Pro/ENGINEER

®

Wildfire™ 2.0

Pro/PROCESS™ for Assemblies

Help Topic Collection

Parametric Technology Corporation

Copyright © 2004 Parametric Technology Corporation. All Rights Reserved.

User and training documentation from Parametric Technology Corporation (PTC) is subject to the

copyright laws of the United States and other countries and is provided under a license agreement that

restricts copying, disclosure, and use of such documentation. PTC hereby grants to the licensed user the

right to make copies in printed form of this documentation if provided on software media, but only for

internal/personal use and in accordance with the license agreement under which the applicable

software is licensed. Any copy made shall include the PTC copyright notice and any other proprietary

notice provided by PTC. This documentation may not be disclosed, transferred, modified, or reduced to

any form, including electronic media, or transmitted or made publicly available by any means without

the prior written consent of PTC and no authorization is granted to make copies for such purposes.

Information described herein is furnished for general information only, is subject to change without

notice, and should not be construed as a warranty or commitment by PTC. PTC assumes no

responsibility or liability for any errors or inaccuracies that may appear in this document.

The software described in this document is provided under written license agreement, contains

valuable trade secrets and proprietary information, and is protected by the copyright laws of the United

States and other countries. It may not be copied or distributed in any form or medium, disclosed to

third parties, or used in any manner not provided for in the software licenses agreement except with

written prior approval from PTC. UNAUTHORIZED USE OF SOFTWARE OR ITS

DOCUMENTATION CAN RESULT IN CIVIL DAMAGES AND CRIMINAL PROSECUTION.

Registered Trademarks of Parametric Technology Corporation or a Subsidiary

Advanced Surface Design, Behavioral Modeling, CADDS, Computervision, CounterPart, EPD,

EPD.Connect, Expert Machinist, Flexible Engineering, HARNESSDESIGN, Info*Engine, InPart,

MECHANICA, Optegra, Parametric Technology, Parametric Technology Corporation, PartSpeak,

PHOTORENDER, Pro/DESKTOP, Pro/E, Pro/ENGINEER, Pro/HELP, Pro/INTRALINK,

Pro/MECHANICA, Pro/TOOLKIT, Product First, PTC, PT/Products, Shaping Innovation, and

Windchill.

Trademarks of Parametric Technology Corporation or a Subsidiary

3DPAINT, Associative Topology Bus, AutobuildZ, CDRS, Create

Collaborate Control, CV, CVact,

CVaec, CVdesign, CV-DORS, CVMAC, CVNC, CVToolmaker, DataDoctor, DesignSuite,

DIMENSION III, DIVISION, e/ENGINEER, eNC Explorer, Expert MoldBase, Expert Toolmaker,

GRANITE, ISSM, KDiP, Knowledge Discipline in Practice, Knowledge System Driver, ModelCHECK,

MoldShop, NC Builder, Pro/ANIMATE, Pro/ASSEMBLY, Pro/CABLING, Pro/CASTING, Pro/CDT,

Pro/CMM, Pro/COLLABORATE, Pro/COMPOSITE, Pro/CONCEPT, Pro/CONVERT,

Pro/DATA for PDGS, Pro/DESIGNER, Pro/DETAIL, Pro/DIAGRAM, Pro/DIEFACE, Pro/DRAW,

Pro/ECAD, Pro/ENGINE, Pro/FEATURE, Pro/FEM-POST, Pro/FICIENCY, Pro/FLY-THROUGH,

Pro/HARNESS, Pro/INTERFACE, Pro/LANGUAGE, Pro/LEGACY, Pro/LIBRARYACCESS, Pro/MESH,

Pro/Model.View, Pro/MOLDESIGN, Pro/NC-ADVANCED, Pro/NC-CHECK, Pro/NC-MILL,

Pro/NCPOST, Pro/NC-SHEETMETAL, Pro/NC-TURN, Pro/NC-WEDM, Pro/NC-Wire EDM,

Pro/NETWORK ANIMATOR, Pro/NOTEBOOK, Pro/PDM, Pro/PHOTORENDER, Pro/PIPING,

Pro/PLASTIC ADVISOR, Pro/PLOT, Pro/POWER DESIGN, Pro/PROCESS, Pro/REPORT,

Pro/REVIEW, Pro/SCAN-TOOLS, Pro/SHEETMETAL, Pro/SURFACE, Pro/VERIFY, Pro/Web.Link,

Pro/Web.Publish, Pro/WELDING, Product Development Means Business, ProductView, PTC Precision,

Shrinkwrap, Simple

Powerful Connected, The Product Development Company,

The Way to Product First, Wildfire, Windchill DynamicDesignLink, Windchill PartsLink,

Windchill PDMLink, Windchill ProjectLink, and Windchill SupplyLink.

Patents of Parametric Technology Corporation or a Subsidiary

Registration numbers and issue dates follow. Additionally, equivalent patents may be issued or pending

outside of the United States. Contact PTC for further information.

6,665,569 B1

16-December-

2003

6,625,607 B1

23-September-

2003

6,580,428 B1

17-June-2003

GB2354684B

02-July-2003

GB2384125

15-October-

2003

GB2354096

12-November-

6,608,623 B1

19 August 2003

6,473,673 B1

29-October-

2002

GB2354683B

04-June-2003

6,447,223 B1

10-Sept-2002

6,308,144

23-October-2001

5,680,523 21-October-1997

5,838,331 17-November-1998

4,956,771 11-September-1990

4,310,615 21-December-1998

4,310,614 30-April-1996

4,310,614

22-April-1999

5,297,053

22-March-1994

5,513,316 30-April-1996

5,689,711

18-November-

1997

5,506,950

09-April-1996

5,428,772

27-June-1995

2003

6,608,623 B1

19 August 2003

GB2353376

05-November-

2003

GB2354686

15-October-

2003

6,545,671 B1 08-April-2003

GB2354685B

18-June-2003

5,058,000 15-October-1991

5,140,321 18-August-1992

5,423,023

05-June-1990

5,850,535 15-December-1998

5,557,176 09-November-1996

5,561,747 01-October-1996

Third-Party Trademarks

Adobe is a registered trademark of Adobe Systems. Advanced ClusterProven, ClusterProven, and the

ClusterProven design are trademarks or registered trademarks of International Business Machines

Corporation in the United States and other countries and are used under license. IBM Corporation does

not warrant and is not responsible for the operation of this software product. AIX is a registered

trademark of IBM Corporation. Allegro, Cadence, and Concept are registered trademarks of Cadence

Design Systems, Inc. Apple, Mac, Mac OS, and Panther are trademarks or registered trademarks of

Apple Computer, Inc. AutoCAD and Autodesk Inventor are registered trademarks of Autodesk, Inc.

Baan is a registered trademark of Baan Company. CADAM and CATIA are registered trademarks of

Dassault Systemes. COACH is a trademark of CADTRAIN, Inc. DOORS is a registered trademark of

Telelogic AB. FLEXlm is a trademark of Macrovision Corporation. Geomagic is a registered trademark

of Raindrop Geomagic, Inc. EVERSYNC, GROOVE, GROOVEFEST, GROOVE.NET,

GROOVE NETWORKS, iGROOVE, PEERWARE, and the interlocking circles logo are trademarks of

Groove Networks, Inc. Helix is a trademark of Microcadam, Inc. HOOPS is a trademark of Tech Soft

America, Inc. HP-UX is a registered trademark and Tru64 is a trademark of the Hewlett-Packard

Company. I-DEAS, Metaphase, Parasolid, SHERPA, Solid Edge, and Unigraphics are trademarks or

registered trademarks of Electronic Data Systems Corporation (EDS). InstallShield is a registered

trademark and service mark of InstallShield Software Corporation in the United States and/or other

countries. Intel is a registered trademark of Intel Corporation. IRIX is a registered trademark of Silicon

Graphics, Inc. LINUX is a registered trademark of Linus Torvalds. MatrixOne is a trademark of

MatrixOne, Inc. Mentor Graphics and Board Station are registered trademarks and 3D Design,

AMPLE, and Design Manager are trademarks of Mentor Graphics Corporation. MEDUSA and

STHENO are trademarks of CAD Schroer GmbH. Microsoft, Microsoft Project, Windows, the Windows

logo, Windows NT, Visual Basic, and the Visual Basic logo are registered trademarks of

Microsoft Corporation in the United States and/or other countries. Netscape and the Netscape N and

Ship's Wheel logos are registered trademarks of Netscape Communications Corporation in the U.S. and

other countries.

Oracle is a registered trademark of Oracle Corporation. OrbixWeb is a registered

trademark of IONA Technologies PLC. PDGS is a registered trademark of Ford Motor Company. RAND

is a trademark of RAND Worldwide. Rational Rose is a registered trademark of Rational Software

Corporation. RetrievalWare is a registered trademark of Convera Corporation. RosettaNet is a

trademark and Partner Interface Process and PIP are registered trademarks of “RosettaNet,” a

nonprofit organization. SAP and R/3 are registered trademarks of SAP AG Germany. SolidWorks is a

registered trademark of SolidWorks Corporation. All SPARC trademarks are used under license and

are trademarks or registered trademarks of SPARC International, Inc. in the United States and in

other countries. Products bearing SPARC trademarks are based upon an architecture developed by Sun

Microsystems, Inc. Sun, Sun Microsystems, the Sun logo, Solaris, UltraSPARC, Java and all Java

based marks, and “The Network is the Computer” are trademarks or registered trademarks of Sun

Microsystems, Inc. in the United States and in other countries. TIBCO, TIBCO Software, TIBCO

ActiveEnterprise, TIBCO Designer, TIBCO Enterprise for JMS, TIBCO Rendezvous, TIBCO Turbo

XML, TIBCO Business Works are the trademarks or registered trademarks of TIBCO Software Inc. in

the United States and other countries. WebEx is a trademark of WebEx Communications, Inc.

Third-Party Technology Information

Certain PTC software products contain licensed third-party technology: Rational Rose 2000E is

copyrighted software of Rational Software Corporation. RetrievalWare is copyrighted software of

Convera Corporation. VisTools library is copyrighted software of Visual Kinematics, Inc. (VKI)

containing confidential trade secret information belonging to VKI. HOOPS graphics system is a

proprietary software product of, and is copyrighted by, Tech Soft America, Inc. G-POST is copyrighted

software and a registered trademark of Intercim. VERICUT is copyrighted software and a registered

trademark of CGTech. Pro/PLASTIC ADVISOR is powered by Moldflow technology. Moldflow is a

registered trademark of Moldflow Corporation. The JPEG image output in the Pro/Web.Publish module

is based in part on the work of the independent JPEG Group. DFORMD.DLL is copyrighted software

from Compaq Computer Corporation and may not be distributed. METIS, developed by George Karypis

and Vipin Kumar at the University of Minnesota, can be researched at

http://www.cs.umn.edu/~karypis/metis. METIS is © 1997 Regents of the University of Minnesota.

LightWork Libraries are copyrighted by LightWork Design 1990–2001. Visual Basic for Applications

and Internet Explorer is copyrighted software of Microsoft Corporation. Parasolid © Electronic Data

Systems (EDS). Windchill Info*Engine Server contains IBM XML Parser for Java Edition and the

IBM Lotus XSL Edition. Pop-up calendar components Copyright © 1998 Netscape Communications

Corporation. All Rights Reserved. TECHNOMATIX is copyrighted software and contains proprietary

information of Technomatix Technologies Ltd. Technology "Powered by Groove" is provided by Groove

Networks, Inc. Technology "Powered by WebEx" is provided by WebEx Communications, Inc. Oracle 8i

run-time and Oracle 9i run-time, Copyright © 2002–2003 Oracle Corporation. Oracle programs

provided herein are subject to a restricted use license and can only be used in conjunction with the PTC

software they are provided with. Apache Server, Tomcat, Xalan, and Xerces are technologies developed

by, and are copyrighted software of, the Apache Software Foundation (http://www.apache.org) – their

use is subject to the terms and limitations at: http://www.apache.org/LICENSE.txt. Acrobat Reader is

copyrighted software of Adobe Systems Inc. and is subject to the Adobe End-User License Agreement as

provided by Adobe with those products. UnZip (© 1990-2001 Info-ZIP, All Rights Reserved) is provided

“AS IS” and WITHOUT WARRANTY OF ANY KIND. For the complete Info-ZIP license see

ftp://ftp.info-zip.org/pub/infozip/license.html. Gecko and Mozilla components are subject to the Mozilla

Public License Version 1.1 at http://www.mozilla.org/MPL. Software distributed under the MPL is

distributed on an "AS IS" basis, WITHOUT WARRANTY OF ANY KIND, either expressed or implied.

See the MPL for the specific language governing rights and limitations. The Java™ Telnet Applet

(StatusPeer.java, TelnetIO.java, TelnetWrapper.java, TimedOutException.java), Copyright © 1996, 97

Mattias L. Jugel, Marcus Meißner, is redistributed under the GNU General Public License. This license

is from the original copyright holder and the Applet is provided WITHOUT WARRANTY OF ANY

KIND. You may obtain a copy of the source code for the Applet at http://www.mud.de/se/jta (for a

charge of no more than the cost of physically performing the source distribution), by sending e-mail to

leo@mud.de or marcus@mud.de—you are allowed to choose either distribution method. The source code

is likewise provided under the GNU General Public License. GTK+The GIMP Toolkit are licensed

under the GNU LGPL. You may obtain a copy of the source code at http://www.gtk.org, which is

likewise provided under the GNU LGPL. zlib software Copyright © 1995-2002 Jean-loup Gailly and

Mark Adler. OmniORB is distributed under the terms and conditions of the GNU General Public

License and GNU Library General Public License. The Java Getopt.jar, copyright 1987-1997 Free

Software Foundation, Inc.; Java Port copyright 1998 by Aaron M. Renn (arenn@urbanophile.com), is

redistributed under the GNU LGPL. You may obtain a copy of the source code at

http://www.urbanophile.com/arenn/hacking/download.html. The source code is likewise provided under

the GNU LGPL. Mozilla Japanese localization components are subject to the Netscape Public License

Version 1.1 (at http://www.mozilla.org/NPL). Software distributed under NPL is distributed on an "AS

IS" basis, WITHOUT WARRANTY OF ANY KIND, either expressed or implied (see the NPL for the

specific language governing rights and limitations). The Original Code is Mozilla Communicator client

code, released March 31, 1998 and the Initial Developer of the Original Code is Netscape

Communications Corporation. Portions created by Netscape are Copyright © 1998 Netscape

Communications Corporation. All Rights Reserved. Contributors: Kazu Yamamoto

(kazu@mozilla.gr.jp), Ryoichi Furukawa (furu@mozilla.gr.jp), Tsukasa Maruyama (mal@mozilla.gr.jp),

Teiji Matsuba (matsuba@dream.com).

UNITED STATES GOVERNMENT RESTRICTED RIGHTS LEGEND

This document and the software described herein are Commercial Computer Documentation and

Software, pursuant to FAR 12.212(a)-(b) (OCT’95) or DFARS 227.7202-1(a) and 227.7202-3(a) (JUN’95),

is provided to the US Government under a limited commercial license only. For procurements

predating the above clauses, use, duplication, or disclosure by the Government is subject to the

restrictions set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software

Clause at DFARS 252.227-7013 (OCT’88) or Commercial Computer Software-Restricted Rights at

FAR 52.227-19(c)(1)-(2) (JUN’87),

as

applicable.

012304

Parametric Technology Corporation, 140 Kendrick Street, Needham, MA 02494 USA

v

Table Of Contents

Pro/PROCESS for Assembly ............................................................................. 1

Using Pro/PROCESS for Assembly .................................................................. 1

About Pro/PROCESS for ASSEMBLIES................................................................ 1

To Use Pro/PROCESS for ASSEMBLIES .............................................................. 1

Functionality with Other Modules ...................................................................... 2

Configuring for Pro/PROCESS for Assembly ..................................................... 3

About Configuring for Pro/PROCESS for Assemblies............................................. 3

To Set Pro/PROCESS for Assembly Configuration Options..................................... 3

curr_proc_comp_def_color .............................................................................. 3

curr_proc_comp_def_font ............................................................................... 3

display_comps_to_assemble............................................................................ 3

offset_line_def_color ...................................................................................... 4

offset_line_def_font ....................................................................................... 4

prev_proc_comp_def_color.............................................................................. 4

prev_proc_comp_def_font............................................................................... 4

Process Assemblies...................................................................................... 4

Basics of Process Assemblies ...................................................................... 4

About Process................................................................................................ 4

To Enter Process Mode.................................................................................... 4

To Display Process Status................................................................................ 5

To Create and Modify Step Parameters.............................................................. 5

To Set the Display of Process Components......................................................... 6

Operations on Components.............................................................................. 7

Accessing the MODIFY Menu Commands............................................................ 7

Using 3-D Notes with Process Steps.................................................................. 7

Creating Different Types of Process Steps .................................................... 8

About Process Assembly Steps ......................................................................... 8

Operations on Steps ....................................................................................... 8

To Create a New Step ..................................................................................... 9

Table Of Contents

vi

To Change the Active Model............................................................................10

To Get Step Information ................................................................................10

To Play Process Steps ....................................................................................10

About the Assemble Step Type........................................................................10

Using the display_comps_to_assemble Configuration Option.............................11

To Create an Assemble Step ...........................................................................11

About the General Step Type ..........................................................................11

To Create a General Step ...............................................................................12

About the Reposition Step Type ......................................................................12

To Create a Reposition Step ...........................................................................12

About the Disassemble Step Type....................................................................13

To Create a Disassemble Step.........................................................................13

About the Reassemble Command ....................................................................13

To Reassemble Step Elements ........................................................................13

Fabrication Units ........................................................................................13

About Fabrication Units ..................................................................................13

To Create a Fabrication Unit ...........................................................................14

Exploding Assemblies..................................................................................15

Basics of Exploding Assemblies ..................................................................15

About Explode Functionality............................................................................15

To Create Exploded States .............................................................................15

To Unexplode an Assembly .............................................................................15

To Change the Explode Position ......................................................................15

Using Offset Lines with Exploded Assemblies ...............................................16

About Using Offset Lines in Exploded Views ......................................................16

Configuration File Options for Offset Lines......................................................16

To Create Offset Lines ...................................................................................16

To Modify Offset Lines ...................................................................................16

To Add or Modify Jogs in Offset Lines ...............................................................17

Documenting the Process ............................................................................17

Set and Change State ..............................................................................17

Table Of Contents

vii

To Set the Assembly State of the Current Process Model.....................................17

To Change the Assembly State in a View ..........................................................17

Create Customized Documentation.............................................................18

About Drawing Mode With Process Documentation .............................................18

To Create a View of a Process Step..................................................................18

To Control the Component Step Display ...........................................................18

Object Parameters in Drawings .......................................................................18

Modifying Exploded Views in Drawing Mode ......................................................19

To Modify an Exploded View in Drawing Mode ...................................................19

Modifying the Explode Positions in Drawing Mode...............................................19

Using the Configuration File Options to Change Color and Line Font......................19

Create Reports and Tables ........................................................................20

About Using Pro/REPORT for Assembly Process Drawings ....................................20

Tip: User-Defined Parameters in Tables............................................................21

Example: Creating a Report............................................................................21

Other Process Functions ..............................................................................22

About Working with Large Design Assemblies....................................................22

Simplified Representations ........................................................................23

About Simplified Representations in Process Assemblies .....................................23

To Create Simplified Representations ...............................................................23

Retrieving a Simplified Representation in a Process Assembly ..............................23

User-Defined Features..............................................................................23

About Process User-Defined Features ...............................................................23

To Create a UDF ...........................................................................................24

Get Information on a Process ....................................................................24

About Obtaining General Information ...............................................................24

BOM and Parts Lists ......................................................................................24

Exporting Process Plans Using Pro/WEB Publish .................................................25

Index ..........................................................................................................27

1

Pro/PROCESS for Assemblies

Using Pro/PROCESS for Assembly

About Pro/PROCESS for ASSEMBLIES

Use Pro/PROCESS for ASSEMBLIES to create assembly process plans and

serviceability documentation.

Specifically, you can use it to complete the following tasks:

• Define the steps of the assembly fabrication process.

• Create a manufacturing BOM for each step in the process.

• Regroup components independent of the design assembly to model the

fabrication structure accurately.

• Assemble tools and fixtures unique to a process step without affecting the design

assembly.

• Perform time and cost estimates for the assembly fabrication.

• Create detailed drawings of each step in the process.

• Customize the display of each process step by defining multiple explode states

with jogged explode-offset lines and by assigning different colors and line fonts to

components based on their status in the step.

To Use Pro/PROCESS for ASSEMBLIES

1. Click File > New to create an assembly process file.

2. Click Assembly and Process Plan.

3. Enter the name for the process plan.

4. To create an assemble step or general step, choose Sequence > New Step >

Assemble > Done. The Step dialog box opens.

5. To retrieve a model, click Add Model > Open.

When creating the first assemble step, you retrieve the model for the design

assembly to be fabricated. The design assembly appears on the screen in a

phantom line font. The process assembly references the design assembly for

placement of components and parameter information, but does not affect the

design assembly.

6. Select components to be assembled directly from the screen or from the Model

Tree. Notice that the line font of assembled components changes from phantom

to solid.

7. Define additional elements (such as, description of the step, a simplified

representation, explode state, and time and cost estimates) for defining the step.

Explode-offset lines, showing how components fit together, are created in an

explode state.

Pro/PROCESS for Assemblies Help Topic Collection

2

8. Click OK when all desired elements are defined.

9. Define additional steps by selecting New Step from the STEPSEQUENCE menu.

The remaining unassembled components are displayed on the screen in phantom

line font for selection during an assemble step. To show the status of components

being assembled and disassembled, add the Process Status column to the tree

tool.

10. While defining an assemble step, you can add additional fixtures and tools to the

process assembly without affecting the design assembly. Click COMP SEL > Add

Model. To place the fixture, use a drag and drop technique. To specify explicit

assembly constraints such as mate and align, select PACKAGE > Finalize.

11. To replay the steps, select Play Steps from the ASM PROCESS menu.

12. Create detail drawings of the process assembly by adding the process assembly

model to a drawing. After you add a model to the drawing, the Process State

dialog box appears, listing the steps in the process assembly. You can select the

desired step and a simplified representation or explode state, and then click OK.

From the VIEW TYPE menu, select a view of the model in the specified step.

13. Use Pro/REPORT to create a manufacturing BOM for the step, which lists only the

components assembled during the active step. The system lists a new set of

report symbols, beginning with a prs prefix, unique to process steps.

14. When you create a view of another step, set the current step by selecting

DRAWING > Views > Dwg Models > Set State. The system displays a dialog

box. You can select a new step from the list through this dialog box.

15. Select Views from the DRAWING menu, and then Disp Mode and Process

Disp to display components in different colors or fonts depending on their

process status (that is, previously assembled or currently being assembled).

Functionality with Other Modules

The table below lists the functionality available when Pro/PROCESS for ASSEMBLIES

is used with other Pro/ENGINEER modules.

If you have...

You can...

Pro/ASSEMBLY

• Create and modify simplified representations.

These simplified representations control the

assembly components retrieved and displayed in

your Pro/ENGINEER session.

Pro/DETAIL

• Set the step to be displayed in a view.

• Create tables in process drawings.

• Add sheets to drawings.

Pro/FEATURE

• Create and modify groups of steps.

Pro/PROCESS for Assemblies

3

• Copy steps.

Pro/REPORT

• Create repeat regions in process drawings.

Configuring for Pro/PROCESS for Assembly

About Configuring for Pro/PROCESS for Assemblies

You can preset environment options and other global settings by entering the

settings you want in a configuration file. To set configuration file options use the

Options dialog box (Tools > Options).

This help module contains a list of configuration options, in alphabetical order,

showing for each option or group of related options:

• Configuration option name.

• Associated variables or values. The default values for the options are shown in

italics.

• Brief description.

To Set Pro/PROCESS for Assembly Configuration Options

1. Click Tools > Options. The Options dialog box opens.

2. Click the Show only options loaded from file check box to see currently

loaded configuration options or clear this check box to see all configuration

options.

3. Select the configuration option from the list or type the configuration option

name in the Option box.

4. In the Value box type or select a value.

Note: The default value is followed by an asterisk (*).

5. Click Add/Change. The configuration option and its value appear in the list. A

green status icon confirms the change.

6. When you finish configuring, click Apply or OK.

curr_proc_comp_def_color

Specify the default color used to display the current component in a process

assembly.

curr_proc_comp_def_font

Specify the default font used on the current component in a process assembly.

display_comps_to_assemble

yes

—The design model goes into memory and displays. Pick process components

from the design model or the Model Tree.

Pro/PROCESS for Assemblies Help Topic Collection

4

no

—Only the Model Tree displays components to assemble. Selected components go

into memory.

offset_line_def_color

Specifies the color offset lines are displayed in drawings.

offset_line_def_font

Specifies the fonts offset lines are displayed in drawings.

prev_proc_comp_def_color

Specify the default color for components added to a process assembly in a previous

step.

prev_proc_comp_def_font

Specify the default font for previously added components in a process assembly.

Process Assemblies

Basics of Process Assemblies

About Process

A process is a Pro/ENGINEER assembly that contains the features defining the

process steps. It follows the naming convention process_name.asm. An assembly

process has dependencies on one or more design assemblies and fixture models. The

process object has a required (for Pro/PDM purposes) dependency on the assemblies

that are assembled into it. If you assemble a part by selecting it from an assembly,

the required dependency is relative to the assembly, not the part. However, if you

assemble a single part by selecting the part directly from its part window, the

required dependency is on the part.

A process consists of all referenced assemblies and parts, as well as the sequence of

steps that define the process actions: assemble, disassemble, reassemble, reposition

and other steps related to fastening, preparing surfaces and so on.

The system retrieves the process model in whatever state it exists before the start of

the process (that is, without retrieving any components and without an active step).

You must use the SET STEP menu to move to an active step. The system displays

only those components required by the indicated step.

To Enter Process Mode

1. To create a new process, click File > New. In the New dialog box, click

Assembly and Process Plan.

To open an existing process, click File > Open and select an existing assembly

process file.

2. For a new process, type the name for the assembly process file.

Pro/PROCESS for Assemblies

5

3. Select an option from the ASM PROCESS menu:

o Sequence—Manipulate a process step (add, create, redefine, and so on)

using the SEQUENCE menu.

o Component—Perform component operations using the COMPONENT

menu.

o Fab Unit—Create, modify, or delete fabrication units using the FAB UNIT

menu.

o Modify—Modify assembly or assembly component dimensions and features

using the PROCESS MOD menu.

o Simplfd Rep—Create, modify, or set simplified representations.

o Explode State—Create and edit explode states using the EXPLODE menu.

o Regenerate—Update modified part and assembly dimensions.

o Play Steps—View assembly at individual steps of the process plan using

the STEP REGEN menu.

o Relations—Add and edit constraint equations.

o Set Up—Set up additional process information.

o Layer—Perform layer operations.

o Program—Access Pro/PROGRAM.

o Integrate—Resolve differences between the source and target processes.

To Display Process Status

The system can display process status in the Info menu. Process Status describes

the current status of the process assembly. Components can be listed as:

• Assembling (assembled by the current step)

• Not Assembled

• Disassembled

Note: Repositioned or reassembled components are listed as assembled. Top-level

assemblies are listed as Design Only.

1. To display the Process Status, click Settings > Tree Columns.

2. Click column types from the left column in the box and move it to the right

column.

To Create and Modify Step Parameters

You can create parameters for individual steps. Parameters in individual steps are

similar to feature parameters—they exist for that step only.

1. Click ASM PROCESS > Set Up > Parameters.

Pro/PROCESS for Assemblies Help Topic Collection

6

2. The Parameters dialog box opens. Select the step from the list in the dialog box

and click OK.

3. Click

to create step parameters or click column headings to modify specific

parameters.

To Set the Display of Process Components

The display of components in an assembly process can be set based upon their

status in the assembly process. When a component is at a particular status, its line

style will change. Using alternate line styles for displaying components as you create

your assembly process can help to differentiate one component from another.

1. Click View > Model Setup > Process Display to open the PROCESS

COMPONENT DISPLAY dialog box.

Here you can modify the display method used for the different status levels of a

component in your assembly process.

2. Set a line style for components at each of the following status levels:

o Previous Components—Components in the process that have already

been assembled as part of an existing step.

o Current Components—Components that are active in the current

assembly step.

o Unused Components—Components that have not yet been used in the

assembly process or have been previously disassembled.

3. You can select a different display setting for each component at two different

display stages:

o Process Display—Component display for all other operations in the

assembly process including playing steps, modifying components, and

redefining steps.

o Selection Display—Component display when defining steps in the

assembly process.

4. The component display can each be set to any of the following line styles:

o Current Environment—Current setting for that component status and

stage.

o Phantom—Phantom line font.

o Blank—Blanked from the display.

o Wireframe—Wireframe model.

o Hidden Line—Hidden line style.

o No Hidden—No hidden lines.

o Shade—Shaded model.

Pro/PROCESS for Assemblies

7

Note:

• Clicking Use Defaults in the PROCESS COMPONENT DISPLAY dialog box sets

the Previous Components and Current Components status for both display

stages to the Current Environment setting. The Unused Components status

for Process Display is set to Blank, while the setting for Selection Display is

Phantom.

• Clicking Minimize Repaints overrides all Process Display settings with those

for Selection Display. Using identical settings for the display stages will

minimize the repaints required after defining a step and redisplaying the process

assembly.

• Display settings for specific components as well as a component's layer status

override any process display setting for that component.

Operations on Components

1. Click ASM PROCESS > Component.

2. Select an option from the COMPONENT menu:

o Package—Move packaged components that are not in the design

assembly.

o Delete—Delete components and their children from the assembly.

o Redefine—Redefine one of the component constraints.

o Reroute—Reassign component references.

o Replace—Replace an existing component with another one.

Accessing the MODIFY Menu Commands

To access the MODIFY menu:

1. Click ASM PROCESS > Modify.

2. Choose a command from the PROCESS MOD menu:

o Mod Part— Modify a part.

o Mod Skel— Modify a skeleton model.

o Mod Subasm—Modify a subassembly.

o Mod Assem—Modify an assembly.

o Mod Dim—Modify dimensions.

Using 3-D Notes with Process Steps

The display of 3-D Notes depends on the display of the step to which the note

belongs. When a step is active or is being used in a drawing step, the system

displays a 3-D note created for the step. When the step is no longer displayed, the

Pro/PROCESS for Assemblies Help Topic Collection

8

note also disappears. Creation of 3-D notes is the default when creating a note in a

step.

3-D notes can be displayed by selecting them from the screen or from the model

tree. They are displayed only when their step is active, even if their status in the tree

is Shown. You can erase only the 3-D notes that belong to the active step.

Creating Different Types of Process Steps

About Process Assembly Steps

Process steps describe the actions used to assemble the product. You activate a step

by selecting it in the Process window. You can only have one active step at any

time. The graphics window displays the assembly in the state created by the active

step. Process step types are: Assemble, Disassemble, Reassemble, Reposition, and

General.

Unused components are not displayed during general, reposition, and disassembled

steps.

Operations on Steps

To access operations on steps, click ASM PROCESS > Sequence. The STEP

SEQUENCE menu opens with the following commands:

• New Step—Create a new step. Opens the STEP TYPE menu with the following

commands:

o Assemble—Create an assemble step.

o Disassemble— Create a disassemble step.

o Reassemble— Create a reassemble step.

o Reposition— Create a reposition step.

o General— Create a general step.

• Copy—Copies steps.

• Delete—Delete steps using options in the DELETE/SUPP menu. Choose from the

options

o Normal—Delete steps by selecting them from the Select Step dialog box.

o Clip—Deletes the selected entity and everything after it in the process.

o Unrelated—Deletes everything but the selected entity.

• Suppress—Suppress steps using options in the DELETE/SUPP menu.

• Resume—Resume suppressed steps using options in the RESUME menu. Choose

from the options:

o All—Resumes all suppressed steps.

o Layer—Resumes the steps on current layer.

Pro/PROCESS for Assemblies

9

o Last Set—Resumes the last set of suppressed steps.

o Feat ID—Enters a step ID to resume.

• Step Library—Group steps together into a UDF.

• Group—Create steps from UDFs.

• Redefine—Redefine a step.

• Reorder—Reorders steps.

• Insert Mode—Activate or cancel Insert Mode.

To Create a New Step

1. Click Asm Process > Sequence > New Step.

2. Choose the type of step from the STEP TYPE menu: Assemble, Disassemble,

Reassemble, Reposition, or General. Click Done.

3. The Step dialog box opens. Define the following elements in the dialog box:

o Components—Select components for the process step (standard

components, fabrication units, cable features, pipe features, tools/fixtures,

and bulk items). Indicate the type of component and select one or more.

You can add components of another type. You must choose at least one

component to create a valid assembly step.

Note: When you select components, the system assumes that the top level

model is the one you used for the last assemble component selection (the

active model).

o Description (optional element)—Type the description of the process step.

You can enter multiple lines of text. Enter a new description in the Step

Description dialog box. You can import text files into the Step

Description dialog box, so you can reuse information from another step, or

import a standard text template.

o Simplfd Rep (optional element)—Use the View Manager to select or create

the simplified representation to be used when displaying this step. The

default is the currently set simplified representation.

o Explode State (optional element)—Select an explode state to be used

when displaying this step. The default state is No Explode. Use the

SELSTATE menu, with the Create and No Explode commands added.

o View—Set up the orientation of the model using the Orientation dialog

box. Click Set to associate the view to the current step.

o Time Estimate (optional element)—Specify the estimated time to perform

this step, in hours.

o Cost Estimate (optional element)—Specify estimated cost to perform this

step. Enter a value or write a relation to calculate it.

Pro/PROCESS for Assemblies Help Topic Collection

10

4. After you defined all required and any optional elements, click OK in the dialog

box.

To Change the Active Model

1. Click Sequence > New Step > Assemble > Done.

2. You can select from the active assembly (displayed in phantom line font) or click

Add Model to retrieve a model other than the one that is currently active.

To Get Step Information

You can obtain information about a particular step.

1. Choose the Info > Process Step.

2. Select a step from the Select Step dialog box.

3. The system displays an Information window, containing the following:

o Step number and type

o References and reference type

o Abbreviated description of the step description

o Time estimate

o Cost estimate

o Simplified representation name

o Explode state name

o Full description

When you show the status of components in the design assembly, you can add a

column in the model tree called Process Status, which lists the current status of all

components (that is, assembled, not assembled, assembling, and so on).

To Play Process Steps

1. Click ASM PROCESS > Play Steps.

2. Select an option from the STEP REGEN menu:

o Set Step—Select a step from the Process window.

o Previous Step—Roll model back one step.

o Next Step—Show the model one step forward.

o Info—Display information for the current step and operation.

Assemble Step Type

About the Assemble Step Type

Pro/PROCESS for Assemblies

11

Use the Assemble step to assemble parts, entire assemblies, and individual

components from reference assemblies into the process assembly. You specify the

component type prior to the selection process.

If you are assembling individual components from an assembly, you must place

them in the process assembly if they are the first ones being placed from that

assembly. This step type adds a new occurrence of the component to the BOM.

To specify the reference components, you select them from a model window. The

last model window that you used to select components is the active window. If the

object in the active window is an assembly, you must specify the components in the

assembly to be assembled in this step.

You can also specify components to assemble by selecting them in an already

partially assembled reference assembly that has either not been assembled yet, or

has been disassembled. When you select components in the process assembly, the

system turns on the display of those components. If you have added components

without retrieving a reference assembly', use the tree tool the logical view of the

process assembly to choose the components.

If you activate a model that is already partially assembled in the process, you can

choose to assemble a new occurrence of the top-level component or continue

assembling components from the already assembled occurrence.

If a simplified representation of the process assembly is active, you can assemble a

simplified representation of another assembly or part into it using the SELECT REP

menu. This is similar to the functionality in Assembly mode, where you can assemble

a simplified representation of a component into a simplified representation of the

top-level assembly.

Using the display_comps_to_assemble Configuration Option

You can use a configuration option display_comps_to_assemble to enhance

performance when working with complex assemblies. When you set this option to no

(default is yes), you can select design assemblies and components from the Model

Tree without displaying them on the screen until they are selected.

If no geometry exists in the process assembly (no features or components are yet

created or assembled, or all components have been disassembled), the system, the

system places the component being assembled in the default orientation and location

(similar to assembling the first component of an assembly). If geometry exists, the

system provides the Package functionality to enable you to place the component.

To Create an Assemble Step

1. Click ASM PROCESS > Sequence > New > Assemble > Done.

2. The Assemble dialog box opens. Define the elements in the dialog box.

General Step Type

About the General Step Type

Pro/PROCESS for Assemblies Help Topic Collection

12

You use the General command in the STEP TYPE menu to create steps for

miscellaneous operations such as painting, cleaning, gluing and so on. Process steps,

similar to features, consist of a set of elements and can have geometric references.

To Create a General Step

1. Click ASM PROCESS > Sequence > New Step > General > Done.

The STEP: General dialog box opens. Define the Type element by selecting from a

list containing all default types as well as any user-defined types that exist in the

current model (Caulk, Clean, Drain, Fill, Inspect, Lubricate, Paint, Torque, Verify).

Click Done. If you select New Type, all elements reset to default values, and you

must enter the name for the step.

2. Define any optional elements in the dialog box.

3. Click OK.

Reposition Step Type

About the Reposition Step Type

Using the Reposition step type, you can reposition a previously assembled

component in the process assembly. You select the component from the process

assembly and move it using the Package functionality.

You can only select components that are currently part of the process assembly. If

you pick a component that is part of a fabrication unit, the entire unit is selected.

To Create a Reposition Step

1. Click ASM PROCESS > Sequence > New Step > Reposition > Done.

2. The STEP:Reposition dialog box opens. Define the following required elements:

o Components—Select components for the process step (standard

components, fabrication units, cable features, pipe features, weld features,

tools/fixtures, and bulk items). You pick the components from the process

assembly. You must choose at least one component to create a valid

reposition step. You can only select components that are currently part of

the process assembly.

o Position—Reposition selected components using the Package interface.

This defines the transformations for the components. Only components

defined by the first element may be repositioned. Only one Package

operation is allowed per step. All of the components will be repositioned

together.

3. Define any additional elements.

4. Click OK.

Disassemble Step Type

Pro/PROCESS for Assemblies

13

About the Disassemble Step Type

Use the Disassemble command in the STEP TYPE menu to disassemble components

that are already assembled. Select components from the process assembly. If you

want to move the assembly to a different work cell or fixture, you can disassemble

all components. Disassembling a component does not remove the model from the

process assembly.

To Create a Disassemble Step

1. Click ASM PROCESS > Sequence > New Step > Disassemble > Done.

2. The Disassemble dialog box opens. Select components to disassemble. You can

only select components that belong to the process assembly. If you select a

component that belongs to a fabrication unit, the entire unit is selected.

3. Define any optional elements.

4. Click OK.

Reassemble Step Type

About the Reassemble Command

Use the Reassemble command in the STEP TYPE menu to reassemble previously

disassembled components. Using the Reassemble step does not add another instance

of the selected model to the BOM. If you want to add another occurrence of the

component to the BOM, use the Assemble step.

You only reassemble components that you have disassembled. Therefore, only

components that have been disassembled are available for this step. Since you

assembled the selected components in a previous step, you do not have to specify a

component type. You need to reconstrain all components that you select for this step

using the COMP/FAB menu.

To Reassemble Step Elements

1. Click ASM PROCESS > Sequence > New Step > Reassemble > Done.

2. The STEP:Reassemble dialog box opens. Select components to reassemble.

3. Define any optional elements.

4. Click OK.

Fabrication Units

About Fabrication Units

Fabrication assemblies are representative of what is actually manufactured and

shipped. These assemblies differ from design assemblies in that they also include

components that are used for shipping purposes only, as well as components that

represent documentation and other support material. For example, a pipe assembly

Pro/PROCESS for Assemblies Help Topic Collection

14

often contains cap parts to protect the open-ended assembly from damage until it is

assembled into a higher level fabrication assembly.

With Pro/PROCESS for ASSEMBLIES, you can use fabrication units to avoid

permanently affecting the design assembly structure. You can create modify, and

delete information about fabrication units using the Fab Unit command in the ASM

PROCESS menu.

Fabrication units are groups of components that you use to create a process plan

showing the actual build Bill of Materials (BOM). They appear in the process BOM as

individual components.

You can use a fabrication unit as a component in an assemble step, which assembles

all of the components in the fabrication unit simultaneously. The system considers

them to be one unit for explode, simplified representations, Bill of Materials, and so

on. You can also select them for the other step types (disassemble, reposition, and

so on).

Pro/ENGINEER considers the groups of components comprising the fabrication units

to be one unit throughout the process plan, you should create them before you use

any of the components in a process step. You can create them even if some of the

components are already in the plan; however, you should redefine that step and

assemble the fabrication unit instead of the individual component. The fabrication

unit cannot include a component that is used in one assemble step and a component

that is used in another.

When working with fabrication units, consider the following:

• Fabrication units do not include placement constraints. The fabrication unit may

include components that have not been assembled yet; you add the placement

constraints for these components when you assemble the fabrication unit into the

process.

• A fabrication unit contains components from a single assembly in the process.

The components may come from multiple levels of that assembly, but there must

be a single assembly that ties them all together.

• You can have multiple occurrences of the same fabrication unit. If there is more

than one other occurrence, the system highlights them one at a time and asks

you to select one. The process BOM and parts list catalogs each occurrence of a

fabrication unit.

• Fabrication units are listed in the manufacturing BOM as a unit. However, the

BOM does not list all components that belong to that unit.

To Create a Fabrication Unit

1. Click ASM PROCESS > Fab Unit > Create.

2. Enter the fabrication unit name.

3. Retrieve the top level design assembly to define the fabrication unit.

4. The top level assembly appears in a phantom font. You can now select

components similarly to adding components to a process step.

Pro/PROCESS for Assemblies

15

Exploding Assemblies

Basics of Exploding Assemblies

About Explode Functionality

In Process mode (as in Assembly mode), you can create exploded states to define

the exploded positions of all components. For each exploded state, you can change

the explode locations of components, create explode offset lines, and toggle the

explode status of components. To access the Explode functionality, click View >

View Manager and click Explode.

You can define multiple exploded states for each assembly, and then explode the

assembly using any of these exploded states at any time. You can also set an

exploded state for each step of the process plan and each drawing view of an

assembly. The default exploded state positions each component based on its

placement constraints.

To create other exploded states, you position components using the mouse cursor to

drag components.

To Create Exploded States

Use the View Manager to set the explode position of components.

1. Click

or View > View Manager. The View Manager dialog box opens.

2. Click Explode.

3. Click Properties .

4. Click

Edit Position. The Explode Position dialog box opens.

5. Select Motion Type of the explosion.

6. Select the component to explode and drag it to a new position.

7. Continue selecting components and dragging them to desired explode positions.

8. Click OK to complete to complete explode positions and return the View

Manager.

To Unexplode an Assembly

To unexplode an assembly, click View > Explode > Unexplode View.

To Change the Explode Position

Use the View Manager to change the explode status of components in your

assembly.

1. Click

or View > View Manager. The View Manager dialog box opens.

2. Click the Explode tab.

Pro/PROCESS for Assemblies Help Topic Collection

16

3. Click Properties and select a model.

4. Click

Toggle Status.

Or

1. Select an exploded state.

2. In the View Manager, click Edit > Redefine. The MOD EXPLODE menu opens.

Click Expld Status.

3. Select the required components to be toggled.

Using Offset Lines with Exploded Assemblies

About Using Offset Lines in Exploded Views

You can use offset lines to show how exploded components align when they are in

their final positions, and then modify or delete them when editing an exploded state.

They display in a dashed font. Offset lines are composed of three straight segments.

You determine the direction of the end segments by selecting references (parallel to

an edge or curve or normal to a surface), and the middle segment connects the two

end segments.

Configuration File Options for Offset Lines

In the configuration file, you can set the default color and font style for offset lines

created for exploded views. The following options are available:

• offset_line_def_font

• offset_line_def_color

To Create Offset Lines

1. Click View > Explode > Offset Lines > Create.

2. Select a pair of start and end anchor points (on an axis, surface, edge, or the

center of an arc).

To Modify Offset Lines

You can modify offset lines by:

• Adding, moving, or deleting jogs

• Changing line font

• Changing line color

1. Click View > Explode > Offset Lines.

2. Choose one of the options in the OFFSET LINES menu:

o Modify—Move, add, or delete a jog.

Pro/PROCESS for Assemblies

17

o Delete—Delete an offset line.

o Mod Line Style—Select a line to modify using options in the Line Style

dialog box.

o Set Def Style—Set a new default line style and color using options in the

Line Style dialog box.

To Add or Modify Jogs in Offset Lines

You can create offset lines with multiple jogs. You can also move as well as delete

the jog points.

1. Click View > Explode > Offset Lines > Modify.

2. Select an offset line to modify.

3. Select an option from the EXPL LINES MODIFY menu:

o Move—Move a jog point.

o Add Jogs—Add a jog to the lines.

o Delete Jogs—Delete a jog by selecting a jog point.

Documenting the Process

Set and Change State

To Set the Assembly State of the Current Process Model

1. Click VIEWS > Dwg Models > Set State.

2. The Process State dialog box appears with the current process state, explode

state, and simplified representation selected in the lists.

The Process State dialog box contains a scrollable tree tool that displays the

process assembly sequence. You can select a step to show in the view. If

simplified representations are available, you can select one from the drop-down

list. You can also select an exploded state from the drop-down list.

To Change the Assembly State in a View

After you have created and placed a drawing view, you can change the process

assembly state shown in that view.

1. Click VIEWS > Modify View > View State.

2. Select a view of a process model. The system displays the Process State dialog

box with the process state, explode state, and simplified representation used in

the view selected in the lists.

3. Select a new assembly state. When you change the process state, explode state,

and/or the simplified representation, the system uses that model when creating

new views.

Pro/PROCESS for Assemblies Help Topic Collection

18

Create Customized Documentation

About Drawing Mode With Process Documentation

In Drawing mode, you can create customized documentation for the assembly

process. You can add views for each step and control the display of a component

based on its status in the step. You can also create report tables using Pro/REPORT.

To create views of a process at a particular step, you must first select a process

assembly in session and then select a process step from a list. The system creates a

default view of the process at that step.

In Drawing mode, you can also do the following:

• Create an exploded state in the context of the drawing (if you have not already

exploded the process assembly at that process step, or if the explode is not

appropriate for that view). The system stores the explode information in the

drawing.

• Control how the system displays the components in the process assembly in the

drawing view. Click View > Drawing Display > Component Display to open

the MEMB DISP menu to define the display colors and fonts. For example, you

can display all assembled components in neutral gray, dashed font, and all

components that you are assembling in red, solid font.

To Create a View of a Process Step

1. In Drawing mode, click DRAWING > Views > Dwg Models > Add Model.

2. Select the process model. The Process State dialog box opens.

3. Using the Process State dialog box, select a process step, an exploded state, or

a simplified representation for that step.

Note: An existing drawing sheet can be used as a template to format new sheets in

a process drawing. The formats and views of the current sheet are used as a

template for a new sheet in the drawing.

4. Continue to define a view as you do for regular drawings.

To Control the Component Step Display

1. Click DRAWING > Views > Disp Mode > Process Disp.

2. The Component Step Display dialog box opens. This dialog box allows you to

determine component display status according to whether or not the component

is referenced in the current step. Change the display of the selected component.

Object Parameters in Drawings

You can use object parameters in your assembly process drawings as you would any

other object parameters. The object parameters can be used in drawing notes just as

you would with other drawings.

In particular, you may want to include the step description in your drawings. This

description can be included as a note which contains the following object parameter:

Pro/PROCESS for Assemblies

19

&description:FID_#

Where # is the feature ID for the step you are documenting.

Exploded Views in Drawing Mode

Modifying Exploded Views in Drawing Mode

In Drawing mode, you can edit explode positions and offset lines by clicking on the

VIEW MODIFY > Mod Expld. The system stores these changes in the drawing, not

in the assembly or process model. A drawing may use an explode state from an

assembly or a process.

The drawing references the assembly or process exploded state as long as the

reference is valid. The reference is no longer valid if you modify the explode from

inside the drawing. When this happens, the system copies the exploded state into

the drawing and removes the reference to the assembly exploded state.

To Modify an Exploded View in Drawing Mode

1. Click VIEW MODIFY > Mod Expld.

2. Select a view to modify.

3. Choose an option from the EXPLD STATE menu:

o Create—Create an exploded state for this view.

o Set Current—Set the current state as default.

o Copy—Copy an exploded state.

o Redefine—Redefine an exploded state. Choose Position to change the

explode positions, or Expld Status to change the exploded status.

Modifying the Explode Positions in Drawing Mode

You can use the Mod Explode command in the VIEW MODIFY menu to modify

explode positions. You can change the explode position of components and you can

toggle the explode status of components to be exploded or unexploded. Changes

made from this menu become part of the drawing; they do not affect the process

assembly.

Note: In steps that have components as references, you can control the display of

components based on their status in the current step using options in the DISP

MODE menu.

Using the Configuration File Options to Change Color and

Line Font

You can set the default color and line font for models in drawing mode. All options

are available as keywords in the configuration file. Color is user-defined by

percentages of red, green, and blue.

For previously assembled components in the step, set the following variables:

Pro/PROCESS for Assemblies Help Topic Collection

20

• prev_proc_comp_def_font

• prev_proc_comp_def_color

For components assembled in the step that is active in the current view, set the

following variables:

• curr_proc_comp_def_font

• curr_proc_comp_def_color

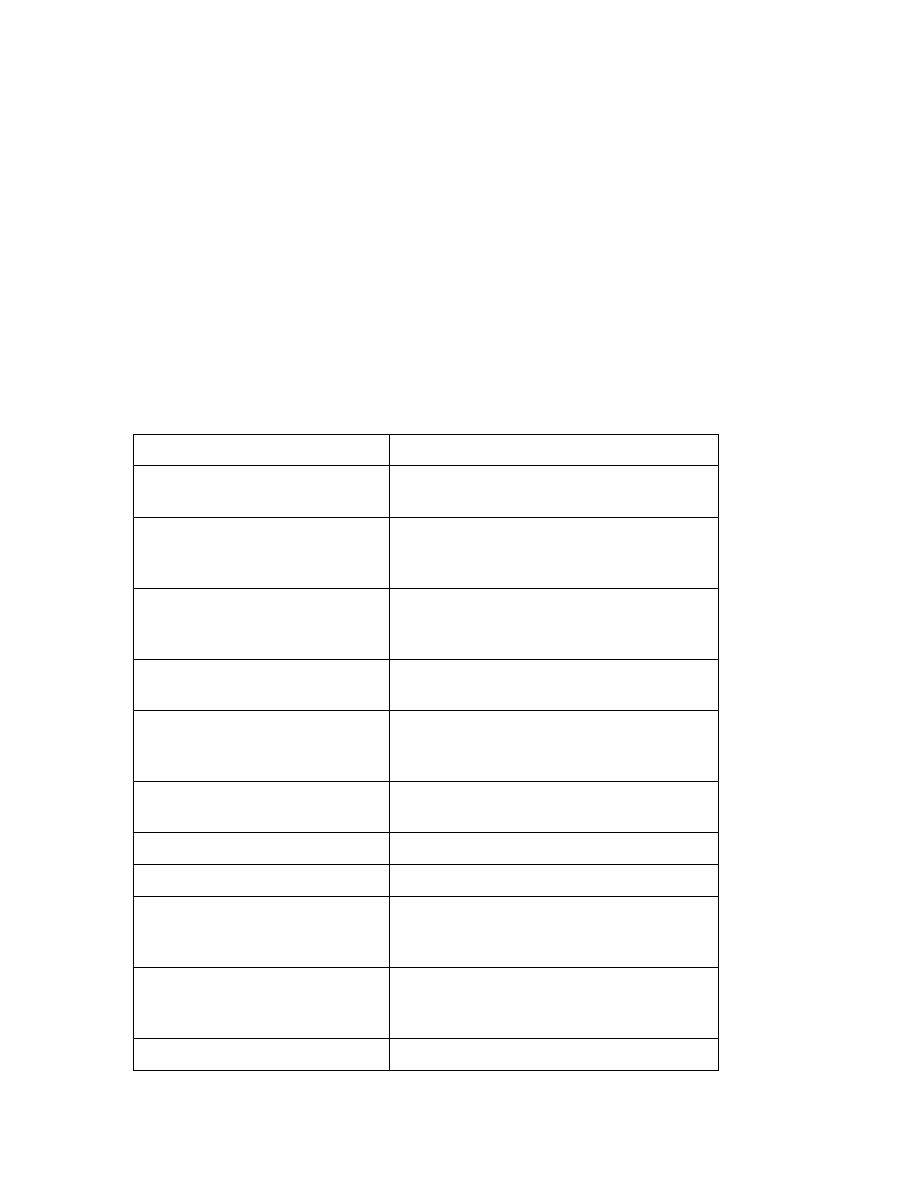

Create Reports and Tables

About Using Pro/REPORT for Assembly Process Drawings

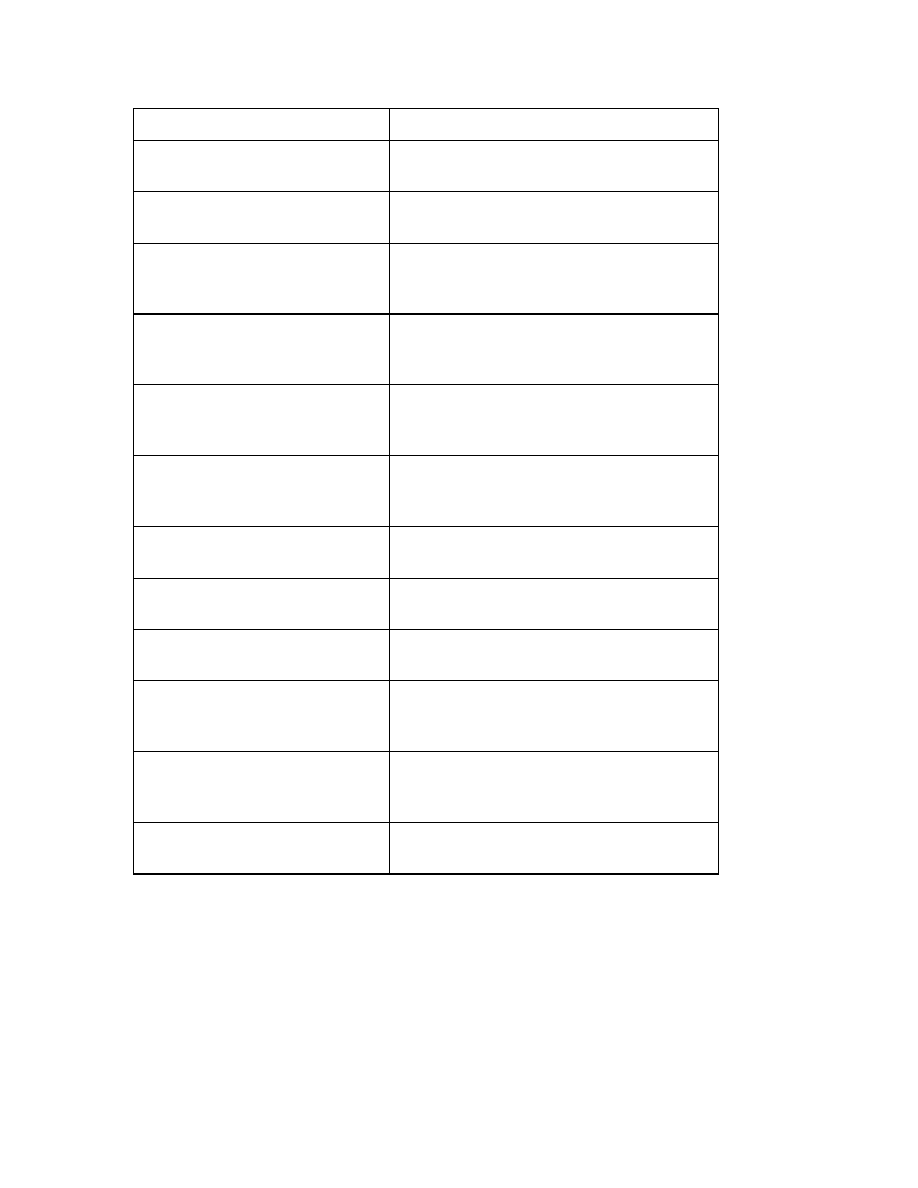

There are special Pro/REPORT parameters that you can use to create a custom table

detailing the assembly process. An entire list of available system parameters appears

in the following table.

Parameter Name

Definition

&prs.actstep.comp.name

Lists the names of all assembly

components in the currently active step.

&prs.actstep.comp.param.name Lists the names of all parameters for each

assembly component in the currently

active step.

&prs.actstep.comp.param.value Lists the values of all parameters for each

assembly component in the currently

active step.

&prs.actstep.comp.type

Lists the method of assembly for each

component in the currently active step.

&prs.actstep.comp.User Defined Lists the values of any user defined

parameters for each assembly component

in the currently active step.

&prs.actstep.desc

Lists the descriptive phrase of the

currently active step.

&prs.actstep.name

Lists the name of the currently active step

&prs.actstep.number

Lists the currently active step number.

&prs.actstep.param.name

Lists the names of all parameters

associated with the current assembly

model.

&prs.actstep.param.value

Lists the values of all parameters

associated with the current assembly

model.

&prs.actstep.type

Lists the names of all parameters

i t d

ith th

t

ti

t

Pro/PROCESS for Assemblies

21

associated with the current active step.

&prs.actstep.User Defined

Lists the values of any user defined

parameters in the currently active steps.

&prs.step.comp.name

Lists the names of all components for each

step displayed in your drawing.

&prs.step.comp.param.name

Lists the names of all parameters for each

assembly component for each step

displayed in your drawing.

&prs.step.comp.param.value

Lists the values of all parameters for each

assembly component for each step

displayed in your drawing.

&prs.step.comp.type

Lists the type of component being

assembled for each step displayed in your

drawing.

&prs.step.comp.User Defined

Lists the values of any user defined

parameters for every assembly component

displayed in your drawing.

&prs.step.desc

Displays the descriptive phrase of each

step shown in your drawing.

&prs.step.name

Displays the name of each step shown in

your drawing.

&prs.step.number

Displays the all step numbers for every

step in your drawing.

&prs.step.param.name

Lists the names of all parameters

associated with the steps displayed in your

drawing.

&prs.step.param.value

Lists the values of all parameters

associated with the steps displayed in your

drawing.

&prs.step.type

Lists the methods of assembly being used

for each step displayed in your drawing.

Tip: User-Defined Parameters in Tables

An item's parameters can also be used in a Pro/REPORT table as a user-defined

parameter. For example, the COST parameter of a part can be used as a user-

defined parameter in a Pro/REPORT table as &prs.step.cost_estimate even though a

system-defined Pro/REPORT parameter called &prs.step.cost_estimate does not

exist.

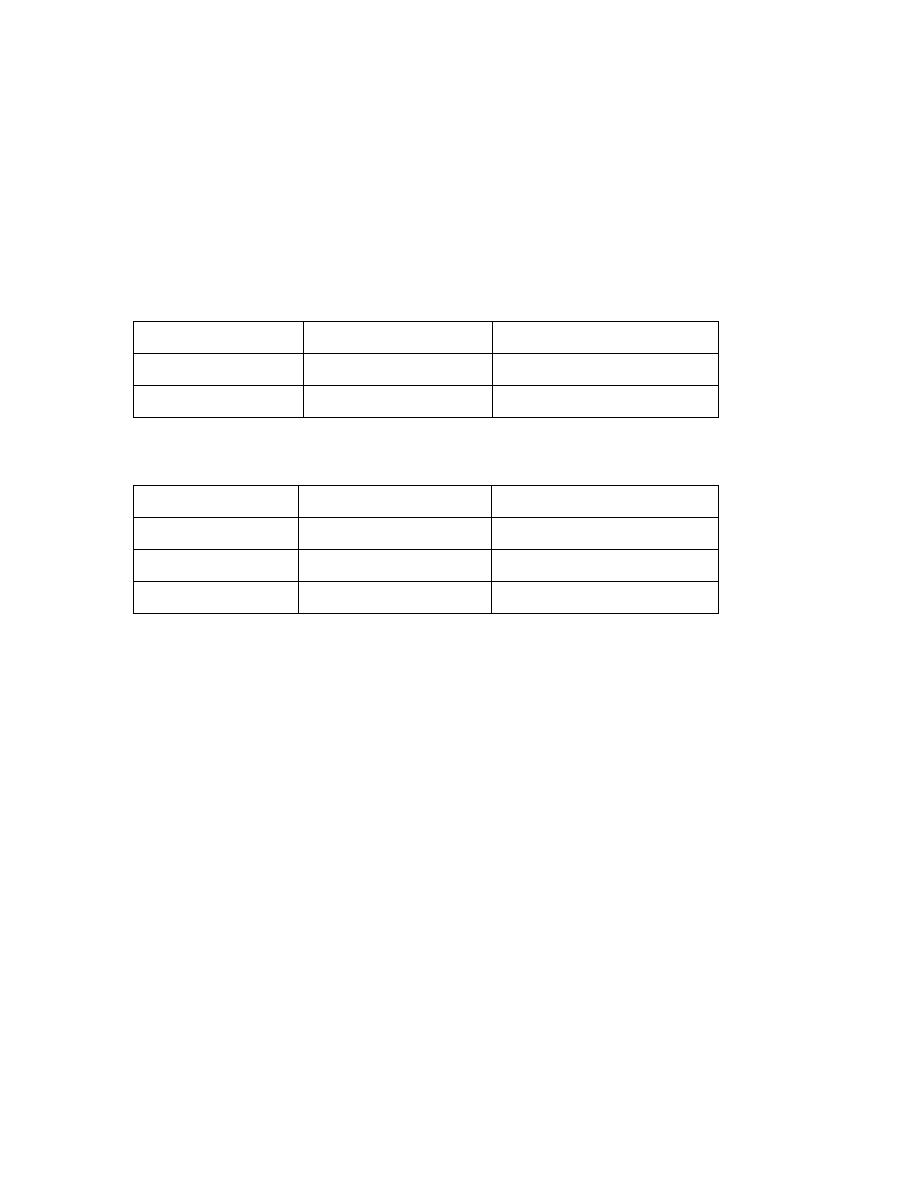

Example: Creating a Report

Pro/PROCESS for Assemblies Help Topic Collection

22

When creating a report, it is important to consider the structuring of the symbols in

the report. Pro/REPORT parameters used in Pro/PROCESS for ASSEMBLIES are based

upon either the current step in the drawing or all steps in the drawing.

Pro/REPORT provides information based upon a hierarchy of specifications

proceeding from left to right. In the example, the parameter &prs.actstep.number

provides the step number of the step in your assembly process that is currently set

as the active model. Similarly, &prs.actstep.type gives the assembly method used

in just the active step. The parameter &prs.actstep.comp.name provides the names

of all assembly components used in the active step.

&prs.actstep.number &prs.actstep.type

&prs.actstep.comp.name

2 ASSEMBLE

8_PORT

2 ASSEMBLE

2_PORT

The table in the next example illustrates the slight differences between similar

parameters

&prs.step.number &prs.step.type

&prs.step.comp.name

1 REPOSITION

BASE

2 ASSEMBLE

8_PORT

2 ASSEMBLE

2_PORT

In this case, instead of using the parameter &prs.actstep.number, the

&prs.step.number

parameter is used. This parameter behaves differently than the

other. While the &prs.actstep.number parameter specifies the name of the step

number, the &prs.step.number parameter lists the step number for all models in

your drawing, regardless of which model is the current one. This parameter is used

to list report information for all steps in a drawing with multiple models. The same

principle can be applied to the other two report parameters.

Other Process Functions

About Working with Large Design Assemblies

There are a number of ways to work effectively with large design assemblies.

• Use simplified representations

• Retrieve the earliest step

Note: Retrieving the earliest desired step when retrieving a process assembly

limits the number of components retrieved into memory because only those

components required for the process step are retrieved and displayed. All

components of the design assembly are retrieved when adding a new step.

• Set appropriate configuration options

Pro/PROCESS for Assemblies

23

Simplified Representations

About Simplified Representations in Process Assemblies

Simplified representations are used to improve visual clarity and performance. They

are used to simplify the process assembly by excluding or substituting components

for all steps, or to simplify only the current state (that is, step). Simplified

representations of the design assembly can also be used when creating assemble

steps in the process assembly.

To Create Simplified Representations

You can define a simplified representation for a process assembly.

1. Click

or View > View Manager. The View Manager opens.

2. Click Simp Reps

3. Click New to create a new simplified representation.

You can specify a simplified representation for particular step while defining or

redefining the step.

1. While defining a step with the STEP dialog box, click the Simplfd Rep element

and Define.

2. The View Manager opens. Click New to create a new simplified representation.

Retrieving a Simplified Representation in a Process Assembly

You can define a simplified representation of the process assembly before adding the

design assembly to the process. Then, when you work with the process assembly,

you can use the View Manager to add a model to the process.

Note: Components excluded in the design assembly do not appear on the screen in

phantom line font but appear in the Model Tree of the assembly where they are

selected.

User-Defined Features

About Process User-Defined Features

You can create and store a user-defined feature (UDF) of one or more General

process steps the same way you would create a standard UDF in Part mode. You pick

the step(s) to include in the UDF, and enter reference prompts, variable elements,

and other data. With a license for Pro/PROCESS for ASSEMBLIES, Pro/ENGINEER

provides a standard library of common process steps:

• Caulk

• Clean

• Drain

• Fill

Pro/PROCESS for Assemblies Help Topic Collection

24

• Inspect

• Lubricate

• Paint

• Torque

• Verify

You can customize the library by adding your own steps or changing the definition of

the steps provided.

To Create a UDF

1. Click SEQUENCE > Step Library.

2. Group steps together into a UDF.

Get Information on a Process

About Obtaining General Information

Using the Info command in the main View menu, you can access general

information concerning mass properties, Bill of Materials, measure, and so on. To

obtain process-specific information such as cost, time estimates, and component

usage lists, use the Process Sequence command in the Info menu.

The Information Window contains the textual information from the process sequence,

including the description and type of each step, all attribute names, and the

corresponding values.

Using these commands, you can access an Information window that displays the

complete process sequence. It includes information such as the step type,

description, all attributes, and their values. The system saves this information to a

file as it is displayed, so you can print it without actually stepping through all of the

steps.

BOM and Parts Lists

To show which components and tools are required to complete a step or group of

steps, you can create and export (to a file or print) a parts list based on Assembly

Status (current, previously assembled, and so on.) and Component Type (Design,

Fixture, Bulk Item, and so on).

You can use the following possible formats, and switch between them:

• Indented list to show hierarchy, as in simplified representations

• Current BOM format

• Flat list with no hierarchy, just a list of components

You can create the list based on a step or a group of steps. To create the list for a

list of steps, define the subset by entering numbers separated by commas or

hyphens.

Pro/PROCESS for Assemblies

25

Exporting Process Plans Using Pro/WEB Publish

With a license for Pro/WEB PUBLISH is available, the process steps created using

Pro/PROCESS for ASSEMBLIES can be exported for viewing on the World Wide Web.

27

Index

3

3-D notes

steps with .................................. 8

3-D notes ..................................... 8

A

assemble step type .......................12

assembly process

accessing ................................... 4

creating ..................................... 1

assembly process........................1, 4

Assembly process drawing

Parameters................................22

Assembly process drawing..............22

B

BOM

getting information .....................26

BOM...................................... 26, 27

D

disassemble step ..........................14

Drawing mode

component display .....................21

Drawing mode ........................ 20, 21

E

explode functionality .....................17

exploded assembly

unexploding ..............................18

exploded assembly........................18