KRC2ed05 SafetyBus mit E/A 11.05.00 en

CONTROL CABINET

KR C2 edition2005

Interface, SafetyBUS with I/Os

Option 00--137--610

Customer Documentation

Issued: 09 Jan 2006

Version: 00

KRC2ed05 SafetyBus mit E/A 11.05.00 en

e

Copyright

2005

KUKA Roboter GmbH

Zugspitzstrasse 140

D--86165 Augsburg

This documentation or excerpts therefrom may not be reproduced or disclosed to third parties without the express permission of the

publishers.

Other functions not described in this documentation may be operable in the controller. The user has no claims to these functions,

however, in the case of a replacement or service work.

We have checked the content of this documentation for conformity with the hardware and software described. Nevertheless,

discrepancies cannot be precluded, for which reason we are not able to guarantee total conformity. The information in this

documentation is checked on a regular basis, however, and necessary corrections will be incorporated in subsequent editions.

Subject to technical alterations without an effect on the function.

3 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

Contents

1

Introduction

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

Use

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2

Configuration

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Safety

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1

Fundamentals

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2

Additional safety instructions, “SafetyBUS with I/Os”

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3

Liability

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4

Designated use

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Product description

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1

Control cabinet, overview

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2

Connection panel

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1

Safety

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2

Overview

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3

SafetyBUS Gateway A

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Power supply for ESC and SafetyBUS Gateway A

12

. . . . . . . . . . . . . .

4.1

Internal power supply via X111

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2

External power supply via X111

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3

External power supply via X111a in interlinked systems

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Start--up function

16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Safeguard in system operation

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1

Error message via SafetyBUS

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2

Error message via ESC

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Connector pin allocation

19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1

Peripheral connector X111

19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2

SafetyBUS X111a IN and X111b OUT

22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3

Service jumper plug for X111 -- KR C2 edition2005

23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Interface signals

24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1

Interface X111

24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2

Interface X111a IN

26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3

Interface X111b OUT

26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface, SafetyBUS with I/Os

4 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

1

Introduction

5 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

1

Introduction

The option “KR C2 edition2005 Interface, SafetyBUS with I/Os” makes it possible

to connect user--specific input and output signals to the KR C2 edition2005 control

cabinet.

The CI3 bus board is used. On this board an additional bus coupler SafetyBUS

Gateway A is mounted. Depending on the interface design, a CI3 Tech board can

also be used.

1.1

Use

The bus coupler SafetyBUS Gateway A makes 8 safe inputs and 2 safe outputs

available at the interface connector X111. 2 further safe outputs each control 2

contactors, K11/K12 and K13/K14, from which each has 1 floating contact routed

to the interface. This bus coupler is connected to the ESC. The external 24 V DC

power supply for the ESC and the SafetyBUS connection is supplied via connector

X111a, and the outgoing connection is made at connector X111b. Thus additional

ESC and SafetyBUS connections of subsequent control cabinets can be supplied

with this voltage. It is also possible to supply this external voltage via connector

X111.

The option “KR C2 edition2005 Interface, SafetyBUS with I/Os” provides the

following functions:

G

SafetyBUS Gateway connection

G

8 safe inputs via SafetyBUS Gateway

G

2 safe outputs via SafetyBUS Gateway

G

2 safe outputs for contactor control

G

ESC and SafetyBUS power supply

S

External power supply

S

Internal power supply

S

Linking of several control cabinets

Interface, SafetyBUS with I/Os

6 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

1.2

Configuration

The basic cabinet is the KR C2 edition2005. Therefore this documentation only

describes the differences from the standard cabinet.

The following hardware components are included in the option “KR C2 edition2005

Interface, SafetyBUS with I/Os”:

G

C13 bus board or C13 Tech board

G

SafetyBUS Gateway A

G

Peripheral connector X111

G

SafetyBUS connectors X111a and X111b

G

Contactors K11 -- K14

G

Terminal block X2.2

2

Safety

7 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

2

Safety

2.1

Fundamentals

Warning!

Failure to observe these safety instructions could result in injury or a fatal

accident and/or damage to the robot system or other property!

G

All pertinent safety regulations as well as the booklet [Safety and Installation

Instructions] are to be observed when working on the system.

G

The KUKA safety chapter [KRC Safety, General] is supplied with the robot

system and must be read and understood before commencing work.

G

The safety instructions in the KR C2 edition2005 Operating Handbook must

be observed.

G

Before connection, testing and installation work, always refer to the

accompanying circuit diagram.

2.2

Additional safety instructions, “SafetyBUS with I/Os”

G

Installation, exchange and service work on this option or individual

components thereof may be performed only by qualified personnel specially

trained for this purpose and acquainted with the risks involved.

G

The max. current load of connectors X111a and X111b is 10 A. Exceeding this

current limit results in overloading and destruction of the connectors.

G

When the start--up function is used, the robot may only be operated in

AUTOMATIC mode if a functioning safeguard is connected!

Interface, SafetyBUS with I/Os

8 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

2.3

Liability

This option is designed and built using state--of--the--art technology and in

accordance with the recognized safety rules. Nevertheless, improper installation

of this option or its employment for a purpose other than the intended one may

constitute a risk to life and limb of operating personnel or of third parties, or cause

damage to or failure of the control cabinet, resulting in damage to or failure of the

entire robot system and other material property.

The option “Interface, SafetyBUS with I/Os” may only be used in technically perfect

condition in accordance with its designated use and only by safety--conscious

persons who are fully aware of the risks involved in its operation. Connection and

use must be carried out in compliance with this documentation.

2.4

Designated use

Using this option for any purpose other than or additional to that described in

Section 1.1 is considered contrary to its designated use. The manufacturer cannot

be held liable for any damage resulting from such use.

The risk lies entirely with the user.

No liability can be accepted if these directions are disregarded.

3

Product description

9 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

3

Product description

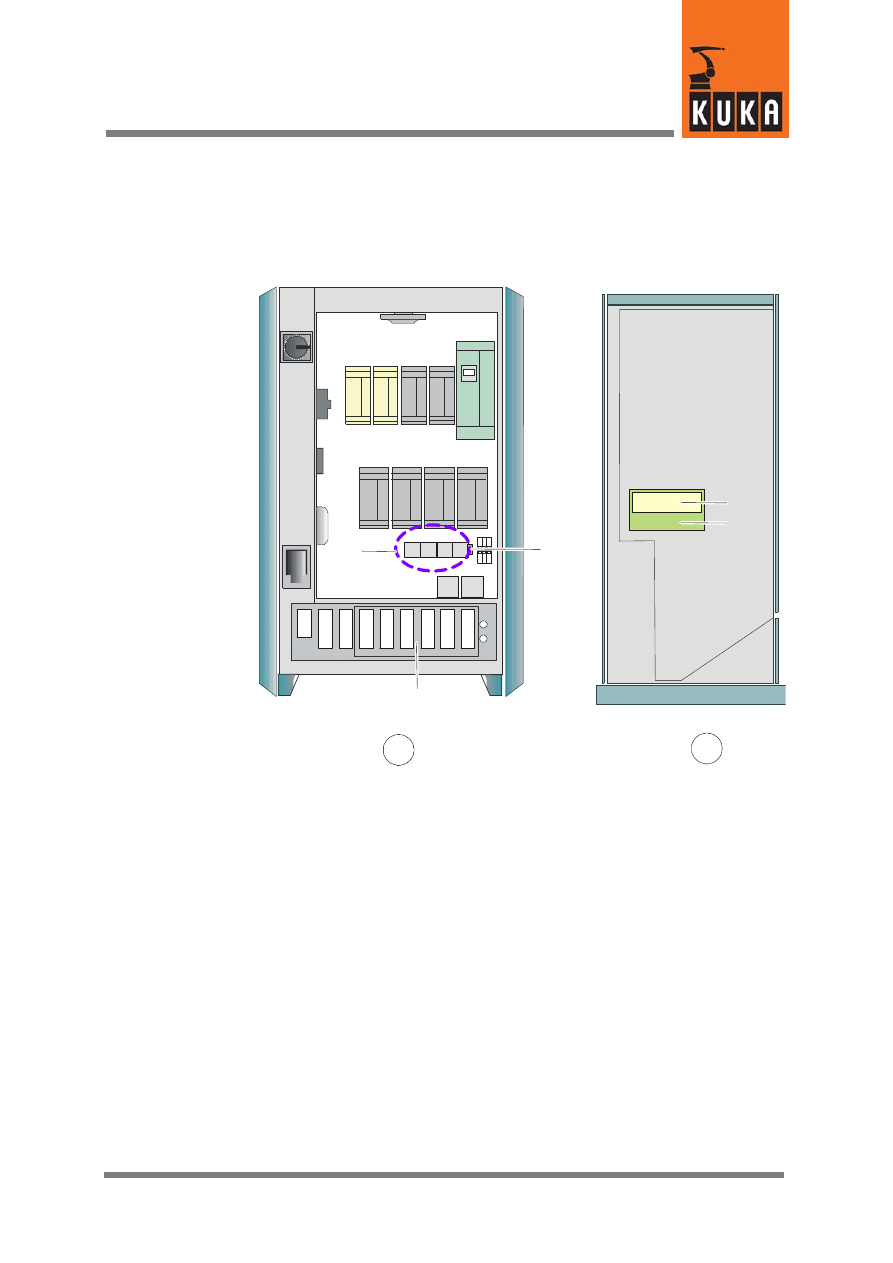

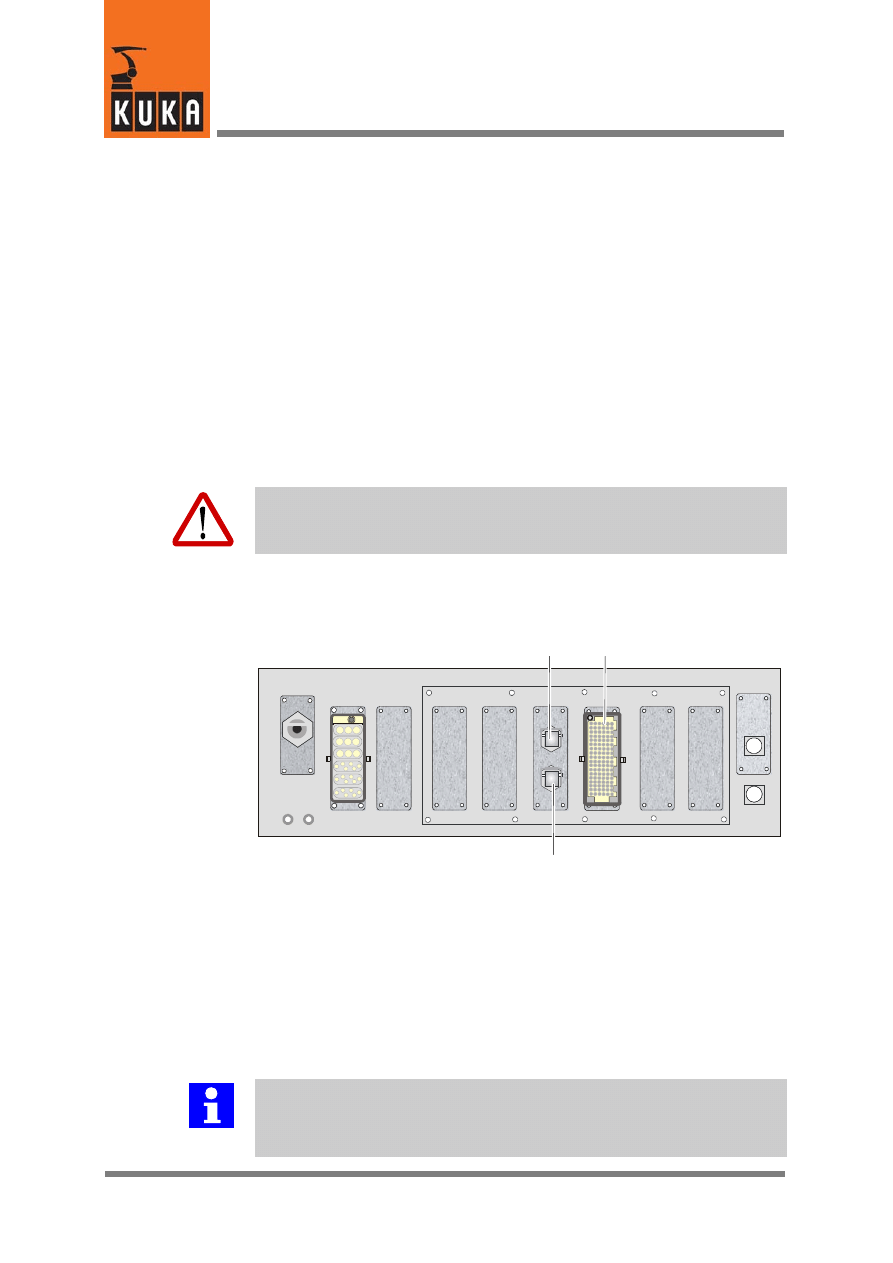

3.1

Control cabinet, overview

1

4

A

B

5

2

3

A

Front view

B

Side view, right

1

Connection panel

2

Contactors K11 -- K14

3

Terminal block 2.2

4

Bus coupler SafetyBUS Gateway A

5

Safety module CI3 Bus board

Fig. 1 Control cabinet, overview

Interface, SafetyBUS with I/Os

10 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

3.2

Connection panel

All the connectors on the connection panel are plug--and--socket connections as

defined by VDE 0627.

Plug--and--socket connections must not be plugged or unplugged while the

controller is operational (i.e. energized).

Requirements:

G

Qualified technical personnel (skilled workers) trained in the handling of

systems and machines.

3.2.1

Safety

Warning!

Before the plug--and--socket connections are plugged or unplugged, the con-

troller and the cables concerned must be deenergized.

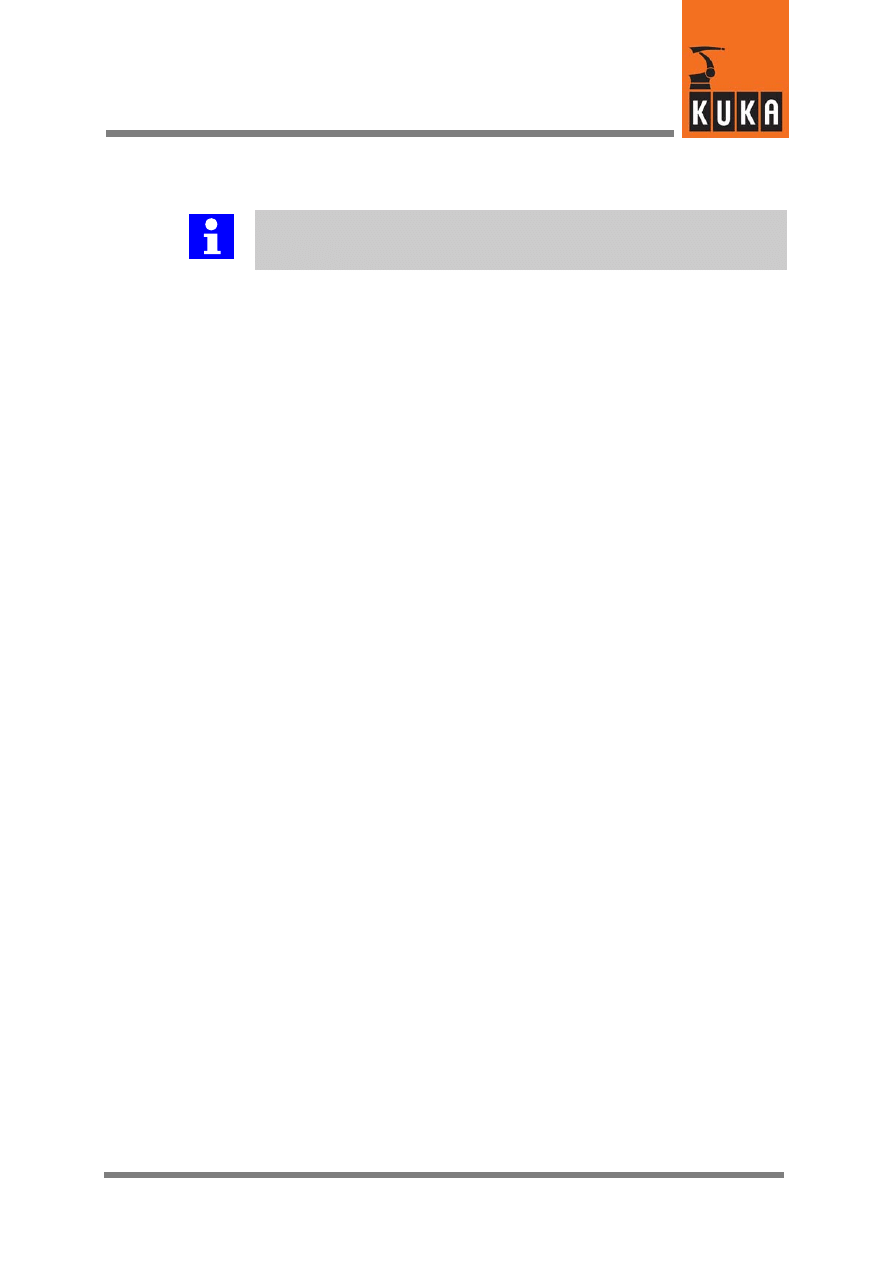

3.2.2

Overview

1

2

3

1

X111a SafetyBUS interface IN

2

X111 Peripheral interface

3

X111b SafetyBUS interface OUT

Fig. 2 Connection panel

The installation positions of the connectors may vary from those illustrated here

depending on the cabinet equipment.

Further information

All contactor, relay and valve coils that are connected to the robot controller

by the user must be equipped with suitable suppressor diodes. (RC elements

and VCR resistors are not suitable.)

3

Product description (continued)

11 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

3.3

SafetyBUS Gateway A

Further information

The SafetyBUS Gateway A is described in detail in the documentation “ESC

Safety System with Gateway”.

Interface, SafetyBUS with I/Os

12 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

4

Power supply for ESC and SafetyBUS Gateway A

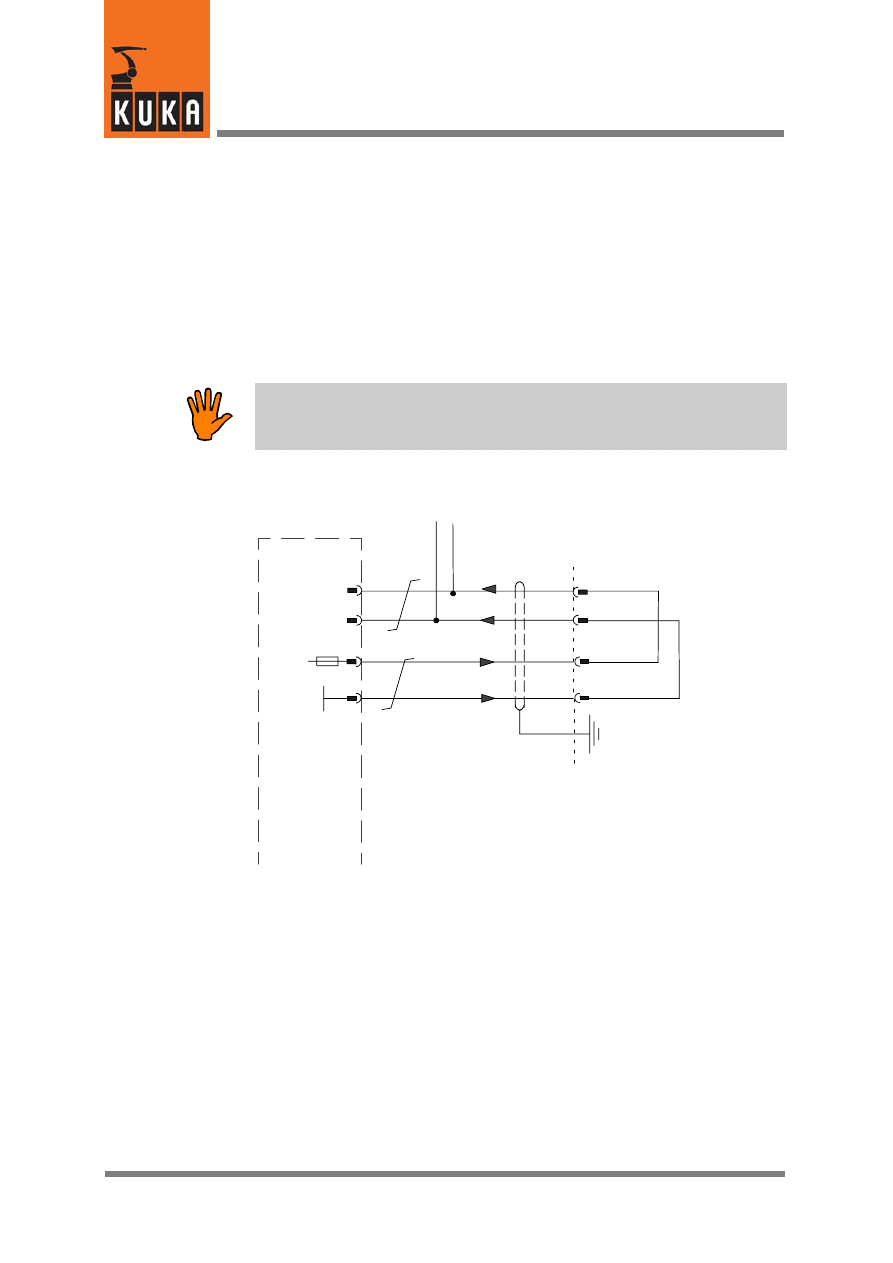

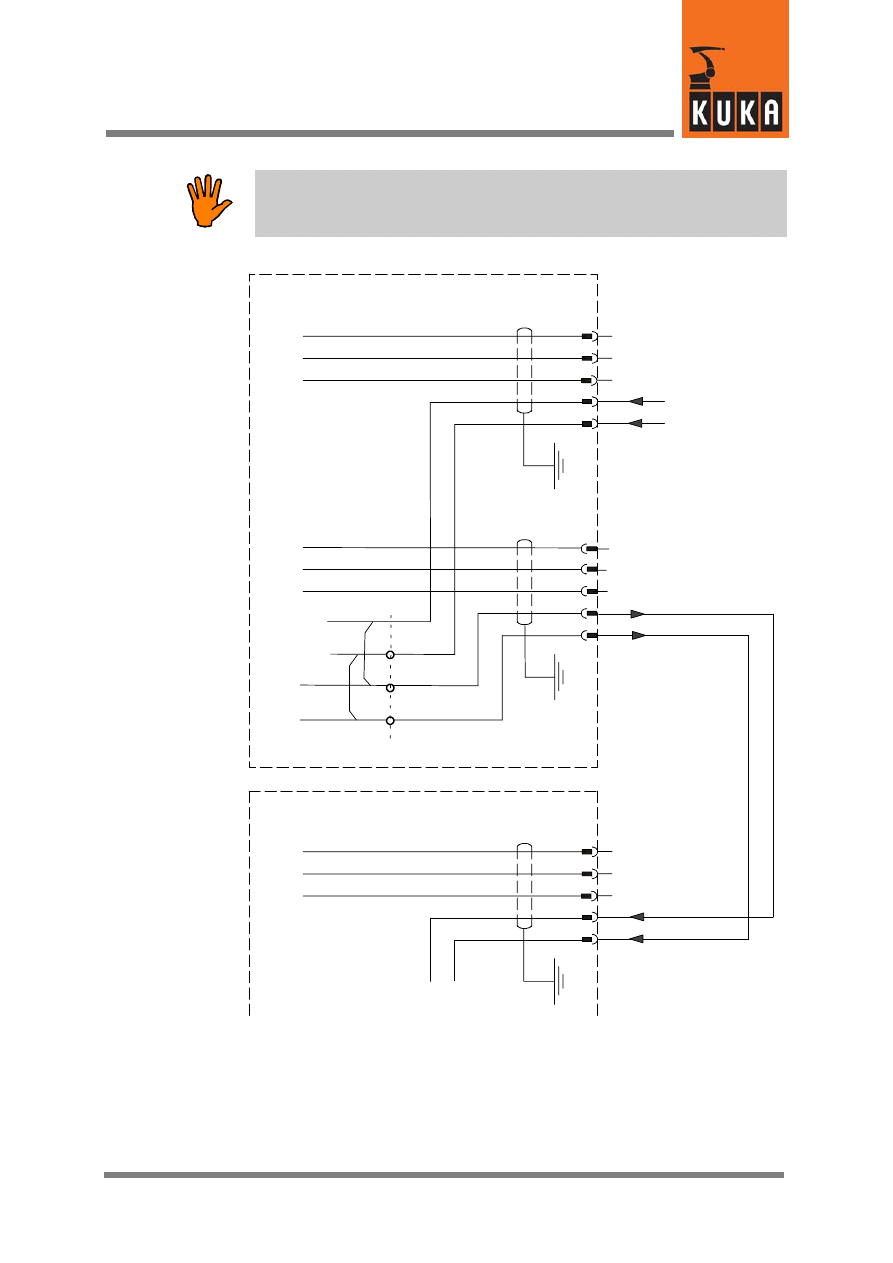

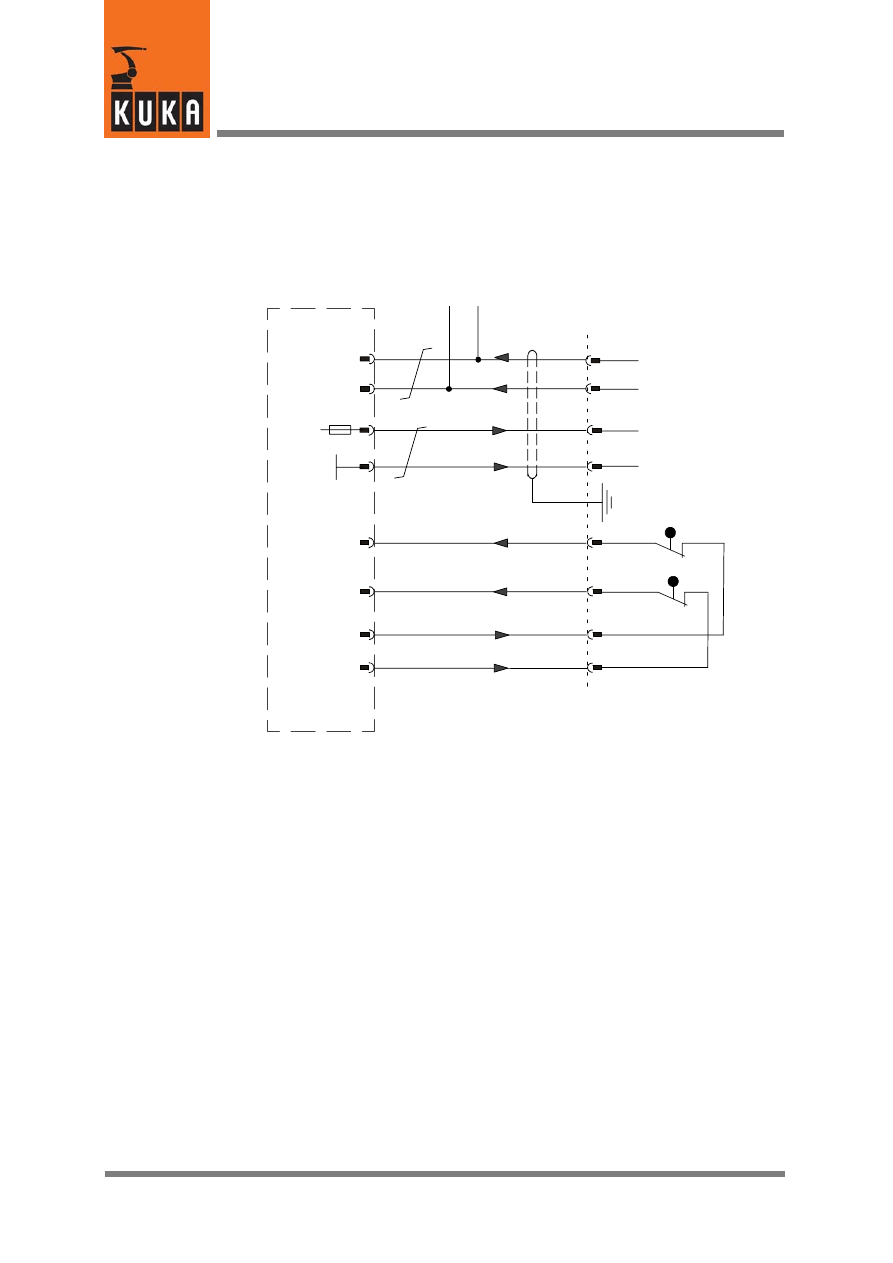

4.1

Internal power supply via X111

The ESC and the SafetyBUS can be supplied with 24 V DC internally via

connector X111, pins 88/89. For this, the jumpers at the interface X111 must be set

in accordance with Fig. 3.

Caution!

In this case, no external power supply may be connected to connector X111a

and no power supply may be routed to other control cabinets via X111b.

X111

88

89

S

afe

ty

modul

e

C

I3

bus

A1

X6

106

107

+24 V internal

0 V internal

7

8

3

4

PE

Via X2.2 to the interfaces

X111a and X111b

4 A

Fig. 3 Internal ESC and SafetyBUS power supply

4

Power supply for ESC and SafetyBUS Gateway A (continued)

13 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

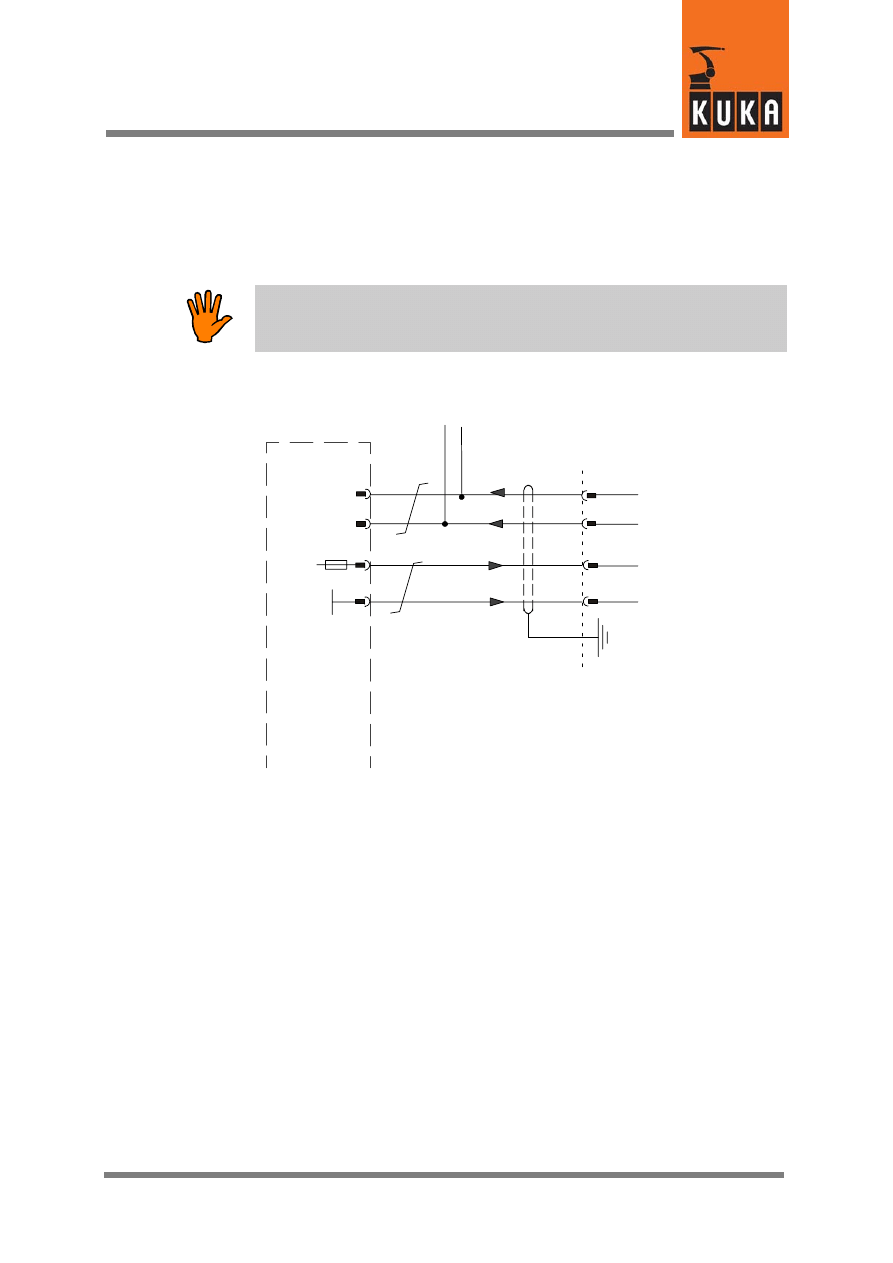

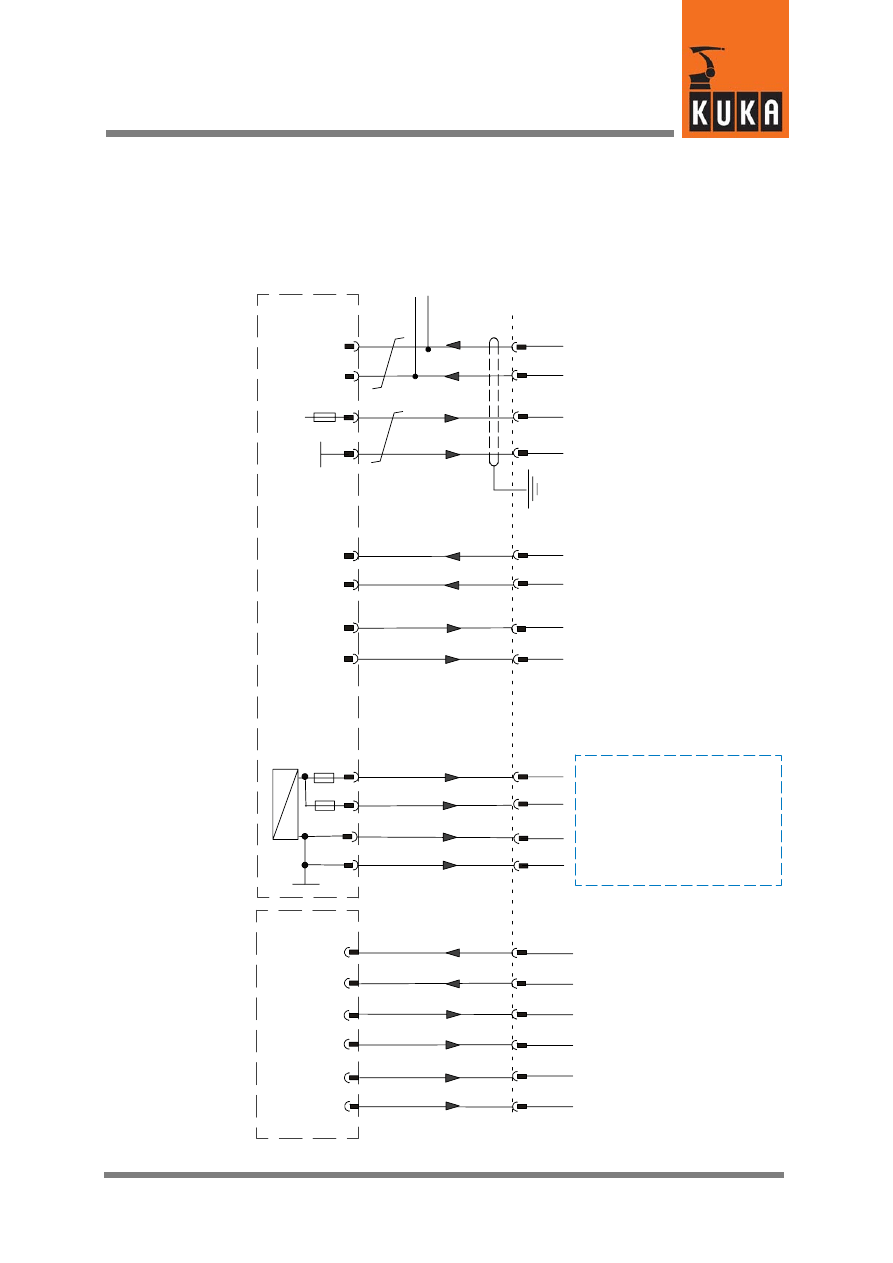

4.2

External power supply via X111

The ESC and the SafetyBUS can be supplied with 24 V DC externally via connector

X111, pins 88/89.

Caution!

In this case, no external power supply may be connected to connector X111a

and no power supply may be routed to other control cabinets via X111b.

X111

24 V external

0 V external

88

89

S

afe

ty

modul

e

C

I3

bus

A1

X6

106

107

+24 V internal

0 V internal

7

8

3

4

PE

Via X2.2 to the interfaces

X111a and X111b

4 A

Fig. 4 External ESC and SafetyBUS power supply

Interface, SafetyBUS with I/Os

14 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

4.3

External power supply via X111a in interlinked systems

The ESC and the SafetyBUS power supply can be applied externally via the

interface connector X111a (Fig. 5). The external power supply then continues in

the control cabinet to the connectors X111b and X111. At connector X111b the

external power supply connection and the SafetyBUS connection to the next

control cabinet can be made.

The number of control cabinets that can be connected in series depends on the

load on the SafetyBUS Gateway A (4 outputs, max. 1 A) and the power consump-

tion of the ESC circuit (max. 1.5 A depending on the number of inputs activated).

Calculation example

Load on output A0:

1.00 A

Load on outputs A1/A2:

0.60 A

(relays K11 -- K14)

Load on output A3:

1.00 A

ESC circuit:

1.50 A

Total current:

4.10 A

In this example, 2 control cabinets can be connected in series.

4

Power supply for ESC and SafetyBUS Gateway A (continued)

15 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

Caution!

The max. current load of connectors X111a and X111b is 10 A. Exceeding this

current limit results in overloading and destruction of the connectors.

X111a IN

1

2

3

1.

CAN GND

CAN L

CAN H

24 V DC external

X111b OUT

1

2

3

1.

CAN GND

CAN L

CAN H

2.

0 V external

2.

X2.2

In

te

rf

ac

e

connec

to

r

X

11

1

X111a IN

1

2

3

1.

CAN GND

CAN L

CAN H

24

V

D

C

ex

ter

nal

2.

0

V

ex

te

rnal

Control cabinet 1

Control cabinet 2

Fig. 5 External power supply in interlinked systems

Interface, SafetyBUS with I/Os

16 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

5

Start--up function

The start--up function makes it possible to activate the safety circuit of the robot

when it is not connected to the SafetyBUS. If a HIGH level (test output A/B) is

detected on the two inputs INB(A) and INB(B) (connector X111, pins 31 und 32),

then the start--up function is activated and the SafetyBUS is ignored. While the

start--up function is activated the digital inputs and outputs of the SafetyBUS

Gateway A will not take effect.

Caution!

When the start--up function is used, the robot may only be operated in AUTO-

MATIC mode if a functioning safeguard is connected!

Further information

In order to be able to operate the robot also in AUTOMATIC mode, two

additional inputs of safeguard channel A (connector X111, pin 13) and of

safeguard channel B (connector X111, pin 14) must detect a HIGH level.

6

Safeguard in system operation

17 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

6

Safeguard in system operation

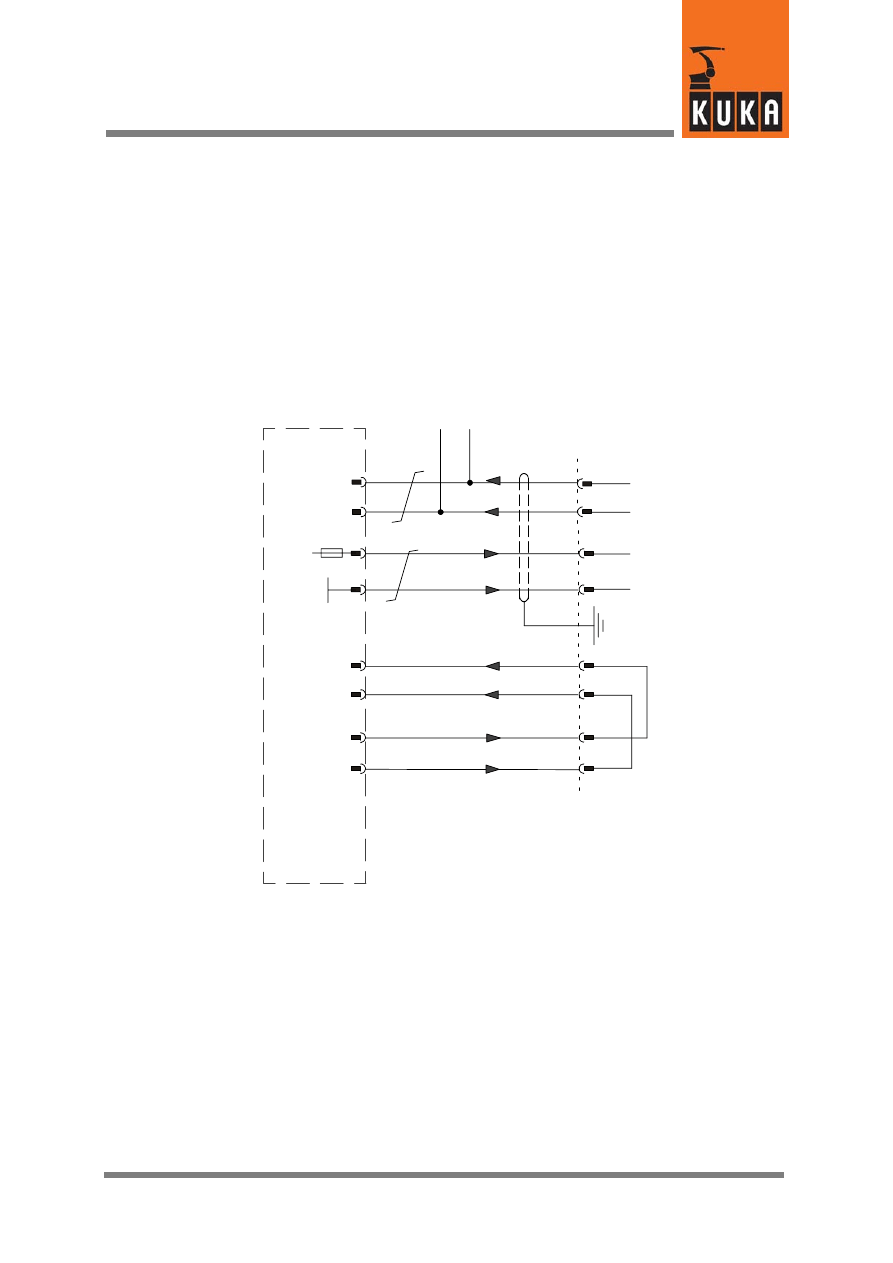

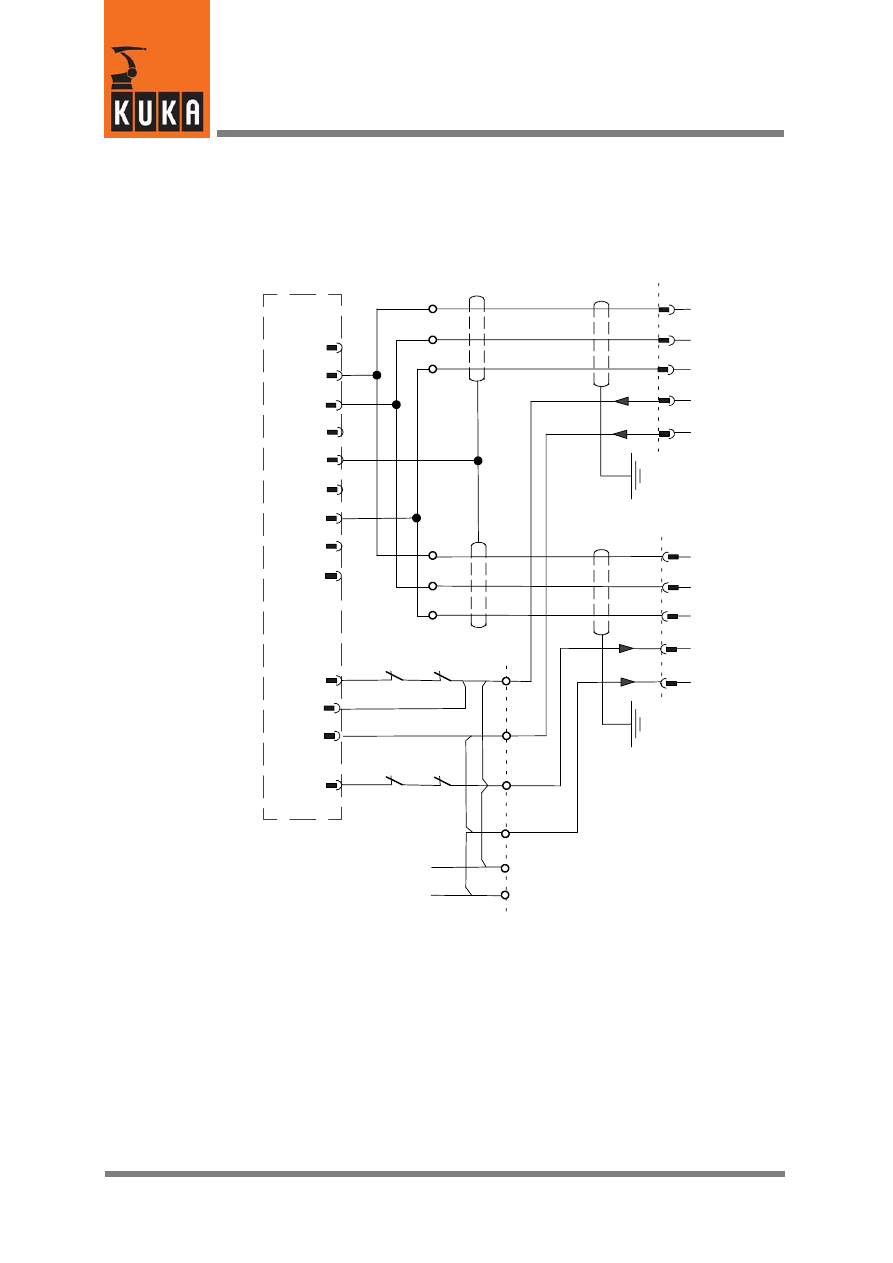

6.1

Error message via SafetyBUS

If the SafetyBUS connection of the KR C2 edition2005 control cabinet signals

operator safety or safeguard via the SafetyBUS, jumpers (pins 13/15 and 14/16)

for the safeguard are required on the X111 interface. If these jumpers are not set,

an operator safety error message is generated via the ESC circuit.

X111

13

Safeguard

Channel A

88

89

S

afe

ty

modul

e

C

I3

bus

A1

X6

X22

106

107

7

8

3

4

9

14

28

15

1

Safeguard

Channel B

Test output A

16

Test output B

20

X 2.2

Interface, SafetyBUS with I/Os

18 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

6.2

Error message via ESC

If operator safety is not signaled via the SafetyBUS, an effective safeguard must

be connected at the terminals X111, pins 13 and 15 and X111, pins 14 and 16.

X111

13

88

89

S

afe

ty

modul

e

C

I3

bus

A1

X6

X22

106

107

7

8

3

4

9

14

28

15

1

S

af

eguar

d

16

20

X 2.2

7

Connector pin allocation

19 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

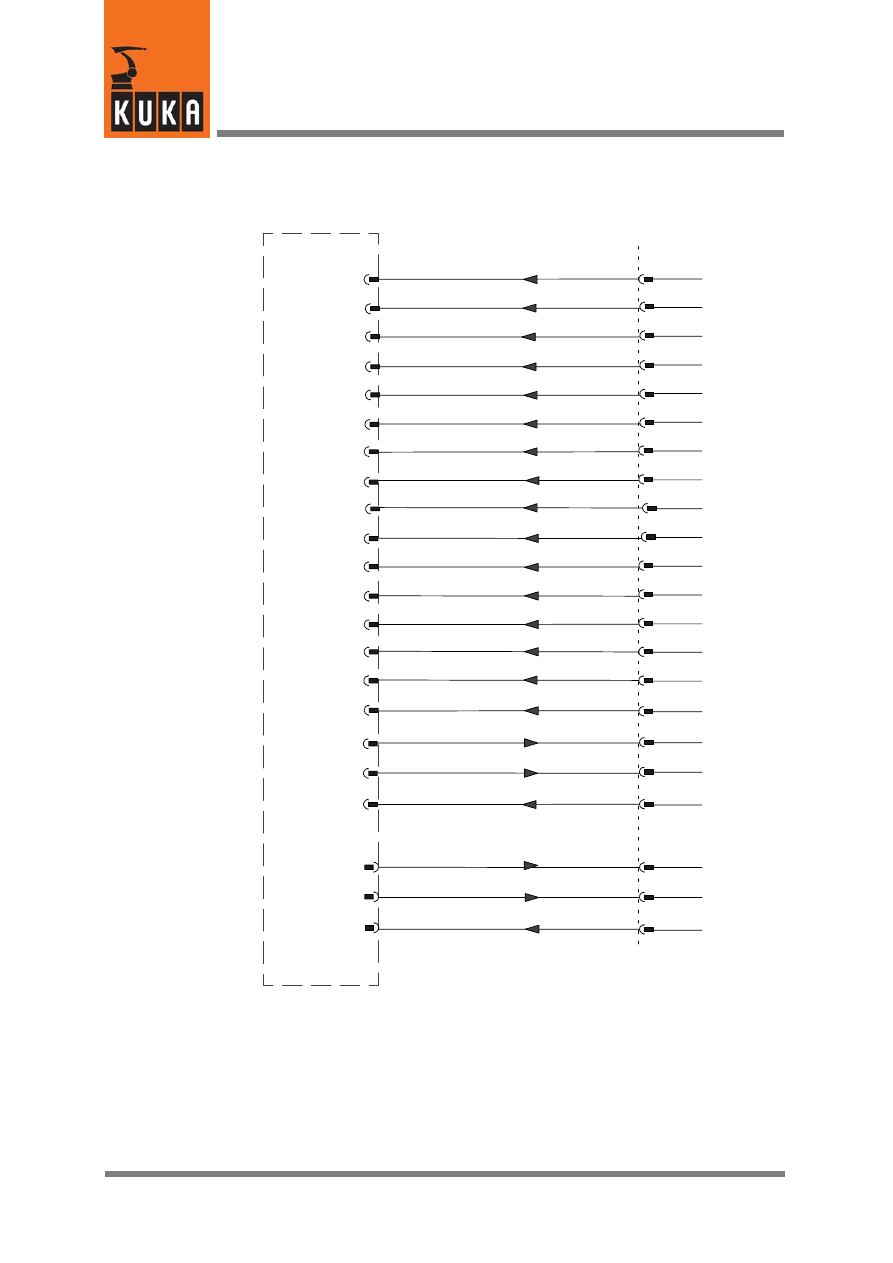

7

Connector pin allocation

7.1

Peripheral connector X111

X111

24 V external

0 V external

13

Safeguard channel A

88

89

S

afe

ty

modul

e

C

I3

bus

A1

X6

X22

106

107

+24 V internal

0 V internal

7

8

3

4

9

14

28

15

1

Safeguard channel B

Test output A

16

Test output B

20

PE

X 2.2

90

24 V DC control voltage, 6 A

36

24 V DC control voltage, 4 A

72

0 V control voltage

18

0 V control voltage

1

2

3

4

X12

Option

X1

INB (B)

17

32

18

/TA24V (A)

20

34

21

31

33

INB (A)

/TA24V (A)

S

afe

ty

BUS

G

ate

w

ay

A

A1

.1

/TA24V (B)

53

22

/TA24V (B)

54

23

Interface, SafetyBUS with I/Os

20 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

S

afe

ty

modul

e

S

af

et

yBUS

G

ate

w

ay

A

A1

.1

X1

X111

D0 (A)

D3 (B)

38

2

39

3

D0 (B)

D1 (A)

40

D1 (B)

4

41

5

42

6

D2 (A)

D2 (B)

7

44

8

D4 (B)

9

46

10

1

D5 (A)

48

12

49

13

D5 (B)

D6 (A)

50

D6 (B)

14

51

15

52

16

D7 (A)

D7 (B)

11

A0 (B)

28

61

30

RAE2--A0

32

37

43

47

45

60

D3 (A)

D4 (A)

A0 (A)

Peripheral connector X111 (continued)

A3 (B)

1

64

3

RAE2--A3

65

5

63

A3 (A)

X8

62

7

Connector pin allocation (continued)

21 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

X111

Relay contact K14

Relay contact K14

78

76

Relay contact K13

Relay contact K12

74

Relay contact K11

73

75

Relay contact K11

Relay contact K12

79

80

77

Relay contact K13

Peripheral connector X111 (continued)

K14

K13

K12

K11

Interface, SafetyBUS with I/Os

22 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

7.2

SafetyBUS X111a IN and X111b OUT

The max. current value for the X111a or X111b 24 V DC external connection is 10 A.

X111a IN

1

2

3

1.

CAN GND

CAN L

CAN H

24 V DC ext.

Shield

X111b OUT

1

2

3

1.

CAN GND

CAN L

CAN H

24 V DC ext.

Shield

1

X2

2

3

4

5

6

7

S

afe

ty

modul

e

S

af

et

yBUS

G

ate

w

ay

A

A1

.1

8

9

CAN

CAN

LOW

GND

LOW

HIGH

GND

HIGH

2.

0 V external

2.

0 V external

X6

6

7

X2.2

1

2

4

int

er

fac

e

connec

to

r

X

11

1

5

K11

K12

X7

5

K13

K14

5

3

6

CI

3

bus

and

7

Connector pin allocation (continued)

23 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

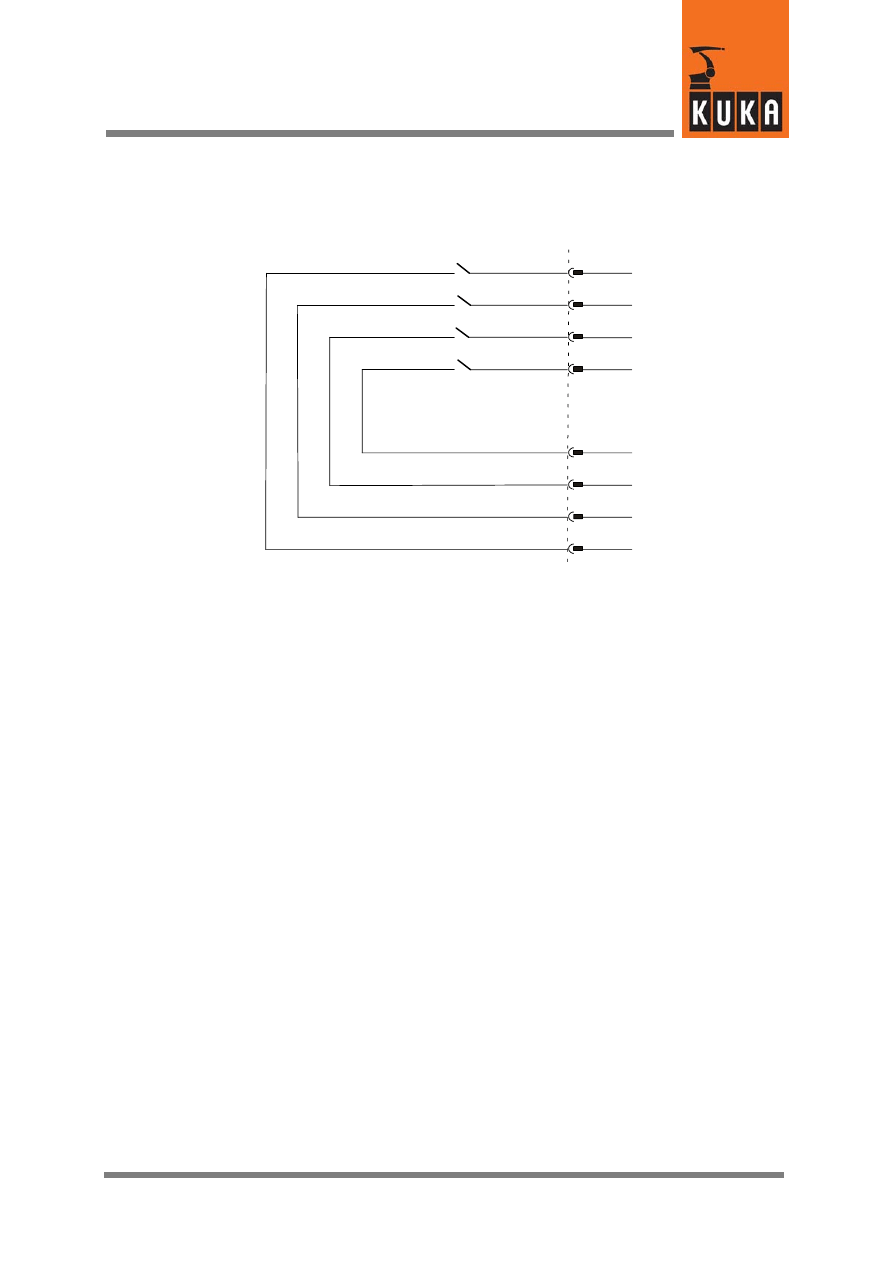

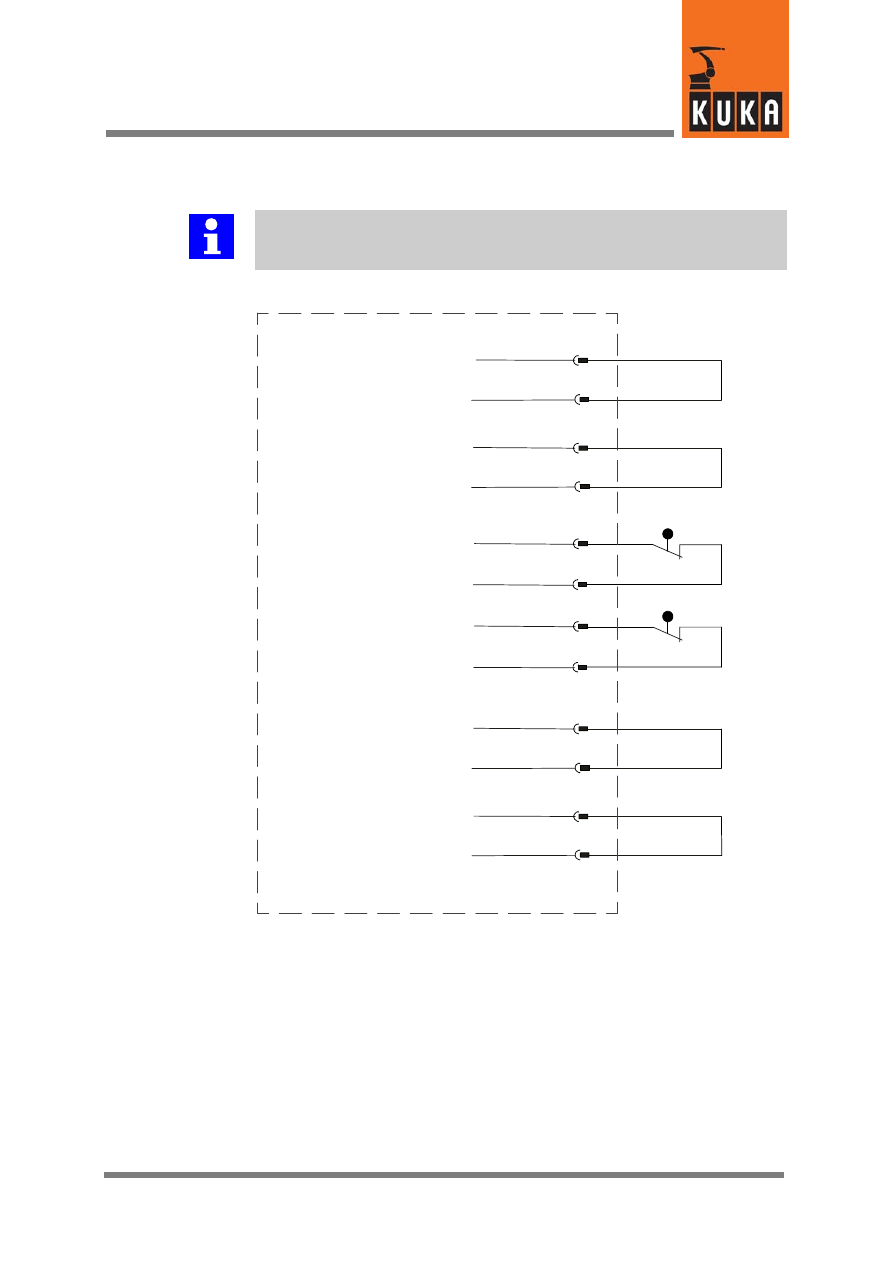

7.3

Service jumper plug for X111 -- KR C2 edition2005

Further information

The jumper plug is only to be used during commissioning and trouble-

shooting.

15

13

S

af

eguar

d

31

33

Test output A

Safeguard channel A

INB (A)

TA24V (A)

32

34

INB (A)

TA24V (A)

16

14

Test output B

Safeguard channel B

88

106

Safety 24 V

24 V

89

107

Safety GND

GND

Interface, SafetyBUS with I/Os

24 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

8

Interface signals

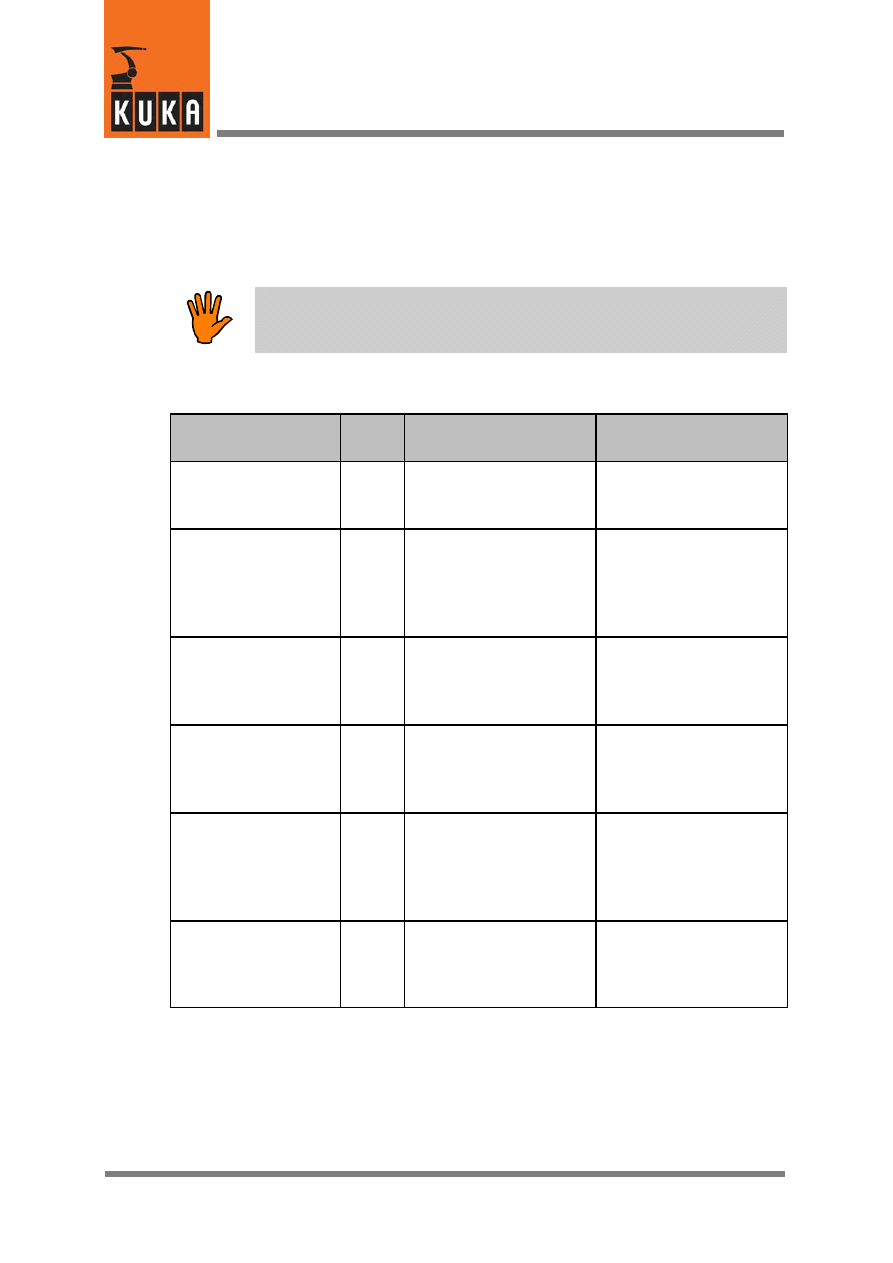

8.1

Interface X111

Caution!

Jumpering or cross--connection of dual--channel inputs is not permitted and

causes immediate disconnection of the drives!

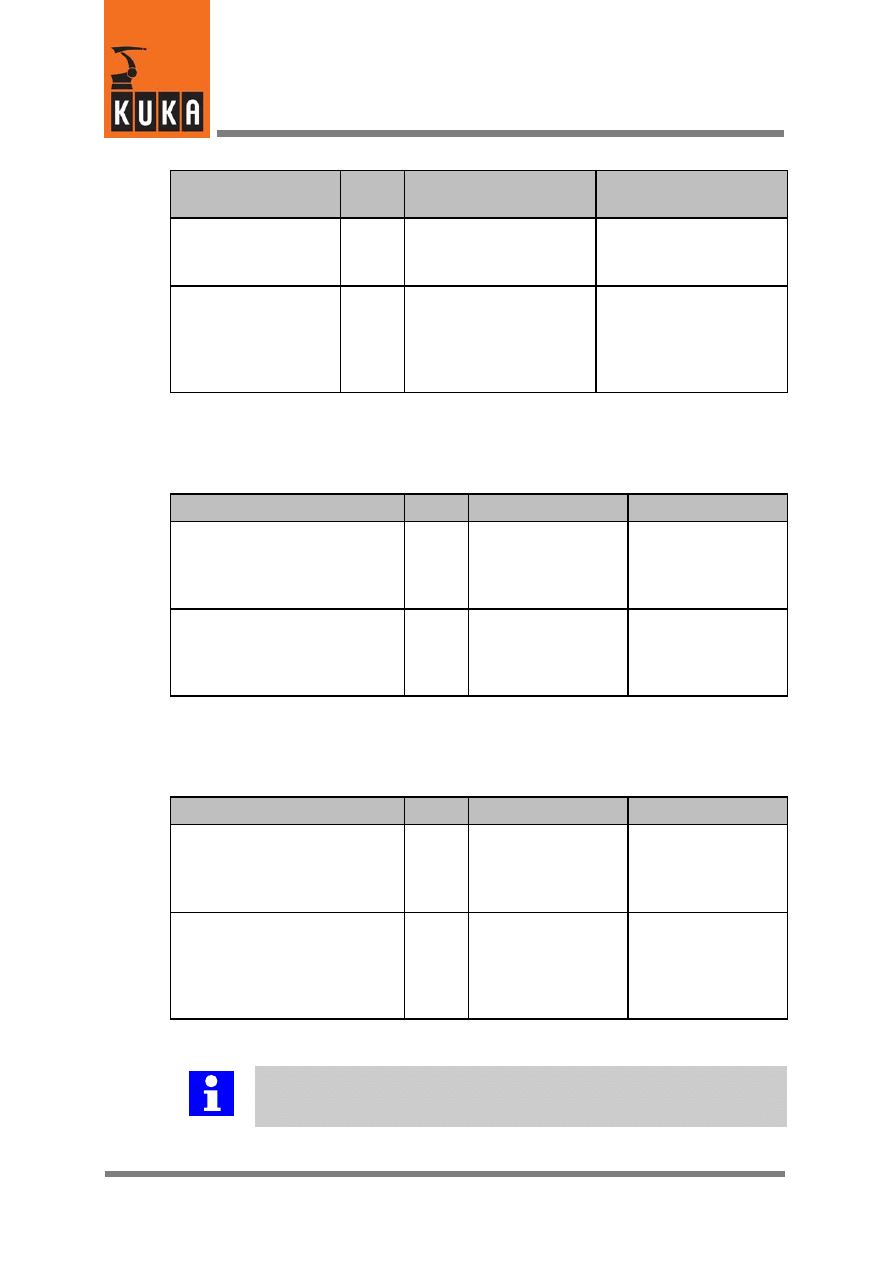

Interface signal

CI bus B board

Pin

Description

Remarks

24 V control voltage

+24 V internal

0 V internal

106

107

ESC power supply

max. 2 A

24 V control voltage

+VCC external

0 V external

88

89

In the absence of an ex-

ternal power supply, 24 V /

0 V must be jumpered in-

ternally (pins 88/106 and

89/107)

An external power supply

is recommended for inter-

linked systems.

24 V control voltage

+24 V

0 V

36

18

24 V control voltage

for supply to external

devices

max. 4 A

Optional. This control volt-

age is available to the cus-

tomer.

Caution: max. 4 A

24 V control voltage

+24 V

0 V

90

72

24 V control voltage

for supply to external

devices

max. 6 A

Optional. This control volt-

age is available to the cus-

tomer.

Caution: max. 6 A

Test output

Channel A

Channel B

15

16

Provides the pulsed volt-

age for the individual inter-

face inputs of both chan-

nels.

Connection example:

safety gate locking mech-

anism is connected under

channel B to pin 16

(TA_B) and pin 14 (B).

Safeguard

Channel A

Channel B

13

14

For dual--channel connec-

tion of a safety gate lock-

ing mechanism

max. 24 V, 10 mA

Only effective in AUTO-

MATIC mode

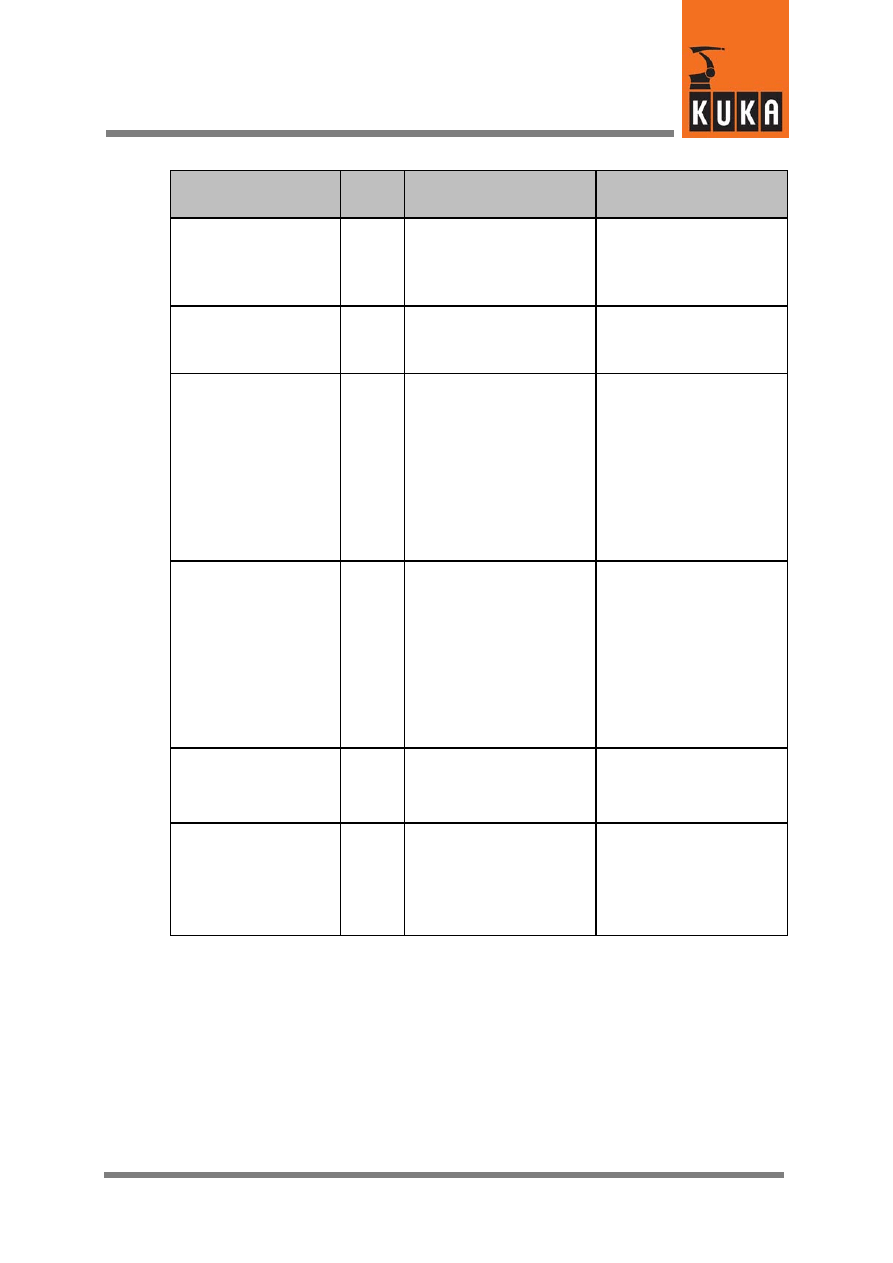

8

Interface signals (continued)

25 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

Interface signal

SafetyBUS Gateway

Pin

Description

Remarks

Test output

Channel A

Channel B

33

34

Provides the pulsed volt-

age for the individual inter-

face inputs of both chan-

nels.

Test outputs for the

start--up function

Start--up

Channel A

Channel B

31

32

Input, start--up

Input A

D0

D1

D2

D3

D4

D5

D6

D7

37

39

41

43

45

47

49

51

Digital safe inputs

Pulsed test output A

(TA24VA)

Input B

D0

D1

D2

D3

D4

D5

D6

D7

38

40

42

44

46

48

50

52

Digital safe inputs

Pulsed test output B

(TA24VB)

Test output

Channel A

Channel B

53

54

Provides the pulsed volt-

age for the individual inter-

face inputs of both chan-

nels.

Output

A0 (A)

A0 (B)

A3 (A)

A3 (B)

60

61

63

64

Digital safe outputs

switches 24 V of output

switches 0 V of output

switches 24 V of output

switches 0 V of output

24 V, resistive/inductive

load, max. 1 A

Interface, SafetyBUS with I/Os

26 of 26

KRC2ed05 SafetyBus mit E/A 11.05.00 en

Interface signal

SafetyBUS Gateway

Pin

Description

Remarks

Return

RAE2--A0

RAE2--A1

62

65

24 V DC unpulsed

Relay contacts

Relay K11

Relay K12

Relay K13

Relay K14

73/74

75/76

77/78

79/80

Floating relay contacts

max. 8 A

8.2

Interface X111a IN

Interface signal

Pin

Description

Remarks

SafetyBUS

CAN L

CAN GND

CAN H

1

2

3

Bus signals

SafetyBUS input

24 V supply voltage

+24 V DC external

0 V external

1.

2.

ESC and SafetyBUS

Gateway power

supply.

Current max. 10 A

8.3

Interface X111b OUT

Interface signal

Pin

Description

Remarks

SafetyBUS

CAN L

CAN GND

CAN H

1

2

3

Bus signals

SafetyBUS output to

further control cabi-

nets.

24 V supply voltage

+24 V DC external

0 V external

1.

2.

Provision of the

24 V DC external

power supply for the

following control cabi-

net.

Further information

When establishing connections, observe the technical data in your specifica-

tions!

1

Index

Index -- i

C

CI3 bus board, 9

Commissioning, 23

Connectors, 10

E

ESC Safety System, 11

I

INB (A), 16

INB (B), 16

Installation positions of the connectors, 10

interlinked systems, 24

K

K11 -- K14, 9

S

Safety instructions, 7

SafetyBUS Gateway A, 9

T

Terminal block 2.2, 9

Troubleshooting, 23

U

Use, 5

X

X111, 10

X111a, 10

X111b, 10

Document Outline

- 1 Introduction

- 2 Safety

- 3 Product description

- 4 Power supply for ESC and SafetyBUS Gateway A

- 5 Start-- up function

- 6 Safeguard in system operation

- 7 Connector pin allocation

- 8 Interface signals

Wyszukiwarka

Podobne podstrony:

krc2 ed05 profibus en

krc2 ed05 pci en

krc2 ed05 interbus en

krc2 ed05 devicenet en

krc2 ed05 external axis 7,8 en

krc2 ed05 kcp holder en

krc2 ed05 20 A Han6 Power Infeed usa en

kb safety en

KRC2 ed05 Profibus

krc2 peri en

KR C2 ed05 Battery Monitoring en

BA KR C2 ed05 Main Switch with Cover en

Safety KR C4 en

new employee safety orientation 1201643571904060 5

Safety net

Budzik Versa wielkość karty kredytowej instrukcja EN

G2 4 PW EN wn Rys 01

więcej podobnych podstron