Combustion, Explosion, and Shock Waves, Vol. 39, No. 1, pp. 75–79, 2003

Semi-Empirical Method for Estimating the Combustion-Wave

Transition through the Contact Surface in a Composite Explosive

UDC 536.46:662.2

V. T. Kuznetsov

1

Translated from Fizika Goreniya i Vzryva, Vol. 39, No. 1, pp. 87–91, January–February, 2003.

Original article submitted January 22, 2002.

Through a comparison of experimental data on stable ignition and combustion of ini-

tial specimens composing igniter trains of pyrotechnic charges, critical conditions

for combustion-wave transition through the contact surface between neighboring

compound-explosive compacts are found.

The evaluation procedure is tested with

twenty explosives representing different combinations of five compacts of pyroxylin

(gun-cotton), black gunpowder, and three types of pyrotechnic mixtures. Minimal

dimensions of an interfacial protuberance promoting combustion-wave propagation

throughout the charge are found.

Key words:

ignition, combustion, heat flux, pyrotechnic mixtures, composite

charge.

Stable propagation of combustion waves in com-

posite explosives is determined by ignition conditions

at contact surfaces between the neighboring compacts.

The critical values of wave-transition parameters in an

explosive depend on the amount of heat accumulated

in the wave, thermal resistance of the interface, and

thermokinetic properties of the specimen [1–3].

The

present paper proposes an engineering procedure for

predicting the possibility of combustion-wave transi-

tion through the interface between the neighboring com-

pacts, which employs experimental results on stable ig-

nition and combustion of explosive components. The

procedure is based on the concept of the so-called “op-

timal” ignition regime, in which the external source of

heat on the surface of a specimen provides for ignition

conditions identical to those at the surface of this speci-

men during stable burning [4]. Hence, the energy in the

combustion wave and, hence, the associated heat flux

can be estimated from ignition tests performed in the

“optimal” regime.

We consider burning of a pyrotechnic charge con-

sisting of a triggering mixture and a main mixture.

We assume that, in the case of a plane interface be-

tween the mixtures and ideal heat transfer between the

1

Institute of Applied Mathematics and

Mechanics, Tomsk State University,

Tomsk 634050; ichan@niipmm.tsu.ru.

neighboring compacts, the combustion wave can pass

through the interface if the energy necessary for ignit-

ing the main mixture (N

main

) at a given heat flux in the

combustion wave traversing the triggering mixture (q

∗

tr

)

does not exceed the energy required for “optimal” igni-

tion of the triggering mixture (N

∗

tr

). The heat flux q

∗

tr

can be found graphically from the experimental depen-

dence N (q) at the minimum value of energy required for

the triggering mixture to be reliably ignited. From the

experimental relation between the stable-ignition time

of the main mixture and the heat flux at a given value

of q

∗

tr

, we can determine the ignition time of the main

mixture (t

ign,main

) and, hence, the energy required for

the mixture to be ignited: N

main

= q

∗

tr

t

ign,main

. Thus,

we can determine the values of N

∗

tr

and N

main

from

the experimental dependences t

ign

(q) for the trigger-

ing and main mixtures and estimate, from their ratio

N

tr

/N

main

, the possibility of combustion-wave transi-

tion through the plane interface between the mixtures.

However, the thermal resistance at the contact surface

caused, for instance, by loose contact between the com-

pacts may result in combustion quenching at the inter-

face even if the above-formulated conditions are fulfilled.

In the case under consideration, the establishment of a

stationary combustion wave as the initial wave traverses

the interface essentially depends on the gap width [3].

Here, stable transition is promoted by conditions under

0010-5082/03/3901-0075 $25.00 c

2003

Plenum Publishing Corporation

75

76

Kuznetsov

TABLE 1

Characteristics of Composite-Explosive Specimens

Specimen

ρ, kg/m

3

a, 10

−8

m

2

/sec

U , mm/sec

t

∗

ign

, sec

N

∗

, 10

4

J/m

2

P

1500

6.77

1.4

0.035

2.5

GP

1700

14.3

9.0

0.020

5.4

A

1700

806

9.6

0.090

]

58.0

]

B

2350

55

3.2

0.045

11.2

C

1800

704

3.5

0.010

]

50.0

]

Note. The values of the parameters were obtained by extrapolating experimental data into

the region of intense heat fluxes are marked by the symbol ].

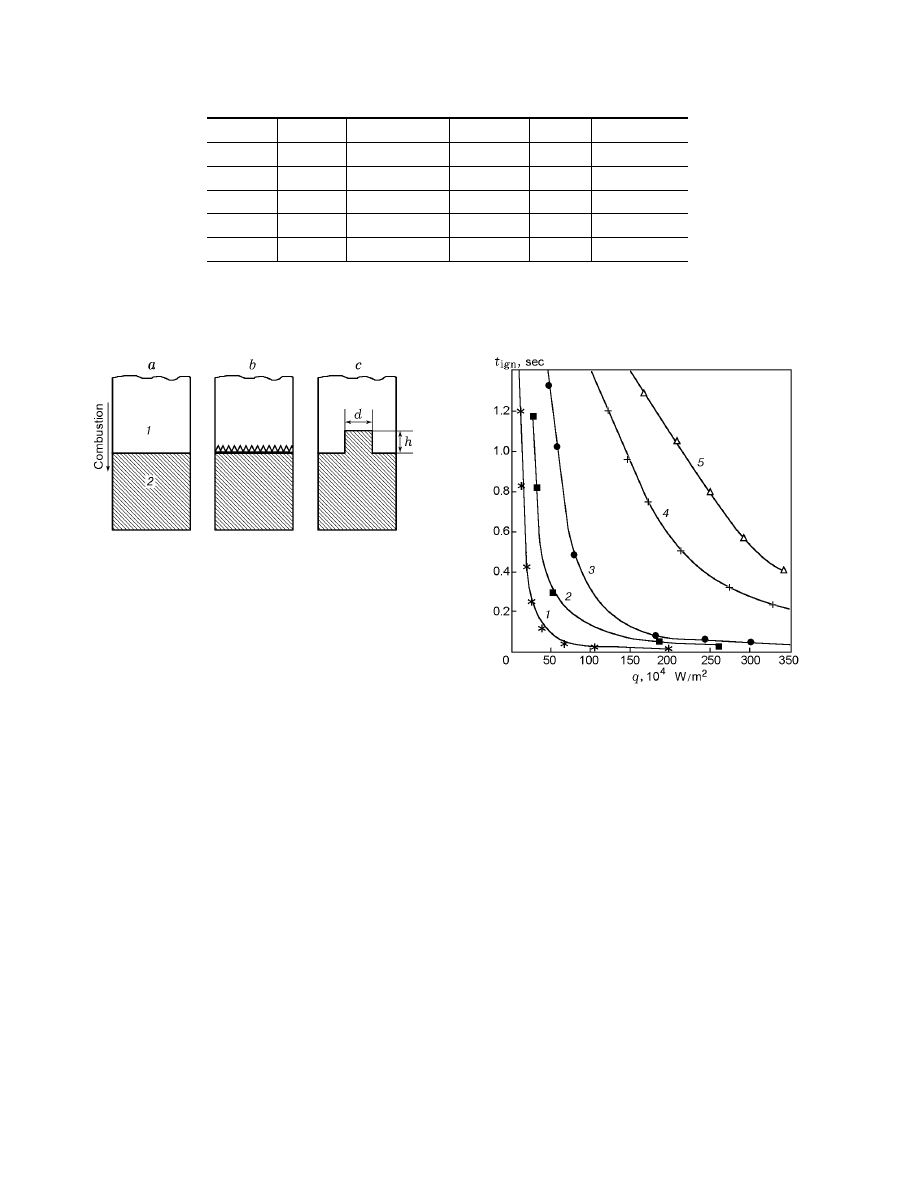

Fig. 1. Diagrams of composite explosives: (a) plane in-

terface between the triggering (1) and main (2) mixtures;

(b) corrugated interface; (c) interfacial main-mixture

protuberance.

which part of the main-mixture surface experiences, for

a certain time, the action by the flame produced by the

triggering mixture. Such conditions can be organized,

for instance, with the help of protuberances prepared

at the interface between the mixtures. Here, we assume

that the burning zone of the triggering mixture is suffi-

ciently wide, and the temperature of combustion prod-

ucts in this zone is higher than the ignition temperature

of the main mixture.

Consider which geometric dimensions of protuber-

ances are critical for stable transition of the combus-

tion wave through the contact surface. Let there be

a cylindrical protuberance of the main mixture at the

interface between the two mixtures. Based on physi-

cal considerations, we can find the minimal height of

the protuberance from the formula h

min

= U

tr

t

ign,main

,

where U

tr

is the burning rate of the triggering mixture

and t

ign,main

is the ignition time of the main mixture at

q = q

∗

tr

. As the minimal diameter of the flame source

in the case of a cylindrical protuberance with allowance

for heat withdrawal through side surfaces, the quantity

d

min

= 6.7(at

∗

ign,main

)

1/2

[5] can be used, where a is the

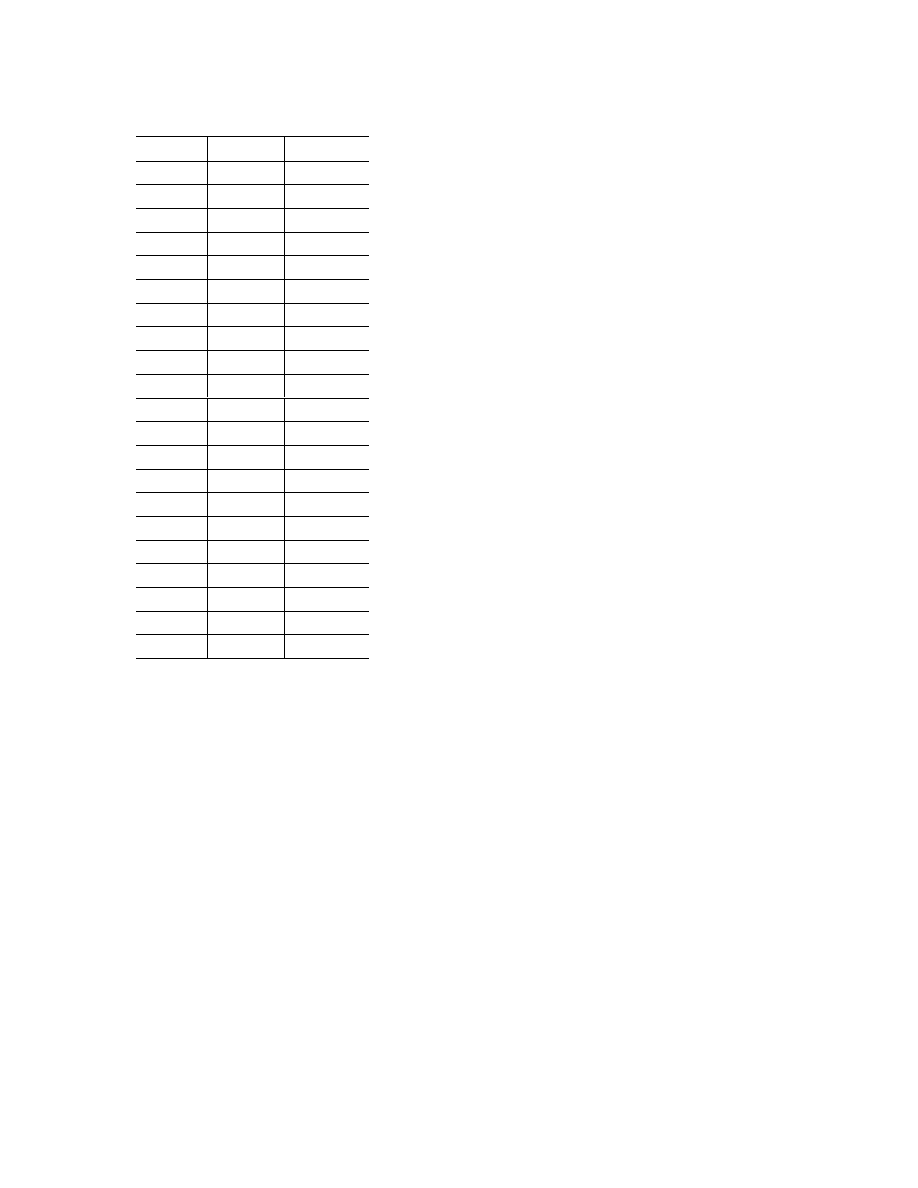

Fig. 2. Ignition time versus heat-flux density: curve 1

refers to pyroxylin, curve 2 to GP, curves 3, 4, and 5

refer to pyrotechnic mixtures B, C, and A, respectively.

thermal diffusivity of the mixture and t

∗

ign,main

is either

the ignition time of the main mixture in the “optimal”

regime or the thermal relaxation time of the heated

layer. Thus, in the case of interest, a protuberance at

the interface between the neighboring compacts can en-

sure stable transition of the combustion wave through

the contact surface.

The proposed procedure was tested in experiments

with composite charges representing various combina-

tions of five dissimilar compacts with a plane interface

between the mixtures and with a protuberance provided

on the main-mixture contact surface. Part of the explo-

sives had corrugated interfaces. Figure 1 shows various

diagrams of the explosives. Depending on the burning

Estimating the Combustion-Wave Transition through the Contact Surface

77

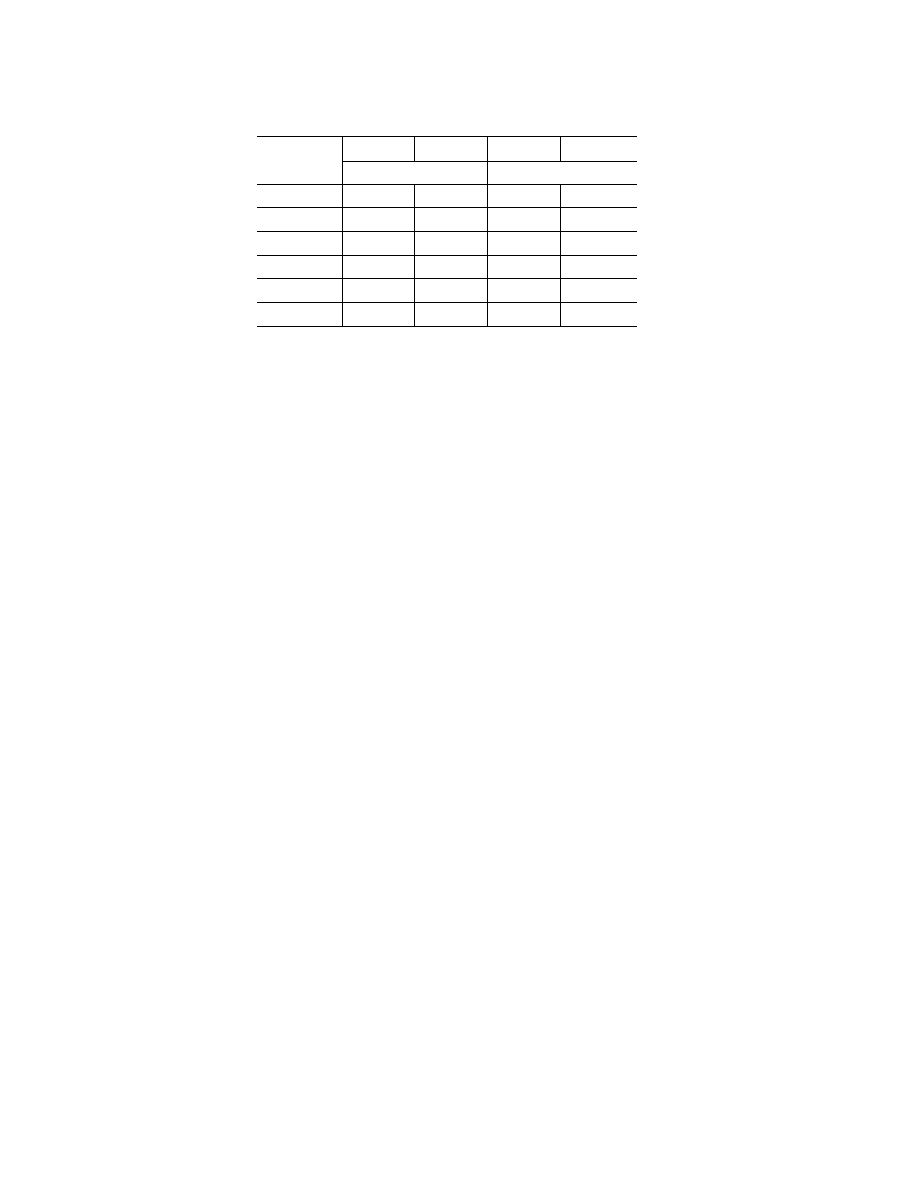

TABLE 2

Combustion of Explosives with

a Plane Interface between the Compacts

Explosive

Test result

N

∗

tr

/N

main

P + GP

+

0.220

P + A

−

0.004

P + B

−

0.065

P + C

−

0.009

GP + P

+

3.552

GP + A

−

0.030

GP + B

−

0.400

GP + B

−

0.060

A + P

+

18.100

A + GP

+

10.069

A + B

−

4.500

A + C

+,

−

1.130

B + P

+

4.978

B + GP

+

1.731

B + A

+,

−

0.060

B + C

+

0.120

C + P

+

16.600

C + GP

+

6.700

C + A

−

0.710

C + B

+

4.000

A + A

−

1.000

Note. The plus and minus denote burning and extinction,

respectively.

direction, the explosives were subdivided into triggering

or main ones. Compacts of gun powder (GP), pyroxylin

No. 1 (P), and pyrotechnic mixtures A, B and, C, based

on sodium, strontium, and barium nitrates containing

up to 60 wt.% of MPF-3 magnesium powder (mixtures

A and C) and up to 40 wt.% of PTM(a) titanium pow-

der (mixture B) were used. To raise the compressibility

of the specimens, various technological additives were

also used. The diameter of the specimens was 15 mm,

and their height was 20 mm.

Explosives with plane

interfaces were prepared by pressing of precompacted

specimens followed by subsequent armoring of their side

surfaces with a linoleum solution in acetone and drying

them at room temperature during three days. Explo-

sives with protuberances at the interfaces between the

triggering and main mixtures were prepared by succes-

sive compacting of mixtures with a puncheon having a

spigot tang. The diameter and height of the tang varied

in the range of 2–6 mm. After compacting, explosives

with interfacial protuberances were also armored with

the linoleum solution. Explosives with corrugated inter-

faces between the neighboring mixtures were prepared

in a similar manner. In the latter case, the surface of

the puncheon had conical tangs 1 mm high with 2-mm

diameter bases. Initial specimens of the composite ex-

plosives were put to tests on stable ignition initiated by

luminous fluxes with intensities (10–300)

· 10

4

W/m

2

.

The testing procedure for the illumination-triggered ig-

nition was described in detail in [6]. The experimental

data for five initial compacts are shown in Fig. 2. Using

these data and assuming that the energy necessary for

stable ignition is minimal in the “optimal” regime, we

determined the critical parameters N

∗

, t

∗

, and q

∗

for all

the compositions. The values of the critical parameters

are listed in Table 1. The same table lists the densities

ρ and thermal diffusivities a of the compacts, and also

the normal burning rates U displayed by the compacts

in air under atmospheric pressure. The mixtures used

in the tests appreciably differ in their characteristics,

and the explosives prepared from them cover a broad

range of the factor under study. The composite explo-

sives were burnt in atmospheric air at room tempera-

ture. The triggering mixture was ignited by a heated

Nichrome spiral. Visual observations of the process were

performed to register the final test result, either com-

plete burn-up of the whole explosive or flame extinction

at the interface between the triggering and main mix-

tures. At least five tests were performed for each pair of

compacts. The experimental data on burning compos-

ite explosives with plane interfaces between the neigh-

boring compacts are listed in Table 2. For each explo-

sive, the same table indicates the energy ratio necessary

for stable ignition of its components. It is seen that

an explosive burns out completely if N

∗

tr

/N

main

> 1;

if N

∗

tr

/N

main

< 1, then the flame fails to penetrate

through the interface between the triggering and the

main mixtures. For N

∗

tr

= N

main

, either propagation

of the combustion wave through the interface or flame

extinction was observed. The only exceptions were the

explosives P + GP and B + C, whose combustion pat-

tern might be affected by the heat-resistant armoring,

and also the compositions A + B and A + A, whose com-

bustion might cause violation of the thermal contacts

between the neighboring compacts. Flame extinction

between similar compacts A + A might also be caused

by the difference between the microstructure of the ex-

plosives at the interface between the compacts and the

microstructure of bulk materials. Indeed, if we have, in-

stead of a plane interface, a corrugated interface, which

78

Kuznetsov

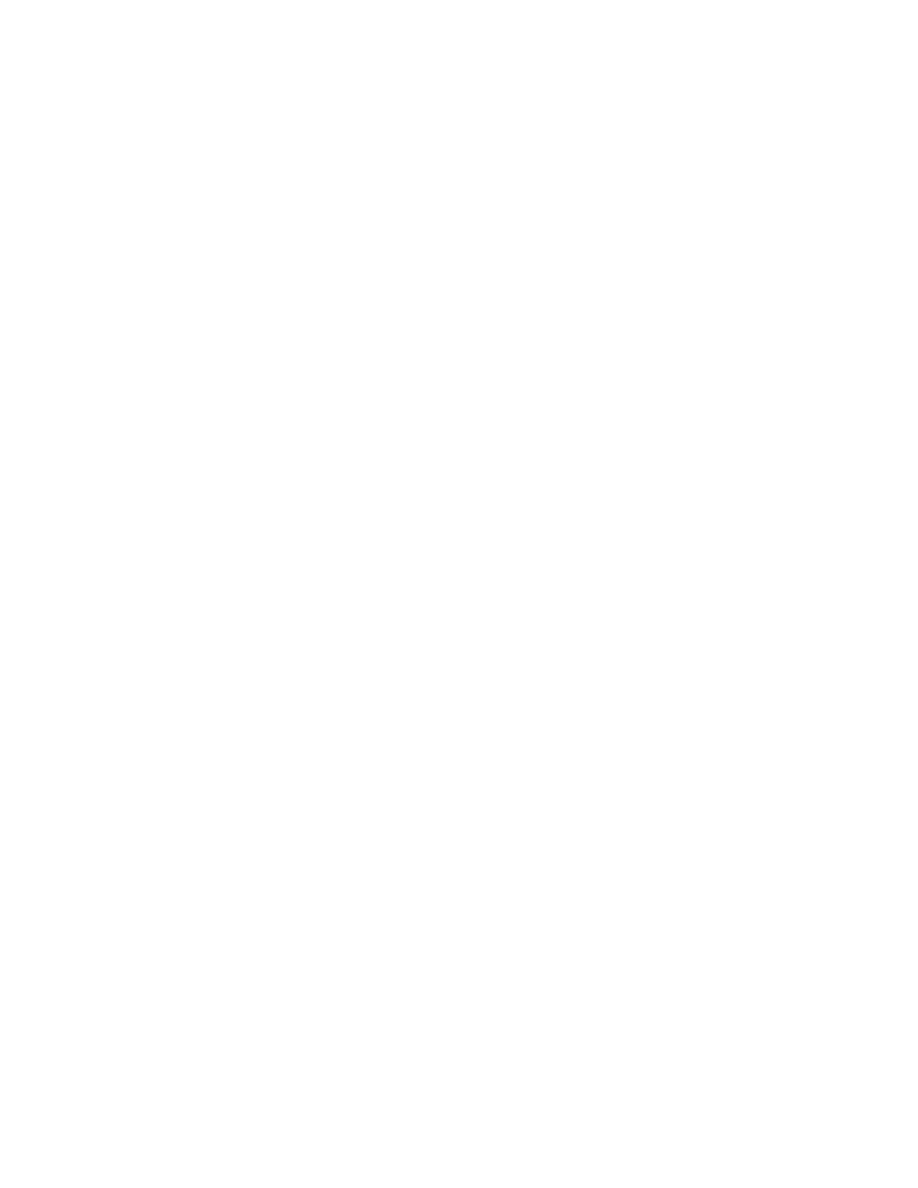

TABLE 3

Minimal Dimensions of the Interfacial Protuberance Ensuring

Stable Propagation of Flame Across Composite Explosives

Explosive

d

min

, mm

h

min

, mm

d

min

, mm

h

min

, mm

composition

Experiment

Calculation

P + A

6

4

5.7

7.0

P + B

3

4

1.0

0.8

P + C

6

6

5.6

5.2

GP+A

6

4

5.7

6.0

GP + B

2

2

1.0

0.4

GP + C

6

4

5.6

3.0

diminishes the probability of violation of the thermal

contact between the compacts, then the combustion

wave does penetrate through the In our tests, we ob-

served stable transition of the combustion wave through

corrugated interfaces in the explosives A + A, A + B,

A + C, and B + A. However, if the ignition energies of

the neighboring compacts considerably differ from each

other, then the interfacial corrugation is insufficient for

the combustion wave to penetrate through the interface.

For instance, corrugation of contact surfaces in the ex-

plosives GP + A, GP + B, and GP + C failed to promote

the propagation of the combustion wave from the trig-

gering to the main mixture. To make the transition

possible, it is required to prepare a main-mixture pro-

tuberance of certain dimensions. Explosives with such

main-mixture protuberances were prepared; the protu-

berances were 2, 3, 4, and 6 mm in diameter and 2, 4,

and 6 mm in height. The specimens were burnt with

atmospheric air at room temperature. No less than 36

tests were performed to determine the minimal dimen-

sions of interfacial protuberances capable of ensuring

stable flame propagation over each composite explosive.

The experimental and predicted minimal diameters of

the interfacial protuberances are listed in Table 3. In

view of the possible difference in compression condi-

tions of the materials in the cylindrical protuberance

and in the main explosives, and also considering the

fact that the firing tests were carried out on explosives

with discrete values of geometrical parameters of the

protuberance, we may consider the agreement between

the experimental and predicted minimal diameters of in-

terfacial protuberances as quite satisfactory. The only

exceptions are explosives with a protuberance 2 mm in

diameter: the thermophysical parameters and ignition

times of the substance (in the protuberance) can differ

from analogous parameters of bulk material of the main

explosive. Thus, a main-mixture protuberance prepared

at the interface of a composite explosive can ensure sta-

ble propagation of the combustion wave through the

contact between the triggering and main mixtures with

sharply differing characteristics (ignition energies, burn-

ing rates, and thermophysical parameters).

Based on the physical concept of ignition and com-

bustion of condensed substances, we proposed an en-

gineering procedure for predicting the possibility of the

combustion-wave transition through the contact surface

in composite explosives. The procedure rests on the

idea of an “optimal” ignition regime under the action of

an external source of heat. Experimental data on igni-

tion and combustion of initial composite-explosive spec-

imens are used. The procedure is tested with twenty

explosives composed of dissimilar compacts differing in

their ignition energies, burning rates, and thermophysi-

cal characteristics. The statements put forward are con-

firmed both qualitatively and quantitatively. Further

development of the procedure and determination of its

applicability limits require a wider range of systems to

be considered. Of special interest here are explosives

with a high metal content and gasless compositions. In

this case, “optimal” ignition conditions can be orga-

nized with the help of heating facilities that can ensure

heating intensities higher than 10

7

W/m

2

.

REFERENCES

1. I. G. Assovsky, “Conditions for the combustion-wave

transition through the contact surface between two fu-

els,” Dokl. Akad. Nauk SSSR,

253, No. 1, 124–128

(1980).

2. V. N. Simonenko, V. E. Zarko, A. B. Kiskin, et al., “Sta-

bility of the combustion of composite metallized sam-

ples,” Combust. Expl. Shock Waves, 19, No. 5, 590–591

(1983).

Estimating the Combustion-Wave Transition through the Contact Surface

79

3. O. Yu. Perevalov, V. T. Kuznetsov, and I. G. Dik,

“Transition of the combustion front through a nonideal

contact of two gasified solid fuels,” Combust. Expl. Shock

Waves, 29, No. 2, 155–157 (1993).

4. Z. I. Aristova and O. I. Leipunskii, “Pre-ignition heating

of gunpowders,” Zh. Fiz. Goreniya Vzryvov, No. 2, 225–

228 (1958).

5. V. N. Vilyunov, Theory of Ignition of Condensed Sub-

stances [in Russian], Nauka, Novosibirsk (1984).

6. V. T. Kuznetsov, V. P. Marusin, and A. I. Skorik, “Igni-

tion mechanism in a heterogeneous system,” Combust.

Expl. Shock Waves, 10, No. 4, 456–458 (1974).

Wyszukiwarka

Podobne podstrony:

Analytical Method To Estimate The Maximum Power For A Photovoltaic Inverter System

Metallographic Methods for Revealing the Multiphase Microstructure of TRIP Assisted Steels TŁUMA

NACA TM 948 A Simple Approximation Method for Obtaining the Spanwise Lift Distribution

Approximate Method for Calculating the Impact Sensitivity Indices of Solid Explosive Mixtures

Numerical method for determining the allowable medium temperature during the heating operation of a

MODELING OF THE ACOUSTO ELECTROMAGNETIC METHOD FOR IONOSPHERE MONITORING EP 32(0275)

the first general method for stille cross couplings aryl chlorides

Method for enhancing solubility of the expressed recombinant protein in E coli

A Simple and Effective Method for the Reduction of Acyl

053 Cost Estimation Methods for Drying

Winning the battles, losing the war Rethinking methodology for forensic computing research

Fearless Resumes The Proven Method for Getting a Great Job Fast

Review of methods for demonstrating redundancy in DP systems for the offshore industry

Roosevelt's Justification for Entering the U S into World W

Free Energy Bedini Device And Method For Pulse Charging A Battery Patent Info 2004

Fibonacci Practical Fibonacci Methode For Forex Trading

Improvements in Fan Performance Rating Methods for Air and Sound

Combinatorial Methods for Polymer Science

Methodology for Assessment Biodiversity

więcej podobnych podstron