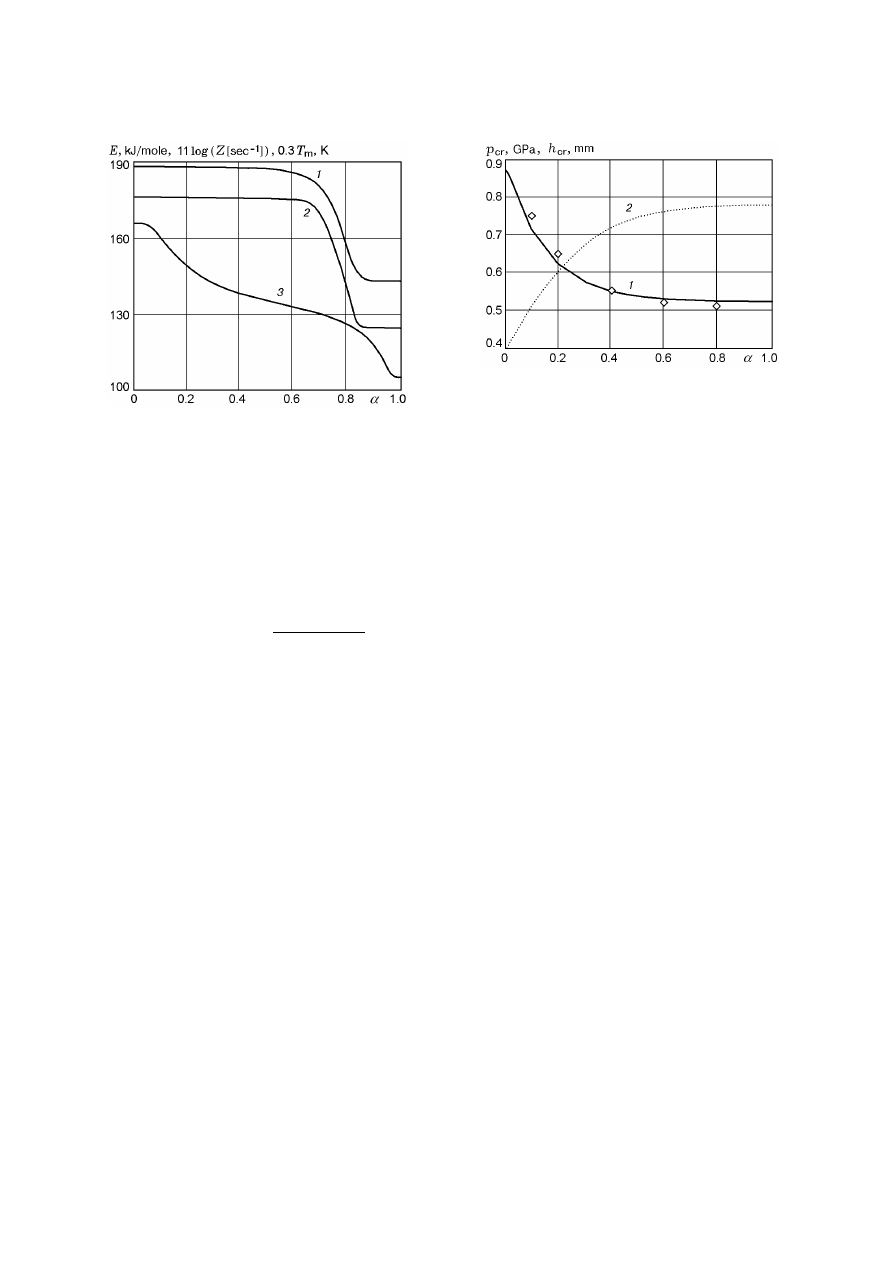

Figure 2 give curves of E(α) and Z(α) calcu-

lated from (8) for an HMX–TNT mixture. They are

obtained for E

1

= 188 kJ/mole, E

2

= 144 kJ/mole,

Z

1

= 10

16

sec

−1

, and Z

2

= 10

11.4

sec

−1

(see [1])

and the following values of the constants: C

1

= 6,

C

2

= 2.7, C

3

= 0.6, C

4

= 7, and α

th

= 0.7. It

is possible to distinguish two typical “zones of influ-

ence” of the components: 0 6 α 6 α

th

for HMX and

α

th

6 α 6 1 for TNT.

1.3. “Melting Point” of the Mixture (T

m

).

The methodical difficulties encountered in Sec. 1.2 in-

crease further in determining the “melting point” of

the mixture T

m

, which implies a certain thermody-

namic characteristic that determines the mechanical

strength of the mixture σ [4]. Taking into account

some similarity between the processes of thermal de-

composition and melting of SEM crystals (initiation

at surface defects, kinetic regime with typical values

102

Dubovik

Fig. 2. Activation energy (1), preexponent (2), and

melting point (3) for an HMX–TNT mixture versus

the TNT content.

of the activation parameters, etc.), we shall arbitrar-

ily describe the quantity T

m

, as a function of the

composition of the mixture, α by formulas similar

to (8) but having different constants C

5

and C

6

and

with transition parameter α

tr

:

T

m

(α) = T

m,1

+ (T

m,2

− T

m,1

)/f

th

(α),

f

th

(α) = 1 + C

5

exp

C

6

(1

− α/α

tr

)

α(1

− α)

.

We note that the quantity T

m

plays no part in cal-

culations of the critical parameters of initiation of

SEM because it enters only as a nonprincipal term

in the sum T

m

+ βp

cr

, which determines the criti-

cal temperature T

cr

of the “hot spot” under impact

[2, 4]. A curve of T

m

(α) for an HMX–TNT mixture

is shown in Fig. 2. It is calculated using values of

T

m,1

= 553 K, T

m,2

= 353.5 K, C

5

= 0.7, C

6

= 0.3,

and α

tr

= 0.7. It is evident that the curve T

m

(α)

is more similar to a strength curve of σ(α) than to

kinetic curves of E(α) and Z(α). The relationship

between the strength σ and the melting point of in-

dividual HE was first indicated in [2].

1.4. Sensitivity Indices for an HMX–TNT

Mixture. If the elemental composition and the en-

thalpy of the composition (∆H

i

) are known, the heat

of explosion of the mixture Q is easily calculated by

well-known rules [5]. The specific heat of the mix-

ture c

p

is usually calculated by the additive relation

c

p

=

P α

i

c

p,i

, which is justified by the small differ-

ence in heat capacities between organic solids. For

the same reason, we assume that the piezoelectric

coefficient of the melting point β is also an additive

function β

i

of the mixture components.

Using the information obtained on the physic-

ochemical and explosive characteristics of SEM, we

Fig. 3. Sensitivity indices for an HMX–TNT mixture

versus TNT content in the mixture: curve 1 and 2

refer to p

cr

and h

cr

, respectively; points refer to the

experimental data of [4].

calculate the sensitivity indices for an HMX–TNT

mixture by the method of [1]. The initial data for

the calculation are given above, except for c

p,1

=

1.05 kJ/(kg

· K), c

p,2

= 1.465 kJ/(kg

· K), β

1

=

0.20 K/MPa, β

2

= 0.29 K/MPa, ∆H

1

= 253 J/kg,

and ∆H

2

=

−328 J/kg [5]. Our calculations show

that the heat of explosion of the mixture depends

practically linearly on the composition and, hence,

Q = (1

− α)Q

1

+ αQ

2

, where Q

1

= 5.53 MJ/kg

and Q

2

= 4.22 MJ/kg. The initiation parameters

of SEM were calculated with a step in the TNT con-

tent ∆α = 0.01. The results are shown in Fig. 3 in

the form of curves of p

cr

(α) and h

cr

(α).

From Fig. 3 it follows that there is a sharp, al-

most jumpwise transition from the value p

cr,1

cor-

responding to the HMX initiation pressure to the

value p

cr,2

typical of TNT when the TNT content in

the mixture is α

≈ 0.7. The obtained value of α coin-

cides with the limiting content of TNT α

th

for which

its influence on the characteristics of thermal decom-

position of the mixture becomes determining (see

Fig. 2). We also note that all physicochemical and

explosive characteristics of SEM, except for thermal-

activation parameters, were assumed to be linearly-

additive in α and, hence, they could not be responsi-

ble for the jumpwise behavior of the curve of p

cr

(α)

(charge strength σ influences the quantity p

cr

only

slightly). Hence it follows that the thermal-activation

parameters play a decisive role in initiation of SEM

by impact. Let us verify this conclusion by calculat-

ing the critical initiation parameters for solid mix-

tures based on ammonium perchlorate (AP).

Calculating the Impact Sensitivity Indices of Solid Explosive Mixtures

103

2. AMMONIUM PERCHLORATE

BASED MIXTURES

The formulas of Sec. 1 cannot be used di-

rectly to calculate the sensitivity indices of AP-based

SEM since the thermal-decomposition mechanism for

AP differs markedly from the thermal-decomposition

mechanism for organic solids. Indeed, the thermal

decomposition of AP proceeds in two stages [6]. In

Stage 1 (low-temperature stage) which proceeds at

crystal defects, a fraction η < 0.3 of the potential

chemical energy of AP is released. The final decom-

position of AP to the end products proceeds at Stage

2 (high-temperature stage) in the bulk of the crystals.

There is the hypothesis [7] that Stage 1 of AP de-

composition is sensitized by perchloric acid (PA) ad-

sorbed at crystal defects. Perchloric acid is thermally

less stable than AP and, hence, acts as an initiator of

AP decomposition. The decomposition of AP begins

with dissociation into ammonia and PA, and then PA

continues the reaction. According to [8], the thermal

decomposition of PA is characterized by parameters

E

PA

= 121 kJ/mole and Z

PA

= 10

12

sec

−1

. The sen-

sitizing effect of PA on AP decomposition is taken

into account by decreasing the activation energy of

AP E

0

= 126 kJ/mole by a value that depends on the

amount of defects in the crystals, i.e., on the quan-

tity η and on the reactivity and content of the fuel

component interacting with AP. As a result, the ac-

tivation energy of AP necessary for the calculations

is written as

E

1

= E

0

(1

− q

1

α

u

th(C

7

η)),

(9)

where q

1

= (E

0

−E

PA

)/E

0

is the relative difference in

activation energy between thermal decompositions of

AP and PA, and u is an empirical constant that de-

scribes the reactivity of the fuel. The constant C

7

is

chosen from the condition that the function tanh(x)

reaches a value close to 1 for a value of η

≈ 0.3 that

corresponds to Stage 1 of AP decomposition. From

this, we find that C

7

= 7–8.

In order that the rate of thermal decomposition

of AP remain unchanged after the introduction of E

1

,

we compensate for the decrease in E

0

by the corre-

sponding increase in the preexponent Z

0

and obtain

Z

1

= Z

0

(1 + q

2

α

v

tanh(C

7

η)),

(10)

where q

2

= (Z

PA

−Z

0

)/Z

0

is the relative difference of

the preexponents of AP and PA and v is a constant

that depends on the reactivity of the fuel. Let us

use the above model concepts of AP thermal decom-

position to calculate some features of the mechanical

initiation of mixtures of AP and fuels.

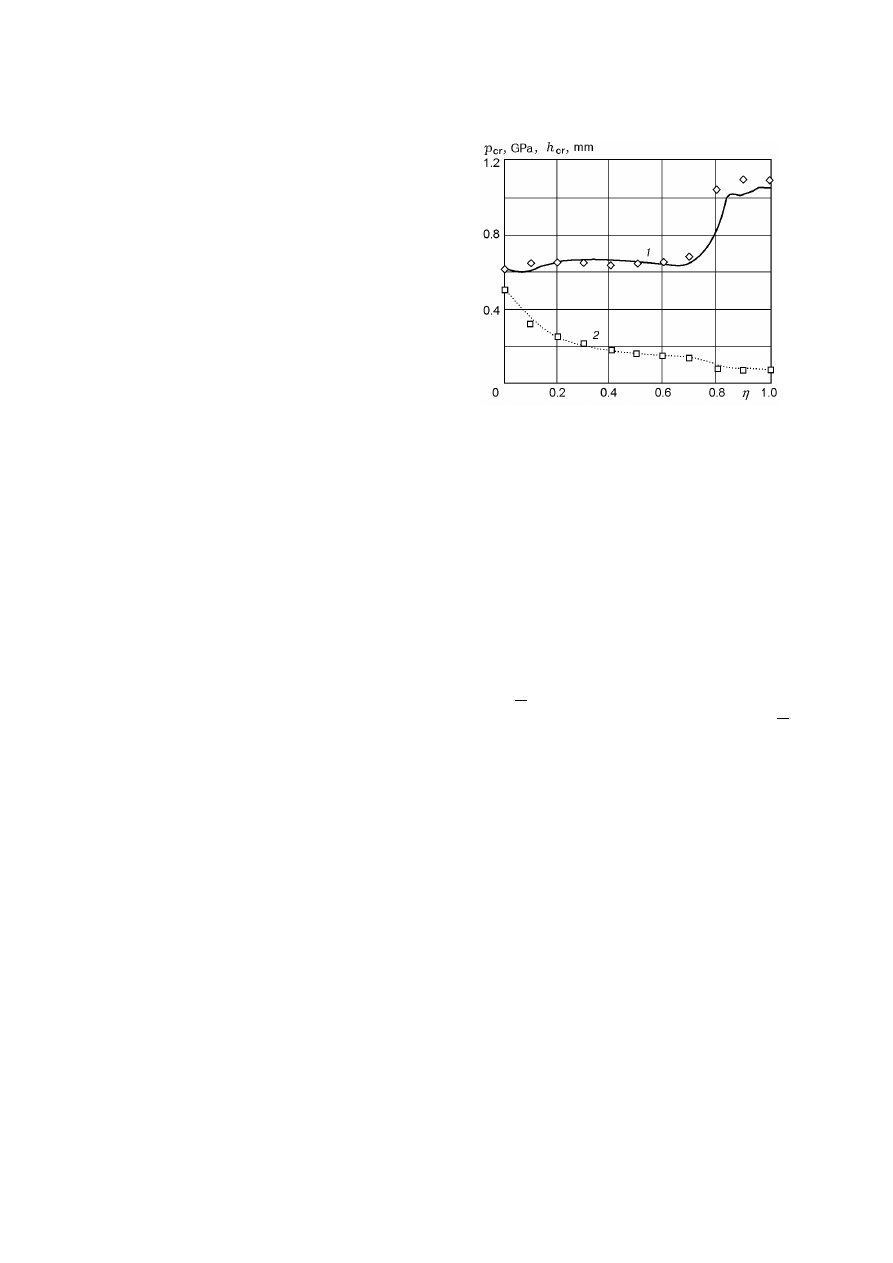

Fig. 4. Calculated and experimental sensitivity in-

dices for an AP–PMMA mixture versus η: curves 1

and 2 refer to p

cr

and h

cr

, respectively; points refer to

the experimental data of [9].

2.1.

A Mixture of AP and an Inexplo-

sive Component (PMMA). In [9], values of p

cr

for an 80/20 AP/PMMA mixture were measured for

0 < η < 0.4.

We recall that PMMA is a linear

polymer compound with density ρ

2

= 1190 kg/m

3

,

strength σ

2

= 118 MPa, and heat capacity c

p,2

=

1.47 kJ/(kg

· K). It is softened at T

m,2

= 393 K and

subjected to pyrolysis at T > 593 K. One reason

for the small thermal stability and light combustibil-

ity of PMMA might be the relatively low strength

of the C

C bond, equal to E

2

= 332 kJ/mole [10].

The characteristic oscillation frequency of the C

C

bond in PMMA estimated from this energy is Z

2

=

8.3

· 10

14

sec

−1

.

Let us calculate the heat effect of chemical in-

teraction between AP and PMMA. Since the active

zones of this reaction are AP crystal defects, whose

fraction in the mass of the material is η, then the

heat release due to interaction of AP with PMMA is

proportional to a certain function η. Therefore, the

heat effect of the reaction is written as

Q = (1

− α)Q

0

+ (Q

m

− (1 − α)Q

0

) tanh(C

7

η)),

(11)

where Q

0

= 1.37 MJ/kg and Q

m

= 4.19 MJ/kg

are the heats of explosion of AP and an 80/20

AP/PMMA mixture, respectively. For η = 0 (defect-

free crystals), there is no interaction between AP and

PMMA and the heat effect is determined only by AP

decomposition. If η > 0.3, interaction of AP with

PMMA proceeds with maximum heat release.

Setting for AP, c

p,1

= 1.3 kJ/(kg

· K), σ

1

=

185 MPa, T

m,1

= 820 K [1], u = 0.5, and v = 3, as-

suming that β

1

= β

2

= 0.26 K/MPa, and character-

izing an 80/20 AP/PMMA mixture by σ = 155 MPa

104

Dubovik

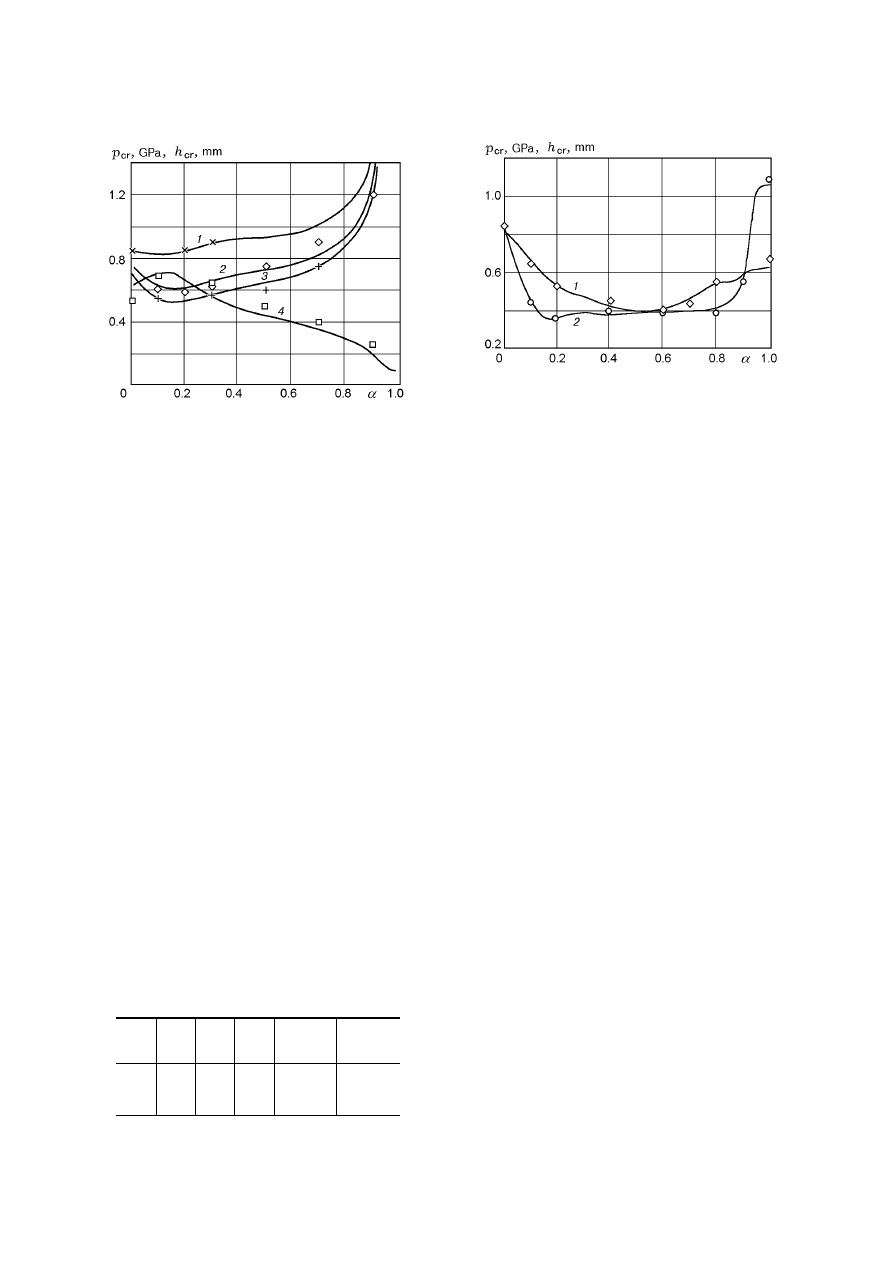

Fig. 5. Calculated and experimental sensitivity in-

dices for an AP–PMMA mixture versus PMMA con-

tent for η = 0.01 (1), 0.1 (2 and 4), and 0.35 (3):

curves 1–3 refer to p

cr

and curve 4 refer to h

cr

; points

refer to the experimental data of [9].

and C

7

= 7, we calculate from [1] the critical initi-

ation parameters of this mixture as functions of the

parameter η. Calculation results for p

cr

(η) and h

cr

(η)

are shown in Fig. 4 together with the experimental

data of [9]. Evidently, there is good agreement be-

tween the theoretical and experimental results. This

is explained primarily by the effect of the heat effect

of reaction (11) on the sensitivity indices and, to a

lesser degree, by the effect of the kinetic characteris-

tics of thermal decomposition of AP because a similar

calculation for E

1

= E

0

and Z

1

= Z

0

gives about the

same agreement of results. From Fig. 4 it also fol-

lows that a mixture of a defectless AP and PMMA

(80/20) is characterized by an initiation pressure of

0.88 GPa, i.e., decreased impact sensitivity (at the

level of pycric acid [1, 2]).

We continue the analysis of impact sensitivity for

a AP/PMMA mixture and calculate the sensitivity

indices as functions of the composition of the mixture

for various fixed values of η. As noted in [9], the de-

gree of decomposition of AP in the 1st stage increases

with increase in the particle size r

1

. This relation

can be written in approximate form η

≈ 10

−2

r

2/3

1

,

where r

1

is given in micrometers.

Therefore, the

TABLE 1

η

r

1

,

µm

r

2

,

µm

Π

p

cr,min

,

GPa

h

cr,min

,

mm

0.01

5

5

0.02

0.825

0.478

0.1

25

5

0.02

0.601

0.712

0.35

250

15

0.03

0.514

0.808

Fig. 6. Calculated and experimental [9, 11] (points)

values of p

cr

for AP–TNT and AP–HMX mixtures

(curves 1 and 2, respectively) versus the HE content.

dependences p

cr

(α, r

1

) and p

cr

(α, η) are equivalent

in the indicated sense. The initial data for calcu-

lating the strengths of charges of AP with PMMA

(r

2

≈ 10 µm) by (7) are shown in Table 1. To calcu-

late the kinetic characteristics of the mixture, in (8)

we set the following values of the constants: C

1

= 1.7,

C

2

= 1.3, C

3

= 400, C

4

= 2.5, C

5

= C

6

= 3,

α

th

= 0.95, and α

tr

= 0.9. From these data, us-

ing the method of [1], we calculated curves of p

cr

(α),

which are shown in Fig. 5 together with the experi-

mental results of [9]. A curve of h

cr

(α) obtained for

the AP-based mixture with r

1

= 25 µm is also given

in Fig. 5.

All calculated dependences are nonmonotonic

and have typical extrema at the point of stoichiom-

etry for the given mixture: α

st

= 0.15. Values of

p

cr,min

and h

cr,max

are listed in Table 1. An analysis

of the results obtained shows the following: 1) the

sensitivity level is determined by the calorific value

of the mixture, which depends on η for all α < α

th

;

2) the effect of the reactivity of the oxidizer as the

AP–PA system on the sensitivity of the mixture is

especially pronounced for small values of α

≈ α

st

.

For the remaining α < α

th

, calculations of the sen-

sitivity indices of the mixture give the same results

as for AP as the oxidizer. In AP–PMMA mixtures,

α

th

≈ α

tr

≈ 0.9. In mixtures of AP with explosive fu-

els, the values of the indicated parameters are much

lower.

2.2. Mixtures of AP and Explosive Com-

ponents. Experimental data on the sensitivity of

mixtures of AP with TNT and HMX are given in

[9, 11], in which “ordinary” AP with η

≈ 0.2 was

used. This value of η was used to calculate the curves

of p

cr

(α) and h

cr

(α) given in Fig. 6. In the calcu-

lations, the following values for the constants were

Calculating the Impact Sensitivity Indices of Solid Explosive Mixtures

105

used: u = 0.2, v = 1.6, C

1

= 0.8, C

2

= 1, C

3

= 400,

C

4

= 2.6, C

5

= C

6

= 3, α

th

= 0.25, and α

tr

= 0.9

for an AP–TNT mixture; u = 0.2, v = 2.3, C

1

= 1.1,

C

2

= 1.2, C

3

= 300, C

4

= 3, C

5

= 0.8, C

6

= 0.7,

α

th

= 0.7, and α

tr

= 0.6 for an AP–HMX mixture.

They differ markedly from the corresponding con-

stants for an AP–PMMA mixture by the values of u

and α

th

, which determine the kinetic characteristics

of the mixtures. The above sets of constants differ

from one another by the values of C

5

, C

6

, and α

tr

,

which determine the strength properties of mixtures.

The above data lead to the following conclu-

sions: 1) the values of u and α

th

show that AP in-

teracts more actively with TNT and HMX than with

PMMA, and the interaction with TNT is more in-

tense than that with HMX; 2) in contrast to mix-

tures of AP with TNT and PMMA, a mixture of AP

and HMX is characterized by high strength, which,

via the store of energy in the loading system, facili-

tates the interaction of the mixture components dur-

ing charge collapse. From this, we have decreased

values for the constants C

5

, C

6

, and α

tr

.

Thus, the approximate physicochemical model

of mechanical initiation of SEM charges proposed in

this paper can be used to calculate the critical pa-

rameters of explosion initiation by an impactor with

accuracy sufficient for applied calculations. Accumu-

lating calculated data supported by experiments, it

will be possible to obtain reliable values for the con-

stants used in the calculation, and, thus, to reliably

predict the sensitivity of new mixed compositions.

REFERENCES

1. A. V. Dubovik, “Calculation of impact sensitivity in-

dices for solid explosives,” Dokl. Akad. Nauk SSSR,

268, No. 2, 377–380 (1986).

2. G. T. Afanas’ev and V. K. Bobolev, Initiation

of Solid Explosives by Impact [in Russian], Nauka,

Moscow (1968).

3. E. A. Stolyarov and N. G. Orlova, Calculation of the

Physicochemical Properties of Liquids [in Russian],

Khimiya, Leningrad (1976).

4. I. A. Karpukhin and V. K. Bobolev, “Critical con-

ditions of impact initiation of an explosion in solid

mixed explosives,” Fiz. Goreniya Vzryva, 3, No. 3,

381–385 (1967).

5. V. I. Pepekin, M. N. Makhov, and Yu. A. Lebedev,

“Heats of explosive decomposition of individual HE,”

Dokl. Akad. Nauk SSSR, 232, No. 4, 852–855 (1977).

6. L. L. Bircumshaw and B. N. Newman, “The ther-

mal decomposition of ammonium perchlorate,” Proc.

Roy. Soc. London, Ser. A, 227, No. 1168, 115–132

(1954); 227, No. 1169, 228–241 (1954).

7. V. Guillory and M. King, “Thermal decomposition

of ammonium perchlorate,” AIAA J., No. 6, 1134–

11362 (1970).

8. V. A. Koroban, V. P. Guk, et al., “Effect of sub-

stituents in the cation on the decomposition of per-

chlorates of ammonium bases,” in: Trans. Mendeleev

Chem. Technol. Inst., No. 104: Chemical Physics of

Condensed Explosive Systems (1979), pp. 44–51.

9. I. A. Karpukhin, V. K. Bobolev, Yu. M. Balinets,

et al., “Certain features of impact initiation of an

explosion and the detonation capability of oxidizer–

fuel mixtures,” Fiz. Goreniya Vzryva,

15, No. 2,

140–146 (1979).

10. A. A. Ravdel’ and A. M. Ponomareva (eds.), Short

Handbook of Physicochemical Quantities [in Russian],

Khimiya, Leningrad (1983).

11. V. K. Bobolev, I. A. Karpukhin, and V. A. Teselkin,

“Role of chemical interaction of components in initi-

ation of an explosion in mixtures of ammonium per-

chlorate and fuel,” in: Combustion and Explosion,

Proc. 3rd All-Union Symp. on Combustion and Ex-

plosion [in Russian], Nauka, Moscow (1972), pp. 515–

518.

Wyszukiwarka

Podobne podstrony:

NACA TM 948 A Simple Approximation Method for Obtaining the Spanwise Lift Distribution

Metallographic Methods for Revealing the Multiphase Microstructure of TRIP Assisted Steels TŁUMA

Semi Empirical Method for Estimating the Combustion Wave Transition through the Contact Surface in a

Numerical method for determining the allowable medium temperature during the heating operation of a

MODELING OF THE ACOUSTO ELECTROMAGNETIC METHOD FOR IONOSPHERE MONITORING EP 32(0275)

the first general method for stille cross couplings aryl chlorides

Analytical Method To Estimate The Maximum Power For A Photovoltaic Inverter System

Method for enhancing solubility of the expressed recombinant protein in E coli

A Simple and Effective Method for the Reduction of Acyl

Winning the battles, losing the war Rethinking methodology for forensic computing research

Fearless Resumes The Proven Method for Getting a Great Job Fast

Eurocode 6 Part 3 1996 2006 Design of Masonry Structures Simplified Calculation Methods for Maso

Difference test sensitivity Comparison of three versions of the duo trio method requiring different

Review of methods for demonstrating redundancy in DP systems for the offshore industry

Gallup Balkan Monitor The Impact Of Migration

Roosevelt's Justification for Entering the U S into World W

THE IMPACT OF SOCIAL NETWORK SITES ON INTERCULTURAL COMMUNICATION

Free Energy Bedini Device And Method For Pulse Charging A Battery Patent Info 2004

Fibonacci Practical Fibonacci Methode For Forex Trading

więcej podobnych podstron