Driver for MELSERVO MR-J2

This manual describes how to connect the MR-J2 controllers from Mitsubishi Electric to

operator terminals, using the MELSERVO MR-J2 driver.

For information about the MR-J2 controller we refer to the manual for the current system.

Sida 2 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Disclaimer

Please note that changes in the controller protocol or hardware, which may interfere

the functionality of this driver, may have occurred since this help file was created.

Therefore, always test and verify the functionality of the application. To accommodate

developments in the controller protocol and hardware, drivers are continuously updated.

Accordingly, always ensure that the latest driver is used in the application.

Sida 3 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

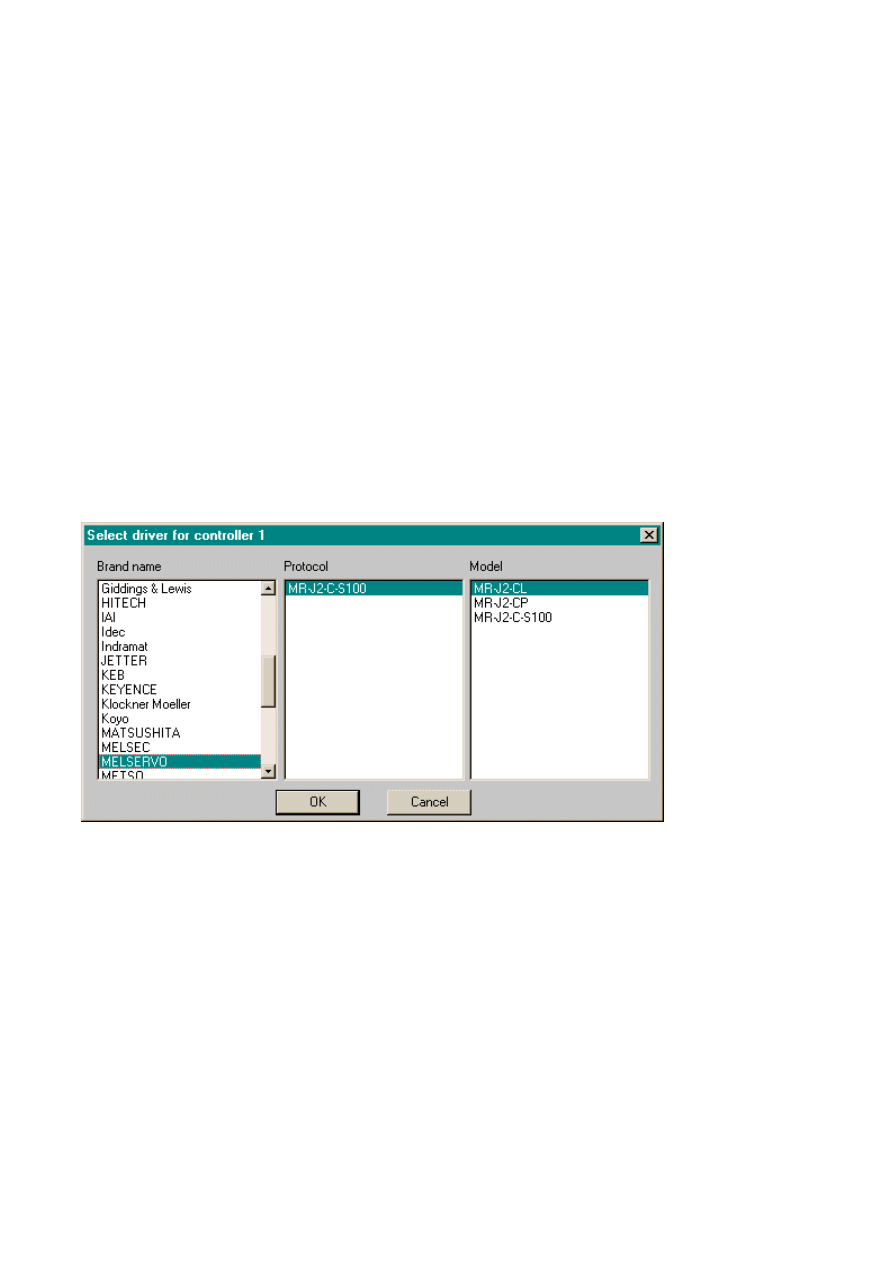

Select Model

Note:

It is very important to choose the correct servo-model for the project. The chosen model

will be transferred to the terminal and will be considered when the terminal reads and

writes the devices.

If the servoprogram is to be read or written from or to the servo, using the terminal it is

very important to choose the correct model between MR-J2-CL and MR-J2-C. The MR-J2-

holds 8 programs and maximum 60 steps while MR-J2-CL holds 16 programs and

maximum 120 steps.

If point table is to be handled by the terminal, the MR-J2-CP must be chosen.

This means that if a MR-J2-CL and a MR-J2-CP is connected to a multidrop, you cannot

both handle the point table and reading and writing servoprograms. If MR-J2-CL is

then servoprogram can be read or written and if MR-J2-CP is chosen then the point table

can be handled.

Sida 4 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

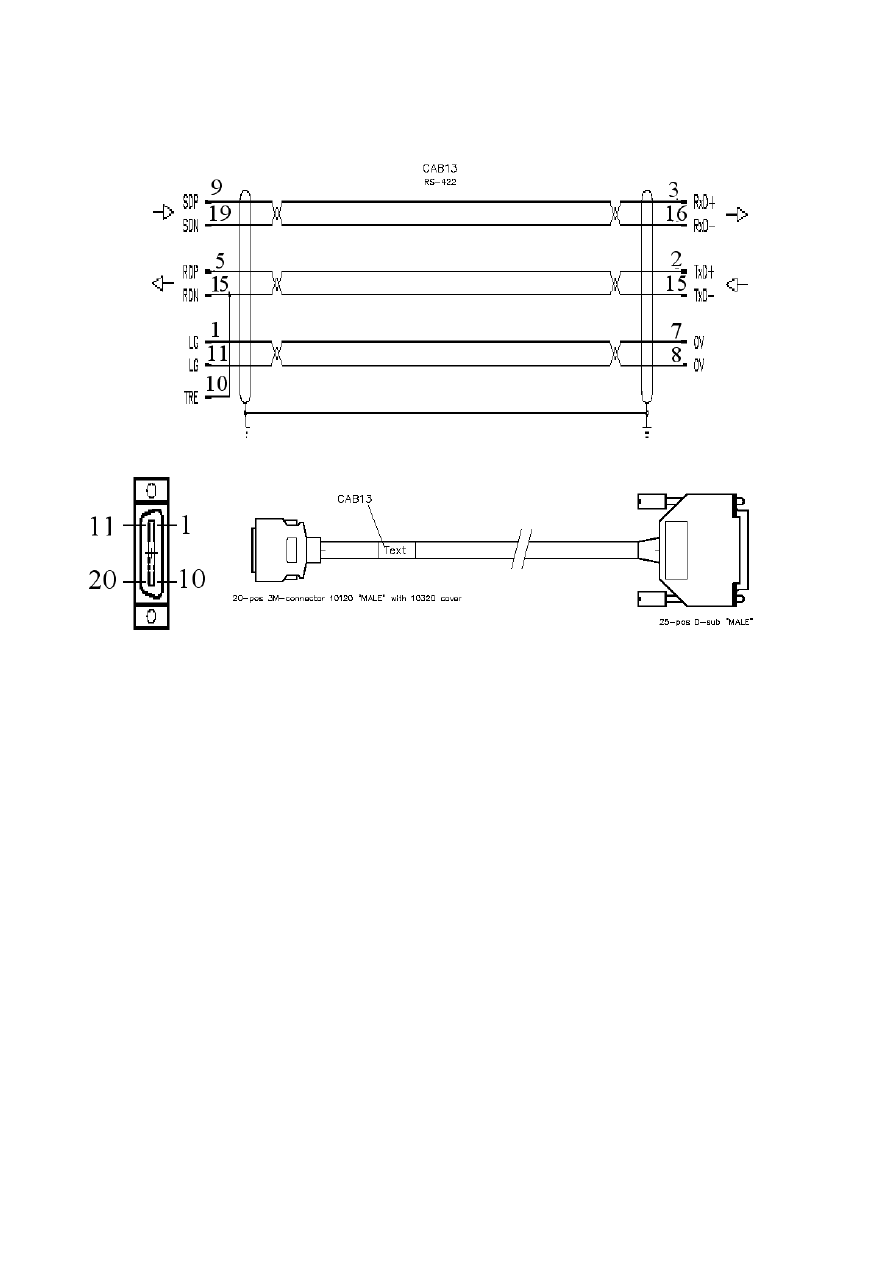

Connecting to the MELSERVO

The connection to the terminal can either be of the type "point to point" or "multidrop".

To connect the terminal RS232, the cable called cable1 is used. To connect to the

controller system RS422 the cable CAB13 are used. CAB13 is a standard cable that can

ordered from Beijer Electronics AB.

For further information about connections we refer to the manual for the MELSERVO.

Sida 5 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

RS422

Sida 6 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

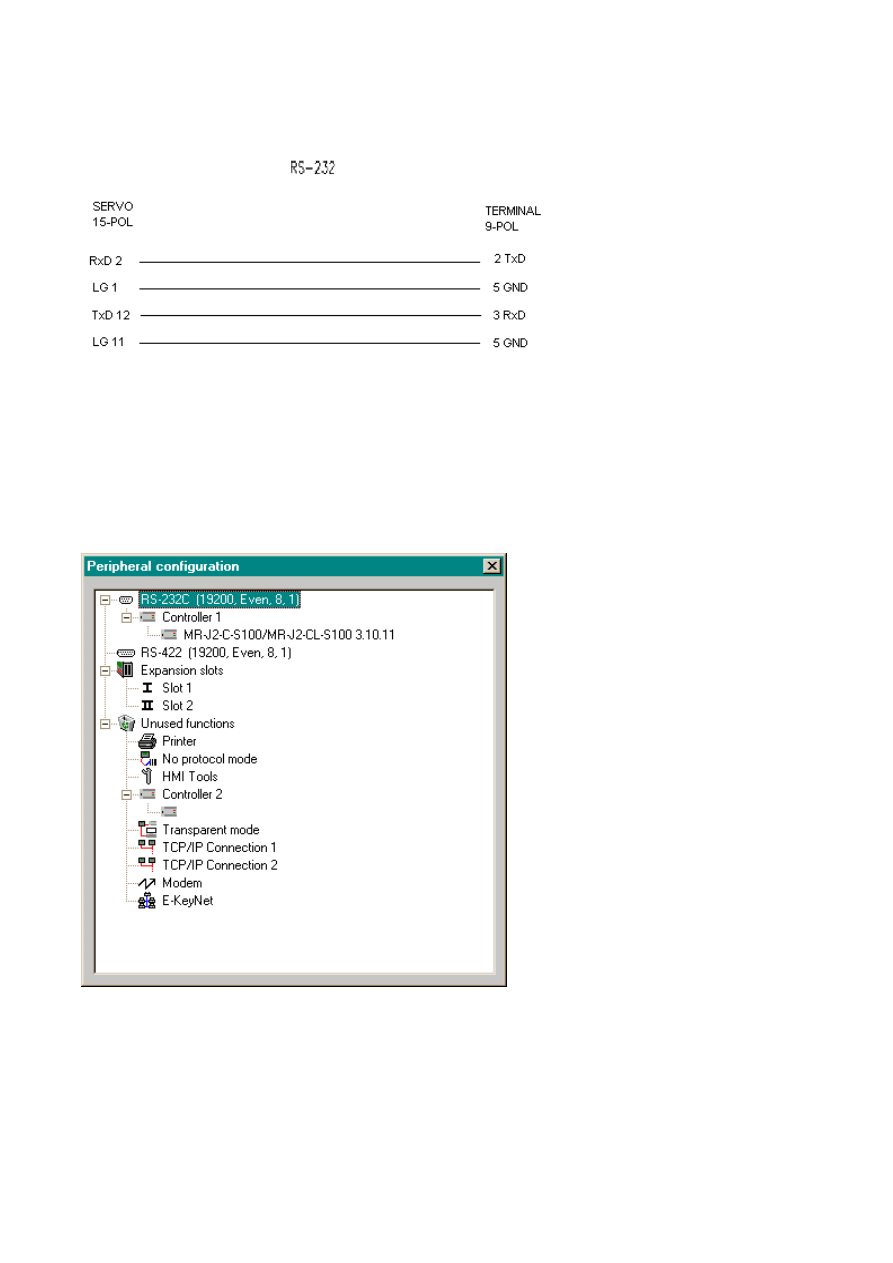

RS232

Communication setup

The settings for the communication between the terminal and the controller are made

under

Setup/Peripherals. Right-click on the controller and select

to change the settings.

Sida 7 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

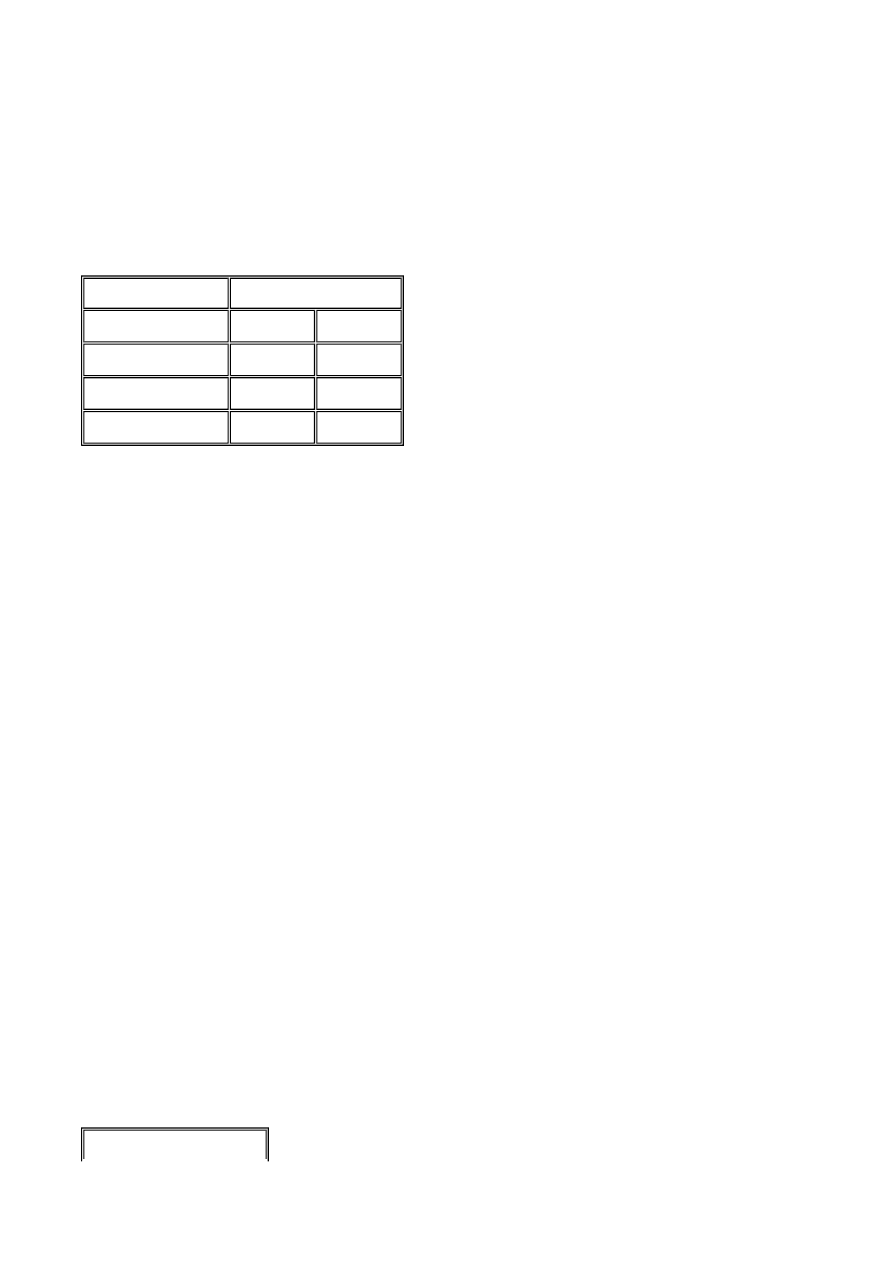

Default settings:

Parameter

Setting

Port

RS232C

Baud rate

*

Data bits

8

Stop bits

1

Parity

None

* For CP-model and CL-model the setting for

Parameter 16 means

RS232

0000 = 9600 Baud, RS-232

0001 = 19200 Baud, RS-232

0002 = 38400 Baud, RS-232

0003 = 57600 Baud, RS-232 ( Does not work due to small difference

between the actual baudrate in servo and terminal)

RS422

0100 = 9600 Baud, RS-422

0101 = 19200 Baud, RS-422

0102 = 38400 Baud, RS-422

0103 = 57600 Baud, RS-422 ( Does not work due to small difference

between the actual baudrate in servo and terminal)

* For C-model, the setting for

16 means

RS232

0100 = 9600 Baud, RS-232

0101 = 19200 Baud, RS-232

0102 = 4800 Baud, RS-232

RS422

0000 = 9600 Baud, RS-422

0001 = 19200 Baud, RS-422

0002 = 4800 Baud, RS-422

Sida 8 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

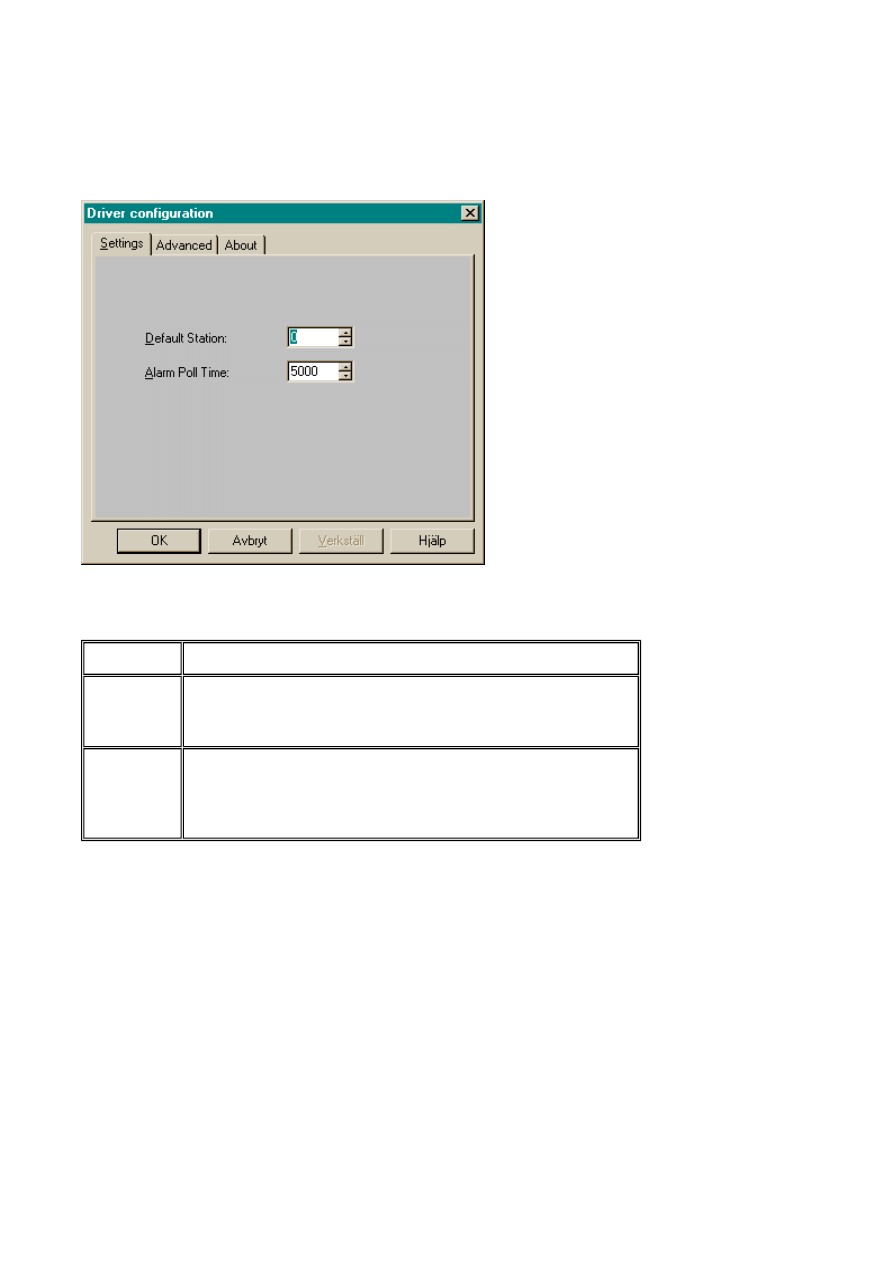

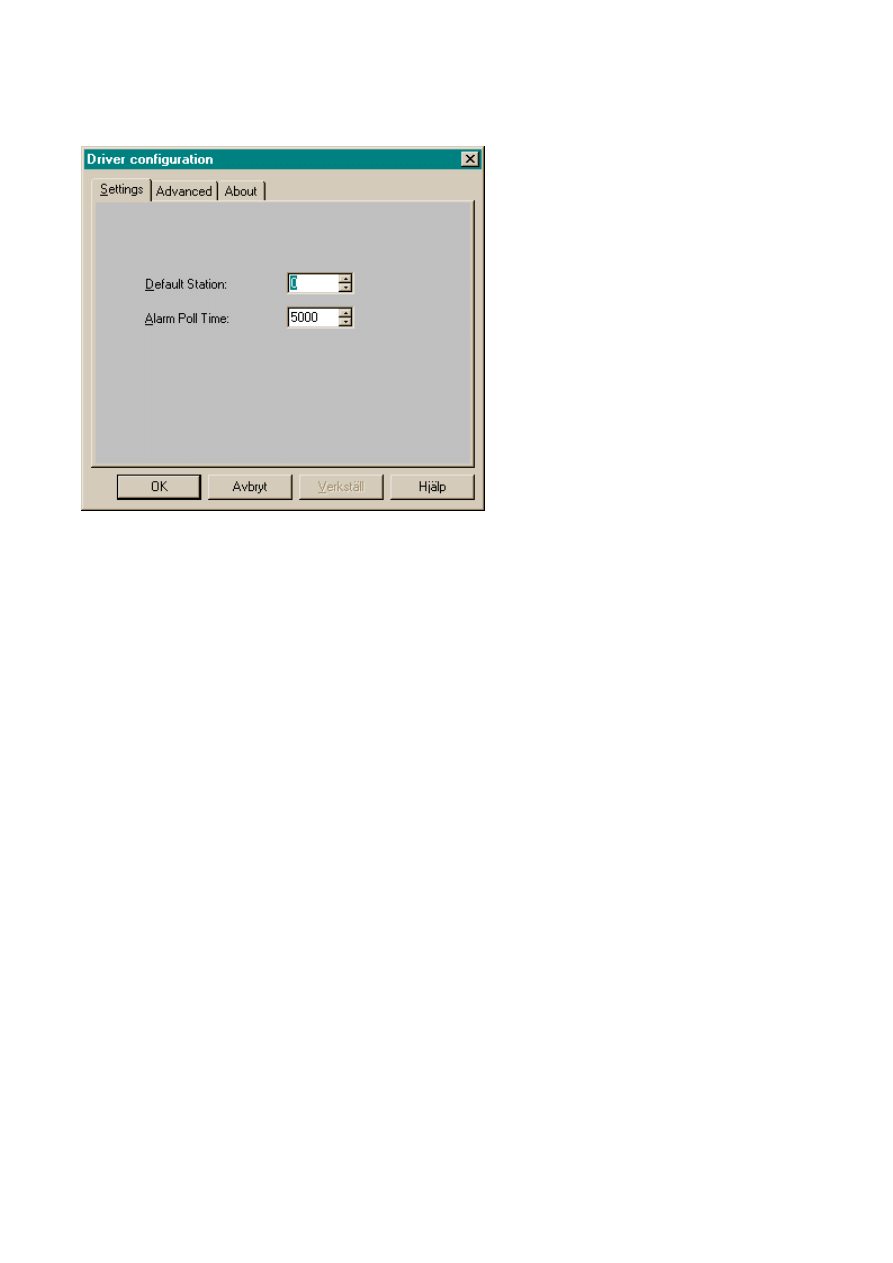

To make specific settings for the selected driver right-click on the driver name and select

Properties.

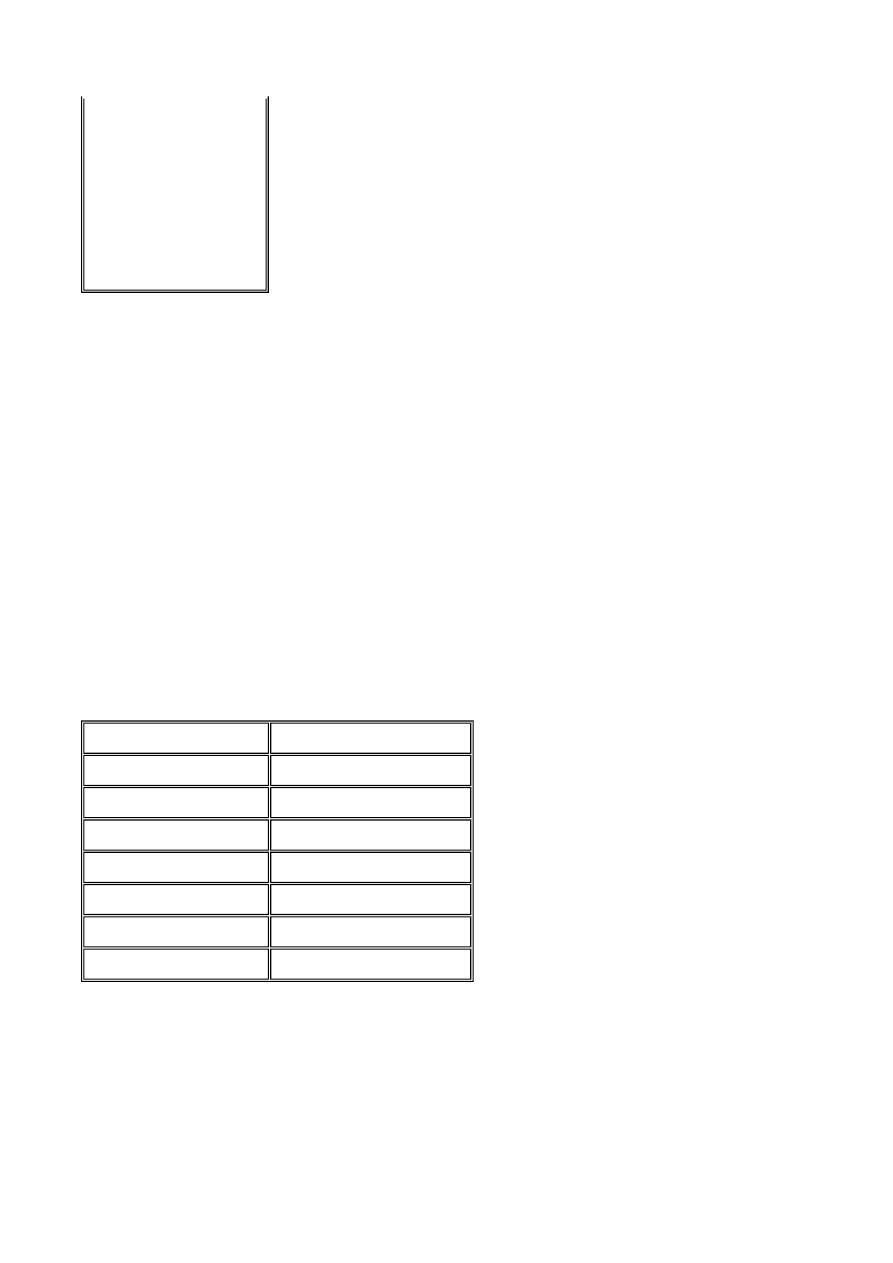

Parameter Description

Default

station

It is the station to the devices when no station number

is stated. Read more about station handling later in

document.

Alarm Poll

Time

If alarms were to be read from servo, it would be a

large disadvantage to read them all the time. The

Poll Time is the time between two readings of the

alarms.

Sida 9 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

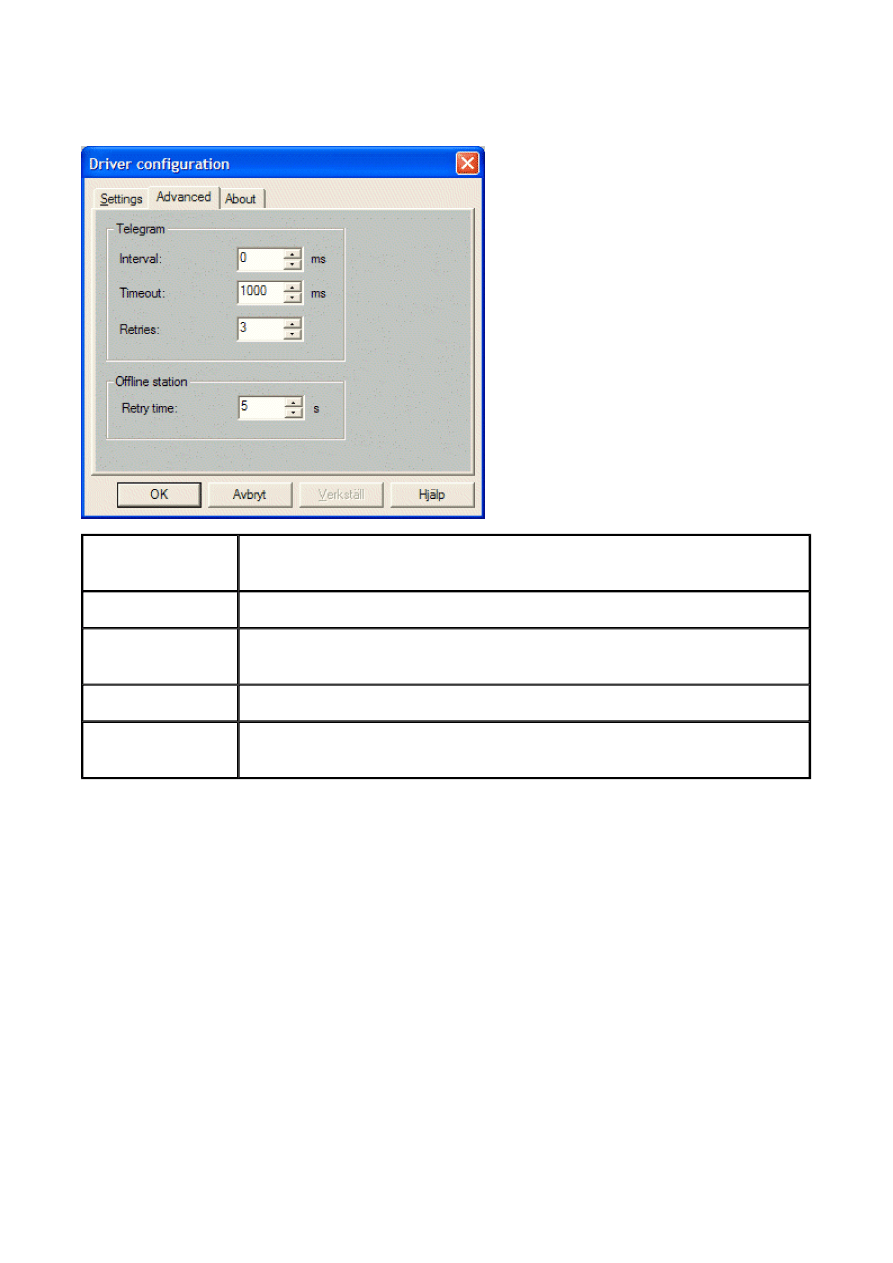

Advanced

Settings for handling communication failures.

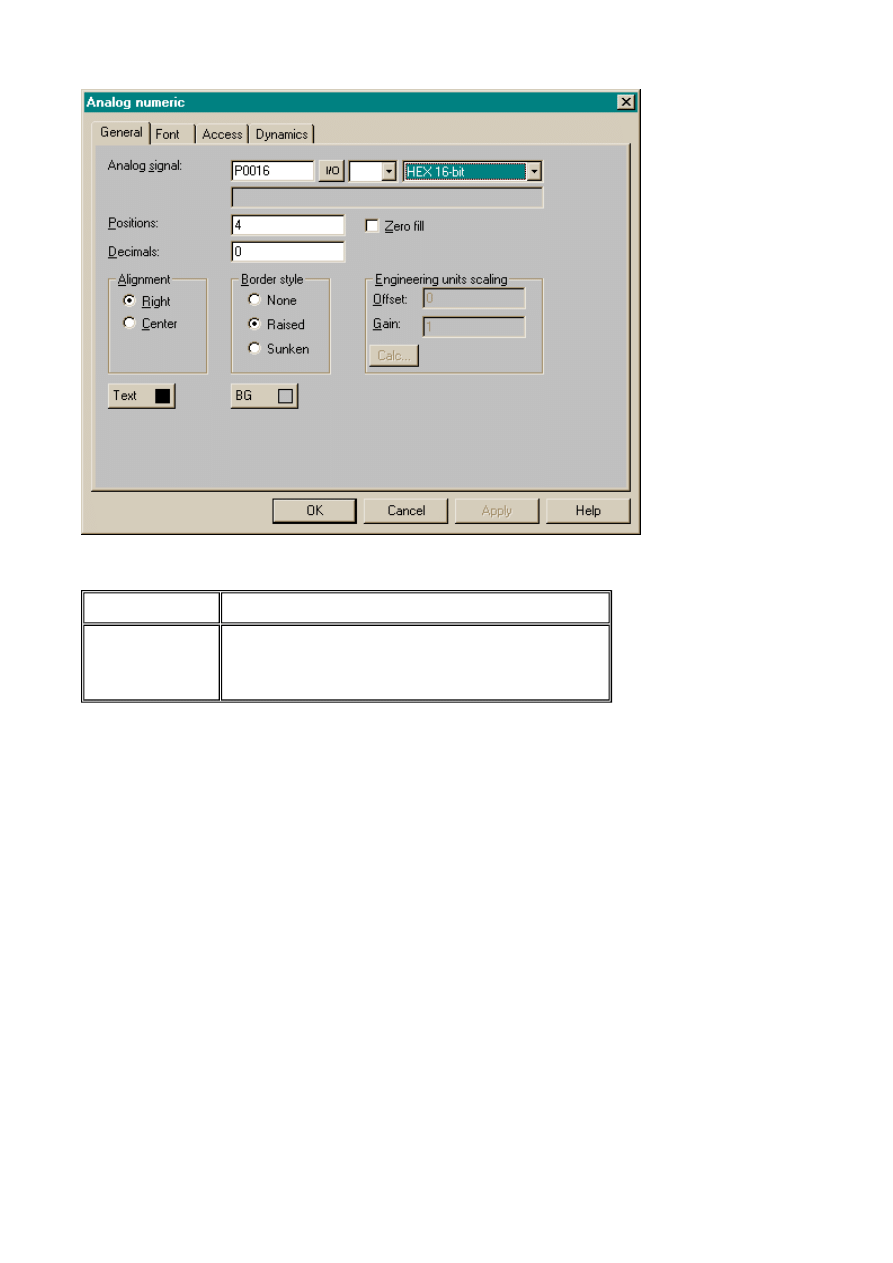

Addressing

The driver can handle the following devices. The format in which the value is to be

is free to chose but we recommend that the manual for the MELSERVO is followed. P16

example would be chosen like

Advanced

settings

Description

Interval

The minimum time between communication packages.

Timeout

The number of milliseconds between retries when communication

fails

Retries

Number of retries before a communication error is detected

Retry time

How long to wait after a communication error before trying to

communication

Sida 10 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Digital objects

P0-19

Basic parameters (see MELSERVO manual)

P20-68

P20-90

Special parameters (see MELSERVO manual)

Special parameters for CP-S100 (see MELSERVO

manual)

Sida 11 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

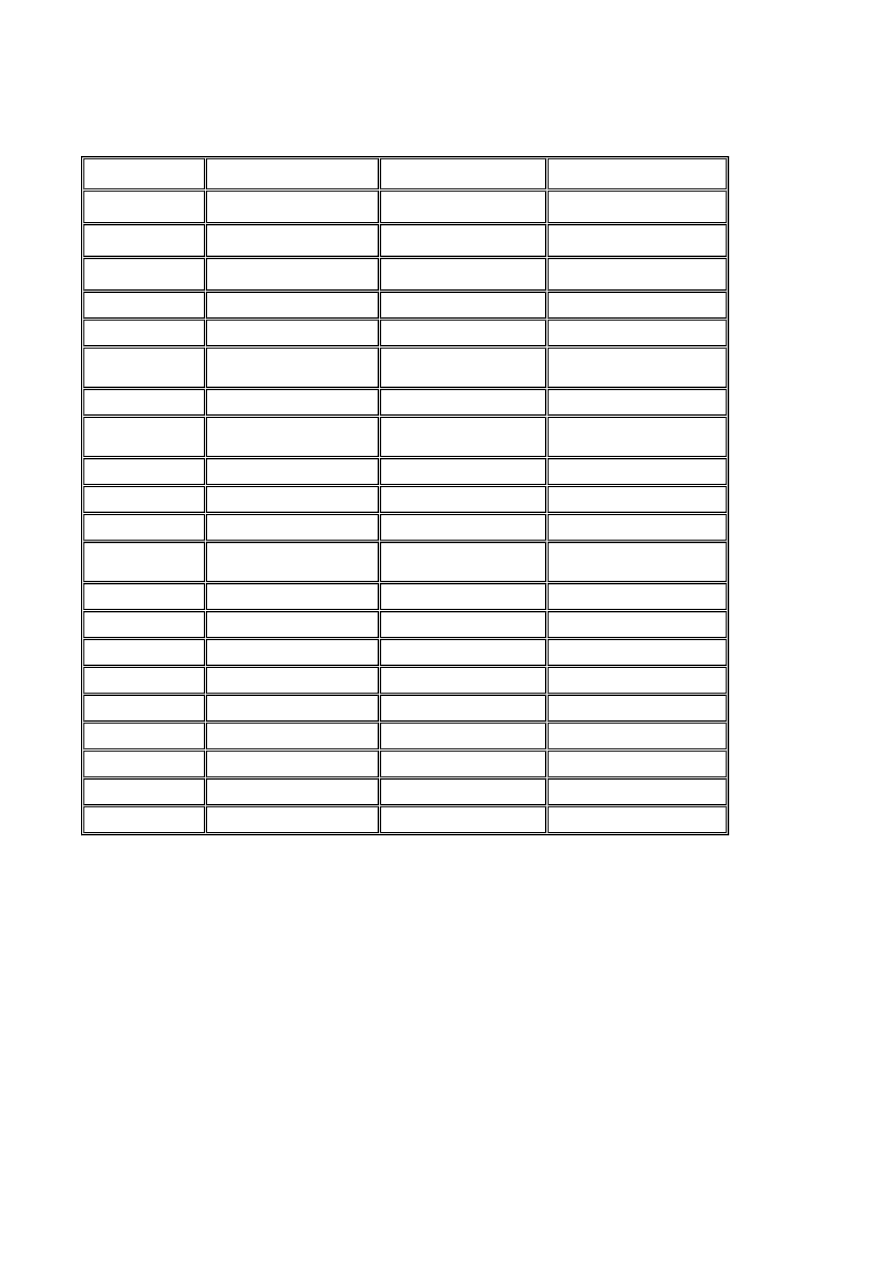

Diagnostics devices

Analog signal

Description

V0

Accumulated power on

V1

Power on times

V2

Tuning pos ctrl gain 1

V3

Tuning speed ctrl gain 1

V4

Tuning pos ctrl gain 2

V5

Tuning speed ctrl gain 2

V6

Tuning speed int.comp

V7

Tuning load inertia ratio

V8

Running step no

Sida 12 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

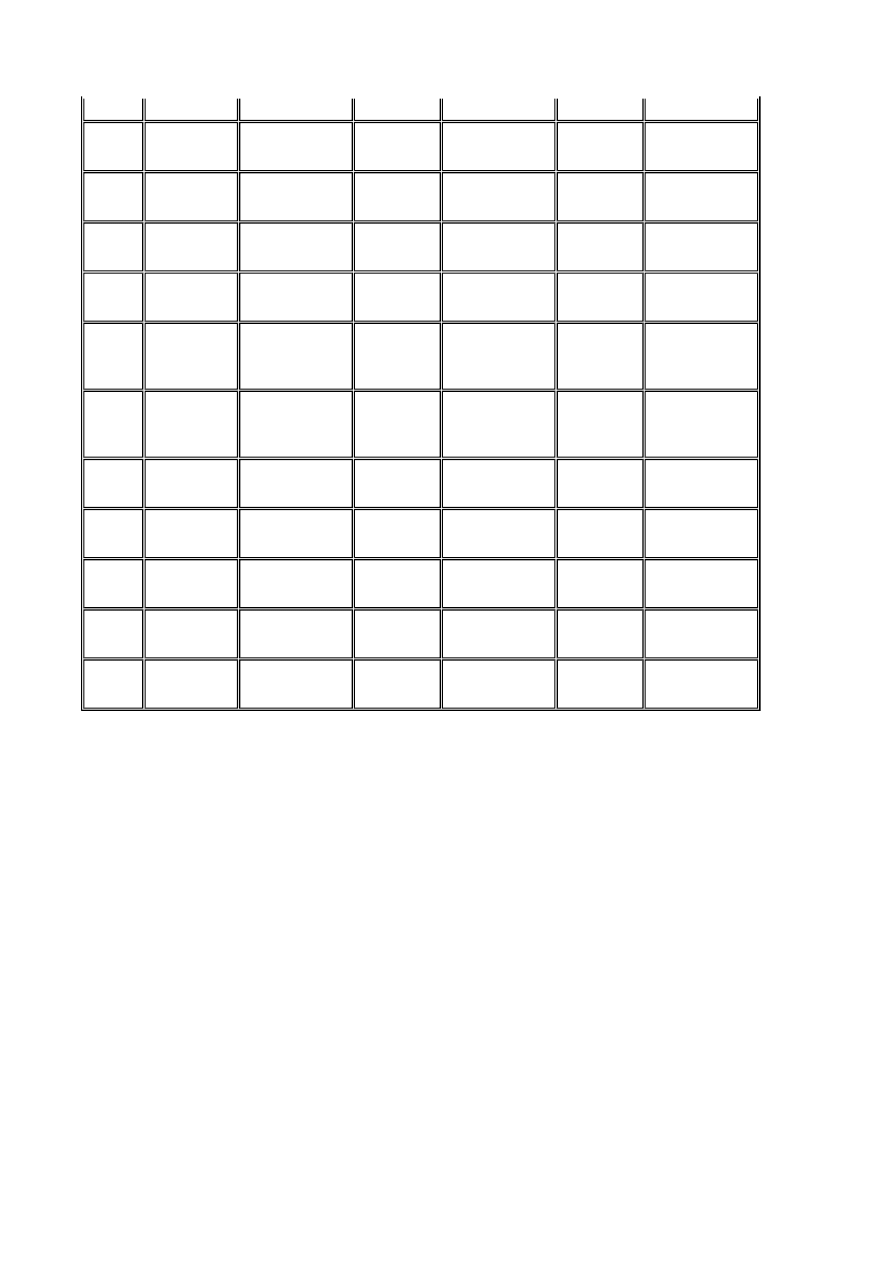

Display devices

Analog signal

Description

Description

Description

MR-J2-S100

MR-J2-CP

MR-J2-CL

S0

Current position

Current position

Current position

S1

Commanded position

Commanded position

Commanded position

S2

Commands remaining

distance

Commands remaining

distance

Commands remaining

S3

Program number

Point table number

Program number

S4

Feedback pulse accumulation

Feedback pulse

accumulation

Step number

S5

Motor speed

Motor speed

Feedback pulse accumulation

S6

Droop pulse

Droop pulse

Motor speed

S7

Override

Override

Droop pulse

S8

Torque limit common voltage

Torque limit common

voltage

Override

S9

Regeneration load factor

Regeneration load factor

Torque limit common voltage

S10

Effective load factor

Effective load factor

Regeneration load factor

S11

Peak load factor

Peak load factor

Effective load factor

S12

Position within one rotation

Instant Torque

Peak load factor

S13

ABS Counter

Position within one rotation

Instant Torque

S14

Load/inertia ration

ABS counter

Position within one rotation

S15

Load/inertia ration

ABS counter

S16

Bus Voltage

Load/inertia ration

S17

Bus Voltage

Sida 13 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

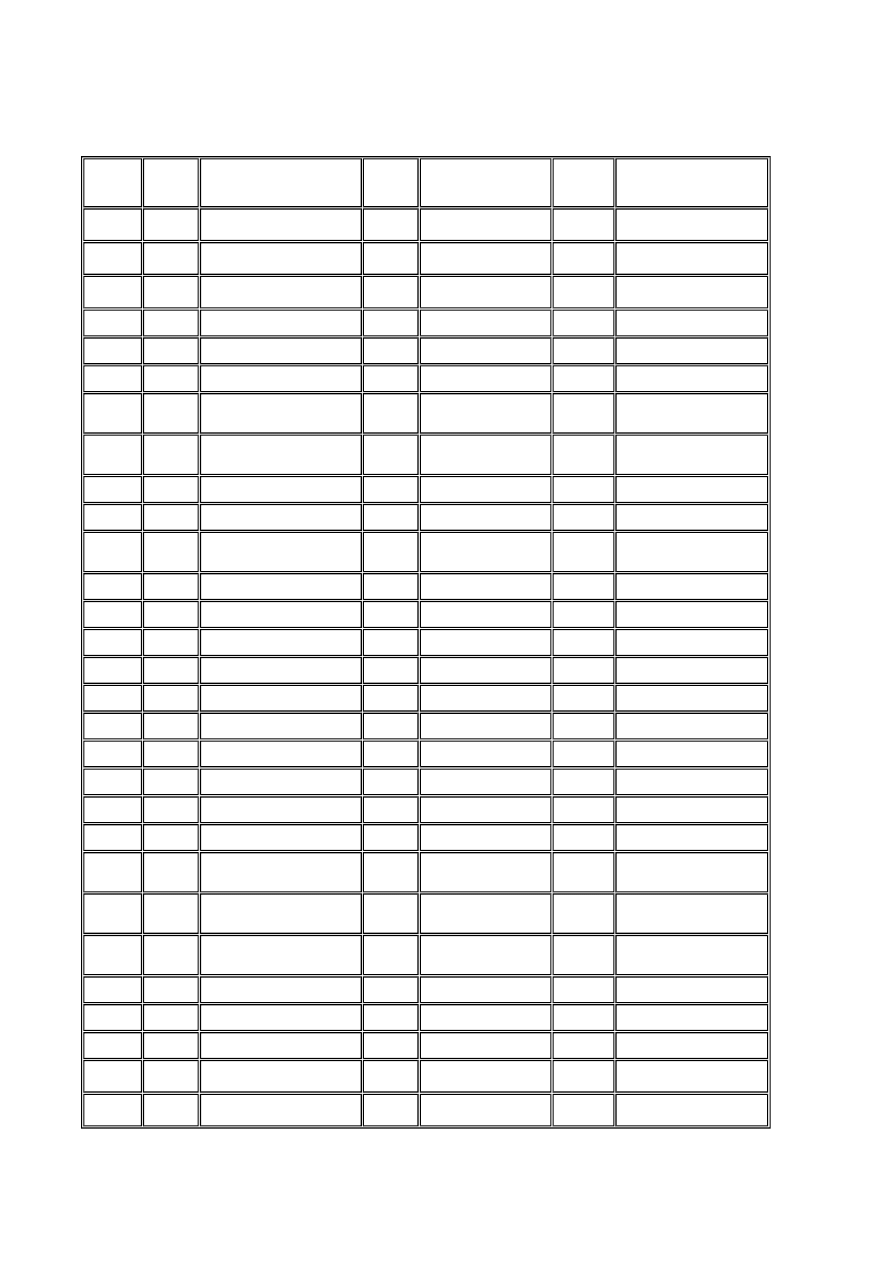

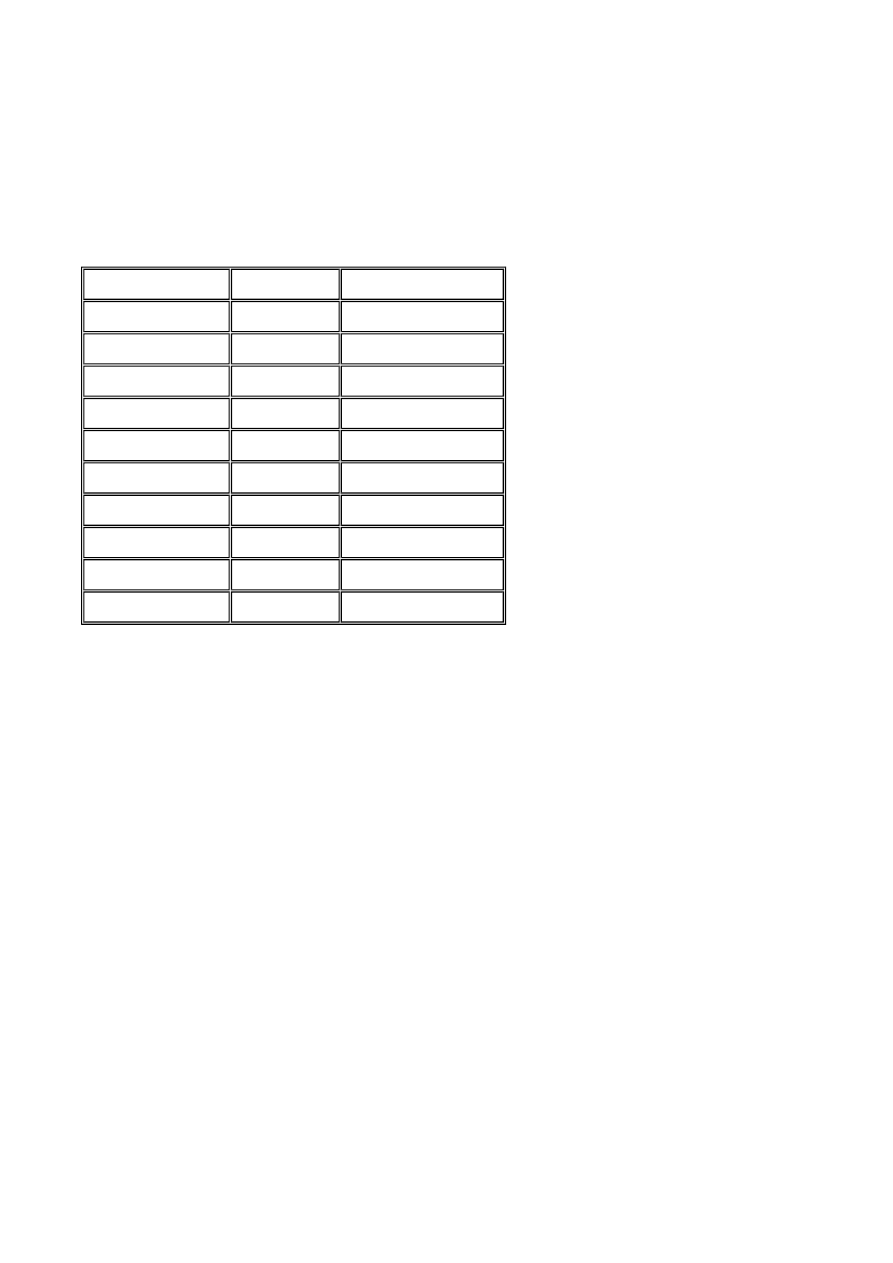

Digital I/O, Input device

Digital

signal

Servo

Signal

Description

Servo

Signal

Description

Servo

Signal

Description

MR-J2-S100

MR-J2-CP

MR-J2-CL

M0

SON

Servo on

SON

Servo on

SON

Servo on

M1

LSP

Forward stroke end

LSP

Forward stroke end

LSP

Forward stroke end

M2

LSN

Reverse stroke end

LSN

Reverse stroke end

LSN

Reverse stroke end

M3

TL

External torque limit

selection

TL

External torque limit

selection

TL

External torque limit

selection

M4

TL2

Internal torque limit

selection

TL2

Internal torque limit

selection

TL2

Internal torque limit

selection

M5

PC

Proportional control

PC

Proportional control

PC

Proportional control

M6

RES

Reset

RES

Reset

RES

Reset

M10

LPS

Current Position Latch

input

M11

ST1

Forward start

ST1

Forward start

ST1

Forward start

M12

ST2

Reverse start

ST2

Reverse start

ST2

Reverse start

M16

EMG

Emergency stop

EMG

Emergency stop

EMG

Emergency stop

M17

MDO

Automatic / Manual

MDO

Automatic / Manual

MDO

Automatic / Manual

M18

DOG

Proximity

DOG

Proximity

DOG

Proximity

M19

PS0

Program No. selection 1

DI0

Point Table # select 1

DI0

Program No. selection 1

M20

PS1

Program No. selection 2

DI1

Point Table # select 2

DI1

Program No. selection 2

M21

PS2

Program No. selection 3

DI2

Point Table # select 3

DI2

Program No. selection 3

M22

PS3

Program No. selection 4

DI3

Point Table # select 4

DI3

Program No. selection 4

M23

OVR

Override selection

OVR

Override selection

OVR

Override selection

M24

STP

Temporary stop / Restart

STP

Temporary stop /

Restart

STP

Temporary stop / Restart

M25

TP0

Manual pulse generator

multiplier 1

TP0

Manual pulse

generator multiplier 1

TP0

Manual pulse generator

multiplier 1

M26

TP1

Manual pulse generator

multiplier 2

TP1

Manual pulse

generator multiplier 2

TP1

Manual pulse generator

multiplier 2

M27

PI1

Program Input 1

CDP

Gain Switch

CDP

Gain Switch

M28

PI2

Program Input 2

M29

PI3

Program Input 3

DI4

Point Table select 5

PI1

Program Input 1

M30

TCH

Teach

PI2

Program Input 2

M31

PI3

Program Input 3

Sida 14 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

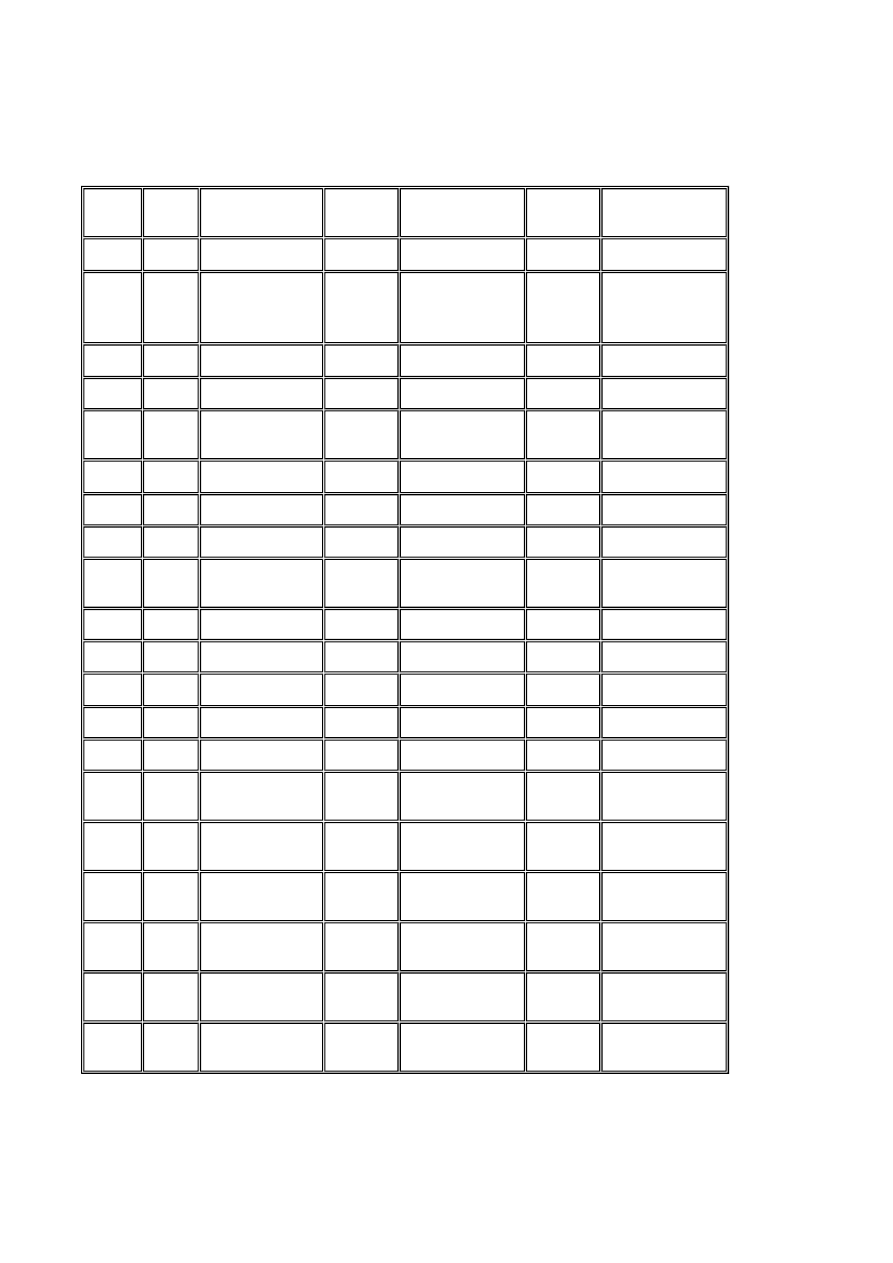

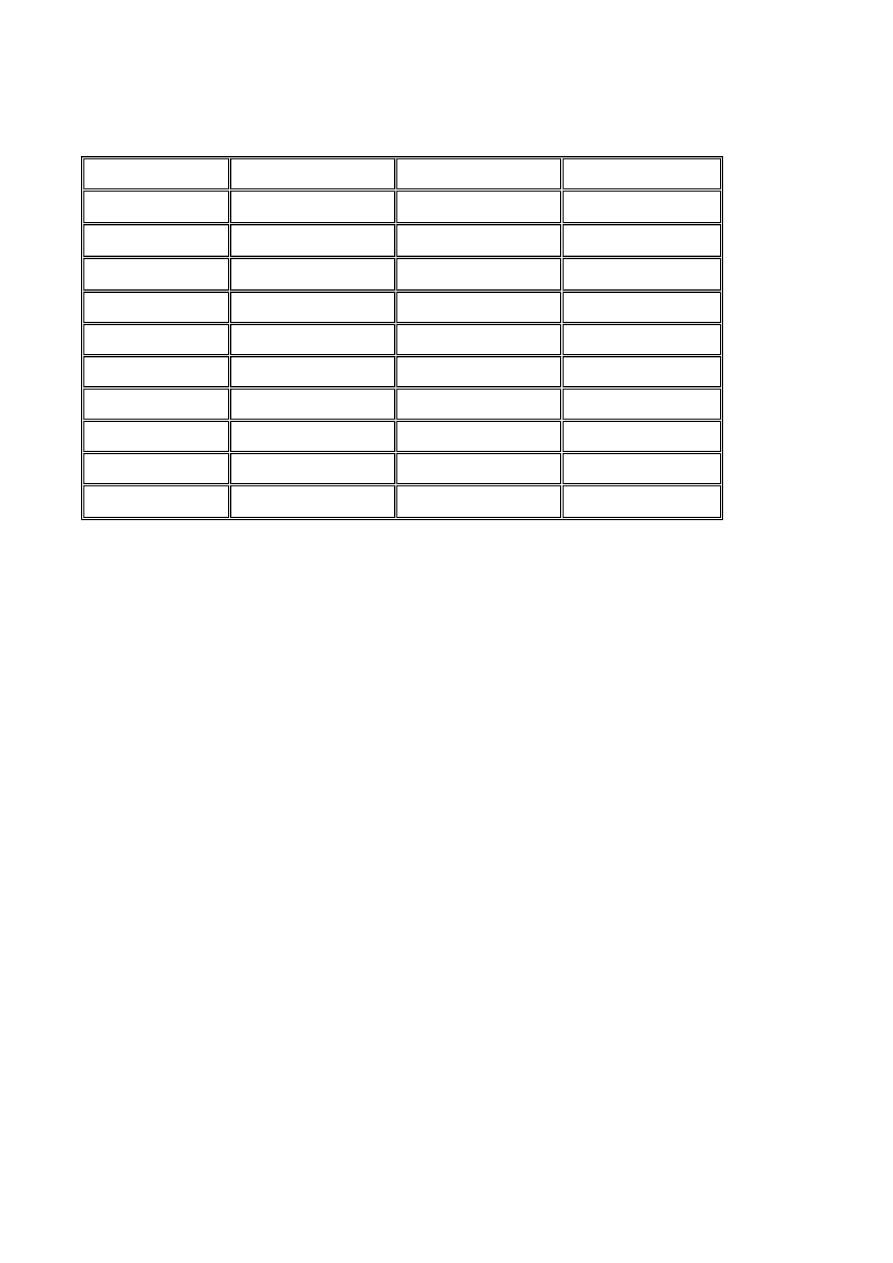

Outputs

Digital

signal

Servo

Signal

Description

Servo

Signal

Description

Servo

Signal

Description

MR-

J2-

S100

MR-J2-

CP

MR-J2-

CL

M300

RD

Ready

RD

Ready

RD

Ready

M303

TLC

Torque limit in

effect

TLC

Torque limit in

effect

TLC

Torque limit in

effect

M305

INP

In position

M307

WNG

Warning output

WNG

Warning output

WNG

Warning output

M308

ALM

Alarm

ALM

Alarm

ALM

Alarm

M310

MBR

Electromagnetic

brake

MBR

Electromagnetic

brake

MBR

Electromagnetic

brake

M311

DRB

Dynamic brake

DRB

Dynamic brake

DRB

Dynamic brake

M315

BWNG

Battery

BWNG

Battery

BWNG

Battery

M316

CPO

Rough match

M317

ZP

Z-phase

ZP

Z-phase

ZP

Z-phase

M318

POT

Position range

POT

Position range

POT

Position range

M319

PUS

Temporary

stopping

PUS

Temporary

stopping

PUS

Temporary

stopping

M320

OUT1

Program output

1

PT0

Point No.

Output1

OUT1

Program

Output1

M321

OUT2

Program output

2

PT1

Point No.

Output2

OUT2

Program

Output1

M322

OUT3

Program output

3

PT2

Point No.

Output3

OUT3

Program

Output1

M323

SOUT

SYNC

synchronous

PT3

Point No.

Output4

SOUT

Program

Output1

M324

PED

Movement

complete

PT4

Point No.

Output5

PED

Movement

Complete

Sida 15 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

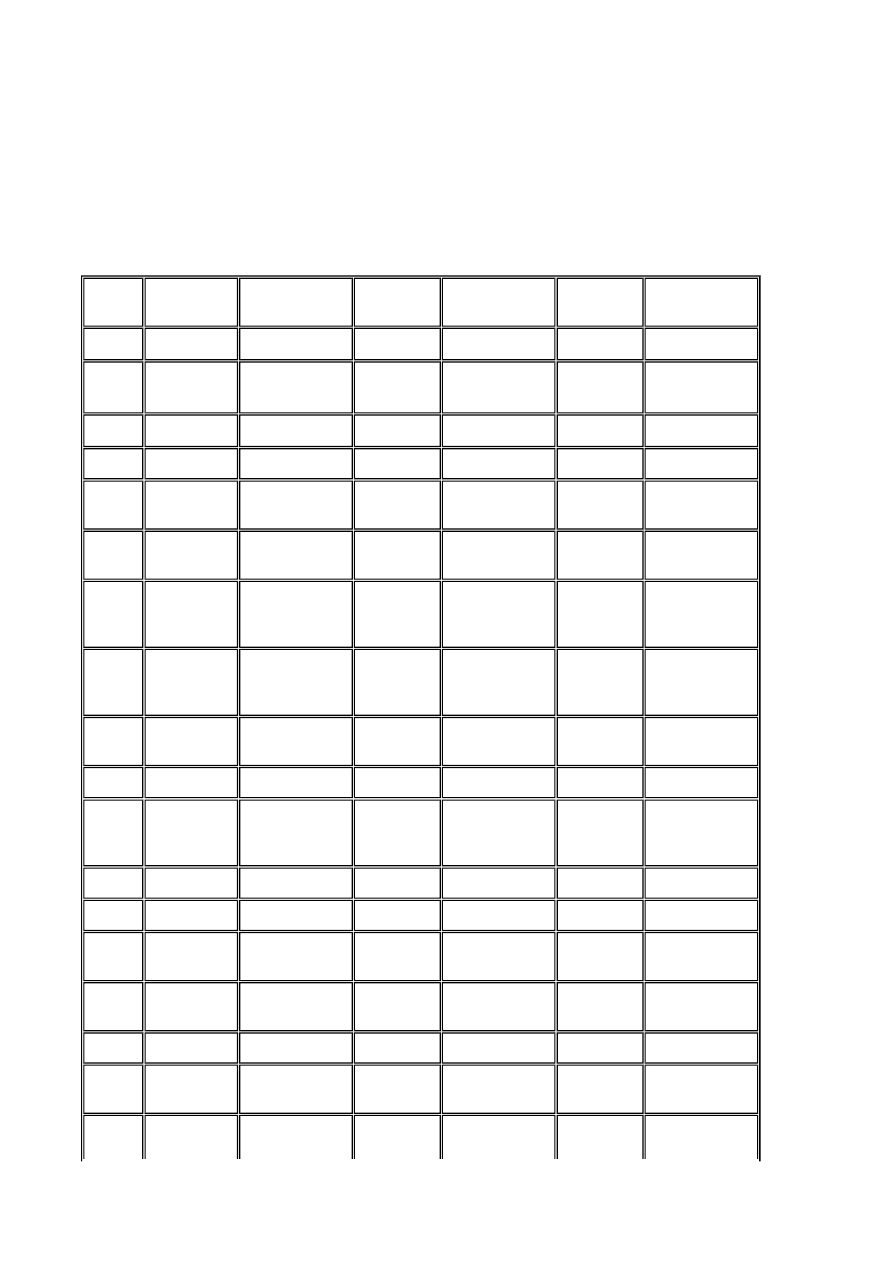

Forcing the Input devices

These signals can be turned ON / OFF forcible. It will be "OR" logic with the external input

Input device

Digital

signal

Servo

Signal

Description

Servo

Signal

Description

Servo

Signal

Description

MR-J2-

S100

MR-J2-CP

MR-J2-CL

M200

SON

Servo on

SON

Servo on

SON

Servo on

M201

LSP

Forward

stroke end

LSP

Forward

stroke end

LSP

Forward

stroke end

M202

LSN

Reverse

stroke end

LSN

Reverse

stroke end

LSN

Reverse

stroke end

M203

TL

External

torque limit

selection

TL

External

torque limit

selection

TL

External

torque limit

selection

M204

TL2

Internal

torque limit

selection

TL2

Internal

torque limit

selection

TL2

Internal

torque limit

selection

M205

PC

Proportional

control

PC

Proportional

control

PC

Proportional

control

M206

RES

Reset

RES

Reset

RES

Reset

M210

LPS

Current

position latch

input

M211

ST1

Forward start

ST1

Forward start

ST1

Forward start

M212

ST2

Reverse start

ST2

Reverse start

ST2

Reverse start

M216

EMG

Emergency

stop

EMG

Emergency

stop

EMG

Emergency

stop

M217

MDO

Automatic /

Manual

MDO

Automatic /

Manual

MDO

Automatic /

Manual

M218

DOG

Proximity

DOG

Proximity

DOG

Proximity

M219

PS0

Program

No.selection 1

DI0

Point Table

No.selection 1

DI0

Program

No.selection 1

M220

PS1

Program

DI1

Point Table

DI1

Program

Sida 16 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

No.selection 2

No.selection 2

No.selection 2

M221

PS2

Program

No.selection 3

DI2

Point Table

No.selection 3

DI2

Program

No.selection 3

M222

PS3

Program

No.selection 4

DI3

Point Table

No.selection 4

DI3

Program

No.selection 4

M223

OVR

Override

selection

OVR

Override

selection

OVR

Override

selection

M224

STP

Temporary

stop / Restart

STP

Temporary

stop / Restart

STP

Temporary

stop / Restart

M225

TP0

Manual pulse

generator

multiplier 1

TP0

Manual pulse

generator

multiplier 1

TP0

Manual pulse

generator

multiplier 1

M226

TP1

Manual pulse

generator

multiplier 2

TP1

Manual pulse

generator

multiplier 2

TP1

Manual pulse

generator

multiplier 2

M227

PI1

Program input

1

CDP

Gain switch

CDP

Gain switch

M228

PI2

Program input

2

M229

PI3

Program input

3

DI4

Point Table

select 5

PI1

Program input

1

M230

TCH

Teach

PI2

Program input

2

M231

PI3

Program input

3

Sida 17 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Reading the Input and Output pins

The Servo has a number of external inputs and outputs. They can be read from the following

digital devices.

Inputs

Digital signal

Group

External input

M100

Input pins

CN1B-16

M101

Input pins

CN1B-17

M102

Input pins

CN1B-15

M103

Input pins

CN1B-5

M104

Input pins

CN1B-14

M105

Input pins

CN1A-8

M106

Input pins

CN1B-7

M107

Input pins

CN1B-8

M108

Input pins

CN1B-9

M109

Input pins

CN1A-19

Sida 18 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Outputs

Digital signal

External input

External input

External input

MR-J2-S100

MR-J2-CP

MR-J2-CL

M400

CN1A-19

CN1A-19

CN1A-19

M401

CN1A-18

CN1A-18

CN1A-18

M402

CN1B-19

CN1B-19

CN1B-19

M403

CN1B-6

CN1B-6

CN1B-6

M404

CN1B-4

CN1B-4

CN1B-4

M405

CN1B-18

CN1B-18

CN1B-18

M406

CN1A-14

CN1A-14

Sida 19 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

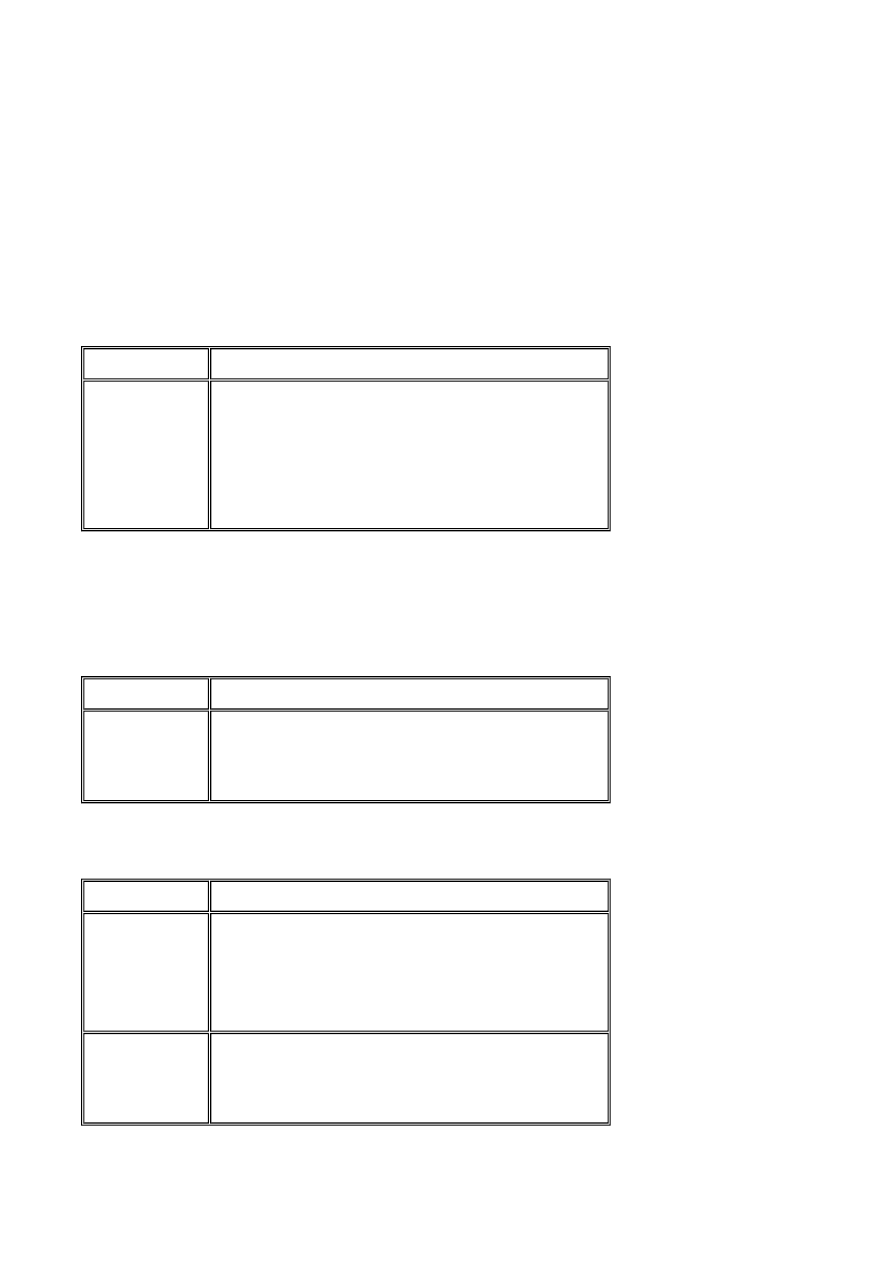

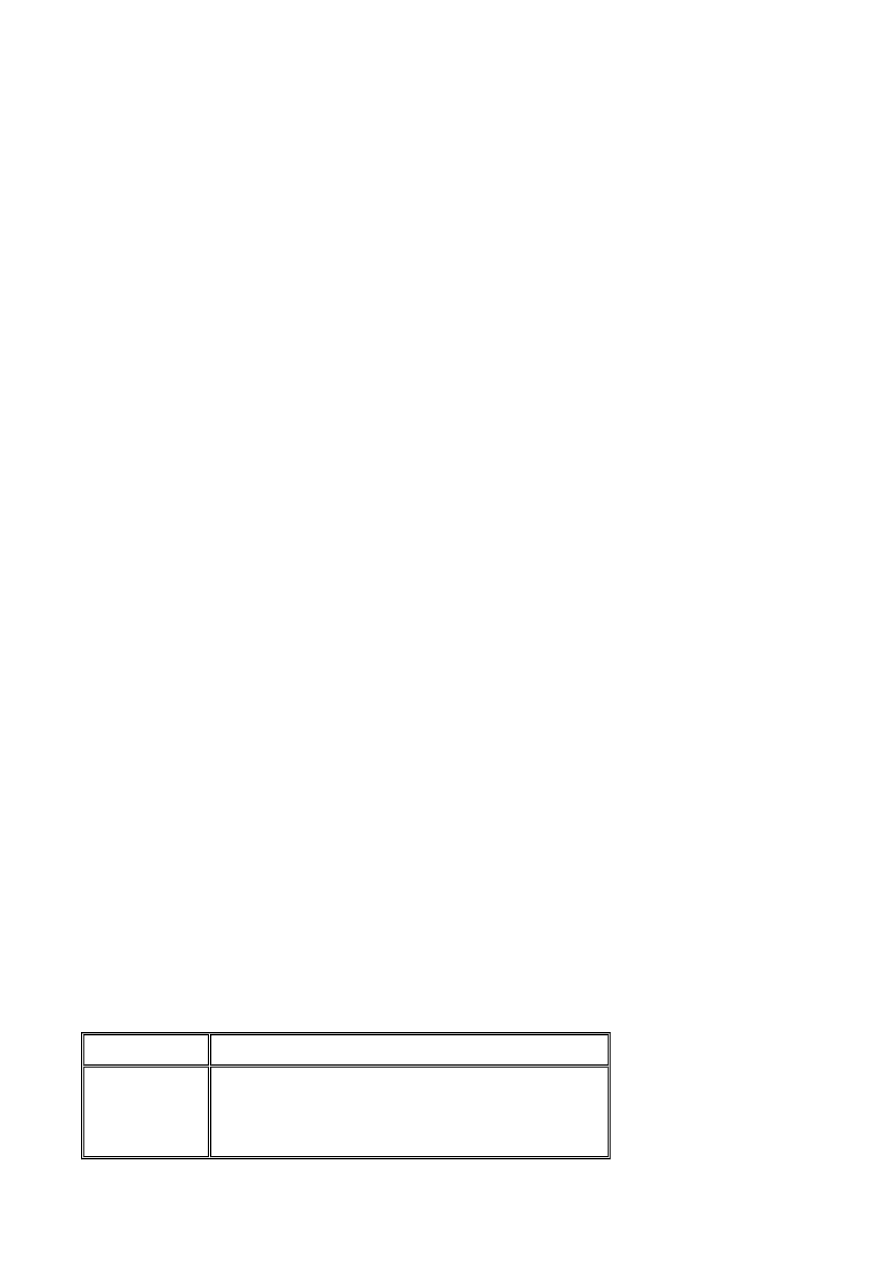

Internal registers

I1 - I8 are internal index registers for indirect addressing of all parameters. Refer to manual for

the terminals for details about index registers. They are reset each time the terminal is

Driverversion up to 3.10.8

Driverversion 3.10.9 and from there on

The I8 has been replaced by a device named STATION

Two devices more are added in this version of the driver

Analog signal

Description

I8

I8 was used to address stations in a multidrop

network. What was held in I8 was the

stationnumber from which the servoprogram

was to be read from and written to. The reading

and acknowledging of servoalarms was also

handled this way by checking the addressed

stationnumber, held in I8.

Analog signal

Description

STATION

The value held in the device STATION will

from what stationnumber servoprogram and

alarms will be read from and written to. I8 now

works as ordinary index like I1-I7.

Digital signal

Description

AREADOFF

The time between the readings of alarms from

the servo can be set in peripherals for the

(The Alarm Poll Time).

We can now also disable the reading of the

alarms by setting the device AREADOFF to 1.

COMMERR

The value held in the device STATION will

from what stationnumber servoprogram and

alarms will be read from and written to. I8 now

works as ordinary index like I1-I7.

Sida 20 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Indirect addressing

The terminals can handle the four indirect registers. These are assigned as follows:

E1 - 2 is the same as R1 - 2, but the value is stored in EEPROM instead of RAM.

In a CL-servo, R1-R4, D1-D4 and E1-E4 can be handled.

Servo Program

There has been a change in how the reading and writing of servoprogram and how

alarmreading is handled. Driverversions up to 3.08 can only read and write

and handle servoalarms if

the terminals E100, E150, E200, E300 and E600 are used.

Driverversion up to 3.08

Editing the MR-J2-C-S100 servo program

Only valid in The MR-J2-C-S100 can handle up to 8 programs with 60 steps in total.

All editing is made in the special block 995.

Create a block jump to block number 995.

If several servos are connected in network, index register I8 can be used to select which

station to edit the program in.

Analog signal

Stored in

RAM

EEPROM

D1 - 2

X

R1 - 2

X

E1 - 2

X

Sida 21 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

When entering block 995 nREADING PROGRAMn will be shown together with xx %

completed.

In block 995 it is possible to choose program number, insert line, delete

line and add commands.

The program number P, program step S and total steps T are shown to the left on the

display.

Use the function keys to choose program number, insert or delete a line. To add a new

command press the ENTER key.

The servo commands are shown in a list. Use the cursor keys to move up and down and

press ENTER to select command.

To exit block 995 in E100, press NUM and ENTER.

Available commands

Please refer to the MELSERVO manual for descriptions.

Press MAIN to leave the editing area.

In E100, F4 means Edit Program. NUM+ENTER means that we go to previous block and

the servoprogram is written.

Note:

It is not possible to: 1.

Create the block 995 2.

See the block 995 in E-

Designer. Add any text

or objects into block

995.

Block 995 is an internal

block in the terminals.

NOP (No operation)

OUTOF

STOP

SPN

TIM

STC

TIMES

STA

TRIP

STB

COUNT

MOV

SYNC

MOVA

OUTON

ZRT

Sida 22 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

In E100, Back (5) + Arrow Left means that we go to previous block and do not write the

servoprogram.

In E150, F5 means Edit Program.

In E150, Back (Arrow) means that we go to previous block and do not write the

servoprogram.

In E150, F1 means that we go to previous block and the servoprogram is written.

The other terminals

If any changes are made to the program it will be automatically be downloaded to the

servo when exiting.

Servo alarm handler

The built in alarm handling in the MR-J2-C-S100 is used. Up to 6 alarms are stored in

servo.

When an alarm occurs the nALARMn message is shown in the upper corner.

To view the alarms press the nLISTn key.

The current alarm is displayed with C as prefix.

Use the function keys to view the alarm time or to reset an alarm.

The servo power needs to be switched OFF and ON to clear a reset alarm in the

If several servos are connected in network, index register I8 can be used to select which

station to display the alarm list from.

Driverversion 3.09 and from there on

Editing the MR-J2-C-S100 servo program

These are devices that are only valid to use when MR-J2S-C-S100, and MR-J2S-CL are

connected (not MR-J2S-CP).

Note:

If servoprograms are going to be written using the terminal then always do a SREAD

before editing the servoprogram and the do a SWRITE to write the new program to the

servo. The terminal does not hold a default-program at power-up and if not SWRITE is

before program is edited then one of the programs 1-8 (or 1-16) can be corrupt when

writing.

Analog signal

Description

STATION

The value held in the device STATION will

from what stationnumber servoprogram and

alarms will be read from and written to. I8 now

works as ordinary index like I1-I7.

Sida 23 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

If the device STATION is not used, then the stationnumber set under peripherals in the

project is used.

Digital signal

Decription

SREAD

Triggs the reading of the servo

program.

SWRITE

Triggs the writing of the servo

program.

Sida 24 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Analog signal

Decription

SINSTR

Servo Program Instuction

SVALUE

Servo Program Value connected

to instruction

STYPE

Servo Program, if R1, R2, D1 or

D2 is used (see below)

SALARM

An analog device where the

values from the

servoalarmhandler can be seen.

Every bit represents a certain

alarmevent. The device can be

handled bitwise (SALARM0.1-

SALARM0.23 hexadecimal)

are 35 different alarmtypes and

seven history alarmevents

(SALARM0-SALARM6) see below

SALARMTIME

The time of the alarmevent can

be shown by using

SALARMTIME0 - SALARMTIME6.

Sida 25 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

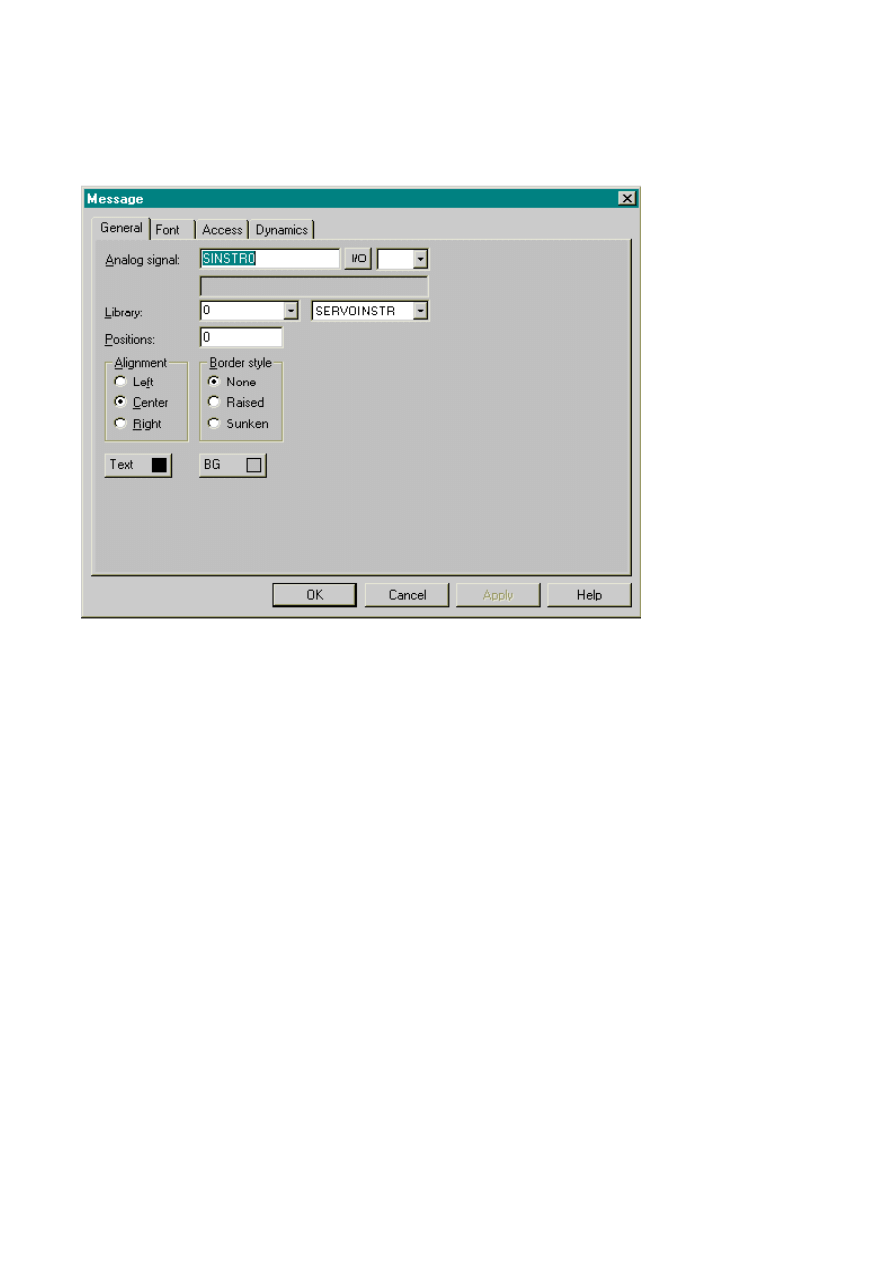

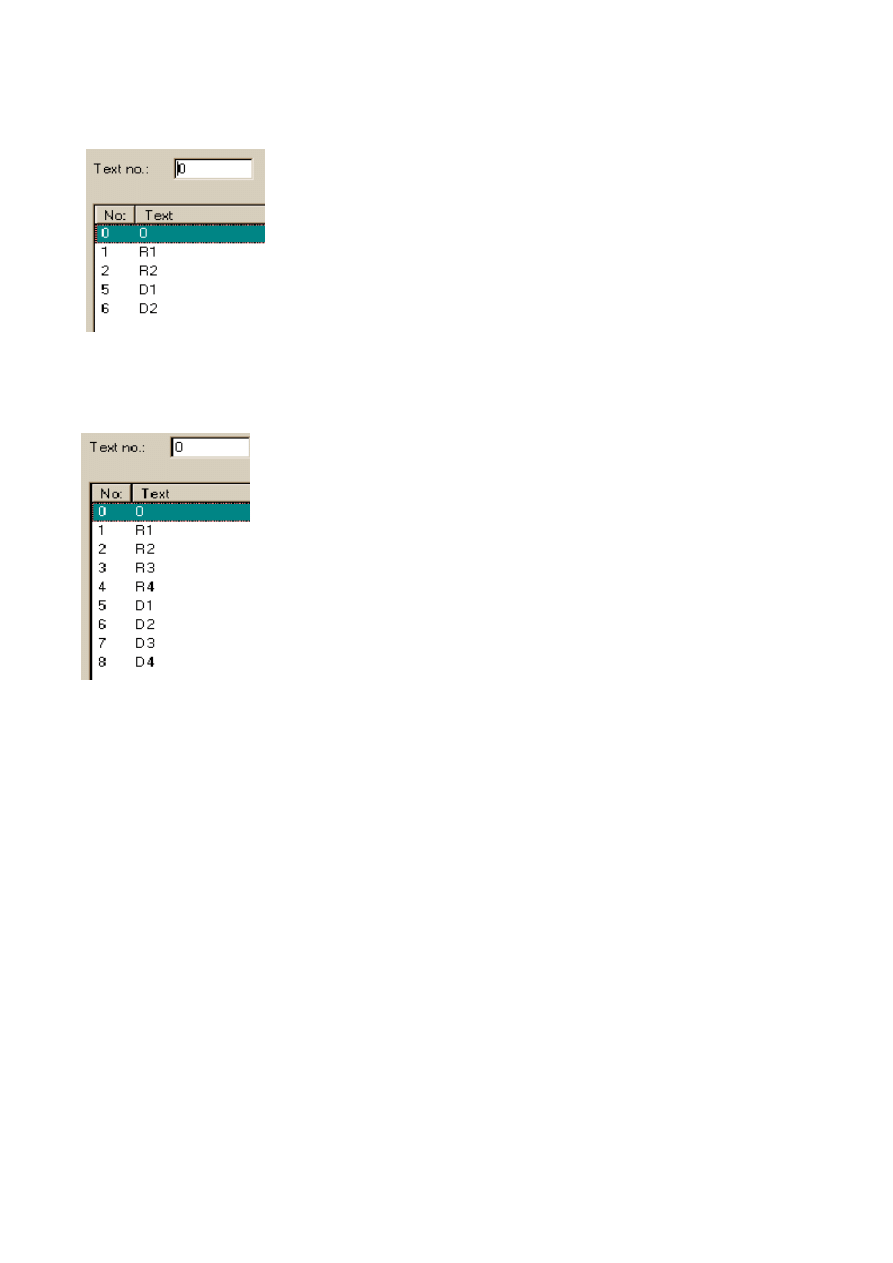

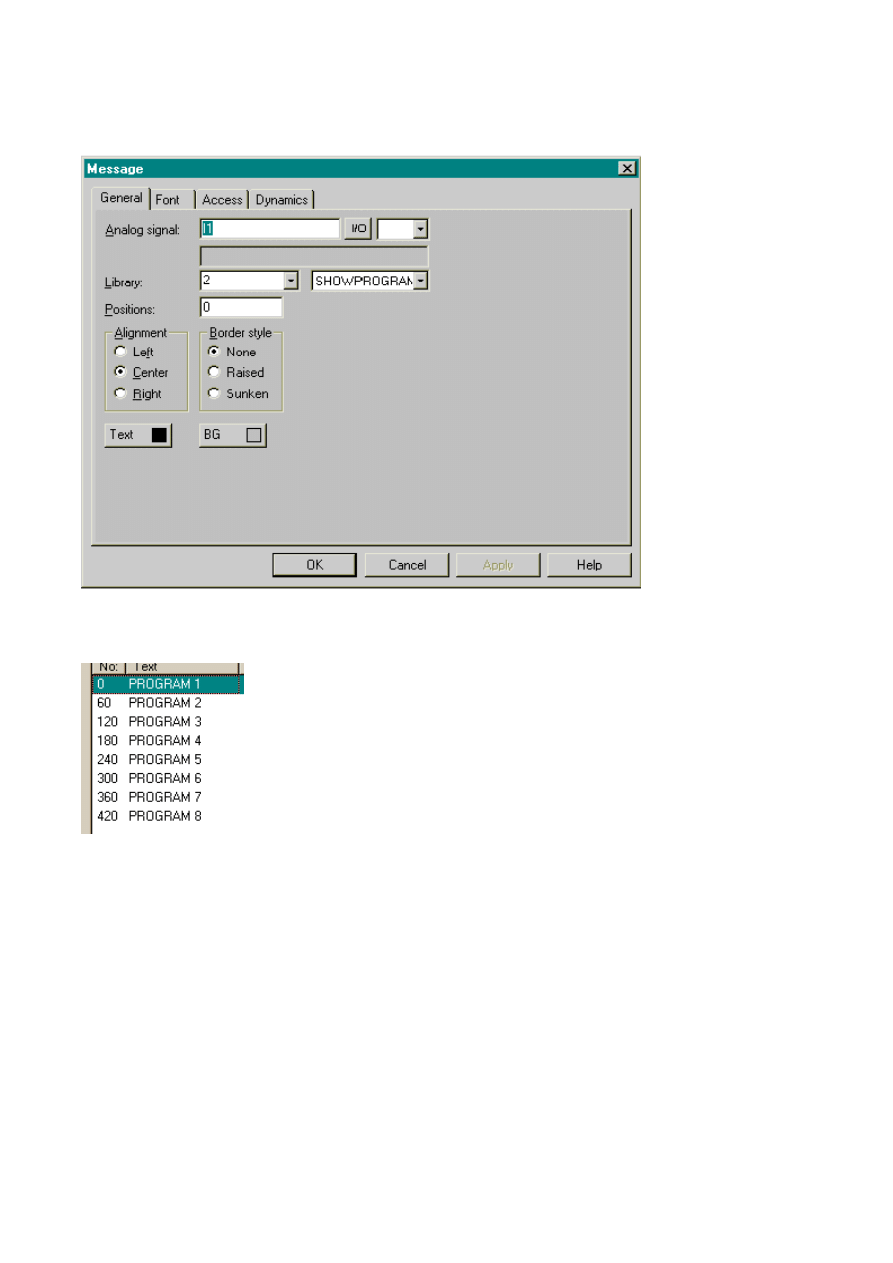

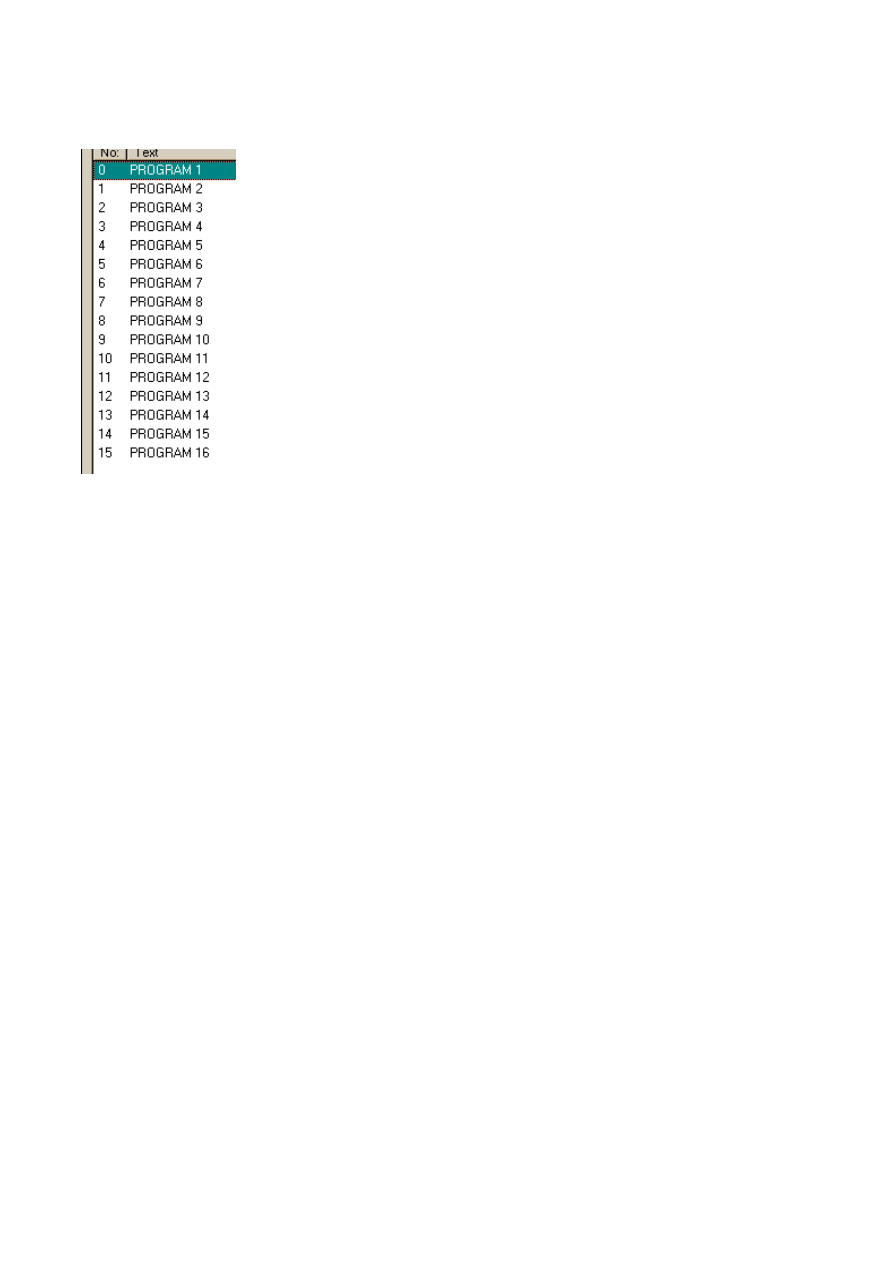

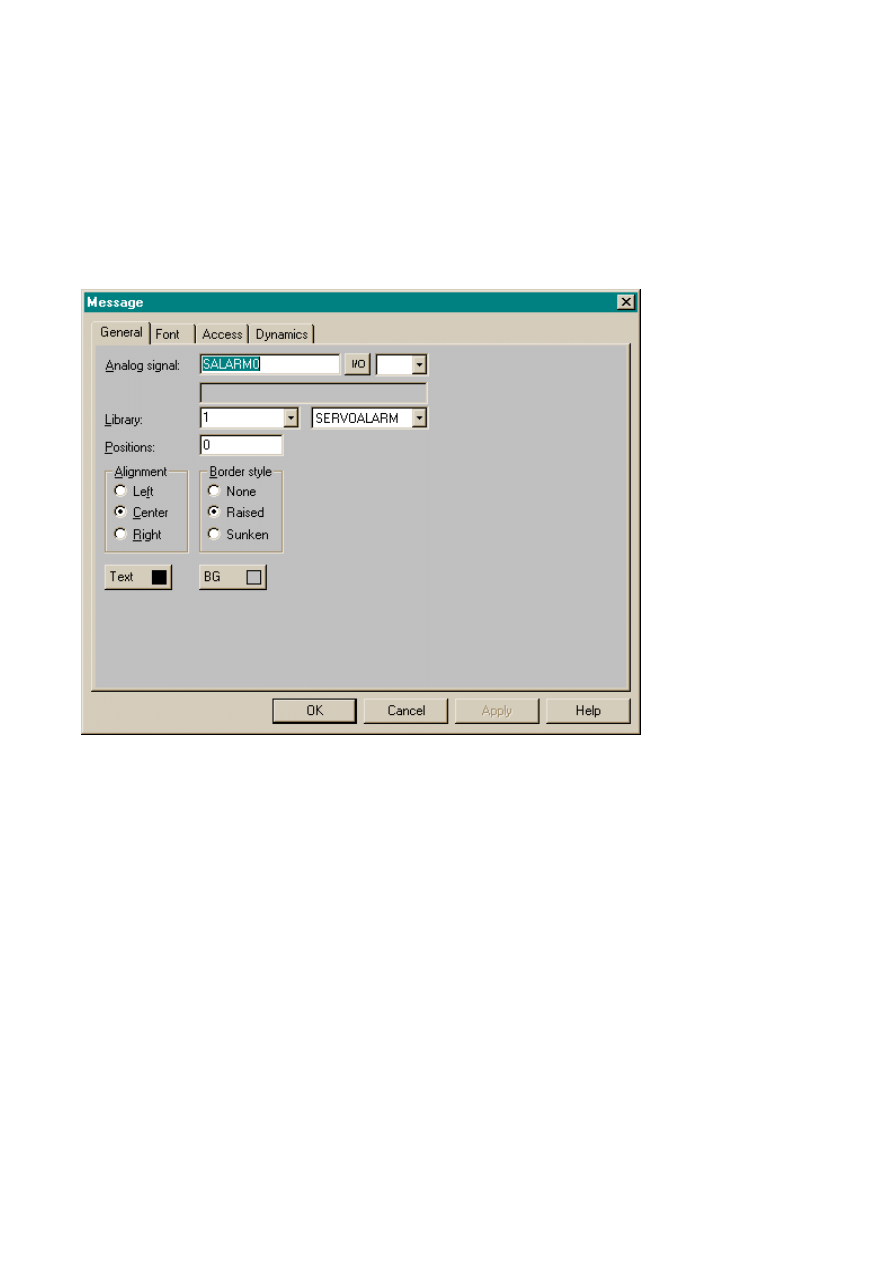

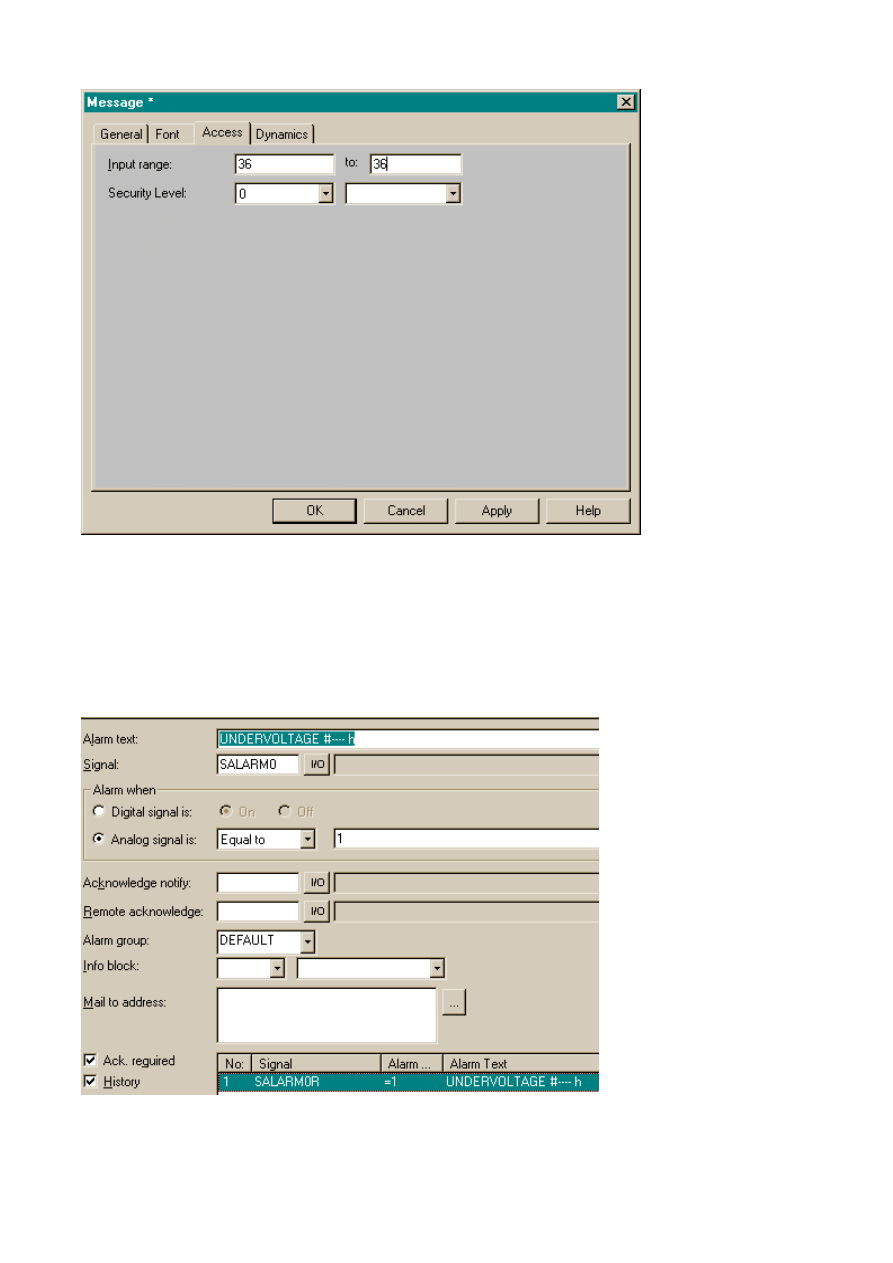

SINSTR ought to be connected to a messagelibrary like below

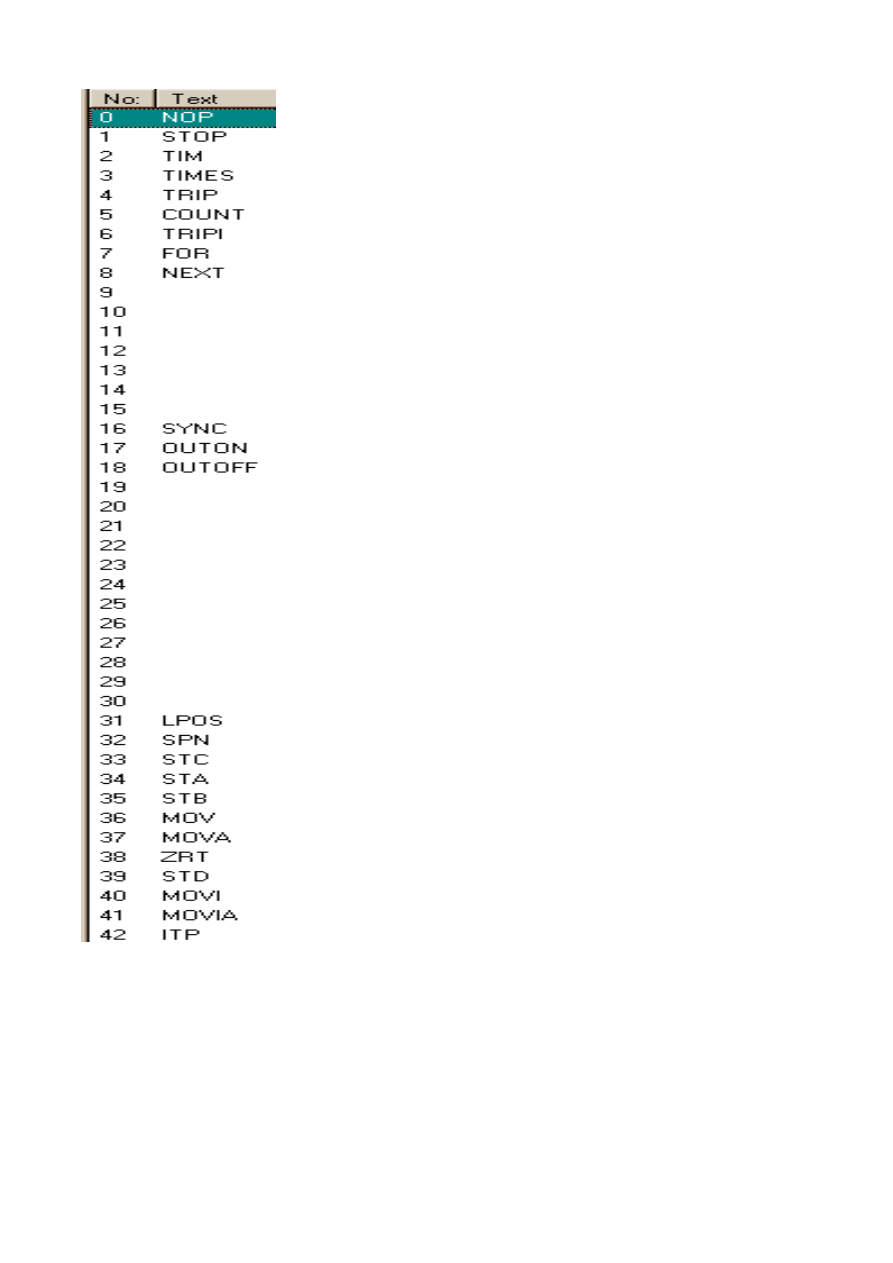

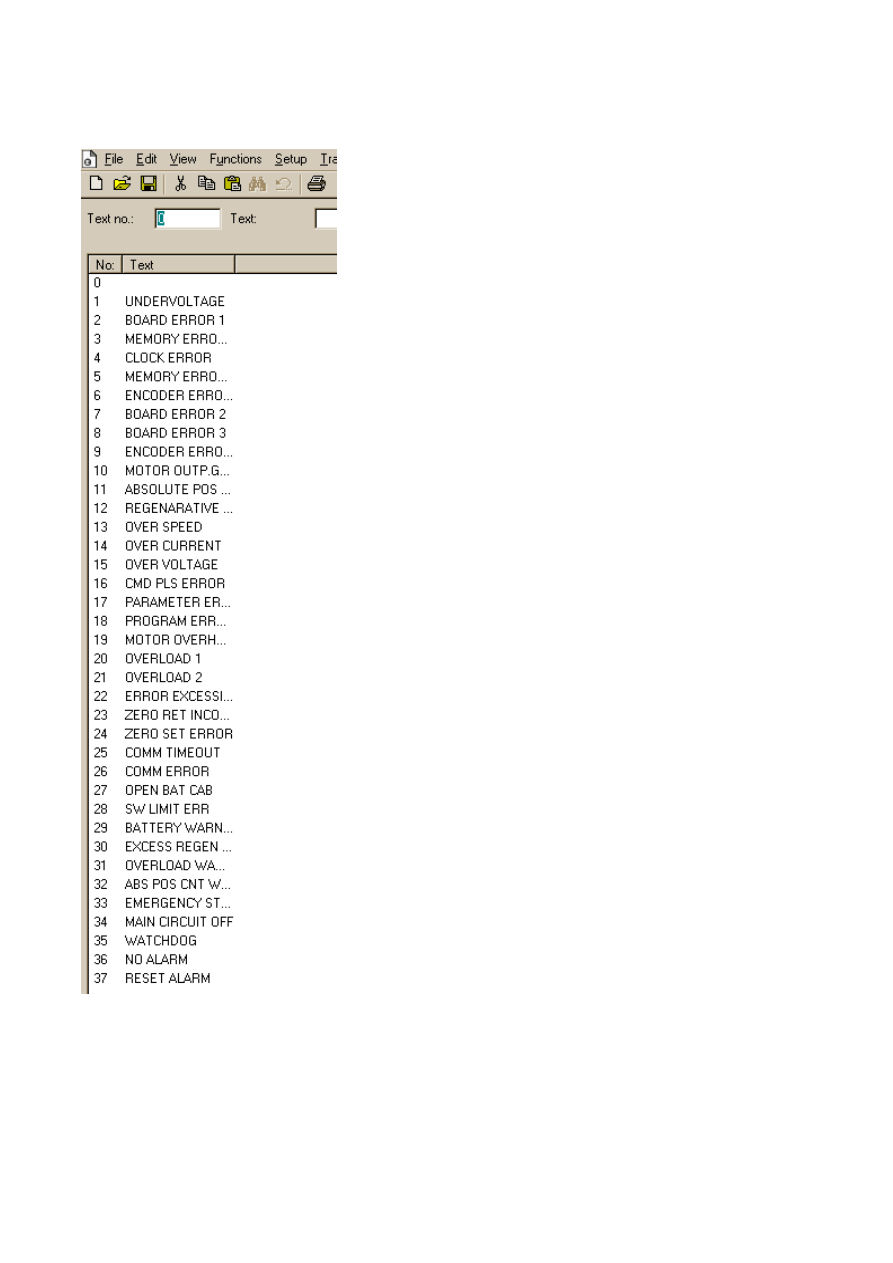

The messagelibrary should then look like

Sida 26 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Sida 27 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Only if MR-J2S-CL -servo the instructions below can be used if it is MR-J2-C-S100 that is

connected, then these instructions can be excluded from the messagelibrary.

The order of the instructions must be as shown above and the empty spaces left

NEXT and SYNC, for example are meant to be there.

The STYPE must be connected to a message library. If STYPE holds other than the value

0, then SVALUE is ignored when writing the servoprogram to the unit. If you know that

the servoprogram does not use R1, R2, D1 or D2, (R1-R4, D1-D4 for CL-servo) then you

do not have to have any objects connected to the STYPE in the block.

STD

FOR

NEXT

MOVI

LPOS

TRIPI

ITP

MOVIA

Sida 28 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

The message library must look like this if a MR-J2-C-S100-servo is connected.

and if a MR-J2S-CL-servo is connected the messagelibrary should look like

A MR-J2-C-S100-servo can hold 8 programs with a total count of 60 steps. The first

program is held by SINSTR0-SINSTR59, SVALUE0-SVALUE59 and STYPE0-STYPE59.

The next program SINSTR60-SINSTR119, SVALUE60-SVALUE119 and STYPE60-

and so on.

These devices can be used with index, try SINSTR0I1 (Index1 has to be connected to I1

the project) then have a key add 60 to I1 when pressed and another to subtract 60 from

I1 when pressed.

A MR-J2S-CL -servo can hold 16 programs with a total count of 120 steps. The first

program is held by SINSTR0-SINSTR119, SVALUE0-SVALUE119 and STYPE0-STYPE119.

The next program SINSTR120-SINSTR239, SVALUE120-SVALUE239 and STYPE120-

STYPE239 and so on.

Sida 29 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

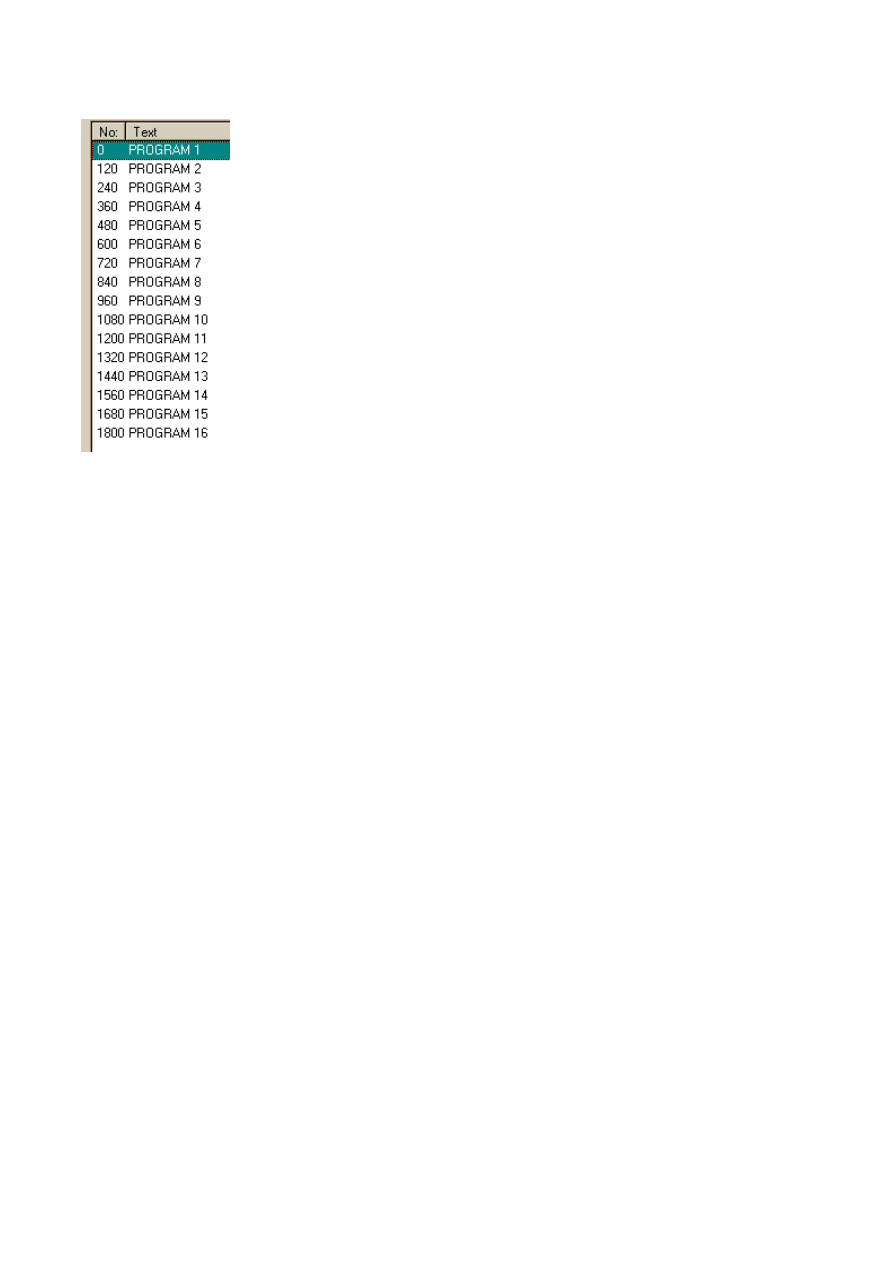

A messagelibrary could be created to show what program is shown in the indexed

The message Library for showprogram for MR-J2-C-S100 should look like

Sida 30 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

and for MR-J2S-CL-servo

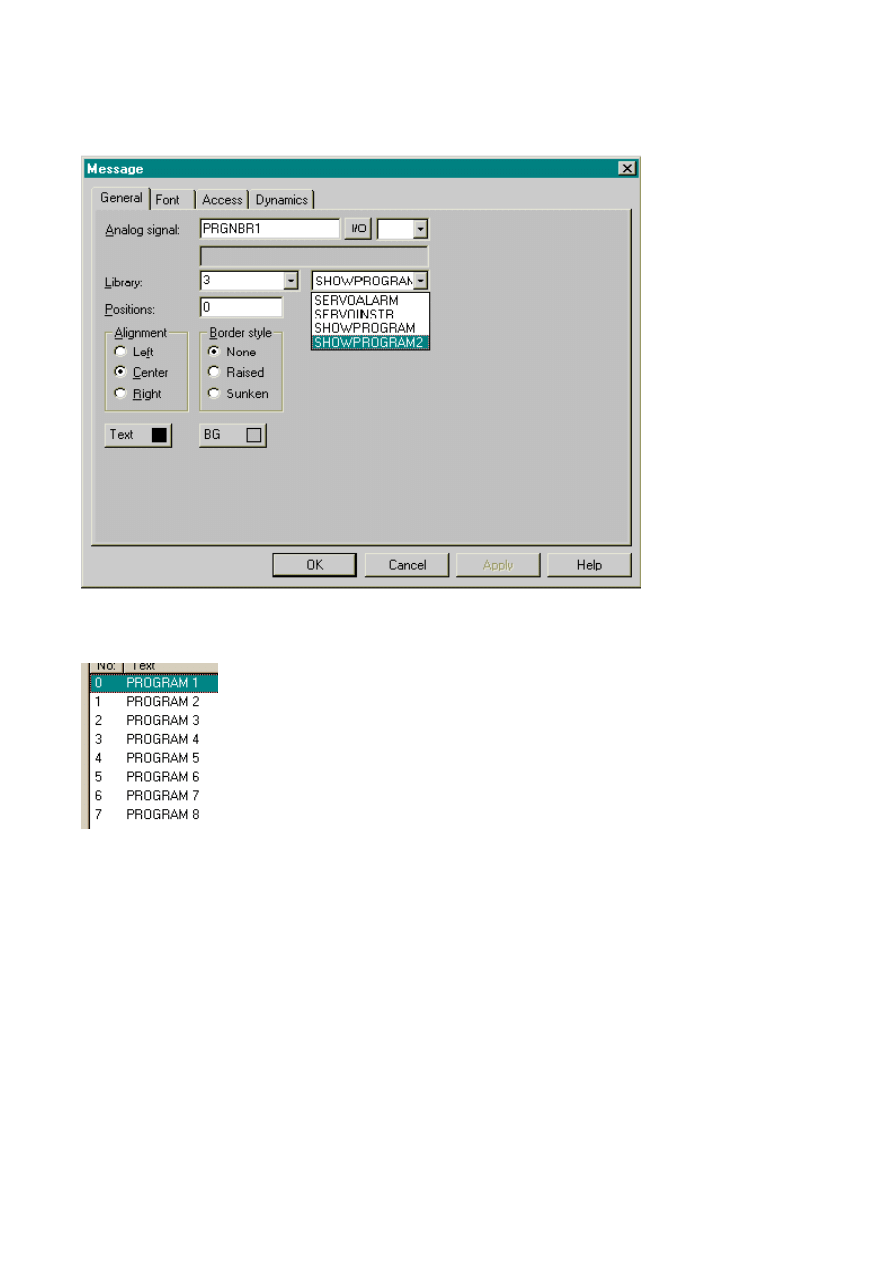

If you also want to be able to chose the program through the use of a message library, a

special device has to be used see PRGNBR1 below, PRGNBR1-PRGNBR8 can be used. If

Index 1 is used to address the SINSTR, SVALUE and STYPE then PRGNBR1 should be

used. If Index 2 is used to address the SINSTR, SVALUE and STYPE then PRGNBR2

be used and so on.

Sida 31 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

PRGNBR is then connected to a message library like below

The message library for MR-J2-C-S100-servo looks like

Sida 32 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

And for MR-J2S-CL-servo

This special device (PRGNBR) works like this.

If MR-J2-C-S100-servo is chosen then when PROGRAM1 is chosen, the value 0 is forced

into I1, when PROGRAM2 is chosen, the value 60 is forced into I2 and so on.

If MR-J2S-CL-servo is chosen then when PROGRAM1 is chosen, the value 0 is forced into

I1, when PROGRAM2 is chosen, the value 120 is forced into I2 and so on.

Sida 33 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Remember that when a new value is written to SINSTR, SVALUE or STYPE, the

internal values are changed, not the values in the servo. When SWRITE is set to 1 (it will

be changed back to 0 by the terminal), then the values are written to the servo. This

be remembered when dataexhange and recipes are used, the values then has to be

written to the servo by the operator after an exchange or a reading of a recipe.

If SWRITE is set by the operator, we would recommend that the operator sets SREAD

after the SWRITE to check if the servoprogram has been recieved correctly by the servo.

The terminal cannot contain any debug-help concerning the writing of the servoprogram,

like the one the pc-software can.

There is one devices that always holds the value 1, this can be used when a

has been performed and we want the terminal to write the new values to the servo. If a

marco first triggs the exchange and last triggs an exchange TRIGG->SWRITE then we

know that the values are written.

Servo Alarms

Driverversion 3.09 and from there on

Servo alarm handler

The servo has a history of seven alarmevents. These are read by adding the device

SALARM to the project. To be able to show all seven alarms and whatever code they

many devices has to be added to the alarms in the project. Only seven questions are

to the servo not 7*36 (the number of alarmdevices added in the project) so it will not

down the terminal much.

Everyone of the seven alarmevents can hold one of the codes below

This is an example of the first event SALARM0

Digital signal

Group

Decription

TRIGG

Always the value 1. Use like

written below for example.

MR-J2-C/ CL

MR-J2-CP

Sida 34 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

SALARM0.1

Undervoltage

Undervoltage

SALARM0.2

Board error 1

Memory error 1

SALARM0.3

Memory error 1

Clock error

SALARM0.4

Clock error

Memory error 2

SALARM0.5

Memory error 2

Encode error 1

SALARM0.6

Encode error 1

Board error

SALARM0.7

Board error 2

Memory error 3

SALARM0.8

Board error 3

Motor combination error

SALARM0.9

Encoder error 2

Encoder error 2

SALARM0.A

Motor outp.gr.f

Main circuit error

SALARM0.B

Absolute pos erase

Absolute pos erase

SALARM0.C

Regenarative error

Regenarative error

SALARM0.D

Over speed

Over speed

SALARM0.E

Over current

Over current

SALARM0.F

Over voltage

Over voltage

SALARM0.10

Cmd pls error

Cmd pls freq error

SALARM0.11

Parameter error

Parameter error

SALARM0.12

Program error

Main circuit device overheat

SALARM0.13

Motor overheat

Servo motor overheat

SALARM0.14

Overload 1

Overload 1

SALARM0.15

Overload 2

Overload 2

SALARM0.16

Error excessive

Error excessive

SALARM0.17

Zero ret incompl

Serial communication time-out

error

SALARM0.18

Zero set error

Serial communication error

SALARM0.19

Comm timeout

Home position return complete

SALARM0.1A

Comm error

Open battery cable warning

SALARM0.1B

Open batt cab

Home position setting warning

SALARM0.1C

SW limit err

Software limit warning

SALARM0.1D

Battery warning

Battery warning

SALARM0.1E

Excess regen warn

Excess regen warn

Sida 35 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

SALARM0.1F

Overload warning

Overload warning

SALARM0.20

Abs pos cnt warn

Abs pos cnt warn

SALARM0.21

Emergency stop

Emergency stop

SALARM0.22

Main circuit off

Main circuit off

SALARM0.23

Watchdog

Watchdog

SALARM0.24

No alarm

No alarm

Sida 36 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

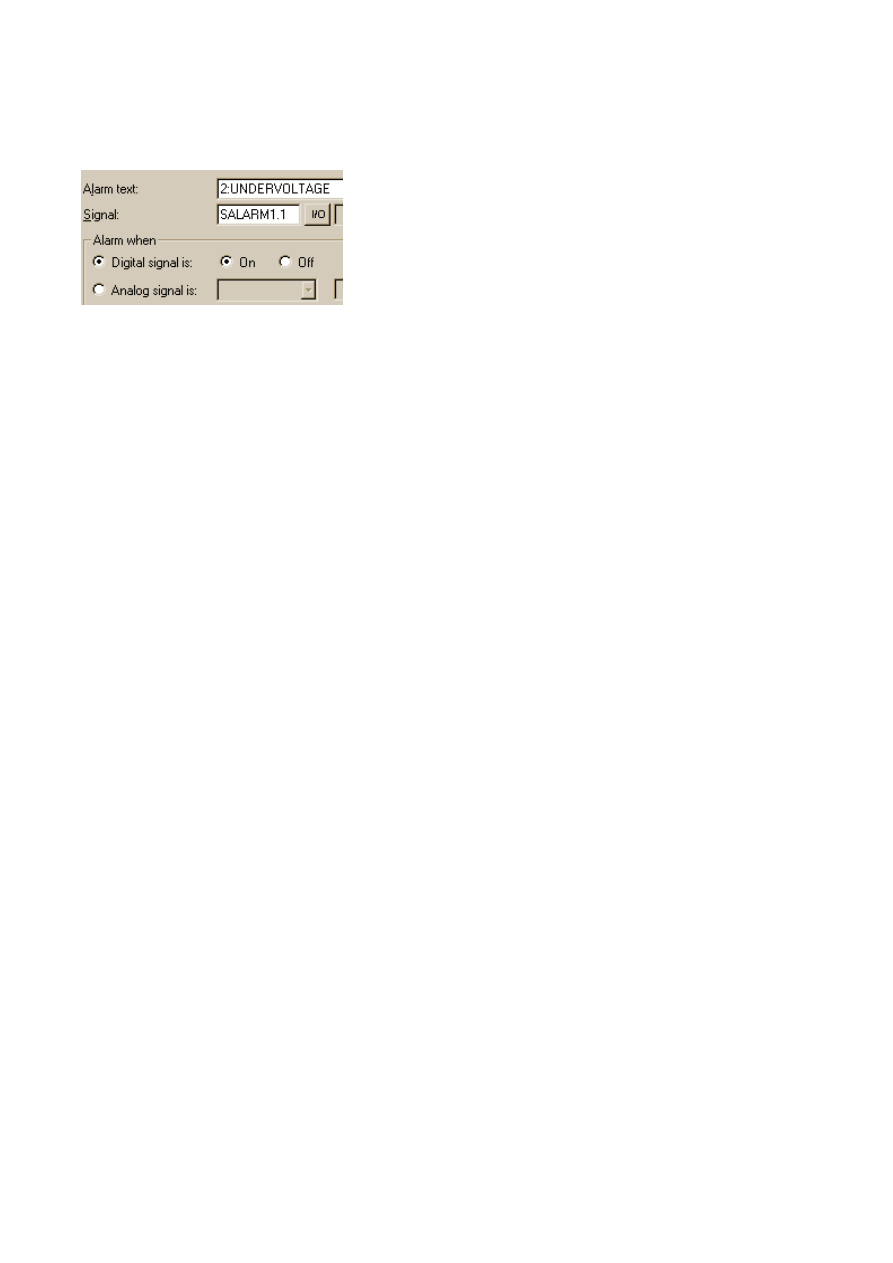

The second event would be SERVOALARM1

SALARM1.1 Undervoltage, SALARM0.2 Board error 1, … SALARM1.24 No alarm

SALARM0-SALARM6 can be connected to a message library, the example below is for MR-J2-

and MR-J2-CL

Sida 37 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

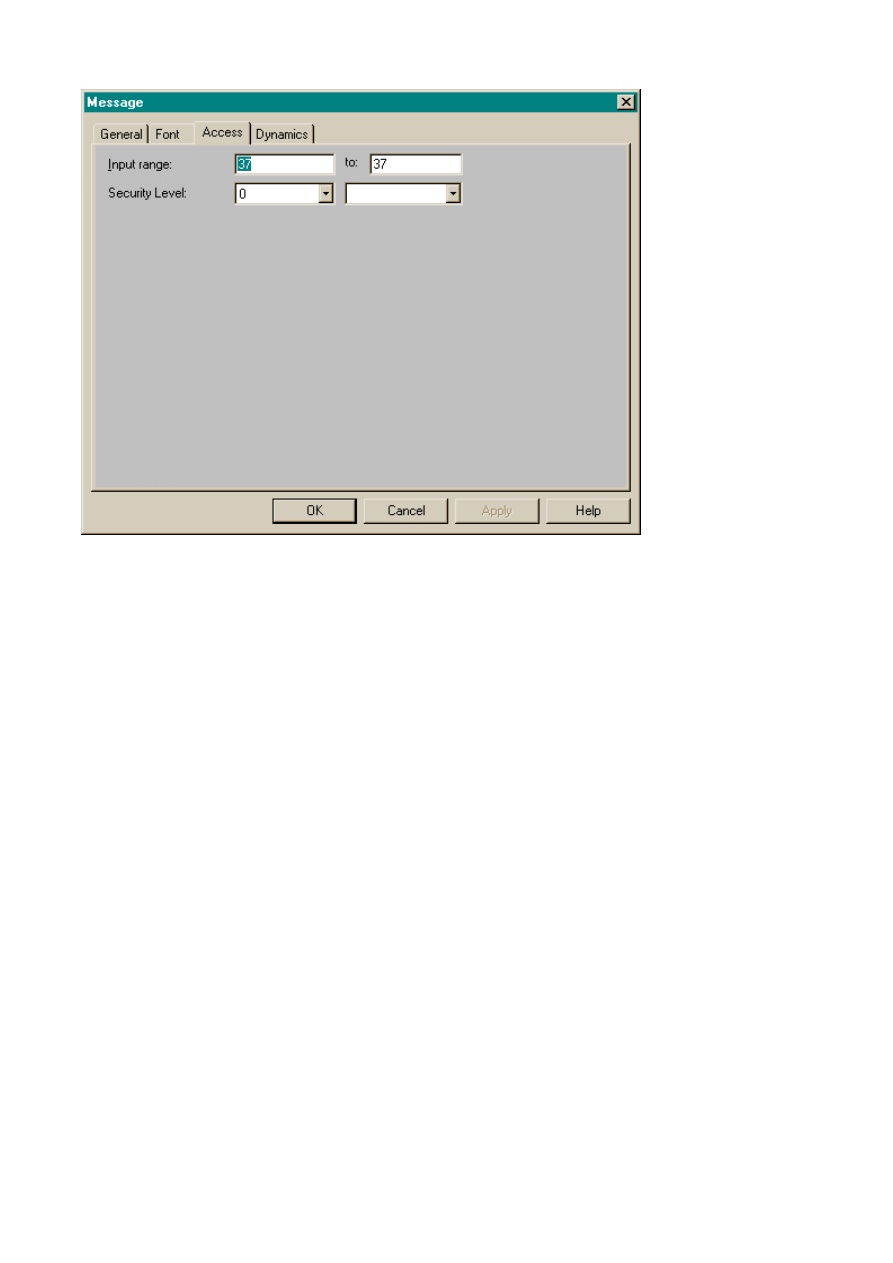

Like below

If we write to the device SALARM, the terminal will send the reset alarm command so

SALARM0 connected to the messagelibrary could be set like

Sida 38 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

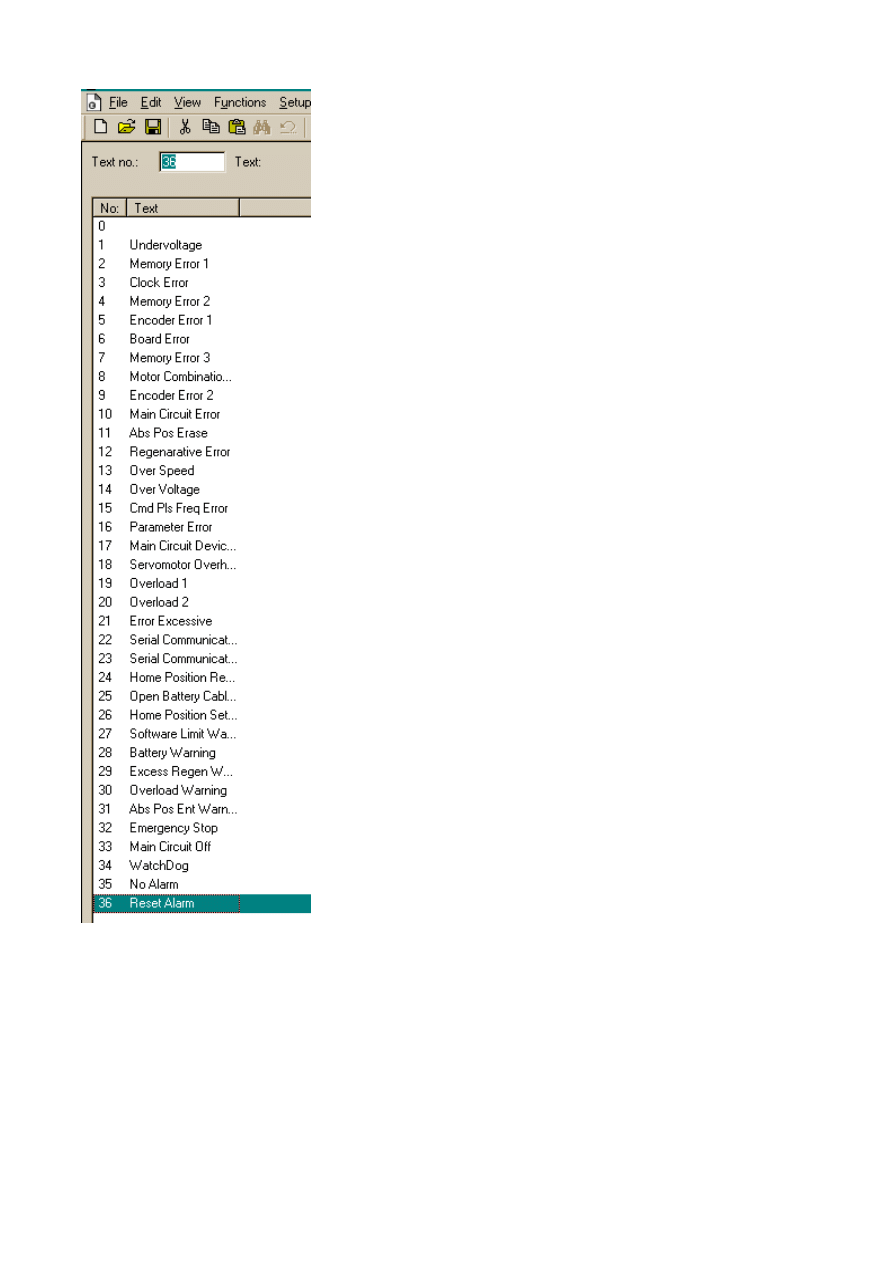

One for MR-J2-CP-S100 would look like

Sida 39 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

If we write to the device SALARM, the terminal will send the reset alarm command so

SALARM0 connected to the messagelibrary could be set like

Sida 40 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

If the alarms from the servo is to be added to the ordinary alarmhandler it could be done like

below

The device added in the Alarm Text is SALARMTIME0.

Sida 41 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

This could be done if the terminal has support for Analog signal alarms. In the smaller

the bit has to be used like

Sida 42 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Station handling

The default station is the station addressed when no station number is stated in front of

devicename. For communication with the other stations, the station number is given as

prefix to the device. This is a fixed number. Example: 3:P0 addresses parameter 0 in

servo with the stationnumber 3.

In the servo, parameter 15 holds the stationnumber.

Beware that servoprogram-reading and writing and servoalarm-reading and

acknowledging is handled in another way concerning the station addressed. Read more

this help-file.

Sida 43 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Point Table

Driverversion 3.09 and from there on

These are some devices that are only valid to use when a MR-J2S-CP (Super

Series) is connected.

In point table there are 6 columns, (Position, Acc-Time,Dec-Time, Dwell-Time, Aux-Func), these

are all accessed by using the device PT.

* The device for postion (PT1.1, PT2.1, PT3.1…) should match what is set in parameter 1 when

comes to the number of decimals. The values for parameter 1 is 0030 = 0 decimals, 0020 = 1

decimal, 0010 = 2 decimals, 0000 = 3 decimals. (see manual for the servo).

The pointtable is read and written to the

stationnumber set under peripherals in the project.

If the pointtable is to be read from another station, then the stationnumber is put in

of the device, like 03:PT1.1 (reads first row, position from stationnumber 3).

Analog signal

Decription

PT1.1

First row, Position *

PT1.2

First row, Speed

PT1.3

First row, Acc-Time

PT1.4

First row, Dec-Time

PT1.5

First row, Dwell-Time

PT1.6

First row, Aux-Func

Digital signal

Decription

TRIGG

Always the value 1. Can be

by the project as you like.

Sida 44 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Efficient Communication

To make the communication between the terminal and the motion controller quick and

efficient the following should be noted about how the signals are read and how the

can be optimized.

Signals affecting the communication time

Only signals to objects in the current block are read continuously. Signals to objects in

other blocks are not read, thus the number of blocks does not affect the communication

time

Besides the signals to objects in the current block, the terminal reads the following

from the motion controller continuously:

Display signals (Block Header)

Print signals (Block Header)

LED registers

Alarm signals

Remote acknowledge signals on alarms and alarm groups

Login signal (Passwords)

Logout signal (Passwords)

Registers for trend curves

Bargraph registers if using min/max indicators

New display register

Buzzer register

Backlight signal

Cursor control block

Recipe control block

Library index register

Index registers

Controller clock register if the controller clock is used in the terminal

List erase signal (Alarm Settings)

No protocol control register

No protocol on signal

Signals not affecting the communication time

The following signals do not affect the communication time:

- Signals linked to function keys

- Time channels

- Objects in alarm messages

Sida 45 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

How to make the communication more efficient

Efficient block changes

Block changes are carried out most rapidly and efficiently through the block jump

on the function keys or through a jump object. "Display signals" in the block header

should only be used when the controller is to force the presentation of another block.

"New Display" register can also be used if the controller is to change the block. This does

not affect communication as much as a larger number of "Display signals".

Use the clock of the terminal

An extra load is put on communication if the clock of the controller is used since the

register must be read to the terminal. Downloading of the clock to the controller also

creates an extra load. The interval between downloads should therefore be as long as

possible.

Group controller devices consecutively

The devices from the controller are read most rapidly if all devices are consecutive. If

devices are spread out (e.g. 4, 17, 45, etc.) the updating is slower.

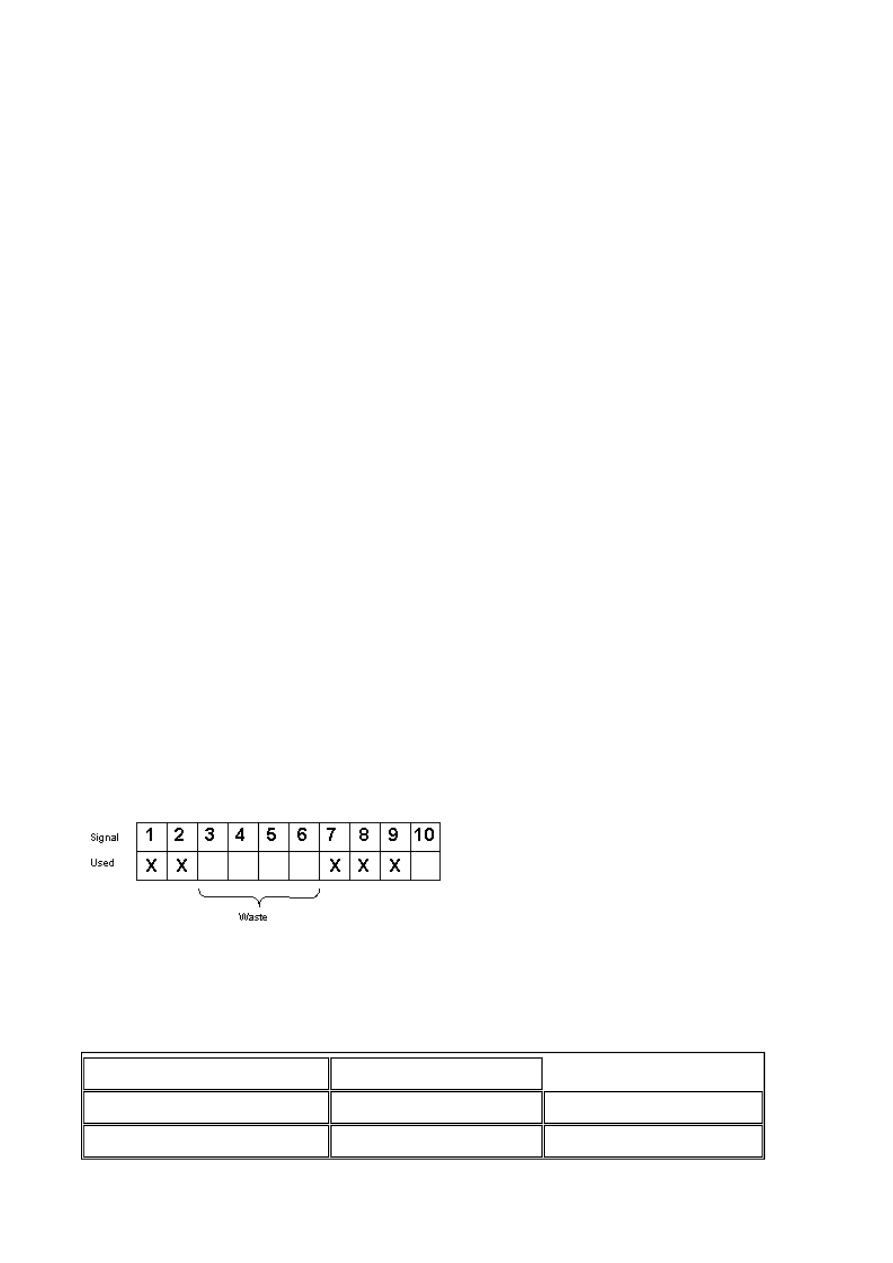

Packaging of signals

When the devices are transferred to the controller, all devices are not transferred

simultaneously. Instead they are divided into packages with a number of devices in each

package. To decrease the number of packages that have to be transferred and make the

communication faster this number has to be considered. The number of devices in each

package depends on the used driver.

To make the communication as fast as possible the number of packages has to be

minimized. Consecutive devices require a minimum of used packages but it is not always

possible to have consecutive signals. In such cases the so-called waste between two

signals has to be considered. The waste is the maximum distance between two signals

can have and still keep them in the same package. The waste depends on the used

Efficient packaging of signals

To make the communication quick and efficient the following should be noted about how

the devices (signals) are read and what that can be done to optimize the reading.

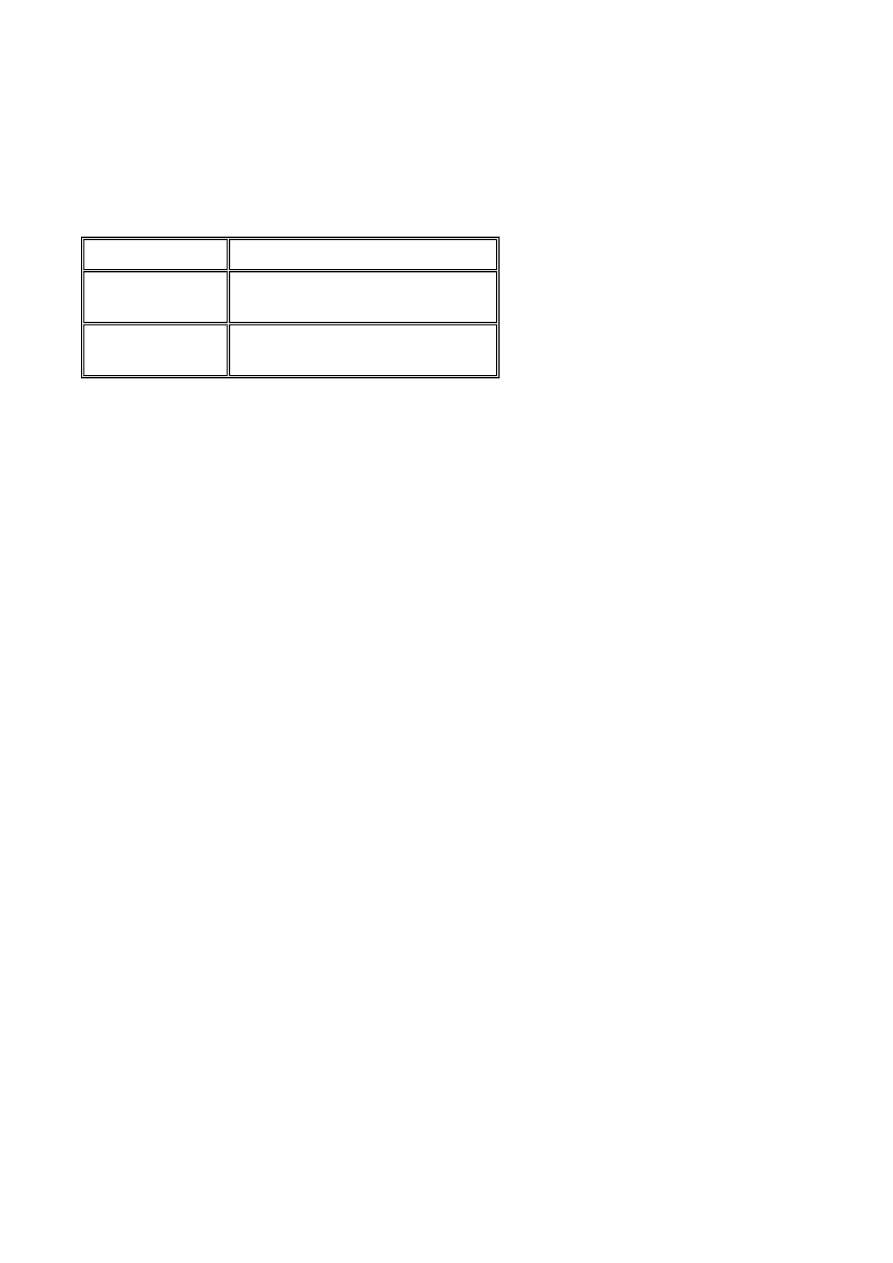

Analog signals

Digital signals

No. of signals/package

1

1

Waste

0

0

Sida 46 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Error messages

Shown in uper left corner of display

If the terminal tries to write a servoprogram that is larger than allowed count of steps,

this will be prevented by the terminal by showing a SYSTEM ERROR message. This will

then result in a reboot of the terminal.

The message looks like

The count of steps is different for various types of servo-systems.

The reason is that to many steps are used. If the servoprogram is not read before

then this problem can occour when trying to wriite to the servo.

Connect a pc to the servo and try to do the same with pc-software from Mitsubishi

Electric.

Error message

Explanation

1:Comm Err Stn X

2:Comm Err Stn X

Communication fails, check

baudrate in terminal and

connected unit. Check cable.

Maybe a device has a non valid

stationnumber or the default

stationnumber for the driver is

set to a stationnumber that is

not connected.

1:… means that it is driver 1

2:… means driver 2

SYSTEM ERROR

Program > 120 Steps

[Enter]:restart

Sida 47 av 47

Introduction

2003-07-01

file://C:\TEMP\~hhAEEB.htm

Document Outline

- Driver for MELSERVO MR-J2

Wyszukiwarka

Podobne podstrony:

CAN Bus Drivers for Atmel C51 Products

Eleanor Cameron Mushroom Planet 04 A Mystery for Mr Bass

On The Specification Of Moving Coil Drivers For Low Frequency Horn Loaded Loudspeakers (W Marshall L

driver for epson workforce 520

apple magic mouse driver for windows 8

wifi drivers for windows 7 on macbook pro

Dynamic gadolinium enhanced subtraction MR imaging – a simple technique for the early diagnosis of L

Data Rescue II (for mac) SN

The Talented Mr Ripley Lulllaby For Cain

USB to RS232 for MAC DOC

driver printer brother dcp 195c for windows 7

Parallels Desktop for Mac Quick Start Guide

więcej podobnych podstron