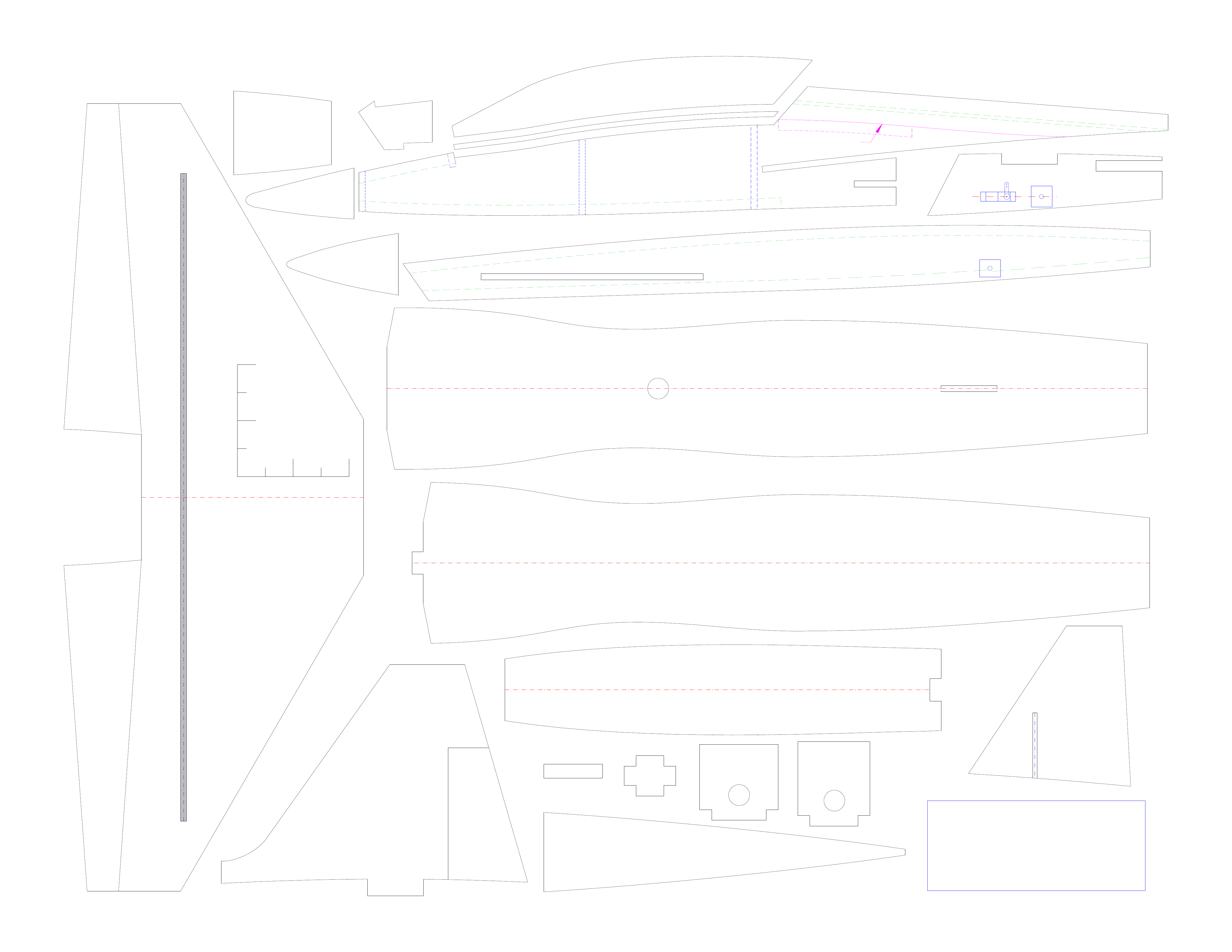

Designed by Steve Shumate

All parts made from 6 mm Depron or

BlueCore foam unless otherwise specified

Copyright © 2005 All Rights Reserved

Stabilators

(make 2)

Turtledeck Top

(make 1)

Aft Fuselage Bottom

(make 1)

Fwd Fuselage Sides (make 2)

Top fwd fuselage

(trim to fit)

Fwd Fuselage Bottom (make 1)

Nosecone top view template

(trace outline on top of nosecone

to assist in carving it to shape)

Bulkhead F-3

(make 1)

Bulkhead F-4

(make 1)

Vertical Tail

(make 1)

Aft Fuselage Top

(make 1)

Dashed green lines indicate where

to attach foam strips

F-1

F-3

F-4

Aft Fuselage Sides

(make 2)

Wing

(make 1)

2

4

0

Scale in inches

2

4

3/4" x 5/8" 1/64" ply

doublers on inboard side

(drill 3/16" hole for pivot

bearing tubes)

3/4" x 3/4" 1/64" ply

doublers on each side

(drill 3/16" hole for pivot

bearing tubes)

Motor mount

(make 2 and

laminate together)

Cut hole for servo

(press fit)

Nosecone

(make 10 with 6 mm Depron

(11 if BlueCore) and

laminate together)

3/8" wide foam strip

3/8" wide foam strip

F-2

Bulkhead F-2

(make 1)

Inlet fence

(make 2 from 3 mm

Depron or 1/8" balsa)

Bulkhead F-1

(make 1)

3/8" wide foam strip (2 layers)

3/8" wid

e foam

strip (2

layers)

Cut access hole as required

to route servo wires to receiver

Laminate 2 foam strips (1/2" outbo

ard, 3/8" inboard)

OPTIONAL: To simulate crease in turtledeck, cut

here, inset top piece inboard slightly, sand corner on

lower piece round, add a foam support strip at

bottom as shown, and glue back together.

Canopy sill pie

ce (make 2)

Canopy

(make 12 with 6 mm Depron

(14 if BlueCore) and

laminate together)

Note: Inside of canopy can be

hollowed out if airplane CG is not

already too far aft

Wyszukiwarka

Podobne podstrony:

T 38 Park Jet Plans (Parts Templates Tiled)

F 14 Park Jet (Parts Templates Non Tiled)

T 38 Park Jet Plans (Assembly Drawing)

F 14 Park Jet (Parts Templates Tiled)

Polaris Parts Templates (Tiled)

Polaris Parts Templates (Nontiled)

F 14 Park Jet (Assembly Drawing)

DIY Mortis Dreadmought Plans & Templates

DIY Land Speeder Plans & Templates

DIY Predator Plans & Templates

DIY Whirlwind Plans & Templates

DIY Mortis Dreadmought Plans & Templates

DIY Stormtalon Plans & Templates

f 18 plans tiled

F15 parts Tiled

F15 plans Tiled

F22 Plans 2of2 3mm Parts

Tiburon Plans Tiled

f 18 Parts tiled

więcej podobnych podstron