HOW TO:

INSTALL A HOT WATER TANK

INTRODUCTION

If you are constantly running out of hot water, a new hot-water cylinder can

give you a faster heat-up time and increased capacity.

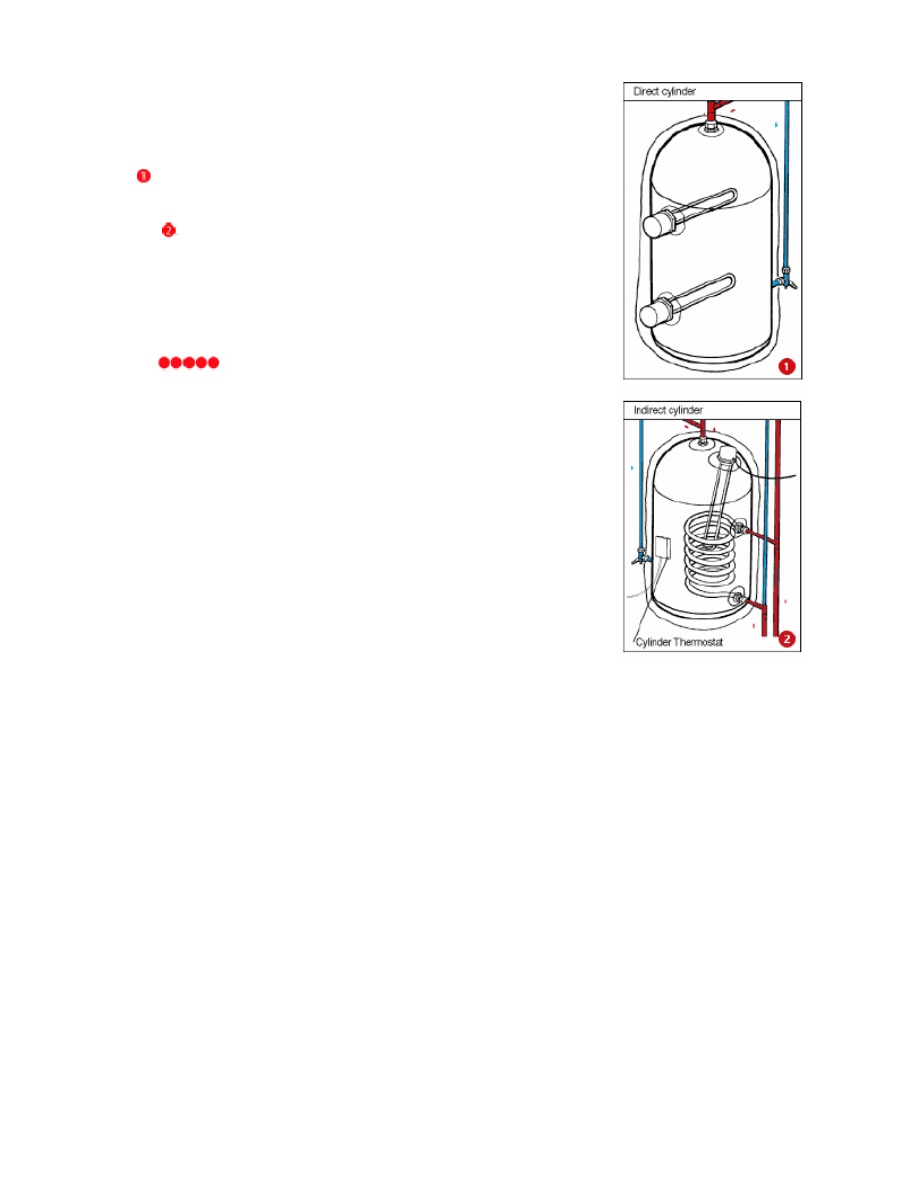

A direct cylinder with an immersion heater has just two connections so it

should be very easy to fit.

An indirect cylinder,

which has a coil inside for transferring heat from the

boiler, is a bit more involved because you need to drain down the boiler and

heating circuit.

If you have an older-style gravity primary hot-water circuit, you might also

want to change over to a more efficient pumped system.

SKILL LEVEL

Plumbing skills are required and electrical knowledge would be useful.

SAFETY FIRST

Turn off the hot water a few hours before you begin draining down. This will

prevent you being scalded if a hose slips off. Isolate electrics before

disconnecting the immersion heater. Get help carrying the cylinder, especially

on stairs.

TO COMPLETE THIS PROJECT

YOU WILL NEED...

• Adjustable

• Plumber’s Wrenches

• Blow Lamp

• Compression Fitting (28mm or 22mm)

• Copper Angled Connector

• Copper Tube (22m or 28mm)

• Cylinder

• Cylinder Unions

• Immersion Heater/Blanking • Plate

• Immersion-Heater Spanner

• Male Iron Thread (1in)

• Pipe Cutters

1 - CHOOSING A CYLINDER

New hot-water cylinders have factory-fitted foam insulation which helps

keep the water hotter for longer. A quick-recovery cylinder can also increase

the efficiency of your boiler by transferring heat faster. In a family home with

heavy demands on the hot water, it is worth fitting a larger cylinder. This can

usually be achieved with minimal changes to the pipework.

A hot-water cylinder can be heated by a boiler or with an electric immersion

heater. It is even possible to run them both at once if you want a really

quick heat-up time but most people keep the electric immersion heater for a

backup in case the boiler breaks down or for heating water in summer.

There are also Economy 7 cylinders for use with off peak electricity. These

have two immersion heaters; one in the top and one in the bottom. The top

heater is wired up to standard rate electricity to give you a daytime top up.

The lower heater is wired to the white meter supply for night-time heating of

the whole cylinder.

2 - PREVENTING FREEZING OF VENT PIPES

A very serious explosion can occur if the feed and vent pipes freeze in the

loft while the cylinder is heating up. It is essential to insulate the pipes very

well and make sure they are within the heated area of the house for as

much of their route as possible.

3 - DRAINING

To remove an existing cylinder you need to drain it down. Even when the

water is turned off and no hot water is coming from the taps there is still a

full cylinder of hot water which needs to be emptied from the bottom.

Turn off the cold supply to the hot-water cylinder and any heating appliance,

including the immersion heater. Turn off the heating and hot-water system

by switching off the boiler control's electricity supply. You should find a valve

on the supply pipe from the cold-water storage tank(s) to turn off. Check the

hot taps aren't running. If they are letting any water through, you will have to

turn off the mains water supply to the tank and then drain the cold-water

tank. This will cut off the water supply to the cylinder.

The water supply may be off for some time, so ensure there is plenty of

water available for drinking and cleaning by filling kettles and saucepans.

Push a hose pipe on the drain spigot, usually found where the cold supply

enters the bottom of the cylinder. Secure the hose with a clip or wire, run

the hose pipe to a lower point outside and open the small square nut on the

drain cock. You should hear water begin to run. You might have a few

dribbles of water around the nut but if the water runs quickly through the

hose it will suck in air rather than leak.

If the drain off point won't work, it is probably because the washer has

baked on or the outlet is full of limescale. The alternative way to drain the

cylinder is through the top connection. You'll need to undo the nut at the top

and lift out the pipe. A small amount of water might come out so have a

towel ready to mop it up. Poke the hose down through the hole in the top of

the cylinder and siphon the water out to a lower point by partially filling the

hose from a garden tap and then letting the water go at once.

Once the cylinder is completely empty, drain the water from the boiler or a

low point on the radiator circuit. Open any motorised valves by sliding the

manual lever against the spring to the open position.

When the heating and primary hot-water circuits have been drained you can

undo all the connections on the cylinder.

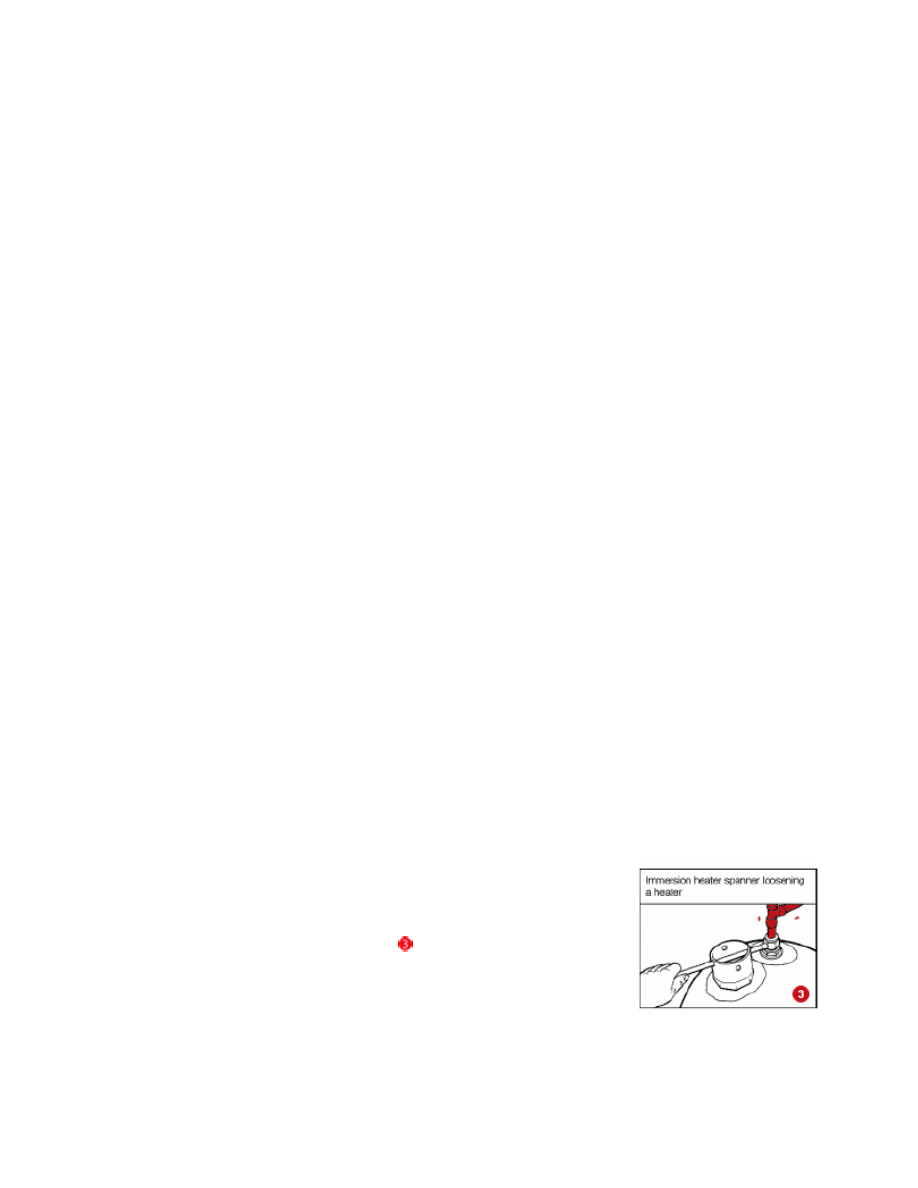

4 - REMOVING AND REFITTING AN IMMERSION HEATER

Turn off the electricity supply to the immersion heater at the consumer unit

by removing the fuse or MCB (miniature circuit breaker). Undo the cover on

the immersion heater and disconnect the three wires. Loosen the flex clamp

and pull the supply flex through.

Use an immersion-heater spanner to loosen the heater. It turns in an

anticlockwise direction. If it won't undo, don't force it or the cylinder will

buckle. Use a hammer and gently tap the spanner handle. If this doesn't

work, use gentle heat from a blowlamp or hot-air gun to warm the brass.

This will soften any linseed-oil-based sealant which has been used.

When you fit an immersion heater, make sure the sealing ring is placed on

the underside. If you want to use some additional sealant, make certain it is

a non-setting variety which is suitable for drinking water. This prevents

bacteria growth.

Again, don't use too much force in tightening the heater or the cylinder will

buckle. Once you fill the cylinder with water you can check for leaks and tap

the spanner slightly to tighten it. When you are sure there aren't leaks, you

can connect the wires. If you connect the wires first and need to tighten the

heater, you won't be able to get the spanner on without disconnecting again.

The live supply must be connected to the thermostat which fits in a dry

pocket. Set the thermostat to 60°C.

Make sure the heater is securely connected to the earth wire.

If the flexible cable from the wall switch to the heater needs renewing, make

sure you use heat-resistant PVC or butyl rubber flex. If you use 1.5mm2,

the length should not exceed 1m, otherwise use 2.5mm2. The supply cable

from the fuse box to the switch must be 2.5mm2.

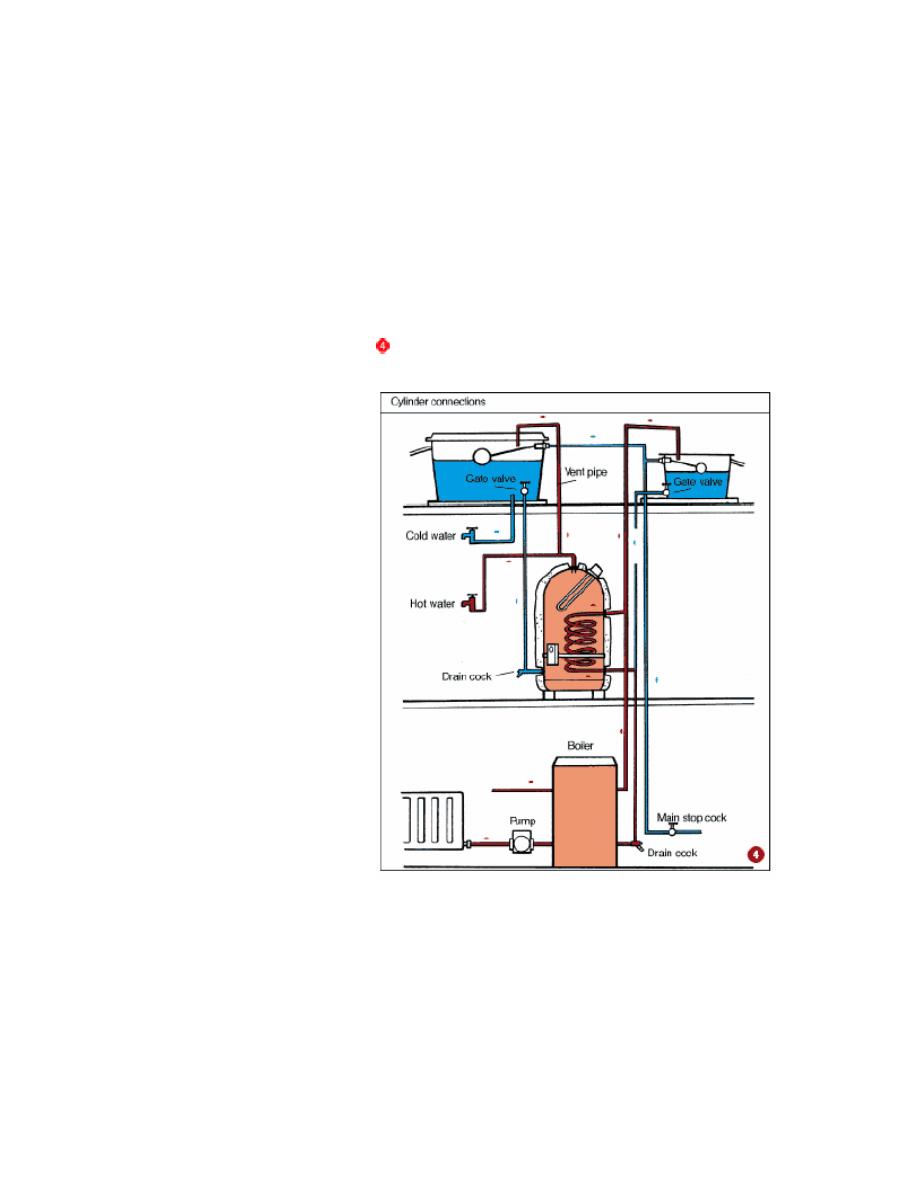

5 - FITTING THE CYLINDER

Try to arrange all pipework so it is easily accessible.

If there are awkward

connections to be made behind the cylinder try to attach the fittings and fit short

lengths of pipe so the cylinder can be moved

into place pre-plumbed. You can then connect

to those pipes in a more accessible position.

6 - COLD FEED

The bottom connection must be made with a

threaded elbow or straight connector. Wrap the

thread with PTFE tape. Be generous with it or

you may find the connection leaks in the future.

The thread should be so tight that a spanner is

needed to complete it. However, don't tighten it

so hard that you damage the relatively thin

cylinder walls.

You must incorporate a drain cock in the lowest

connection to empty the cylinder in the future.

Secure the pipe to the wall and take it up to the

gate valve. The gate valve must be above the

cylinder level

7 - VENT PIPE

Wrap the top threaded connector and screw

into the hole so the elbow is in the right

direction to take the pipe to the vent pipe.

It will be either 3/4 in or 1in British Standard pipe

thread. The 22mm pipe must rise to the open

vent which hooks over the top of the cold-water

tank. Make sure the vent pipe doesn't dip into the water.

On no account must any valve be fitted to the vent pipe.

Avoid running a pipe over the top of the immersion heater or it will be impossible

to change the heater when it burns out.

Don't run the vent pipe directly up from the middle of the cylinder because the

hot water tends to rise and fall inside the pipe and this takes heat out of the

cylinder.

8 - HOT SUPPLY TO TAPS

The branch to the taps is taken from the vent pipe close to the cylinder. It must

fall away slightly towards the taps so any air in the pipe is automatically released

to the vent. If the pipe runs upwards even slightly, you will have problems with air

locks.

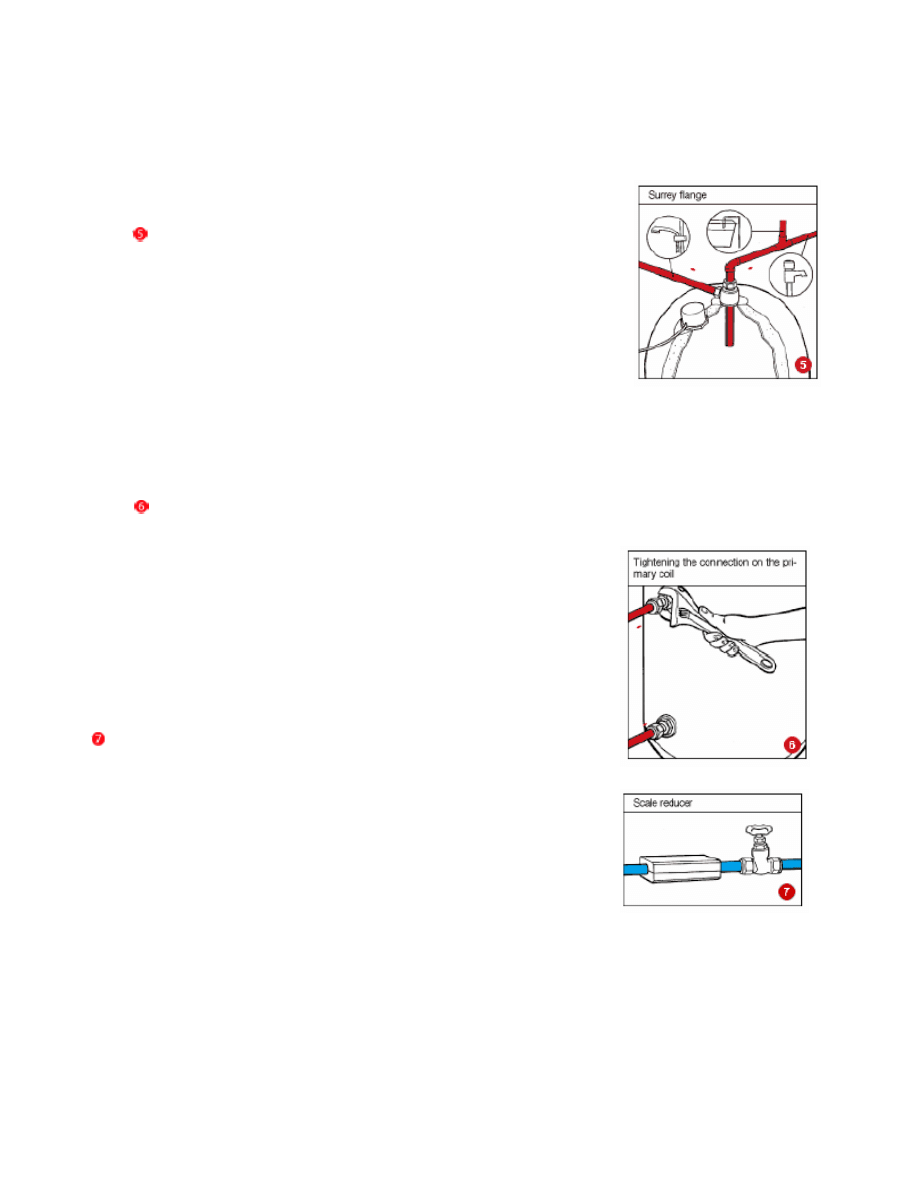

9 - SHOWER CONNECTIONS

If you have a pumped shower, you might want to fit a separate supply. This can

be done with a spe ial dip pipe flange (Surrey Flange) which screws into the top

c

of the cylinder .

10 - PRIMARY COIL CONNECTION TO THE BOILER CIRCUIT

On a gravity system, which uses the weight difference between hot and cold

water to circulate water from the boiler to the cylinder, it is essential that the flow

enters the side of the cylinder at the top of the coil. On fully pumped systems it

doesn't matter.

You can use 1in male threaded connectors to connect the primary pipework to

the cylinder, or use purpose-made cylinder unions (which look like large tap

connectors). If the system is fully pumped, 22mm pipes will be enough. Where

the pump only circulates the radiator water you will need 28mm pipework and

connections. Don't reduce the size going into the cylinder.

Check that the top primary connection is level or slightly rising from the cylinder

to the vent pipe

. Some systems have a venting mechanism at this point so the

pipework can drop down to a vent elsewhere.

The bottom connection returning to the boiler is connected in the same way. On

fully pumped systems there is often a valve at this point to balance the water

between the radiator circuits and the cylinder.

Do not connect copper pipes to galvanized-iron pipes (silver coloured) because

an electrolytic action will cause the pipes to corrode and block. If you need to

keep old pipework, connect plastic hot-water pipes to it.

11 - PREVENTING SCALE

If you live in a hard-water area, fit a scale-reducing device to the cold feed of the

cylinder .

Even a small build-up of scale will add several pounds to your fuel

bills and slow down the rate at which your cylinder will heat up.

12 - ATTACHING A CYLINDER THERMOSTAT

If you have a clamp-on thermostat on your old cylinder, you will need to fit it to

the new cylinder. Cut a small rectangle out of the insulation on the opposite side

to the boiler primary pipes. The height of the thermostat should be about one

third up the cylinder. See illustration (2) for reference.

Wyszukiwarka

Podobne podstrony:

How to Install the Power Quality Teaching Toy

How to install

How to install HD Audio driver?ter installation of slipstreamed XP SP3

HOW TO INSTALL PHOTOSHOP?TIONS

How to Be a Hot Guy

How to Install & Update the Language Packs the Tutorial

How to Install Windows`XP on SATA

how to install mb sd c4 wifi card

How to Install the Power Quality Teaching Toy

How to Install Ansys 14

How to install pvc downpipes

How to Install And Run Windows XP From USB drive

How to Install & Update the Language Packs the Tutorial

więcej podobnych podstron