Optimization of Intake System and Filter of an

Automobile using CFD analysis

Ravinder Yerram

and

Nagendra Prasad

Quality Engineering and Software Technologies (QuEST), Bangalore

Prakash Rao Malathkar

and

Vasudeo Halbe

Mahindra & Mahindra Ltd., Nashik

Shashidhara Murthy K

MNR Filters India Pvt. Ltd., Bangalore

1. ABSTRACT

Air intake system and filter play major role in getting

good quality air into automobile engine. It improves the

combustion efficiency and also reduces air pollution.

This paper focuses on optimizing the geometry of an

intake system in automobile industry to reduce the

pressure drop and enhance the filter utilization area.

3D viscous CFD analysis was carried out for an

existing model to understand the flow behavior through

the intake system, air filter geometry and filter media.

Results obtained from CFD analysis of the existing

model showed good correlation with experimental

data. Based on existing model CFD results,

geometrical changes like baffle placement in inlet

plenum of the filter, inclusion of bell mouth in outlet

plenum and dirty pipe , optimization of mesh size,

removal of contraction in clean pipe of intake system

etc are carried out, to improve the flow characteristics.

The CFD analysis of the optimized model was again

carried out and the results showed good improvement

in flow behavior, better filter utilization with

considerable reduction in pressure drop and significant

reduction in re-circulation zones of the air filter

geometry. By using 3D CFD analysis, optimal design

of the intake system for an automobile engine is

achieved with considerable reduction in development

time and cost.

2. INTRODUCTION

The work of an air filter is to filter the dirt particles from

the intake air and supply cleaner air to the automobile

engine. Air enters the filter through dirty pipe and inlet

side plenum, which guides the flow uniformly through

the filter media. Optimum utilization of filter can

significantly reduce the cost of filter replacements

frequently and keep the filter in use for longer time. To

optimize intake system and filter, thorough

understanding of flows and pressure drop through the

system is essential. Computational Fluid Dynamics

(CFD) is considered to be the most cost effective

solution for flow analysis of intake system along with

filter media. This paper focuses on the optimization of

the intake system and filter by CFD analysis results.

3. GEOMETRY MODEL

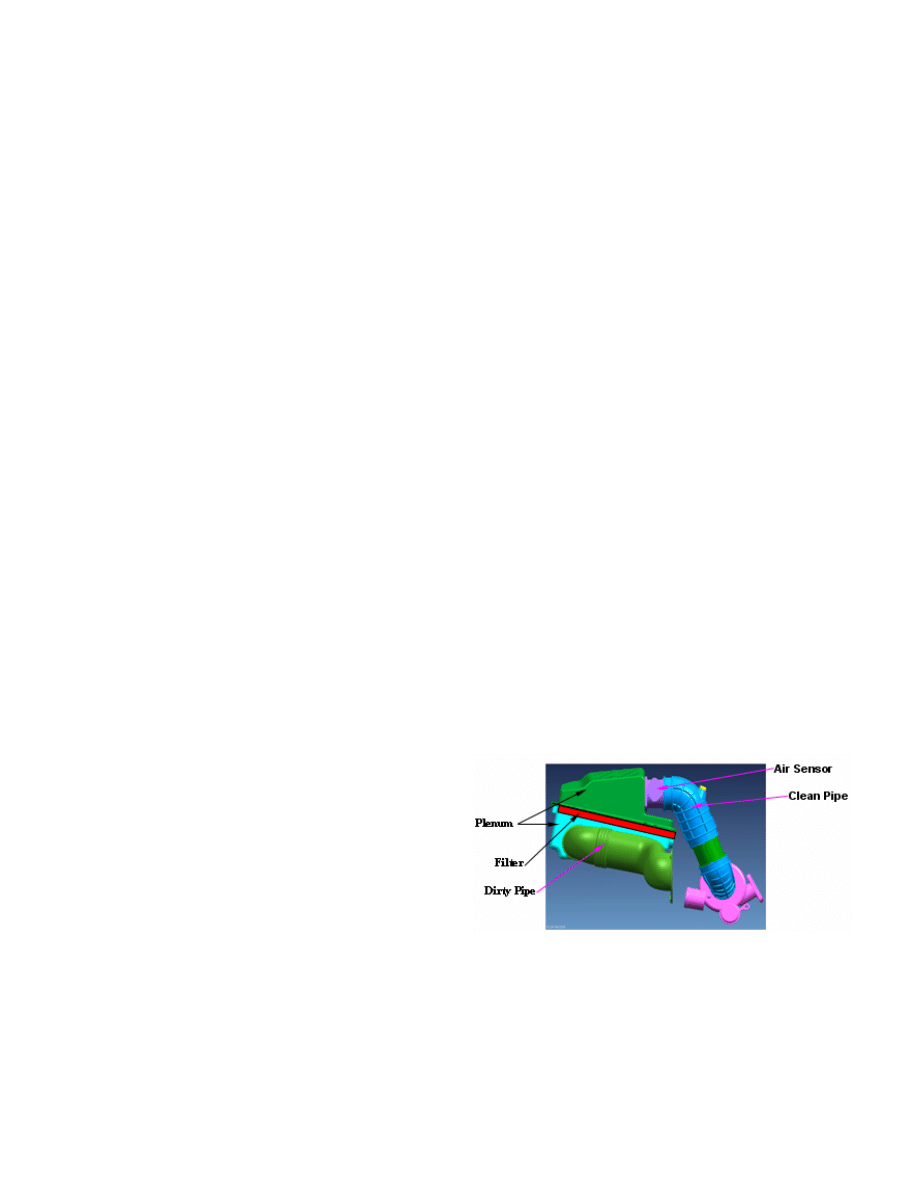

Figure (3.1) shows solid model of intake system and

filter. In order to save the CFD computational time and

cost, trivial geometric details that are unimportant from

fluid flow point of view, such as fillets, blends,

stiffeners and steps have been ignored. Ignoring all the

above-mentioned, so called a cleaned geometry was

obtained from solid model.

Figure (3.1): Intake system solid model

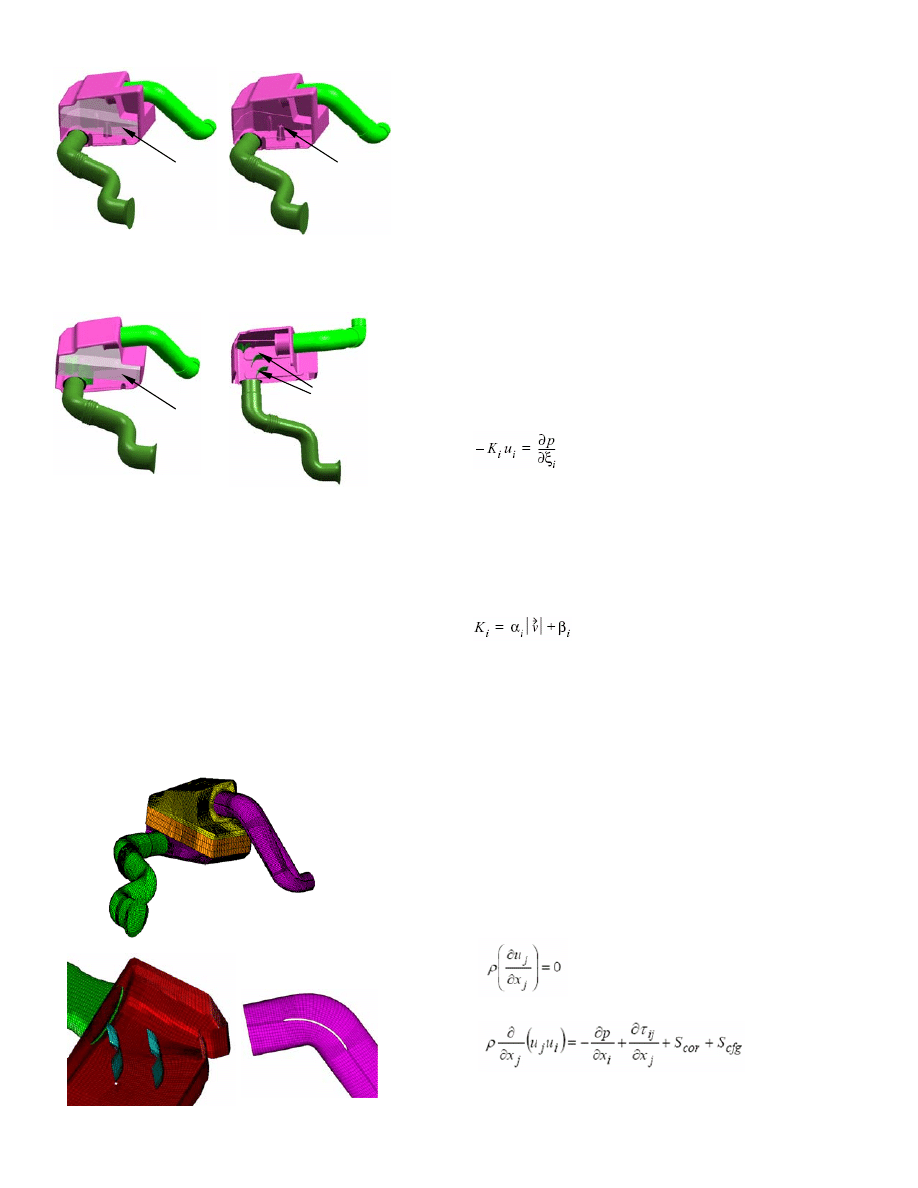

Figure (3.2) shows the fluid volume for the existing

intake system and filter and figure (3.3) shows the fluid

volume for the modified intake system with baffles.

where filter media is approximated to rectangular

volume and considered as porous media. For mesh

generation, all surfaces and curves were extracted

from the cleaned model.

Figure (3.2): Fluid volume of existing intake system

Figure (3.3): Fluid volume of modified intake system

4. CFD MESHING

To capture the three-dimensional flow inside the

domain with reasonable accuracy, one needs good

quality mesh. Multi-block structured hexagonal mesh

was considered to be the best for this case and was

created using commercial mesh generator (ICEM-

CFD). The model was approximately 0.55 million

hexagonal fluid elements. Boundary layer was

resolved for y+ of 40 to 200 to capture physics inside

the complicated regions. Figure (4.1) shows

hexahedral mesh of intake system fluid domain. Figure

(4.2) shows hexahedral mesh near baffles and clean

air pipe elbow.

Figure (4.1): Intake system hexahedral mesh

Figure (4.2): Hexahedral mesh near baffles and elbow

5. CFD MODEL DESCRIPTION

Air was used as fluid media, which was assumed to be

steady and incompressible. High Reynolds number k-

ε

turbulence model [2] was used in the CFD model. This

turbulence model is widely used in industrial

applications. The equations of mass and momentum

were solved using SIMPLE algorithm [1] to get velocity

and pressure in the fluid domain. The assumption of an

isotropic turbulence field used in this turbulence model

was valid for the current application. The near-wall cell

thickness was calculated to satisfy the logarithmic law of

the wall boundary. Other fluid properties were taken as

constants. Filter media of intake system and air sensor

were modeled as porous media using coefficients.

Support

Filter

For porous media, it is assumed that, within the

volume containing the distributed resistance [3], there

exists a local balance everywhere between pressure

and resistance forces such that

Baffles

Filter

(1)

Where

ξ

I

(i = 1, 2, 3) represents the (mutually

orthogonal) orthotropic directions.

K

i

is the permeability

u

i

is the superficial velocity in direction

ξ

i

The permeability K

i

is assumed to be a quasilinear

function of the superficial velocity magnitude of the

form

(2)

Where

α

i

and

β

i

are user-defined coefficients [4].

Superficial velocity at any cross section through the

porous medium is defined as the volume flow rate

divided by the total cross sectional area (i.e. area

occupied by both fluid and solid). In this analysis,

α

i

and

β

i

are assumed to be same.

6. GOVERNING EQUATIONS

Commercial CFD solver Star-CD was used for this

study. It is a finite volume approach based solver

which is widely used in the industries. Governing

equations solved by the software for this study in

tensor Cartesian form are following:

Continuity:

(3)

Momentum:

(4)

Where ρ is density, u

j

is jth Cartesian velocity, p is

static pressure,

τ

ij

is viscous stress tensor.

7. BOUNDARY CONDITIONS

Various boundary conditions for the different

components applied to this study were as follows:

For inlet, the mass flow rate was imposed using the

fixed mass inlet boundary condition. The value of

density (1 kg/m

3

), total pressure (1 atm) and

turbulence intensity (5%) were specified at the inlet

boundary. For outlet, outflow boundary condition was

imposed with flow rate weighting of 1. No slip

boundary condition was applied on all wall surfaces.

For main filter media, porous media boundary was

imposed with

α

i

=

β

I

= 3000. For air sensor, porous

media boundary was imposed with

α

i

=

β

I

= 290.

Whole domain was considered at 1 atm and at 298 K

as initial condition.

8. RESULTS AND DISCUSSION

To

have effective cleaning of air from filter, it was

suggested to have uniform velocity of air pass through

filter.

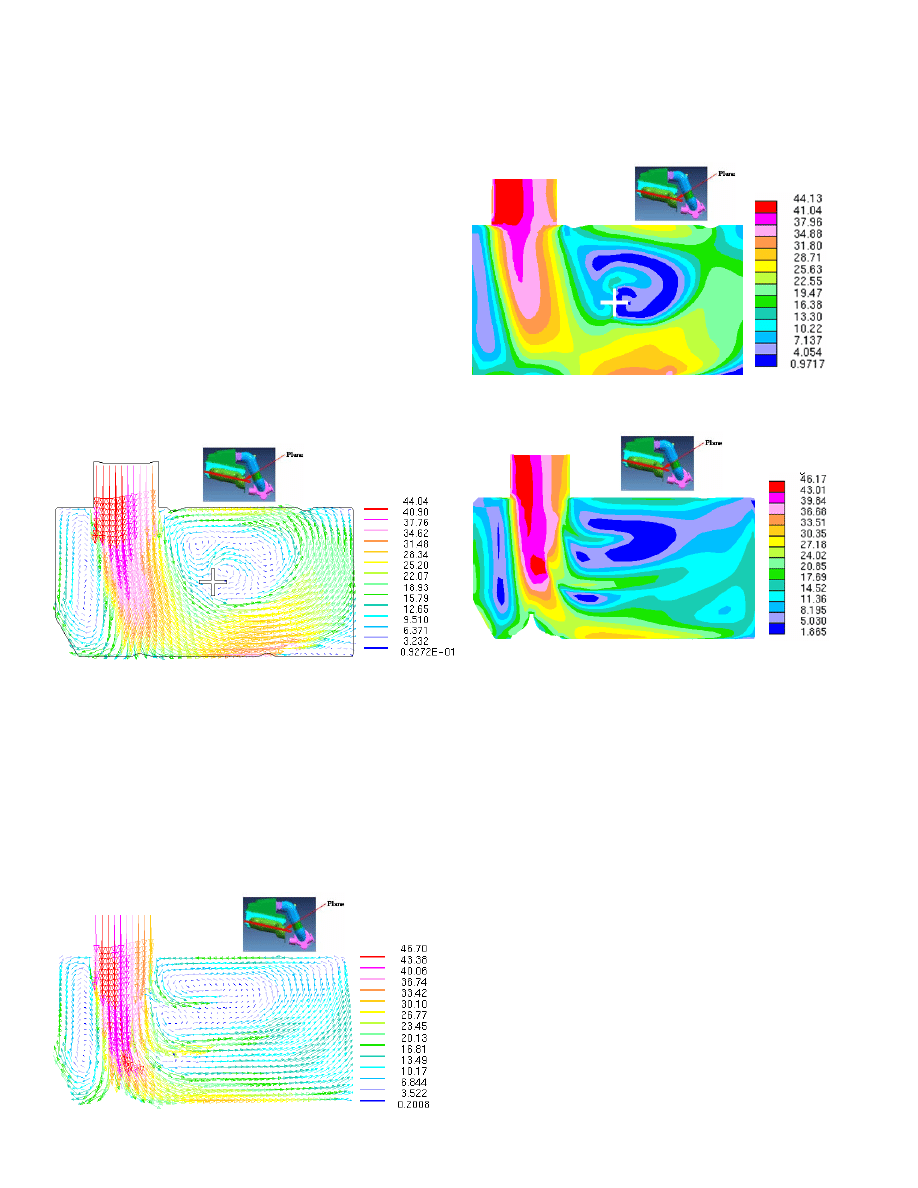

Figure (8.1-a): Velocity vector (m/s) plot for the existing model

Figure (8.1-a) shows two recirculation zones right

below the filter needed to be considered for

optimization as the recirculation in flow field causes

energy dissipation. In order to avoid the recirculation,

introducing the baffle was suggested which would

guide the flow to avoid recirculation.

After the baffle was introduced in the existing model,

CFD analysis was again carried out to decide the

location and effect of baffle. Velocity vector plot of

modified model in figure (8.1-b) below gives a clear

picture of less recirculating flow field.

Figure (8.1-b): Velocity vector (m/s) plot for the modified model

It is worth to mention that introducing baffle in the inlet

plenum below the filter has enhanced the efficiency by

guiding the flow and reducing the pressure drop

significantly that was present earlier.

Figure (8.2-a): Velocity magnitude (m/s) contour plot for the existing

model

Figure (8.2-b): Velocity magnitude (m/s) contour plot for the existing

model

Figure (8.2-a) and figure (8.2-b) show the velocity

magnitude contour plot in the critical region in the flow

domain.

In the figure (8.2-b) it can be seen the effect of baffle

as the flow is relaxed and better flow distribution.

Near outlet plenum exit, flow was separating and

recirculating at both the ends. This phenomenon can

be seen figure (8.3-a). To avoid separation and

recirculation in this region, a bell-mouth was

introduced. This can be clearly seen in figure (8.3-b) of

velocity vectors.

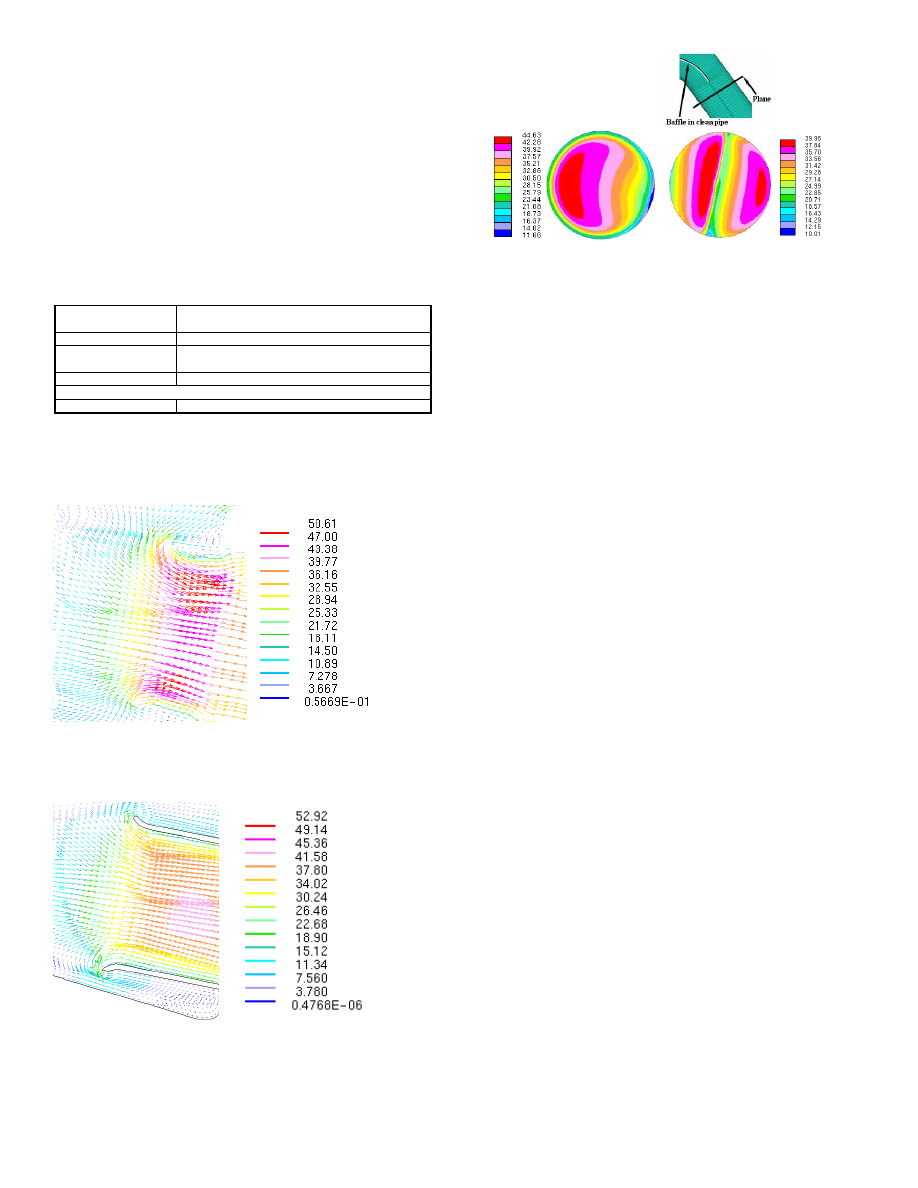

Figure (8.4) shows a separation zone at one side after

the first bend of clean pipe. And more concentrated

velocity magnitude contours were seen at the other

end which is typical phenomenon that can be seen in

bends. To overcome such phenomenon of separation,

a baffle was introduced that guides the flow and make

the flow uniform. This will possibly improve engine

performance.

Table (8.1) presents percentage improvement in total

pressure drop (reduction) in the intake system with

various design modifications. By changing mesh type

(simplified rectangular grid) near entry to intake system

and bell-mouth in dirty pipe inlet, pressure drop

improved by 33%.

By placement of baffles in inlet plenum before filter

media the performance has improved by 28% that is

significant in intake system. Bell-mouth and baffle

inside the clean pipe improved the flow and pressure

drop by 6.5%.

Table (8.1): Percentage Improvements in total pressure drop

(reduction) in various regions

Figure (8.3-a): Velocity vectors plot near outlet plenum

before modification

Figure (8.3-b): Velocity vectors plot near outlet plenum

after introducing bell-mouth

a. Without baffle

b. With baffle

Figure (8.4): Velocity magnitude contours after clean pipe baffle

9. CONCLUSION

Percentage improvement (reduction) in Total

Pressure drop with baffles and other modifications

CFD analysis was done using commercial CFD solver

Star-CD to understand the flow phenomenon in an

intake system. CFD results of the existing intake

system had shown recirculation and separation zones

before and after the filter media. Following design

modifications were considered to improve the flow and

pressure drop through the intake system

• Changing of mesh type (simplified rectangular

grid) in dirty pipe.

• Introduction of bell-mouth in dirty and clean pipe

• Introduction of baffles inside inlet plenum just

below filter media.

• Introduction of baffle in clean pipe bend

All the above changes incorporated in the design

improved overall pressure drop by 22%.

10. ACKNOWLEDGMENTS

The authors would like to sincerely thank Mr. Mihir

Desai and Mr. Veerabathra Swamy for their support in

CFD analysis in this project.

11. REFERENCES

(1) Patankar, S.V. 1980, “Numerical Heat Transfer and

Fluid Flow”, Hemisphere, Washington, D.C.

(2) Launder, B.E., and Spalding, D.B. 1974, “The

Numerical Computation of Turbulent Flows”, Comp.

Meth. in Appl. Mech. and Eng., 3, pp. 269-289.

(3) STAR-CD Methodology

(4) MNR Filters India Pvt. Ltd., experimental resources

12. CONTACT

Ravinder Yerram

Senior Technical Leader, CFD Team

Quality Engineering & Software Technologies (QuEST)

#55 QuEST Towers, Whitefield Main Road,

Mahadevapura, Bangalore-560 048

Tel: +91-80-41190909 Extn. 313

Fax: (91) 80-41190901

Dirty pipe with mesh

33

take System, Filter

d Air Sensor

28

ean Pipe

6.5

hrough out the domain

22

In

an

Cl

T

Wyszukiwarka

Podobne podstrony:

Optimization of headspace sampling using SPME for volatile c

A systematic review and meta analysis of the effect of an ankle foot orthosis on gait biomechanics a

21 269 287 Effect of Niobium and Vanadium as an Alloying Elements in Tool Steels

Summary of an artice 'What is meant by style and stylistics'

[Mises org]Hayek,Friedrich A A Free Market Monetary System And Pretense of Knowledge(1)

Design and performance optimization of GPU 3 Stirling engines

Munster Application of an acoustic enhancement system for outdoor venues

Multi objective thermodynamic optimization of combined Brayton and inverse Brayton cycles using gene

54 Shooting and Finishing Progression 3 – A Variety of An

Identification and fault diagnosis of a simulated model of an industrial gas turbine I6C

The Problem Of Order In Society, And The Program Of An Analytical Sociology Talcott Parsons,

Dr Gary L Glum Calling Of An Angel The True Story Of Rene Caisse And An Indian Herbal Medicine Cal

A dynamic model for solid oxide fuel cell system and analyzing of its performance for direct current

Optimization of Extraction Conditions and Fiber Selection fo

A Free Market Monetary System and The Pretense of Knowledge

The story of an hour summary and analisisdocx

więcej podobnych podstron