Rotax 125 MAX

Adjustable

Variable

Exhaust

Introduction:

This information is in addition to the valid repair manual.

Safety requirement has to be taken from the valid repair manual.

This information is only for internal usage.

Without commitment to advise modifications.

BRP-Powertrain

2010.04.09

Presentation Rotax exhaust valve – only for internal use

3

Without commitment to advise modifications

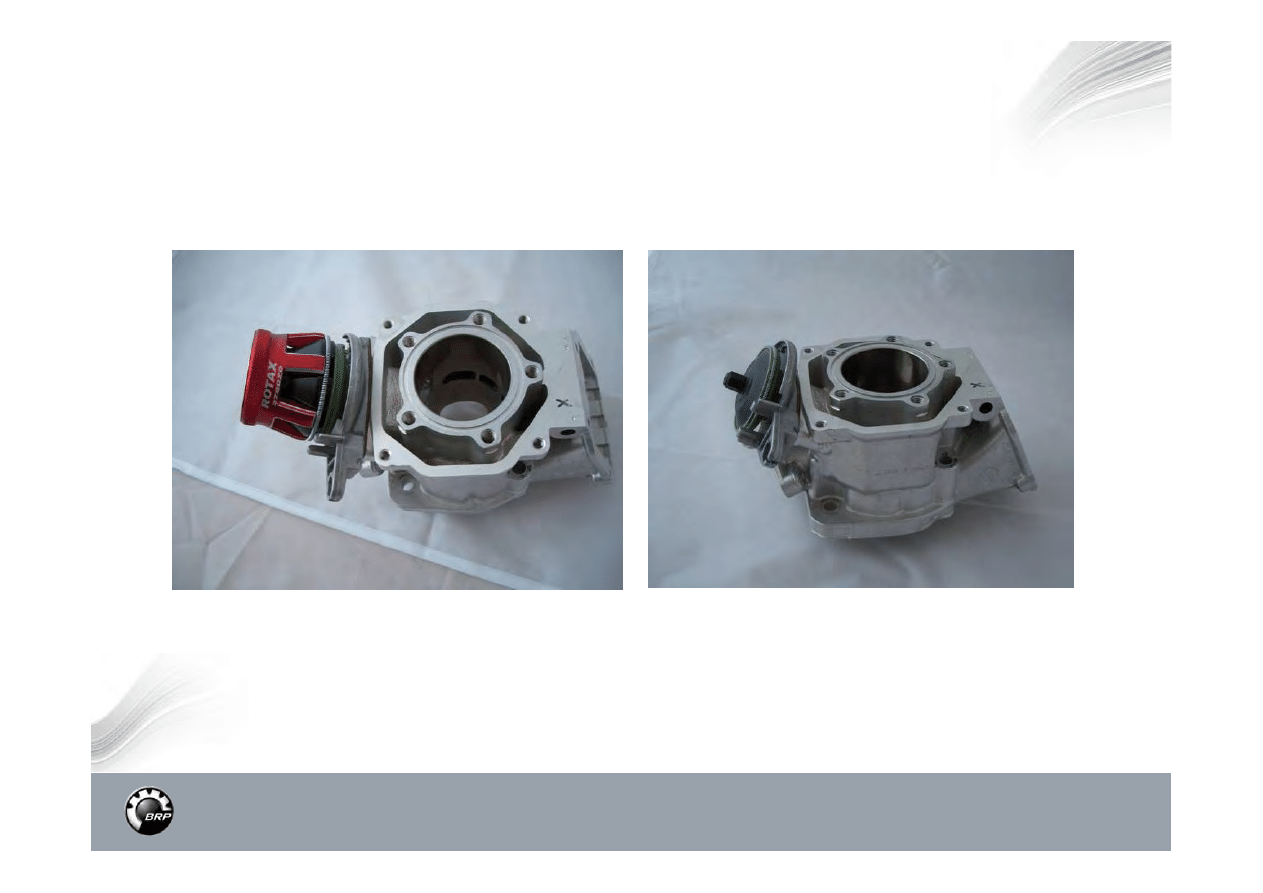

Installation

n

1.

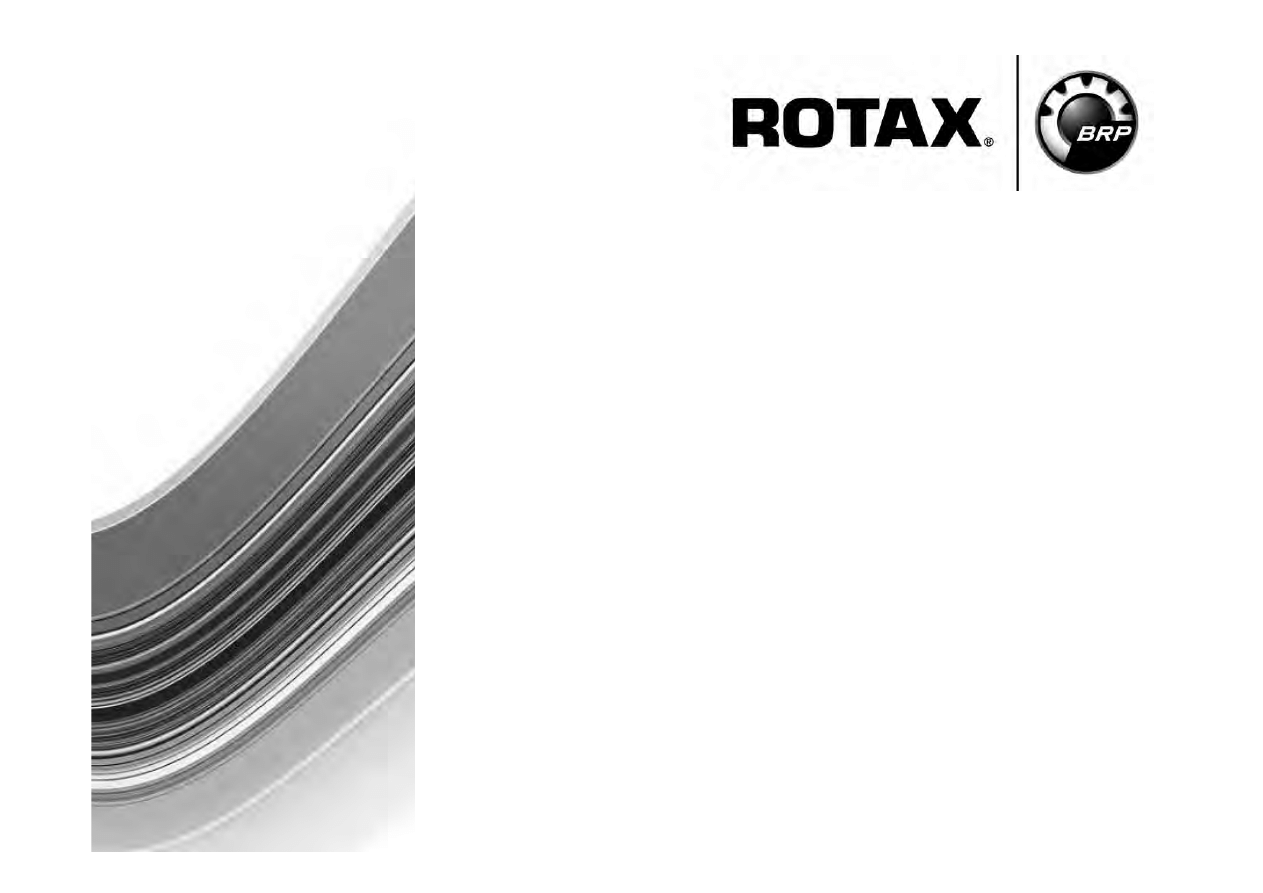

Clean the cylinder with brake cleaner and check impulse bore for cleanliness. (visual)

Presentation Rotax exhaust valve – only for internal use

4

Without commitment to advise modifications

Installation

n

2.

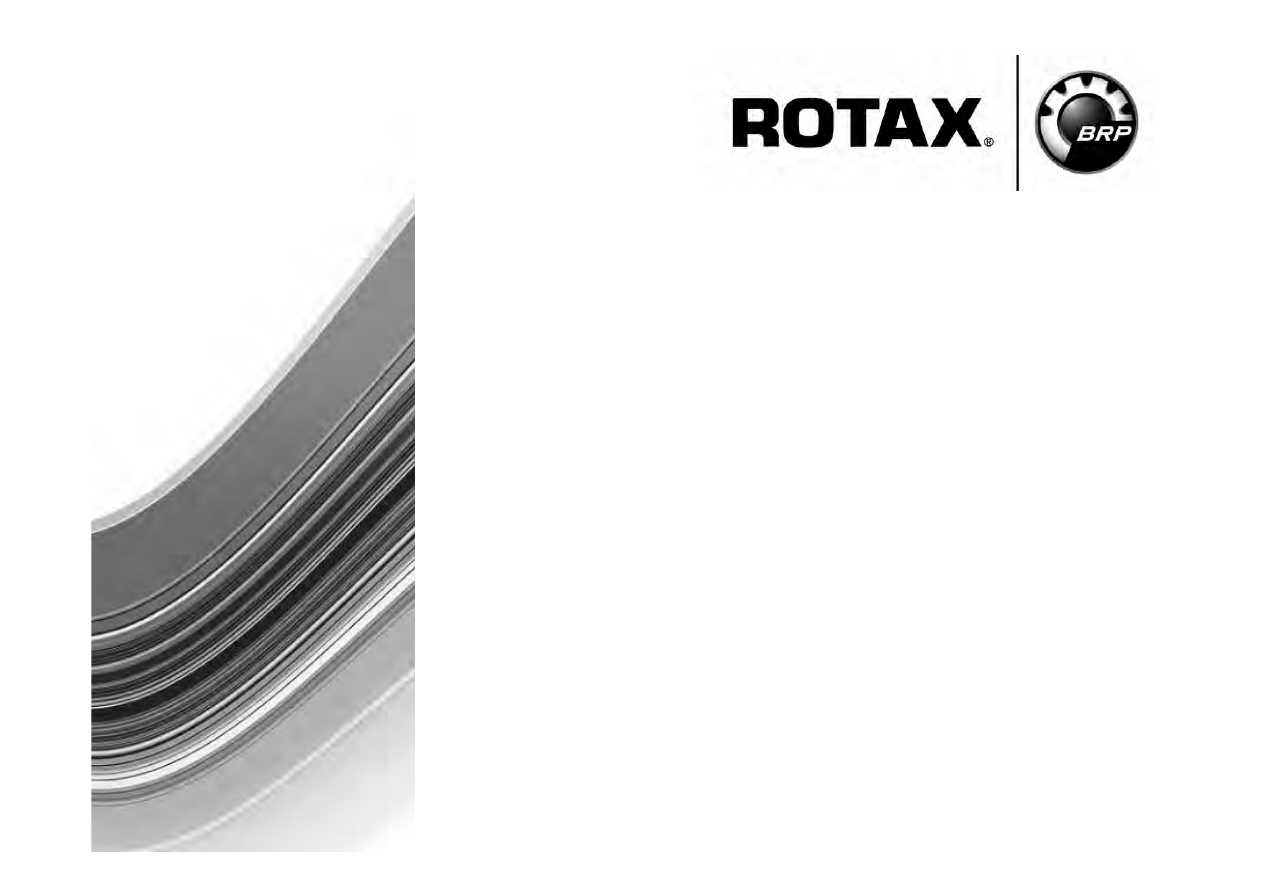

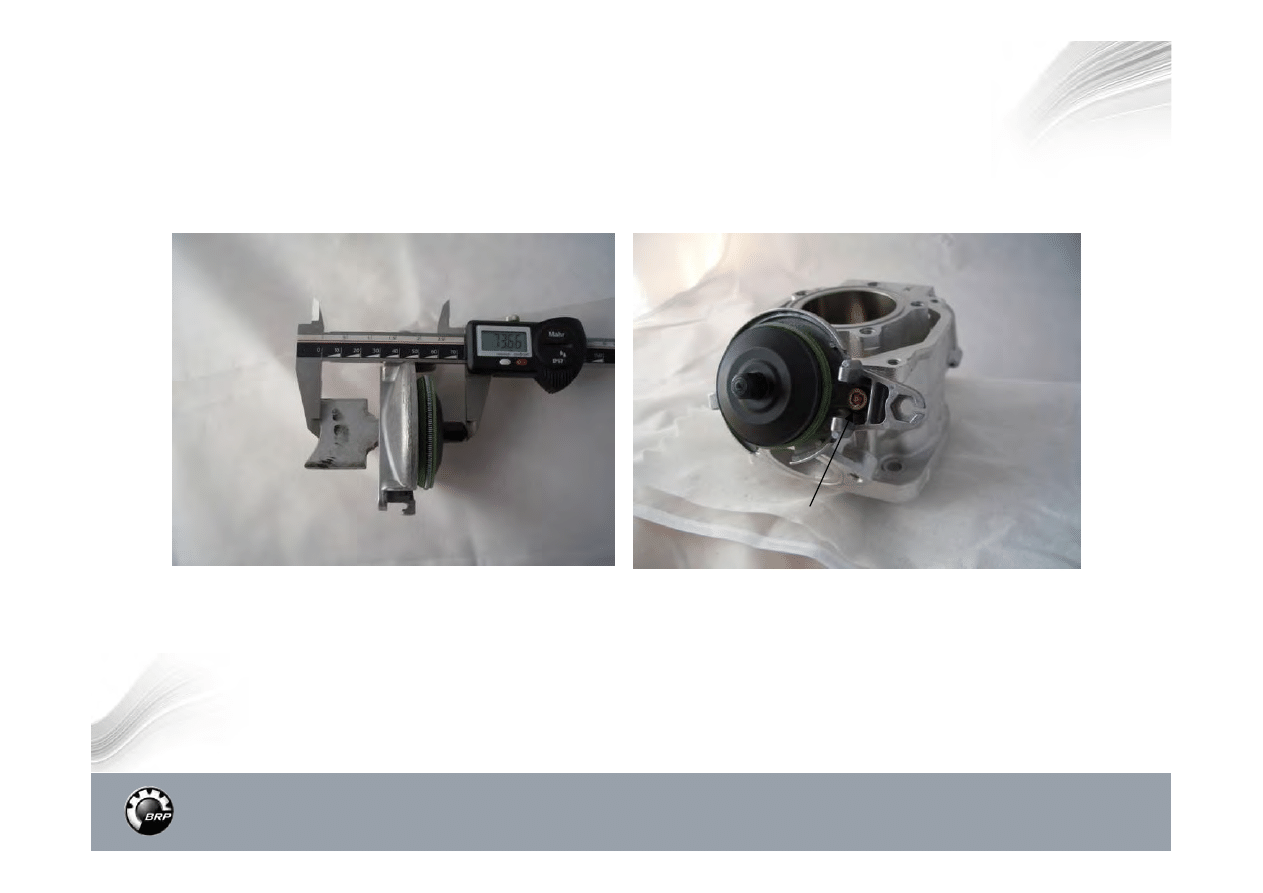

Clean the Exhaust valve with brake cleaner and scotch brite and check the total length of the exhaust

valve. ( 72 +/- 0,3)

ATTENTION: Stud screw has to be locked with LOCTITE 648

Presentation Rotax exhaust valve – only for internal use

5

Without commitment to advise modifications

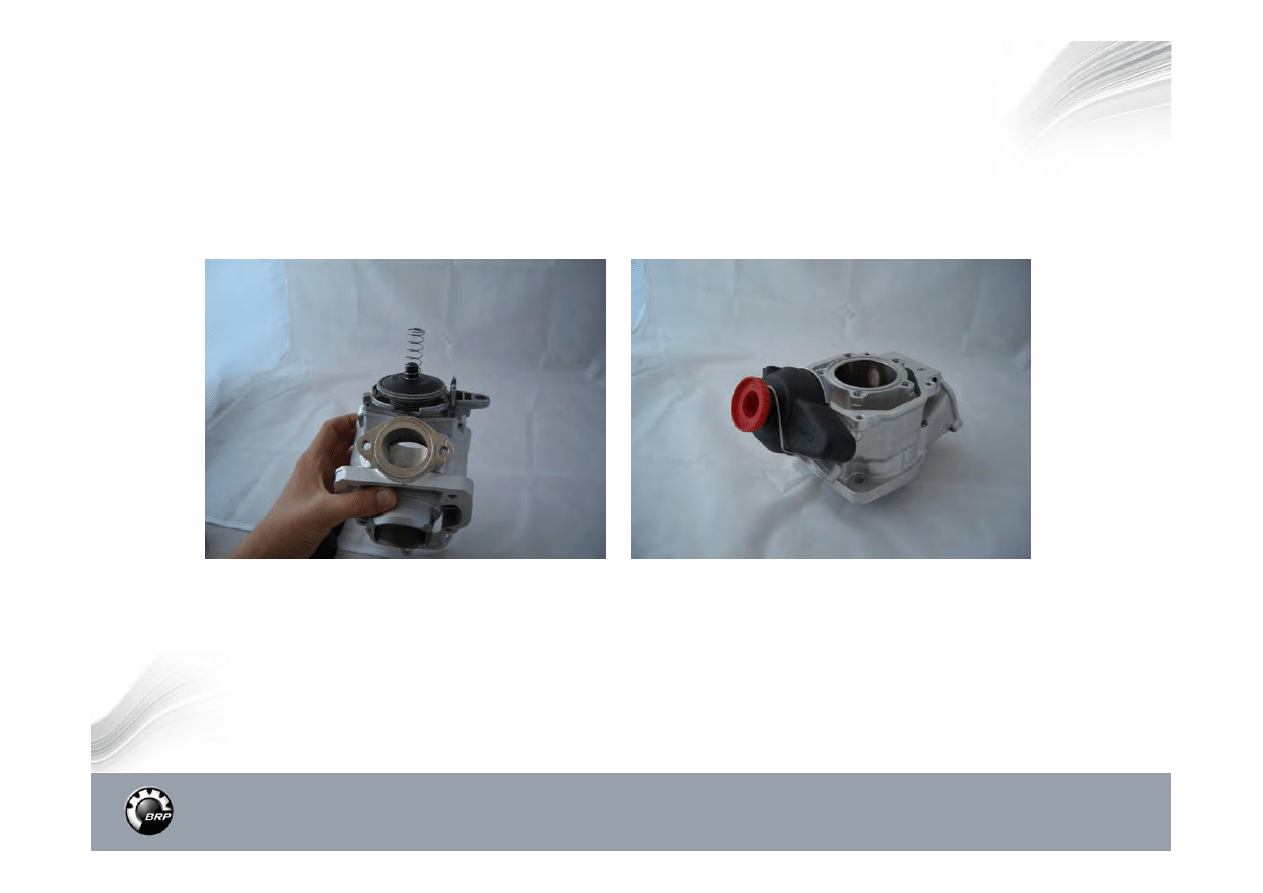

Installation

n

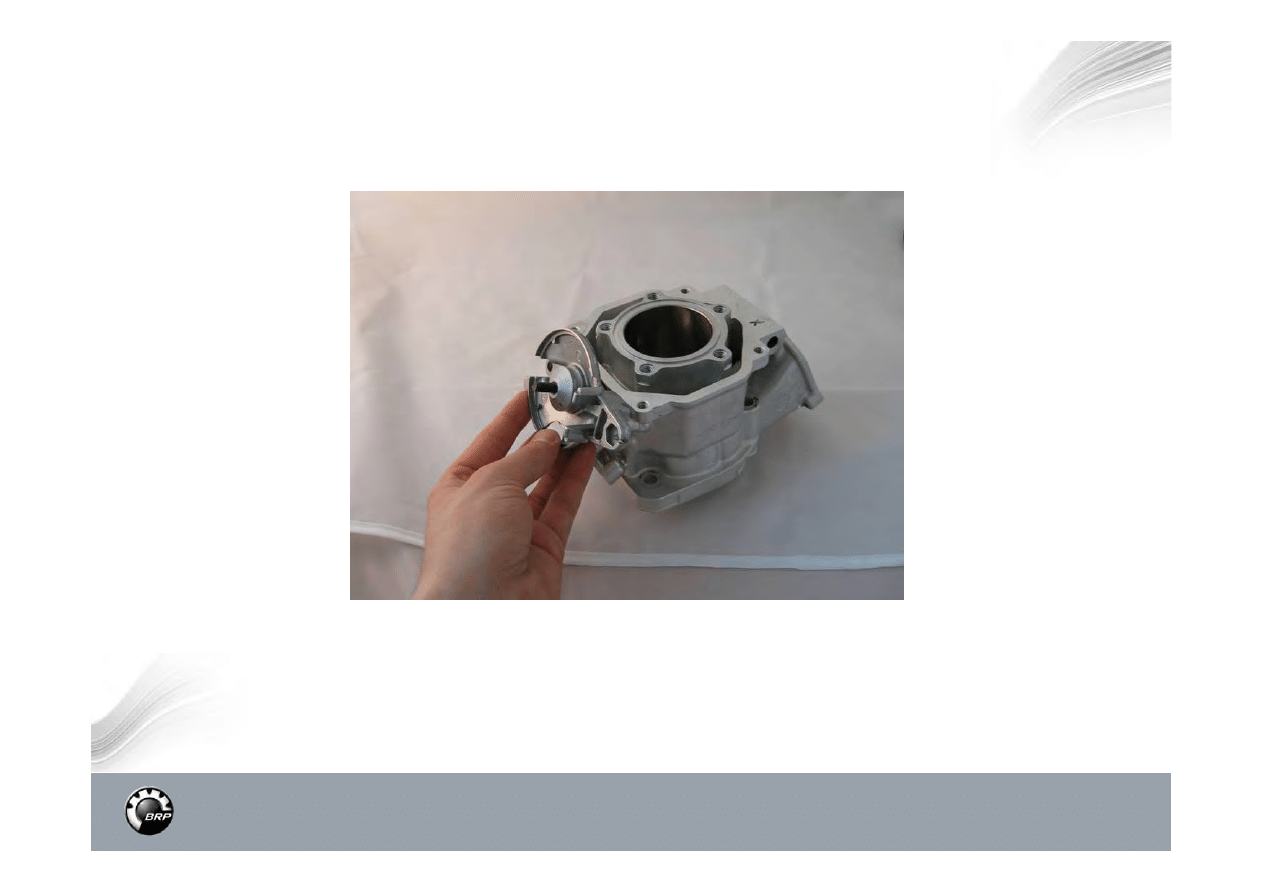

3.

Insert the exhaust valve as shown on the picture and assure free movement of the exhaust valve.

Presentation Rotax exhaust valve – only for internal use

6

Without commitment to advise modifications

Installation

n

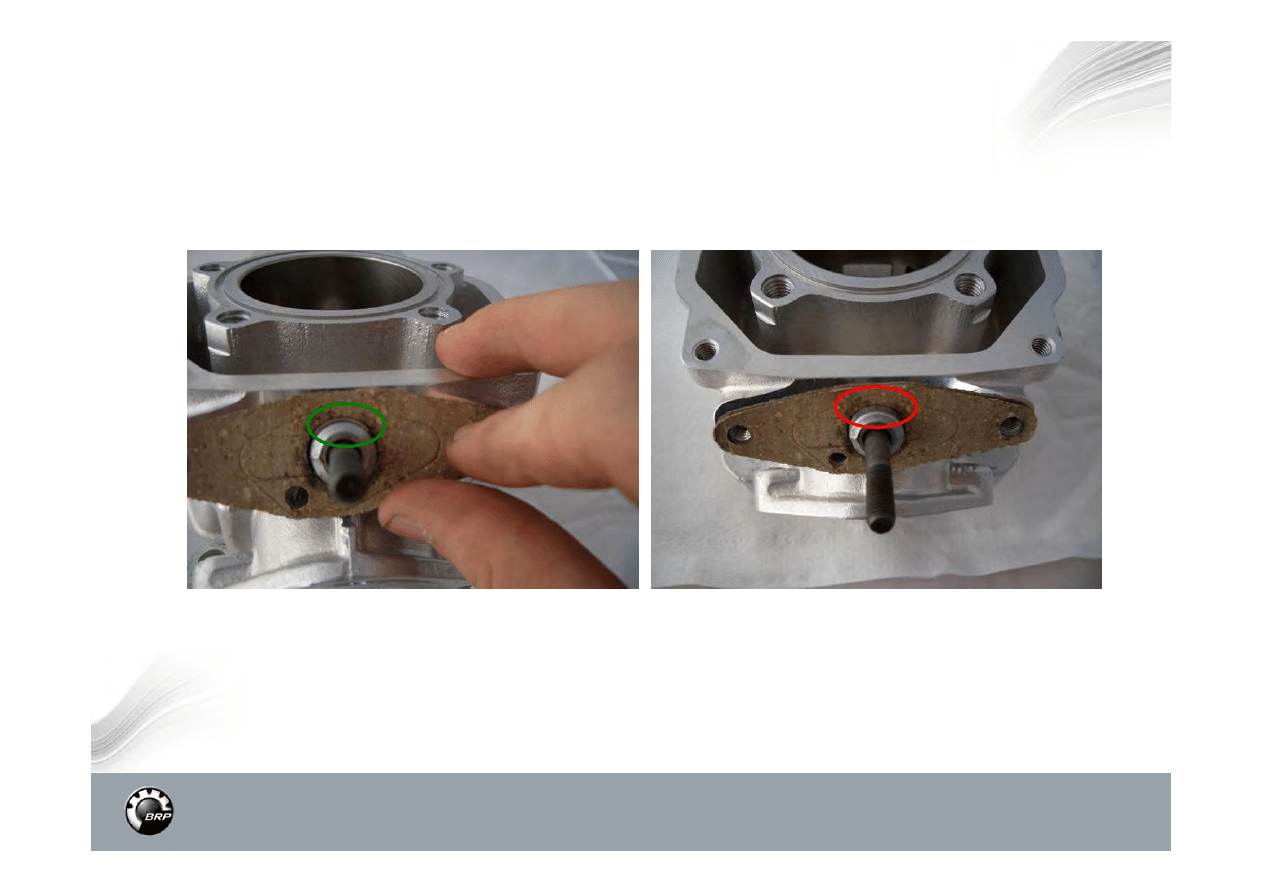

4.

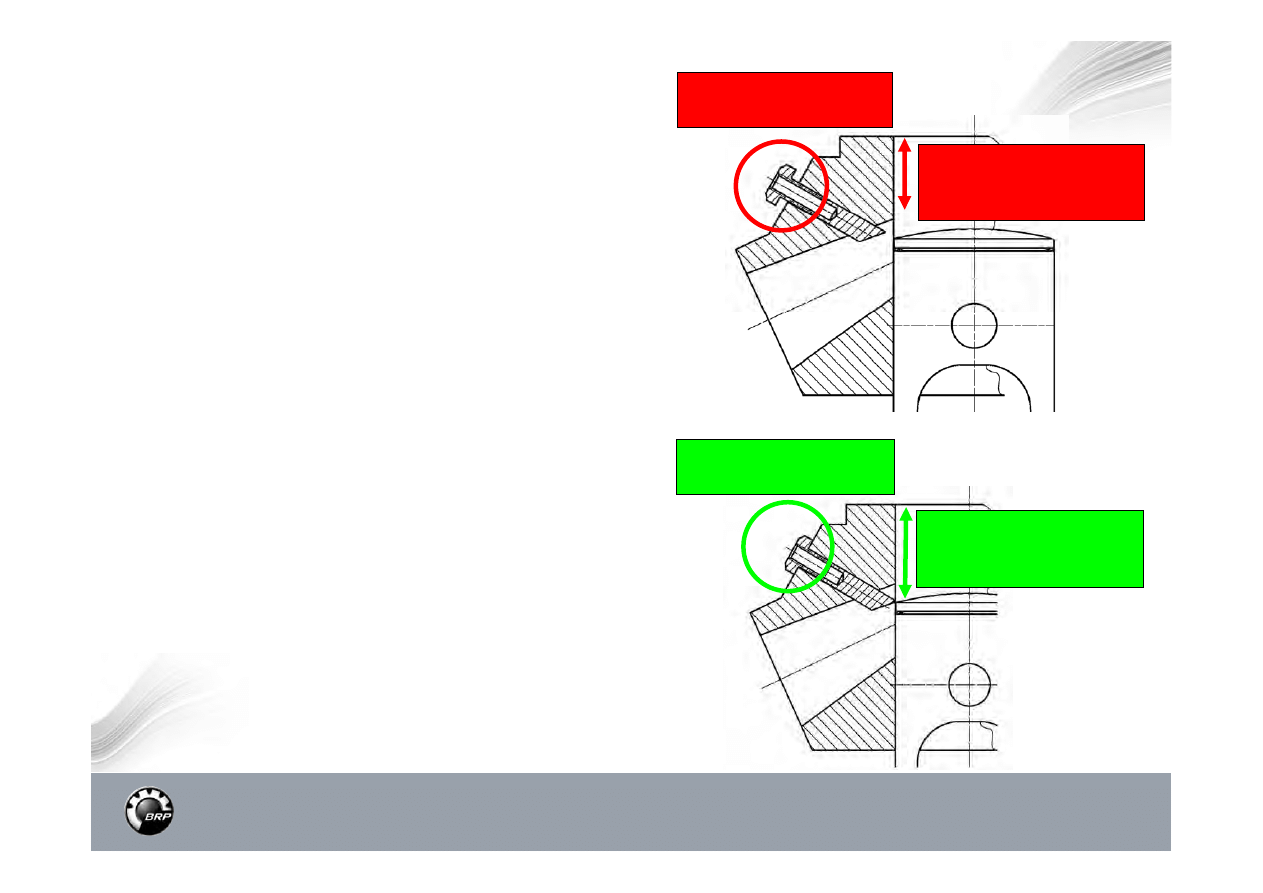

not correct –

gasket interferes contact between valve and

cylinder

Apply the gasket on the cylinder and assure metallic contact between exhaust valve and cylinder.

correct –

metallic contact between valve and cylinder

Presentation Rotax exhaust valve – only for internal use

7

Without commitment to advise modifications

Installation

n

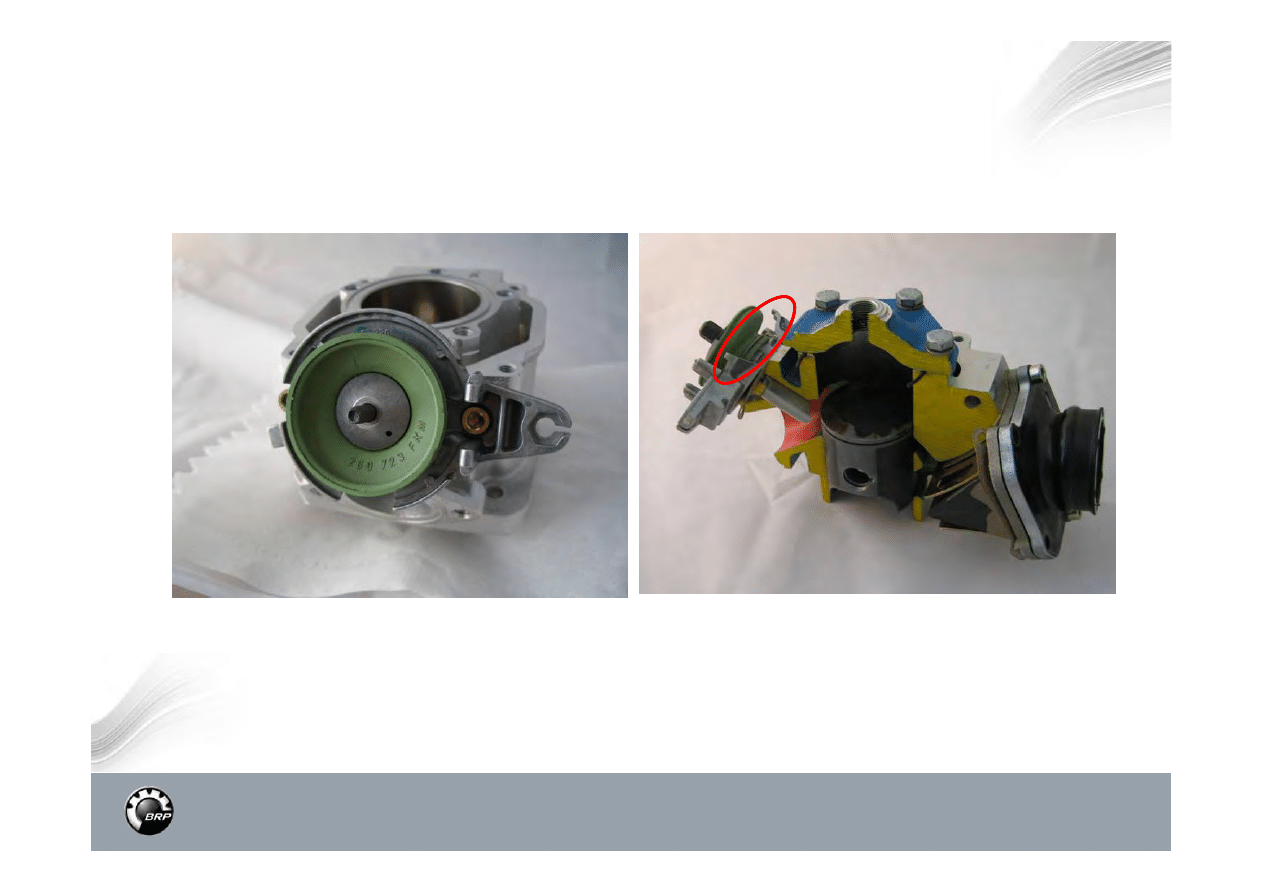

5.

Apply the valve rod housing to the cylinder and check the exhaust valve for free movement.

In case the exhaust valve piston get caught, check the position of the valve rod housing.

Presentation Rotax exhaust valve – only for internal use

8

Without commitment to advise modifications

Installation

n

6.

Apply the o-ring to the stud screw.

Presentation Rotax exhaust valve – only for internal use

9

Without commitment to advise modifications

Installation

n

7.

Apply the bellow on the valve housing and check the sealing surface for proper sealing. The small hose

spring at the bottom of the bellow has to be installed correctly to the groove of the bellow.

Presentation Rotax exhaust valve – only for internal use

10

Without commitment to advise modifications

Installation

n

8.

Hand tighten the exhaust valve piston to the stud screw and adjust a total length of 73,5 +/- 0,3 mm

Torque the exhaust valve with 10 Nm to the cylinder.

10 NM

Presentation Rotax exhaust valve – only for internal use

11

Without commitment to advise modifications

Installation

n

9.

Apply the hose spring with Rotax special tool 276070 to the bellow. Assure free movement of the

exhaust valve and make a visual check for the correct installation of the hose spring to the groove.

Presentation Rotax exhaust valve – only for internal use

12

Without commitment to advise modifications

Installation

n

10.

Apply the compression spring to the Exhaust Valve and mount the Valve Cover by means of the spring

clip to the housing.

Presentation Rotax exhaust valve – only for internal use

13

Without commitment to advise modifications

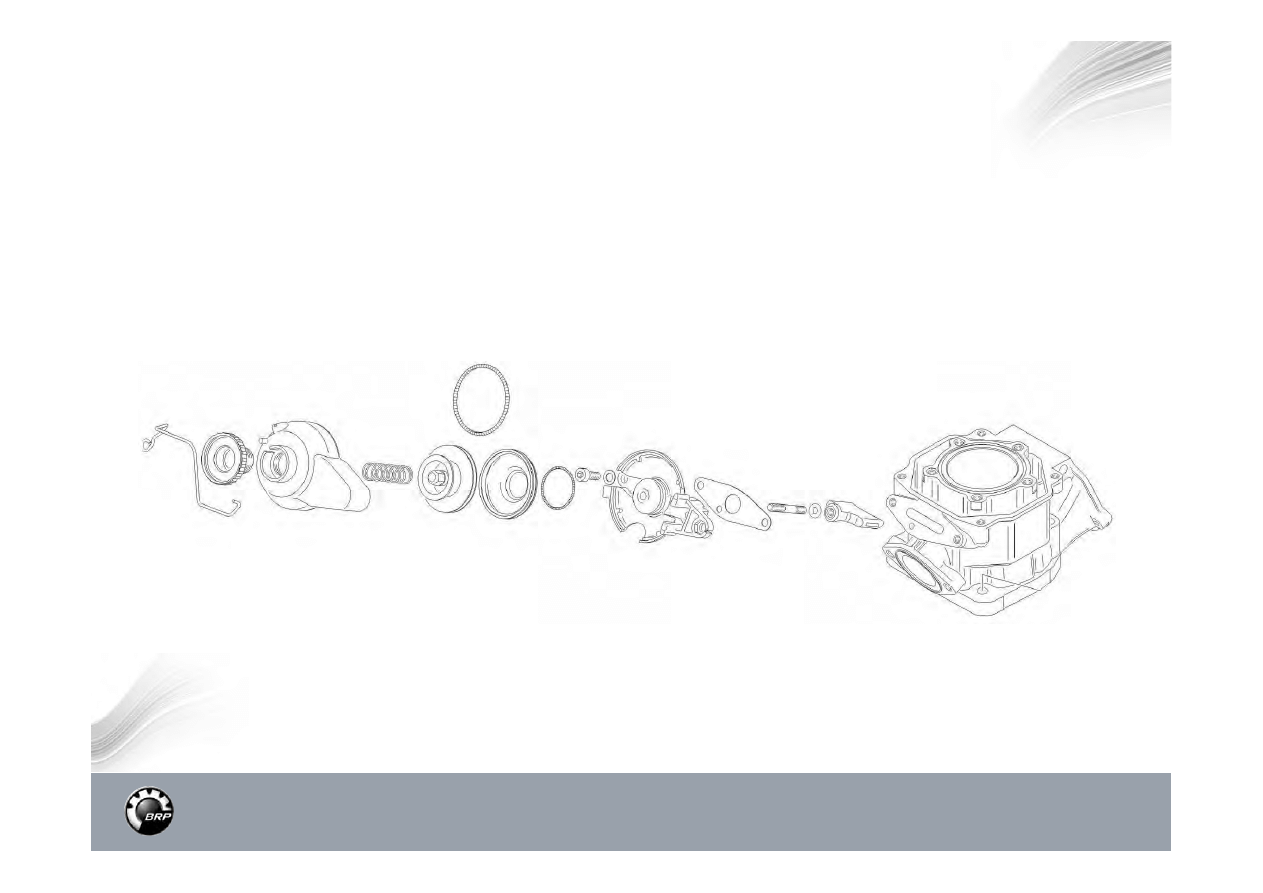

Troubleshooting

R.A.V.E (ROTAX ADJUSTABLE VARIABLE EXHAUST)

Presentation Rotax exhaust valve – only for internal use

14

Without commitment to advise modifications

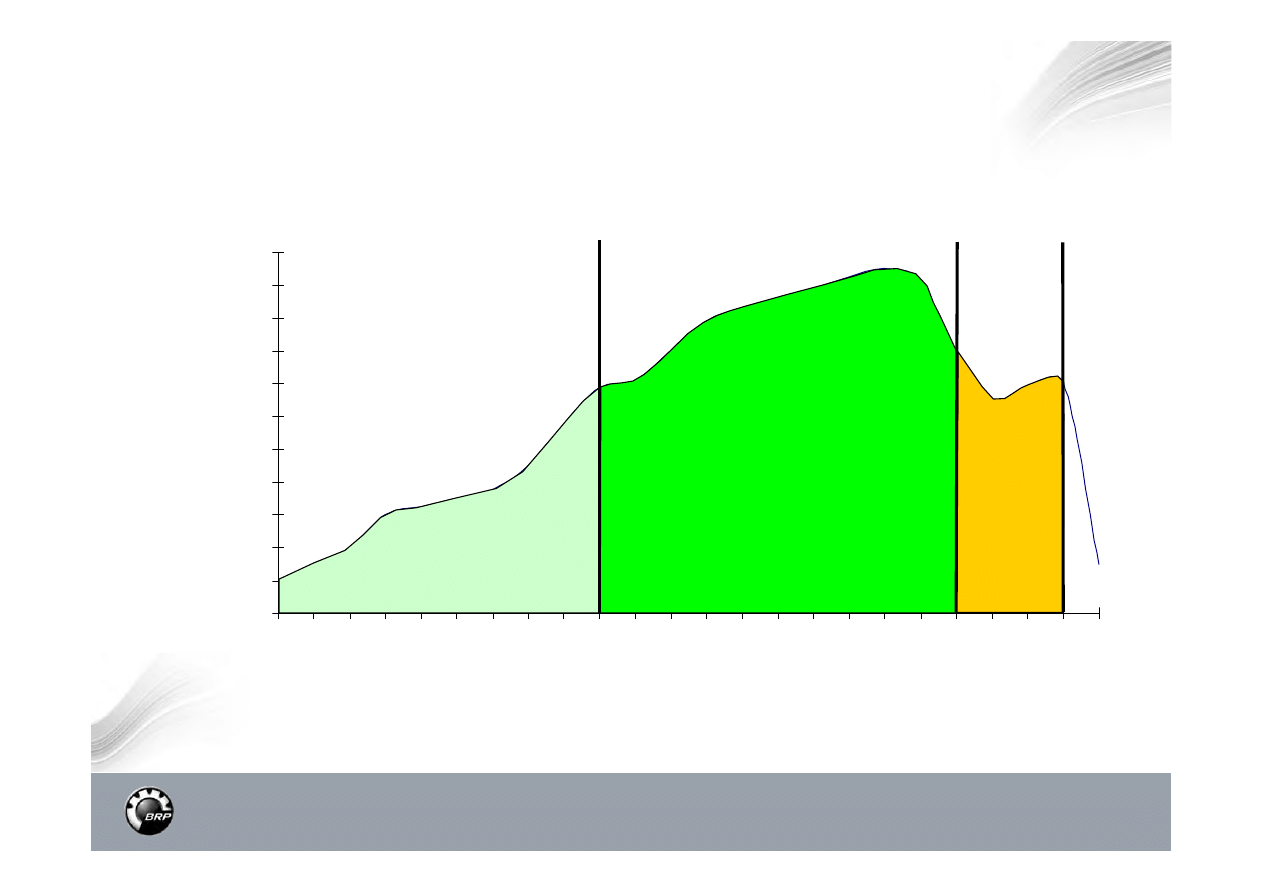

Engine concept Rotax engine 125 MAX

0

2

4

6

8

10

12

14

16

18

20

22

30

00

40

00

50

00

60

00

70

00

80

00

90

00

100

00

110

00

120

00

130

00

140

00

150

00

160

00

170

00

180

00

190

00

200

00

engine speed [rpm]

en

g

in

e

p

er

fo

rm

an

ce

[kW

]

125 Max

100cc

5-8% oil

2% oil

n

Rotax 125 MAX versus typical 100cc kart engines

Presentation Rotax exhaust valve – only for internal use

15

Without commitment to advise modifications

Engine concept Rotax engine 125 MAX

0

2

4

6

8

10

12

14

16

18

20

22

30

00

40

00

50

00

60

00

70

00

80

00

90

00

10

00

0

11

00

0

12

00

0

13

00

0

14

00

0

engine speed [rpm]

pe

rf

or

m

a

nc

e

of

e

ngi

ne

[

k

w

]

Exhaust valve closed

till 7.500 rpm

Tuned exhaust pipe in

combination with ignition timing

7.500 rpm – 12.500 rpm

Ignition

timing

12.500 –

14.000

rpm

n

Performance characteristic of Rotax engine 125 MAX

Presentation Rotax exhaust valve – only for internal use

16

Without commitment to advise modifications

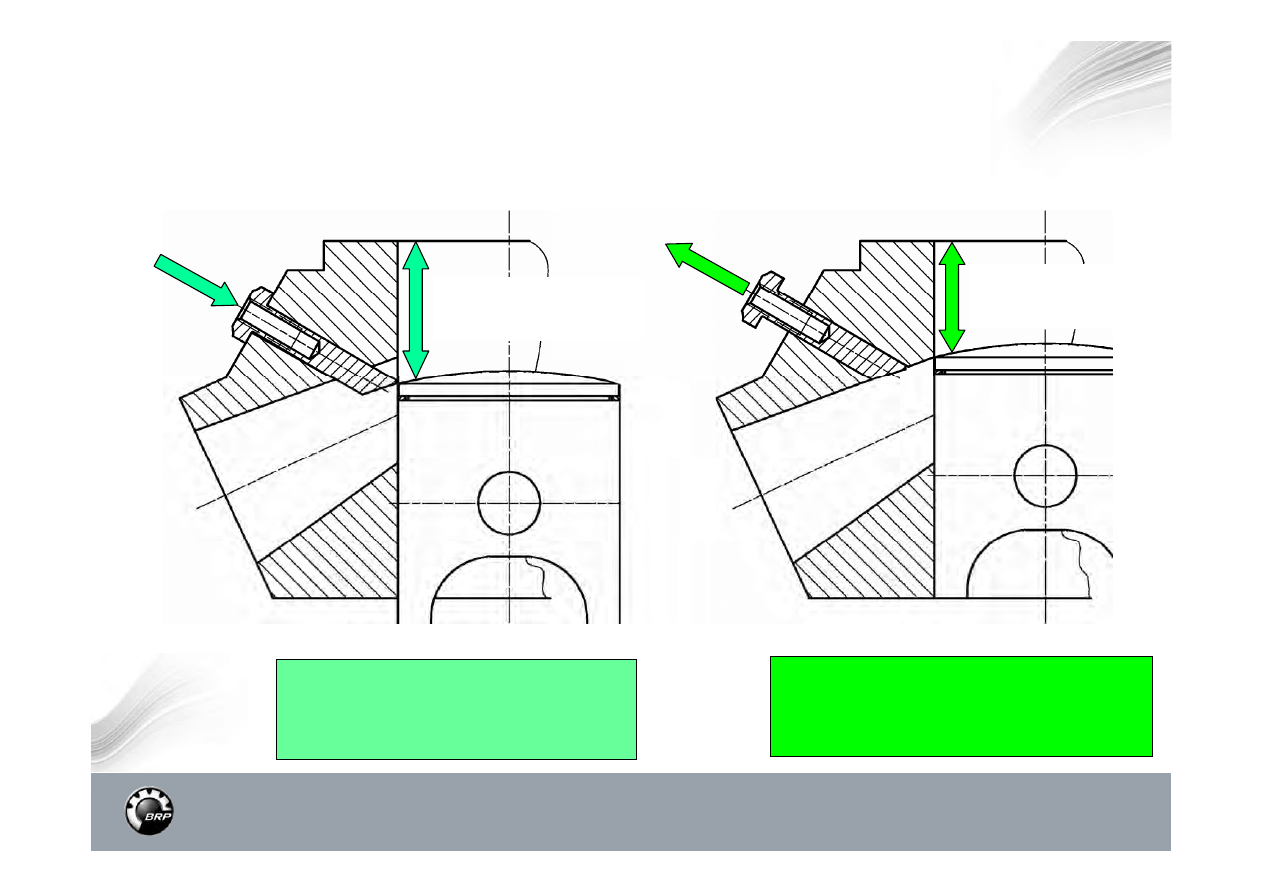

1) Exhaust valve

At 7.500 rpm:

Exhaust valve opens through raising

pressure in the exhaust system

Till 7.500 rpm:

Exhaust valve closes by

compression spring (adjustable)

Low exhaust port timing

= longer use of

combustion energy

exhaust valve closed

exhaust valve opened

High exhaust port

timing = shorter use

of combustion energy

Presentation Rotax exhaust valve – only for internal use

17

Without commitment to advise modifications

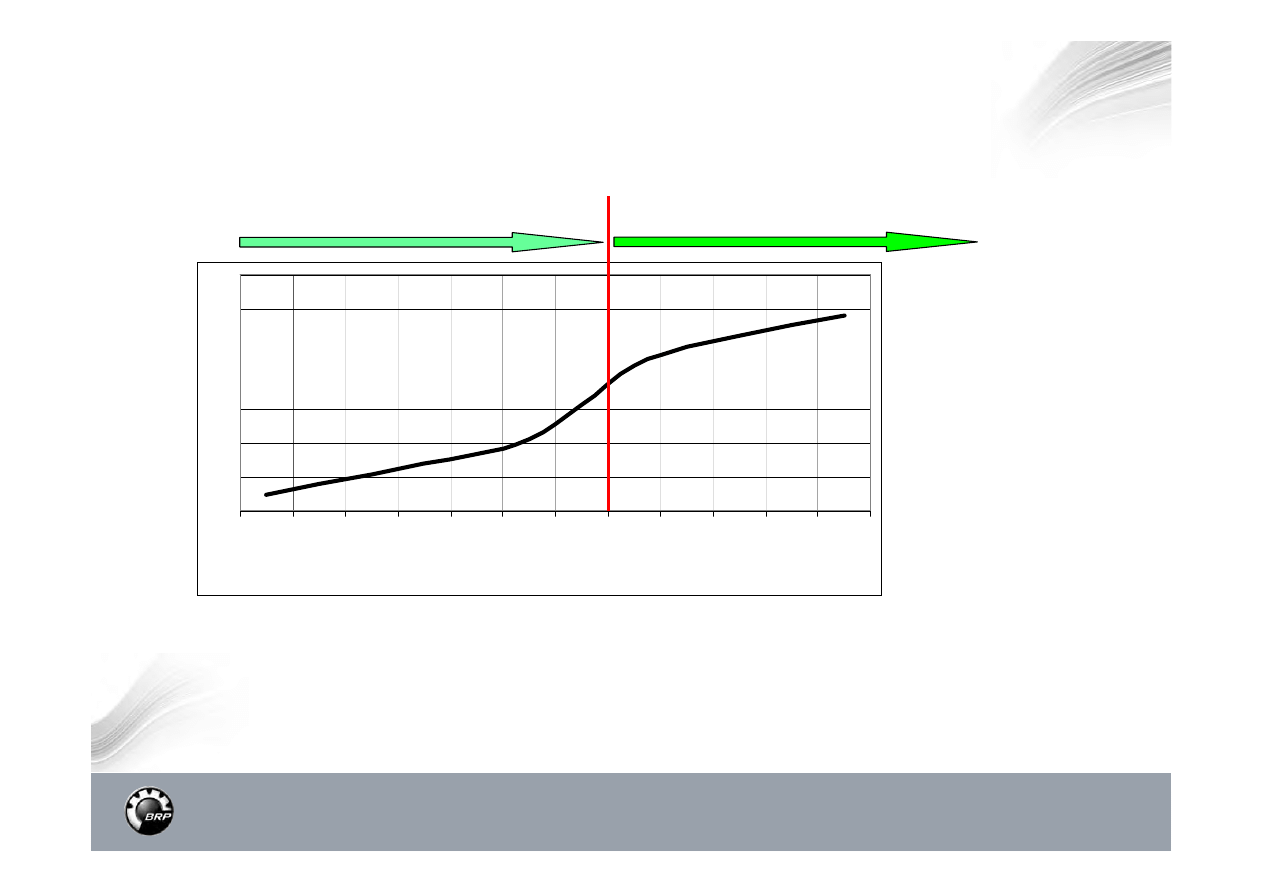

1) Exhaust valve

The raising pressure in the exhaust system causing the exhaust

valve to open.

n

Pressure in the exhaust system (schematic diagram)

1

2

3

4

5

6

7

8

9

10

11

12

engine speed (rpm)

pr

e

s

s

ur

e

exhaust valve closed

exhaust valve open

Presentation Rotax exhaust valve – only for internal use

18

Without commitment to advise modifications

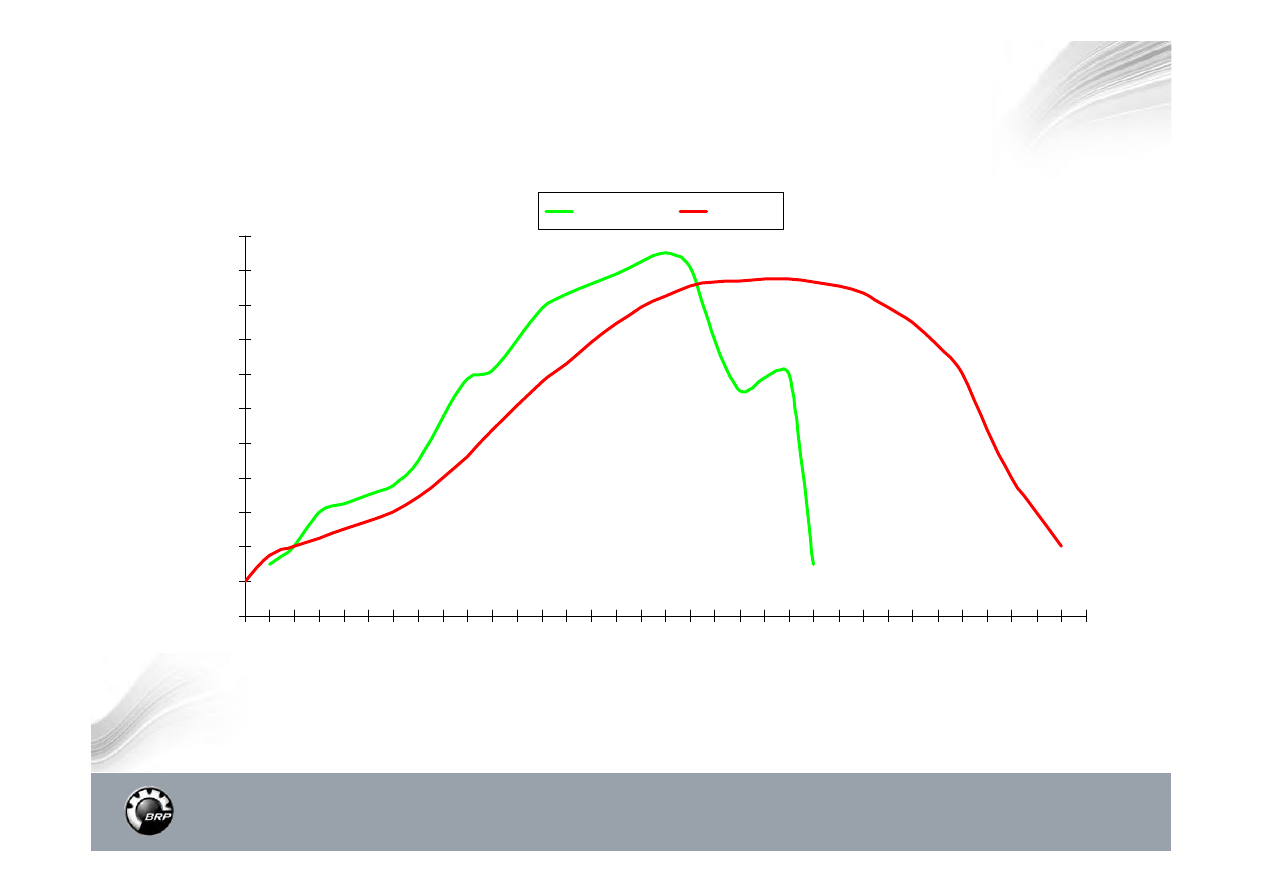

Leistungskurven mit geschlossenem und offenem Auslaßschieber

performance graphs with closed and open exhaust valve

0

2

4

6

8

10

12

14

16

18

20

22

3.

0

0

0

4.

0

0

0

5.

0

0

0

6.

0

0

0

7.

0

0

0

8.

0

0

0

9.

0

0

0

10

.0

00

11

.0

00

12

.0

00

13

.0

00

14

.0

00

15

.0

00

Motordrehzahl [1/min.], speed [rpm]

Motorleistung [kW],

performance of engine [kW]

Leistungskurve 2,

performance graph 2

Leistungskurve 1,

performance graph 1

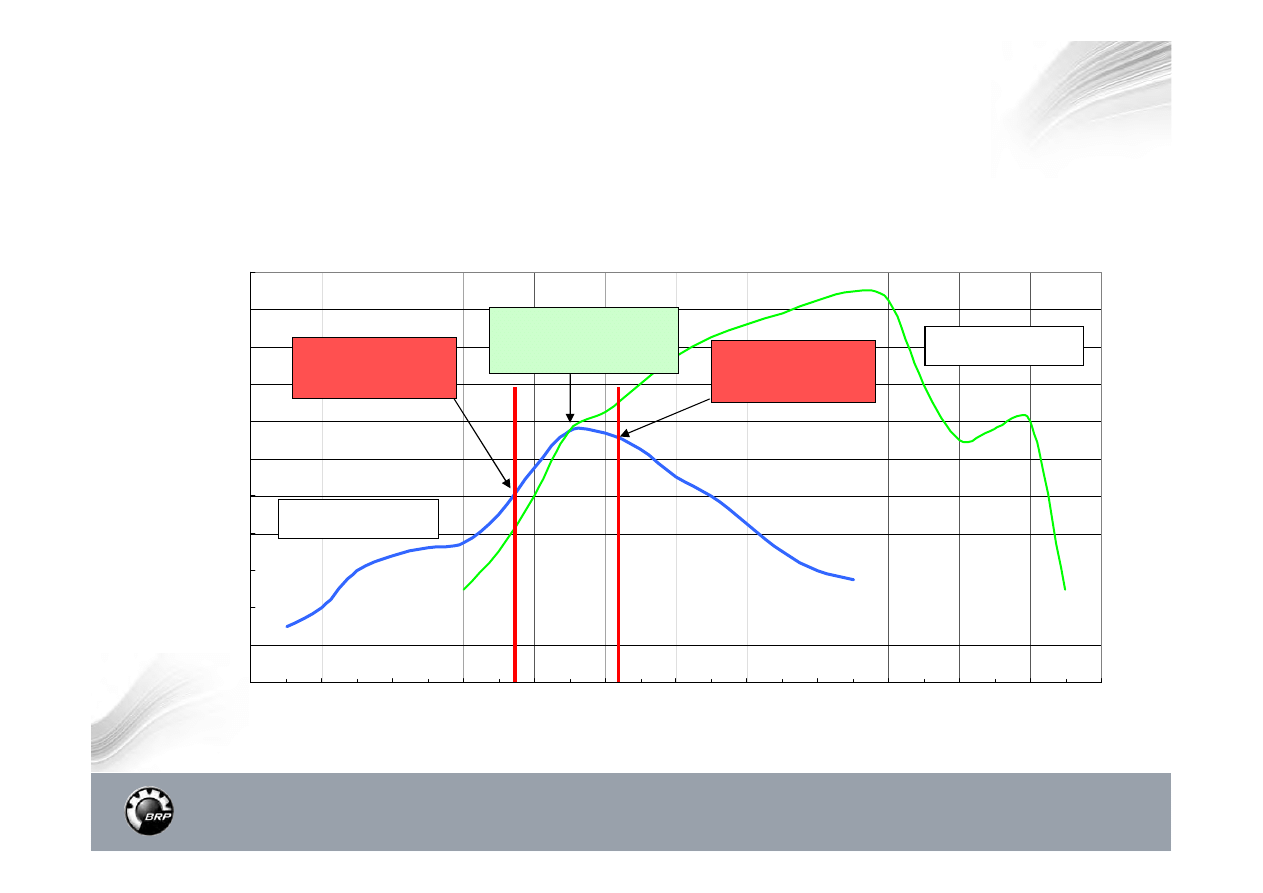

1) Exhaust valve

Optimal opening

timing 7.500 rpm

Opening timing

too late

Opening timing

too early

n

Correct opening timing of the exhaust valve

Presentation Rotax exhaust valve – only for internal use

19

Without commitment to advise modifications

1) Exhaust valve

n

Standard setting of the exhaust valve

5 mm = approx. 2 inch

n

Adjustment of the exhaust valve

è at the race track

è engine must have operation temperature

è accelerate from 5.000 rpm at full throttle

as soon as exhaust valve opens, noise is

changing significantly.

è exhaust valve has to be adjusted to open at 7.500 rpm

n

Adjustable rpm range for exhaust valve opening

Approximately +/- 300 rpm

Presentation Rotax exhaust valve – only for internal use

20

Without commitment to advise modifications

1) Exhaust valve

Re-adjustment of the exhaust valve

… is just necessary if the

è cylinder or the height of the cylinder (base gasket) has been

changed

è condition of the isolating mat in exhaust muffler has changed

(worn).

Presentation Rotax exhaust valve – only for internal use

21

Without commitment to advise modifications

1) Exhaust valve –

Troubleshooting

n

Problem: Missing performance till

7.500 rpm (“bottom end

performance”)

n

Possible reason: Exhaust valve

does not completely close.

n

Solution: Check assembly of

exhaust valve. Exhaust valve has

to touch the cylinder surface in

closed position. Metallic noise at

closing has to be noticeable.

Exhaust valve does not

close completely

wrong

Short use of combustion

energy = high exhaust

port timing

correct

Exhaust valve

completely closed

Long use of combustion

energy = low exhaust

port timing

Presentation Rotax exhaust valve – only for internal use

22

Without commitment to advise modifications

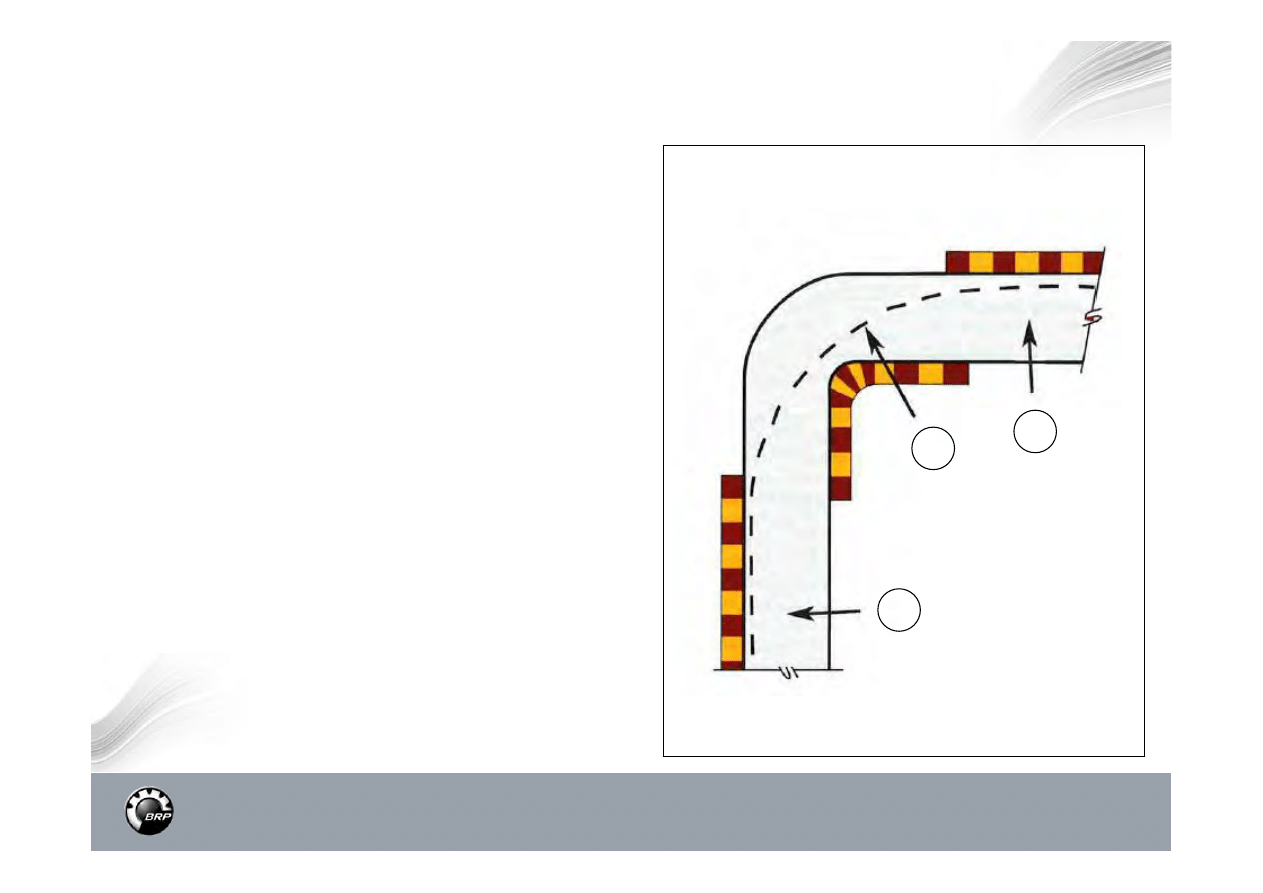

1) Exhaust valve - Troubleshooting

n

Problem: Delayed throttle

response out of the curve.

n

• To the curve: Engine revs

12.500 rpm, exhaust valve is

open.

n

‚ Middle of the curve: Engine

revs drop to 9.000 rpm,

carburettor slide is closed,

exhaust pressure drops

à

exhaust valve closes.

n

ƒ Out of the curve: Engine

revs 9.000 rpm, carburettor

slide open – delayed response

of the engine…

Track sector:

1

2

3

Presentation Rotax exhaust valve – only for internal use

23

Without commitment to advise modifications

Ski-Doo

®

Lynx

™

Sea-Doo

®

Evinrude

®

Johnson

®

Rotax

®

Can-Am

™

© 2006 Bombardier Recreational Products Inc. All rights reserved.

® ™Trademark of Bombardier Recreational Products Inc. or its affiliates.

Wyszukiwarka

Podobne podstrony:

instrukcja bhp skrocona instrukcja obslugi konserwacji i bhp urzadzen oraz instalacji chlodniczych w

Instrukcja organizacji bezpiecznej pracy przy urządzeniach i instalacjach

Mac OS X 10 3 Panther Info (Burn and Install Instruction) choose Disk Copy burn Image install

Alpine 3555 Power Ampl Instal

2006 Seiko Quartz Caliber Power Consumption & Battery Guide

Yamaha Aerox 50 YQ50 YQ50L Instrukcja Obsługi Owner Manual

atx Power Supply Design Guide

Instrukcja Power Scan OBD2

HY3010 power supply, Elektronika, Zasilacze, Zasilacz HY3010, Zasilacz HY3010, HY3010 ,INSTRUKCJA

AD620 Low Cost Low Power Instru Nieznany

Instrukcja resetowania ustawień drukarki HP DJ 920

INSTRUKCJA PRZYWRACANIA NAWIGACJI DO USTAWIEIEŃ FABRYCZNYCH

Power Training in the Zone II Instructions

08 INSTRUCTION MANUAL TEMPERATURE CONTROL VALVE 12160 3078

Instructions Brain Power

Siemens Power Amplifier for thermic valve acutators UA1T N3591 (Eng)

więcej podobnych podstron