Abstract We examined an improved preparation method

of recycled unsaturated polyester resin from recovered

monomeric materials obtained from the depolymerization

of fi ber-reinforced plastics (FRPs). The formation of unsat-

urated polyester progressed smoothly in the presence of

catalytic amounts of Ca(OAc)

2

and Ti(OBu)

4

. The quality

of the resin was estimated by the durometer hardness test.

The strength test of FRP board prepared from recycled

resin showed suffi cient hardness for practical use (about

94% of the tensile strength of new resin). We examined the

recycled resin by using it to mold successfully an actual test

product.

Key words Chemical recycling · Recycled resins · Hardness

test · Acid catalysts · Unsaturated polyester

Introduction

Waste fi ber-reinforced plastic (FRP) has been causing

serious environmental problems. Appropriate and conve-

nient disposal of waste FRP is very diffi cult due to its

mechanical strength and chemical stability. As a result,

most waste FRP is either incinerated or disposed off in

landfi lls. FRP is made from carbon sources that are primar-

ily derived from petroleum. Therefore, from the perspec-

tive of carbon source conservation, suitable recycling of

waste FRP is strongly desired. However, waste FRP con-

tains a thermosetting resin whose material recycling is not

easy. In addition, the glass fi bers present in FRP cause

serious problems in incinerators when being thermally

treated for energy recycling. Chemical recycling is a process

in which waste FRP yields monomeric materials that are

recycled as feedstock. This is regarded as the only proce-

dure likely to improve the prospect for proper recycling of

FRP.

There have been several reports on the chemical

recycling of FRP; most of them use the glass fi bers or part

of the resin.

Recently, we reported a novel solubilization

of waste FRP under supercritical methanol conditions in the

presence of 4-dimethylaminopyridine (DMAP). In this

process, the ingredients of FRP, i.e., monomer derivative,

linker, glass fi ber, and calcium carbonate, were separated

in a simple operation.

From the recovered monomeric

material and glass fi ber, the possibility of the formation

of recycled plastic was examined.

However, further

improvements in the formation of recycled resin are neces-

sary to make our method practical and widely applicable.

This article reports an improved formation of recycled resin

as well as on the mechanical strength of an FRP test product

prepared using this resin.

Experimental

Depolymerization of FRP and preparation of recycled

monomer derivatives were performed in a 30-l pilot plant

autoclave following the previously reported procedure.

The dimethyl phthalate contents were evaluated by Gas

Chromatography analysis.

Formation of new resins in the presence of Ti(OBu)

4

– a

typical procedure. Dimethyl phthalate (100 g, 0.51 mol)

and propylene glycol (82.3 g, 1.08 mol) were poured into a

1-l separable fl ask and Ca(OAc)

2

(0.647 g, 3.6 mmol) and

Ti(OBu)

4

(0.172 g, 0.51 mmol) were then added. The

mixture was heated at 210°C for 3 h, during which about

27 g of MeOH was distilled out from the mixture. Maleic

anhydride (55.6 g, 0.57 mol) was added to the hot mixture

and the resulting reaction mixture was heated at 220°C for

an additional 3 h. The mixture was then cooled for 2 h.

Styrene monomer (145 g) was added to the mixture and the

entire resin was poured into a plastic beaker (500 ml).

Radical initiator (organic peroxide) and accelerator (cobalt

J Mater Cycles Waste Manag (2010) 12:271–274

© Springer 2010

DOI 10.1007/s10163-010-0296-7

Kazuo Yamada · Fumiaki Tomonaga · Akio Kamimura

Improved preparation of recycled polymers in chemical recycling of fi ber-

reinforced plastics and molding of test product using recycled polymers

K. Yamada · A. Kamimura (*)

Department of Applied Molecular Bioscience, Graduate School of

Medicine, Yamaguchi University, Ube 755-8611, Japan

Tel.

+

81-836-85-9231; Fax

+

81-836-85-9201

e-mail: ak10@yamaguchi-u.ac.jp

K. Yamada · F. Tomonaga

Yamaguchi Prefectural Industrial Technology Institute, Ube, Japan

Received: October 12, 2009 / Accepted: March 16, 2010

ORIGINAL ARTICLE

272

naphthenate) were added to the mixture, which yielded an

unsaturated polyester polymer plate. The quality of the

resin was estimated by the durometer hardness of the cured

product.

Preparation of recycled resins on a larger scale – typical

procedure. Reagent grade dimethyl phthalate (1.70 kg,

8.75 mol) and propylene glycol (1.524 kg, 20 mol) were

mixed, and to the mixture, recovered dimethyl phthalate

(57% purity, 3.2 kg, 9.4 mol), Ti(OBu)

4

(1 g), and Ca(OAc)

2

(5.7 g) were added. The mixture was heated at 200°C to

remove MeOH (545

g). Maleic anhydride (1.957

kg,

20.0 mol) was then added to the hot mixture and heated at

200°C for several hours to remove MeOH and water. This

crude polyester was cooled and transferred to an appropriate

vessel. Styrene (5.12 kg) and radical initiator were added to

start the radical polymerization. After curing, 7.73 kg of

recycled unsaturated polyester resin was obtained.

Molding of FRP board

FRP board was molded using a hand lay-up molding

method. Six 450-g/m

3

glass fi ber strand mats were set into

a stainless mold (150 mm

×

160 mm

×

5 mm cavity) that was

coated with mold lubricant. These mats were then

impregnated with the resin. The mold was pressed by a

metal plate and allowed to stand at 35°C in a thermostatically

controlled oven.

Strength test of FRP

Test pieces of the molded FRP board were examined at

25°C and 55% humidity. Tensile and bending strength were

tested according to the Japanese Industrial Standards (JIS)

K7113 and K7013. Charpy impact tests were performed

according to JIS K7061 in the fl atwise direction. Barcol

hardness was examined by Type A of JIS K7060.

Results and discussion

Waste FRP was depolymerized under standard conditions

(Scheme 1). We avoided using DMAP as a catalyst to facili-

tate the later polymerization reactions using recovered

materials, as has been discussed previously.

When resin was synthesized from the recycled monomer

under standard conditions, there was a problem with insuf-

fi cient hardness after curing. We attributed this to an insuf-

fi cient progress of the ester exchange reaction during

polyester formation. In fact, the amounts of MeOH distilled

out during the conventional esterifi cation reaction were

estimated to be less than the calculated amounts. Since the

recovered material usually contains undesirable impurities

that may negatively affect the Lewis acidity of Ca(OAc)

2

,

the rate of the ester exchange reaction decreased. To

increase the reaction rate, a stronger Lewis acid seemed

appropriate. Titanium alkoxide is known as moderately

strong Lewis acid and its acidity can be considered to be

higher than that of Ca(OAc)

2

. We examined commercially

available Ti(OBu)

4

to be used as a co-catalyst for the reac-

tion. The reaction was optimized using freshly purchased

dimethyl phthalate for these experiments (Scheme 2). As

expected, when a mixture of Ti(OBu)

4

and Ca(OAc)

2

was

added to the reaction, the amounts of MeOH that were

distilled out increased and the formation of the polyester

was accelerated. The results are summarized in Table 1.

In Table 1, certain combinations of catalysts did not

improve the transesterifi cation. We marked such entries,

where less than 70% of MeOH distilled out during the reac-

tion, with an x. In contrast, resins were successfully formed

in those reactions where more than 70% of MeOH was

distilled out. The durometer hardness of these products is

summarized in Table 1. It should be noted that most of the

resins formed under these conditions were suffi ciently hard

and of good quality because their durometer hardness

values exceeded 80. Thus, the addition of Ti(OBu)

4

enabled

acceleration of the reaction and promoted better resin for-

mation. The best hardness was observed in the resin formed

when 0.72 mol% of Ca(OAc)

2

and 0.1 mol% of Ti(OBu)

4

FRP

flakes

supercritical MeOH

275 °C

MeOH-soluble oil

insoluble inorganic residue

+

Scheme 1. Depolymerization of waste fi ber-reinforced plastic (FRP)

CO

2

Me

CO

2

Me

OH

OH

+

Ca(OAc)

2

Ti(OBu)

4

O

O

O

+

styrene

radical initiator

unsaturated

polyester

Scheme 2. Optimization of the resin formation from dimethyl phthalate and glycol

Table 1. Durometer hardness of polymer

Ca(OAc)

2

(mol% vs DMP)

Ti(OBu)

4

(mol% vs DMP)

0.00

0.05

0.10

0.15

0.20

0.25

0

×

×

0.18

×

×

0.36

×

83

86

0.54

×

86

86

86

0.72

87

0.9

×

86

87

Durometer hardness (HDD) of cured product using new resin was 88

DMP, dimethyl phthlate;

×

, transesterifi cation was not improved

273

were used. We applied these conditions to the large-scale

preparation of recycled resin as the optimum reaction

conditions.

We next performed strength tests on recycled FRP pre-

pared from the recovered materials. The outline of the pro-

cedure is summarized in Scheme 3. Three types of FRPs

were formed by our method; the molding conditions used

are summarized in Table 2. Type A FRP was made with

new resin and was used as a control; types B and C were

recycled resins prepared from recovered materials. Type C

was made from 100% recycled material and type B was

made from an equal (50:50) blend of new and recovered

materials. We performed several tests with the three types

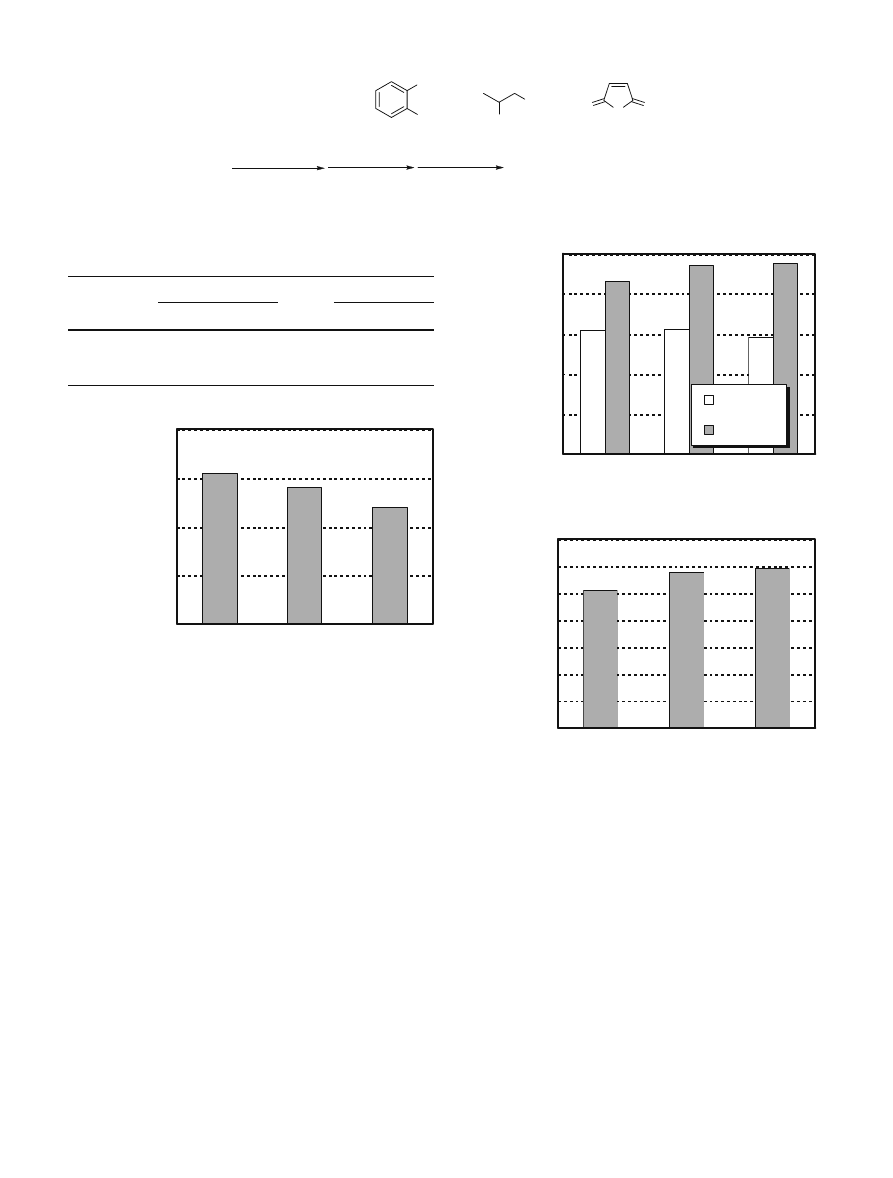

of FRPs and the results are shown in Figs. 1–3.

Figure 1 represents the results of the Barcol hardness

tests on the FRPs. As the contents of recovered materials

increased, the hardness decreased slightly. However, the

decrease in hardness was only about 2% and so this may

not be considered as a serious defect. The mechanical

strengths of the FRPs were then determined (Fig. 2). As

shown in Fig. 2, the tensile strengths were approximately

the same for both the new and recycled resins. It is interest-

ing to note that the bending strengths for the recycled resin

were slightly higher than those for the new resin.

Figure 3 represents the results for the Charpy impact test

on the resins. It was again observed that FRPs B and C

molded using recovered materials were stronger than the

newly formed FRP A. These unexpectedly superior quali-

ties of recycled FRP are probably due to their increased

softness as compared to the newly formed FRP. Thus, the

impurities in the recovered materials made the recycled

resins softer than the newly formed resins. This was due to

incomplete polymerization. The softness provided slightly

better results for the bending test and impact strength. In

the bending test, tensile stress occurs on the outside of the

bent section, and when transformation of the stretched

resin exceeds the limit, failure occurs. Since the soft resin

followed this transformation more closely, its bending

Recovered material

+

CO

2

Me

CO

2

Me

OH

OH

+

O

O

O

+

Ca(OAc)

2

Ti(OBu)

4

styrene

radical initiator

recycled FRP

glass fiber mat

Scheme 3. The formation of recycled FRP

Table 2. Conditions for the formation of recycled fi ber-reinforced

plastic (FRP)

TYPE

Resin used

Glass fi ber content

(wt% vs total amount)

(wt% vs FRP)

A

New resin 100

38

B

New 50

+

recycled 50

39

C

Recycled resin 100

39

40

42

44

46

48

A

B

C

Barcol hardness (HBI-A)

Fig. 1. Barcol hardness of recycled fi ber-reinforced plastic (FRP)

0

50

100

150

200

250

A

B

C

Tensile

Bending

Strength(MPa)

Fig. 2. Mechanical strength of recycled FRP

0

20

40

60

80

100

120

140

A

B

C

Charpy impact strength (kJ/m2)

Fig. 3. Charpy impact test on recycled FRP

274

strength became stronger. In the impact test, the resin trans-

formation in a larger area caused absorption of more

energy. Hence, the quality of the recycled FRP was deemed

satisfactory.

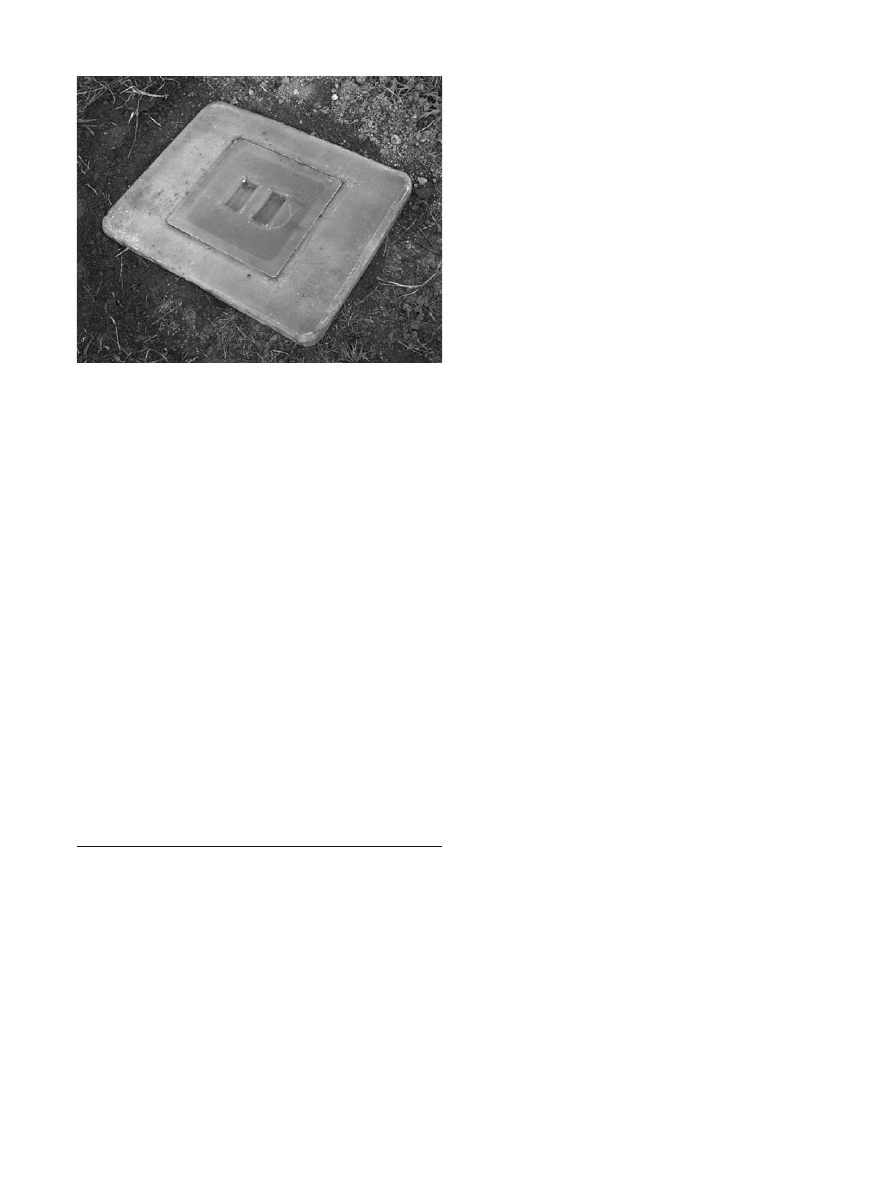

Finally, we performed resin production on a large scale

and used it to prepare a test product. We chose the lid of a

composter in which food garbage is recycled into compost

as the test product. A total of 20 wt% of recycled resin was

used for the production of the material. The production

went smoothly, and the test product was prepared success-

fully. Figure 4 shows the product. The test product exhib-

ited suffi cient strength and had no problems when an adult

(about 70 kg) stepped on the product. This product was

used in the fi eld for 8 months without any problems.

In conclusion, we developed an improved method for the

preparation of unsaturated polyester, with which we suc-

cessfully prepared recycled plastics on a large scale. Use of

Ti(OBu)

4

effectively catalyzed the resin formation and

shortened the reaction time. The obtained recycled plastic

was of better quality compared to new plastics. We con-

cluded that the successful formation of a recycled test

product will open a new avenue for chemical recycling of

FRP.

References

1. Research Association of Feedstock Recycling of Plastics, Japan

(ed) (2005) Technology for feedstock recycling of plastic wastes.

CMC, Tokyo

2. Nomaguchi K, Nakagawa T (2009) FRP recycling in EU, NA, and

the Pacifi c Rim area – challenging development in chemical recy-

cling by subcritical water process. Rev Automot Eng 30:3–10

3. Nomaguchi K, Shibata K (2008) FRP recycling. Promotion toward

commercialization of next-generation chemical recycling technol-

ogy (in Japanese). Purasuchikkusu Eji 54:73–75

4. Ohsawa I, Takahashi J, Uzawa K, Ashida T, Shibata K (2008) Re-

molding and the fl exural, compressive and interlaminar shear

evaluation of unidirectional-CF/epoxy using recycling carbon fi ber

(in Japanese). Kyoka Purasuchikkusu 54:285–291

5. Nakagawa T (2008) Chemical recycling of FRP using subcritical

water: enhanced and horizontal recycling of thermosetting resin

waste (in Japanese). Fain Kemikaru 37:14–24

6. Shibata K (2007) FRP recycling technology (in Japanese). Net-

towaku Porima 28:247–256

7. Nomaguchi K, Nakagawa T (2007) Latest trends in FRP recycling.

Proliferation of cement kiln processes, thriving development of

next-generation chemical recycling technology, and the challenges

of environmentally compatible design (in Japanese). Purasuchik-

kusu Eji 53:88–91

8. Sasaki M, Iwaya T, Goto M (2007) Subcritical fl uid fractionation

of fi ber-reinforced plastics and chemicals recovery (in Japanese).

Chorinkai Saishin Gijutsu 9:27–31

9. Shibata K (2006) FRP recycling using depolymerization of unsatu-

rated polyester under ordinary pressure (in Japanese). Fain Kemi-

karu 35:14–20

10. Nakagawa T, Urabe T, Hidaka M, Maekawa T, Okumoto S,

Yoshida H (2006) FRP recycling technology using subcritical water

hydrolysis (in Japanese). Nettowaku Porima 27:88–95

11. Yoshikai K, Sakamoto J (2004) Research on chemical recycling of

mannequins made of FRP using glycol decomposition (in Japa-

nese). Kyoka Purasuchikkusu 50:398–402

12. Shibata K (2003) Trend of chemical recycling of thermosets (in

Japanese). Nippon Setchaku Gakkaishi 39:226–230

13. Kubota S, Maeda T, Mori H (2003) Feedstock recycling of polyes-

ter resin wastes by decomposition with hydroxy carboxylic acid (in

Japanese). Nippon Setchaku Gakkaishi 39:240–247

14. Okajima I, Yamada K, Sugata T, Sako T (2002) Decomposition of

epoxy resin and recycling of CFRP with sub- and supercritical

water (in Japanese). Kougakukai Ronbunshu 28:553–558

15. Kamimura A, Yamada K, Kuratani T, Oishi Y, Watanabe T,

Yoshida T, Tomonaga F (2008) DMAP as an effective catalyst to

accelerate suffi cient solubilization of waste FRP: a new method for

recycling waste plastics. ChemSusChem 1:845–850

16. Kamimura A, Konno E, Yamamoto S, Watanabe T, Yamada K,

Tomonaga F (2009) Formation of recycled plastics from depoly-

merized monomers derived from waste fi ber reinforced plastics. J

Mater Cycles Waste Manag 11:38–41

17. Kamimura A, Konno E, Yamamoto S, Watanabe T, Yamada K,

Tomonaga F (2009) Improved method for the formation of recy-

cled resins from depolymerized products of waste fi ber-reinforced

plastics (FRP): simple and effective purifi cation of recovered

monomers by washing with water. J Mater Cycles Waste Manag

11:133–137

18. Kamimura A, Tomonaga F, Yamada K (2008) Novel chemical

recycling of waste FRP using supercritical alcohol and organocata-

lysts (in Japanese). Kagakukougyo 59:560–568

Fig. 4. Image of test product made using 20% recycled FRP

Wyszukiwarka

Podobne podstrony:

w3 recykling tworzyw sztucznych

w3 recykling tworzyw sztucznych

36 Zbiórki i recyklingu tworzyw sztucznych w rur odpadów budowlanych i rozbiórkowych strumienia

30 Recykling tworzyw sztucznych ognioodpornych z WEEE, problemów technicznych i środowiskowych

19 Recykling tworzyw sztucznych Wgląd metod oceny wpływu cyklu życia

24 Reakcje polimerów w nadkrytycznym płynów do chemicznego recyklingu odpadów z tworzyw sztucznych

C1 Recykling chemiczny PMMA, PET RECYKLING, Przetwórstwo tworzyw sztucznych

23 Recyklingu polimerów, materiałów opakowaniowych z tworzyw sztucznych, stosując technikę rozpuszcz

Recykling odpadowych tworzyw sztucznych

RECYKLING ODPADÓW SZTUCZNYCH

2013 03 26 W 7 TRM Przygotowanie obiektu i budowyid 28270 ppt

cygan,podstawy ochrony środowiska, recykling odpadów sztucznych

Recykling odpadów sztucznych. sprawko, Mechatronika, Recykling

Instrumenty pochodne (26 stron), Rynek instrumentów pochodnych w Polsce znajduje się dopiero w bardz

Fermentacja 1 kolo lepsze, uniwersytet warmińsko-mazurski, inżynieria chemiczna i procesowa, rok III

Podstawy procesu uplastyczniania., PET RECYKLING, Przetwórstwo tworzyw sztucznych

Tworzywa sztuczne i metale, Klub Miłośników Przyrody - kółko przyrodnicze klasa 1, Recykling, Inform

więcej podobnych podstron