Journal of Ancient Civilizations, Vol. 23, 2008

The exchanges of copper in the Ancient Middle East

Nicolas Gailhard, Institute for the History of Ancient Civilizations (IHAC)

1

Introduction

In Anatolia, the birth and the development of metallurgy intervened between the 9th

and 3rd millenniums as well as testify the more and more frequent apparitions of metals

artefacts in the inventory of the archeological objects of this period.

The transformations of the technologies of working copper and its organization during

the period of the Chalcolithic, from the middle of the 6th millennium at the end of the 4th

millennium, are incontestably observable. In the same way, a change of the system of

production and the organization of work was necessary considering the multiplication of

objects made in copper and a larger distribution. The origins of the copper in Ancient Middle

East are multiple with sources in Anatolia, Iran, Transcaucasia and Arabia Peninsula. These

modifications are also the consequence of an evolution of the society’s and permitted the

development of new shapes of exchanges.

During this period, the role of the metallic objects has been upset, their function and

their value evolved to become symbol of prestige and power

2

. The exchanges of precious

goods, as the objects made of copper and of bronze, characterize a new diffusion system that

gradually substitute itself for an elder fashion of exchanges which did not satisfy the societies

anymore at the end of the Chalcolithic. Some networks got in place and created important

regional dynamics that the archaeological discoveries often noted on big axes as those of the

valley of the Euphrates or the mountain of Zagros.

To observe these zones of regional development where the metallurgy of the copper

played an important role is an indication, an archaeological witness among others between

Chalcolithic and Bronze Age on several sites as Arslantepe, Hacinebi, Husband, Susa and

others.

In this article, we will try to make a spatial analysis of this diffusion before and after

these changes were observed in the transformation of the copper. All results evoked here, are

1

http://nicogailhard.shos.fr/

2

GAILHARD N. 2007, p. 93

Journal of Ancient Civilizations, Vol. 23, 2008

largely developed in a Doctorate thesis of Paris 1 Sorbonne-Pantheon University that will be

published shortly in its entirety

3

.

1. The principle of our survey: Through some questions, we can

raise a picture of use and diffusion of copper in a definite space.

To the question “Under what shapes is the copper recovered?”several answers exist:

- As raw material: ore. In this case, the refinement takes maybe place on

the site of extraction. The operative chain is concentrated in part in a precise place. The

presence of fire for the roasting, of slag are the witnesses of this activity. This description

corresponds to the elaboration or extraction metallurgy.

- When copper completely or partially refined of the ore impurities, the

formatting of the object begins. We note the presence of ovens of melting, molds, ingots and

tools for the transformation of the copper in objects. We are front of metallurgy of

transformation.

- As objects finished in copper or bronze. There is often absence of

material trace of work, and the places where we found the object are different of a workshop

(habitats, tombs.).

What is the nature of the products manufactured on each previous states of the copper? What

are the methods of production used?

Our approach is to classify the various witnesses of coppers according to various criteria:

- By sorting out the different types of copper ore (native, oxide, sulfide)

- By technological sorting, situating every product in the operative

chain. It requires the identification of the techniques and the methods of development,

refinement and transformation of the products and scraps. It is

,

then

,

possible to achieve

deductions of the relative proportions of every technological class with the help of histograms.

We can determine the character, thus, more or less complete of the met operative chains.

- By the study of all set which is the whole of the states that the copper

takes during the technological process of metallurgy, including studying of the produced

scraps.

2. The obtained results

3

GAILHARD N. 2007 "The transformation of copper in Near East from the Neolithic to the end of the 3rd

millennium. Survey of a technological chain." and in press a new version to the Editions BAR.

Journal of Ancient Civilizations, Vol. 23, 2008

"Pre-metallurgical" phase (from the 9th to the 7th millennium): Discovery of the native

copper and the rich oxide of copper, first annealed, limited exchanges.

The used copper types: During this period, we have the attestation of the use of two

copper types: the native copper and some ores of rich copper oxide as the malachite. They are

mainly worked in zones richly provided in raw materials as central Anatolia. We cannot make

the impasse on the fact that the site of Çayönü Tepesi represents 92 % of the discoveries of

this period.

Attestations of the various copper types and the

metals during the "pre-metallurgical" phase

23%

76%

1%

Natif Copper

Copper oxide (Malachite mainly)

Lead / Galena

There is a strong disproportion between these two types of copper, considering the

situation of Çayönü Tepesi which represents 76 % of the total with the ore of oxide as the

malachite. We observe, however, the strong use of the native copper with 23 %: it is the big

novelty with the discovery of the copper in its shape raw as new material possessing a set of

important qualities. Finally, the usage to the end of this leading phase, mainly in North

Mesopotamia and Galena in Çatal Hüyük represents 1 %.

The used techniques: The work of these two types of copper is rather comparable to

the methods used for the work of semiprecious stones especially for the case of the malachite

which is not considered totally as having a direct family tied with the copper. The cold and

hot hammering, the reduction of copper oxides without casting iron are three mainly used

techniques. Concerning the manufacturing of pearls, the use of fine bands (strips) of metal

rolled up on an armature is attested as the simple drilling of small copper ball. We observe

Journal of Ancient Civilizations, Vol. 23, 2008

that it is not the structural transformation of the metal that is realized here but only the

modeling of natural forms of the native metal or ores.

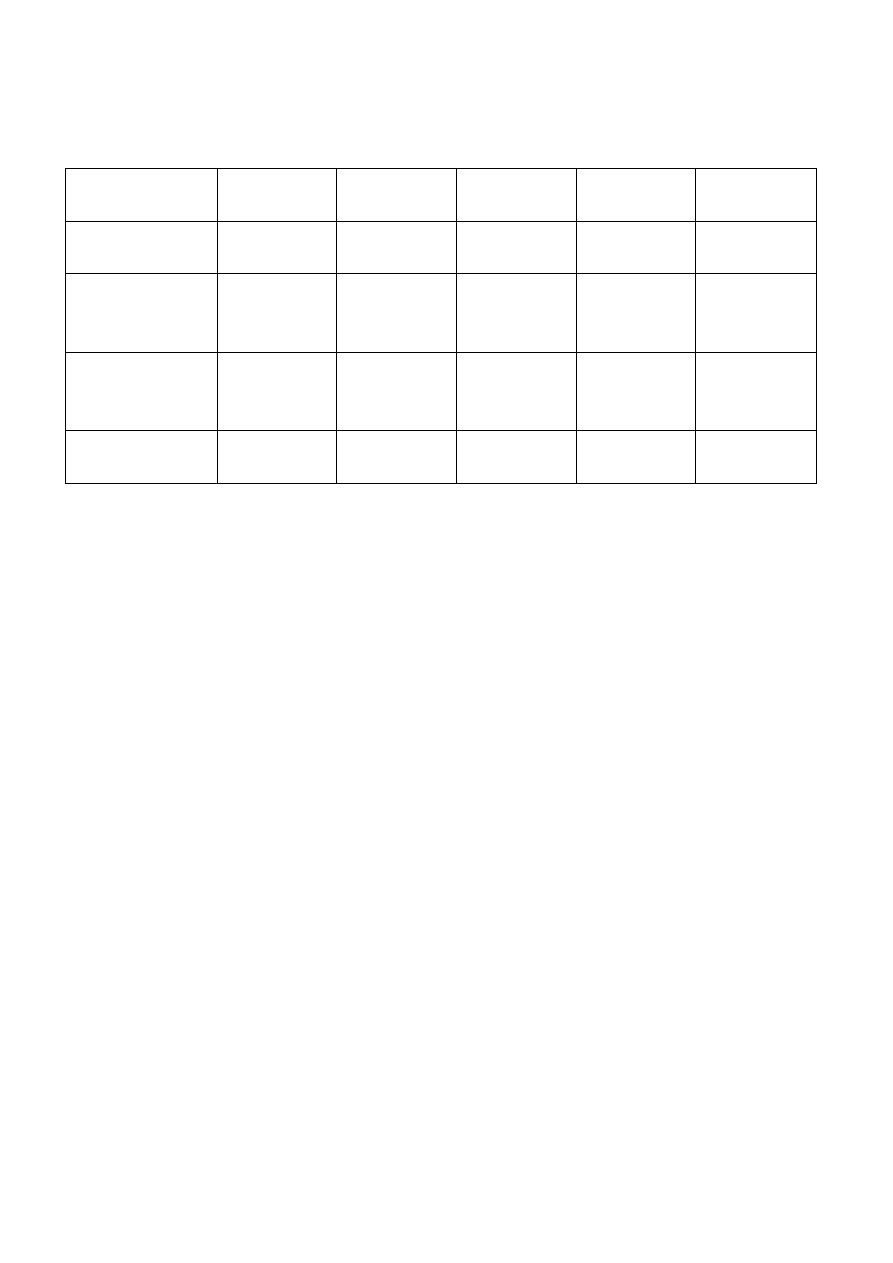

Anatolia

Mesopotamia

Iran

Transcaucasia

Arabia

Peninsula

Cold hammering

Tell

Maghzaliyah

Ali Kosh

Hot hammering

(Annealed)

Çayönü Tepesi ;

Aşıklı Höyük ;

Can Hasan

Copper leaf and

armature

Çayönü Tepesi ;

Aşıklı Höyük ;

Nevali Çori

Full copper

Çayönü Tepesi ;

Aşıklı Höyük ?

Board n°1: The different techniques used according to the regions

If we are interested in the distribution and in the attestation of each of these methods,

we observe that it is in Anatolia where techniques are the most numerous and the most

diversified during this period. Techniques as the hot hammering with the practice of the

annealing seem only attested in Anatolia.

It also corresponds to the state of the current researches because more excavations

took place in Anatolia in the last decades bringing a precise view for certain regions of the

Euphrates valley for example. In consequence, because a larger number of Neolithic sites

were found the copper presence in Anatolia, it is more important regarding to Mesopotamia or

Iranian plateau.

Nevertheless, the situation is not forcing the same between Mesopotamia and Iranian

plateau. Indeed, the first one has no appropriate copper resource and has to import this

resource as many other raw materials (obsidian, lapis lazuli, wood) and despite of everything,

the first attestation of use copper takes place on the 7th millennium in Mesopotamia. This

indicates the relations of exchanges existing between the North and the South of the river axes

of the Tiger and the Euphrates. Through taking several forms but always allowing the

contribution of these raw materials and techniques to exploit them, they will be more and

more important in time. It is certainly the median position of Mesopotamia between the

western steppes and the North and East mountains which have made a great catalyst of the

discoveries and the technical evolutions on these various regions.

Journal of Ancient Civilizations, Vol. 23, 2008

Concerning the Iranian plateau, vast heterogeneous place, the situations vary

according to the available resources. Susiana is finally placed in a situation rather similar to

North Mesopotamia with regard to the Anatolia and its rich cupriferous zones. This also has to

import the copper and the techniques of the other regions of Iran richly provided. These

imports intervene only from the foundation of Susa 1 (4200-3700 B.C.), such a long time after

the "pre-metallurgical" phase.

The Iranian regions which possess ores resources are hardly more active in the copper

production before the 6th millennium. Of course, we noted some examples in Ali Kosh

4

but it

is only the millennium later that appears a practically constituted metallurgy using all the

main techniques then (like the reduction of oxides).

The use: One of the first usages of these copper ores consisted in the confection of

coloration of pigment. Let's take the example of the paintings of Çatal Hüyük in the VII levels

and VI.

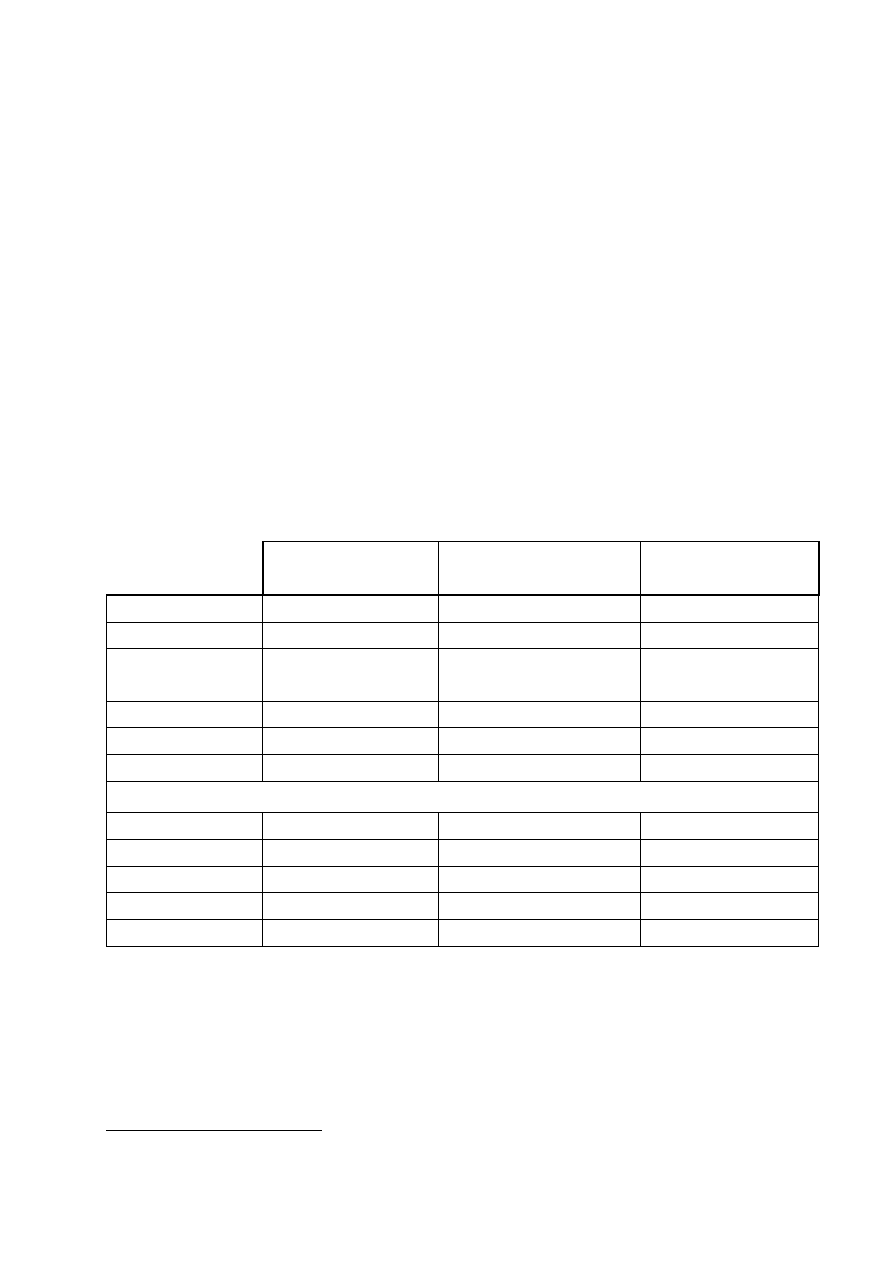

Native copper

Oxide of copper

(Malachite mainly)

Lead / Galena

Pearls

77

466

6

Marquetry

26

Leaves, sheet metal

and indeterminate

60

55

Pendants

2

Bracelets

1

Total :

139

547

7

Awls / Drill

15

Points

5

Fishhooks

4

Heads of mass

1

Total :

25

Board n°2: Materials used for every category of objects

Afterwards, the first metallic objects have been made. We can divide them into two

groups. At first, jewels and ornamental elements as pearls, bracelets, necklaces, patches of

marquetry which are enough for many and often associated in funeral contexts. They

represent the majority of the discoveries for this period with more than 96 % of objects. It is

also in this category are attested all the objects in malachite and all the lead and galena objects.

4

We found pearls, small ornaments and tools, such as awls and pins.

Journal of Ancient Civilizations, Vol. 23, 2008

The second group is constituted by tools: Small blades, burins, needles and fishhooks.

The picture of distribution of objects shows clearly that the first group constitutes the majority

of the usage for the native copper. But the existence of the second ones shows the

ambivalence of the usage of the pure copper. It has been already simulated by these first

communities to a semiprecious stone but also to a solid material and a sharp edge useful for

the conception of tools as already known stones (obsidians, flint). On the other hand, we can

ask the question of the degree of understanding which had the actors of the relation between

copper oxide and native copper. We indeed see that the usages are partially identical but that

the native copper plays a particular role with regard to the malachite. It is maybe in a second

time, after the proprieties of the temperature are assimilated and included, that will be

determined the presence of the same element, the copper, with different concentrations in

oxides, then sulfides.

The exchanges: On long distances, the circulation of copper objects does not seem

really intense in this period, although technically practicable for the other raw materials as the

obsidian or the stone dishes

5

.

Indeed, from the middle of the 8th millennium, we attend the disappearance of the

regional "borders" which characterized the previous phases. This phenomenon is clearly

observable in the East, but also in Djezirah

and in western Zagros. The usage of road marked

out by villages which could control or at least supervise and allow the exchanges on long

distances is the proof of the circulation of persons transporting objects and raw materials. The

quantitative jump of the exchanged volumes is observed from this period, as well as the

adoption of architectural shape on vaster zones.

The particular case of the copper explains by its relative rarity and the novelty of this

product still badly exploited and badly known which, in the course of time, becomes more

common and begins to travel. We have trace of copper pearls found on sites very remote from

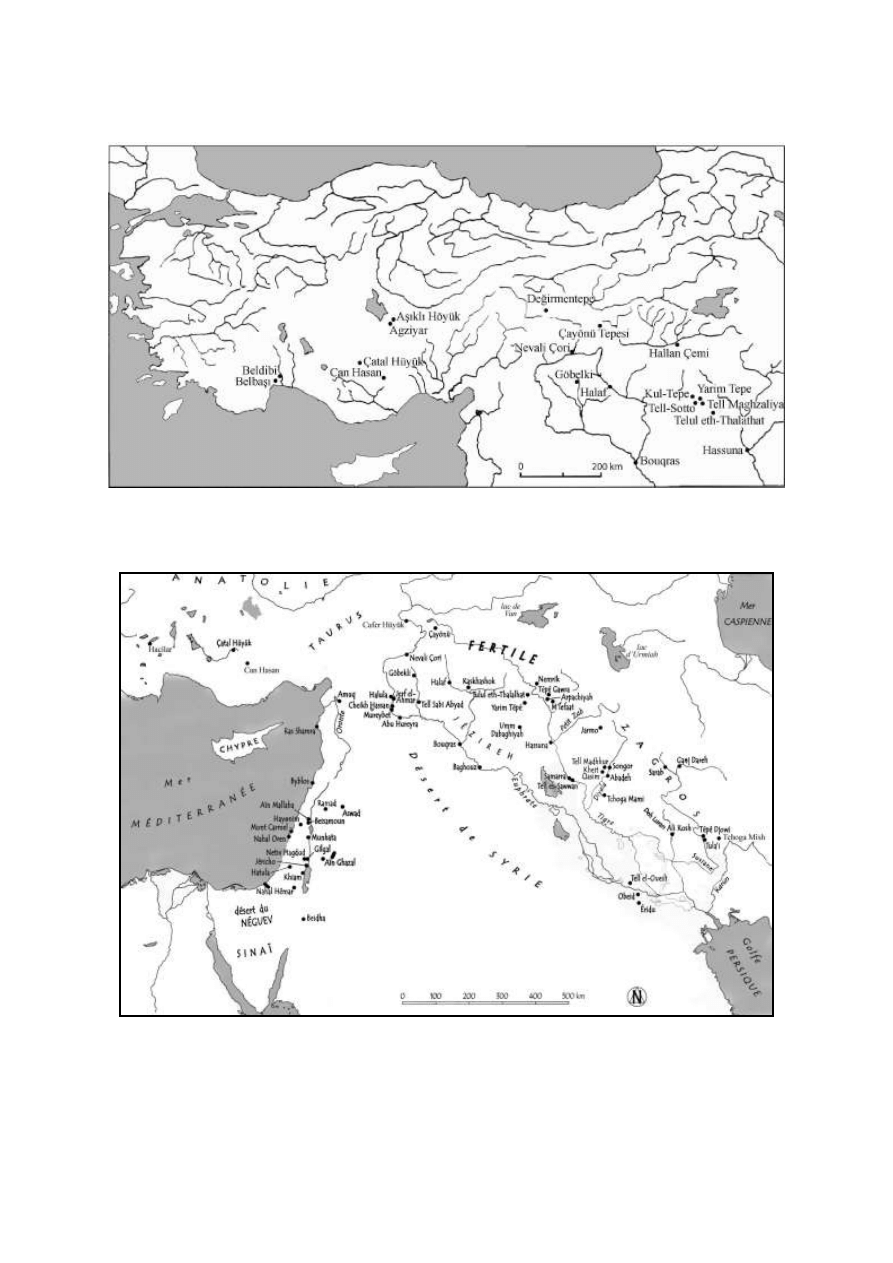

deposits. The maps of distribution of the sites of the Middle East of the pre-metallurgical

phase indeed indicate these places which are not naturally rich zones in copper (See maps n°1

and n°2)

6

. The North Mesopotamia is the example of a vast zone which is in touch with rich

regions, where the first metallic witnesses appear in the 7th millennium.

It remains to wonder about the meanings to make circulation of these materials that

leads us to ask the question of the meanings of locomotion. In some words, it seems that the

5

GAILHARD N. 2007, p. 101.

6

GAILHARD N. 2007, p. 49, example of the site of Hallan Çemi.

Journal of Ancient Civilizations, Vol. 23, 2008

human force was probably the only meaning of transportation for this type of products rare

and spread in small quantities. Was that assured by peddlers of specialized goods? Is it

possible that specialists of these new materials travelled to propose their services in new

regions which, besides the simple finished objects, would have benefited from a first

distribution of the knowledge relative to the work of these materials?

This debate is difficult to break, because in both cases, it implies a certain shape of

specialization which is difficult to conceive for ancient periods. In the hypothesis that was

about the finished products circulated, it is necessary to suppose intermediaries' system

between the producer and the distributor. Beside the objects in obsidian or beside the stone

dishes, peddlers would also diffuse these new copper objects (pearls and the other jewels).

If it was about itinerant craftsmen, they would be added to the elaboration of objects in

semiprecious stones during their journey, the integration of the native copper and the

malachite considering the little difference between the traditional techniques of manufacturing

of stone jewels and those realized with copper.

These practices will become more present from the second phase of the metallurgy

when the prestigious goods will begin to circulate and when the working techniques of the

copper will be better asserted and original.

Conclusion: In spite of these discoveries, the "pre-metallurgical" phase did not really

inaugurate a new technical era and did not modify the structure of the societies of this period.

It however saw the introduction of a new material, with new technique as the annealing. The

bases have been put, so that the development of the copper for the manufacturing of tools and

prestigious objects would be more complex than the simple pearl takes place. The discovery

and the use of native copper were one of the essential elements to create the possibilities that

offer this material. It remained to identifying it under more numerous forms (oxides and

sulfides) allowing to work on it oftener and easier.

3.2.2. Phase of the "first metallurgy" (from the 6th to the 4th millennium):

Reductions of copper oxides and copper sulfides, appearance of the first alloys Cu / As,

realization of tools and prestigious goods, distributions of objects and supply in diversified

rough materials.

The used copper forms: The "family" relationship between copper ore and the pure

copper was understood during this period. The passage from one to another, which was not

Journal of Ancient Civilizations, Vol. 23, 2008

carried out in the "pre-metallurgical" phase, is now completely realized. Copper ores are

going to be widely used and transformed to obtain some copper but also alloys with arsenic,

then tin until the end of the 4th millennium.

When was the transformation of copper ore on the scale of the Ancient Middle East

realized? The first smelting copper was known and used in the whole Mesopotamia, Anatolia,

Iranian Plateau, Arabian Peninsula and Transcaucasia from the 5th millennium and especially

in the 4th millennium. It became, then, impossible to identify clearly which types of ores were

used to make objects, if we do not find production sites with the raw ores and the waste of

reduction. The smelting of ores entails important chemical reorganizations. The practice of

smelting with several types of ores or the smelting of the same ore resulting from several

sources and the re-smelting of already realized objects still complicate the determination of

the origins and the exact types of the used raw material.

According to the modern techniques of investigation, the research for the leading

isotopes sometimes constitutes a means to advance the hypotheses. But this process still

remains a bit reliable considering the complexity of the possibilities and the weak sampling of

databases for every source of copper ore, arsenic and tin. If we would add its important cost, it

did not become a systematic practice yet and keeps developing.

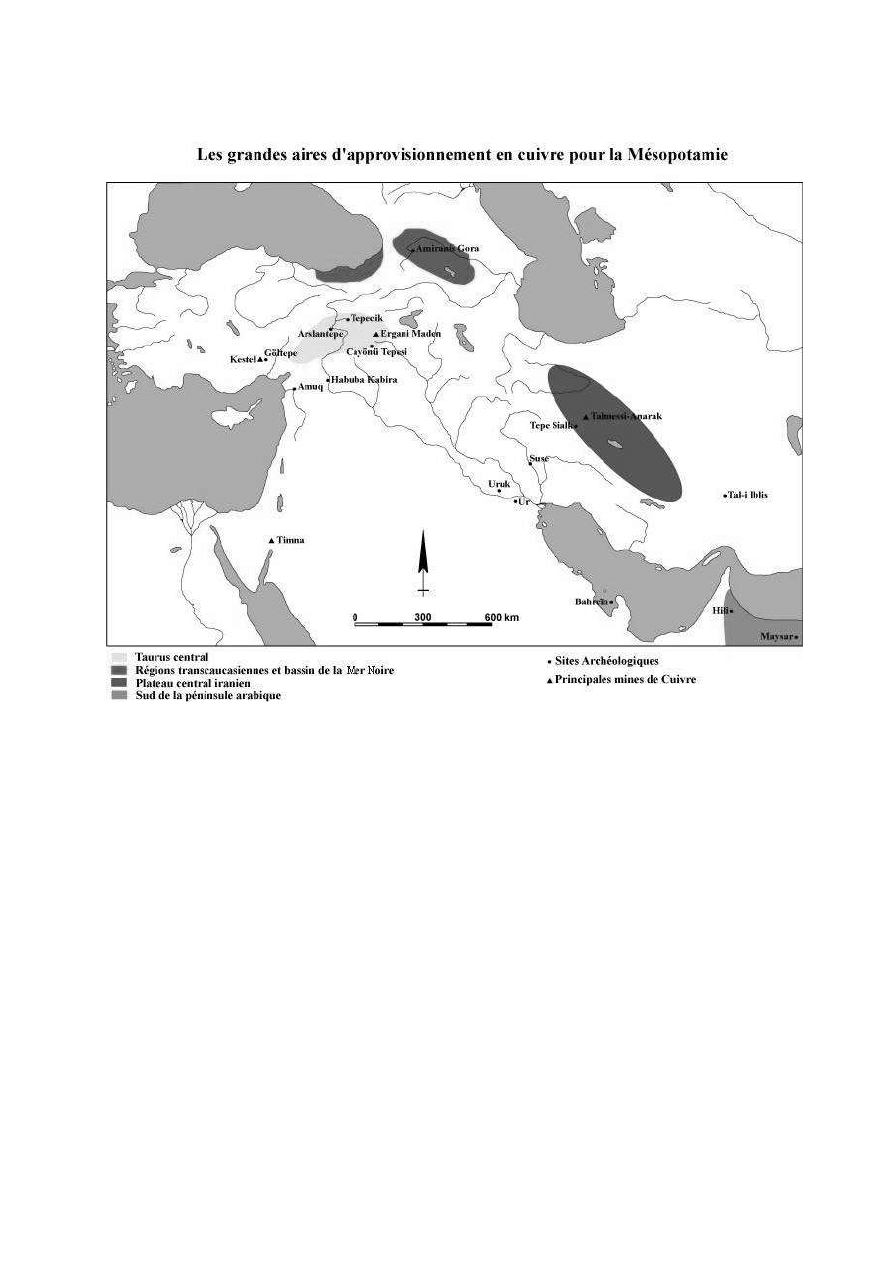

The crossed technological jump was in this situation during this period when there was

an explosion of the sources of raw materials. They were more diversified as the map of the

cupriferous zones of the Middle East (See the map n°3) shows. The sources of raw materials

can be also multiple on the same site as it was demonstrated in Arslantepe for several levels

among which the oldest of the end of Chalcolithic (Period VII of the site)

7

.

It was during this period when the first alloys appeared between several metals as the

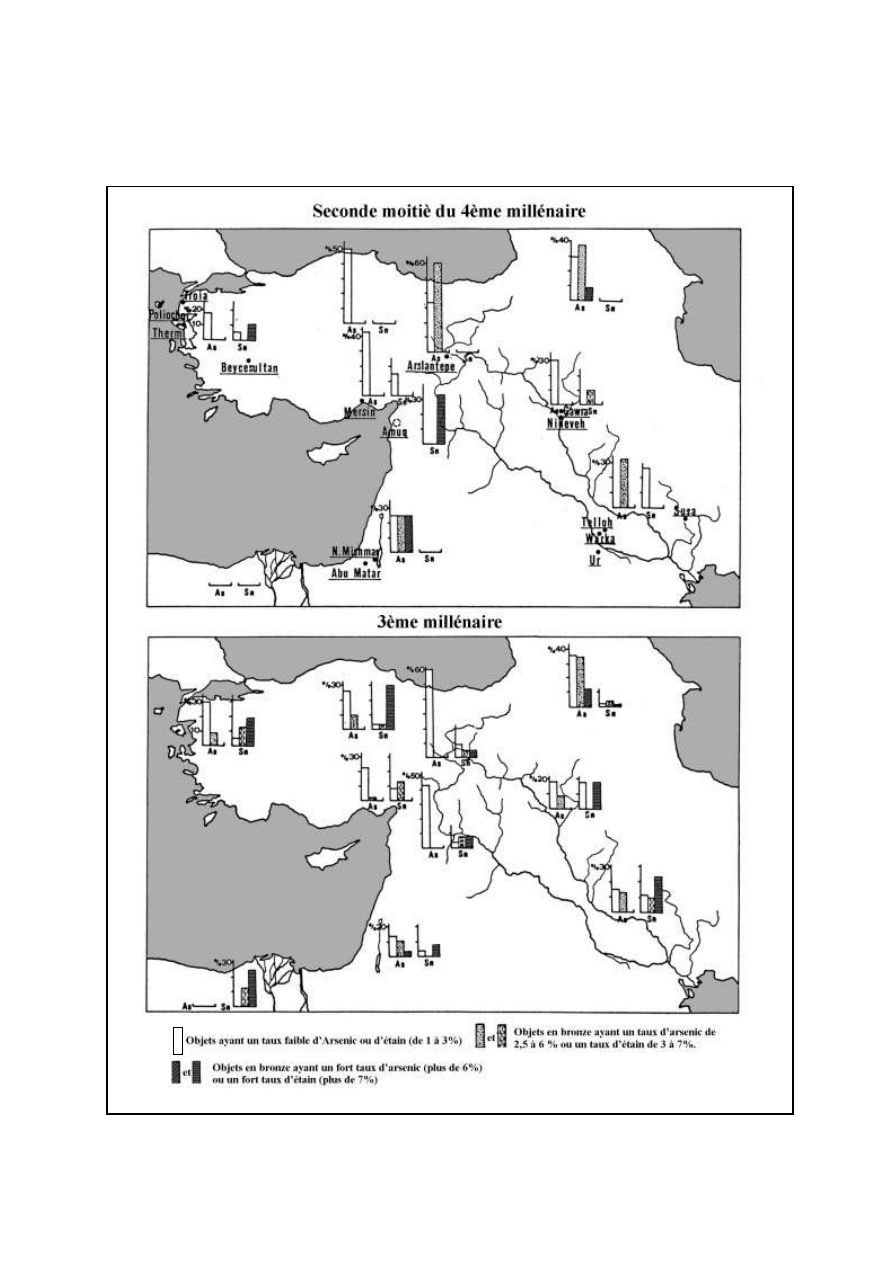

association between copper and arsenic or copper and tin. The alloy of bronze tells the arsenic

copper was the first to be used. It is attested since the middle of the 4th millennium on sites of

Anatolia as Beycesultan level XXXIV or Arslantepe period VII

8

. One recovers it as directly in

the Transcaucasian objects of the Kuro-Arax culture with percentages from 2 to 8% of arsenic.

But it doesn't seem to have existed in this region a "pre-metallurgic" development phase

9

. We

arrive directly to an important technological stage without passing by the phase of groping

and discovery of these new raw materials. This new centre of metallurgic already appears

constituted.

7

PALMIERI A. and al. 1999, p. 143 and 147.

8

MONTERO FENOLLOS J-L. 1998, p. 103

9

KAVTARADZE G. L. 1999, p. 74.

Journal of Ancient Civilizations, Vol. 23, 2008

We observe that strongest percentages are recovered on objects of the 3rd millennium.

The map of distribution indicates the rate of arsenic well for all regions associated to the

copper (See map n°4).

The techniques used: During this period, the big technological innovation is

undoubtedly the realization of alloy. If it is purposeful, whatever is the means to get this alloy,

this evolution permitted to achieve, following the type of object, some mix of specific metals

having precise features. For example, for the manufacture of weapons and tools, the hardness

and the size of the objects require some parameters that an object made of copper won't

perfectly possess. In Arslantepe, the arsenical concentrations are rather important and specific

in certain objects, which suggested to the authors that had deliberately been obtained

10

.

It seems like in Ikiztepe; a distinction between swords, spears and the other objects

can be established. The spearhead have a maximum contents of arsenic from 2.5 % to 3 %, for

the swords, the variation is between 4.5 % to 5 %.

Was a choice deliberated on the quantity of arsenic following the function of the object

able to be made? Had we a technical control pushed enough to make a difference of some

percentages without measuring device? Under what shape was the arsenic, in the form of

metal? Then, what technology of elaboration, in the form of oxide? Which practices of

identification, and especially identification of content? We return to the same questioning

there and it is thus the archaeological translation of the analytical information and the results

which remain delicate to interpret.

However, it is difficult to believe in a simple coincidence. It is many specific

techniques which are mastered by the metallurgists to realize certain type of objects. The

modern methods of investigation allowed noticing that the process of carburizing is probably

the phenomenon, the easiest way to bring to a successful conclusion to arrive at the voluntary

enrichments in arsenic observed on certain objects

11

. It is about a process of treatment in

isolation. The arsenic is concentrated in a more or less deep zone of the object to modify its

aspect or to improve certain properties of the material with which is constituted. For example:

bigger hardness, better corrosion resistance...

A blade by which we would like to increase the content in arsenic on its surface should

rather be subjected to the process of carburizing. The object presents an important contact

10

CANEVA C. and PALMIERI A. 1983, p. 643-644.

11

The carburizing or the thermo-chemical treatment of distribution is a general term indicating any heat

treatment by which we modify more or less profoundly the nature of a metal by distribution of elements of alloy

from its surface.

Journal of Ancient Civilizations, Vol. 23, 2008

area, favorable to this type of treatment. The formation of arsenic on a blade maybe inferred

by an impregnation in closed melting pot. On the surface of the blade, we can put down a

powder on the base of arsenic.

The traces elements of the analyses of ores and objects show that, since the

Chalcolithic, the former metallurgists knew that some ores produced metal with different

properties. They possessed an understanding of the interactions between different metals that,

even though it was not felt or was translated in precise terms, constituted a fundamental

progress in the knowledge of metallurgy. This awareness stopped to a convenient and

pragmatic level with the observation that the mixture of some ores brought a different quality

to the finished products.

Concerning the exchanges, this apparition of alloys was fast on an important

geographical area. Considering this large distribution, it doesn't seem to have existed a more

advanced regional mastery in particular zones. We have observed that, in the previous phase,

Anatolia had a length of advance in the first usage of the native copper and some techniques

as annealing. Now, some regions as South Mesopotamia, Transcaucasia, Iran are perfectly

masters in copper / arsenic alloys. How did the different necessary knowledge appear to

achieve complex objects? Can we speak of export of a knowledge come besides and

assimilated to pass the initiate stage? The too fragile discoveries for the older periods in some

parts of Middle East maybe change our vision of the first metallurgic for regions like Iran,

Transcaucasia? These hypotheses are not antagonists: they were able to combine it in some

regions. To bring an explanation to these questions, it is necessary to lead micro regional

studies and to make new excavations and surveys in some regions.

At the end of this second period, the apparition of the alloys is a new technique

completely mastered. The complete and total melting of copper ores, oxide and sulfide, been

part of the necessary stages to arrive to a mastery of metallurgy. It must precede the stage of

the alloys of which can be the motor with poly-metallic ores, where copper and other

elements are mixed naturally.

We know that this work of purification is important, often difficult and require a

certain technical mastery in different related domains. For example, the conduct of fire must

be optimal to achieve reductions of ores are sometimes complicated. The structures of

combustions evolved clearly during this period. It is on this period, we date the first real

structures of combustions dedicated to a metallurgic work (Değirmentepe, Norşuntepe, Tepe

Journal of Ancient Civilizations, Vol. 23, 2008

Ghabristan, Tepe Sialk, Amiranis Gora, Baba-dervish)

12

. Their constructions require the

understanding of the properties of some recalcitrant materials to resist the heat (clay, silica

and fiber).

These materials enter in the composition of another element frequently recovered on

the archaeological fields: the crucible. We think that this tool was the case of the raw ore or

more often of ore purified in order to sink it in the molds.

To increase the temperature, the artificial means as the systems of bellows (tuyères,

pots bellows, and fireplace) became indispensable. The crucibles are, like the tuyères for

example, precious archaeological witnesses. First, we observe that the zones of productions

concern Anatolia and Iran for the 5th millennium. From the 4th millennium, it appears in

strength of the Transcaucasia with the advent of the culture Kuro-Arax that shows a complete

mastery of the technical devices to drive a fire with elevated temperatures required by

metallurgy.

In the domain of casting, numerous innovations are attested during this second phase.

The molds became fluently objects discovered and are of several types. We know four

different types of molds which intervenes three types of techniques

13

: The technique said of

the open mold, the one of the bivalve mold and the technique of the lost wax. The first two are

attested well during this phase on several regions of Middle East: Anatolia, Transcaucasia,

Iran and North Mesopotamia. The last is more difficult to observe, because these molds are

destroyed in the process of use: It may stay only the objects that, in some cases, indicates us

the use of this technique that would have appeared since the end of the 4th millennium.

The use: There again, the corpus diversifies in an astonishing manner with objects

coming from different indexes. For example, we recover the two groups of the first phase:

The ornaments (jewelry, jewels) and the instruments / tools. But a considerable difference

appears: The group of the tools made of copper enlarged considerably as well as in quantity

that in the different expressions that it can take. The axes heads are now declined under

multiple shapes.

To these traditional groups, a new category of copper objects or in alloy is added: the

weapons

14

. Composed of swords and spearheads, this group develops itself since the 4th

millennium with notably the swords of Arslantepe. This discovery permits to discern the

12

These various structures of reductions or smelting are dated between 5th and 4th millenniums. See details in

GAILHARD N. 2007, p. 147.

13

GAILHARD N. 2007, p. 208 to 214.

14

GERMEZ G., 2007. He realizes a very complete study on this type of object.

Journal of Ancient Civilizations, Vol. 23, 2008

function of these objects and their symbolic value better. This group of weapons are

constituted by nine swords and twelve spearheads found in a public building of the period

VIA. It doesn't make any doubt that these weapons had a symbolic role and was instruments

of power and prestige. Their importance passes the simple function of weapons. It specifies

here the power of the elites because of their presence in a public space.

Besides, this tendency that is to grant a symbolic use to the objects made of metal is

reinforced by the large proportion of bronzes of the 4th millennium recovered as treasures,

associated the most often deliberately to tombs or hiding places

15

. This simultaneous

emergence of hierarchized societies and the apparition of metallurgy in some parts of the

Ancient Middle East provoked a reciprocal stimulation and reinforced the development of the

two phenomena

16

.

What is the distribution between the various uses and the types of metallic objects? It

is difficult to know, because the number of objects became very important. It is necessary to

achieve a heavy statistical seriation work on a big scale. It is a fully-fledged research. This

article on the techniques and the exchanges of copper to the Ancient Middle East doesn't have

vocation to achieve it. Some projects as ARCANE where a part of work concerns the objects

made of metal can create important and systematic data bases

17

. Besides, a common and

internationally recognized typology permitting simple exchanges between researchers will be

able to be adopted.

Nevertheless, some limits to such a work are to note here: It is obvious that the

conservation of the objects to utilitarian goal is worse than the one of those intended to a

prestige use. The use of the tools entails their fast deterioration, occasionally their breaking.

The tools can be recast, whereas the jewelry, weapons and adornments were kept carefully

with their owner in the tomb. This reality entailed effects of concentrations of the discoveries

on a type rather than another.

But it is certain that considering this new role played by metal; its development is

going to provoke important changes in its distribution. The exchanges go extensively to

develop itself at the same time as the production is going to increase.

The exchanges: It is a real change of scale that comes true during this second phase.

This important transformation of the exchanges can be observed according to three axes:

15

One of the most famous examples is the treasure of Nazhal Mishmar during this period.

16

YENER K.A. 2000, p. 47.

17

ARCANE Project: Synchronizing Cultures and Civilizations of the Ancient Near East and the Eastern

Mediterranean in the Third Millennium BC

Journal of Ancient Civilizations, Vol. 23, 2008

The distribution of the knowledge. It allows practicing the metallurgy in

numerous copper-rich regions or not.

The distribution of raw materials. They are now exploited in more

numerous regions.

The distribution on long distances of more complex and diversified metal

objects.

At the end of this second phase, we observe new strategies to get these metal objects.

This phenomenon is called "the Uruk expansion" would have allowed a supply in exotic

objects in South Mesopotamia where the hierarchical societies are rapidly growing. It is a

particular case, because it is about a very organized and planned strategy, but it reveals the

importance of the increase of goods traffic.

This complex expression of exchanges of goods shows that the traffic of objects

becomes an important issue in the Middle East societies. From this moment, the metal will

keep a particular status and a strategic importance because, afterwards, it is quoted regularly

in texts as constituent business objects, spoils of war or accurately listed in the inventories of

palaces.

Conclusion: The phase of the "first metallurgy" such as we have just described

represents the first stage of the copper metallurgy. The first metallurgists succeeded and

understood the intrinsic relation between pure copper and ore, fundamental technological

stage which allowed secondly the idea of mixture which ended in alloys.

The function of the copper also becomes more important thanks to the combination of

several factors: The increase of the production, a diversified use with a more important

catalogue of objects and a geographical extension of the zones where people practice the

metallurgy and use the metallic objects.

At the end of the 4th millennium, almost all the problems met by the former

metallurgists to obtain specific objects following their functions are resolved.

The distribution also begins to be much more important and affected very different

regions. Concretely, the complex topography and the geographical mosaic of the Middle East

allowed a distribution of metallurgy techniques. But the ideas and the knowledge, the needs

and the desires of more or less distant but finally nearby societies appeared and the influences

then showed themselves.

Journal of Ancient Civilizations, Vol. 23, 2008

Furthermore, it became more and more current that small archeological sites reveal

some metallic objects indicating the important penetration of the metal in the common life at

the end of this period. It is the end of the discovery of the metallurgy; we are going to enter

into the millennium of the metal use.

3.2.3. Phase of the "full copper metallurgy" ( 3rd millennium): Reductions of

complex ores in numerous regions, first use of the alloy Cu / Sn without disappearance of Cu /

As, vast and diversified corpus resulting from complex methods of casting and from work of

forge.

The used copper forms: From the 3rd millennium, the various types of copper ore are

well known by the populations of the Ancient Middle East, allowing a more important

production. It is economic and political choices which are going to influence more or less the

origin of the ore, more than its shape (oxide or sulfide). In these more and more structured and

complex societies, political and economic decisions are determining the place for find raw

materials. The appearance of new commercial roads with the South Arabia Peninsula is the

change for the origin of the supply of Mesopotamia in the 3rd millennium. New sources of

copper ore are then available for the rich city of South Mesopotamian.

Globally, we thus find on archeological sites the same quantity of sulfide ores as

copper oxide. It is also necessary to consider the more and more usual practice of remelting.

The production becomes more important, to reuse the bronze objects to melt again becomes

more frequent and the remelting is often described or implied in texts.

The massive use of objects allying the copper to the tin indicates us that a new shape

of alloy is understood and realized by the metallurgists. This new bronze shape, even if it lives

with the former shape of bronze with arsenic, has still increased the attractiveness of products

to answer to the demand better. Parallel to this important development of the bronze, the gold

and the silver are also more and more used.

All this agitation certainly contributed to develop new techniques to make more

complex objects. It facilitated also certainly the emergence of a real more and more structured

crafts which was able to be associated with the administration of palaces and temples for their

supply as indicate it texts of the end of the 3rd millennium

18

.

18

BOTTERO J. 1964, p. 654

Journal of Ancient Civilizations, Vol. 23, 2008

The used techniques: Indeed, the 3rd millennium marks the introduction or the

distribution of techniques as the lost wax casting process and the casting in bivalve mould.

The people do not content ourselves any more with the simple hammering: One casting

asymmetrical objects with numerous decorations, sometimes in several parts. The complex

objects, as small statuettes, are now practicable.

The case of the copper statuette discovered in Tell Agule is eloquent

19

. We noticed that

beyond the control of the technique of the lost wax, the nucleus in clay allowing an economy

of metal was also known and used by the metallurgists.

Another region, as Luristan, knows at the end of the 3rd millennium, the beginning of

rich periods in the manufacturing of bronzes with the lost wax casting process (like axes

heads found in Bactrian).

Other techniques appear as the manufacturing of gouges to octagonal section, or the

casting of a handle on the silk of a blade of dagger according to the technique of the master

mould. More ancient inventions as the hafting to fix a handle (first certificate in Sialk in the

4th millennium) are developed and improved with specific axes. They are axes with

transverse hafting. This type of axe requires a casting in a bivalve mould. We find these

weapons in Ur, Kish, Mari and Susa.

The use: The bronze serves to casting weapons, vases, pins, bracelets, "religious" objects,

statuettes. At this time, the variety is very important. For example, more than 1588 vases in

metal (copper, bronze, gold, silver, electrum and lead) were found in Iraq from the beginning

of the metallurgical production until the Akkad period. The frequency of the discoveries

became more important and sites of smaller importance also deliver metallic objects

indicating a certain popularization of this type of objects.

Many bronze objects reached us because they were protected inside graves against the

practice of remelting. The corpus is certainly little representative because resulting from a

choice deliberated on certain types of objects. Nevertheless, its examination indicates us that

the production for graves was mainly weapons (axes, daggers, spearheads and arrowheads).

We can sometimes discover vases and jewels. It is clear that all these objects must be put in

contact with the buried persons.

19

GAILHARD N. 2007, p. 214.

Journal of Ancient Civilizations, Vol. 23, 2008

The exchanges: With the last studies led on the exchanges from the Ancient Bronze,

we discern two vast zones. They are two recognizable roads used at most possibly left by the

physical geography. The first one is the Trans-Tigris axis emerging from the region of Diyala

and can connect Mesopotamia and Iranian plateau. The second is the Arabian-Persian axis

beginning in Turan, then Oman and his copper mines, crossing Persian Gulf to finish in South

Mesopotamia. This new axis of communication have repercussions on the system of copper

supply in Mesopotamia generally and more particularly for the South Mesopotamian.

This new road of the copper sources seems to have shown itself during the 3rd

millennium

20

and even if no site can be connected to the exploitation of copper before the

period of Umm an-Nar. It would seem that the mining and metallurgical activities began in

Oman from the 4th millennium

21

. In any case, the relations between this region and

Mesopotamia are attested well by the presence of Obeid shards on numerous sites of the

Arabian Peninsula (al-Markh, Abou Khamis, Ras al Khaimah et Ain Qannas).

From the 3rd millennium, the relations became even more net with the discovery of bi-

chrome painted vases, characteristics of Djemdet Nasr period and discovered in Oman, in the

region of Djebel Hafit where we know that the ore was smelted around 3000 B.C. as the

example of a copper pin resulting from Hili 8

22

. The mine of Maysar, exploited during the 3rd

millennium, delivered numerous ingots: it is another proof of the exploitation of the copper.

This copper source in the Ancient Bronze 1, from the gulf, does not seem any more be

questioned. It is even better informed for more recent periods in the documentation written

from Early Dynastic and Akkadian periods.

Gulf was in competition with other copper regions like the Iranian plateau or Anatolia

and played a role of crossroads between various regions rich in ores and woods. Indeed we

mostly note that Gulf doesn’t have resources of tin: it was necessary to find it somewhere else

because the bronze objects tin began in the 3rd millennium to become more and more

important.

The import of this new raw material was inevitable. The traditional source quoted by

the researchers are situated in Afghanistan and made the road East / West the essential actor of

distribution of tin. But it is now advisable to consider the other possible sources as those of

the central Anatolia and central Asia. This information shows how much, from the 3rd

20

HUOT J-L. 2004, p. 223.

21

QUENET Ph. 2000, p. 206.

22

CLEUZIOU S. 1982, p. 18 and POTTS D.T. 1990.

Journal of Ancient Civilizations, Vol. 23, 2008

millennium, the exchanges of raw materials as metals became extremely complex, leaning on

several possible sources.

Conclusion: during this phase of the "full copper metallurgy", a real complex around

the metallurgy is now in place. Several elements drive us to this conclusion:

The important variety of the used ores. Oxide, sulfide, in

association with some arsenic and some tin. The

development of use of lead, gold and silver, all the

metals and their ores can be now worked. Sources are

known better

and

exploited. This

reality

has

consequences on the geographical areas of production or

supply in raw materials.

A real explosion of the working techniques of the metal.

The realizations are more complex, allow to make until

then impracticable objects, looking some more of

importance to the metal and to those who know how to

transform it. This knowledge is widely spread or

acquired because we saw more and more new regions

producing an important metallurgy (Bactrian, South

Mesopotamian, regions of the Gulf). It is unmistakable

that at this level of technical complexity, the metallurgist

is a highly qualified person, working on the metal

regularly.

At the same time, as the development of the techniques

of transformation of copper and manufacturing of bronze

objects, the use of these objects is going to become more

important and more common, even if the copper remains

as a rare material. Moreover, the first texts testify of this

rarity and the practice of the burial of bronze objects

give evidence of its importance.

Finally, the exchanges became more consequent and

diversified. This phenomenon is also general because the

development of more complex societies facilitates the

Journal of Ancient Civilizations, Vol. 23, 2008

exchange of raw materials, techniques and objects. The

implementation of commercial roads following mostly

geographical axes allows this admixture of knowledge

and materials and facilitates the technical development.

Conclusion

In this article, we understood how much the organization of the work had evolved and

how much the exchanges had exploded allowing the development of a full and complex

technology. The specialization became necessary for the development of a technique of

copper transformation and requiring a specific knowledge. The appearance of a complex

industry of metal at the end of the 3rd millennium is now a fact which is concretely translated

through the discovery of zones of important productions (workshops), numerous bronze

objects and using several specific techniques in the metallurgical work. Another consequence

of this development is a more important distribution of copper and bronze. The precious

objects requiring an important expertise, the bronze objects are at the top of their art and the

metallurgists are about to investigate new horizons with the iron ore.

The metallurgy participated as other raw materials in the multiplication of contacts and

exchanges between remote populations, playing an important role in the distribution of the

knowledge and the goods. Some people considered that the metallurgy had such an impact as

they granted her a major role in the development of civilizations by giving the name of a

metal or an alloy for every period. Considering the complexity of the phenomena of

development of societies, we, now, have to put this simple vision in perspective. But, it

remains true that, in certain cases, the copper and the metallurgy in the Middle East are

largely participated in the development of certain regions. In particular, we can think of the

pre-metallurgical phase in central Anatolia and also the development of the city like Mari in

the 3rd millennium. Without the development of the copper work, this city would not have

had such an important development.

Journal of Ancient Civilizations, Vol. 23, 2008

Map n°1: Distribution of the "pre-metallurgical" Anatolian sites

Map n°2: Distribution of the "pre-metallurgical" Mesopotamian sites and

the zone of the "Fertile Crescent".

Journal of Ancient Civilizations, Vol. 23, 2008

Map n°3: The cupriferous zones

Journal of Ancient Civilizations, Vol. 23, 2008

Map n°4: Map of distributions of the rates of arsenic and tin in the bronze

objects of the Middle East

Journal of Ancient Civilizations, Vol. 23, 2008

Bibliography

BOTTERO J.

1964

« Asie occidentale » dans le Dictionnaire Archéologique des techniques, Tome II.

Editions de l’accueil, Paris, p. 649-657.

CANEVA C., PALMIERI A. M.

1983

« Metalwork at Arslantepe in the late Chalcolithic and early bronze I : The evidence

from metal analyses », dans Origini XII, 2 (Preistoria e protostoria della civiltà

antiche), Roma, p. 637-54.

CLEUZIOU S.

1982

« Hili and the Beginning of Oasis Life in Eastern Arabia » dans Proceedings of the

Seminar for Arabian Studies 12, pp. 15-22.

GAILHARD N.

2007

"The transformation of copper in Near East from the Neolithic to the end of the 3rd

millennium. Survey of a technological chain.", », Thèse de Doctorat, Université de

Paris I – Panthéon-Sorbone, Paris,

, in 2009 a new version in British Archaeological

Reports, Oxford.

GERMEZ G.

2007

“L'armement en métal au Proche et Moyen-Orient : des origines à 1750 av. J.-C.”, »,

Thèse de Doctorat, Université de Paris I – Panthéon-Sorbone, Paris,

http://tel.archives-ouvertes.fr/tel-00339404/fr/

HUOT J-L.

2004 « Une archéologie des peuples du Proche-Orient, Des premiers villageois aux peuples

des cités-états », Tome 1, Ed. errance, Paris.

KAVTARADZE G. L.

1999

« The Importance of Metallurgical data for the Formation of a Central

Transcaucasian Chronoly » dans Proceedings of the International Conference The

Beginnings of Metallurgy, Der Anschnitt, beiheft 9, Bochum 1995, p. 67-101.

MONTERO FENOLLOS J-L.

1998

« La Metalurgia en el Proximo Oriente Antiguo (III y II milenios a. C.)», dans Aula

Orientalis-Supplementa, Barcelone.

PALMIERI A., FRANGIPANE M., HAUPTMANN A., HESS K.

1999

« Early metallurgy at Arslantepe during the Late Chalcolithic and the Early Bronze

Age IA - IB periods » dans Proceedings of the International Conference The

Beginnings of Metallurgy, Der Anschnitt, beiheft 9, Bochum 1995, p. 141-148.

POTTS D.

1990

« The Arabian Gulf in Antiquity », 2 volumes, Clarendon Press, Oxford.

Journal of Ancient Civilizations, Vol. 23, 2008

QUENET P.

2000

« Un point de vue sur les échanges dans l’Asie Antérieure du Bronze Ancien : Les

relations du Nord de la Mésopotamie avec ses voisins proche-orientaux de la fin de

l’Uruk au début d’Agadé », Thèse de Doctorat, Université de Paris I – Panthéon-

Sorbone, Paris.

YENER K.A.

2000

« The Domestication of Metals. The rise complex metal industries in Anatolia », Brill

(Culture & History of the Ancient Near East), Leiden.

Wyszukiwarka

Podobne podstrony:

PORTER, SCHWARTZ Sacred Killing the archeology of sacrifice in the ancient near east

RECHTE Human sacrifice in the ancient near east

Maps Of The World Middle East

Maps Of The World Middle East

Maps Of The World Middle East

Standing Trial Law and the Person in the Modern Middle East

Speculations on the Origins and Symbolism of Go in Ancient China

Exchange of Goods and Ideas between Cyprus and Crete in the ‚Dark Ages’

Donald H Mills The Hero and the Sea, Patterns of Chaos in Ancient Myth (pdf)(1)

Natural variations detected in the isotopic composition of copper possible applications to archeolo

Fregni A study of the manufacture of copper spearheads in the old copper complex

Jacobsson G A Rare Variant of the Name of Smolensk in Old Russian 1964

Guide to the properties and uses of detergents in biology and biochemistry

Newell, Shanks On the Role of Recognition in Decision Making

A Chymicall treatise of the Ancient and highly illuminated Philosopher

How?n the?stitution of Soul in Modern Times? Overcome

Political Thought of the Age of Enlightenment in France Voltaire, Diderot, Rousseau and Montesquieu

Glass Menagerie, The The Theme of Escape in the Play

więcej podobnych podstron