1008D–01

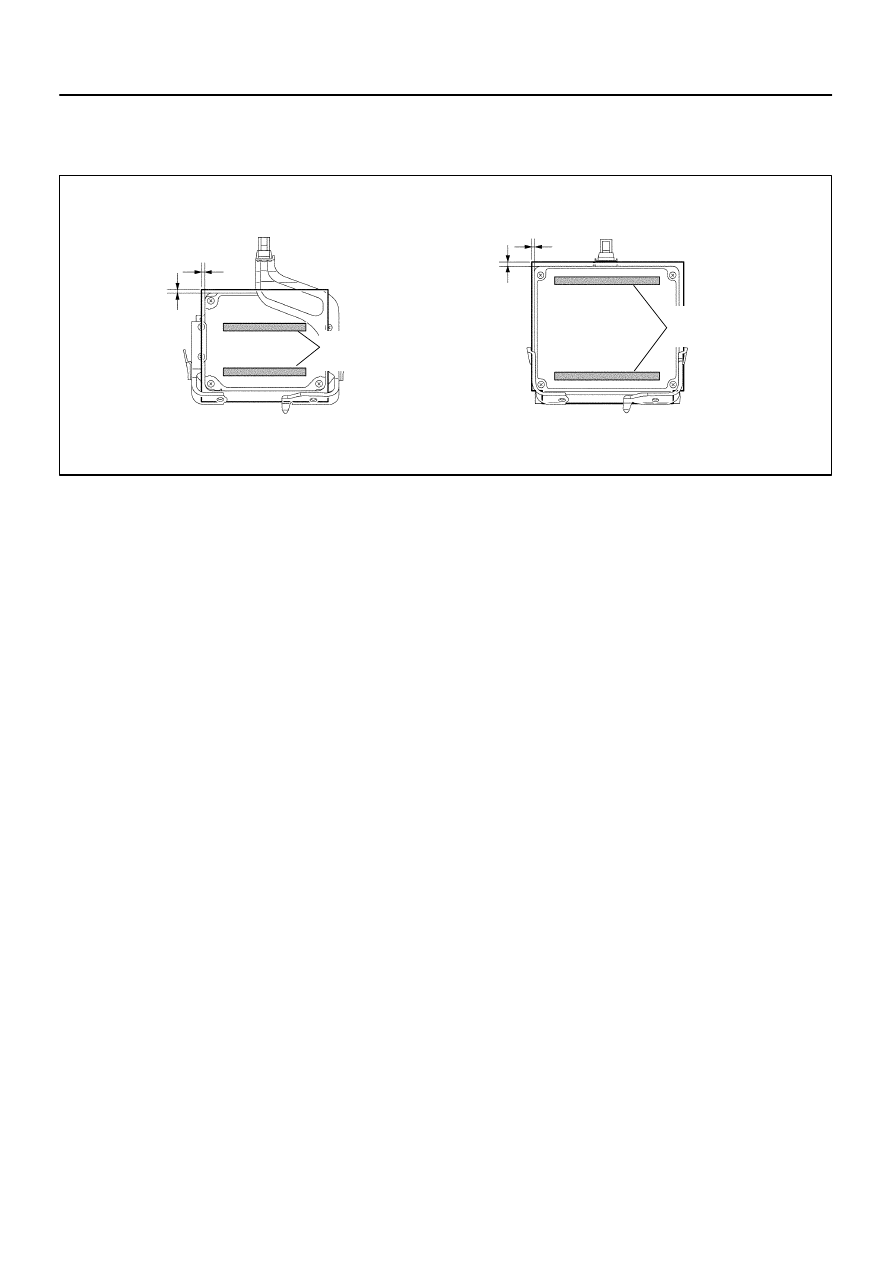

Valve

Close

Open

Valve

A50374

–

ENGINE CONTROL SYSTEM

SFI SYSTEM

10–1

955

Author:

Date:

2004 COROLLA (RM1037U)

SFI SYSTEM

ON–VEHICLE INSPECTION

1.

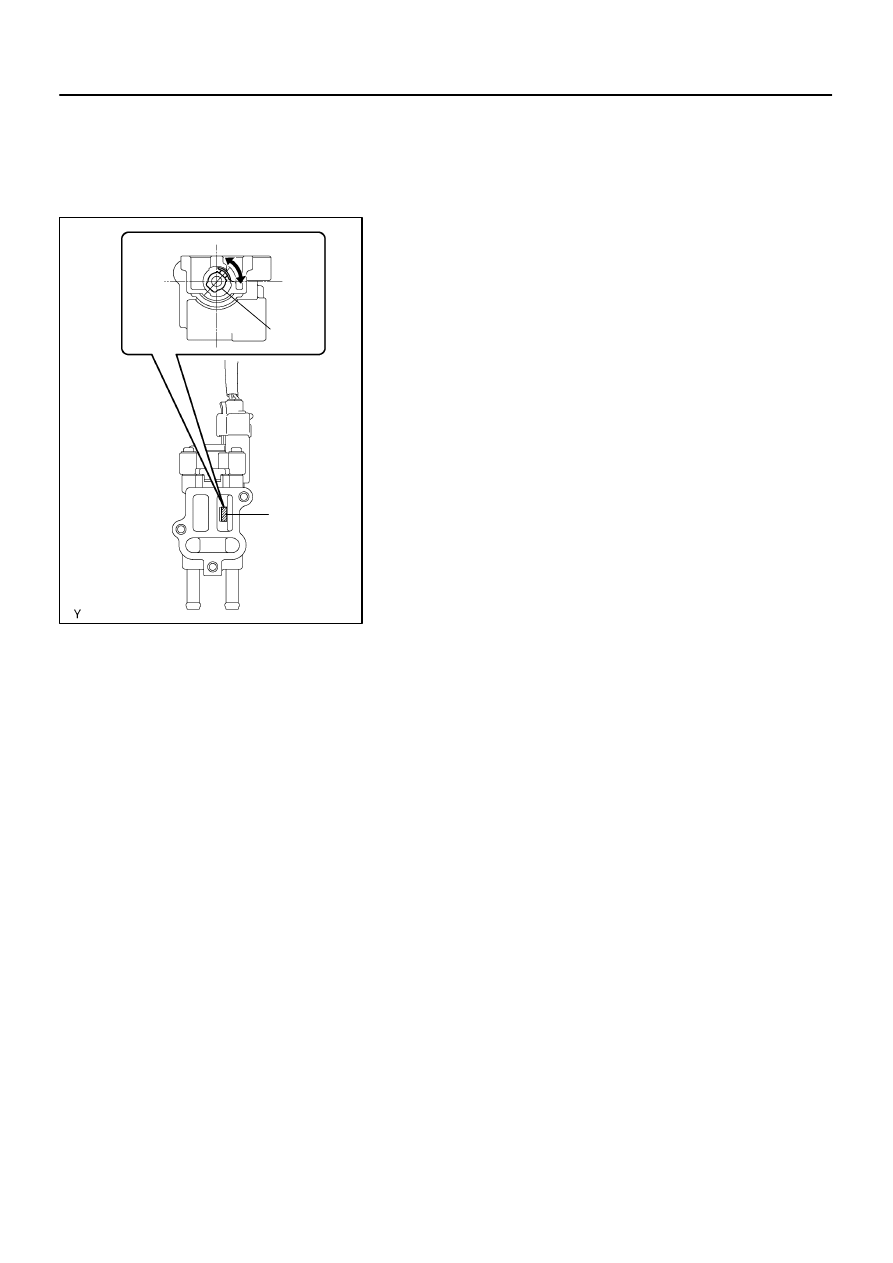

INSPECTION THROTTLE BODY IDLE SPEED

CONTROL VALVE ASSY

NOTICE:

It is impossible to check the resister value and the op-

eration of ISC valve by itself, because the ISC valve

has an IC circuit inside it, which transforms the duty

signal from the ECM to the derive signal.

After checking, erase the DTC.

Clear the DTC after inspection.

HINT:

When the ISC valve system has malfunctions except for its ad-

herence, DTC P0505 is detected.

(a)

Operation inspection.

(1)

Connect the ISC connector to the ISC valve.

(2)

Check the ISC valve movement when the ignition

switch is turned ON.

Movement:

Half open

→

fully close

→

fully open

→

half open

HINT:

ISC valve moves within 0.5 second.

1008E–02

A65170

E2

THA

Ohmmeter

A66622

Air

VG

E2G

Voltmeter

Valve

1

2

B01689

10–2

–

ENGINE CONTROL SYSTEM

SFI SYSTEM

956

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION

1.

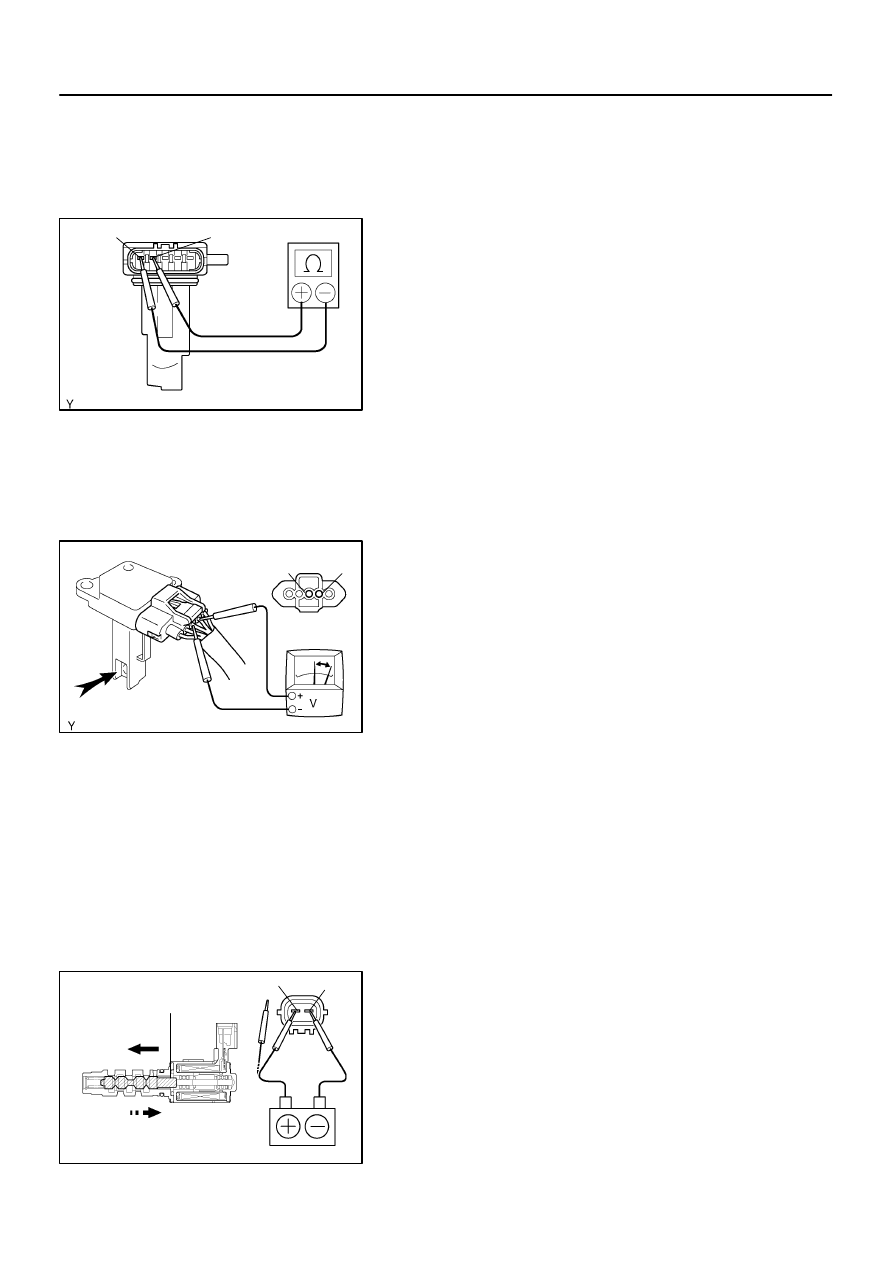

INTAKE AIR FLOW METER SUB–ASSY

(a)

Inspect the intake air flow meter resistance.

(1)

Using an ohmmeter, measure the resistance be-

tween terminals THA and E2.

Resistance:

At –20

C (–4

F) 13.6 to 18.4 k

Ω

At 20

C (68

F) 2.21 to 2.69 k

Ω

At 60

C (140

F) 0.49 to 0.67 k

Ω

HINT:

If the resistance is not as specified, replace the intake air flow

meter.

(b)

Inspect the intake air flow meter operation.

(1)

Connect the intake air flow meter connector.

(2)

Turn the ignition switch to ON.

(3)

Using a voltmeter, connect the positive (+) tester

probe to terminal VG, and negative (–) tester probe

to terminal E2G.

(4)

Blow air into the intake air flow meter, and check that

the voltage fluctuates.

HINT:

If operation is not as specified, replace the intake air flow meter.

(5)

Turn the ignition switch to LOCK.

(6)

Disconnect the intake air flow meter connector.

2.

CAMSHAFT TIMING OIL CONTROL VALVE ASSY

(a)

Resistance inspection.

(1)

Using an ohmmeter, measure the resistance be-

tween the terminals.

Resistance: 6.9 to 7.9

Ω

at 20

C (68

F)

(b)

Movement inspection.

(1)

Connect the positive (+) lead from the battery to ter-

minal 1 and negative (–) lead to terminal 2, and

check the movement of the valve.

NOTICE:

Confirm the valve does not adhere.

HINT:

Bad returning of the valve by entrance of foreign objects causes

subtle pressure leak to the advanced direction. Then, DTC can

be detected.

A66635

Throttle Stop Screw

Throttle Lever

A65173

VTA

E2

VC

2

3

1

–

ENGINE CONTROL SYSTEM

SFI SYSTEM

10–3

957

Author:

Date:

2004 COROLLA (RM1037U)

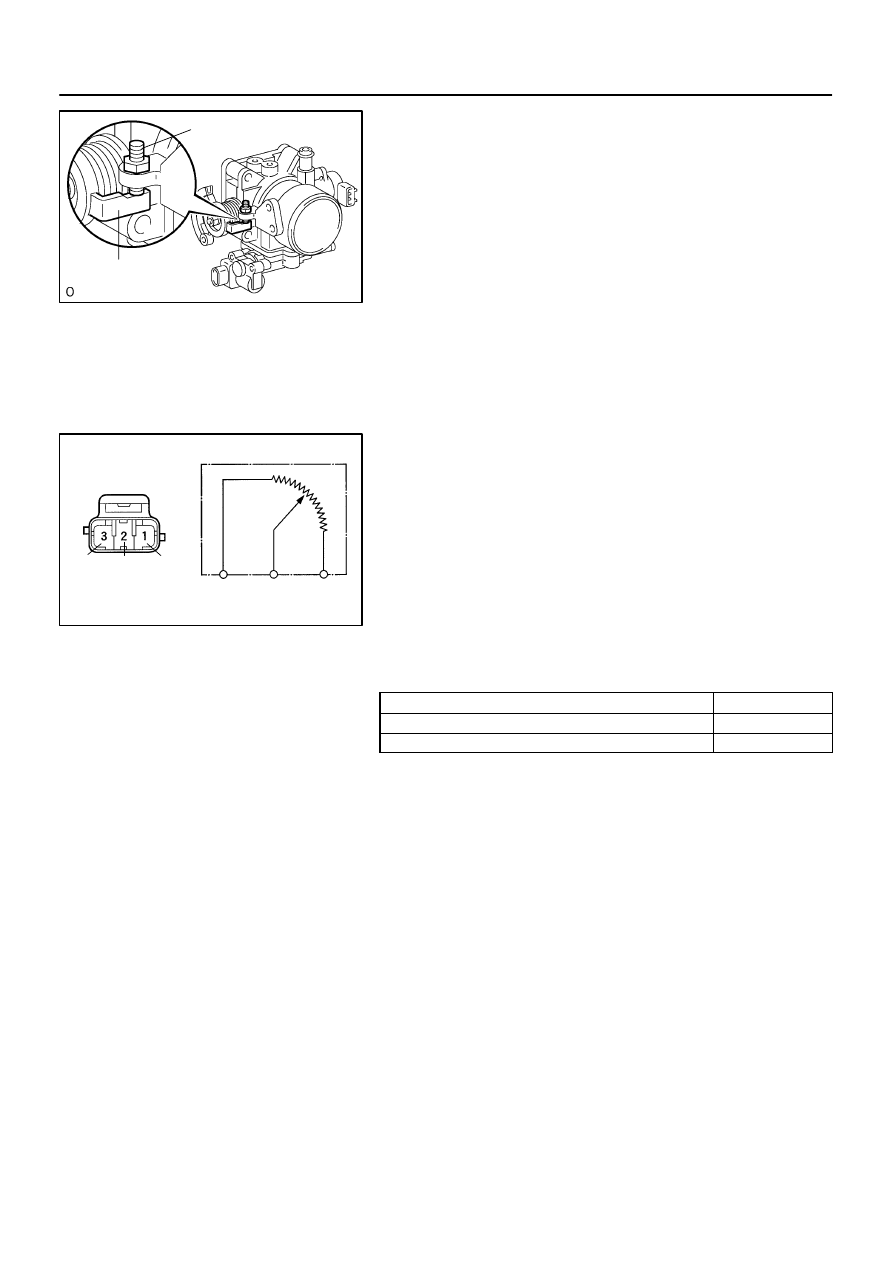

3.

THROTTLE BODY ASSY

(a)

Check throttle body.

(1)

Check that throttle valve shaft is not rickety.

(2)

Check that each port is not stopped up.

(3)

Check that throttle valve opens and closes smooth-

ly.

(4)

Check that there is no clearance between the

throttle stop screw and throttle lever at the throttle

closed position.

NOTICE:

Do not adjust the throttle stop screw.

4.

E.F.I. THROTTLE POSITION SENSOR

(a)

Resistance inspection.

(1)

Disconnect the throttle position sensor connector.

(2)

Using an ohmmeter, measure the resistance be-

tween terminals VC and E2.

Resistance: 2.5 to 6.0 k

Ω

(3)

Check the change of resistance between terminals

VTA and E2.

Change of resistance:

The resistance value increases in proportion to the

throttle lever opening value.

HINT:

Throttle valve

Resistance

Fully close

0.2 to 5.7 k

Ω

Fully open

2.0 to 10.2 k

Ω

TEMPERATURE

C(

F)

RESIST

ANCE k

Ω

30

20

10

5

2

1

0.5

0.3

0.2

0.1

3

–20

0

20 40

60

80 100

(–4) (32) (80)

(140)

(104)

(212)

(176)

A50371

Ohmmeter

A65174

Ohmmeter

E12471

E12471

10–4

–

ENGINE CONTROL SYSTEM

SFI SYSTEM

958

Author:

Date:

2004 COROLLA (RM1037U)

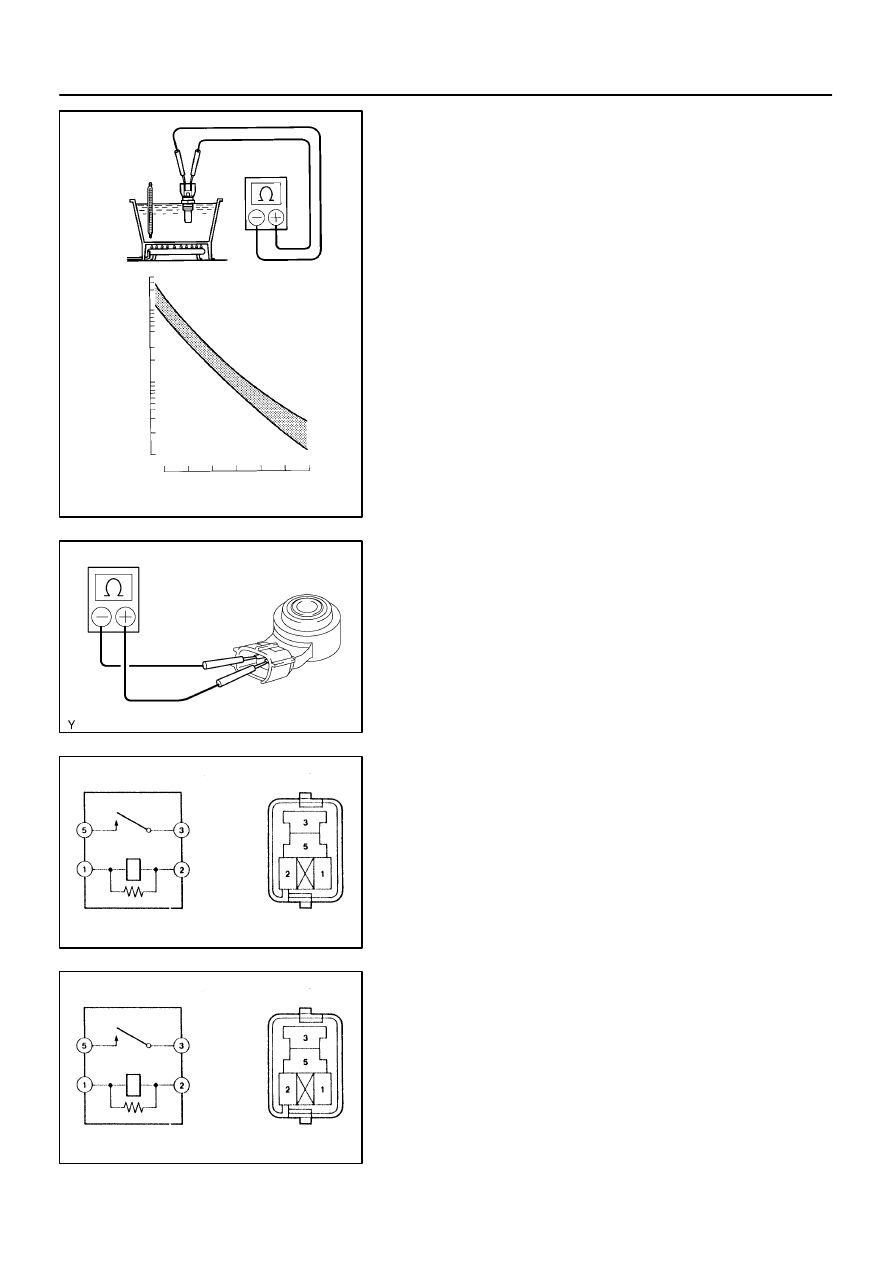

5.

E.F.I. ENGINE COOLANT TEMPERATURE SENSOR

(a)

Resistance inspection.

(1)

Using an ohmmeter, measure the resistance be-

tween each terminal.

Resistance:

At 20

C (68

F) 2.32 – 2.59 k

Ω

At 80

C (176

F) 0.310 – 0.326 k

Ω

NOTICE:

In case of checking the water temperature sensor in the wa-

ter, be careful not to allow water to go into the terminals,

and after checking, wipe out the sensor.

6.

KNOCK CONTROL SENSOR

(a)

Using an ohmmeter, measure the resistance between ter-

minals.

Resistance: 120 – 280 k

Ω

at 20

C (68

F)

HINT:

If the resistance is not specified, replace the sensor.

7.

E.F.I. CIRCUIT OPENING RELAY ASSY

(a)

Continuity inspection.

(1)

Using an ohmmeter, check that continuity exists be-

tween each terminal.

Specified condition:

Between terminals 1 and 2 Continuity

Between terminals 3 and 5 No continuity

(2)

Using an ohmmeter, check that continuity exists be-

tween terminals 3 and 5 when the battery voltage is

applied across terminals 1 and 2.

8.

E.F.I ECU RELAY

(a)

Continuity inspection.

(1)

Using an ohmmeter, check that continuity exists be-

tween each terminal.

Specified condition:

Between terminals 1 and 2 Continuity

Between terminals 3 and 5 No continuity

(2)

Using an ohmmeter, check that continuity exists be-

tween terminals 3 and 5 when the battery voltage is

applied across terminals 1 and 2.

1008F–01

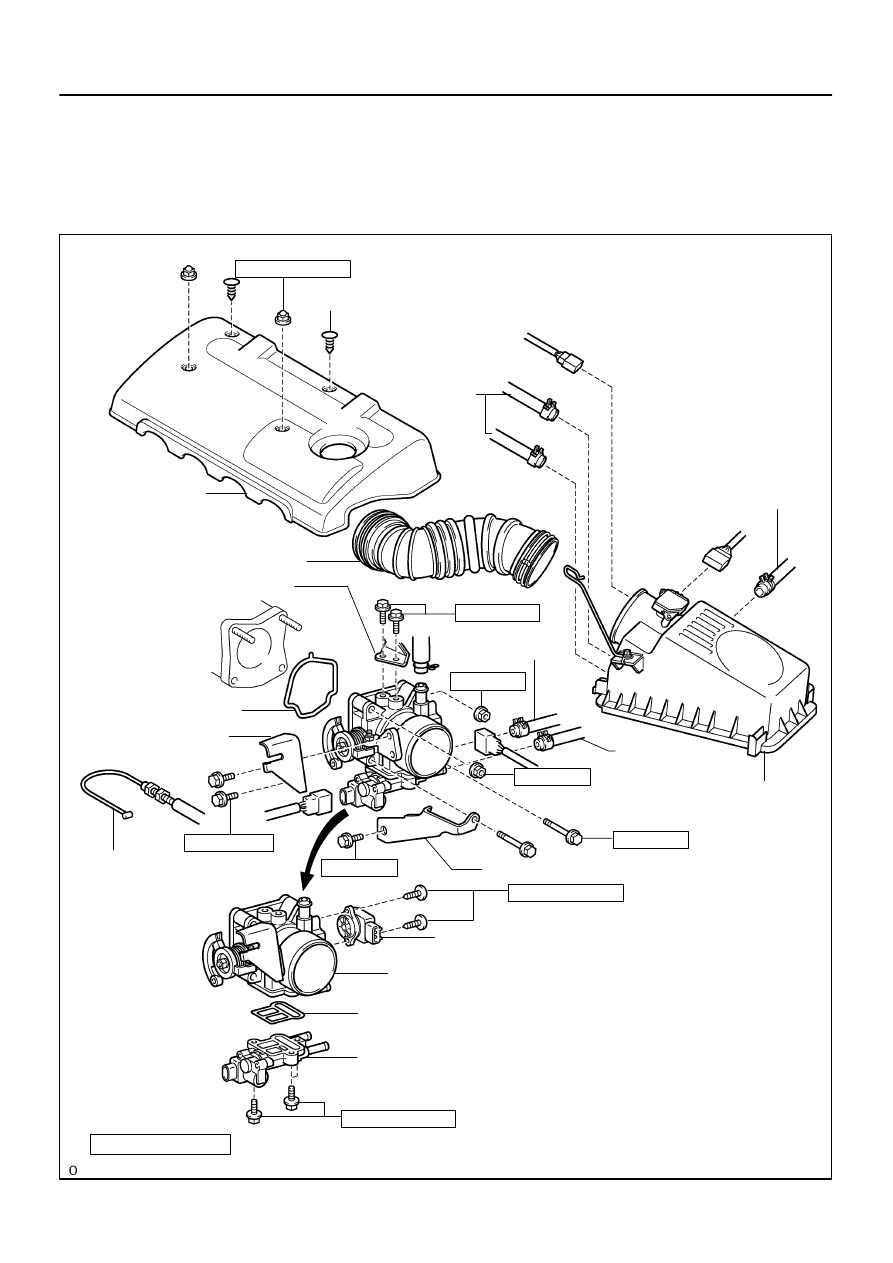

A65206

Cylinder Head

Cover No. 2

Gasket

Accelerator Control

Cable Bracket Sub–assy

Throttle Body Assy

N·m (kgf·cm, ft·lbf)

: Specified torque

Non–reusable part

E.F.I. Throttle Position Sensor

Clip

7.0 (71, 62 in.·lbf)

Air Cleaner Hose No. 1

Manifold Stay No. 2 (M/T)

13 (133, 9.6)

Accelerator

Control Cable Assy

13 (133, 9.6)

30 (306, 22)

3.7 (38, 33 in.·lbf)

Gasket

2.0 (20, 18 in.·lbf)

Throttle Body Bracket

30 (306, 22)

Air Cleaner Cap

30 (306, 22)

30 (306, 22)

Throttle Body Idle Speed Control Valve Assy

Vacuum Hose

Vacuum Hose

Water By–pass

Hose

Water By–pass Hose

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

10–5

959

Author:

Date:

2004 COROLLA (RM1037U)

THROTTLE BODY ASSY

COMPONENTS

1008G–02

A65077

A65177

A65188

10–6

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

960

Author:

Date:

2004 COROLLA (RM1037U)

Removal & Installation and Disassembly & Reassembly

1.

DRAIN COOLANT(See page

16–7

)

2.

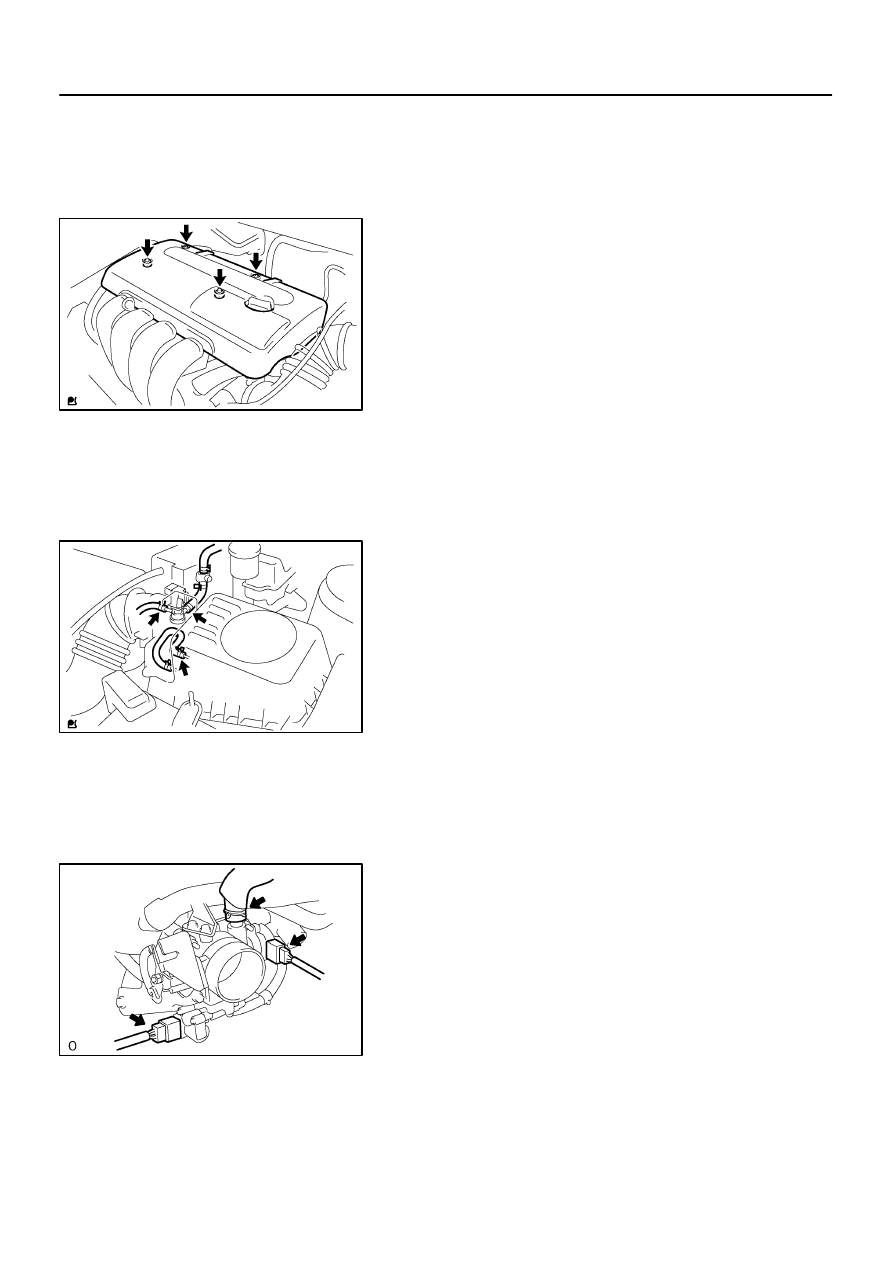

REMOVE CYLINDER HEAD COVER NO.2

(a)

Remove 2 nuts, 2clips and the cylinder head cover No. 2.

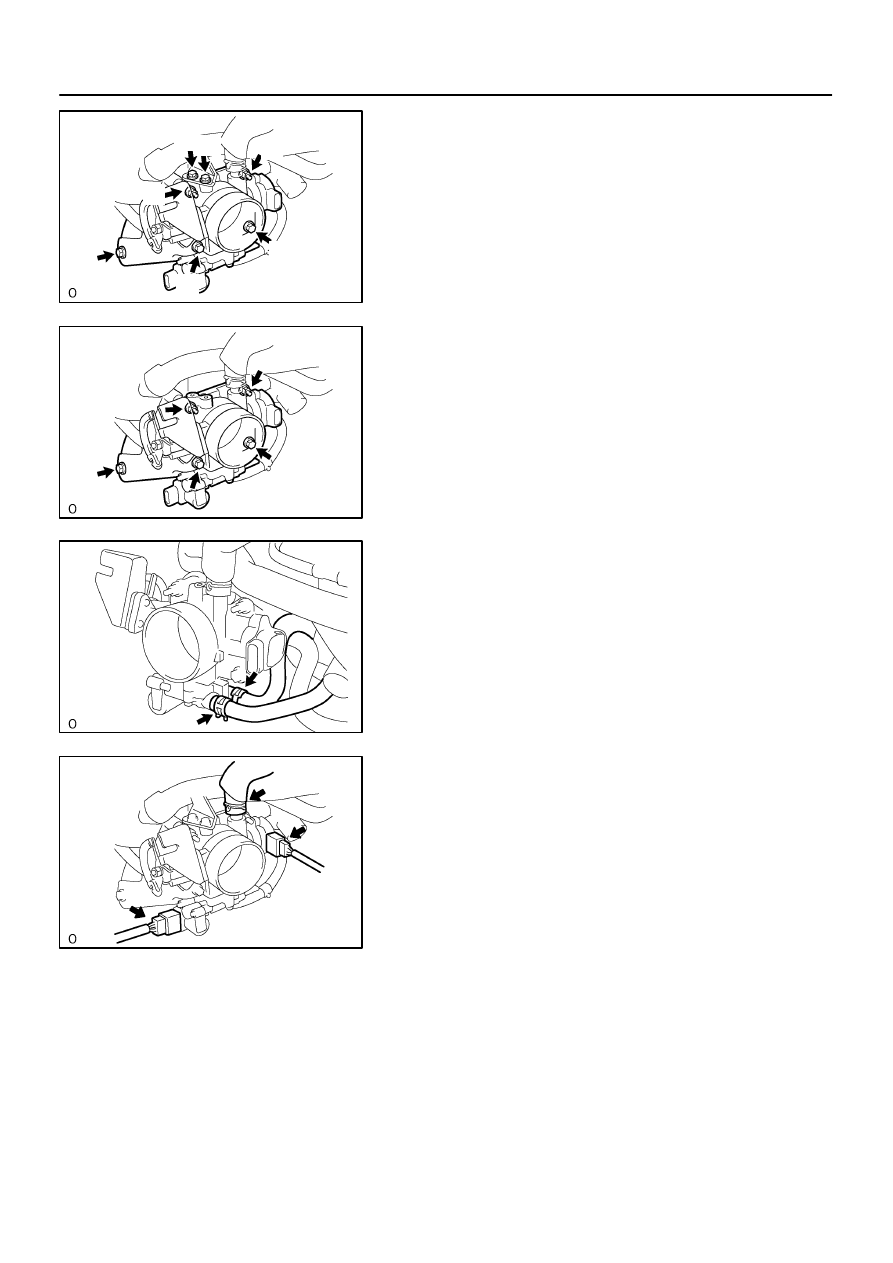

3.

REMOVE AIR CLEANER CAP SUB–ASSY

(a)

Disconnect the MAF connector.

(b)

Disconnect the VSV connector.

(c)

Disconnect 3 vacuum hoses, as shown in the illustration.

(d)

Loosen an air cleaner hose clump and disconnect an air

cleaner hose No. 1.

(e)

Remove the air cleaner cap.

4.

REMOVE AIR CLEANER HOSE NO.1

5.

SEPARATE ACCELERATOR CONTROL CABLE ASSY

6.

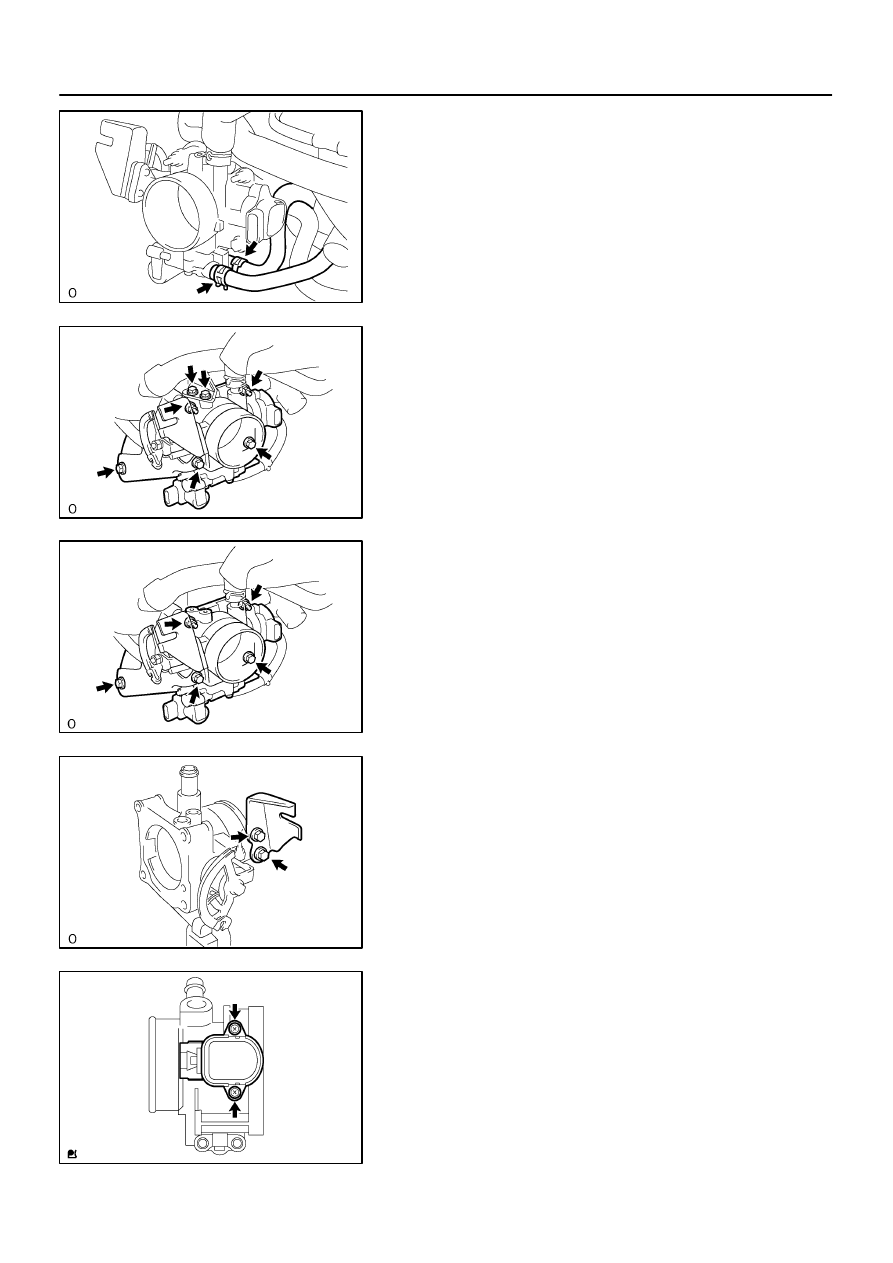

REMOVE THROTTLE BODY ASSY

(a)

Disconnect an throttle position sensor connector.

(b)

Disconnect a throttle body ISC valve assy connector.

(c)

Disconnect a PCV hose.

A65189

A65190

A66636

A65192

A65181

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

10–7

961

Author:

Date:

2004 COROLLA (RM1037U)

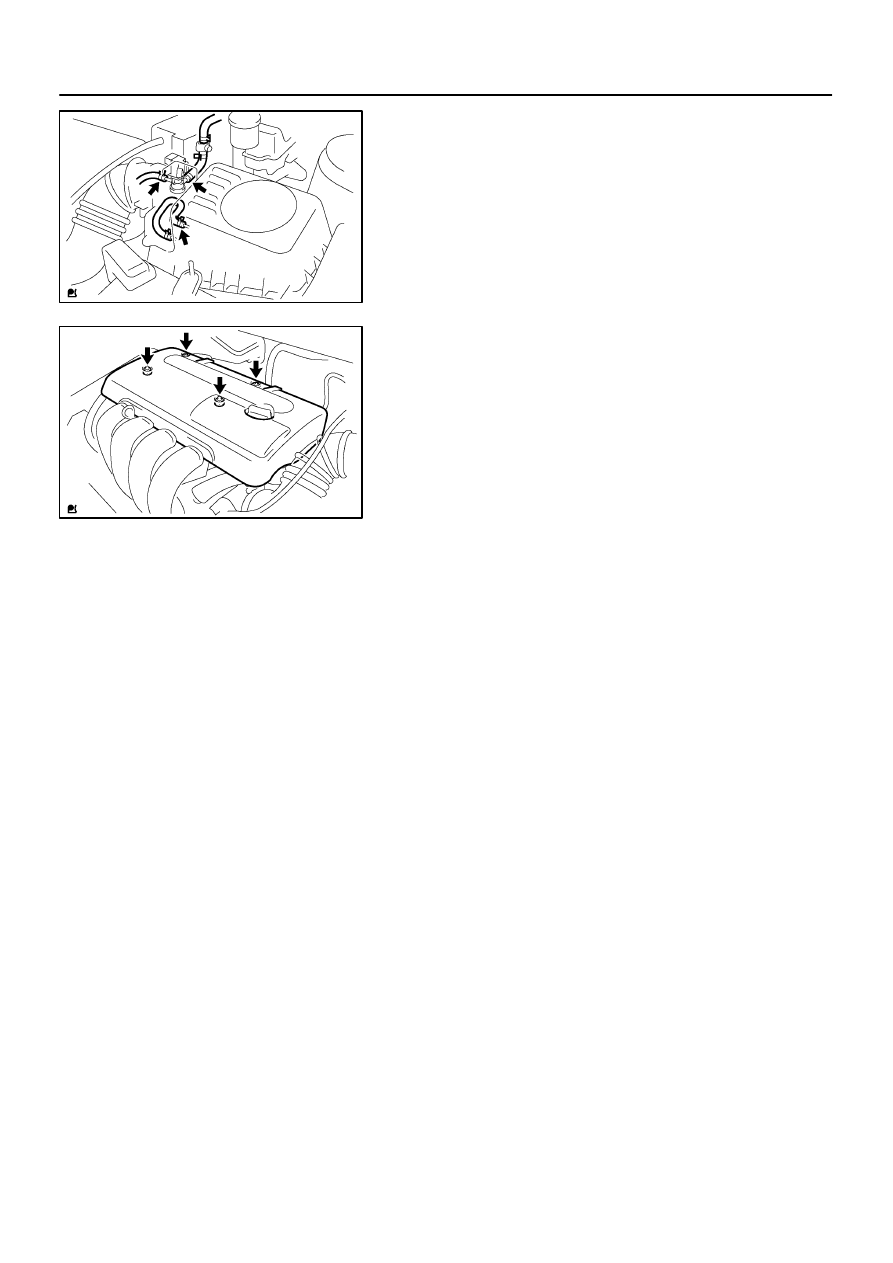

(d)

Disconnect 2 water by–pass hoses.

(e)

Remove 5 bolts, 2 nuts, throttle body bracket and throttle

body. (Transaxle M/T)

(f)

Remove 3bolts, 2nuts and throttle body. (Transaxle A/T)

(g)

Remove 2 bolts and accelerator cable bracket.

7.

REMOVE E.F.I. THROTTLE POSITION SENSOR

(a)

Remove 2 screws and the throttle position sensor as

shown in the illustration.

A65182

A65183

A65192

A65184

10–8

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

962

Author:

Date:

2004 COROLLA (RM1037U)

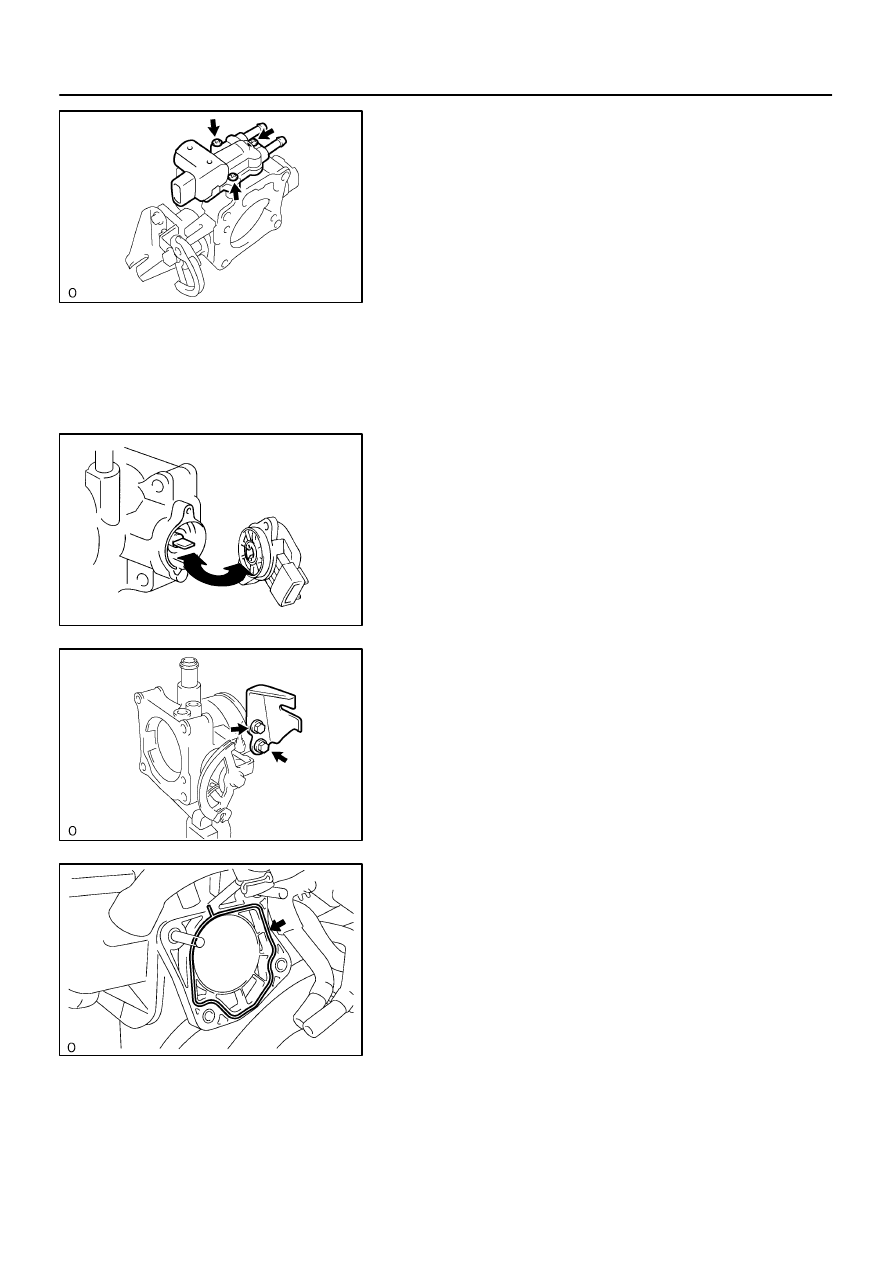

8.

REMOVE THLOTTLE BODY IDLE SPEED CONTROL

VALVE ASSY

(a)

Remove 3 screws and the idle speed control valve assy.

(b)

Remove the gasket from the throttle body.

9.

INSTALL THLOTTLE BODY IDLE SPEED CONTROL VALVE ASSY

(a)

Install a new gasket on the throttle body.

(b)

Install the idle speed control valve assy with 3 screws.

Torque: 3.7 N

⋅

m (38 kgf

⋅

cm, 33 in.

⋅

lbf)

10.

INSTALL E.F.I. THROTTLE POSITION SENSOR

(a)

Check that the throttle valve is fully close.

(b)

insert the throttle position sensor to the throttle body with

it turned counterclockwise by 30

to 90

against the fully

close valve position.

(c)

By turning the throttle position sensor clockwise, tighten

2 screws.

Torque: 2.0 N

⋅

m (20 kgf

⋅

cm, 18 in.

⋅

lbf)

11.

INSTALL THROTTLE BODY ASSY

(a)

Install the accelerator control bracket with 2 bolts.

Torque: 13 N

⋅

m (133 kgf

⋅

cm, 9.6 ft

⋅

lbf)

(b)

Install a new gasket on the intake manifold, as shown in

the illustration.

A65190

A

B B

A

A

A

A

A66636

A65189

A65188

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

10–9

963

Author:

Date:

2004 COROLLA (RM1037U)

(c)

Install the throttle body with 5 bolts and 2 nuts.(Transaxle

M/T)

Torque:

A 30 N

⋅

m (306 kgf

⋅

cm, 22 ft

⋅

lbf)

B 13 N

⋅

m (133 kgf

⋅

cm, 9.6 ft

⋅

lbf)

(d)

Install the throttle body with 3 bolts and 2 nuts.(Transaxle

A/T)

Torque: 30 N

⋅

m (306 kgf

⋅

cm, 22 ft

⋅

lbf)

(e)

Connect 2 water by–pass hoses to the throttle body.

(f)

Connect the PCV hose to the throttle body.

(g)

Connect the throttle body idle speed control valve assy

connector to the throttle body.

(h)

Connect the throttle position sensor connector to the

throttle body.

12.

INSTALL AIR CLEANER CAP SUB–ASSY

(a)

Install the air cleaner cap.

(b)

Connect the air cleaner hose.

A65177

A65077

10–10

–

ENGINE CONTROL SYSTEM

THROTTLE BODY ASSY

964

Author:

Date:

2004 COROLLA (RM1037U)

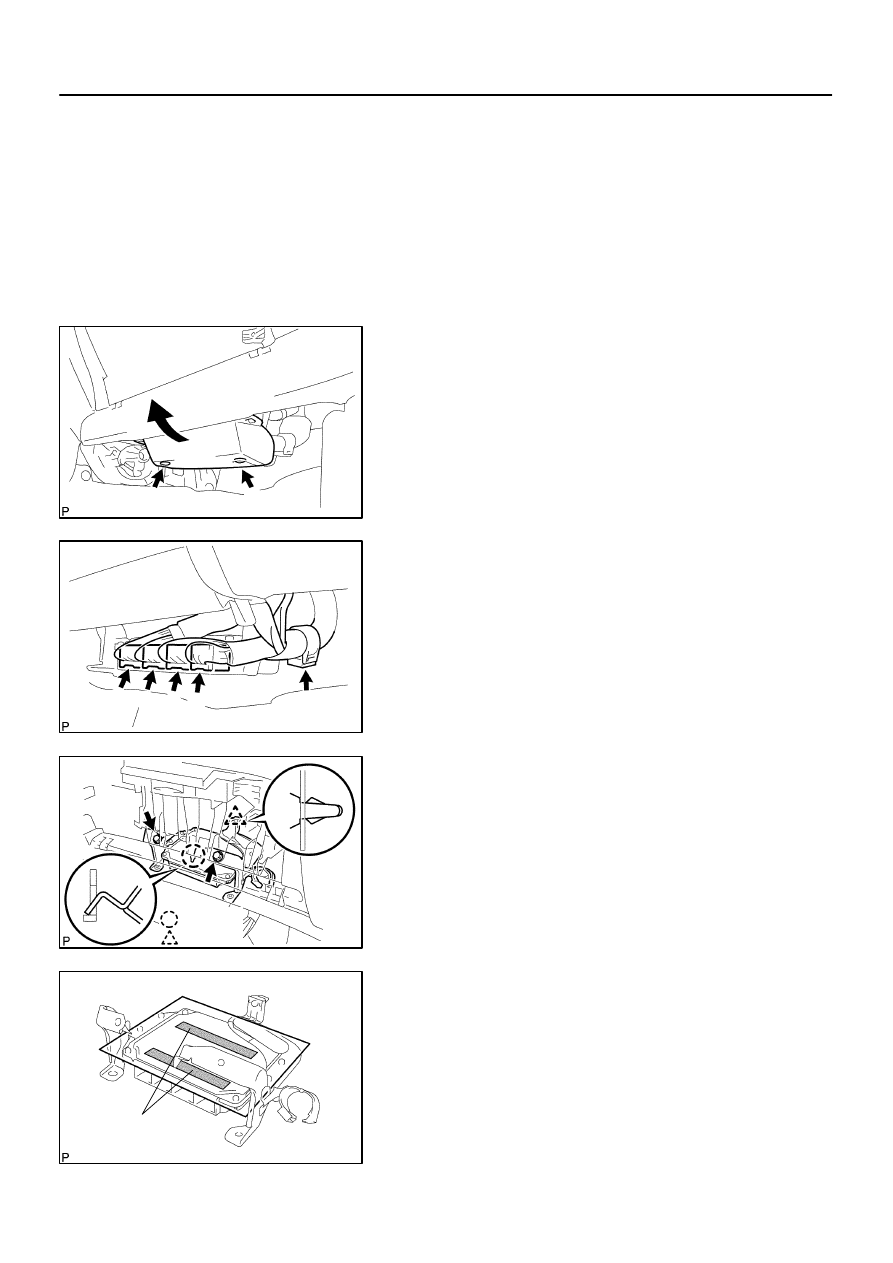

(c)

Connect 3 vacuum hoses, as shown in the illustration.

(d)

Connect the VSV connector.

(e)

Connect the intake air flow meter connector.

13.

INSTALL CYLINDER HEAD COVER NO.2

(a)

Install the cylinder head cover No. 2 with 2 nuts and 2

clips.

Torque: 7.0 N

⋅

m (71 kgf

⋅

cm, 62 in.

⋅

lbf)

14.

ADD COOLANT(See page

16–7

)

15.

CHECK ENGINE COOLANT LEAK(See page

16–1

)

100HN–02

A83791

(a)

(a)

A83792

(b) (b) (b) (b)

(c)

A83793

: Claw

: Clip

A83794

2 Double–sided

Adhesive Tapes

–

ENGINE CONTROL SYSTEM

ECM (1ZZ–FE) (April, 2003)

10–11

965

Author:

Date:

2004 COROLLA (RM1037U)

ECM (1ZZ–FE) (April, 2003)

REPLACEMENT

1.

DISCONNECT BATTERY NEGATIVE TERMINAL

2.

REMOVE GLOVE COMPARTMENT DOOR ASSY (See Page

71–10

)

3.

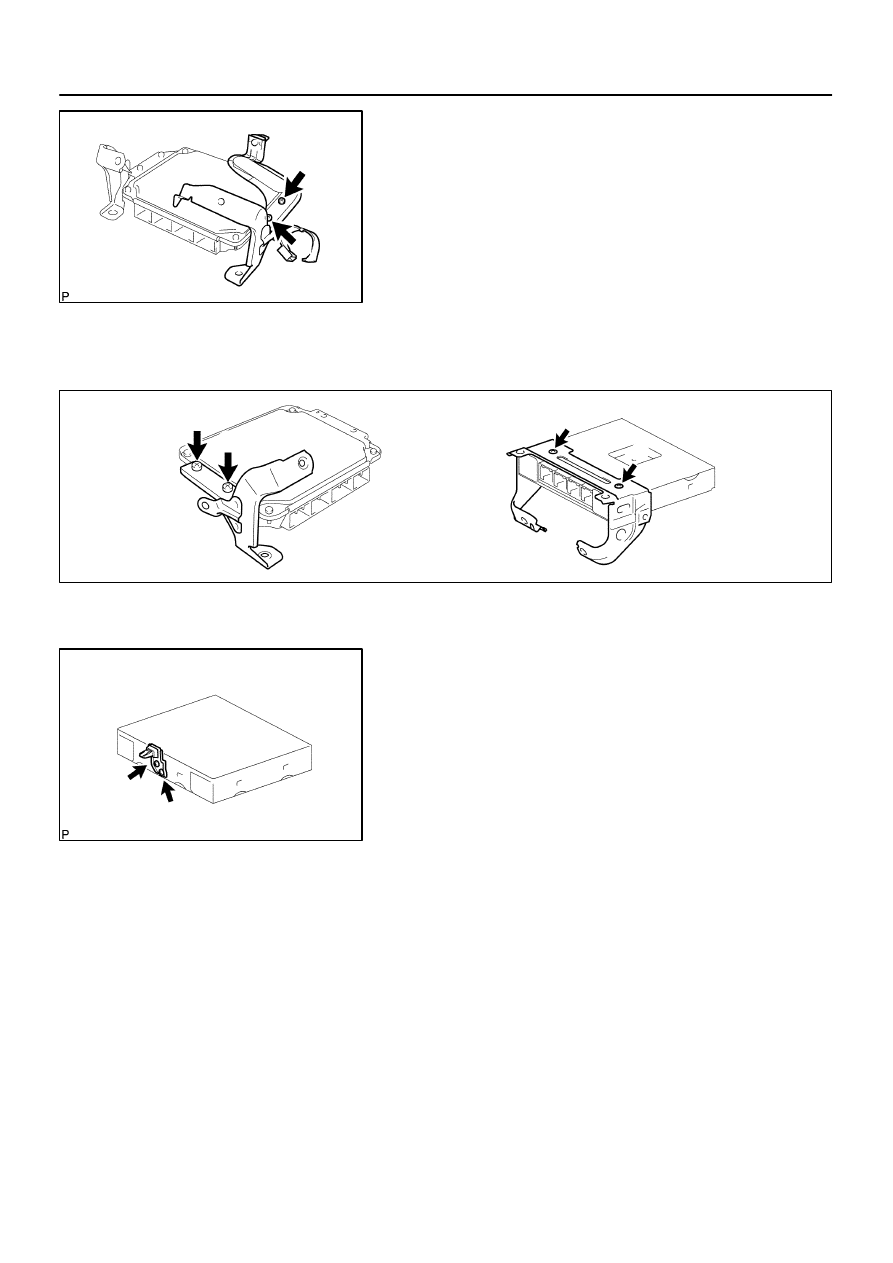

REMOVE ECM

(a)

Remove the 2 clips using a clip remover. Then, open the

cover.

(b)

Disconnect the 4 ECM connectors.

(c)

Remove the wire harness from the wire harness clamp.

(d)

Remove the 2 bolts.

(e)

Unfasten the claw and clip, then remove the ECM.

4.

REMOVE ECM COVER

(a)

Take the 2 double–sided adhesive tapes off the ECM,

then remove the ECM cover.

A83795

(a)

(a)

A84658

A83796

A84669

DELCO Made:

(a)

(a)

DENSO Made:

(a)

(a)

A84659

(a)

(a)

10–12

–

ENGINE CONTROL SYSTEM

ECM (1ZZ–FE) (April, 2003)

966

Author:

Date:

2004 COROLLA (RM1037U)

5.

REMOVE ECM BRACKET NO.2 (DENSO MADE)

(a)

Remove the 2 screws, then remove the ECM bracket No.

2.

6.

REMOVE ECM BRACKET NO.1

(a)

Remove the 2 screws, then remove the ECM bracket No.

1.

7.

REMOVE ECM BRACKET NO.3 (DELCO MADE)

(a)

Remove the 2 screws, then remove the ECM bracket No.

3.

8.

INSTALL ECM BRACKET NO.3 (DELCO MADE)

Torque: 3.2 N

⋅

m (33 kgf

⋅

cm, 28 in.

⋅

lbf)

9.

INSTALL ECM BRACKET NO.1

Torque: 3.2 N

⋅

m (33 kgf

⋅

cm, 28 in.

⋅

lbf)

10.

INSTALL ECM BRACKET NO.2 (DENSO MADE)

Torque: 3.2 N

⋅

m (33 kgf

⋅

cm, 28 in.

⋅

lbf)

A84660 A84664

A84670

DENSO Made:

4.5 mm (0.177 in.)

5 mm

(0.197 in.)

2 Double–sided

Adhesive Tapes

DELCO Made:

1 to 6.2 mm (0.039 to 0.244 in.)

2 Double–sided

Adhesive Tapes

0 to 2.5 mm

(0 to 0.098 in.)

–

ENGINE CONTROL SYSTEM

ECM (1ZZ–FE) (April, 2003)

10–13

967

Author:

Date:

2004 COROLLA (RM1037U)

11.

INSTALL ECM COVER

(a)

Install a new ECM cover to the ECM as shown in the il-

lustration.

12.

INSTALL ECM

Torque: 3.0 N

⋅

m (31 kgf

⋅

cm, 27 in.

⋅

lbf)

13.

INSTALL GLOVE COMPARTMENT DOOR ASSY

14.

CONNECT BATTERY NEGATIVE TERMINAL

Torque: 5.4 N

⋅

m (55 kgf

⋅

cm, 48 in.

⋅

lbf)

15.

RESET MEMORY (A/T TRANSAXLE)

CAUTION:

Perform the RESET MEMORY (AT initialization) when replacing the ECM, engine assembly or auto-

matic transaxle assembly.

(a)

The hand–held tester only.

(1)

Connect the hand–held tester to the DLC3.

(2)

Turn the ignition switch ON.

(3)

Perform the RESET MEMORY procedure from the ENGINE menu.

CAUTION:

After performing the RESET MEMORY, be sure to perform the ROAD TEST as described earlier.

Wyszukiwarka

Podobne podstrony:

10 Engine Control System

10 Engine Control System

10 Engine Control System

10 Engine Control System

10 Emission control system

ENGINE CONTROL SYSTEM

10 Emission control system

10 Emission control system

32 Audi A6 Cruise control system petrol engines

10 Reprezentacja liczb w systemie komputerowymid 11082 ppt

wyklad 2012 10 25 (Struktury systemów komputerowych)

Control System Toolbox

ver 10 rozkad urzadzenia i systemy wytw cnc

M31f1 Engine Controls 1 54

07 emission control system

Computer engine control

M31f4 Engine Controls 280 324

więcej podobnych podstron