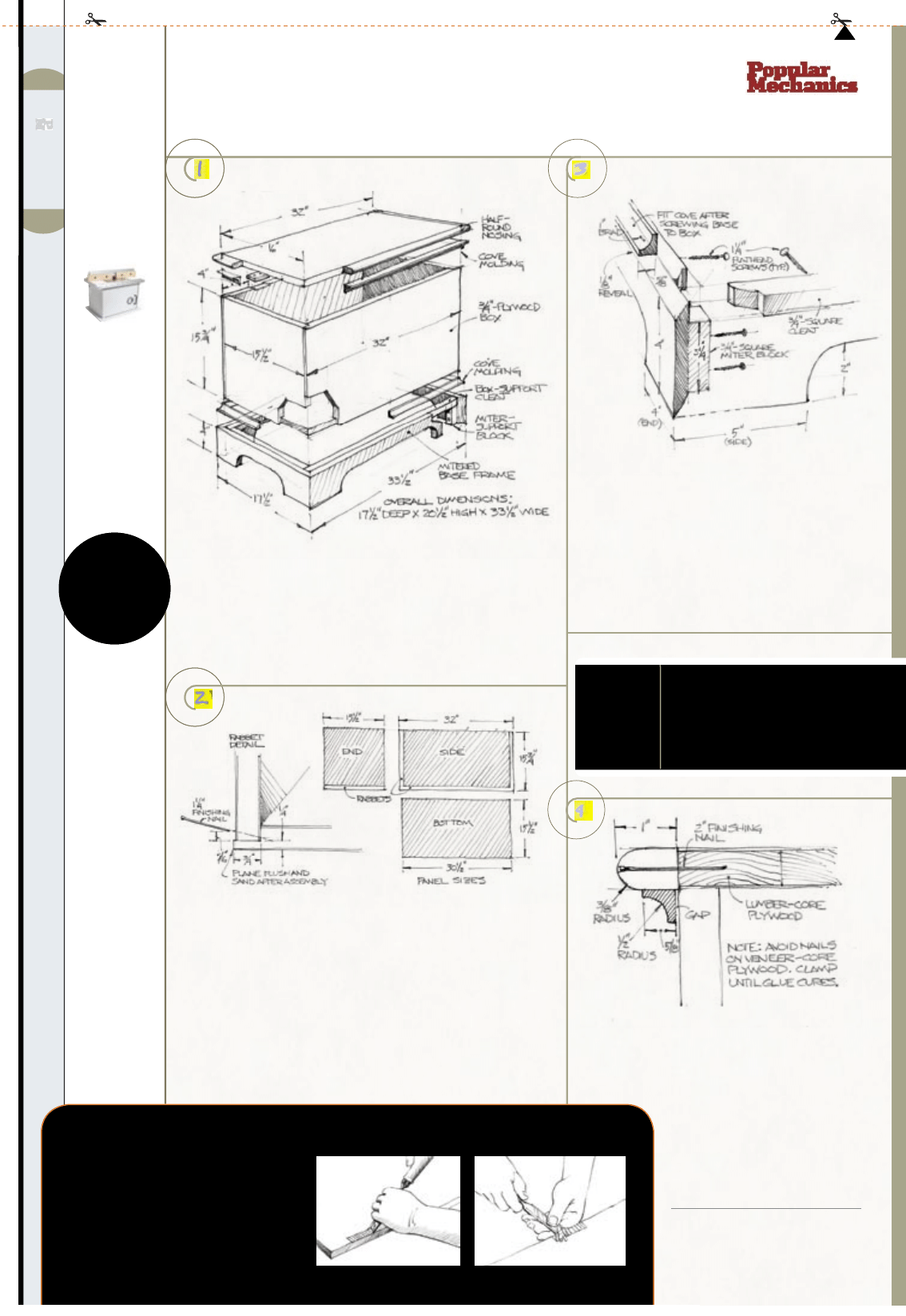

Miter the 4-in.-wide pine base frame pieces to length so

the inside dimensions of the assembled frame match

the outside box dimensions. Use a jigsaw to cut the leg

profiles. Before assembling the frame, glue and screw

miter blocks to the pieces to support the miter joints

and make assembly easier. Then, assemble the frame

and glue and nail the miters. Glue and screw support

cleats to the inside of the frame. When the glue is

dry, place the base on the inverted box, make sure it’s

centered and secure the box with screws. Attach the

cove molding with 1-in. brads, set all nails and fill.

The chest is made in three parts: the box, the stand and the lid. If you can’t

find lumber-core plywood (your dealer may be able to order it) you can

use veneer-core. But, edge-band the top edges of the sides and ends, and

the back edge of the top, with

3

⁄

4

-in.-square pine. We also used pine for the

moldings and cut the shapes on the router table.

Cut the top panel just larger than the box dimensions and

joint the edges to exact size. We glued the pine nosing

to the front and side edges of the panel and used 2-in.

finishing nails for clamps. Let the nosing extend past

the rear edge—you can cut it flush later. If you’re using

veneer-core plywood, avoid the nails since they’re likely to

split the veneers apart. Take great care

to align the nosing so it’s flush or just

slightly proud of the plywood surface.

The veneer is extremely thin—forget

about planing it down to match the

nosing. To install the cove, lay the box

upside down on the inverted top and

use thin cardboard spacers to maintain

a uniform gap around the box.

Quick

Tip

Wet glue is slippery. To keep things

in place while nailing, dry position

the parts and drive the nails so

they just poke into the adjacent

piece. Then, spread glue and use

the points to align the joint.

P L E A S E C U T H E R E

C

la

s

s

ic

s

S

K

E

T

C

H

B

O

O

K

B

Y

T

H

O

M

A

S

K

L

E

N

C

K

BLANKET CHEST

We assembled the sides and ends first, then cut the bottom to fit. Cut the

side and end panels slightly longer than necessary and just a shade over in

width. Joint the ripped edges so they’re straight, smooth and parallel. Then,

crosscut the pieces squarely to exact length. The squareness of the box

depends on like pieces being exactly the same length, so take care when

crosscutting.

Rout the rabbets in a series of steps to reach the finished

3

⁄

4

-in. depth.

This is not only easier on the router, it means you can use a

1

⁄

2

- or

5

⁄

8

-in. bit

for the job. Note that

3

⁄

4

-in. plywood is really

23

⁄

32

in. thick. This will leave a

1

⁄

32

-in. overhang in the assembled joint that you can trim flush.

Spread glue in each joint and secure with 1

1

⁄

4

-in. finishing nails. Angle

the nails slightly to draw the joint tight and drive them nearly flush so your

hammer doesn’t strike and mar the wood. When the glue is dry, set the

nails below the surface and fill with wood filler.

TABLE SAW:

You could use a

portable circular

saw, but a table

saw will do a

better job of

making straight,

parallel cuts.

ROUTER

TABLE:

This

tool not only

serves to cut

the moldings,

but it handles

the rabbets in

the side and end

panels. Plus,

you can use it to

joint the edges

of your stock so

they’re straight

and smooth. To

do this, install a

straight bit and

set the fence

to take about

a

1

⁄

16

-in. cut.

Then, shim the

outfeed side of

the fence the

same amount so

it supports the

stock after it’s

trimmed.

Tools &

Hardware

YOU’LL ALSO

USE:

Portable drill

and bits

Jigsaw

Block plane

Orbital sander

Hammer and

nailset

5

⁄

8

-in. straight bit

1

⁄

2

-in. cove bit

3

⁄

8

-in. half-round

bit

HARDWARE:

We used 70 x

40mm solid

brass hinges

(No. 01D7040),

available from

Lee Valley (www

.leevalley.com;

800-871-8158).

To support the

lid, we installed

left and right

friction lid stays,

also available

from Lee Valley

(Nos. 00T0750

and 00T0760).

PAINT:

Soldier

Blue milk paint,

(No. 811153),

available from

Woodcraft (www

.woodcraft.com;

800-225-1153).

Correction: In our picnic table project

(August ’05), a problem in the final stage of

production caused the lettering to become mis-

aligned in two drawings. You’ll find the corrected

drawings at www.popularmechanics.com.

The hinge leaves are

1

⁄

16

in. thick. To set each

one flush, first scribe the outline of the leaf

with a knife and use a marking gauge to lay

out the mortise depth. Make vertical cuts just

shy of the knife lines with a sharp chisel. Then,

angle the chisel and make a series of cuts that

reach the mortise depth (near right). Pare

the material away (far right) and finish the

mortise by cutting up to the scribed lines.

C U T T I N G T H E H I N G E M O R T I S E S

Wyszukiwarka

Podobne podstrony:

Chest Pine Blanket Chest

Chest shaker blanket chest

Blanket chest id 89967 Nieznany

Blanket chest

Chest Early American Blanket Chest

paneled blanket chest

Chest blanket

Glottodydaktyka, Traditionelle und alternative Unterrichtsmethoden

Łojek Magdziarz Is Jihad a Living Tradition in Islam

Pius VIII Traditi

Illuminati NWO Blank?rdlist

chest i dolg vmeste s rossiej 3

Pressure Points Chest

Jo Walton Tradition

Little Yoda Baby Blanket

Document Chest

TRADITION synonimy

więcej podobnych podstron