Biomaterials 22 (2001) 3085–3090

Mechanical properties of artificial tracheas composed

of a mesh cylinder and a spiral stent

Satoshi Kawaguchi

a

, Tatsuo Nakamura

b,

*, Yasuhiko Shimizu

b

, Toshiro Masuda

a

,

Toshikazu Takigawa

a

, Yu Liu

b

, Hiroki Ueda

b

, Takashi Sekine

b

, Kazuya Matsumoto

b

a

Department of Material Chemistry, Kyoto University, Yoshida, Sakyo-ku, Kyoto 606-8501, Japan

b

Institute for Frontier Medical Sciences, Kyoto University, Shogoin, Sakyo-ku, Kyoto 606-8507, Japan

Received 08 February 2000; accepted 20 January 2001

Abstract

Much work has been done on the materials used for mesh-type artificial tracheas, but a precise mechanical evaluation of these

structures has not yet been performed. In the present study, we determined the mechanical properties of typical mesh-type artificial

tracheas and compared them with those of native trachea. Four types of artificial trachea were made and used for the mechanical

tests. The basic frame of all the specimens was composed of a mesh cylinder and a spiral stent. The specimen whose mesh was sealed

with collagen sponge showed almost the same behavior in the force-strain curve under compression, suggesting that collagen sealing

has little effect on mechanical properties. Agreement between measured and estimated mechanical properties was good, especially in

the lowstrain region, suggesting that artificial tracheas can be designed in terms of mechanical properties by mainly considering the

basic frame structure. # 2001 Elsevier Science Ltd. All rights reserved.

Keywords:

Artificial trachea; Canine trachea; Compression test; Tensile test; Mechanical property; Young’s modulus

1. Introduction

Tracheal cartilage provides mechanical strength for

the trachea. Human tracheal cartilage is horseshoe

shaped; the dorsal portion of the trachea lacks cartilage

and is called the ‘‘membrane portion’’. Tracheal

cartilage prevents collapse of the air-way during

inspiration, and prevents over-expansion during expira-

tion.

Recently, the effectiveness and long-term safety of

mesh-type artificial tracheas have been demonstrated

in vivo [1,2], and a newtype of artificial trachea, with

collagen sponge layers added on both the inner and

outer surfaces of the prosthesis, has also been developed

[3]. With regard to the mechanical properties of native

tracheas, there have already been several studies on the

human trachea [4–10]. Although the mechanical proper-

ties of artificial tracheas play an important role in their

practical use, fewstudies have been done on artificial

tracheas [11,12] and a precise mechanical analysis has

not yet been performed for these structures. In the

design of currently used mesh-type artificial tracheas,

the main frame is composed of a mesh cylinder and a

polypropylene (PP) spiral [1–3]. The PP spiral gives the

mesh cylinder mechanical strength, acting like tracheal

cartilage. To make the mesh cylinder airtight and to

enhance the biocompatibility of the mesh, collagen or

collagen sponge may be coated on the mesh cylinder. In

this study, we studied the mechanical properties of

artificial tracheas and compared them with those of

native trachea. In addition, we analyzed the relationship

between structure and mechanical properties.

2. Materials and methods

2.1. Materials

Four typical types of artificial trachea were manu-

factured. They were composed of a fine Marlex

1

mesh

(C.R. Bard Inc., Billerica, MA) cylinder and an outer

spiral PP stent. The stent was attached to the outside of

the mesh cylinder by melting at several points and

*Corresponding author. Tel.: +81-75-751-4148; fax:+81-75-751-

4844.

E-mail address:

nakamura@frontier.kyoto-u.ac.jp (T. Nakamura).

0142-9612/01/$ - see front matter # 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 0 5 6 - 4

further fixed by 6-0 Prolene sutures (Ethicon Inc.,

Somerville, NJ). Table 1 summarizes the sample code,

cross-sectional shape of the stent, outer diameter of the

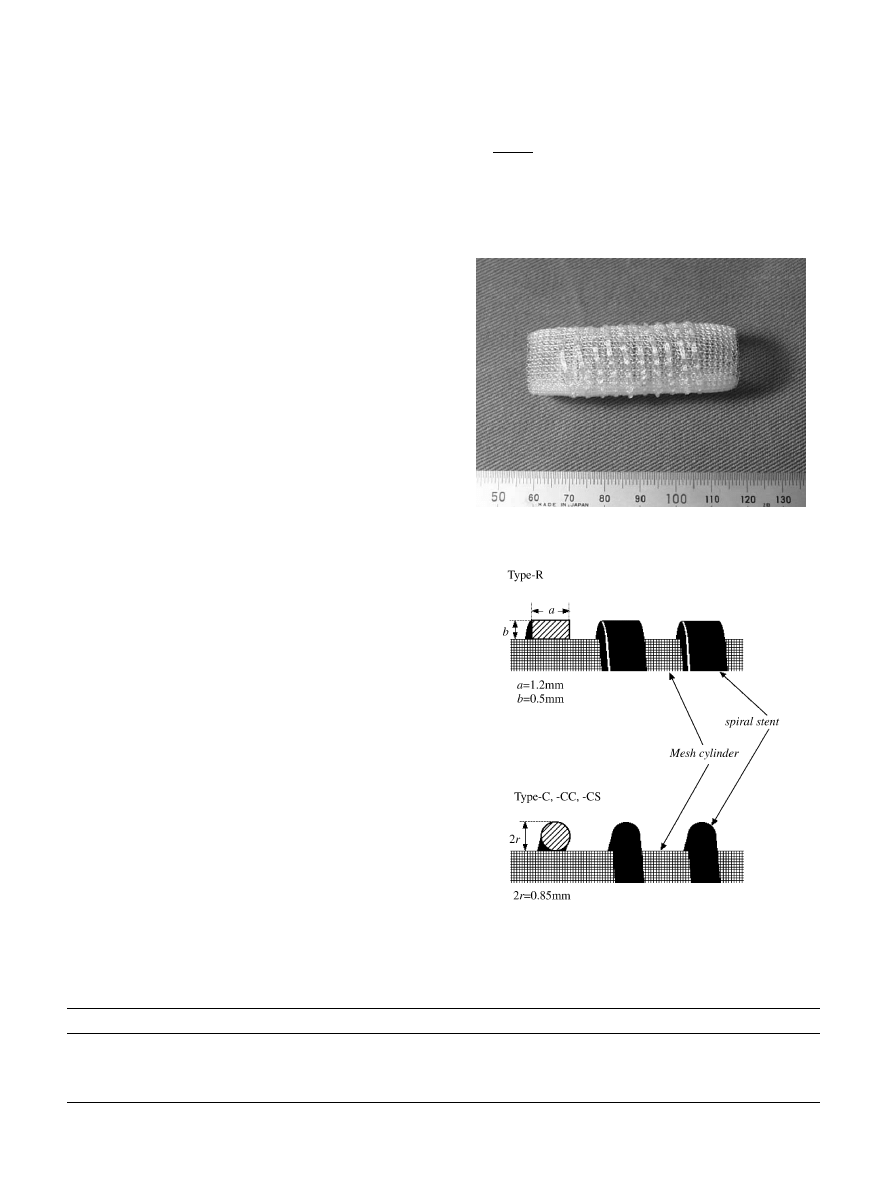

spiral and pitch of the spiral. The stent in Type-R is

rectangular in cross-section, and that in Type-C is

circular. Type-CC has the same main frame as Type-C,

but the surface of the specimen was coated with

collagen. Type-CS was made from Type-CC by laminat-

ing collagen sponge layers with a thickness of 0.5 mm on

both inner and outer surfaces. The lengths of the four

samples were 44–47 mm. Fig. 1 shows a macroscopic

viewof a Type-R specimen, and Fig. 2 show

s a

schematic representation of the specimens. For compar-

ison, we also examined the mechanical properties of

fresh canine trachea. Measurements on the canine

trachea were performed within four hours after removal.

The outer diameter of the canine trachea sample was

14 mm, and a length of 15 mm was used. Since the cross-

section was not exactly circular, the diameter given is the

shortest distance across. For tensile testing of the

cartilage, rectangular specimens (1.0 mm 0.7 mm) were

cut from the whole cartilage.

2.2. Mechanical testing

A tensile tester, RTM-500 (Orientec Co., Tokyo,

Japan), was used. Two parallel plates with diameters of

10 cm (upper plate) and 15 cm (bottom) were used for

the compression tests. The cross-head speed was set to

50 mm/min. Samples were compressed in the radial

direction (Fig. 3), and the force and displacement were

monitored. The same compression test was also done on

the canine trachea. Measurements were made in air for

Type-R and Type-C specimens, and in a saline solution

for Type-CC, Type-CS and canine trachea specimens.

The tensile properties of the tracheal cartilages in the

circumferential direction were examined using the same

apparatus as for the compression tests. In the tensile

test, the measurements were carried out in air and three

cross-head speeds (2, 10 and 100 mm/min) were em-

ployed to clarify the effect of tensile speed on the

mechanical properties of the tracheal cartilages.

2.3. Data analysis

The mechanical properties of the artificial tracheas

under compression were analyzed as force per pitch (f )

and strain (e

c

). e

c

was defined as

e

c

¼

d

0

d

d

0

ð1Þ

where d is the outer diameter of the specimen (stent) and

d

0

is the initial value of d. In data analysis of the

mechanical properties of the canine trachea, a combina-

Table 1

Sample codes and characteristic dimensions of artificial tracheas

Code

Cross-section of stent

Outer diameter of spiral stent (mm)

Pitch of spiral stent (mm)

Type-R

Rectangle

20.8

3.9

Type-C

Circle

20.5

3.9

Type-CC

Circle

18.5

2.7

Type-CS

Circle

18.3

3.2

Fig. 2. Schematic representation of the basic structure of the artificial

tracheas.

Fig. 1. Photograph of Type-R trachea.

S. Kawaguchi et al. / Biomaterials 22 (2001) 3085–3090

3086

tion of force per unit length (w) and e

c

was used. The

data for tensile testing were analyzed in terms of stress

(s) and tensile strain (e

t

). They are given by

s ¼

F

S

0

ð2Þ

e

t

¼

l l

0

l

0

ð3Þ

where F; S

0

and l are the force, the initial cross-sectional

area and the length, respectively, l

0

being the initial

value of l.

3. Results

3.1. Force–strain curves of tracheal specimens

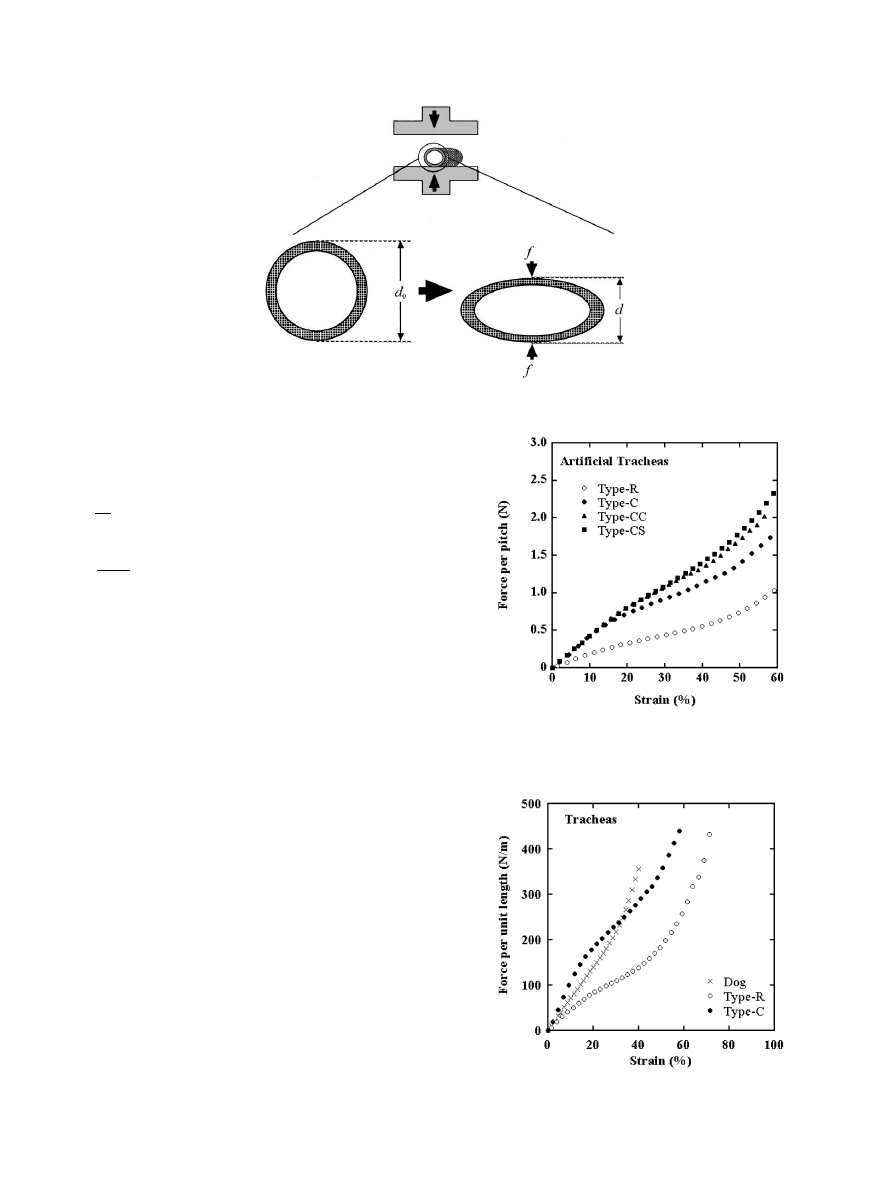

In Fig. 4, f is shown as a function of e

c

for all artificial

tracheas used. At lowstrains, f was proportional to e

c

for all the specimens. The values of f for the Type-C

group (namely, Type-C, Type-CC and Type-CS) were

almost the same in the lowstrain region of e

c

5 15

%.

The difference between the three curves was marked at

higher strains. The force level in this strain region

decreased in the order Type-CS, Type-CC and Type-C.

The values of f for the Type-C group were larger than

those for Type-R over the whole strain range.

In Fig. 5, the force per unit tube length (w) is shown as

a function of the strain (e

c

) for Type-R, Type-C and

canine tracheas. The w2e

c

curve of the canine trachea

lay between the curves of the artificial tracheas at low

strains, but was located above the curves of the artificial

tracheas at high strains. As far as the force level is

concerned, however, canine trachea resembled Type-C

rather than Type-R in its mechanical behavior under

compression.

Fig. 3. Schematic representation for the compression tests.

Fig. 4. Force per pitch vs. strain plots for Type-R, Type-C, Type-CC

and Type-CS artificial tracheas.

Fig. 5. Force per unit length vs. strain plots for Type-R and Type-C

artificial tracheas and canine trachea.

S. Kawaguchi et al. / Biomaterials 22 (2001) 3085–3090

3087

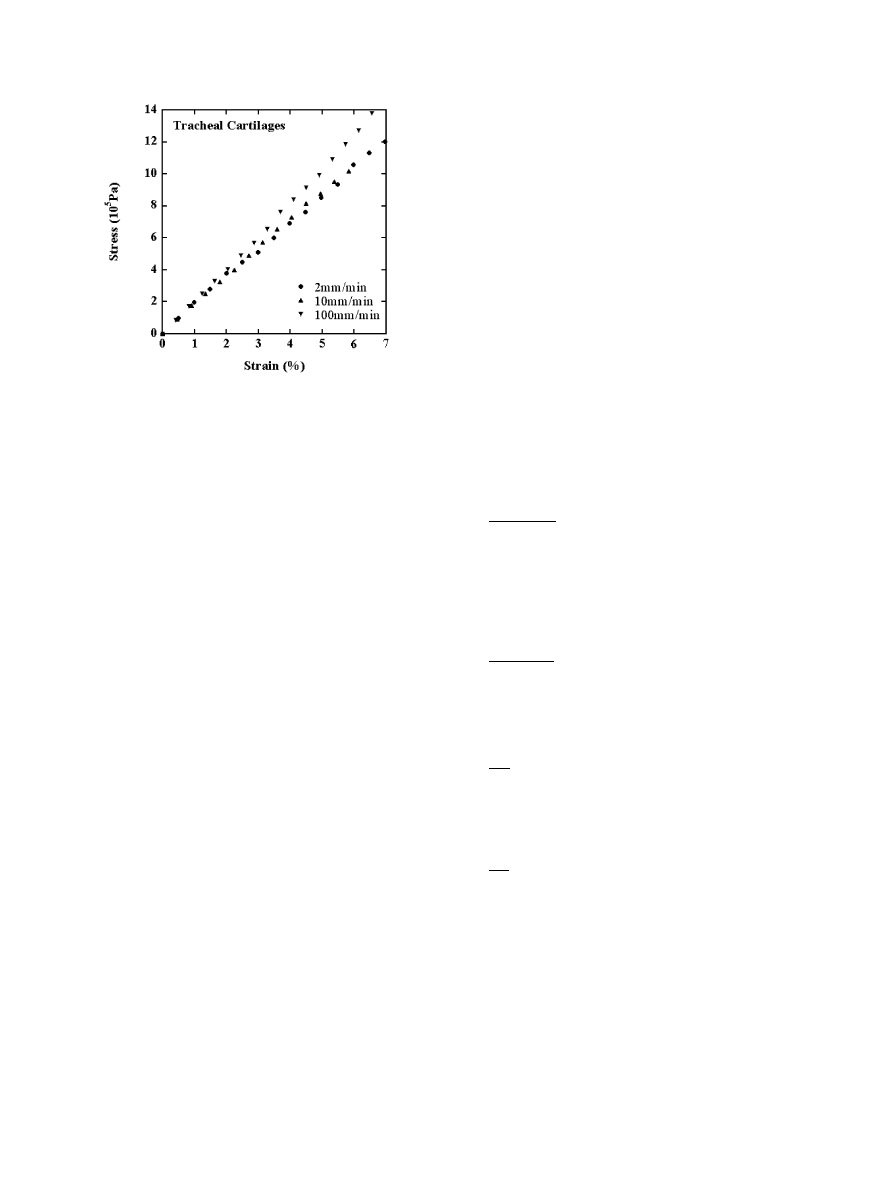

3.2. Stress–strain curves of tracheal cartilages

In Fig. 6, s is shown as a function of e

c

for tracheal

cartilages. The curve at 2 mm/min was almost identical

to that at 10 mm/min over the entire strain range

examined, whereas the curve at 100 mm/min was shifted

upwards compared with the others.

4. Discussion

Fine Marlex

1

mesh has a suitable pore size for

regeneration of tracheal tissue [13] and it has been used

clinically for reconstruction of the air-way. However, it

is necessary to support the mesh tube with a stent,

because a tube made from fine Marlex

1

mesh alone is

too soft (weak). However, there has never been any

systematic analysis of the relation between the mechan-

ical properties of stents and their material and shape.

An artificial trachea has to possess sufficient mechan-

ical strength to sustain the air-way, but a prosthesis that

is too stiff is also problematic. In this sense the initial

mechanical properties are of high importance for the

artificial trachea, since mismatch of these properties

often causes granulation at the anastomoses which

induces fatal obstruction or bleeding [14], or collapse of

the air-way.

4.1. Force–strain curves of trachea specimens

We calculated the ratio of f for Type-R to that for

Type-C over a wide range of e

c

. The ratio was almost

independent of e

c

, suggesting that the curves are similar

in shape, although the force level itself was different. As

mentioned previously, Type-C was composed of a mesh

cylinder and a spiral yarn with a circular cross-section.

Type-R had almost the same architecture as Type-C but

with a rectangular cross-section. The difference between

these two specimens was only the shape of the cross-

section of the stent, because the dimensions of both

specimens are almost the same, including the cross-

sectional area of the stents (see Fig. 2). The fact that the

shape of the two curves was almost the same suggests

that the shape of the f –e

c

curve is governed basically by

the architecture of the artificial trachea, whereas the

force level depends on the shape and dimensions of the

components.

As stated previously, the outer diameters of the

artificial tracheas were not the same (Fig. 4). Therefore,

direct comparison of the absolute values of the force is

not meaningful. The mechanical properties of the

artificial tracheas used here were chiefly provided by

the spiral stent around the mesh cylinder, as stated

previously. However, direct analysis of a spiral model is

complex, so for simplicity we here regard the spiral as a

series of hoops with the distance between the hoops set

equal to the pitch of the original spiral. When a

compression force (designated as f ) is imposed on a

hoop in the radial direction, f is given by

f ¼

8pEI DR

ðp

2

8ÞR

3

0

ð4Þ

where E is Young’s modulus, I is the second moment of

area, R

0

is the initial radius of curvature at the neutral

surface, and DR is the displacement of R

0

by loading

[15]. For the specimens used here, Eq. (4) can be

simplified to

f ¼

32pEI

ðp

2

8Þd

2

0

e

c

ð5Þ

because R

0

ffi d

0

=2 and DR

0

ffi ðd

0

dÞ=2. Here, e

c

is

the strain under compression as already defined by

Eq. (1). The quantity I is given by

I ¼

ab

3

12

ð6aÞ

for a Type-R specimen, where a and b are dimensions

characterizing the cross-section of the stent, as shown in

Fig. 2. Similarly, I is given by

I ¼

pr

4

4

ð6bÞ

for a Type-C specimen, where r is the radius of cross-

section (circle) of the stent (Fig. 2). In practice, the

validity of Eq. (4) (and also Eq. (5)) is limited to the low

strain region, because the equations are based on the

infinite deformation theory. At lowstrains, f was

proportional to e

c

for all specimens (Fig. 4), suggesting

that the experimental data for the artificial tracheas used

here can be analyzed by Eq. (5) as long as the applied

strain is low. The value of f depends on d

0

, and the

dependence of f on d

0

is clear from Eq. (5) at low

strains. Since the dependence of f on d

0

is not clear at

high strains, the corrected force per pitch (f

corr

) for the

Fig. 6. Stress vs. strain plots for canine tracheal cartilages under

extension. The cross-head speeds used are specified in the figure.

S. Kawaguchi et al. / Biomaterials 22 (2001) 3085–3090

3088

artificial tracheas was calculated based on Eq. (5) in the

whole strain range by

f

corr

¼ f

d

0

d

0;corr

2

ð7Þ

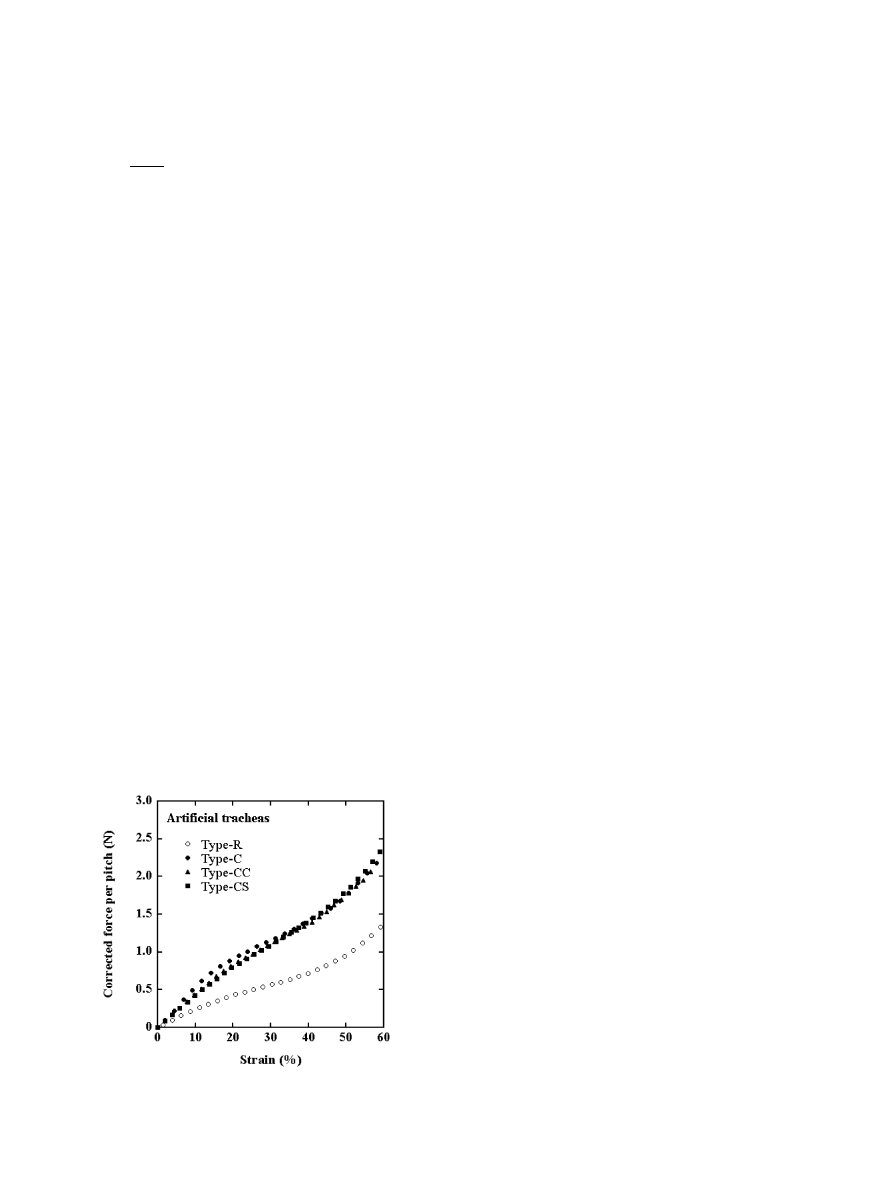

Fig. 7 shows force per pitch vs. strain plots for the

artificial tracheas similar to those in Fig. 4, but in these

plots the outer diameters of Type-C, Type-CC and

Type-R were reduced to that of Type-CS (18.3 mm),

which we designate hereafter d

0;corr

. The f

corr

2

e

c

curves

of the Type-C group (Type-C, Type-CC and Type-CS)

were located above the curve for Type-R. The curves for

the Type-C group almost overlapped over the whole

strain range examined, indicating that they have very

similar mechanical properties under compression. Spe-

cifically, coating with collagen as well as laminating with

collagen sponge did not affect the mechanical properties

of the tracheas.

By using Eq. (5), E of the stent is calculated from the

slope of the f –e

c

curve in the region of e

c

55%. The

values of E for the Type-R and Type-C stents were

evaluated from the curves shown in Fig. 4. In the

estimation of E; I was calculated by Eq. (6a) for Type-R

and by Eq. (6b) for Type-C, using the dimensions of the

stents shown in Fig. 2. The value of E was 1.2 10

9

Pa

for the Type-C stent and 1.1 10

9

Pa for the Type-R,

which agreed well with each other. The values of E for

the stents also agreed with the typical value for

polypropylene (1.17 10

9

Pa) reported in the literature

[16].

4.2. Stress–strain curves of tracheal cartilages

In Fig. 5, E for 100 mm/min was higher than those for

the others. Little difference was observed in E for 2 and

10 mm/min. The latter result may occur because the

difference in cross-head speed is small. In our experi-

ments, only one test was made for each cross-head

speed, so that we cannot say definitely that E of the

tracheal cartilages is cross-head speed dependent. We

are planning to make more repeats of the test to support

the above deduction. It is well known that articular

cartilages showthe viscoelasticity [17], and the visco-

elasticity originates from the collagen fibers in the

cartilages. This strongly suggests that the tracheal

cartilages behave viscoelastic bodies; namely, the

cross-head speed dependence appears in E in the

elongation tests.

E

for the tracheal cartilages could be obtained from

the slope of the s2e

t

curves. The values at 2, 10 and

100 mm/min were 1.9 10

7

, 1.9 10

7

and 2.1 10

7

Pa,

respectively. E can also be estimated independently from

the w2e

c

curve in Fig. 5. Assuming that the trachea is a

cylinder composed only of cartilage, with d

0

¼ 14 mm

and b ¼ 0:74 mm, E can be calculated to be 7.6 10

7

Pa.

E

estimated by both the deformation modes is of the

same order of magnitude, approximately 10

7

Pa.

5. Conclusions

Considering that the values of f correspond to

strength, the resistance of Type-C group tracheas to

collapse was greater than that of Type-R. The strength

of Type-C group tracheas was almost identical at all

values of strain when corrected for the outer diameter of

the stent. Therefore, neither collagen coating nor

laminating with collagen sponge appear to affect the

resistance of artificial tracheas to collapse. The resis-

tance of canine trachea to collapse was closer to that of

Type-C than to that of Type-R at high strains. The

shape of the w2e

c

curve of canine trachea was different

from that of artificial trachea. The shapes of the f 2e

c

curves of Type-R and Type-C artificial tracheas were

similar. The s2e

t

curves of tracheal cartilages were

suggested to be dependent on the tensile cross-head

speed. The Young’s modulus of tracheal cartilages was

estimated to be of the order of 10

7

Pa by both

compression and tensile tests.

As shown in this report, it is possible to estimate the

mechanical properties of a mesh-type artificial trachea

by using standard formulae. In other words, we can

design in advance artificial tracheas with adequate

mechanical properties. In this sense, these formulae will

contribute to the design of newprostheses for the

trachea.

Acknowledgements

This work was supported in part by Grant-in-Aid for

Scientific Research from the Ministry of Education,

Science, Sports and Culture of Japan (No. 10305069),

Fig. 7. Corrected force per pitch vs. strain plots for Type-R, Type-C,

Type-CC and Type-CS artificial tracheas.

S. Kawaguchi et al. / Biomaterials 22 (2001) 3085–3090

3089

and by JSPS Research for the Future Program,

Biological Tissue Engineering Project, No. JSPS-RFTF

98100201.

References

[1] Okumura N, Nakamura T, Natsume T, Tomihata K, Ikada Y,

Shimizu Y. Experimental study on a newtracheal prosthesis made

from collagen-conjugated mesh. J Thorac Cardiovasc Surg

1994;108:337–45.

[2] Teramachi M, Okumura N, Nakamura T, Kiyotani T, Takimoto

Y, Matsuda S, Ikada Y, Shimizu Y. Intrathoracic tracheal

reconstruction with a collagen-conjugated prosthesis: evaluation

of the efficacy of omental wrapping. J Thorac Cardiovasc Surg

1997;113:701–11.

[3] Teramachi M, Nakamura T, Yamamoto Y, Kiyotani T,

Takimoto Y, Shimizu Y. Porous-type tracheal prosthesis sealed

with collagen sponge. Ann Thorac Surg 1997;64:965–9.

[4] Rains JK, Bert JL, Roberts CR, Par

!ee PD. Mechanical properties

of human tracheal cartilage. J Appl Physiol 1992;72(1):219–25.

[5] Roberts CR, Rains JK, Par

!ee PD, Walker DC, Wiggs B, Bert JL.

Ultrastructure and tensile properties of human tracheal cartilage.

J Biomech 1998;31:81–6.

[6] Roberts CR, Par

!ee PD. Composition changes in human tracheal

cartilage in growth and aging, including changes in proteoglycan

structure. Am J Physiol 1991;261:L92–101.

[7] Lambert RK, Baile EM, Moreno R, Bert J, Par

!ee PD. A method

for estimating the Young’s modulus of complete tracheal cartilage

rings. J Appl Physiol 1991;70(3):1152–9.

[8] Ishida K, Par

!ee PD, Blogg T, Schellenberg RR. Effects of elastic

loading on porcine trachealis muscle mechanics. J Appl Physiol

1990;69(3):1033–9.

[9] Penn RB, Wolfson MR, Shaffer TH. Developmental differences in

tracheal cartilage mechanics. Pediatr Res 1989;26:429–33.

[10] Begis D, Delpuech C, Tallec PL, Loth L, Thiriet M, Vidrascu M.

A finite-element model of tracheal collapse. J Appl Physiol

1988;64(4):1359–68.

[11] Petrasch U, Hinrichsen G. On the further development of a

human alloplastic trachea prosthesis. Biomed Technik 1994;

39:244–50.

[12] Gustin B, G’Sell C, Cochelin B, Wourms P, Ferry MP. Finite

element determination of the forces exerted by endotracheal tubes

on the upper airways. Biomater 1996;17:1219–25.

[13] Shimizu Y, Tamura K, Tato H, Teramatsu T, Hino T. Study on

the artificial trachea using mesh. Jpn J Artif Org 1983;12:486–9.

[14] Deslauriens J, Ginsberg RJ, Nelems JM, Pearson FG. Innominate

artery rupture: a major complication of tracheal surgery. Ann

Thorac Surg 1975;20:671–7.

[15] Roark RJ, Young WC. Formulas for stress and strain. 5th ed.

Tokyo: McGraw-Hill Kogakusha, 1975.

[16] Brandrup J, Immergut EH, Grulke EA, editors. Polymer hand-

book. 4th ed. NewYork: Wiley, 1999.

[17] Fung YC. Biomechanics, mechanical properties of living tissues.

2nd ed. NewYork: Springer, 1993.

S. Kawaguchi et al. / Biomaterials 22 (2001) 3085–3090

3090

Wyszukiwarka

Podobne podstrony:

MECHANICAL PROPERTIES TITANIUM

52 737 754 Relationship Between Microstructure and Mechanical Properts of a 5%Cr Hot Works

32 425 436 Ifluence of Vacuum HT on Microstructure and Mechanical Properties of HSS

W Borek Mechanical properties of high manganese austenitic TWIP type steel

Mechanical Properties of Native and Cross linked Type I Collagen Fibrils Yang

Fibrillar Structure and Mechanical Properties of Collagen

Effect of heat treatment on microstructure and mechanical properties of cold rolled C Mn Si TRIP

95 1373 1389 A new Investigation on Mechanical Properties of Ferro Titanit

1 0 mechanical properties Gentleman

MECHANICAL PROPERTIES OF METALS

Microstructure and mechanical properties of plasma sprayed H

[42]Oxidative breakage of cellular DNA by plant polyphenols A putative mechanism for anticancer prop

więcej podobnych podstron